Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

5615 & 5619 Series

5615 & 5619 Série

5615 & 5619 Serie

FPO

HEAVY-DUTY ROUTERS

TOUPIES EXTRA-ROBUSTES

BURILADORAS PARA SERVICIO PESADO

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND

OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET

BIEN COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y

ENTENDER EL MANUAL DEL OPERADOR.

Page 2

GENERAL SAFETY RULES

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and

well lit. Cluttered benches and dark

areas invite accidents.

2. Do not operate power tools in ex-

plosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust

or fumes.

3. Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can cause

you to lose control. Protect others in

the work area from debris such as

chips and sparks. Provide barriers or

shields as needed.

ELECTRICAL SAFETY

4. Grounded tools must be plugged

into an outlet properly installed

and grounded in accordance with

all codes and ordinances. Never

remove the grounding prong or

modify the plug in any way. Do not

use any adaptor plugs. Check with

a qualified electrician if you are in

doubt as to whether the outlet is

properly grounded. If the tools

should electrically malfunction or break

down, grounding provides a low resistance path to carry electricity away

from the user.

5. Double Insulated tools are

equipped with a polarized plug

(one blade is wider than the other).

This plug will fit in a polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse

the plug. If it still does not fit, contact a qualified electrician to install

a polarized outlet. Do not change

WARNING!

the plug in any way. Double insulation eliminates the need for the

three wire grounded power cord and

grounded power supply system.

6. Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators. There is

an increased risk of electric shock if

your body is grounded.

7. Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of electric shock.

8. Do not abuse the cord. Never use

the cord to carry the tools or pull

the plug from an outlet. Keep cord

away from heat, oil, sharp edges

or moving parts. Replace damaged

cords immediately. Damaged cords

increase the risk of electric shock.

9. When operating a power tool out-

side, use an outdoor extension

cord marked W-A or W. These

cords are rated for outdoor use and

reduce the risk of electric shock.

PERSONAL SAFETY

10. Stay alert, watch what you are doing, and use common sense when

operating a power tool. Do not use

tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while op-

erating power tools may result in serious personal injury.

11. Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair can

be caught in moving parts.

12. Avoid accidental starting. Be sure

switch is off before plugging in.

Carrying tools with your finger on the

switch or plugging in tools with the

switch on invites accidents.

13. Remove adjusting keys or

wrenches before turning the tool

on. A wrench or a key that is left at-

tached to a rotating part of the tool may

result in personal injury.

14. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the tool in unexpected

situations.

15. Use safety equipment. Always

wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

16. Use clamps or other practical way

to secure and support the

workpiece to a stable platform.

Holding the work by hand or against

your body is unstable and may lead to

loss of control.

17. Do not force tool. Use the correct

tool for your application. The correct tool will do the job better and safer

at the rate for which it is designed.

18. Do not use tool if switch does not

turn it on or off. Any tool that cannot

be controlled with the switch is dangerous and must be repaired.

19. Disconnect the plug from the

power source before making any

adjustments, changing accessories, or storing the tool. Such pre-

ventive safety measures reduce the

risk of starting the tool accidentally.

20. Store idle tools out of reach of chil-

dren and other untrained persons.

Tools are dangerous in the hands of

untrained users.

21. Maintain tools with care. Keep cut-

ting tools sharp and clean. Properly

maintained tools with sharp cutting edge

are less likely to bind and are easier to

control. Do not use a damaged tool.

Tag damaged tools Do not use until

repaired.

22. Check for misalignment or bind-

ing of moving parts, breakage of

parts, and any other condition that

may affect the tools operation. If

damaged, have the tool serviced

before using. Many accidents are

caused by poorly maintained tools.

23. Use only accessories that are rec-

ommended by the manufacturer

for your model. Accessories that may

be suitable for one tool, may become

hazardous when used on another tool.

SERVICE

24. Tool service must be performed

only by qualified repair personnel.

Service or maintenance performed by

unqualified personnel could result in a

risk of injury.

25. When servicing a tool, use only

identical replacement parts.

Follow instructions in the Maintenance section of this manual. Use

of unauthorized parts or failure to follow Maintenance Instructions may create a risk of electric shock or injury.

2 3

Page 3

GROUNDING

EXTENSION CORDS

WARNING!

Improperly connecting the

grounding wire can result in the

risk of electric shock. Check

with a qualified electrician if you

are in doubt as to whether the

outlet is properly grounded. Do

not modify the plug provided

with the tool. Never remove the

grounding prong from the plug.

Do not use the tool if the cord or

plug is damaged. If damaged,

have it repaired by a MILWAUKEE

service facility before use. If the

plug will not fit the outlet, have a

proper outlet installed by a qualified electrician.

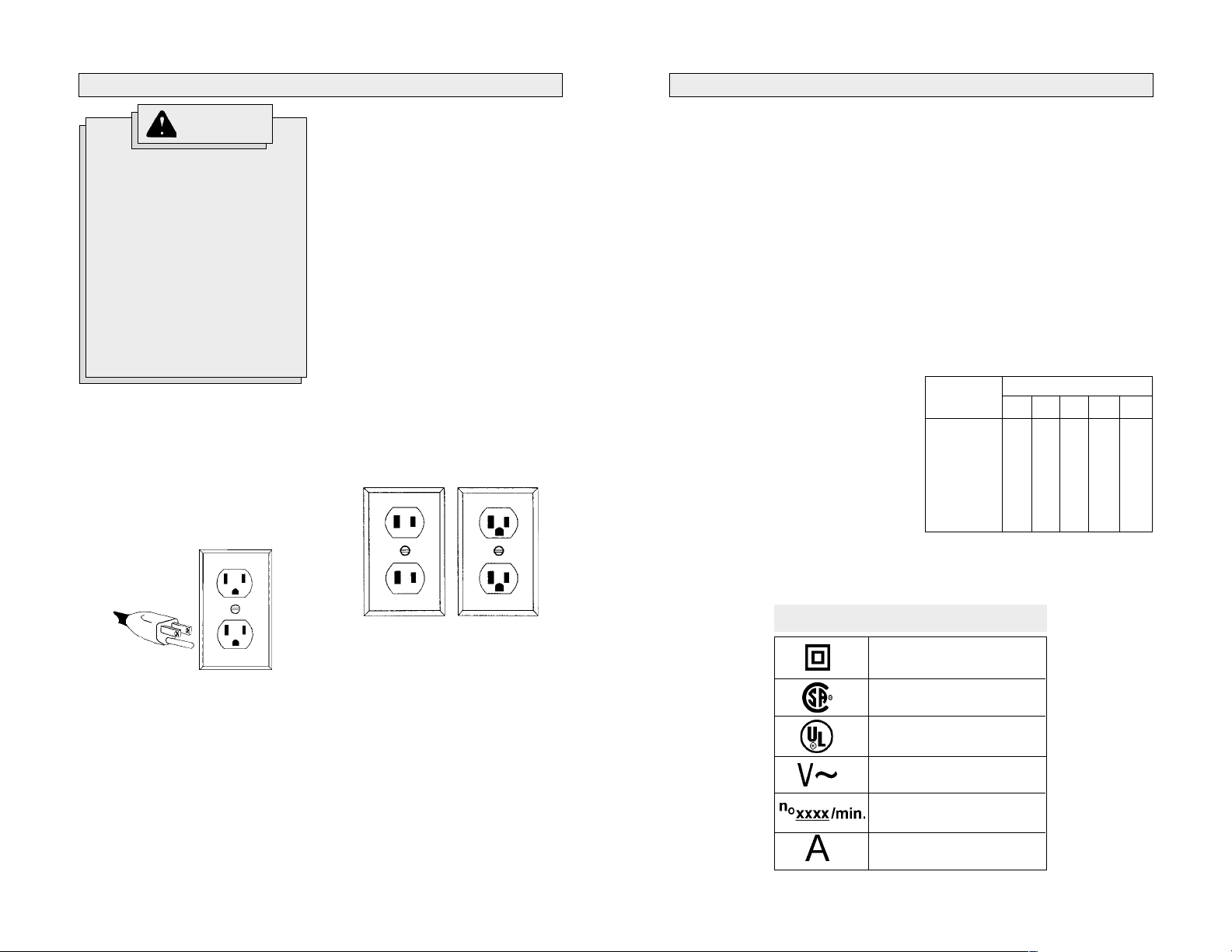

Grounded Tools:

Tools with Three Prong Plugs

Tools marked Grounding Required have

a three wire cord and three prong grounding plug. The plug must be connected to a

properly grounded outlet (See Figure A). If

the tool should electrically malfunction or

break down, grounding provides a low resistance path to carry electricity away from

the user, reducing the risk of electric shock.

The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool.

The green wire in the cord must be the

only wire connected to the tool's grounding system and must never be attached to

an electrically live terminal.

Your tool must be plugged into an appropriate outlet, properly installed and

grounded in accordance with all codes and

ordinances. The plug and outlet should look

like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked Double Insulated do not require grounding. They have a special

double insulation system which satisfies

OSHA requirements and complies with the

applicable standards of Underwriters Laboratories, Inc., the Canadian Standard Association and the National Electrical Code.

Double Insulated tools may be used in either of the 120 volt outlets shown in

Figures B and C.

Grounded tools require a three wire extension cord. Double insulated tools can

use either a two or three wire extension

cord. As the distance from the supply outlet increases, you must use a heavier

gauge extension cord. Using extension

cords with inadequately sized wire causes

a serious drop in voltage, resulting in loss

of power and possible tool damage. Refer

to the table shown to determine the required minimum wire size.

The smaller the gauge number of the wire,

the greater the capacity of the cord. For

example, a 14 gauge cord can carry a

higher current than a 16 gauge cord. When

using more than one extension cord to make

up the total length, be sure each cord contains at least the minimum wire size required. If you are using one extension cord

for more than one tool, add the nameplate

amperes and use the sum to determine the

required minimum wire size.

Guidelines for Using Extension Cords

If you are using an extension cord out-

doors, be sure it is marked with the

suffix W-A (W in Canada) to indicate that it is acceptable for outdoor

use.

Be sure your extension cord is prop-

erly wired and in good electrical

condition. Always replace a damaged

extension cord or have it repaired by a

qualified person before using it.

Protect your extension cords from

sharp objects, excessive heat and

damp or wet areas.

Recommended Minimum Wire

Gauge for Extension Cords*

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

* Based on limiting the line voltage drop to

five volts at 150% of the rated amperes.

Extension Cord Length

25'

18

18

18

18

16

14

12

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE.

50'

18

18

18

16

14

12

10

75'

18

18

16

14

12

10

100'

150'

18

16

16

14

14

12

12

12

10

--

--

--

--

--

--

Fig. A

Fig. B

4 5

Fig. C

Symbology

Double Insulated

Canadian Standards

Association

Underwriters

Laboratories, Inc.

Volts Alternating Current

No Load Revolutions

per Minute (RPM)

Amperes

Page 4

SPECIFIC SAFETY RULES - ROUTERS

FUNCTIONAL DESCRIPTION

1. Hold tool by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring or its own cord. Contact with a live

wire will make exposed metal parts of tool live and shock the operator.

2. Maintain labels and nameplates. These carry important information. If

unreadable or missing, contact a MILWAUKEE service facility for a free replacement.

3. Always wear safety goggles and dust mask. Use only in a well ventilated

area. Using personal safety devices and in a safe environment reduce the risk for

injury.

4. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

lead from lead-based paint

crystalline silica from bricks and cement and other masonry products, and

arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specifically

designed to filter out microscopic particles.

5. Some woods contain preservatives that can be toxic. Take extra care to

prevent inhalation and skin contact when working with these materials. Request, and

follow, any safety information available from your material supplier.

6. Always make sure the workpiece is free from nails, screws and other

foreign objects. Keep the working edge away from the clamping surface.

Cutting these objects can cause loss of control of the tool and damage to the bit.

7. Never hold the workpiece in one hand and the tool in the other hand when

using the tool. Never place hands near or below cutting surface. Clamping

the material and guiding the tool with both hands is safer.

8. Never use dull or damaged bits. Sharp bits must be handled with care.

Damaged bits can break during use. Dull bits require more force to push the tool,

which could cause the bit to break. Damaged bits can throw carbide pieces and burn

the workpiece.

9. After changing the bit or making any adjustments, make sure the collet nut

and any other adjustment devices are securely tightened. Loose adjustment

devices can unexpectedly shift, causing loss of control. Loose rotating components

will be violently thrown. Watch for vibration or wobbling that could indicate an improperly installed bit.

10. Maintain firm grip on router when starting motor to resist starting torque.

11. Always keep the power supply cord away from moving parts on the tool.

Keep the cord away from the direction of the cut.

12. Never start the tool when the bit is in contact with the material. The bit cutting

edge may grab the material causing loss of control of the tool.

13. Never lay the tool down until the bit has come to a complete stop. The

spinning bit can grab the surface and pull the tool out of your control.

14. Never touch the bit during or immediately after use. After use the bit may be

hot enough to burn bare skin.

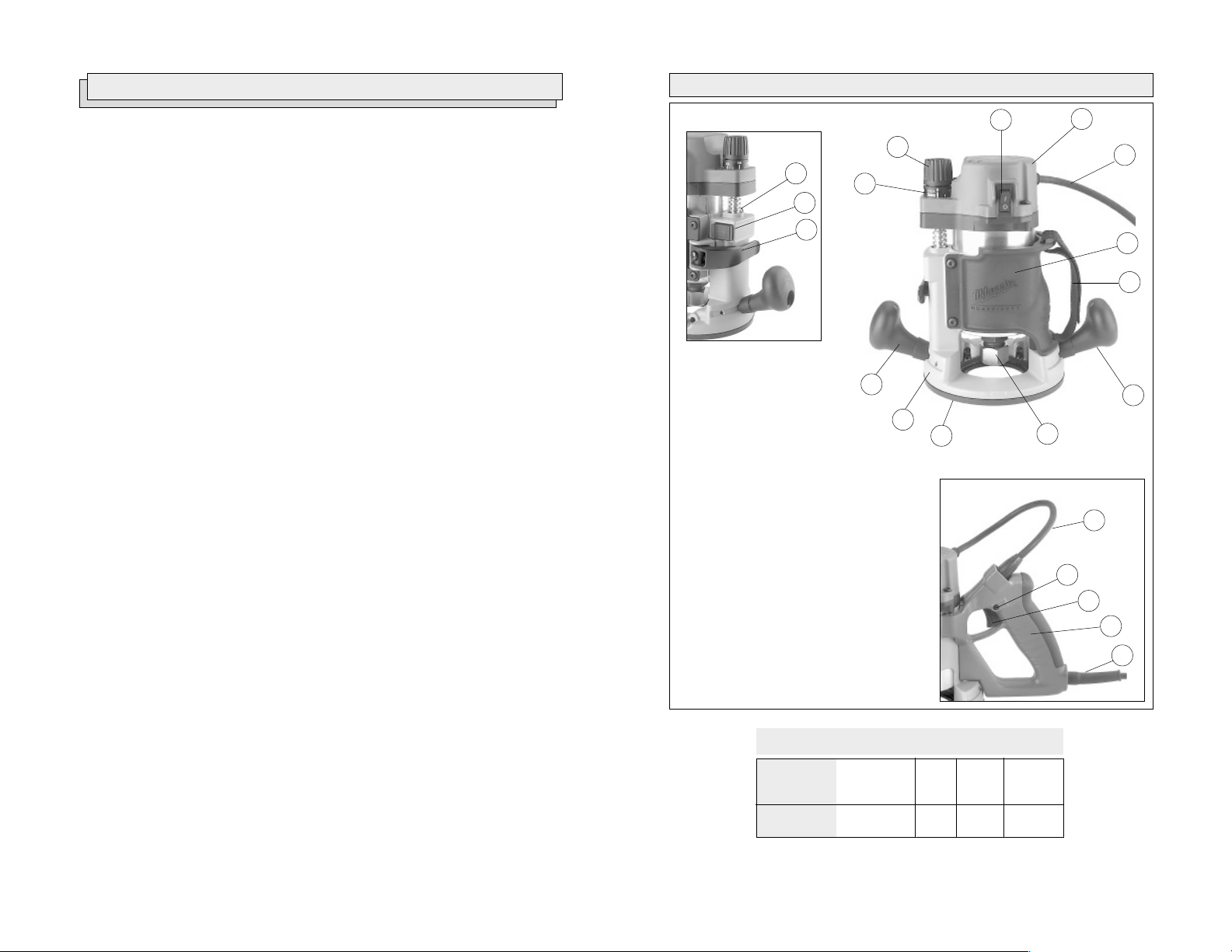

Cat. No. 5615 Series

1

2

3

1. Depth adjustment screw

2. Motor release button

3. Locking lever

4. Scale

5. Depth adjustment knob

6. On/Off switch

7. Motor

8. Cord

9. Body grip

10. Strap

11. Handle

12. Collet assembly

13. Sub-Base

14. Base

15. Lock button

16. Trigger

17. D-handle

Motor/Base

Cat. No

5615-20

5619-20

.

5

4

11

14

Specifications

Motor Only

Cat. No.

5615-29

5619-29

13

Volts

AC

120

120

6

12

Cat. No. 5619 Series

No Load

Amps

RPM

24,000

11

24,000

11

7

8

9

10

11

8

15

16

17

8

6 7

Page 5

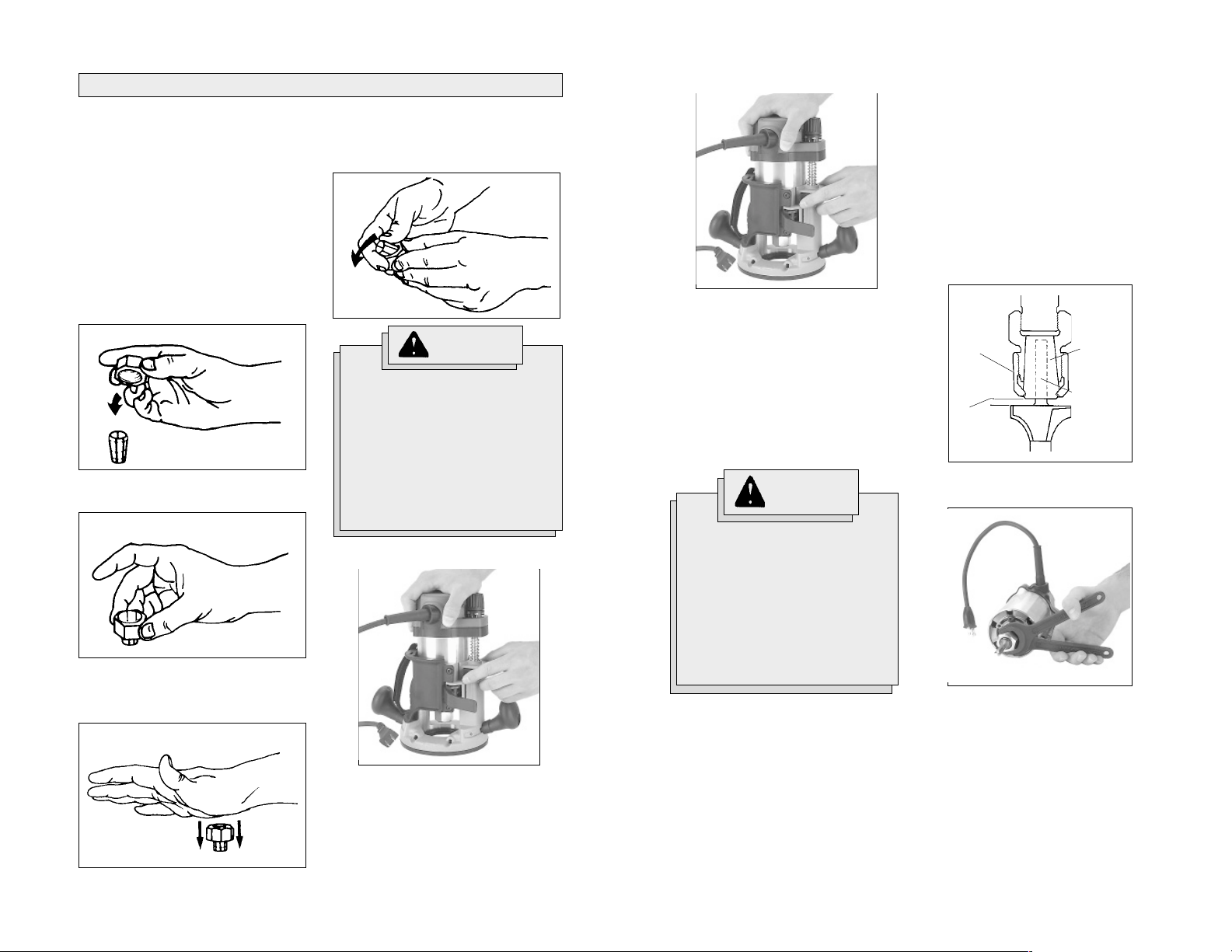

TOOL ASSEMBLY

Collets

The collet must be attached to the collet

nut before it is put into the collet shaft. Be

sure that the size of the collet matches the

size of the bit shank being used. If the

wrong size bit shank is used, the collet

may break. For attaching or detaching the

collet nut to the collet, follow the illustrated

instructions on this page.

Attaching Collet to Collet Nut

FPO

To assemble, place the narrow end of the

collet on an even surface. Take the nut

and place it over the collet (Fig. 1).

Fig. 1

Position nut squarely over collet with the

smaller opening of the nut facing up (Fig. 2).

Fig. 2

Snap nut and collet together by firmly applying downward pressure into assembly

with palm of hand (Fig. 3).

Fig. 3

To remove collet from nut, hold nut firmly

with one hand and press the collet to one

side with the other hand (Fig. 4).

Fig. 4

WARNING!

To reduce the risk of injury,

always unplug tool before attaching or removing accessories

or making adjustments.

If hand is not securely on motor,

pressing the motor release button will cause the motor housing

to drop down, which may cause

personal injury or damage to the

tool or workpiece.

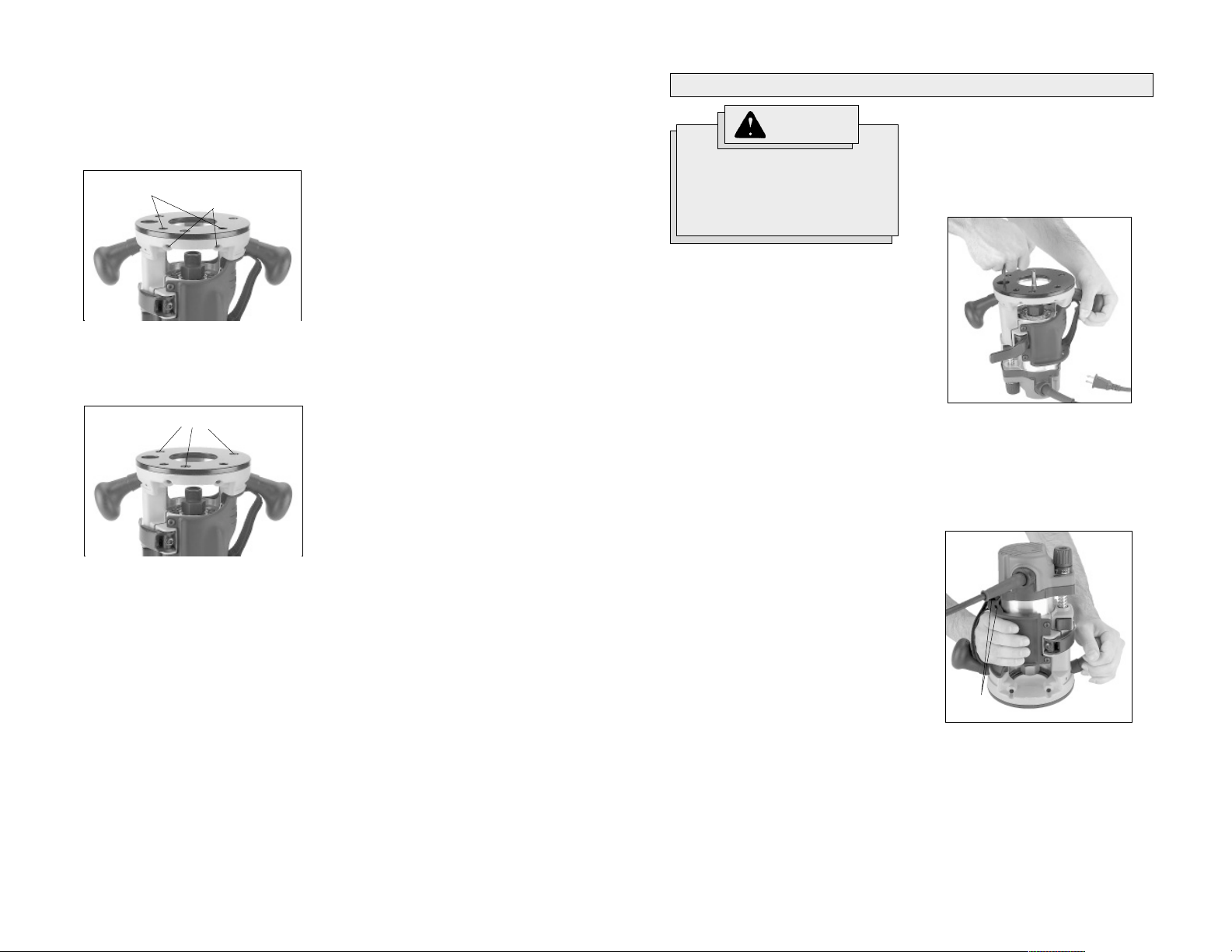

Removing Motor from Base (Fig. 5)

Fig. 5

1. Unplug tool. Release locking lever to

fully open position.

2. Firmly grasp motor. Press and hold

motor release button and pull out

motor from base.

Placing Motor into Base (Fig. 6)

Fig. 6

1. Unplug tool. Make sure locking lever is

fully open.

2. Align depth screw on the motor with

hole on base.

3. Press and hold motor release button

and lower motor into base to desired

depth.

4. Release motor release button and

push-in locking lever to fully closed

position.

WARNING!

To reduce the risk of injury, wear

safety goggles or glasses with

side shields.

To reduce the risk of injury,

always unplug tool before attaching or removing accessories or

making adjustments.

Use only specifically recommended accessories. Others may

be hazardous.

Installing the Bit

It is not necessary to remove the motor

from the base to install a collet assembly

or a bit. If removal of the base is desired,

see previous section. Always wipe wood

chips, dust or other foreign materials from

the collet shaft and collet assembly before

assembling.

Insert the collet assembly into the collet

shaft. Insert the bit shank into the collet as

follows:

1. Insert the bit shank into the collet as

far as it will go.

2. Back the bit shank out slightly to avoid

bottoming out.

3. Be sure there is a minimum of 1/16"

between the bottom of the collet assembly and the radius to the cutting

portion of the bit (Fig. 7).

4. Be sure that the collet is not clamped

to a fluted section on the bit shank.

The collet should be clamped to a solid

part on the bit shank.

Fig. 7

Collet nut

Minimum

1/16"

To tighten the bit in the collet assembly, use

two wrenches (Fig. 8).

Fig. 8

NOTE: Never tighten a collet assembly with-

out inserting a bit shank of the proper size.

This may damage the collet.

Removing the Bit

1. Loosen the collet nut from the collet

shaft using two wrenches.

2. Once loose, unscrew the collet nut by

hand until it feels tight again.

3. Return to using the wrenches until the

bit shank can be pulled out.

Collet

Bit shank

8 9

Page 6

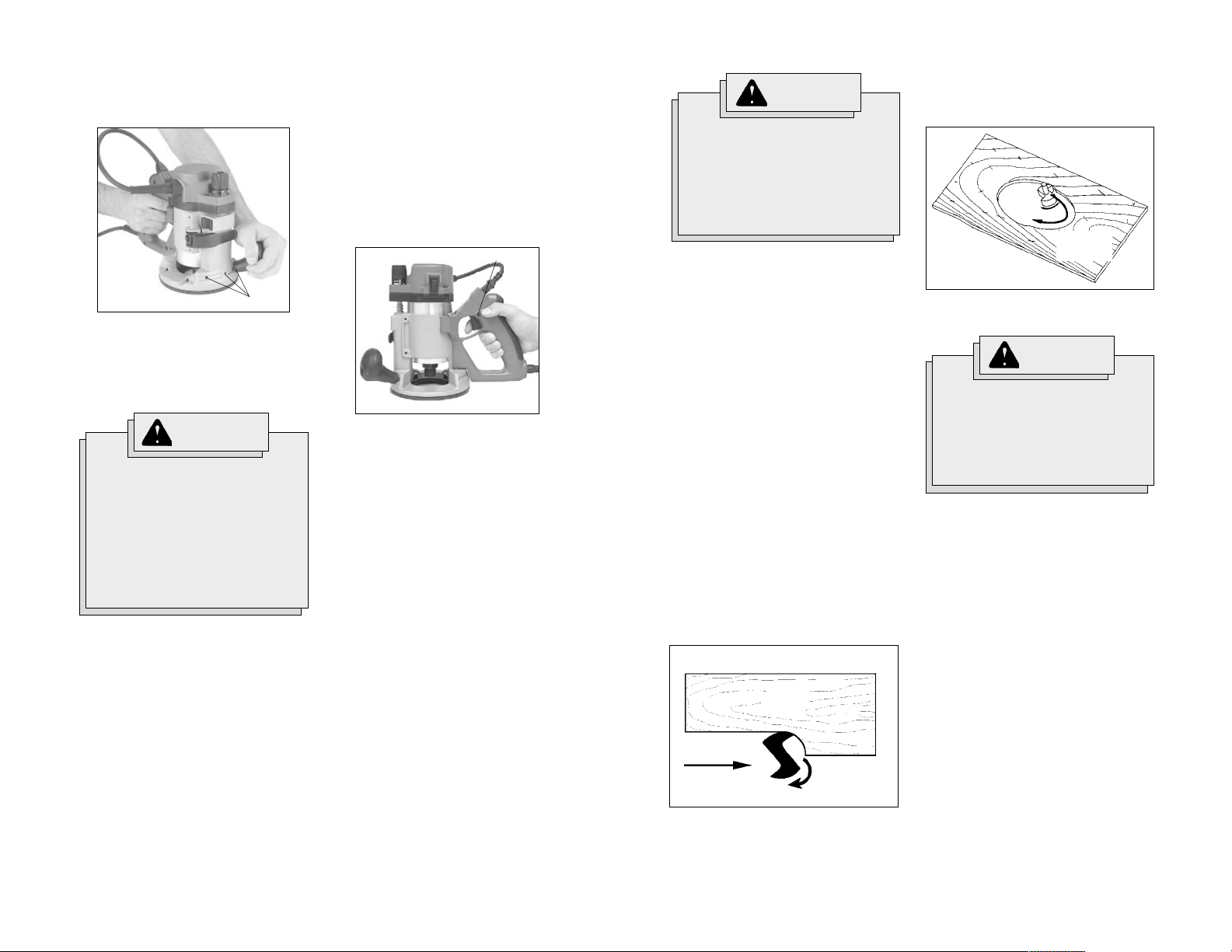

Installing/Removing Edge Guide

(Fig. 9)

To install an edge guide, loosen the two

rod screws. Insert the edge guide rods

into the rod holes and tighten the rod

screws.

Fig. 9

Rod screws

Installing/Removing Sub-base (Fig. 10)

Remove the sub-base screws. Place a subbase onto the tool. Replace sub-base

screws.

Fig. 10

Sub-base screws

Rod holes

Installing Templet Guide

To install a templet guide, insert guide into

the center hole of router base and secure

according to templet guide instructions.

NOTE: The sub-base provided with this

tool does not accept templet guides. An

accessory sub-base is avaivable that

accepts 1-3/16" threaded inserts.

OPERATION

WARNING!

Unplug the tool before changing

accessories or making adjustments.

Never make adjustments while

the router is running.

Adjusting the Depth of Cut

The tool depth can be adjusted by using

the depth adjustment knob or a 3/8" socket

wrench.

When using the depth adjustment knob, fully

open the locking lever and rotate knob to

the desired depth of cut. One revolution of

the depth adjustment knob is equal to 0.2".

For fine adjustments less than 5/32", use

the independent scale on the depth adjustment knob.

For deeper cuts:

1. Align the "0" on the scale with the arrow on the tool.

2. Rotate depth adjustment knob clockwise to desired depth measurement.

For shallower cuts:

1. Align the desired depth measurement

with the arrow on the tool.

2. Rotate depth adjustment knob counterclockwise to "0."

Push-in locking lever to fully closed position when finished adjusting.

When using a socket wrench, place the

router on a flat surface and fully open the

locking lever. Insert a 3/8" socket wrench

into the hole on the base and turn to desired depth (Fig. 11). Push-in locking lever

to fully closed position.

Fig. 11

Holding the Tool

For Body Grip Base (Fig. 12):

You can hold this tool using the body grip

and handle or both handles. The body grip

features an adjustable strap, which can

be attached in two different positions for

maximum control and comfort.

Fig. 12

10 11

Alternate

strap positions

Page 7

For D-handle Base (Fig. 13):

Grip the D-handle with one hand and place

the other on the handle.

Fig. 13

Alternate handle positions

For both bases:

One handle on both bases may be adjusted

to three different positions for maximum

control and comfort.

NOTE: Use both hands at all times.

WARNING!

To reduce the risk of injury, wear

safety goggles or glasses with

side shields.

To reduce the risk of injury, keep

hands, body and cord away from

the bit and all moving parts.

Before plugging the tool into a

power outlet, make sure the on/

off switch is in the "O" position.

Starting and Stopping Router Motor

For Body Grip Base:

1. To start the motor, grasp the tool firmly

and push the On/Off switch to the "I"

position.

2. To stop the motor, push the on/off

switch to the "O" position and place

the router so the bit is away from you.

Hold the tool until the bit stops turning.

For D-handle Base:

1. Push the On/Off switch to the "I" position.

2. To start the motor, grasp the tool firmly

and pull the trigger.

3. To stop the motor, release the trigger.

Locking the D-handle Base Trigger

(Fig. 14)

The lock button holds the trigger in the ON

position for continuous use.

Fig. 14

1.To lock the trigger, hold-in the lock

button while pulling the trigger. Release

the trigger.

2. To unlock the trigger, pull the trigger

and release. The lock button will pop

out.

Lock button

WARNING!

To reduce the risk of injury,

always wear eye protection.

To reduce the risk of explosion,

electric shock and property

damage, always check the work

area for hidden pipes and wires

before routing.

Making the Cut

The speed and depth of cut will depend

largely on the type of material being worked.

Keep the cutting pressure constant but do

not use excessive force on the router so

the motor speed slows excessively. It may

be necessary on exceptionally hard woods

or problem materials to make more than

one pass to get the desired depth of cut.

Before beginning the cut on the actual

workpiece, it is advisable to take a sample

cut on a scrap piece of lumber. This will

show you exactly how the cut will look as

well as enable you to check dimensions.

Always be sure the workpiece is secure

before routing. When routing edges, the

router should be held firmly down and

against the work using handles.

Since the cutter rotates clockwise, more

efficient cutting will be obtained if the router

is moved from left to right as you stand

facing the work. The arrows on the base

of the tool indicate the direction of bit rotation. When working on the outside of an

edge, move router in a counterclockwise

direction (Fig. 15).

Fig. 15

Work

Router feed

Top view

Bit rotation

When working on an inside edge, move

the router in a clockwise direction (Fig. 16).

Fig. 16

Direction

of feed

Moving the router in the opposite direction

is known as "climb cutting."

WARNING!

To reduce the risk of injury, avoid

"climb cutting." Climb cutting increases the potential for loss of

control of the tool and damage to

the workpiece. If climb cutting

can not be avoided, use extreme

caution.

12 13

Page 8

MAINTENANCE

ACCESSORIES

WARNING!

To reduce the risk of injury, always unplug your tool before

performing any maintenance.

Never disassemble the tool or try

to do any rewiring on the tool's

electrical system. Contact a

MILWAUKEE service facility for

ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a

regular maintenance program. Before use,

examine the general condition of your tool.

Inspect guards, switches, tool cord set and

extension cord for damage. Check for

loose screws, misalignment, binding of

moving parts, improper mounting, broken

parts and any other condition that may affect its safe operation. If abnormal noise

or vibration occurs, turn the tool off immediately and have the problem corrected

before further use. Do not use a damaged

tool. Tag damaged tools DO NOT USE until

repaired (see Repairs).

Under normal conditions, relubrication is

not necessary until the motor brushes

need to be replaced. After six months to

one year, depending on use, return your

tool to the nearest MILWAUKEE service

facility for the following:

Lubrication

Brush inspection and replacement

Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

Electrical inspection (switch, cord,

armature, etc.)

Testing to assure proper mechanical

and electrical operation

Cleaning

Clean dust and debris from vents. Keep

the tool handles clean, dry and free of oil

or grease. Use only mild soap and a damp

cloth to clean your tool since certain cleaning agents and solvents are harmful to plastics and other insulated parts. Some of

these include: gasoline, turpentine, lacquer

thinner, paint thinner, chlorinated cleaning

solvents, ammonia and household detergents containing ammonia. Never use flammable or combustible solvents around

tools.

WARNING!

To reduce the risk of injury, electric shock and damage to the tool,

never immerse your tool in liquid

or allow a liquid to flow inside the

tool.

Repairs

If your tool is damaged, return the entire

tool to the nearest service center listed on

the back cover of this operators manual.

WARNING!

To reduce the risk of injury,

always unplug the tool before

attaching or removing accessories. Use only specifically

recommended accessories. Others may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric Tool catalog. To

obtain a catalog, contact your local distributor or a service center listed on the back cover

of this operators manual.

Sub-Bases

1. Sub-base for templet guides. Accepts

industry-standard 1-3/16" threaded guides.

2. Sub-base with 2-1/2" opening.

Wrench

1-1/8" forged-steel, open-end wrench.

Collet Assemblies

1. 1/4" collet with collet nut.

2. 1/2" collet with collet nut.

WARRANTY

Every MILWAUKEE tool is thoroughly inspected and tested before leaving our manufacturing facilities. Should any trouble develop, return the complete tool prepaid to our

Corporate Office, Branch Office/Service Center or nearest Authorized MILWAUKEE

Service Station. If inspection shows the trouble is caused by defective workmanship

or material, all repairs will be made without charge, and the tool will be returned,

transportation prepaid. Battery packs for cordless tools are warranted for one year from

the date of purchase.

This warranty does not apply where: (1) repairs or attempted repairs have been made by

persons other than MILWAUKEE personnel or Authorized Service Station personnel; (2)

repairs are required because of normal wear; (3) the tool has been abused or involved in

an accident; (4) misuse is evident, such as caused by overloading the tool beyond its

rated capacity; (5) the tool has been used after partial failure or (6) the tool has been used

with an improper accessory. No other warranty, written or verbal, is authorized.

14 15

Page 9

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT!

VOUS DEVEZ LIRE ET COMPRENDRE TOUTES

LES INSTRUCTIONS

Le non-respect, même partiel, des instructions ci-après entraîne

un risque de choc électrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

AIRE DE TRAVAIL

1. Veillez à ce que laire de travail soit

propre et bien éclairée. Le désordre

et le manque de lumière favorisent les

accidents.

2. Nutilisez pas doutils électriques

dans une atmosphère explosive,

par exemple en présence de

liquides, de gaz ou de poussières

inflammables. Les outils électriques

créent des étincelles qui pourraient

enflammer les poussières ou les

vapeurs.

3. Tenez à distance les curieux, les

enfants et les visiteurs pendant

que vous travaillez avec un outil

électrique. Ils pourraient vous distraire

et vous faire faire une fausse manoeuvre. Installez des barrières ou des

écrans protecteurs si nécessaire.

SÉCURITÉ DES ÉLECTRIQUE

4. Les outils mis à la terre doivent

être branchés dans une prise de

courant correctement installée et

mise à la terre conformément à

tous les codes et règlements

pertinents. Ne modifiez jamais la

fiche de quelque façon que ce soit,

par exemple en enlevant la broche

de mise à la terre. Nutilisez pas

dadaptateur de fiche. Si vous

nêtes pas certain que la prise de

courant est correctement mise à

la terre, adressez-vous à un

électricien qualifié. En cas de

défaillance ou de défectuosité électrique

de loutil, une mise à la terre offre un

trajet de faible résistance à lélectricité

qui autrement risquerait de traverser

lutilisateur.

5. Les outils à double isolation sont

équipés dune fiche polarisée (une

des lames est plus large que

lautre), qui ne peut se brancher

que dune seule façon dans une

prise polarisée. Si la fiche nentre

pas parfaitement dans la prise,

inversez sa position ; si elle nentre

toujours pas bien, demandez à un

électricien qualifié dinstaller une

prise de courant polarisée. Ne

modifiez pas la fiche de loutil. La

double isolation é limine l e besoin dun

cordon dalimentation à trois fils avec

mise à la terre ainsi que dune prise de

courant mise à la terre.

6. Évitez tout contact corporel

avec des surfaces mises à la terre

(tuyauterie, radiateurs, cuisinières,

réfrigérateurs, etc.). Le risque de

choc électrique est plus grand si votre

corps est en contact avec la terre.

7. Nexposez pas les outils

électriques à la pluie ou à leau. La

présence deau dans un outil électrique

augmente le risque de choc électrique.

8. Ne maltraitez pas le cordon. Ne

transportez pas loutil par son cordon et ne débranchez pas la fiche

en tirant sur le cordon. Nexposez

pas le cordon à la chaleur, à des

huiles, à des arêtes vives ou à des

pièces en mouvement. Remplacez

immédiate-ment un cordon

endommagé. Un cordon endommagé

augmente le risque de choc électrique.

9. Lorsque vous utilisez un outil

électrique à lextérieur, employez

un prolongateur pour lextérieur

marqué « W-A » ou « W ». Ces cor-

dons sont faits pour être utilisés à

lextérieur et réduisent le risque de choc

électrique.

16 17

SÉCURITÉ DES PERSONNES

10. Restez alerte, concentrez-vous sur

votre travail et faites preuve de

jugement. Nutilisez pas un outil

électrique si vous êtes fatigué ou

sous linfluence de drogues,

dalcool ou de médicaments. Un in-

stant dinattention suffit pour entraîner

des blessures graves.

11. Habillez-vous convenablement. Ne

portez ni vêtements flottants ni

bijoux. Confinez les cheveux longs.

Napprochez jamais les cheveux,

les vêtements ou les gants des

pièces en mouvement. Des

vêtements flottants, des bijoux ou des

cheveux longs risquent dêtre happés

par des pièces en mouvement.

12. Méfiez-vous dun démarrage

accidentel. Avant de brancher

loutil, assurez-vous que son

interrupteur est sur ARRÊT. Le fait

de transporter un outil avec le doigt sur

la détente ou de brancher un outil dont

linterrupteur est en position MARCHE

peut mener tout droit à un accident.

13. Enlevez les clés de réglage ou de

serrage avant de démarrer loutil.

Une clé laissée dans une pièce tournante

de loutil peut provoquer des blessures.

14. Ne vous penchez pas trop en avant.

Maintenez un bon appui et restez

en équilibre en tout temps. Un

bonne stabilité vous permet de mieux

réagir à une situation inattendue.

15. Utilisez des accessoires de

sécurité. Portez toujours des lunettes ou une visière. Selon les con-

ditions, portez aussi un masque

antipoussière, des bottes de sécurité

antidérapantes, un casque protecteur

et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN

DES OUTILS

16. Immobilisez le matériau sur une surface stable au moyen de brides ou

de toute autre façon adéquate. Le fait

de tenir la pièce avec la main ou contre

votre corps offre une stabilité insuffisante

et peut amener un dérapage de loutil.

17. Ne forcez pas loutil. Utilisez loutil

approprié à la tâche. Loutil correct

fonctionne mieux et de façon plus

sécuritaire. Respectez aussi la vitesse de

travail qui lui est propre.

18. Nutilisez pas un outil si son

interrupteur est bloqué. Un outil que

vous ne pouvez pas commander par

son interrupteur est dangereux et doit

être réparé.

19. Débranchez la fiche de loutil avant

deffectuer un réglage, de changer

daccessoire ou de ranger loutil.

De telles mesures préventives de

sécurité réduisent le risque de

démarrage accidentel de loutil.

20. Rangez les outils hors de la portée

des enfants et dautres personnes

inexpérimentées. Les outils sont

dangereux dans les mains dutilisateurs

novices.

21. Prenez soin de bien entretenir les

outils. Les outils de coupe doivent

être toujours bien affûtés et

propres. Des outils bien entretenus,

dont les arêtes sont bien tranchantes,

sont moins susceptibles de coincer et

plus faciles à diriger. Nutilisez pas un

outil défectueux. Fixez-y une étiquette

marquée « Hors dusage » jusquà ce

quil soit réparé.

22. Soyez attentif à tout désalignement

ou coincement des pièces en

mouvement, à tout bris ou à toute

autre condition préjudiciable au

bon fonctionnement de loutil. Si

vous constatez quun outil est

endommagé, faites-le réparer

avant de vous en servir. De nombreux

accidents sont causés par des outils en

mauvais état.

23. Nutilisez que des accessoires que

le fabricant recommande pour

votre modèle doutil. Certains

accessoires peuvent convenir à un outil,

mais être dangereux avec un autre.

RÉPARATION

24. La réparation des outils électriques

doit être confiée à un réparateur

qualifié. Lentretien ou la réparation dun

outil électrique par un amateur peut avoir

des conséquences graves.

25. Pour la réparation dun outil,

nemployez que des pièces de

rechange dorigine. Suivez les directives données à la section

« Réparation » de ce manuel. Lemploi

de pièces non autorisées ou le

non-respect des instructions dentretien

peut créer un risque de choc électrique

ou de blessures.

Page 10

MISE À LA TERRE

AVERTISSEMENT!

Si le fil de mise à la terre est

incorrectement raccordé, il peut

en résulter des risques de choc

électrique. Si vous nêtes pas

certain que la prise dont vous

vous servez est correctement

mise à la terre, faites-la vérifier

par un électricien. Naltérez pas la

fiche du cordon de loutil.

Nenlevez pas de la fiche, la dent

qui sert à la mise à la terre.

Nemployez pas loutil si le cordon

ou la fiche sont en mauvais état.

Si tel est le cas, faites-les

réparer dans un centre-service

MILWAUKEE accrédité avant de

vous en servir. Si la fiche du cordon ne sadapte pas à la prise,

faites remplacer la prise par un

électricien.

Outils mis à la terre :

Outils pourvus dune fiche de

cordon à trois dents

Les outils marqués « Mise à la terre

requise» sont pourvus dun cordon à trois

fils dont la fiche a trois dents. La fiche du

cordon doit être branchée sur une prise

correctement mise à la terre (voir

Figure A). De cette façon, si une

défectuosité dans le circuit électrique de

loutil survient, le relais à la terre fournira

un conducteur à faible résistance pour

décharger le courant et protéger

lutilisateur contre les risques de choc

électrique.

La dent de mise à la terre de la fiche est

reliée au système de mise à la terre de

loutil via le fil vert du cordon. Le fil vert du

cordon doit être le seul fil raccordé à un

bout au système de mise à la terre de loutil

et son autre extrémité ne doit jamais être

raccordée à une borne sous tension

électrique.

Votre outil doit être branché sur une prise

appropriée, correctement installée et mise

à la terre conformément aux codes et

ordonnances en vigueur. La fiche du cordon et la prise de courant doivent être

semblables à celles de la Figure A.

Outils à double isolation :

Outils pourvus dune fiche de

cordon à deux dents

Les outils marqués « Double Isolation » nont

pas besoin dêtre raccordés à la terre. Ils

sont pourvus dune double isolation

conforme eux exigences de lOSHA et

satisfont aux normes de lUnderwriters

Laboratories, Inc., de lAssociation

canadienne de normalisation (ACNOR) et

du « National Electrical Code » (code national de lélectricité). Les outils à double

isolation peuvent être branchés sur

nimporte laquelle des prises à 120 volt

illustrées ci-contre Figure B et C.

CORDONS DE RALLONGE

Si lemploi dun cordon de rallonge est

nécessaire, un cordon à trois fils doit être

employé pour les outils mis à la terre. Pour

les outils à double isolation, on peut employer indifféremment un cordon de

rallonge à deux ou trois fils. Plus la longueur

du cordron entre loutil et la prise de courant est grande, plus le calibre du cordon

doit être élevé. Lutilisation dun cordon de

rallonge incorrectement calibré entraîne

une chute de voltage résultant en une perte

de puissance qui risque de détériorer loutil.

Reportez-vous au tableau ci-contre pour

déterminer le calibre minimum du cordon.

Moins le calibre du fil est élevé, plus sa

conductivité est bonne. Par exemple, un

cordon de calibre 14 a une meilleure

conductivité quun cordon de calibre 16.

Lorsque vous utilisez plus dune rallonge

pour couvrir la distance, assurez-vous que

chaque cordon possède le calibre minimum

requis. Si vous utilisez un seul cordon pour

brancher plusieurs outils, additionnez le

chiffre dintensité (ampères) inscrit sur la

fiche signalétique de chaque outil pour

obtenir le calibre minimal requis pour le

cordon.

LISEZ ATTENTIVEMENT CES

INSTRUCTIONS ET

CONSERVEZ-LES POUR LES

CONSULTER AU BESOIN.

Pictographie

Double Isolation

Directives pour lemploi des cordons

de rallonge

Si vous utilisez une rallonge à

lextérieur, assurez-vous quelle est

marquée des sigles « W-A » (« W » au

Canada) indiquant quelle est adéquate

pour usage extérieur.

Assurez-vous que le cordon de

rallonge est correctement câblé et en

bonne condition. Remplacez tout cordon derallonge détérioré ou faites-le

remettre en état par une personne

compétente avant de vous en servir.

Tenez votre cordon de rallonge à lécart

des objets ranchants, des sources de

grande chaleur et des endroits humides

ou mouillés.

Calibres minimaux recommandés

pour les cordons de rallonge*

Fiche

signalétique

Ampères

0 - 5,0

5,1 - 8,0

8,1 - 12,0

12,1 - 15,0

15,1 - 20,0

* Basé sur sur une chute de voltage limite

de 5 volts à 150% de lintensité moyenne

de courant.

Longueur du cordon de

rallonge (m)

15,2

7,6

16

16

14

12

10

16

16

14

12

10

22,8

16

14

12

10

10

30,4

14

12

10

10

--

45,7

12

10

--

--

--

60,9

12

--

--

--

--

Fig. A

lAssociation canadienne

Fig. B

18 19

Fig. C

de normalisation (ACNOR)

Underwriters

Laboratories Inc.

Couvant alternatif

Tours-minute á vide (RPM)

Ampères

Page 11

RÈGLES DE SÉCURITÉ PARTICULIÈRE

1. Tenez loutil par ses parties isolées lorsquil y a risque de contact de loutil

avec des fils sous tension ou même, le cordon de loutil. Le contact dune

partie métallique de loutil avec un fil sous tention comporte un risque de choc électrique.

2. Entretenez les étiquettes et marqies di fabricant. Les indications qu'elles

contiennent sont précieuses. Si elles deviennent illisibles ou se détachent, faites-les

remplacer gratuitement à un centre de service MILWAUKEE accrédité.

3. Portez toujours des lunettes à coques latérales et un masque antipoussière.

Utilisez loutil dans un endroit bien aéré. Lemploi déquipement de sécurité et le choix

dun environnement sain réduisent les risques de blessures.

4. AVERTISSEMENT! La poussière degage par perçage, sclage, perçage et autres

travaux de construction contient des substances chimiques reconnues comme pouvant

causer le cancer, des malformations congénitales ou dautres troubles de reproduction. Voici quelques exemples de telles substances :

Le plomb contenu dans la peinture au plomb.

Le silice cristallin contenu dans la brique, le béton et divers produits de maçonnerie.

Larsenic et le chrome servant au traitement chimique du bois.

Les risque associés à lexposition à ces substances varient, dépendant de la fréquence

des travaux. Afin de minimiser lexposition à ces substances chimiques, assurezvous de travailler dans un endroit bien aéré et dutiliser de lequipement de sécurité tel

un masque antipoussière spécifiquement conçu pour la filtration de particules

microscopiques.

5. Certains bois contiennent des préservatifs qui peuvent être toxiques.

Prenez les mesures nécessaires pour éviter linhalation et le contact avec la peau

lorsque vous travaillez avec de tels matériaux. Exigez de connaître linformation de

sécurité disponible auprès de votre fournisseur de matériaux et conformez-vous aux

instructions.

6. Assurez-vous que le matériau est exempt de clous, vis, et autres objets.

Veillez à ce que le rebord du matériau dépasse amplement la surface

dappui sous le matériau. Le contact de loutil avec la surface dappui peut causer

un perte de maîtrise et endommager louti.

7. Lorsque vous travaillez avec la toupie, ne tenez pas le matériau dune main

et loutil de lautre. Ne placez jamais les mains près ou en dessous de la

surface à couper. La fixation du matériau et la maîtrise de loutil à deux mains sont

plus sécuritaires.

8. Nutilisez jamais une mèche émoussée ou endommagée. Les mèches

bien affûtées doivent être manipulées avec soin. Les mèches

endommagées peuvent se briser durant le perçage. Les mèches émoussées

requièrent plus de pression sur la mèche et pourraient entraîner un bris. Les mèches

endommagées peuvent projeter des particules de carbure et brûler la surface du

matériau.

9. Après un changement de mèche ou un réglage, assurez-vous que lécrou

de douille de serrage et tous les autres dispositifs de serrage sont serrés

à fond. Un réglage lâche peut entraîner un glissement inattendu et une perte de

maîtrise. Les composants rotatifs lâches seront violemment éjectés. Surveillez les

vibrations ou la nutation qui pourraient indiquer que la mèche nest pas correctement

installée.

10. Pour résister au couple de démarrage, assurez une solide prise de la

toupie lorsque vous mettez le moteur en marche.

11. Gardez toujours le cordon électrique à lécart des pièces de loutil en

mouvement. Gardez le cordon à lécart de la ligne de coupe.

12. Ne mettez pas le moteur en marche lorsque la mèche est en contact avec

le matériau, le tranchant de la mèche peut agripper le matériau et entraîner une perte

de maîtrise de loutil.

13. Ne posez pas loutil avant que la mèche ne soit complètement immobile. Un

mèche en mouvement peut agripper le matériau et entraîner une perte de maîtrise.

14. Ne touchez pas à la mèche durant ou immédiatement après lusage. Après

lusage, la mèche peut être assez chaude pour causer une brûlure sur la peau nue.

DESCRIPTION FONCTIONNELLE

No de cat. série 5615

4

1

2

3

11

1. Vis de réglage de profondeur

2. Bouton de dégagement du moteur

3. Levier de verrouillage

4. Échelle

5. Bouton de réglage de profondeur

6. Interrupteur On-Off

7. Moteur

8. Cordon

9. Prise de boîtier

10. Courroie

11. Poignée

12. Douille de serrage

13. Embase

14. Socle

15. Bouton de verrouillage

16. Détente

17. Poignée en étrier

5

14

13

6

No de cat. série 5619

7

12

8

15

16

17

8

8

9

10

11

20 21

Page 12

Specifications

No de Cat.

Moteur-Socle

5615-20

5619-20

No de Cat.

Moteur seul

5615-29

5619-29

MONTAGE DE L'OUTIL

Douilles de serrage

La douille de serrage doit être fixée à lécrou

de douille avant dêtre placée sur le pivot.

Assurez-vous que le calibre de la douille

correspond à celui de la tige de la mèche à

utiliser. Si le calibre de la mèche ne correspond pas, la douille de serrage pourra se

briser. Pour fixer ou enlever lécrou de la

douille de serrage, suivez les instructions

illustrées dans cette page.

Fixation de la douille de serrage à

lécrou de douille

Pour assembler, placez le bout rétréci de

la douille de serrage sur une surface plane.

Placez ensuite lécrou sur la douille (Fig. 1).

Fig. 1

Positionnez lécrou à plat sur la douille, face

étroite sur le dessus (Fig. 2).

Fig. 2

Vol ts

120

120

Enclenchez lécrou et la douille en pesant

sur lécrou avec la paume de la main (Fig. 3).

Pour détacher la douille de lécrou, tenez

solidement lécrou dune main et, de lautre

main, pressez la douille sur le côté pour la

détacher (Fig. 4).

CA

Fig. 3

Fig. 4

Amperes

11

11

T/min.

á vide

24,000

24,000

AVERTISSEMENT!

Pour minimiser les risques de

blessures, débranchez toujours

loutil avant dy attacher des

accessoires, den enlever ou

deffectuer des réglages.

AVERTISSEMENT!

AVERTISSEMENT!

Si la main nest pas fermement

posée sur le moteur, le boîtier du

moteur sabaissera lorsque vous

actionnerez le bouton de

dégagement du moteur. Cette

situation pourra causer des

blessures à lutilisateur et des

dommages à loutil ou au

matériau.

Retrait du moteur du socle (Fig. 5)

Fig. 5

1. Débranchez loutil. Dégagez le levier

de verrouillage à pleine ouverture.

2. Tenez fermement le moteur. Appuyez

et retenez le bouton de dégagement

du moteur et tirez le moteur hors du

socle.

Installation du moteur dans le socle

(Fig. 6)

Fig. 6

1. Débranchez loutil. Assurez-vous que

le levier de verrouillage est grand

ouvert.

2. Alignez la vis de profondeur , sur le

moteur, avec le trou dans le socle.

3. Appuyez et retenez le bouton de

dégagement du moteur et abaissez le

moteur dans le socle à la profondeur

désirée.

4. Relâchez le bouton de dégagement du

moteur et poussez le levier de

verrouillage à la position complètement

fermée.

AVERTISSEMENT!

Pour minimiser les risques de

blessures, portez des lunettes de

sécurité ou des lunettes à coques

latérales.

Pour minimiser les risques de

blessures, débranchez toujours

loutil avant dy installer des

accessoires, den enlever ou

deffectuer des réglages.

Lemploi daccessoires autres

que ceux qui sont spécifiquement

recommandés peut comporter

des risques.

Installation de la mèche

Il nest pas nécessaire de retirer le moteur

de la base pour y installer une douille de

serrage ou la mèche. Si le retrait du moteur

est désiré, consultez les sections qui

précèdent. Enlevez toujours les rognures

de bois, la poussière et les autres corps

étrangers du pivot de la douille et de la

douille de serrage avant de faire une installation.

Introduisez la douille de serrage dans le

pivot de douille. Introduisez la tige de la

mèche dans la douille tel quindiqué ci-après :

1. Introduisez la tige de la mèche dans la

douille aussi loin que possible.

2. Retirez un peu la tige de la mèche pour

éviter quelle ne touche au fond.

22 23

Page 13

3. Assurez-vous quil y ait un minimum

de 1,6mm (1/16") entre le fond de la

douille de serrage et le rayon à la partie

tranchante de la mèche (Fig. 7).

4. Assurez-vous que la douille nest pas

fixée à une section cannelée de la tige

de mèche. La douille devrait être fixée

à une partie massive unie de la tige de

mèche.

Fig. 7

Fig. 9

FPO

Écrou de

douille

Minimum

1,6mm

(1/16")

Pour serrer la mèche dans la douille de

serrage, utilisez deux clés (Fig. 8).

Fig. 8

N.B. Ne serrez pas la douille de serrage

sur une tige de mèche de mauvais calibre.

Cela pourrait endommager la douille.

Retrait de la mèche

1. Desserrez lécrou de douille du pivot

de la douille à laide de deux clés.

2. Une fois relâché, dévissez lécrou de

douille à la main jusquà ce quil soit

serré à nouveau.

3. Utilisez les deux clés jusquà ce que la

mèche puisse être retirée de la douille.

Douille

de serrage

Tige de la

mèche

Installation du guide-margeur (Fig. 9)

Pour installer un guide-margeur, desserrez

les deux vis de fixation du guide.

Introduisez les bras du guide-margeur dans

les trous prévus pour les bras et serrez

les vis de fixation.

Fig. 9

Installation et retrait de lembase

(Fig. 10)

Enlevez les vis de lembase. Placez

lembase sur loutil. Remettez les vis de

lembase en place.

Fig. 10

Installation de la règle-guide

Pour installer la règle-guide, introduisez la

règle-guide dans le trou central du socle et

fixez-la conformément aux instructions

dinstallation.

N.B. Lembase qui accompagne loutil ne

permet pas linstallation dune règle-guide.

Une embase, offerte en accessoire

accepte les insertions filetés de 30mm

(1-3/16").

Vis de tige

Trous de tige

Vis d'embase

MANIEMENT

AVERTISSEMENT!

Débranchez loutil avant de

changer les accessoires ou de

faire des réglages.

Ne faites jamais de réglages pendant que loutil tourne encore.

Réglage de la profondeur de coupe

La profondeur de coupe peut être ajustée

au moyen du bouton de réglage de

profondeur de loutil ou avec une clé à

douille de 9,5mm (3/8").

Lorsque vous utilisez le bouton de réglage,

ouvrez complètement le levier de

verrouillage et tournez le bouton de réglage

à la profondeur de coupe désirée. Un tour

complet du bouton de réglage de

profondeur égale 5,1mm (0,2"). Pour un

réglage de moins de 4mm (5/32"), utilisez

léchelle séparée sur le bouton de réglage

de profondeur.

Pour des coupes plus profondes :

1. Alignez le « 0 » de léchelle sur la

flèche sur loutil.

2. Faites tourner le bouton de réglage de

profondeur en sens horaire à la

profondeur désirée.

Pour des coupes moins profondes :

1. Alignez la profondeur désirée sur la

flèche sur loutil.

2. Faites tourner le bouton de réglage de

profondeur en sens inverse-horaire

jusquà la marque « 0 ».

Après le réglage, poussez le levier de

verrouillage à la position fermée.

Lorsque vous utilisez une clé à douille,

placez la toupie sur une surface plane et

ouvrez complètement le levier de

verrouillage. Introduisez la clé à douille dans

le trou du socle et tournez-la à la profondeur

désirée (Fig. 11). Poussez ensuite le levier

de verrouillage à la position fermée.

Fig. 11

Maîtrise de loutil par la prise de

boîtier (Fig. 12)

Vous pouvez tenir cet outil par sa prise de

boîtier et sa poignée ou les deux poignées.

La prise de boîtier comporte une courroie

réglable qui peut être fixée à deux

positions pour une maîtrise et un confort

maximum.

Fig. 12

Positions alternatives de courroie

24 25

Page 14

Socle à poignée en étrier (Fig. 13)

Tenez la poignée en étrier dune main et

placez lautre main sur lautre poignée.

Fig. 13

Positions de poignée alternatives

Pour les deux types de socles :

Pour une maîtrise et un confort maximum,

une poignée peut être réglée à trois

différentes positions sur les deux types

de socles.

N.B. Utilisez vos deux mains en tout temps.

AVERTISSEMENT!

Pour minimiser les risques de

blessures, portez des lunettes à

coques latérales.

Pour minimiser les risques de

blessures, gardez les mains, le

corps et le cordon à lécart de la

mèche et des pièces en

mouvement.

Avant de brancher loutil sur une

source de courant, assurezvous que linterrupteur ON/OFF

est à la positon « O ».

.

Démarrage et arrêt du moteur dune

toupie à prise sur le boîtier

1. Pour mettre le moteur en marche, tenez

solidement loutil et poussez

linterrupteur ON/OFF à la position « l ».

2. Pour arrêter le moteur, poussez

linterrupteur ON/OFF à la position

«O» et placez la toupie pour que la

mèche soit à lopposé de votre corps.

Tenez loutil jusquà ce que la mèche

arrête de tourner.

Pour les socles à poignée en étrier :

1. Poussez linterrupteur ON/OFF à la position « l ».

2. Pour mettre le moteur en marche,

saisissez loutil solidement et appuyez

sur la détente.

3. Pour arrêter le moteur, relâchez la

détente.

Verrouillage de la détente de la

poignée en étrier (Fig. 14)

Le bouton de verrouillage maintient la

détente à la position ON pour un usage

continu.

Fig. 14

1.Pour verrouiller la détente, enfoncez

le bouton de verrouillage et maintenezle tandis que vous appuyez sur la

détente. Ensuite, relâchez la détente.

2. Pour déverrouiller la détente,

appuyez sur la détente et relâchez-la.

Le bouton de verrouillage va se

déclencher.

Bouton de verrouillage

AVERTISSEMENT!

Pour réduire les risques de

blessures, portez toujours des

lunettes de protection.

Pour réduire les risques

dexplosion, choc électrique et

dommages à la propriété,

vérifiez toujours lendroit du travail à la toupie pour y déceler les

tuyaux et les câbles électriques.

Pour faire la coupe

La vitesse et la profondeur de coupe

dépendront surtout du genre de matériau à

couper. Gardez la pression de coupe

constante mais nappliquez pas une

pression excessive sur la toupie au point

de ralentir le moteur. Il peut être nécessaire,

dans des bois très durs ou des matériaux

à problème, de repasser plus dune fois à

des profondeurs différentes pour obtenir

la profondeur de coupe désirée.

Avant de commencer une coupe sur un

matériau, il est conseillé de faire un essai

sur un morceau de bois de rebut. Ceci vous

fera voir comment sera la coupe et vous

permettra de vérifier si les dimensions sont

exactes. Avant de commencer, assurezvous que la pièce à travailler est rigidement

assujettie. Pour toupiller un rebord, la toupie

devrait être fermement maintenue contre

le bois avec les deux mains sur les

poignées de guidage.

Étant donné que la mèche tourne dans le

sens horaire, vous obtiendrez un meilleur

rendement en dirigeant la toupie de la

gauche vers la droite lorsque vous vous

tenez face à la pièce à travailler.Les flèches

sur le socle de loutil indiquent le sens de la

rotation de la mèche. Lorsque vous toupillez

à lextérieur du rebord, déplacez la toupie

dans le sens inverse-horaire (Fig. 15).

Fig. 15

Travail

Avance de

la toupie

Vue du dessus

Lorsque vous faites une coupe à lintérieur

dun rebord, déplacez la toupie en sens

horaire (Fig. 16).

Fig. 16

Le déplacement de la toupie dans la direction opposée sappelle « climb cutting » ou

coupe ascendante.

Rotation de

la mèche

Sens de

lavance

AVERTISSEMENT!

Pour minimiser les risques de

blessures, évitez de faire des

coupes ascendantes. Lescoupes

ascendantesaugmentent les

risques de perte de maîtrise et de

dommage au matériau. Si une

coupe ascendante ne peut être

évitée, soyez extrêmement

prudent.

26 27

Page 15

MAINTENANCE

ACCESSOIRES

AVERTISSEMENT!

Pour minimiser les risques de

blessures, débranchez toujours

loutil avant dy effectuer des

travaux de maintenance. Ne faites

pas vous-même le démontage de

loutil ni le rebobinage du

système électrique. Consultez

un centre de service

MILWAUKEE accrédité pour

toutes les réparations.

Entretien de loutil

Gardez loutil en bon état en adoptant un

programme dentretien ponctuel. Avant de

vous en servir, examinez son état en

général. Inspectez-en la garde, interrupteur,

cordon et cordon de rallonge pour en

déceler les défauts. Vérifiez le serrage des

vis, lalignement et le jeu des pièces mobiles, les vices de montage, bris de pièces

et toute autre condition pouvant en rendre

le fonctionnement dangereux. Si un bruit

ou une vibration insolite survient, arrêtez

immédiatement loutil et faites-le vérifier

avant de vous en servir de nouveau.

Nutilisez pas un outil défectueux. Fixez-y

une étiquette marquée « HORS DUSAGE »

jusquà ce quil soit réparé (voir

« Réparations »).

Normalement, il ne sera pas nécessaire de

lubrifier loutil avant que le temps ne soit

venu de remplacer les balais. Après une

période pouvant aller de 6 mois à un an,

selon lusage, retournez votre outil à un

centre de service MILWAUKEE accrédité

pour obtenir les services suivants :

Lubrification

Inspection et remplacement des balais

Inspection et nettoyage de la

mécanique (engrenages, pivots,

coussinets, boîtier etc.)

Inspection électrique (interrupteur, cor-

don, induit etc.)

Vérification du fonctionnement

électromécanique

Nettoyage

Débarrassez les évents des débris et de

la poussière. Gardez les poignées de loutil

propres, à sec et exemptes dhuile ou de

graisse. Le nettoyage de loutil doit se faire

avec un linge humide et un savon doux.

Certains nettoyants tels lessence, la

térébenthine, les diluants à laque ou à

peinture, les solvants chlorés, lammoniaque

et les détergents dusage domestique qui en

contiennent pourraient détériorer le plastique

et lisolation des pièces. Ne laissez jamais de

solvants inflammables ou combustibles

auprès des outils.

AVERTISSEMENT!

Pour minimiser les risques de

blessures, choc électrique et

dommage à l'outil, n'immergez

jamais l'outil et ne laissez pas de

liquide s'y infiltrer.

Réparations

Si votre outil doit être réparé, retournez-le

en entier au centre-service le plus près

selon la liste apparaissant à la dernière

page de ce manuel.

Pour minimiser les risques de

blessures, débranchez toujours

loutil avant dy installer ou den

enlever les accessoires.

Lemploi daccessoires autres

que ceux qui sont expressément

recommandés pour cet outil peut

présenter des risques.

Pour une liste complète des accessoires, prière de se reporter au catalogue MILWAUKEE

Electric Tool. Pour obtenir un catalogue, il suffit de contacter votre distributeur local ou l'un

des centres-service énumérés sur la page de couverture de ce manuel.

Embases

1. Embases pour règles-guides. conforme aux

normes de lindustrie pour guides filetés de

30mm (1-3/16").

2. Embase à ouverture de 64mm (2-1/2").

Clé

Clé à fourche en acier forgé 29mm (1-1/8").

Douilles de serrage

1. Douille 6,4mm (1/4") avec écrou.

2. Douille 13mm (1/2") avec écrou.

AVERTISSEMENT!

GARANTIE

Chaque outil fabriqué par MILWAUKEE est minutieusement vérifié avant de quitter lusine.

Sil survient un trouble, retournez loutil port payé au siège social de la compagnie ou à une

succursale ou un centre de service MILWAUKEE accrédité. Si lexamen de loutil démontre

que le trouble est dû à un défaut de fabrication ou de matériaux, les réparations seront

effectuées gratuitement et loutil vous sera retourné aux frais de la compagnie. Les

batteries servant aux outils sans cordon sont garanties pour un an à compter de la date

dachat.

La présente garantie ne sapplique pas dans les cas suivants : (1) Des réparations ont été

effectuées ou tentées par dautres personnes que des techniciens mandatés par

MILWAUKEE ou ses centres de service accrédités. (2) Les réparations sont rendues

nécessaires par lusure normale de loutil. (3) Loutil a été employé abusivement ou a été

endommagé accidentellement. (4) Lusage anormal ou la surcharge de loutil sont évidents.

(5) Loutil a été utilisé après une défaillance partielle. (6) Loutil a été employé avec un

28 29

accessoire non compatible. Nulle autre garantie, tant écrite que verbale, nest valable.

Page 16

REGLAS GENERALES DE SEGURIDAD

¡ADVERTENCIA!

LEA Y ENTIENDA TODAS LAS INSTRUCCIONES

El no seguir las instrucciones a continuación puede ocasionar

una descarga eléctrica, incendio y/o lesiones graves.

GUARDE ESTAS INSTRUCCIONES

AREA DE TRABAJO

1. Mantenga el área de trabajo limpia

e iluminada. Las mesas de trabajo

desordenadas y las áreas con poca

iluminación propician los accidentes.

2. No opere las herramientas con

motor en ambientes explosivos,

tales como los ambientes

con líquidos, gases o polvo

inflamables. Las herramientas con

motor producen chispas que pueden

inflamar el polvo o los gases.

3. Mantenga a las personas alejadas

mientras esté utilizando una

herramienta con motor. Las

distracciones pueden causar la pérdida

del control de la herramienta. Proteja a

las demás personas en el área de

trabajo contra escombros, tales como

astillas y chispas. Instale barreras si se

necesitan.

SEGURIDAD ELECTRICA

4. Las herramientas conectadas a

tierra deben estar enchufadas

en un toma corriente que

esté instalado correctamente y

conectado a tierra de acuerdo con

todos los códigos y ordenanzas

vigentes. Nunca retire la clavija de

conexión a tierra o modifique el

enchufe de ninguna manera. No

use enchufes adaptadores.

Consulteun electricista capacitado

si tiene dudas para asegurar

que el tomacorriente esté

correctamente conectado a tierra.

Si las herramientas sufren fallas

eléctricas, la conexión a tierra

proporciona una trayectoria de baja

resistencia para que el usuario no quede

expuesto a la electricdad.

5. Las herramientas con aislamiento

doble están equipadas con un

enchufe polarizado (una clavija es

SEGURIDAD PERSONAL

10. Esté alerta. Revise su trabajo y use

el sentido común. No opere su

herramienta cuando esté cansado,

distraído o bajo la influencia de

drogas alcohol o medicamentos.

Un momento de descuido cuando

operando un herramienta electrica

puede resultar en lesiones graves.

11. Utilice ropa adecuada. No use ropa

suelta o joyas. Mantenga el cabello largo,

más ancha que la otra). Hay una

sola manera de introducir este

enchufe en una toma polarizada.

Si el enchufe no se ajusta

completamente en la toma, dé

vuelta el enchufe. Si el problema

persiste, póngase en contacto con

un electricista calificado para que

instale una toma polarizada. No

cambie la toma de ninguna manera.

El aislamiento doble elimina la

necesidad de un cable de energía con

conexión a tierra con 3 alambres y la de

un sistema de suministro de energía con

conexión a tierra.

6. Evite contacto físico con las super-

ficies conectadas a tierra, tales

como tuberías, radiadores, cocinas

y refrigeradores. Existe un riesgo de

un choque eléctrico mayor si su cuerpo

está expuesto a tierra.

7. No exponga las herramientas

eléctricas a condiciones de lluvia o

humedad. El agua que entra en una

herramienta eléctrica aumentará el

riesgo de choque eléctrico.

8. No maltrate el cable. Nunca use el

cable para transportar las

herramientas ni para sacar el

enchufe de la toma eléctrica.

Mantenga el cable lejos de

calefacción, petróleo, bordes

afilados o cualquier parte movible.

Reemplace inmediatamente cualquier cable dañado. Los cables

dañados aumentan el riesgo de choque

eléctrico.

9. Al operar una herramienta eléctrica

a la intemperie, use un cordón de

extensión para la intemperie

marcado W-A o W. Estos

cordones están aprobados para usos

exteriores y reducen el riesgo del

choque eléctrico.

30 31

ropa y guantes alejados de las partes

móviles.

12. Evite los arranques accidentales.

Verifique que el interruptor esté

apagado antes de enchufar la

herramienta. Transportar la herramienta

por el gatillo o enchufarla con el

interruptor encendido puede ocasionar

accidentes

13. Saque las llaves de ajuste antes de

encender la herramienta. Una llave

sujeta a una parte en movimiento puede

causar lesiones.

14. No se esfuerce, mantenga el con-

trol y el balance en todo momento.

Mantenga siempre una postura y un balance adecuados. Una postura y un balance correctos otorga un mejor control

ante situaciones inesperadas.

15. Utilice el equipo de seguridad.

Siempre use protección para los

ojos. Se debe usar una máscara con-

tra el polvo, zapatos de seguridad

antidelizantes, casco y protector para

los oídos, cuando las condiciones así lo

requieran.

USO Y MANTENIMIENTO DE

LA HERRAMIENTA

16. Utilice abrazaderas u otra manera

práctica para sujetar y apoyar el material en una plataforma estable.

Tener el material en la mano o contra el

cuerpo es inestable y puede causar la

pérdida del control.

17. No fuerce la herramienta. Utilice la

herramienta apropiada para la

aplicación. La herramienta realizará el

trabajo de manera más eficaz y segura,

si la opera a la velocidad apropiada.

18. Si el gatillo no enciende o apaga

la herramienta, no utilice la

herramienta. Una herramienta que no

se puede controlar con el gatillo es

peligrosa y debe ser reparada.

19. Desconecte el enchufe de la

fuente de energía antes de

realizar cualquier ajuste, cambiar

los accesorios o almacenar

la herramienta. Tales medidas

precautorias de seguridad reducen el

riesgo de encender la herramienta

accidentalmente.

20. Almacene las herramientas que no

se estén usando fuera del alcance

de los niños y de personas que no

estén capacitadas. Es peligroso

permitir a los usuarios utilizar las

herramientas, si no están capacitados

previamente.

21. Mantenga las herramientas

en buenas condiciones. Las

herramientas cortadoras deben

mantenerse afiladas y limpias. Esto

reduce el riesgo de que la herramienta

se atasque y facilita el control de la

misma. No utilice una herramienta

dañada. Colóquele una etiqueta que diga

No Debe Usarse hasta que sea

reparada.

22. Verique que las partes en

movimiento estén alineadas y no

estén atascadas. También debe

verificarse que las partes no estén

rotas o tengan cualquier otra

condición que pueda afectar el

funcionamiento de la herramienta.

Si está dañada, se debe reparar la

herramienta antes de utilizarla.

Muchos accidentes se deben al

mantenimiento incorrecto de la

herramienta.

23. Utilice solamente los accesorios

recomendados por el fabricante

para ese modelo. Los accesorios que

son apropiados para una herramienta

pueden aumentar el riesgo de lesiones

cuando se usan con otra herramienta.

SERVICIO

24. El servicio de mantenimiento debe

ser realizado solamente por

personal técnico debidamente

capacitado. El servicio o mantenimiento

realizado por personal no calificado

puede aumentar el riesgo de lesiones.

25. Cuando realice el servicio de

mantenimiento, utilice solamente

repuestos idénticos. Siga las

instrucciones en la sección de

mantenimiento de este manual. El

uso de partes no autorizadas o el

incumplimiento de las instrucciones de

mantenimiento puede aumentar el riesgo

de descarga eléctrica o lesiones.

Page 17

¡ADVERTENCIA!

Puede haber riesgo de descarga

eléctrica si se conecta el cable de

conexión de puesta a tierra

incorrectamente. Consulte con

un electricista certificado si tiene

dudas respecto a la conexión de

puesta a tierra del tomacorriente.

No modifique el enchufe que se

proporciona con la herramienta.

Nunca retire la clavija de conexión

de puesta a tierra del enchufe. No

use la herramienta si el cable o el

enchufe está dañado. Si está

dañado antes de usarlo, llévelo a

un centro de servicio MILWAUKEE

para que lo reparen. Si el enchufe

no se acopla al tomacorriente,

haga que un electricista

certificado instale un tomacorriente adecuado.

Herramientas con conexión a tierra:

Herramientas con enchufes de tres

clavijas

Las herramientas marcadas con la frase

Se requiere conexión de puesta a tierra

tienen un cable de tres hilo y enchufes de

conexión de puesta a tierra de tres clavijas.

El enchufe debe conectarse a un

tomacorriente debidamente conectado a

tierra (véase la Figura A). Si la herramienta

se averiara o no funcionara

correctamente, la conexión de puesta a

tierra proporciona un trayecto de baja

resistencia para desviar la corriente

eléctrica de la trayectoria del usuario,

reduciendo de este modo el riesgo de

descarga eléctrica.

TIERRA

La clavija de conexión de puesta a tierra

en el enchufe está conectada al sistema

de conexión de puesta a tierra de la

herramienta a través del hilo verde dentro

del cable. El hilo verde debe ser el único

hilo conectado al sistema de conexión de

puesta a tierra de la herramienta y nunca

se debe unir a una terminal energizada.

Su herramienta debe estar enchufada en

un tomacorriente apropiado, correctamente

instalado y conectado a tierra según todos

los códigos y reglamentos. El enchufe y el

tomacorriente deben asemejarse a los de

la Figura A.

Herramientas con doble aislamiento:

Herramientas con clavijas de dos

patas

Las herramientas marcadas con Doble

aislamiento no requieren conectarse a

tierra. Estas herramientas tienen un

sistema aislante que satisface los

estándares de OSHA y llena los estándares

aplicables de UL (Underwriters Laboratories), de la Asociación Canadiense de

Estándares (CSA) y el Código Nacional de

Electricidad. Las herramientas con doble

aislamiento pueden ser usadas en

cualquiera de los toma corriente de 120

Volt mostrados en las Figuras B y C.

Fig. B

Fig. C

EXTENSIONES ELECTRICAS

Las herramientas que deben conectarse a

tierra cuentan con clavijas de tres patas y

requieren que las extensiones que se

utilicen con ellas sean también de tres

cables. Las herramientas con doble

aislamiento y clavijas de dos patas pueden

utilizarse indistintamente con extensiones

de dos a tres cables. El calibre de la

extensión depende de la distancia que

exista entre la toma de la corriente y el sitio

donde se utilice la herramienta. El uso de

extensiones inadecuadas puede causar

serias caídas en el voltaje, resultando en

pérdida de potencia y posible daño a la

herramienta. La tabla que aquí se ilustra

sirve de guía para la adecuada selección

de la extensión.

Mientras menor sea el número del calibre

del cable, mayor será la capacidad del

mismo. Por ejemplo, un cable calibre 14

puede transportar una corriente mayor que

un cable calibre 16. Cuando use mas de

una extensión para lograr el largo deseado,

asegúrese que cada una tenga al menos,

el mínimo tamaño de cable requerido. Si

está usando un cable de extensión para

mas de una herramienta, sume los amperes

de las varias placas y use la suma para

determinar el tamaño mínimo del cable de

extensión.

LEA Y GUARDE TODAS LAS

INSTRUCCIONES PARA FUTURAS

REFERANCIAS.

Guías para el uso de cables de

extensión

Si está usando un cable de extensión

en sitios al aire libre, asegúrese que

está marcado con el sufijo W-A (W

en Canadá) el cual indica que puede

ser usado al aire libre.

Asegúrese que su cable de extensión

está correctamente cableado y en

buenas condiciones eléctricas. Cambie

siempre una extensión dañada o