Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Cat. No.

No de cat.

5455

5460

5540

HEAVY-DUTY POLISHERS

POLISSEUSES EXTRA ROBUSTES

PULIDORAS EXTRA RESISTENTES

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S

MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN

COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL

MANUAL DEL OPERADOR.

Page 2

GENERAL POWER TOOL SAFETY WARNINGS

WARNING READ ALL SAFETY WARNINGS AND INSTRUCTIONS.

Failure to follow the warnings and instructions may result in electric shock, fi re and/or

serious injury. Save all warnings and instructions for future reference

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

• Keep work area clean and well lit. Cluttered or

WORK AREA SAFETY

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. W ater entering a power tool will increase

the risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the risk

of electric shock.

• If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the infl uence of drugs, alcohol or medi-

cation. A moment of inattention while operating

power tools may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your fi nger on the switch or energising power

tools that have the switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair , clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

• Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

• Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc., in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the power

tool for operations different from those intended

could result in a hazardous situation.

SERVICE

• Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

2

SPECIFIC SAFETY RULES

Safety Warnings Common for Polishing Operations:

• This power tool is intended to function as a

polisher. Read all safety warnings, instructions, illustrations and specifi cations provided

with this power tool. Failure to follow all instruc-

tions listed below may result in electric shock, fi re

and/or serious injury.

• Operations such as grinding, sanding, wire

brushing or cutting-off are not recommended

to be performed with this power tool. Opera-

tions for which the power tool was not designed

may create a hazard and cause personal injury.

• Do not use accessories which are not specifi -

cally designed and recommended by the tool

manufacturer. Just because the accessory can

be attached to your power tool, it does not assure

safe operation.

• The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and fl y apart.

• The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

• The arbour size of wheels, fl anges, backing

pads or any other accessory must properly

fi t the spindle of the power tool. Accessories

with arbour holes that do not match the mounting

hardware of the power tool will run out of balance,

vibrate excessively and may cause loss of control.

• Do not use a damaged accessory . Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for

loose or cracked wires. If power tool or accessory is dropped, inspect for damage or install

an undamaged accessory. After inspecting

and installing an accessory, position yourself

and bystanders away from the plane of the

rotating accessory and run the power tool

at maximum no-load speed for one minute.

Damaged accessories will normally break apart

during this test time.

•

Wear personal protective equipment. Depending on application, use face shield, safety

goggles or safety glasses. As appropriate,

wear dust mask, hearing protectors, gloves

and work shop apron capable of stopping

small abrasive or workpiece fragments. The

eye protection must be capable of stopping

fl ying debris generated by various operations.

The dust mask or respirator must be capable of

fi ltrating particles generated by your operation.

Prolonged exposure to high intensity noise may

cause hearing loss.

• Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken accessory

may fl y away and cause injury beyond immediate

area of operation.

• Hold power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring

or its own cord. Cutting accessory contacting a

live wire may make exposed metal parts of the

power tool live and shock the operator.

• Position the cord clear of the spinning acces-

sory. If you lose control, the cord may be cut or

snagged and your hand or arm may be pulled into

the spinning accessory.

• Never lay the power tool down until the ac-

cessory has come to a complete stop. The

spinning accessory may grab the surface and pull

the power tool out of your control.

• Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

• Regularly clean the power tool’ s air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

• Do not operate the power tool near fl ammable

materials. Sparks could ignite these materials.

• Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging causes

rapid stalling of the rotating accessory which in turn

causes the uncontrolled power tool to be forced in

the direction opposite of the accessory’s rotation

at the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

• Maintain a fi rm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or

kickback forces, if proper precautions are taken.

• Never place your hand near the rotating acces-

sory. Accessory may kick back over your hand.

• Do not position your body in the area where

power tool will move if kickback occurs. Kickback will propel the tool in direction opposite to

the wheel’s movement at the point of snagging.

3

Page 3

• Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

• Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create frequent kickback and loss of control.

Safety Warnings Specifi c for Polishing Opera-

tions:

• Do not allow any loose portion of the polishing

bonnet or its attachment strings to spin freely.

Tuck away or trim any loose attachment strings.

Loose and spinning attachment strings can entangle your fi ngers or snag on the workpiece.

Additional Safety Warnings

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Y our risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to fi lter out microscopic particles.

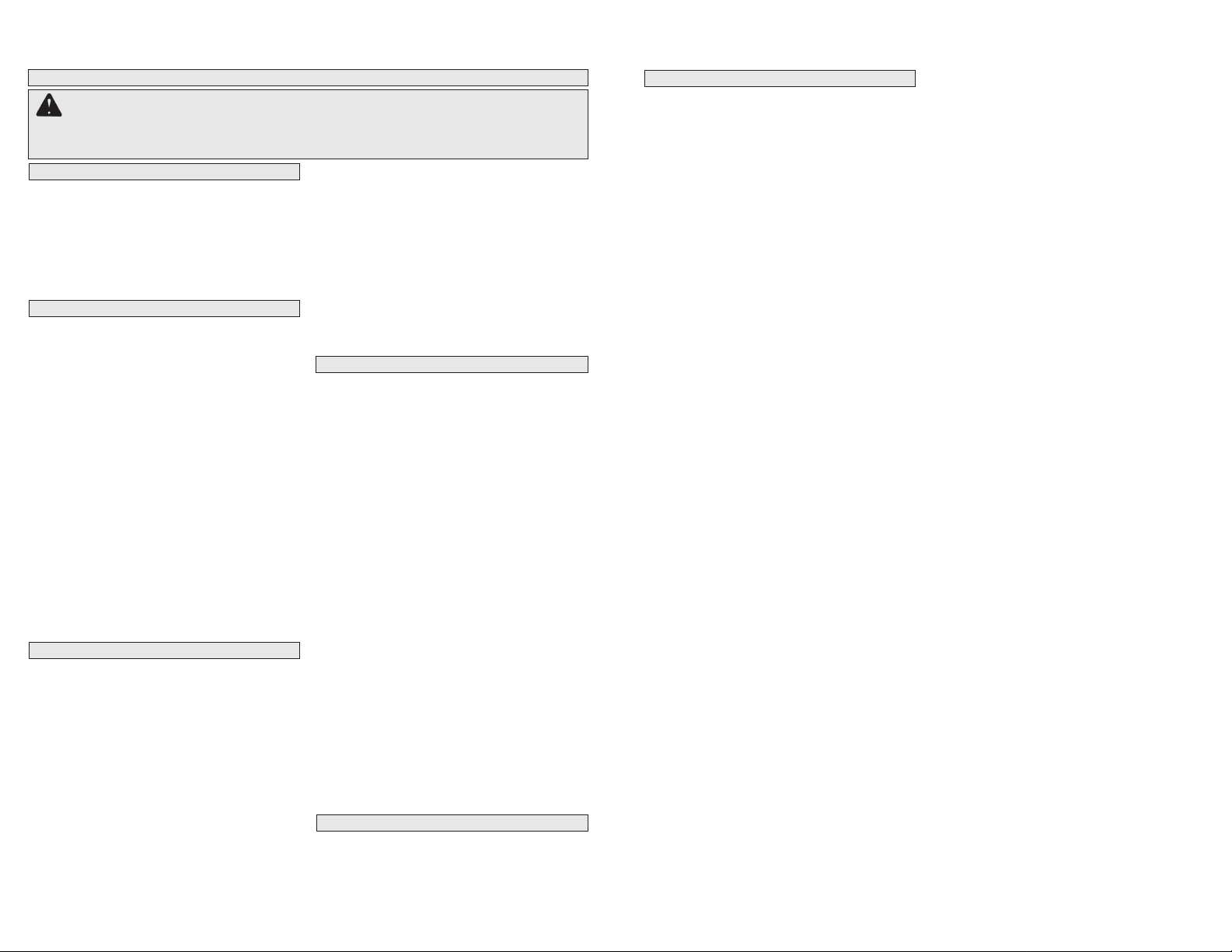

Functional Description

1

10

9

8

7

1. Handle

2. Speed control dial

3. Tool rest

4. Side handle

5. Polishing pad

6. Rubber backing pad

7. Spindle lock button

6

2

3

8. Vents

9. Trigger

10.Cord

4

5

GROUNDING

WARNING Improperly connecting the

grounding wire can result in the risk of

electric shock. Check with a qualifi ed electri-

cian if you are in doubt as to whether the

outlet is properly grounded. Do not modify

the plug provided with the tool. Never remove

the grounding prong from the plug. Do not

use the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE

service facility before use. If the plug will not

fi t the outlet, have a proper outlet installed by

a qualifi ed electrician.

Grounded Tools: Tools with Three Prong Plugs

Tools marked “Grounding Required” have a three

wire cord and three prong grounding plug. The

plug must be connected to a properly grounded

outlet (See Figure A). If the tool should electrically

malfunction or break down, grounding provides a

low resistance path to carry electricity away from

the user, reducing the risk of electric shock.

The grounding prong in the plug is connected

through the green wire inside the cord to the

grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's

grounding system and must never be attached to

an electrically “live” terminal.

Y our tool must be plugged into an appropriate outlet, properly installed and grounded in

accordance with all codes and ordinances.

The plug and outlet should look

like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require

grounding. They have a special double insulation system which satisfi es OSHA requirements

and complies with the applicable standards of

Underwriters Laboratories, Inc.,

the Canadian Standard Association and the National Electrical Code. Double Insulated

tools may be used in either of

the 120 volt outlets shown in

Figures B and C.

Fig. A

Fig. B

Fig. C

Specifi cations

Cat.

5455

5460

5540

4

No.

Volts

120 AC/DC

120 AC

120 AC

No Load

RPM

1750

0 - 1750

0 - 2800

Pad

Diameter

7"/9"

7"/9"

7"

Spindle

Size

5/8"-11

5/8"-11

5/8"-11

Grounded tools require a three wire extension

cord. Double insulated tools can use either a two

or three wire extension cord. As the distance from

the supply outlet increases, you must use a heavier

gauge extension cord. Using extension cords with

inadequately sized wire causes a serious drop in

voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the

required minimum wire size.

The smaller the gauge number of the wire, the

greater the capacity of the cord. For example, a 14

gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension

cord to make up the total length, be sure each cord

contains at least the minimum wire size required. If

you are using one extension cord for more than one

tool, add the nameplate amperes and use the sum

to determine the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors,

be sure it is marked with the suffi x “W-A” (“W”

in Canada) to indicate that it is acceptable for

outdoor use.

• Be sure your extension cord is properly wired

and in good electrical condition. Always replace

a damaged extension cord or have it repaired by

a qualifi ed person before using it.

• Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

Recommended Minimum Wire Gauge

* Based on limiting the line voltage drop to fi ve volts

at 150% of the rated amperes.

for Extension Cords*

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

Extension Cord Length

25'

18

18

18

18

16

14

12

50'

18

18

18

16

14

12

10

75'

18

18

16

14

12

10

100'

18

16

14

12

10

150'

16

14

12

12

READ AND SAVE ALL

INSTRUCTIONS FOR FUTURE USE.

Symbology

Double Insulated

No Load Revolutions per

Minute (RPM)

Volts Alternating Current/

Direct Current

Volts Alternating Current

Amps

Underwriters Laboratories, Inc.,

United States and Canada

EXTENSION CORDS

ASSEMBLY

WARNING T o reduce the risk of injury ,

always unplug tool before attaching

or removing accessories or making adjustments. Use only specifi cally recommended

accessories. Others may be hazardous.

Removing and Replacing Quik-Lok® Cords

MILWAUKEE's exclusive Quik-Lok

instant fi eld replacement or substitution.

Fig. 1

1. To remove the Quik-Lok® Cord, turn the cord nut

1/4 turn to the left and pull it out.

2. T o replace the Quik-Lok® Cord, align the connector keyways and push the connector in as far as

it will go. Turn the cord nut 1/4 turn to the right

to lock.

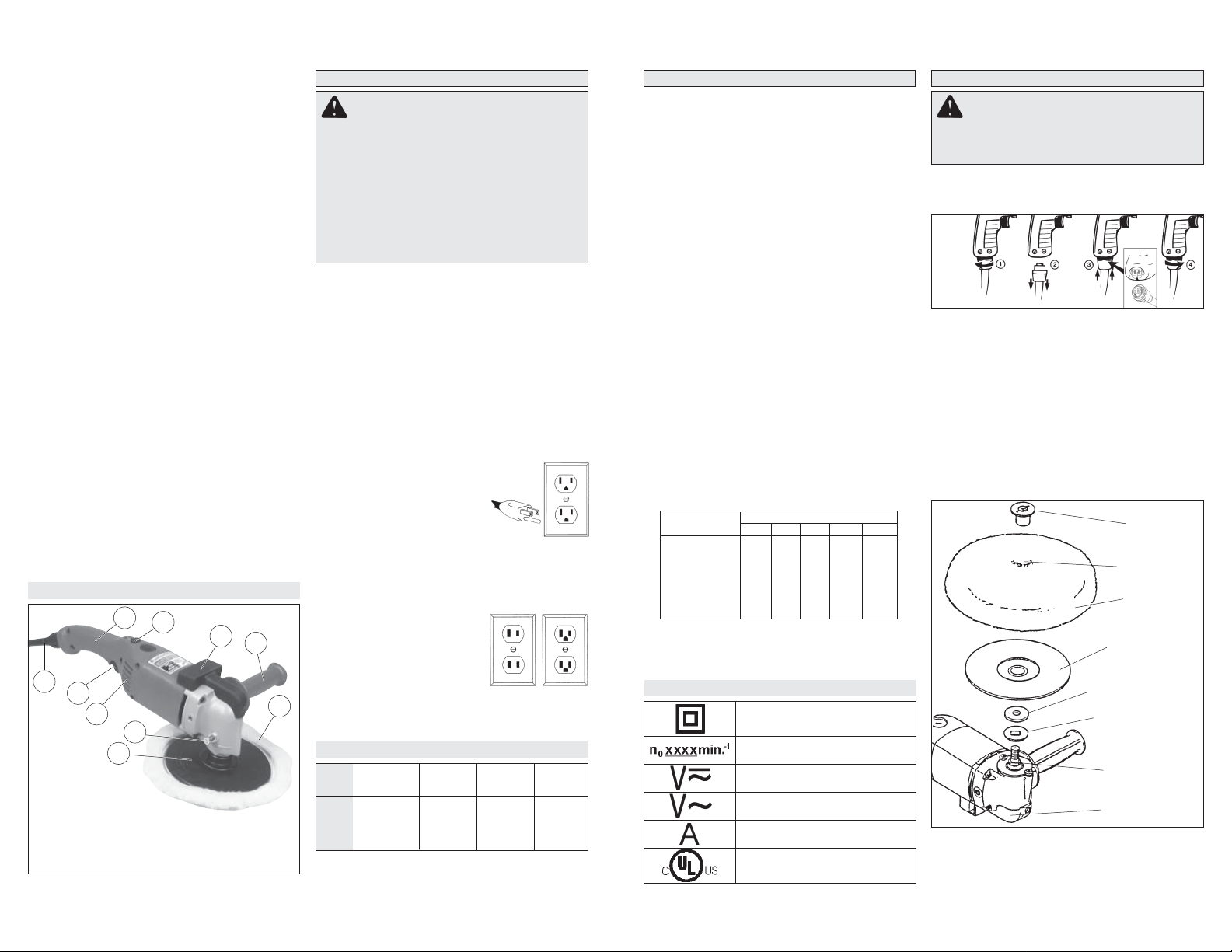

Polishing Pads

MILWAUKEE polishing pads are available in two

different materials. 100% lambswool pads are ideal

for compounding on non-clearcoat fi nishes. Wool/

polyester blend pads are softer, making them acceptable for clearcoat fi nishes.

Fig. 2

1. To install polishing pads, unplug the tool and

place it on its tool rest with the spindle upright.

5

®

Cords provide

Disc nut

Arbor hole

Polishing

pad

Rubber

backing pad

Spindle washer

Washer fl ange

Spindle

Tool rest

Page 4

2. Make sure the washer fl ange and spindle washer

are installed on spindle. Then, slide the disc

nut through the arbor hole in both the polishing

pad and the rubber backing pad, making sure

to spread the fi bers in the pad so the disc nut

seats on pad backing.

3. Push in the spindle lock button (located on left

side of gear case) and simultaneously screw the

disc nut & polishing pad assembly clockwise onto

the spindle. Securely hand-tighten the disc nut

and polishing pad.

4. To remove the polishing pad, push in the spindle

lock button and turn the disc nut counterclockwise to unscrew the assembly.

Wool/Polyester Bonnets

Fig. 3

Wool/polyester

bonnet

Bonnet strings

Disc nut

Rubber

backing pad

Spindle washer

Washer fl ange

Spindle

Tool rest

1. To install wool/polyester bonnets, unplug the

tool and place it on a tool rest with the spindle

upright.

2. Make sure the washer fl ange and spindle washer

are installed on spindle. Then, slide the rubber

backing pad onto the spindle.

3. Push in the spindle lock button and screw the

disc nut onto the spindle clockwise. Securely

hand-tighten the disc nut.

4. Cover the rubber backing pad with the bonnet.

Securely tie bonnet strings and tuck the strings

into the bonnet so they do not interfere with

polishing.

5. To remove, untie and remove the bonnet. Push

in the spindle lock button and turn the disc nut

and rubber backing pad counterclockwise.

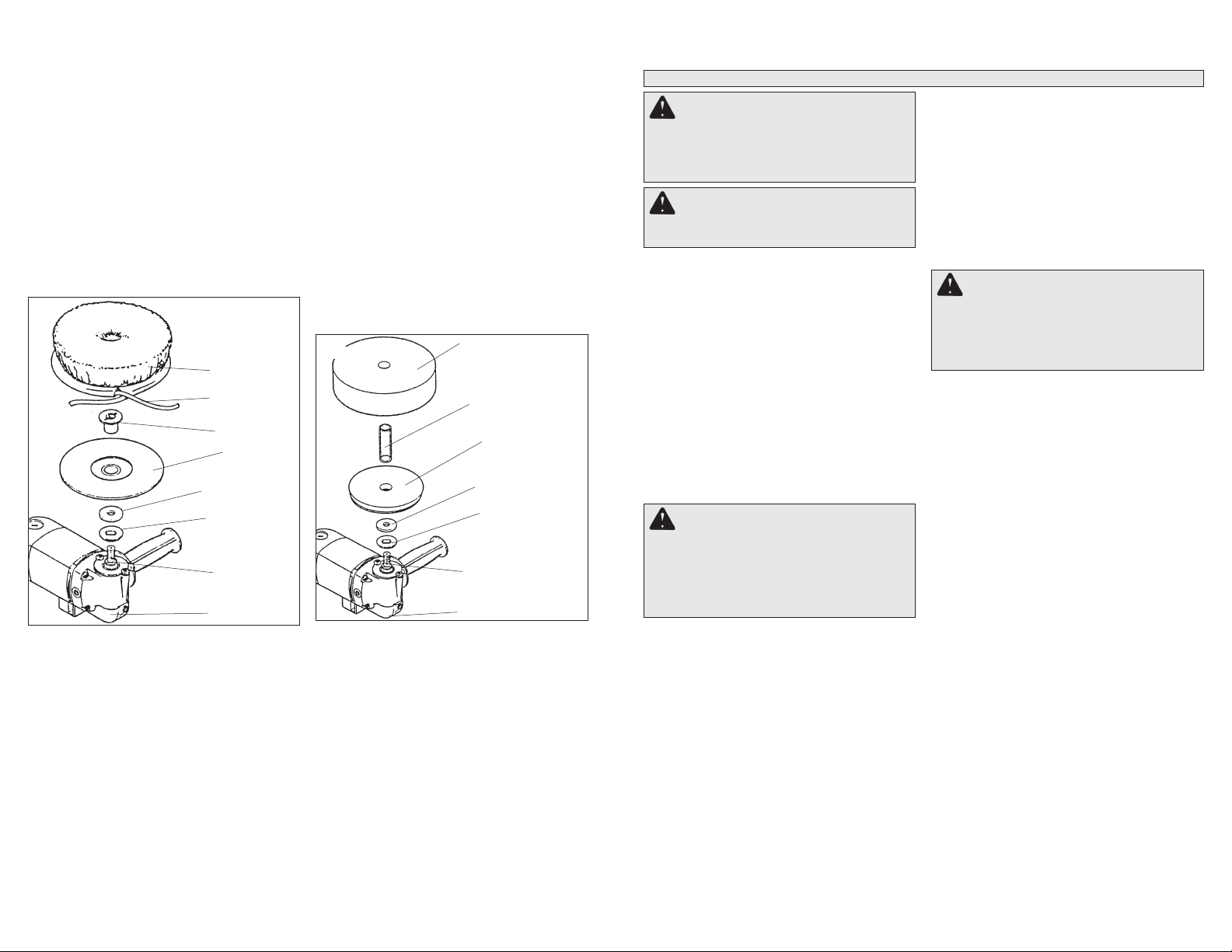

Hook and Loop Pads

Hook & loop pads are available in both wool/polyester and foam. Foam pads should be used on slower/

low speed dial settings when using polisher Cat.

Nos. 5540 and 5460. Foam pads are not recommended for the inexperienced operator.

Foam pad Cat. No. 49-36-1550 is ideal for use

with clearcoat finishes and micro-fine rubbing

compounds. It will remove light surface scratches,

environmental pollutants, wet-sanding scratches

and hazy paint.

Foam pad Cat. No. 49-36-0650 is ideal for glazing

and fi nishing on clearcoat fi nishes. It will remove

buffi ng swirls, hard water spots, carwash brush

swirls and mild hazing. A centering tool, Cat. No.

49-67-0130, is supplied with hook and loop backing

pads, Cat. No. 49-36-2150, to properly align the

backing pad with the polishing pad, providing the

proper balance for your polisher.

Fig. 4

1. To install hook and loop pads, unplug the tool

and place it on tool rest with spindle upright.

2. Make sure washer fl ange and spindle washer

are installed on spindle. Then slide hook and

loop backing pad onto spindle.

3. Push in the spindle lock button and spin the

backing pad clockwise until it is securely handtightened.

4. Insert the centering tool (supplied with the backing pad) into the center hole in the hook and

loop backing pad. Push desired hook and loop

polishing pad over the centering tool so that

the polishing pad fastens to the hook and loop

backing pad. Remove centering tool.

5. To remove, "peel" off the polishing pad. Push in

the spindle lock button and rotate backing pad

counterclockwise to remove.

NOTE: Use side handles for better control and

safety.

6

Foam pad with

hook and loop

Centering tool

(remove before

using tool)

Backing pad with

hook and loop

Spindle washer

Washer fl ange

Spindle

Tool rest

OPERATION

WARNING To reduce the risk of injury ,

always unplug tool before attaching or removing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

WARNING To reduce the risk of injury ,

wear safety goggles or glasses with side

shields.

Starting, Stopping and Controlling Speed

Cat. No. 5455: To start the tool, pull the trigger. To

stop the tool, release the trigger.

Cat. Nos. 5540 & 5460 feature a dial speed control,

which controls the polisher's maximum rotations

per minute. The speed will remain variable to the

chosen dial setting by use of the trigger switch. Dial

settings range from 1 through 5. Lower numbers

correspond to lower speeds and higher numbers

correspond to higher speeds. Generally, lower

speeds are recommended for tight work areas and

higher speeds are ideal for large surface areas. Use

the setting that best suits your job.

To control the speed, set the dial to the desired

number. Then pull the trigger . Increase or decrease

pressure on the trigger to vary the speed. To stop

the tool, release the trigger.

WARNING To reduce the risk of in-

jury, keep the cord set away from the path

of the polisher. Otherwise the cord set may

become caught by the pad and wrap around

the spindle; this may cut through the cord

and expose live wires or make the gear box

electrically "live."

Polishing

Always use side handle for proper control. Move the

polisher back and forth in long, sweeping strokes.

Too much pressure, the wrong angle or improper

motion may cause swirl marks or burning.

For detailed polishing instructions, read the instructions provided with your fi nishes, waxes and

polishes.

Preventing Burning Through Paint

It is easy to burn through the paint on a surface.

This can occur if you polish at too high a speed or

if you allow the polishing pad to stay in one spot

for even a short period of time. To prevent burning

through paint, use very light pressure and keep the

polisher moving constantly, especially when working near edges or where there are abrupt changes

in the contour of the work surface.

Be particularly careful when using Cat. No. 5540,

which are high RPM polishers and are more likely

to burn through paint.

WARNING T o reduce the risk of injury ,

follow instructions for preventing snagging.

Snagging may cuase the tool to kick back

and the operator to suddenly lose control of

the tool. Always use side handle to maintain

control.

Preventing Snagging

Snagging occurs when polishing pads get caught

on rough edges of a work surface. Snagging can

cause the tool to suddenly "kick back" and it may

cause the pad to burn through the paint. T o reduce

the risk of snagging, use the polisher at low speeds

when polishing rough surfaces. For tricky areas

such as near trim or between a mirror and window

on a car, do not take chances with a polisher . Polish

these surfaces by hand.

When using Cat. Nos. 5460 and 5540 with the

trigger speed control, release the trigger slightly

so the rotation of the pad is slowed.

To prevent snagging while using Cat. No. 5455

without trigger speed control, it is best to use the

"coast-down" technique to avoid snagging. To

coast-down, turn the motor ON for a few seconds,

then turn it OFF and apply the polishing pad to the

surface. This way , when the pad touches the work

surface, it will be rotating more slowly than it is when

the motor is ON. Use coast-down when working in

areas where crevices or pockets are present.

7

Page 5

MAINTENANCE

WARNING To reduce the risk of

injury, always unplug your tool before

performing any maintenance. Never disassemble the tool or try to do any rewiring

on the tool’s electrical system. Contact a

MILWAUKEE service facility for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, broken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. T ag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

Under normal conditions, relubrication is not necessary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical operation

WARNING T o reduce the risk of injury ,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include: gasoline, turpentine, lacquer thinner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

ACCESSORIES

WARNING T o reduce the risk of injury ,

always unplug the tool before attaching

or removing accessories. Use only specifi -

cally recommended accessories. Others may

be hazardous.

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

8

LIMITED WARRANTY - USA AND CANADA

Every MILWAUKEE power tool (including cordless product – tool, battery pack(s) & battery charger and Work Light – cordless fl ashlight) is war-

ranted to the original purchaser only to be free from defects in material and workmanship. Subject to certain exceptions, MILWAUKEE will repair

or replace any part on an electric power tool which, after examination, is determined by MILWAUKEE to be defective in material or workmanship

for a period of fi ve (5) years* after the date of purchase. Return of the power tool and a copy of proof of purchase to a MILWAUKEE factory

Service Center location or MILWAUKEE Authorized Service Station, freight prepaid and insured, are required for this warranty to be effective.

This warranty does not apply to damage that MILWAUKEE determines to be from repairs made or attempted by anyone other than MILWAUKEE

authorized personnel, misuse, alterations, abuse, normal wear and tear, lack of maintenance, or accidents.

*Every MILWAUKEE V™-technology (V18™ & V28™) LITHIUM-ION Battery Pack and M18 XC LITHIUM-ION Battery Pack is warranted for fi ve

(5) years / 2000 charges from the date of purchase, whichever fi rst occurs. The fi rst 1000 charges or 2 years of the warranty, whichever fi rst

occurs, are covered through free replacement of the defective battery. This means that for the earlier of the fi rst 1000 charges or two (2) years

from the date of purchase/fi rst charge, a replacement battery will be provided to the customer for any defective battery free of charge. Thereafter,

the remaining charges up to a total of 2000 or the remainder of the fi ve (5) year period from the date of purchase, whichever fi rst occurs, will

be covered on a pro rata basis. This means that every customer gets an additional 1000 charges or three (3) years of pro rata warranty on the

V™-technology LITHIUM-ION Battery Pack and M18 XC LITHIUM-ION Battery Pack depending upon the amount of use.

*The warranty period for ALL other LITHIUM-ION Battery Packs is two (2) years from the date of purchase.

*The warranty period for M12 2-Beam Laser & M12 Power Port, Ni-CD Battery Packs, Job Site Radios, and Trade Titan™ Industrial Work Carts

is one (1) year from the date of purchase.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE product. The manufacturing date of the product will

be used to determine the warranty period if no proof of purchase is provided at the time warranty service is requested.

ACCEPTANCE OF THE EXCLUSIVE REP AIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN IS A CONDITION OF THE CONTRACT

FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT . IF YOU DO NOT AGREE TO THIS CONDITION, YOU SHOULD NOT PURCHASE

THE PRODUCT. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR ANY INCIDENT AL, SPECIAL, CONSEQUENTIAL OR PUNITIVE DAM-

AGES, OR FOR ANY COSTS, ATTORNEY FEES, EXPENSES, LOSSES OR DELAYS ALLEGED TO BE AS A CONSEQUENCE OF ANY

DAMAGE TO, FAILURE OF, OR DEFECT IN ANY PRODUCT INCLUDING, BUT NOT LIMITED TO, ANY CLAIMS FOR LOSS OF PROFITS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES, WRITTEN OR ORAL. TO THE EXTENT PERMITTED BY LA W, MILWAUKEE DISCLAIMS ANY IMPLIED WARRANTIES, INCLUDING

WITHOUT LIMITA TION ANY IMPLIED WARRANTY OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR USE OR PURPOSE; TO THE

EXTENT SUCH DISCLAIMER IS NOT PERMITTED BY LAW, SUCH IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THE

APPLICABLE EXPRESS WARRANTY AS DESCRIBED ABOVE. SOME ST ATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU, THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

Please consult the ‘Service Center Search’ in the Parts & Service section of MILWAUKEE’s website www.milwaukeetool.com or call 1.800.SA W-

DUST (1.800.729.3878) to locate your nearest service facility for warranty and non-warranty service on a MILWAUKEE electric power tool.

LIMITED WARRANTY - MEXICO, CENTRAL AMERICA AND CARIBBEAN

TECHTRONIC INDUSTRIES' warranty is for 5 year since the original purchase date.

This warranty card covers any defect in material and workmanship on this Power Tool.

To make this warranty valid, present this warranty card, sealed/stamped by the distributor or store where you purchased the product, to the

Authorized Service Center (ASC). Or, if this card has not been sealed/stamped, present the original proof of purchase to the ASC.

Call toll-free 1 800 832 1949 to fi nd the nearest ASC, for service, parts, accessories or components.

Procedure to make this warranty valid

Take the product to the ASC, along with the warranty card sealed/stamped by the distributor or store where you purchased the product, and

there any faulty piece or component will be replaced without cost for you. We will cover all freight costs relative with this warranty process.

Exceptions

This warranty is not valid in the following situations:

a) When the product is used in a different manners from the end-user guide or instruction manual.

b) When the conditions of use are not normal.

c) When the product was modifi ed or repaired by people not authorized by TECHTRONIC INDUSTRIES.

Note: If cord set is damaged, it should be replaced by an Authorized Service Center to avoid electric risks.

Model:

Date of Purchase:

Distributor or Store Stamp:

9

SERVICE AND ATTENTION CENTER

Rafael Buelna No.1.

Col. Tezozomoc Mexico, Azcapotzalco D.F.

Ph. 01 800 832 1949

IMPORTED AND COMMERCIALIZED BY:

TECHTRONIC INDUSTRIES MEXICO, .S.A. DE C.V.

Av. Santa Fe 481 piso 6, Col. Curz Manca.

CP 05349, Cuajimalpa, D.F.

Page 6

RÈGLES DE SÉCURITÉ GÉNÉRALES RELATIVES AUX

OUTILS ÉLECTRIQUES

AVERTISSEMENT LIRE TOUTES LES RÈGLES ET INSTRUCTIONS DE SÉCURITÉ.

Ne pas suivre l’ensemble des règles et instructions peut entraîner une électrocution, un incendie

ou des blessures graves. Conserver les règles et les instructions à des fi ns de

référence ultérieure. Le terme «outil électrique» fi gurant dans les avertissements ci-dessous

renvoie à l’outil électrique à alimentation par le réseau (à cordon) ou par batterie (sans fi l).

SÉCURITÉ DU LIEU DE TRA VAIL

• Maintenir la zone de travail propre et bien

éclairée. Les zones encombrées ou mal éclairées

sont favorables aux accidents.

• Ne pas utiliser d’outil électrique dans une at-

mosphère explosive, telle qu’en en présence

de liquides, de gaz ou de poussières infl am-

mables. Les outils électriques génèrent des

étincelles qui peuvent enfl ammer les poussières

ou les fumées.

• Tenir les enfants et les personnes non au-

torisées à l’écart pendant le fonctionnement

d’un outil électrique. Un manque d’attention de

l’opérateur risque de lui faire perdre le contrôle de

l’outil.

SÉCURITÉ ÉLECTRIQUE

• La fi che de l’outil électrique doit correspondre

à la prise d’alimentation. Ne jamais modifi er la

fi che d’une manière quelconque. Ne pas utiliser d’adaptateur avec les outils électriques mis

à la terre (à la masse). Des fi ches non modifi ées

et des prises d’alimentation assorties réduisent le

risque de choc électrique.

• Éviter tout contact corporel avec des surfaces

reliées à la masse ou à la terre telles que tuyaux, radiateurs, cuisinières et réfrigérateurs.

Un risque de choc électrique plus élevé existe si

le corps est relié à la masse ou à la terre.

• Ne pas exposer les outils électriques à la pluie ou

à l’humidité. Le risque de choc électrique augmente

si de l’eau s’infi ltre dans un outil électrique.

• Prendre soin du cordon. Ne jamais utiliser le

cordon pour transporter, tirer ou débrancher

l’outil électrique. Tenir le cordon à l’écart de la

chaleur, des huiles, des arêtes coupantes ou

des pièces en mouvement. Un cordon endom-

magé ou emmêlé présente un risque accru de

choc électrique.

• Se procurer un cordon d’alimentation appro-

prié en cas d’utilisation d’un outil électrique à

l’extérieur. L’utilisation d’un cordon d’alimentation

pour usage extérieur réduit le risque de choc

électrique.

• S’il est nécessaire d’utiliser l’outil électrique

dans un endroit humide, installer un appareil

à courant résiduel (RCD). L’utilisation d’un RCD

réduit le risque de décharge électrique.

10

SÉCURITÉ INDIVIDUELLE

• Être sur ses gardes, être attentif et faire preuve

de bon sens en utilisant un outil électrique. Ne

pas utiliser un outil électrique en cas de fatigue

ou sous l’infl uence de drogues, d’alcool ou

de médicaments. Un instant d’inattention lors

de l’utilisation d’un outil électrique peut entraîner

des blessures graves.

• Porter l’équipement de protection requis.

Toujours porter une protection oculaire.

Selon les conditions, porter aussi un masque antipoussières, des bottes de sécurité antidérapantes,

un casque protecteur ou une protection auditive

afi n de réduire les blessures.

• Empêcher les démarrages accidentels.

S’assurer que la gâchette est en position

d’arrêt avant de brancher l’outil à une source

de courant, d’insérer la batterie, de le ramasser

ou de le transporter. Le fait de transporter

l’outil en gardant le doigt sur la gâchette ou de le

brancher lorsque la gâchette est en position de

marche favorise les accidents.

• Retirer toute clé de réglage avant de mettre

l’outil sous tension. Une clé laissée attachée sur

une pièce mobile de l’outil électrique peut entraîner

des blessures.

• Ne pas travailler à bout de bras. Bien garder

un bon équilibre à tout instant. Ceci permet de

mieux préserver la maîtrise de l’outil électrique

dans des situations imprévues.

• Porter des vêtements adéquats. Ne pas porter

de vêtements amples ni de bijoux. Ne pas approcher les cheveux, vêtements et gants des

pièces en mouvement. Les vêtements amples,

les bijoux ou les cheveux longs risquent d’être

happés par les pièces en mouvement.

• Si des dispositifs sont prévus pour l’extraction

et la récupération des poussières, vérifier

qu’ils sont connectés et utilisés correctement.

L’utilisation de ces dispositifs peut réduire les

risques liés aux poussières.

UTILISATION ET ENTRETIEN

DE L’OUTIL ÉLECTRIQUE

• Ne pas forcer l’outil électrique. Utiliser l’outil

électrique approprié à l’application considérée.

L’outil électrique adapté au projet considéré produira de meilleurs résultats, dans des conditions de

sécurité meilleures, à la vitesse pour laquelle il a

été conçu.

• Ne pas utiliser l’outil électrique si le com-

mutateur ne le met pas sous ou hors tension.

Tout outil électrique dont le commutateur de

marche-arrêt est inopérant est dangereux et doit

être réparé.

• Débrancher la fi che de la prise d’alimentation

et/ou la batterie de l’outil électrique avant

d’effectuer des réglages, de changer

d’accessoires ou de ranger l’outil. De telles

mesures de sécurité préventive réduisent le risque

de mettre l’outil en marche accidentellement.

• Ranger les outils électriques inutilisés hors

de la portée des enfants et ne pas laisser des

personnes qui connaissent mal les outils électriques ou ces instructions utiliser ces outils.

Les outils électriques sont dangereux dans les

mains d’utilisateurs non formés à leur usage.

• Entretien des outils électriques. S’assurer de

l’absence de tout désalignement ou de grippage des pièces mobiles, de toute rupture de

pièce ou de toute autre condition qui pourrait affecter le bon fonctionnement de l’outil

électrique. En cas de dommages, faire réparer

l’outil avant de l’utiliser de nouveau. Les outils

électriques mal entretenus sont à la source de

nombreux accidents.

• Garder les outils de coupe affûtés et propres.

Les outils de coupe correctement entretenus et

bien affûtés risquent moins de se gripper et sont

plus faciles à manier.

• Utiliser l’outil électrique, les accessoires, les

grains etc. conformément à ces instructions

en tenant compte des conditions de travail

et de la tâche à effectuer. L’utilisation de cet

outil électrique pour effectuer une opération pour

laquelle il n’est pas conçu peut occasionner une

situation dangereuse.

ENTRETIEN

• Faire effectuer l’entretien de l’outil électrique

par un technicien qualifi é qui n’utilisera que

des pièces de rechange identiques. La sécurité

d’utilisation de l’outil en sera préservée.

RÈGLES DE SÉCURITÉ

SPÉCIFIQUES

Règles de sécurité générales pour le polissage :

• Cet outil électrique est conçu pour servir de

polissage. Lire tous les avertissements et

toutes les instructions, les illustrations et les

caractéristiques fournis avec cet outil électrique. Ne pas suivre l’ensemble des instructions

décrites ci-dessous peut entraîner une électrocution, un incendie ou des blessures graves.

• Il n’est pas recommandé d’utiliser cet outil

électrique pour servir de meuleuse, de ponceuse, de brosse métallique ou d’outil de

coupe. Le fait d’utiliser l’outil pour effectuer des

tâches pour lesquelles il n’est pas conçu peut

présenter un risque et entraîner des blessures.

• Ne pas utiliser des accessoires qui ne sont pas

spécialement conçus pour le modèle d’outil ou

qui ne sont pas recommandés par le fabricant.

Le simple fait qu’un accessoire peut s’ajuster sur

l’outil électrique ne signifi e pas qu’il peut être utilisé

en toute sécurité.

• La vitesse nominale de l’accessoire doit au

moins être égale à la vitesse maximale indiquée sur l’outil électrique. Les accessoires qui

sont utilisés à une vitesse supérieure à leur vitesse

nominale peuvent se briser et se détacher.

• Le diamètre extérieur et l’épaisseur de

l’accessoire doivent être conformes à la capacité de l’outil électrique. Il est impossible de

protéger ou de contrôler adéquatement un accessoire de dimension inappropriée.

• La taille de l’arbre des meules, des brides, des

plateaux porte-disque ou de tout autre accessoire doit convenir parfaitement à la broche

de l’outil électrique. Si les accessoires utilisés

sont dotés d’alésages centraux qui ne conviennent pas à la pièce de montage de l’outil, ils se

déstabiliseront, vibreront de façon excessive et

pourront causer une perte de contrôle.

• Ne pas utiliser un accessoire endommagé.

Inspecter l’accessoire avant chaque utilisation

afi n de s’assurer que les meules, par exemple,

sont exemptes d’ébréchures et de fi ssures, que

le plateau porte-disque est exempt de fi ssures

et qu’il n’est pas usé de façon excessive, et que

la brosse métallique ne comprend pas de fi ls

détachés ou craquelés. Si l’outil électrique ou

l’accessoire est échappé, s’assurer qu’il n’est

pas endommagé ou installer un autre accessoire. Après avoir effectué cette opération, se

tenir à distance de l’accessoire en rotation

et faire fonctionner l’outil à sa vitesse à vide

maximale pendant une minute. S’assurer que

personne ne se tient à proximité de l’outil. Les

accessoires endommagés se brisent généralement lors de cette vérifi cation.

• Porter de l’équipement de protection de qualité

professionnelle. Selon le type d’opération, porter un masque de protection ou des lunettes

de sécurité. Au besoin, porter également

un masque anti-poussières, un protecteur

d’oreille, des gants et un tablier d’atelier résistant aux petits fragments abrasifs ou aux

fragments provenant des pièces à travailler.

La protection oculaire utilisée doit résister aux

débris projetés lors des différentes opérations.

Le masque anti-poussières et le masque fi ltrant

doivent filtrer les particules produites lors de

l’opération. Une exposition prolongée à un bruit

fort peut entraîner une perte auditive.

• S’assurer que personne ne se tient à proximité

du lieu de travail. Toute personne qui entre

sur le lieu de travail doit porter l’équipement

de protection requis. Des fragments provenant

de la pièce à travailler ou d’un accessoire brisé

peuvent être projetés et causer des blessures,

11

Page 7

même à des personnes se tenant à une certaine

distance du lieu de travail immédiat.

• Tenir l’outil par ses surfaces de préhension

isolées lors des opérations pendant lesquelles

l’accessoire de coupe peut entrer en contact

avec du câblage caché ou avec son propre cordon d’alimentation. Le contact avec un fi l sous

tension « électrifi e » les pièces métalliques expo-

sées de l’outil et peut électrocuter l’utilisateur.

• Tenir le cordon loin de l’accessoire en rotation. En cas de perte de contrôle, le cordon peut

être coupé ou accroché, et la main ou le bras

de l’utilisateur risquent d’entrer en contact avec

l’accessoire en rotation.

• Ne jamais déposer l’outil électrique avant

l’arrêt complet de l’accessoire. L’accessoire en

rotation peut accrocher la surface et occasionner

une perte de contrôle.

• Ne jamais laisser l’outil électrique fonctionner

en le transportant à ses côtés. L’accessoire en

rotation peut s’accrocher accidentellement aux

vêtements et entrer en contact avec l’utilisateur.

• Nettoyer régulièrement les évents d’aération

de l’outil électrique. Le ventilateur du moteur

aspire la poussière dans le logement et crée une

accumulation excessive de métal fritté, ce qui peut

causer un risque électrique.

• Ne pas faire fonctionner l’outil électrique à

proximité de matériaux inflammables. Les

étincelles peuvent enfl ammer ces matériaux.

• Ne pas utiliser d’accessoires qui nécessitent

des liquide de refroidissement. L’utilisation

d’eau ou d’un autre liquide de refroidissement

peut entraîner une électrocution ou un choc électrique.

REBONDS ET AVERTISSE-MENTS CONNEXES

Un rebond est une réaction soudaine attribuable

au pincement ou à l’accrochage de la meule, du

plateau porte-disque, de la brosse ou de tout

autre accessoire en rotation. Un pincement ou

un accrochage provoque le blocage immédiat de

l’accessoire en rotation qui, à son tour, entraîne

l’outil incontrôlé dans le sens opposé à la rotation

de l’accessoire, à l’endroit du coincement.

Par exemple, si une meule abrasive est accrochée

ou pincée par la pièce à travailler, le rebord de la

meule qui entre dans le point de pincement peut

s’enfoncer dans la surface du matériau, éjectant la

meule de la pièce à travailler ou la faisant rebondir,

vers l’utilisateur ou loin de lui, selon le sens du mouvement de la meule au point de pincement. Dans

ces conditions d’utilisation, les meules abrasives

peuvent également se briser.

Un rebond est attribuable à une mauvaise utilisation

de l’outil ou au non-respect des procédures ou des

conditions d’utilisation. Pour empêcher les rebonds,

respecter les directives décrites ci dessous.

• Tenir fermement l’outil électrique et placer

le corps et les mains de manière à pouvoir

résister aux rebonds. Toujours utiliser la

poignée auxiliaire, s’il y en a une, pour assurer un contrôle optimal en cas de rebond

ou de réaction de couple lors du démarrage de

l’outil. L’utilisateur peut contrôler les rebonds et

les réactions de couple s’il respecte les directives

prescrites.

• Ne jamais placer les mains à proximité de

l’accessoire en rotation. En cas de rebond,

l’accessoire peut dévier sur celles ci.

• Ne pas positionner le corps à l’endroit où

sera entraîné l’outil électrique si un rebond se

produit. Un rebond entraînera l’outil dans le sens

opposé au mouvement de la meule, à l’endroit de

l’accrochage.

• Faire preuve d’une extrême prudence au moment d’utiliser l’outil sur des coins ou des

rebords tranchants. Les coins, les rebords

tranchants et les surfaces rebondissantes ont

tendance à s’accrocher à la pièce en rotation et à

causer une perte de contrôle ou des rebonds.

• Ne pas fi xer une lame de sculpteur pour scie à

chaîne ou une lame de scie dentée. Ces deux

types de lame occasionnent de nombreux rebonds

et des pertes de contrôle fréquentes.

Règles de sécurité particulières pour Polissage :

• Ne permettre à aucune partie desserrée de la

coiffe à polir ou de ses fi laments de tourner

librement. Mettre à l’écart ou couper tous les

fi laments libres. Les fi laments libres et en rotation

peuvent enchevêtrer les doigts ou s’accrocher à

la pièce à travailler.

Règles de sécurité supplémentaires

• Maintenir en l’état les étiquettes et les plaques

d’identifi cation. Des informations importantes y

fi gurent. Si elles sont illisibles ou manquantes,

contacter un centre de services et d’entretien

MILWAUKEE pour un remplacement gratuit.

• AVERTISSEMENT : Certaines poussières générées par les activités de ponçage, de coupe,

de rectifi cation, de perçage et d’autres activités de

construction contiennent des substances considérées être la cause de malformations congénitales

et de troubles de l’appareil reproducteur. Parmi ces

substances fi gurent:

• le plomb contenu dans les peintures à base de

plomb;

• la silice cristalline des briques, du ciment et

d’autres matériaux de maçonnerie, ainsi que

• l’arsenic et le chrome des sciages traités chimiquement.

Les risques encourus par l’opérateur envers ces

expositions varient en fonction de la fréquence

de ce type de travail. Pour réduire l’exposition

à ces substances chimiques, l’opérateur doit:

travailler dans une zone bien ventilée et porter

l’équipement de sécurité approprié, tel qu’un

masque anti-poussière spécialement conçu pour

fi ltrer les particules microscopiques.

12

MISE A LA TERRE

A VERTISSEMENT Si le fi l de mise à

la terre est incorrectement raccordé, il peut

en résulter des risques de choc électrique.

Si vous n’êtes pas certain que la prise dont

vous vous servez est correctement mise à

la terre, faites-la vérifi er par un électricien.

N’altérez pas la fi che du cordon de l’outil.

N’enlevez pas de la fi che, la dent qui sert à

la mise à la terre. N’employez pas l’outil si

le cordon ou la fi che sont en mauvais état.

Si tel est le cas, faites-les réparer dans un

centre-service MILWAUKEE accrédité avant

de vous en servir. Si la fi che du cordon ne

s’adapte pas à la prise, faites remplacer la

prise par un électricien.

Outils mis à la terre : Outils pourvus d’une fi che

de cordon à trois dents

Les outils marqués « Mise à la terre requise »

sont pourvus d’un cordon à trois fi ls dont la fi che a

trois dents. La fi che du cordon doit être branchée

sur une prise correctement mise à la terre (voir

Figure A). De cette façon, si une défectuosité dans

le circuit électrique de l’outil survient, le relais à la

terre fournira un conducteur à faible résistance pour

décharger le courant et protéger l’utilisateur contre

les risques de choc électrique.

CORDONS DE RALLONGE

Si l’emploi d’un cordon de rallonge est nécessaire,

un cordon à trois fi ls doit être employé pour les

outils mis à la terre. Pour les outils à double isolation, on peut employer indifféremment un cordon

de rallonge à deux ou trois fi ls. Plus la longueur

du cordron entre l’outil et la prise de courant est

grande, plus le calibre du cordon doit être élevé.

L’utilisation d’un cordon de rallonge incorrectement

calibré entraîne une chute de voltage résultant en

une perte de puissance qui risque de détériorer

l’outil. Reportez-vous au tableau ci-contre pour

déterminer le calibre minimum du cordon.

Moins le calibre du fi l est élevé, plus sa conductivité

est bonne. Par exemple, un cordon de calibre 14 a

une meilleure conductivité qu’un cordon de calibre

16. Lorsque vous utilisez plus d’une rallonge pour

couvrir la distance, assurez-vous que chaque cordon possède le calibre minimum requis. Si vous

utilisez un seul cordon pour brancher plusieurs

outils, additionnez le chiffre d’intensité (ampères)

inscrit sur la fi che signalétique de chaque outil pour

obtenir le calibre minimal requis pour le cordon.

LISEZ ATTENTIVEMENT CES INSTRUCTIONS ET

CONSERVEZ-LES POUR LES CONSULTER AU BESOIN.

La dent de mise à la terre de la fi che est reliée au

système de mise à la terre de l’outil via le fi l vert

du cordon. Le fi l vert du cordon doit être le seul fi l

raccordé à un bout au système de mise à la terre

de l’outil et son autre extrémité ne doit jamais être

raccordée à une borne sous tension électrique.

Votre outil doit être branché sur une prise appropriée, correctement installée et mise à la

terre conformément aux codes et ordonnances en vigueur. La fi che du

cordon et la prise de courant

doivent être semblables à celles

de la Figure A.

Fig. A

Outils à double isolation : Outils pourvus d’une

fi che de cordon à deux dents

Les outils marqués « Double Isolation » n’ont pas

besoin d’être raccordés à la terre. Ils sont pourvus

d’une double isolation conforme eux exigences de

l’OSHA et satisfont aux normes de l’Underwriters

Laboratories, Inc., de l’Association canadienne de

normalisation (ACNOR) et du « National Electrical Code » (code national de

l’électricité). Les outils à double

isolation peuvent être branchés

sur n’importe laquelle des prises

à 120 volt illustrées ci-contre

Figure B et C.

Fig. B

Fig. C

Directives pour l’emploi des cordons de rallonge

• Si vous utilisez une rallonge à l’extérieur, assurez-

vous qu’elle est marquée des sigles « W-A »

(« W » au Canada) indiquant qu’elle est adéquate

pour usage extérieur.

• Assurez-vous que le cordon de rallonge est

correctement câblé et en bonne condition. Remplacez tout cordon derallonge détérioré ou faitesle remettre en état par une personne compétente

avant de vous en servir.

• Tenez votre cordon de rallonge à l’écart des objets

ranchants, des sources de grande chaleur et des

endroits humides ou mouillés.

Calibres minimaux recommandés pour

les cordons de rallonge*

Fiche signalétique

Ampères

0 - 5,0

5,1 - 8,0

8,1 - 12,0

12,1 - 15,0

15,1 - 20,0

* Basé sur sur une chute de voltage limite de 5 volts à

150% de l’intensité moyenne de courant.

Longueur du cordon de rallonge (m)

7,6

15,2

16

16

16

16

14

14

12

12

10

10

22,8

16

14

12

10

10

30,4

14

12

10

10

--

45,7

12

10

--

--

--

13

60,9

12

--

--

--

--

Page 8

Description Fonctionnelle

1

2

10

9

8

7

1. Poignée

2. Indicateur de

réglage de vitesse

3. Appui de l'outil

4. Poignée latérale

5. Tampon polisseur

6. Disque d'appui en

caoutchouc

6

7. Bouton de verrouillage

8. Évents

9. Détente

10.Cordon

Pictographie

Double Isolation

Tours-minute á vide (RPM)

Tension CA et CD

Couvant alternatif

Ampères

Underwriters Laboratories, Inc.,

États-unis et Canada

Spécifi cations

Volts

Rotation

à Vide

(T/Min.)

1750

0 - 1 750

0 - 2 800

No de

Cat.

5455

5460

5540

120 ca/cd

120 ca

120 ca

3

Diam./Disque

178/229 mm

(7"/9")

178/229 mm

(7"/9")

178 mm (7")

4

5

Dimen-

sion

Pivot

5/8"-11

5/8"-11

5/8"-11

MONTAGE DE L’OUTIL

AVERTISSEMENT Pour minimiser

les risques de blessures, débranchez

toujours l’outil avant d’y faire des réglages,

d’y attacher ou d’en enlever les accessoires.

L’usage d’accessoires autres que ceux qui

sont spécifi quement recommandés pour cet

outil peut comporter des risques.

Retrait et remplacement du cordon Quik-Lok

Les cordons Quik-Lok® exclusifs à MILWAUKEE

permettent d’installer le cordon ou de le remplacer

sur place en un tournemain.

Fig. 1

1. Pour retirer le cordon Quik-Lok®, tournez l’écrou du

cordon 1/4 de tour vers la gauche et retirez-le.

2. Pour remettre le cordon en place, alignez les

rainures à clavettes du connecteur et poussez

le connecteur aussi loin que possible. Tournez

ensuite l’écrou du cordon 1/4 de tour vers la

droite pour le verrouiller.

Tampons en laine d’agneau

Les tampons polisseurs MILWAUKEE sont offerts

en deux textures différentes. Les tampons à 100%

de laine d’agneau sont excellents pour polir les

couches de fi ni non lustré. Les tampons faits d’un

mélange de laine et polyester sont plus doux et

plus appropriés aux fi nis lustrés.

Fig. 2

14

Écrou de

fi xation

du disque

Trou d'arbre

Tampon

de laine

Disque

d'appui en

caoutchouc

Rondelle

de pivot

Bride

Pivot

Appui de l'outil

1. Pour installer les tampons de laine d’agneau,

débranchez l’outil et renversez-le sur son appui,

le pivot en haut.

2. Assurez-vous que la bride et la rondelle de

caoutchouc sont en place sur le pivot. Glissez

ensuite l’écrou de fi xation du disque d’appui dans

le trou d’arbre du tampon de laine et du disque

d’appui en veillant à ce que les fi bres ne nuisent

pas à sa stabilité sur l’endos du tampon.

®

3. Enfoncez le bouton de verrouillage du pivot (à la

gauche de la boîte d’engrenages) et en même

temps, vissez l’écrou de fi xation et le tampon

de laine ensemble sur le pivot et serrez-les à la

main.

4. Pour retirer le tampon, enfoncez le bouton

de verrouillage du pivot et dévissez l’écrou du

disque d’appui en sens inverse-horaire.

Coiffes en laine/polyester

Fig. 3

Coiffe laine/

polyester

Cordons de

la coiffe

Écrou du disque

Disque d'appui

en caoutchouc

Rondelle de pivot

Bride

Pivot

Appui de l'outil

1. Pour installer la coiffe en laine/polyester, débranchez l’outil et posez-le sur son appui, le

pivot vers le haut.

2. Assurez-vous que la bride et la rondelle de

caoutchouc sont en place sur le pivot et ensuite,

glissez le disque d’appui en caoutchouc sur le

pivot.

3. Enfoncez le bouton de verrouillage du pivot et

vissez l’écrou de fi xation en sens horaire. Serrez-

le en place à la main.

4. Couvrez entièrement le disque d’appui en caoutchouc avec la coiffe à polir. Liez solidement les

cordons de la coiffe et passez-les sous la coiffe

pour éviter qu’ils ne nuisent àvotre travail.

5. Pour retirer la coiffe, déliez les cordons et

enlevez-la. Enfoncez le bouton de verrouillage

du pivot. Dévissez l’écrou de fi xation et le disque

d’appui en caoutchouc en les faisant tourner en

sens inverse-horaire.

Tampons auto-adhérents “Hook and Loop”

Les tampons auto-adhérents “Hook and Loop”

sont offerts en laine/polyester et en mousse. Ils

ne sont pas à conseiller non plus pour l’utilisateur

inexpérimenté.

Le tampon de mousse no de cat. 49-36-1550

est idéal pour les fi nis lustrés et les polis super

fi ns. Il sert à faire disparaître de la surface les

égratignures de moyenne taille, les taches de pollution, la peinture ternie et les marques laissées

par le ponçage à l’eau.

Le tampon de mousse no de cat. 49-36-0650 est

excellent pour glacer les fi nis lustrés, faire disparaî-

tre les traits de polissage, les taches d’eau, les

ternissures superfi cielles et les marques causées

par les brosses des lave-autos.

Un dispositif de centrage, no de cat. 49-67-0130,

accompagne le disque d’appui (no de cat. 49-36-

2150) du tampon “Hook and Loop” afi n d’en assurer

l’alignement sur le tampon polisseur et l’équilibre

de la polisseuse lorsqu’elle est en marche.

Fig. 4

1. Pour installer les tampons “Hook and Loop”,

débranchez l’outil et posez-le sur son appui, le

pivot pointant vers le haut.

2. Assurez-vous que la bride et la rondelle de

caoutchouc sont en place sur le pivot. Glissez

le disque d’appui “Hook and Loop” sur le pivot.

15

Tampon/mousse

“hook and loop”

Dispositif de

centrage

(retirer avant

d’utiliser l’outil)

Disque

d’appui “hook

and loop”

Rondelle

de pivot

Bride

Pivot

Appui de l'outil

Page 9

3. Enfoncez le bouton de verrouillage du pivot et

faites tourner le disque d’appui en sens horaire

et serrez-le fermement à la main.

4. Insérez le dispositif de centrage (qui accompagne le disque d’appui) dans le trou au centre du

tampon “Hook and Loop”. Abaissez le tampon

“hook and Loop” le long du dispositif de centrage

et fi xez-le au disque d’appui “Hook and Loop”.

MANIEMENT

AVERTISSEMENT Pour minimiser

les risques de blessures, débranchez toujours l’outil avant d’y faire des réglages, d’y

attacher ou d’en enlever les accessoires.

L’usage d’accessoires autres que ceux qui

sont spécifi quement recommandés pour cet

outil peut comporter des risques.

Démarrage, arrêt et contrôle de la rotation

No de cat. 5455: Pour mettre l'outil en marche, ap-

puyez sur la détente. Pour l'arrêter, relâchez-la.

Nos de cat. 5540 et 5460 sont pourvus d'un

contrôle de rotation à cadran qui permet de régler

la vitesse maximale de rotation (t/min.) de la polisseuse. La rotation peut être variée par la commande à détente sans jamais excéder la vitesse

maximale réglée sur le cadran. Les positions de

réglage vont de 1 à 5. Les chiffres les plus bas

correspondent aux plus basses vitesses de rotation

tandis que les chiffres les plus hauts correspondent

aux vitesses plus grandes. Généralement, on utilise

les vitesses de rotation plus basses pour polir les

petites surfaces et les plus hautes vitesses pour

les surfaces plus étendues. Choissez le réglage de

rotation le plus approprié à votre tâche.

Pour contrôler la vitesse de rotation, réglez le

cotrôle à cadran à la position désirée. Ensuite, appuyez sur la détente en augmentant ou en diminuant la pression du doigt pour varier la vitesse de

rotation. Pour arrêter l'outil, relâchez la détente.

AVERTISSEMENT Pour minimiser

les riques de blessures, écartez le cordon

du trajet de la polisseuse. Autrement, le

cordon pourra être happé par le tampon. En

s'enroulant autour du pivot, l'isolation du

cordon pourra se briser et les fi ls électriques

se dénuder, exposant la boîte d'engrenages à

la tension électrique.

Ensuite, retirez le dispositif de centrage.

5. Pour retirer le tampon polisseur, décapez-le.

Enfoncez le bouton de verrouillage du pivot et

dévissez le disque d’appui en le faisant tourner

en sens inverse-horaire.

N.B. Pour un maniement ferme et sécuritaire de

l’outil, utilisez la poignée latérale.

Polissage

Utilisez toujours la poignée latérale pour maîtriser

correctement l’outil. Déplacez la polisseuse en

larges mouvements de va-et-vient. Une pression

trop grande, un mauvais angle ou des mouvements désordonnés pourront laisser des marques

de polissage.

Consultez les instructions détaillées qui accompagnent les produits de cirage, fi nition et polissage

que vous employez.

Prévention des brûlures de la surface peinte

Les surfaces peintes sont sensibles aux brûlures de

polissage. Cela peut se produire si vous polissez

à une trop grande vitesse ou si vous maintenez le

tampon polisseur au même endroit trop longtemps.

Pour éviter de brûler la peinture, n’appuyez pas

trop sur la polisseuse et déplacez-la constamment,

surtout lorsque vous polissez les contours d’un

objet ou d’une surface.

Soyez particulièrement prudent lorsque vous utilisez la polisseuse no de cat. 5540 dont la vitesse de

rotation très élevée peut occasionner des brûlures

de surfaces peintes.

AVERTISSEMENT Pour minimiser

les risques de blessures, suivez les instructions relatives à la prévention du grippage.

Lorsqu'il survient, le grippage peut provoquer

un brusque mouvement de recul pouvant

entraîner la perte de contrôle de l'outil par

l'utilisatueur. Employez toujours la poignée

latérale afi n d'assurer une meilleure maîtrise

de l'outil.

Prévention du grippage

Le grippage peut survenir si le tampon de la polisseuse se prend dans les aspérités de la surface.

Lorsque cela arrive, il peut se produire un brusque

mouvement de recul de l’outil pouvant causer

une brûlure du fi ni. Pour minimiser les risques de

grippage, maniez la polisseuse à basse vitesse

lorsque vous êtes en présence d’une surface rugueuse. Pour les endroits diffi ciles d’accès, près

des garnitures, miroirs ou portières de l’auto, par

exemple, ne prenez pas de risques avec la polisseuse, fi nissez-les à la main.

Lorsque vous utilisez la polisseuse no de cat.

5460 et 5540 à commande de vitesse variable,

relâchez légèrement la détente pour diminuer la

vitesse de rotation.

MAINTENANCE

AVERTISSEMENT Pour minimiser

les risques de blessures, débranchez toujours

l’outil avant d’y effectuer des travaux de maintenance. Ne faites pas vous-même le démontage

de l’outil ni le rebobinage du système électrique.

Consultez un centre de service MILWAUKEE

accrédité pour toutes les réparations.

Entretien de l’outil

Gardez l’outil en bon état en adoptant un programme d’entretien ponctuel. Avant de vous en

servir, examinez son état en général. Inspectez-en

la garde, interrupteur, cordon et cordon de rallonge

pour en déceler les défauts. Vérifi ez le serrage des

vis, l’alignement et le jeu des pièces mobiles, les

vices de montage, bris de pièces et toute autre

condition pouvant en rendre le fonctionnement dangereux. Si un bruit ou une vibration insolite survient,

arrêtez immédiatement l’outil et faites-le vérifi er

avant de vous en servir de nouveau. N’utilisez pas

un outil défectueux. Fixez-y une étiquette marquée

« HORS D’USAGE » jusqu’à ce qu’il soit réparé

(voir « Réparations »).

Normalement, il ne sera pas nécessaire de lubrifi er

l’outil avant que le temps ne soit venu de remplacer

les balais. Après une période pouvant aller de 6

mois à un an, selon l’usage, retournez votre outil à

un centre de service MILWAUKEE accrédité pour

obtenir les services suivants:

• Lubrifi cation

• Inspection et remplacement des balais

• Inspection et nettoyage de la mécanique (engrenages, pivots, coussinets, boîtier etc.)

• Inspection électrique (interrupteur, cordon, induit

etc)

• Vérifi cation du fonctionnement électromécanique

Pour éviter le grippage, lorsque vous employez

les polisseuses no de cat. 5455 sans commande

variable à détente, il est préférable d’utiliser la

technique de “marche par inertie”. Cette technique

consiste à faire démarrer le moteur pour quelques

secondes pour ensuite couper le contact et appliquer le tampon polisseur sur la surface alors que

l’outil tourne sur son erre. De cette façon, la rotation

du tampon est moins rapide que lorsqu’il est mû

par le moteur. Cette technique est recommandée

pour les endroits de la surface qui présentent des

fi ssures ou des cloques.

A VERTISSEMENT Pour minimiser

les risques de blessures, choc électrique

et dommage à l’outil, n’immergez jamais l’outil

et ne laissez pas de liquide s’y infi ltrer.

Nettoyage

Débarrassez les évents des débris et de la

poussière. Gardez les poignées de l’outil propres, à

sec et exemptes d’huile ou de graisse. Le nettoyage

de l’outil doit se faire avec un linge humide et un

savon doux. Certains nettoyants tels l’essence, la

térébenthine, les diluants à laque ou à peinture, les

solvants chlorés, l’ammoniaque et les détergents

d’usage domestique qui en contiennent pourraient

détériorer le plastique et l’isolation des pièces. Ne

laissez jamais de solvants infl ammables ou com-

bustibles auprès des outils.

Réparations

Si votre outil est endommagé, retourne l'outil entier

au centre de maintenance le plus proche.

ACCESOIRES

A VERTISSEMENT Débranchez tou-

jours l’outil avant de changer ou d’enlever

les accessoires. L’utilisation d’autres accessoires que ceux qui sont spécifi quement

recommandés pour cet outil peut comporter

des risques.

Pour une liste complète des accessoires, prière de

se reporter au catalogue MILWAUKEE Electric Tool

ou visiter le site internet www.milwaukeetool.com.

Pour obtenir un catalogue, il suffi t de contacter votre

distributeur local ou l'un des centres-service.

16

17

Page 10

Chaque outil électrique MILW AUKEE (y compris les produits sans fi l [outils, batteries, chargeurs de batterie, et les lampes de travail-lampes de poche

sans fi l]) est garanti à l’acheteur d’origine être exempt de vice du matériau et de fabrication. Sous réserve de certaines exceptions, MILWAUKEE

réparera ou remplacera toute pièce d’un outil électrique qui, après examen par MILW AUKEE, s’est avérée être affectée d’un vice du matériau ou de

fabrication pendant une période de cinq (5) ans* après la date d’achat. Retourner l’outil électrique, accompagné d’une copie de la preuve d’achat, à un

centre de réparations en usine MILW AUKEE ou à un poste d’entretien agréé MILWAUKEE, en port prépayé et assuré. Cette garantie ne couvre pas les

dommages que MILW AUKEEdétermine être causés par des réparations ou des tentatives de réparation par quiconque autre que le personnel agréé par

MILWAUKEE, des utilisations incorrectes, des altérations, des utilisations abusives, une usure normale, une carence d’entretien ou les accidents.

*Toutes les batteries MILWAUKEE V™ (V18™ & V28™) au LITHIUM-ION et M18 XC au LITHIUM-ION sont garanties pendant cinq (5) ans ou

pour 2 000 charges, selon la première échéance. La garantie couvre les 1 000 premières charges ou les deux premières années de la garantie,

selon la première échéance. Cela signifi e que pour les 1 000 premières charges, ou pendant les deux premières années de la garantie à partir

de la date d’achat ou de la première charge, une batterie de rechange sera remise tout à fait gratuitement à l’utilisateur si la batterie d’origine

est défectueuse. Par la suite, la garantie couvrira les charges restantes, jusqu’à concurrence de 2 000, ou les années restantes de la période

de garantie de cinq (5) ans à partir de la date d’achat, selon la première échéance, et ce, au pro rata. Cela signifi e que chaque consommateur

bénéfi cie de 1 000 charges supplémentaires ou d’une garantie supplémentaire de proportionnalité de trois (3) ans sur les batteries avec technologie

V™ au LITHIUM-ION et M18 XC au LITHIUM-ION, selon la durée de l’utilisation.

*La période de la garantie applicable à TOUTES les batteries autres au LITHIUM-ION est d’une durée de deux (2) ans à partir de la date d’achat.

* La période de garantie applicable pour le laser à deux faisceaux M12 et le port d’alimentation M12, les batteries au nickel-cadmium, les radios

de chantier et les chariots de travail industriels Trade Titan™ est d’une durée d’un (1) an à partir de la date d’achat.

L’enregistrement de la garantie n’est pas nécessaire pour bénéfi cier de la garantie en vigueur sur un produit MILWAUKEE. La date de fabrication du

produit servira à établir la période de garantie si aucune preuve d’achat n’est fournie lorsqu’une demande de service sous garantie est faite.

L’ACCEPT A TION DES RECOURS EXCLUSIFS DE RÉPARA TION ET DE REMPLACEMENT DÉCRITS AUX PRÉSENTES EST UNE CONDITION

DU CONTRAT D’ACHA T DE TOUT PRODUIT MILWAUKEE. SI VOUS N’ACCEPTEZ PAS CETTE CONDITION, VOUS NE DEVEZ PAS ACHETER

LE PRODUIT. EN AUCUN CAS MILWAUKEE NE SAURAIT ÊTRE RESPONSABLE DE TOUT DOMMAGE ACCESSOIRE, SPÉCIAL OU INDIRECT ,

DE DOMMAGES-INTÉRÊTS PUNITIFS OU DE TOUTE DÉPENSE, D’HONORAIRES D’AVOCATS, DE FRAIS, DE PERTE OU DE DÉLAIS

ACCESSOIRES À TOUT DOMMAGE, DÉFAILLANCE OU DÉFAUT DE TOUT PRODUIT, Y COMPRIS NOTAMMENT LES PERTES DE PROFIT .

CERTAINS ÉT A TS ET PROVINCES NE PERMETT ANT P AS L ’EXCLUSION OU LA LIMIT A TION DES DOMMAGES DIRECTS OU INDIRECTS, LES

RESTRICTIONS CI-DESSUS PEUVENT NE PAS ÊTRE APPLICABLES. CETTE GARANTIE EST EXCLUSIVE ET REMPLACE TOUTE AUTRE

GARANTIE EXPRESSE, QU’ELLE SOIT VERBALE OU ÉCRITE. DANS LA MESURE PERMISE P AR LA LOI, MILWAUKEE RENONCE À TOUTE

GARANTIE IMPLICITE Y COMPRIS, SANS S’Y LIMITER, TOUTE GARANTIE IMPLICITE DE QUALITÉ MARCHANDE OU D’ADAPT A TION À UNE

UTILISATION OU À UNE FIN P ARTICULIÈRE. DANS LA MESURE OÙ UNE TELLE STIPULATION D’EXONÉRATION N’EST P AS PERMISE P AR

LA LOI, LA DURÉE DE CES GARANTIES IMPLICITES EST LIMITÉE À LA PÉRIODE APPLICABLE DE LA GARANTIE EXPRESSE, TEL QUE CELA

EST DÉCRIT PRÉCÉDEMMENT. CERTAINS ÉTATS ET PROVINCES NE PERMETTANT PAS DE LIMITATION DE DURÉE DES GARANTIES

IMPLICITES, LES RESTRICTIONS CI DESSUS PEUVENT NE PAS ÊTRE APPLICABLES. LA PRÉSENTE CONFÈRE À L’UTILISATEUR DES

DROITS LÉGAUX PARTICULIERS; IL BÉNÉFICIE ÉGALEMENT D’AUTRES DROITS QUI VARIENT D’UN ÉTAT À L’AUTRE.