Milwaukee 5366-1, 5368-1, 5368-6 Operating Instructions Manual

Installing Bits (Fig 1.)

This tool is designed with a universal drive system that

accepts SDS, SDS Plus and Hilti-TE-C style bits. Always

clean and lubricate the shank of the bit before installing it

into your tool to help prevent heat build-up and to protect the

bit shank from wear due to abrasive concrete dust.

1. To install a bit, pull

the chuck collar back

toward the tool.

2. Line up the recesses on

the shank of the bit with

the marks on the chuck

collar as shown. Then,

insert the bit into the

spindle as far as possible.

3. Release the chuck collar, locking the bit into

position. Rotate the bit

slightly to be sure it is

locked securely.

4. To remove the bit, pull

the chuck collar back

toward the tool and

remove the bit.

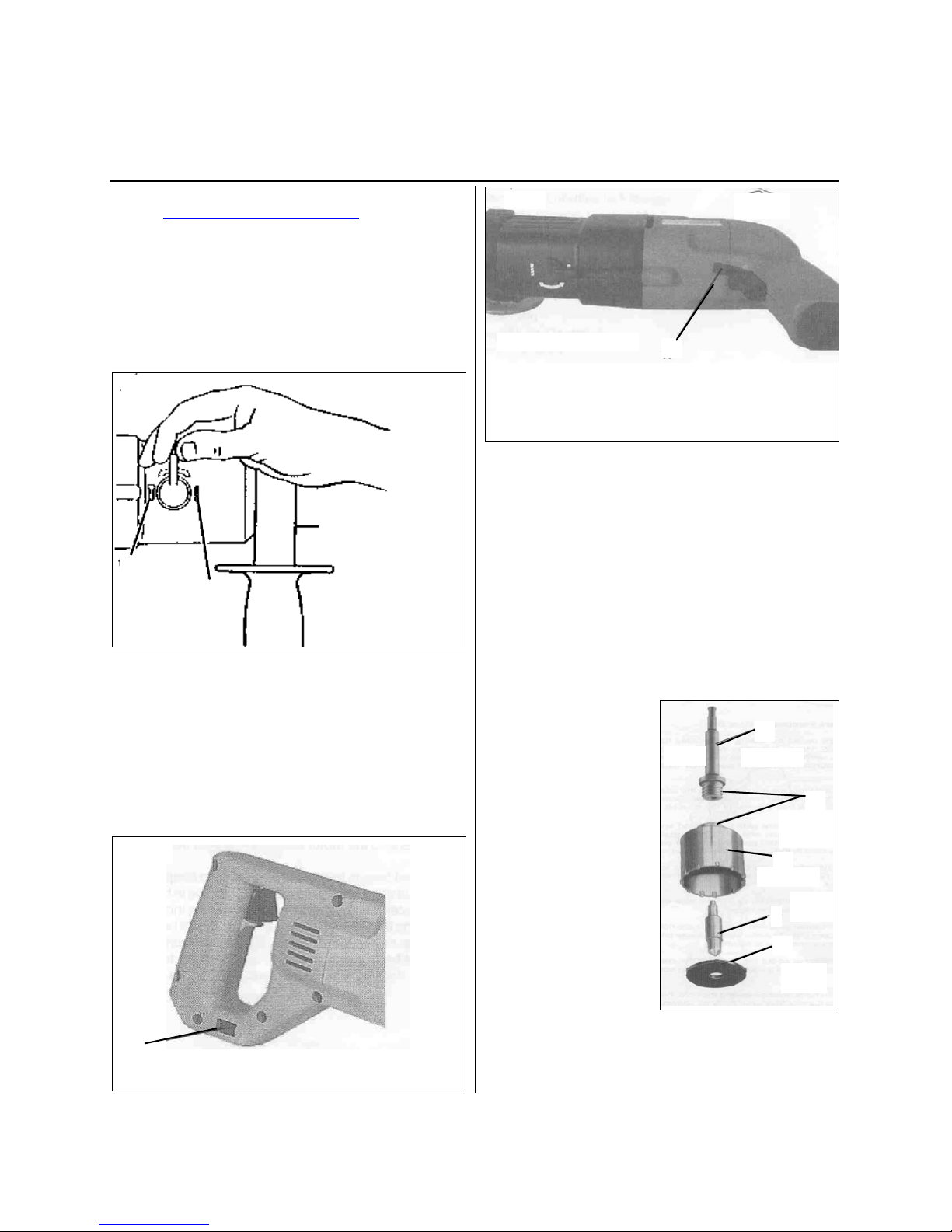

Installing the Side Handle and the Depth Gauge

The tool is shipped with the side handle and depth rod packaged separately.

1.To install the handle assembly, pry open the black handle

ring (wedging the head of a large screwdriver in the handle

ring gap may be helpful) and slip it over the nose of the gear

case, making sure that the molded keys on the inside diameter of the handle ring engage the groove on the gear case.

2. Pass the bolt through the hole in the handle ring and screw

on the red side handle.

3. The depth rod passes through the auxiliary hole in the

handle ring and is clamped in place when the side handle is

tightened. To loosen the rod, partially unscrew the handle as

indicated above.

4. The drilling depth is the distance between the portion of

the bit where the flutes end and the tip of the depth rod (Fig

2.) Slide the depth rod backward or forward until it is set for

the desired depth. Then tighten the side handle securely.

Selecting Drill or Rotary Hammer Action (Fig 3.)

MILWAUKEE 3/4” Rotary Hammers have two settings: rotation only or rotary hammering.

1. To select rotation only, rotate the shift knob 180° in the

direction of the double arrow so that the tab portion of the

knob points toward the “Drill” symbol. Do not shift the tool

when it is running or coasting to a stop.

Milwaukee Tool

Heavy-Duty Falcon Rotary Hammers

Model Numbers: 5366-1, 5368-1, 5368-6 (kit)

Operating Instructions

Page 1

RenTrain INC

RenTrain INC

To reduce the risk of injury, always unplug tool

before attaching or removing accessories. Use

only specifically recommended accessories.

Others may be hazardous.

WARNING!

ASSEMBLY

OPERATION

Fig. 1

Fig. 2

1.

1.

2.

2.

3.

1. Line up the recesses on the

shank...

2. With the marks on the

chuck collar

1. Drilling Depth

2. Tip of Depth Rod

3. Flutes end here

When drilling in wood or steel, shift knob to Rotation Only

and use chuck adapter kit shown on page 3

.

2. To select rotary hammering, rotate the shift knob 180° in

the direction of the double arrow so that the tab portion of the

knob points toward the “Hammer” symbol.

NOTE: To engage the hammering mechanism, maintain

pressure on the bit. When pressure on the bit is released, the

hammering action will stop.

Using the Forward/Reverse Switch (Fig. 4 & Fig. 5)

1. For forward (clockwise) rotation, hold the tool with the

nose pointing away from you and push the forward/reverse

switch to the left. For the pistol grip hammer, hold the tool

with the nose pointing away from you and push the

forward/reverse switch to the left.

2. For reverse (counterclockwise) rotation, hold the tool with

the nose pointing away from you and push the

forward/reverse switch to the right. To prevent damage to the

gears and motor, allow the tool to coast to a full stop before

reversing. For the pistol grip hammer, hold the tool with the

nose pointing away from you and push the forward/reverse

switch to the right. To prevent damage to the gears and

motor, allow the tool to coast to a full stop before reversing.

Starting, Stopping & Controlling Speed

1. To start the tool, pull the trigger.

2. To vary driving speed, simply increase or decrease pressure on the trigger. The further the trigger is pulled, the

greater the speed.

3. To stop the tool, release the trigger.

Rotary Hammering (Fig 6.)

Position the tool, grasp the

handles firmly and pull the

trigger. Always use the side

handle. Hold the tool securely and maintain control. Use

only enough pressure to hold

the tool in place and to prevent the tip of the bit from

wandering. This tool has

been designed to achieve top

performance with only moderate pressure. Heavier pressure will not significantly

increase the drilling rate and

it may overload the motor

and cause premature bit

wear.

If the speed begins to drop off when drilling deep holes, pull

the bit partially out of the hole while the tool is running to

help clear dust. Do not use water to settle the dust since it

will clog the bit flutes and tend to make the bit bind in the

Operating Instructions (continued)

Page 2

RenTrain INC

RenTrain INC

Fig. 3

Fig. 4

Fig. 6

1.

Adapter

Clean &

lubricate

threads

2.

3.

4.

5.

1.Rotary Hammer Symbol

2. Drill Symbol

1. Forward/Reverse Switch

2.

1.

1.

Fig. 5

1. Forward/Reverse Switch

Tool is shown in forward

Pistol Grip Tool

1.

Core Bit

Center

Pin

Guide

Plate

Loading...

Loading...