Milwaukee 4935, 4995, 5091, 4991, 5051 User Manual

...

Catalog No.

No de Cat.

Catálogo No.

4931

4935

4991

4995

5051

OPERATOR'S MANUAL

MANUEL DE L'UTILISATEUR

MANUAL DEL OPERARIO

5091

HEAVY-DUTY BENCH GRINDER

ESMERILADORA DE BANCO PARA SERVICIO PESADO

MEULEUSE D’ÉTABLI EXTRA ROBUSTE

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE MANUEL

DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL OPERADOR.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE. Before use, be sure everyone using this tool reads and understands this manual as well

as any labels packaged with or attached to the tool.

WORK AREA

1. KEEP WORK AREA CLEAN AND WELL LIT. Cluttered, dark work

areas invite accidents.

2. AVOID DANGEROUS ENVIRONMENTS. Do not use your power tool

in rain, damp or wet locations or in the presence of explosive atmospheres (gaseous fumes, dust or flammable materials). Remove

materials or debris that may be ignited by sparks.

3. KEEP BYSTANDERS AWAY. Children and bystanders should be kept

at a safe distance from the work area to avoid distracting the operator and contacting the tool or extension cord.

4. PROTECT OTHERS IN THE WORK AREA from debris such as chips

and sparks. Provide barriers or shields as needed.

5. MAKE WORKSHOP CHILD PROOF with padlocks, master switches,

or by removing starter keys.

ELECTRICAL SAFETY

6. GROUNDED TOOLS MUST BE PLUGGED INTO AN OUTLET PROPERLY INSTALLED AND GROUNDED IN ACCORDANCE WITH ALL

CODES AND ORDINANCES. Never remove the grounding prong or

modify the plug in any way. Do not use any adaptor plugs. Check

with a qualified electrician if you are in doubt as to whether the

outlet is properly grounded. If the tool should electrically malfunction

or break down, grounding provides a low resistance path to carry

electricity away from the user.

7. DOUBLE INSULATED TOOLS ARE EQUIPPED WITH A POLARIZED

PLUG (ONE BLADE IS WIDER THAN THE OTHER.) THIS PLUG

WILL FIT IN A POLARIZED OUTLET ONLY ONE WAY. IF THE PLUG

DOES NOT FIT FULLY IN THE OUTLET, REVERSE THE PLUG. IF IT

STILL DOES NOT FIT, CONTACT A QUALIFIED ELECTRICIAN TO

INSTALL A POLARIZED OUTLET. DO NOT CHANGE THE PLUG IN

ANY WAY. Double insulation eliminates the need for the three

wire grounded power cord and grounded power supply system.

8. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with

grounded surfaces such as pipes, radiators, ranges and refrigerators. When making blind or plunge cuts, always check the work

area for hidden wires or pipes. Hold your tool by insulated nonmetal

grasping surfaces. Use a Ground Fault Circuit Interrupter (GFCI) to

reduce shock hazards.

9. DO NOT EXPOSE TO RAIN OR USE IN DAMP

LOCATIONS.

10. DO NOT ABUSE THE CORD. NEVER USE THE CORD TO CARRY

THE TOOLS OR PULL THE PLUG FROM AN OUTLET. KEEP CORD

AWAY FORM HEAT, OIL, SHARP EDGES OR MOVING PARTS. REPLACE DAMAGED CORDS IMMEDIATELY. Damaged cords in-

crease the risk of electric shock.

PERSONAL SAFETY

11. KNOW YOUR POWER TOOL. Read this manual carefully to learn

your power tool’s applications and limitations as well as potential

hazards associated with this type of tool.

12. STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COM-

MON SENSE WHEN OPERATING A POWER TOOL. DO NOT USE

TOOL WHILE TIRED OR UNDER THE INFLUENCE OF DRUGS, ALCOHOL, OR MEDICATION. A moment of inattention while operating

power tools may result in serious personal injury.

13. DRESS PROPERLY. Do not wear loose clothing or jewelry. Wear a

protective hair covering to contain long hair. These may be caught in

moving parts. When working outdoors, wear rubber gloves and

insulated non-skid footwear. Keep hands and gloves away from

moving parts.

14. REDUCE THE RISK OF UNINTENTIONAL STARTING. Be sure your

tool is turned off before plugging it in. Do not use a tool if the power

switch does not turn the tool on and off. Do not carry a plugged-in

tool with your finger on the switch.

15. REMOVE ALL ADJUSTING KEYS AND WRENCHES. Form the habit

of checking that adjusting keys, wrenches, etc. are removed from

the tool before turning it on.

16. DO NOT OVERREACH. MAINTAIN CONTROL. Keep proper footing

and balance at all times. Maintain a firm grip. Use extra care when

using tool on ladders, roofs, scaffolds, etc.

17. USE SAFETY EQUIPMENT. Everyone in the work area should wear

safety goggles or glasses with side shields complying with

current safety standards. Everyday eyeglasses only have impact

resistant lenses. They are not safety glasses. Wear hearing

protection during extended use and a dust mask for dusty operations. Hard hats, face shields, safety shoes, etc. should be used

when specified or necessary. Keep a fire extinguisher nearby.

18. KEEP GUARDS IN PLACE and in working order.

19. NEVER STAND ON TOOL. Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contacted.

20. KEEP HANDS AWAY FROM ALL CUTTING EDGES AND MOVING

PARTS.

TOOL USE AND CARE

21. SECURE WORK. Use a clamp, vise or other practical means to hold

your work securely, freeing both hands to control the tool.

22. DO NOT FORCE TOOL. Your tool will perform best at the rate for

which it was designed. Excessive force only causes operator

fatigue, increased wear and reduced control.

23. USE THE RIGHT TOOL. Do not use a tool or attachment to do a job

for which it is not recommended. For example, do not use a circular

saw to cut tree limbs or logs. Do not alter a tool.

24. UNPLUG TOOL when it is not in use, before changing accessories

or performing recommended maintenance.

25. STORE IDLE TOOLS. When not in use, store your tool in a dry,

secured place. Keep out of reach of children.

26. NEVER LEAVE THE TOOL RUNNING UNATTENDED. Turn power

off. Do not leave the tool until it comes to a complete stop.

27. CHECK FOR DAMAGED PARTS. Inspect guards and other parts

before use. Check for misalignment, binding of moving parts, improper mounting, broken parts and any other conditions that may

affect operation. If abnormal noise or vibration occurs, turn the tool

off immediately and have the problem corrected before further use.

Do not use a damaged tool. Tag damaged tools “DO NOT USE” until

repaired. A guard or other damaged part should be properly repaired or replaced by a

insist on only identical replacement parts.

MILWAUKEE

service facility. For all repairs,

Page 3

28. USE PROPER ACCESSORIES. Consult this manual for recom-

mended accessories. Using improper accessories may be hazardous. Be sure accessories are properly installed and maintained. Do

not defeat a guard or other safety device when installing an accessory or attachment.

29. MAINTAIN TOOLS CAREFULLY. Keep handles dry, clean and free

from oil and grease. Keep cutting edges sharp and clean. Follow

instructions for lubricating and changing accessories. Periodically

inspect tool cords and extension cords for damage. Have damaged

parts repaired or replaced by a

30. MAINTAIN LABELS & NAMEPLATES. These carry important infor-

mation. If unreadable or missing, contact a

facility for a free replacement.

MILWAUKEE

service facility.

MILWAUKEE

service

31. TOOL SERVICE MUST BE PERFORMED ONLY BY QUALIFIED RE-

PAIR PERSONNEL. Service or maintenance performed by unqualified personnel may result in a risk of injury.

32. WHEN SERVICING A TOOL, USE ONLY IDENTICAL REPLACEMENT

PARTS. FOLLOW INSTRUCTIONS IN THE MAINTENANCE SECTION OF THIS MANUAL. Use of unauthorized parts or failure to

follow maintenance instructions may create a risk of shock or injury.

SERVICE

SPECIFIC SAFETY RULES — BENCH GRINDERS

1. Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its

own cord. Contact with a “live” wire will make exposed metal parts of tool “live” and shock the operator.

2. Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a

replacement.

3. ALWAYS USE PROPER GUARDS AND EYE SHIELDS WITH GRINDING, BUFFING AND WIRE WHEELS. Keep guards in place and in working order.

A guard protects the operator from broken wheel fragments.

4. ACCESSORIES MUST BE RATED FOR AT LEAST THE SPEED ON THE TOOL NAMEPLATE. Wheels and other accessories running over rated

speed can fly apart and cause injury.

5. REPLACE CRACKED WHEELS IMMEDIATELY.

6. DO NOT OVER TIGHTEN WHEEL NUT.

7. USE ONLY FLANGES FURNISHED WITH THE GRINDER.

8. ADJUST DISTANCE BETWEEN THE WHEEL AND THE WORK REST TO MAINTAIN 1/8” OR LESS OF SEPERATION AS THE DIAMETER OF THE

WHEEL DECREASES WITH USE.

9. FREQUENTLY CLEAN GRINDING DUST FROM BENEATH THE GRINDER.

10. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such as those dust masks that are specifically designed to filter out

microscopic particles.

MILWAUKEE

service facility for a free

Page 4

SYMBOLOGY

Canadian Standards Association

Underwriters Laboratories, Inc.

Catalog

Number

4931*

Volts AC

ONLY

115

SPECIFICATIONS

Phase

Amps

3.8

1

Speed

RPM

3450

Wheel

Size

6"

Hole

Dia.

1/2"

Space

Between

Wheels

12-1/2"

NEMA

Rated

H.P.

1/3

4935**

4991*

4995**

5051*

5091*

NOTE: H.P. is NEMA rated

* With Illuminated Eye Shields

** With Plexiglass Eye Shields

115

115

115

115

115/230

3.8

4.0

4.0

4.4

8.5/4.2

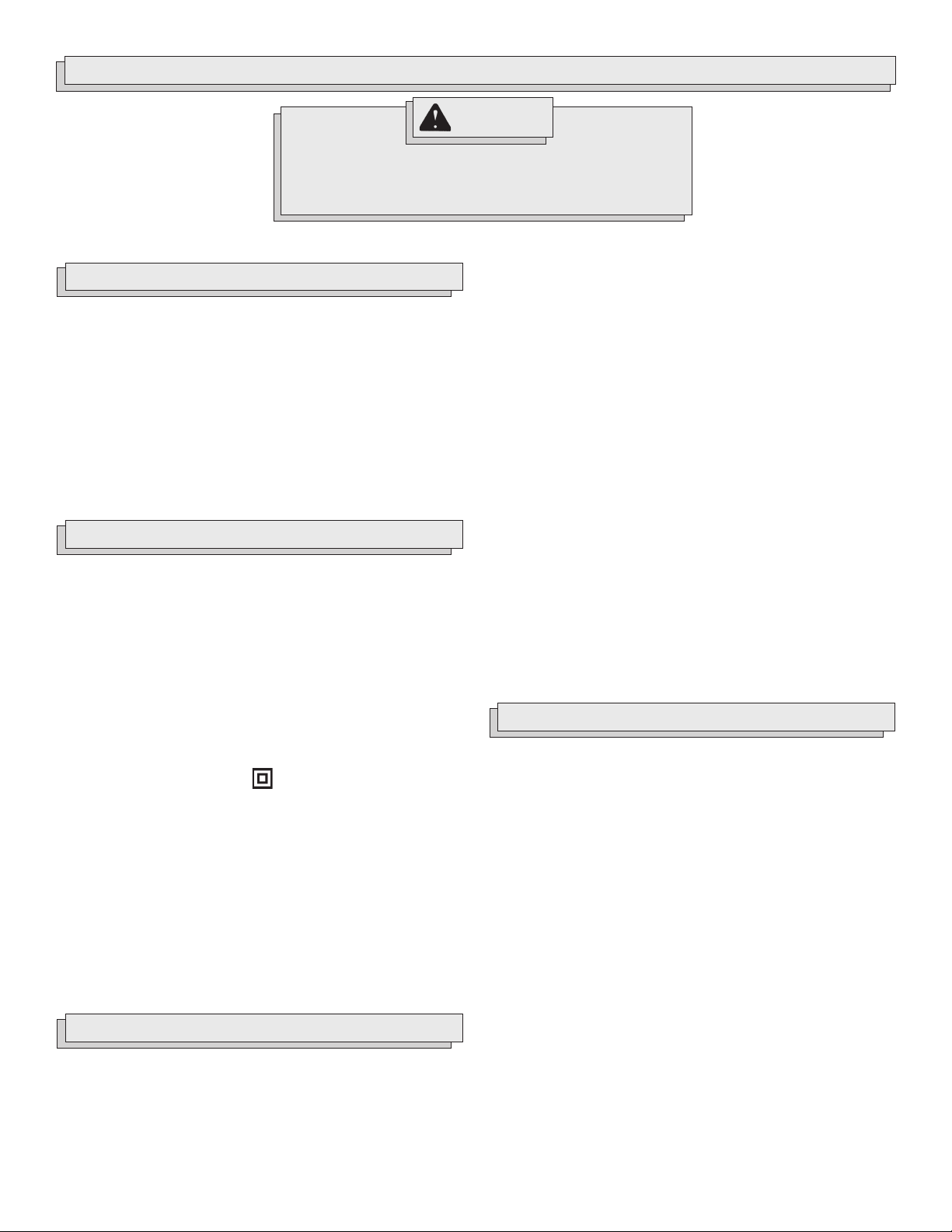

FUNCTIONAL DESCRIPTION

1

3450

1

3450

1

3450

1

3450

1

1725

1

3

2

6"

7"

7"

8"

10"

1/2"

5/8"

5/8"

3/4"

3/4"

12-1/2"

15-1/8"

15-1/8"

15-5/8"

17-3/8"

4

1/2

3/4

1

1. Spark guard

2. Grinding wheel

3. Eye shield clamp

4. Eye shield

5. Cooling tray

6. On/Off switch

7. Nameplate/Warning label

8. Tool rest

9. Wheel guard end cover

9

5

8

7

6

Page 5

GROUNDING

EXTENSION CORDS

Improperly connecting the grounding wire can

result in the risk of electric shock. Check with a

qualified electrician if you are in doubt as to

whether the outlet is properly grounded. Do not

modify the plug provided with the tool. Never

remove the grounding prong from the plug. Do

not use the tool if the cord or plug is damaged. If

damaged, have it repaired by a

service facility before use. If the plug will not fit

the outlet, have a proper outlet installed by a

qualified electrician.

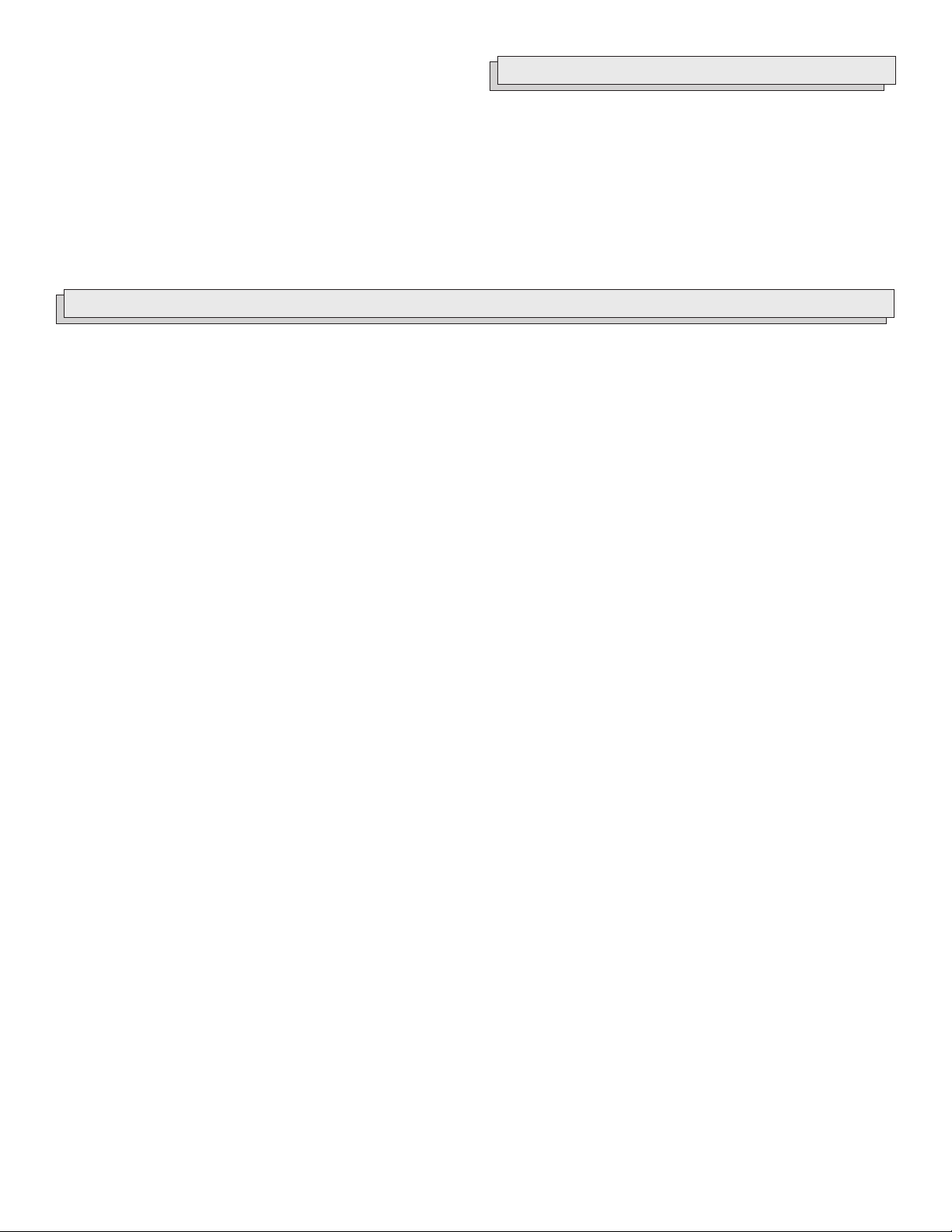

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required” have a three wire cord and

three prong grounding plug. The

plug must be connected to a properly grounded outlet (See Figure A

and B). If the tool should electrically malfunction or break down,

grounding provides a low resistance path to carry electricity away

from the user, reducing the risk of

electric shock.

The grounding prong in the plug is

connected through the green wire

inside the cord to the grounding

system in the tool. The green wire

in the cord must be the only wire

connected to the tool's grounding

system and must never be attached

to an electrically “live” terminal.

Your tool must be plugged into an

appropriate outlet, properly installed and grounded in accordance with all codes and ordinances. If the plug and outlet look

like those in Figure A, your tool is

rated for use on less than 150

volts. If your plug and outlet look

like those in Figure B, your tool is

rated for use on 150 to 250 volts.

Temporary adapters are not available for this type of plug.

Figure C illustrates a temporary

adapter available for connecting

grounded plugs (Figure A) to two

prong outlets. The green rigid ear

or lug extending from the adapter

must be connected to a permanent

ground such as a properly

grounded outlet box or receptacle.

Simply remove the center screw

from the outlet, insert the adapter

and reattach the screw through

the green grounding ear to the outlet. If in doubt of proper grounding,

call a qualified electrician. A temporary adapter should only be

used until a properly grounded

outlet can be installed by a qualified electrician. The Canadian Electrical Code prohibits the use of

temporary adapters.

WARNING!

Temporary

Adapter

Green Grounding Ear

MILWAUKEE

Fig. A

Fig. B

Fig. C

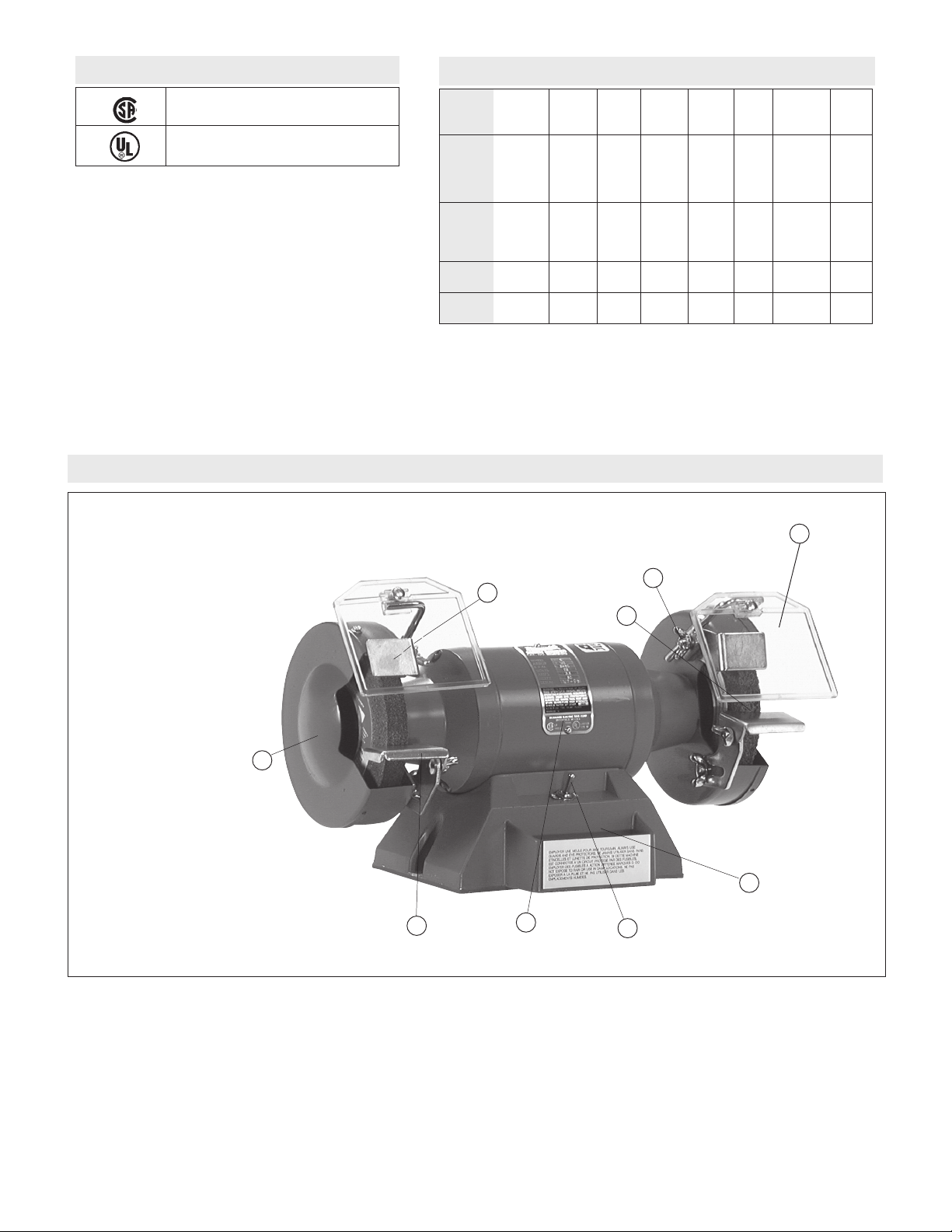

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes

a serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table at right to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked

with the suffix “W-A” (“W” in Canada) to indicate that it is

acceptable for outdoor use.

• Be sure your extension cord is properly wired and in good

electrical condition. Always replace a damaged extension cord

or have it repaired by a qualified person before using it.

• Protect your extension cords from sharp objects, excessive

heat and damp or wet areas.

Recommended Minimum Wire Gauge

for Extension Cords*

Nameplate

Amperes

0 - 5

5.1 - 8

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

Extension Cord Length

100'

75'

50'

25'

14

16

16

16

12

14

16

16

10

12

14

14

10

10

12

12

--

10

10

10

150'

12

10

--

--

--

200'

12

--

--

--

--

Page 6

TOOL ASSEMBLY

WARNING!

To reduce the risk of personal injury and

damage to the tool, use ONLY accessories

rated at or above the RPM listed on the tool's

nameplate.

1. Examine a new unit carefully for signs of shipping damage (wheels,

guards etc.). Make sure all parts are tight but do not overtighten

wheel nut. See “Mounting Wheels”, Fig. 3.

2. Do not operate grinder unless it is securely bolted in place. Two

mounting holes are provided in the base of the grinder.

3. Inspect wheel for flaws or cracks and replace a damaged wheel

immediately. Use only wheels with a safe speed rating at least as

high as the no load speed of the grinder and follow the instructions

in Fig. 2.

4. It is possible for a wheel to have concealed flaws. To prevent injury

or damage, stand clear of wheel on start up and allow to run for one

minute. If vibration and/or noise are present, dress the wheel as

instructed in Fig. 5. If the vibration or noise continues, investigate

cause and correct before using.

Plexiglass Eye Shields (Fig. 1)

(Standard Equipment for Cat. Nos. 4935 and 4995)

Two separate eye shields (one for each wheel) are supplied and must

be used when operating the grinder.

Fig. 1

Notched

Area

Wing

Nut

Rod

Eye Shield

Clamp

Wheel Guard

12 Volt Automotive

Light Bulb

Eye Shield

The

MILWAUKEE

1H.P. Bench Grinder is dual voltage rated at 115/230

Volts. The grinder is factory wired for 115 Volts. The voltage may be

changed to 230 Volts, by rewiring the motor connections.

The rewiring should be performed by a qualified electrician or Authorized

MILWAUKEE

Service Station Personnel.

The wiring diagrams and connections are inside the baseplate of the

grinder. Unplug the grinder before removing the baseplate. When changing to 230 volts, the cord set must be wired directly to the power source

or wired with a proper 230 volt attachment cord set.

Grinding Wheels

When selecting abrasive wheels, only high quality aluminum oxide or

silicon carbide wheels should be used. Aluminum oxide, although not as

hard as silicon carbide, is tougher and more resistant to breakage.

Coarse wheels (36 grains of grit per inch) are recommended for rough

grinding. Medium grit wheels (60 grit) are excellent for the jobs such as

smoothing welds or preparing surfaces for finishing. Fine grit wheels

(80 grit) are for sharpening or fine finishing.

Inspecting Grinding Wheels (Fig. 2)

Fig. 2

Test wheels before mounting by tapping it lightly with a nonmetallic tool

such as the handle of a screwdriver. If it rings, it is in good condition. If

it does not, discard the wheel. Wheel must be dry when applying this

test or the sound will be deadened. Tap wheels about 45° on either side

of the vertical center line and about 1 or 2 inches from the outside edge

as indicated in Fig. 2. Rotate the wheel 45° and repeat the test.

NOTE: Organic bonded wheels do not emit the same clear metallic ring

as verified and silicated wheels.

Mounting Wheels (Fig. 3)

Fig. 3

Wrong Right

No Wheel Blotter

Flange Not Recessed

Inner Flange Not

Keyed To Spindle

Wrong

Properly

Mounted

Wheel

Illuminated Eye Shields (Fig. 1)

(Standard Equipment for Cat. Nos. 4931, 4991, 5051 and 5091)

Illuminated eye shields are furnished with a 12 volt automotive bulb to

light both sides and the face of the grinding wheel. The light socket and

bulb are held in place, under each eye shield, by a bolt and a nut that

passes through a slot in the rear edge of the eye shield, to clamp the

socket assembly in place. Two separate eye shields (one for each

wheel) are supplied and must be used when operating the grinder.

Installing Eye Shields

The clamping assemblies for the eye shields are factory installed.

1. To install the eye shields, loosen the wing nut.

2. Insert the rod portion of the shield assembly between the wheel

guard and the notched area of the clamp.

3. Adjust the eye shield assembly to the proper height. Tighten the

wing nut.

1H.P. Grinder (Cat. No. 5091)

It is recommended that a No. 14 wire, fused with a 15 amp time lag fuse,

be used to supply power to all 1H.P. grinders, regardless of their electric

rating. This hook up should be independent of other electrical equipment.

End Nut

Too Tight

1. Unplug tool.

2. To mount the grinding wheels, remove the wheel guard covers from

the guards. Remove the hex nuts - the threads on the spindle are

such that the nut tightens as the wheel rotates when the tool is in

operation.

3. Check to be sure that blotters are undamaged and in place.

4. Slide the grinding wheels on to the spindle so that the blotter rests

firmly against the inner wheel flange.

5. Replace the outer wheel flange and nut. Make sure the cupped

portion of the outer flange is resting on the wheel (See Fig. 3).

6. Tighten the end nuts only enough to hold the wheel firmly. Too much

pressure may damage the wheel or related parts.

7. After the wheel has been mounted, stand aside and run the wheel

for at least one minute before grinding. NOTE: Never stand in direct

line of the wheel.

Page 7

Tool Rests and Spark Guards (Fig. 4)

Fig. 4

Spark Guard

Tool Rest

The tool rests and spark guards are adjustable and should be reset

whenever a wheel has been replaced, after dressing or as a wheel

becomes worn. The tool rest should be positioned close to the wheel at

all times to provide maximum support. The distance from the wheel

should not exceed 1/8". A level tool rest, set slightly below the center of

the wheel, is the most practical and safest position.

The spark guards are located at the top of each wheel and should be

adjusted for wheel wear so that the guard is approximately 3/16" from

the wheel. This will prevent sparks from striking the operator.

OPERATION

WARNING!

Grinding wheels should be dressed when worn, out of round or the

surface face is clogged or worn smooth. New wheels should be balanced by dressing to eliminate vibration. For dressing abrasive wheels,

a diamond dresser is preferred. A more common disc-type dresser contains a replaceable set of star or gear-shaped pieces of hard metal.

These discs rotate freely and rapidly when held in contact with the

moving face of the wheel and dig in to remove the loading and small bits

of dulled grain.

To dress wheels, adjust the tool rest away from the wheel so the heel of

the dresser hooks over the rest and is guided by it as the dresser is

moved evenly across the wheel face. Dressing should start at the

highest surface of the wheel face. If vibration is still evident after

dressing, loosen the wheel, rotate 90° and tighten. Repeat the dressing

procedure.

For Wire Wheel Brush Application

WARNING!

Unplug tool before removing or attaching

accessories. Maximum Safe Operating

Speed of wire brush or grinding wheel must

be greater than no load RPM of tool. Guards

must be used with grinding wheels and wire

wheels. Only use specifically recommended

accessories. Others may be hazardous.

To reduce the risk of personal injury, always

use safety glasses. Every day eye glasses

only have impact resistant lenses. They are

NOT safety glasses.

Too much pressure applied to a cold wheel is a common cause of wheel

failure and must be avoided. Work should never be forced against a cold

wheel but applied gradually, giving the wheel an opportunity to warm

and minimize the chance of breakage. This applies to starting work on

used wheels as well as to new wheels which have been stored in a

cool place. Do not grind on a wheel while it is coasting to a stop or

before it has reached full speed.

For best results, always keep grinding wheels properly dressed and in

good balance. The use of well balanced wheels will add to the life of the

bearings of the grinder by eliminating the most common cause of vibration

and permits more accurate work. (See "Dressing Grinding Wheels", Fig. 5.)

When making heavy cuts, use the face, not the sides of the cutting

wheel. Grinding on the flat sides of a straight wheel is hazardous and

should not be attempted. Special abrasive disc wheels should be used

when it is necessary to grind on the flat side of straight wheels. The

discs are designed to be mounted with one flat side against a suitable

steel machine plate to safely withstand the side pressure.

WARNING!

To reduce the risk of personal injury and

damage to the tool, use ONLY accessories

rated at or above the RPM listed on the tool's

nameplate.

Dressing Grinding Wheels (Fig. 5)

Fig. 5

Wrong

Installing Wire Wheel Brushes

1. Unplug tool.

2. To mount the wire wheels, remove the wheel guard covers from the

guards. Remove the hex nuts - the threads on the spindle are such that

the nut tightens as the wheel rotates when the tool is in operation.

3. Slide the wire wheel on to the spindle so that the wheel rests firmly

against the flange.

4. Replace the outer wheel flange and nut. Make sure the cupped

portion of the outer flange is resting on the wheel (See Fig. 3).

5. Tighten the end nuts only enough to hold the wheel firmly. Too much

pressure may damage the wheel or related parts.

Using Wire Wheel Brushes

WARNING!

Never exceed Maximum Safe Operating

Speed of brush. Do not use a damaged brush

or one which is functioning improperly

(throwing wires, out-of-balance, etc.). These

conditions increase the possibility of further

brush failure and possible injury. Discard

and replace damaged brushes immediately.

Wire brushes are useful for removing rust, scale, burrs, weld sag, etc.

A wide variety of wire brushes are available for many applications.

Test wire brush for balance and loose or damaged wires by running tool

at no load speed for at least 30 seconds before applying it to your work.

During this time, no one should stand in front of or in line with the tool.

When applying brush to work, avoid using too much pressure. This

causes over-bending of wires and heat buildup resulting in premature

wire breakage, rapid dulling and reduced brush life. Instead of using

more pressure, use a wire brush with more aggressive cutting action

(increased wire size, decreased wire length or different brush type, i.e.

knot type instead of crimped wire type).

Page 8

WARNING!

Right

Because the wires on wire wheel

brushes are directed towards the operator, a guard must be used to protect the

operator when fatigued wires break.

MAINTENANCE

ACCESSORIES

WARNING!

To reduce the risk of injury, always unplug

your tool before performing any maintenance. Never disassemble the tool or try to

do any rewiring on the tool's electrical system. Contact a

for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular maintenance program. Before use, examine the general condition of your tool. Inspect

guards, switches, tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving parts, improper mounting, broken parts and any other condition that may affect its safe operation. If abnormal noise or vibration occurs, turn the tool off immediately

and have the problem corrected before further use. Do not use a damaged tool. Tag damaged tools "DO NOT USE" until repaired

(see "Repairs").

MILWAUKEE

service facility

WARNING!

To reduce the risk of injury, electric shock

and damage to the tool, never immerse your

tool in liquid or allow liquid to flow inside the

tool.

Repairs

If your tool is damaged, return the entire tool to the nearest service

center listed on the back cover of this operator’s manual.

WARNING!

To reduce the risk of injury, use only

identical replacement parts.

FIVE YEAR TOOL LIMITED WARRANTY

Every

MILWAUKEE

ranted to be free from defects in material and workmanship.

will repair or replace (at

tool (including battery chargers) which examination proves to be defective in material or workmanship from five (5) years after the date of

purchase. Return the tool and a copy of the purchase receipt or other

proof of purchase to a

Branch location or

paid and insured. This warranty does not cover damage from repairs

made or attempted by other than

abuse, normal wear and tear, lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are warranted for one (1) year

from the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN ARE

EXCLUSIVE. IN NO EVENT SHALL

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, OR CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal rights. You may also have other

rights that vary from state to state and province to province. In those

states that do not allow the exclusion of implied warranties or limitation

of incidental or consequential damages, the above limitations or exclusions may not apply to you. This warranty applies to the United States,

Canada, and Mexico only.

tool is tested before leaving the factory and is war-

MILWAUKEE

MILWAUKEE

MILWAUKEE

MILWAUKEE

’s discretion), without charge, any

Factory Service/Sales Support

Authorized Service Station, freight pre-

MILWAUKEE

MILWAUKEE

authorized personnel,

BE LIABLE FOR ANY

WARNING!

Unplug tool before removing or attaching

accessories. Maximum Safe Operating

Speed of wire brush and grinding wheel

must be greater than no load RPM of tool.

Guards must be used with grinding wheels

and wire wheels. Only use specifically

recommended accessories. Others may

be hazardous.

For a complete listing of accessories refer to your

Tool catalog or go on-line to www.mil-electric-tool.com. To obtain a catalog, contact your local distributor or a service center listed on the back

cover of this operator’s manual.

Wheels For Bench Grinders

NOTE: The maximum safe operating speed shown on the grinding and

wire wheels must be greater than the load speed of the tool.

Grinding Wheels

Grinding Wheels are available in 36, 60, and 80 vitrified grit for all types

of grinding.

Knot Wire Wheels

Use Knot Wire Wheels for removing rust, scales and file marks.

Brushes

Brushes are made of select steel wire and have a face width of 3/4".

Cloth Buffing Wheels

Use Cloth Buffing Wheels for buffing metal surfaces. These wheels

are made of multiple layers of select

buffing cloth sewed securely together and can be coated with glue

and dipped in emery grit for finish

grinding or rough polishing.

Plexiglass Lens

Replacement lens for all light eye

shield models and Catalog No. 4995.

Supplied individually.

Plexiglass Eye Shield (Pair)

Furnished as standard equipment on

Catalog No. 4935. Easily replaced

when pitted. Supplied as a pair.

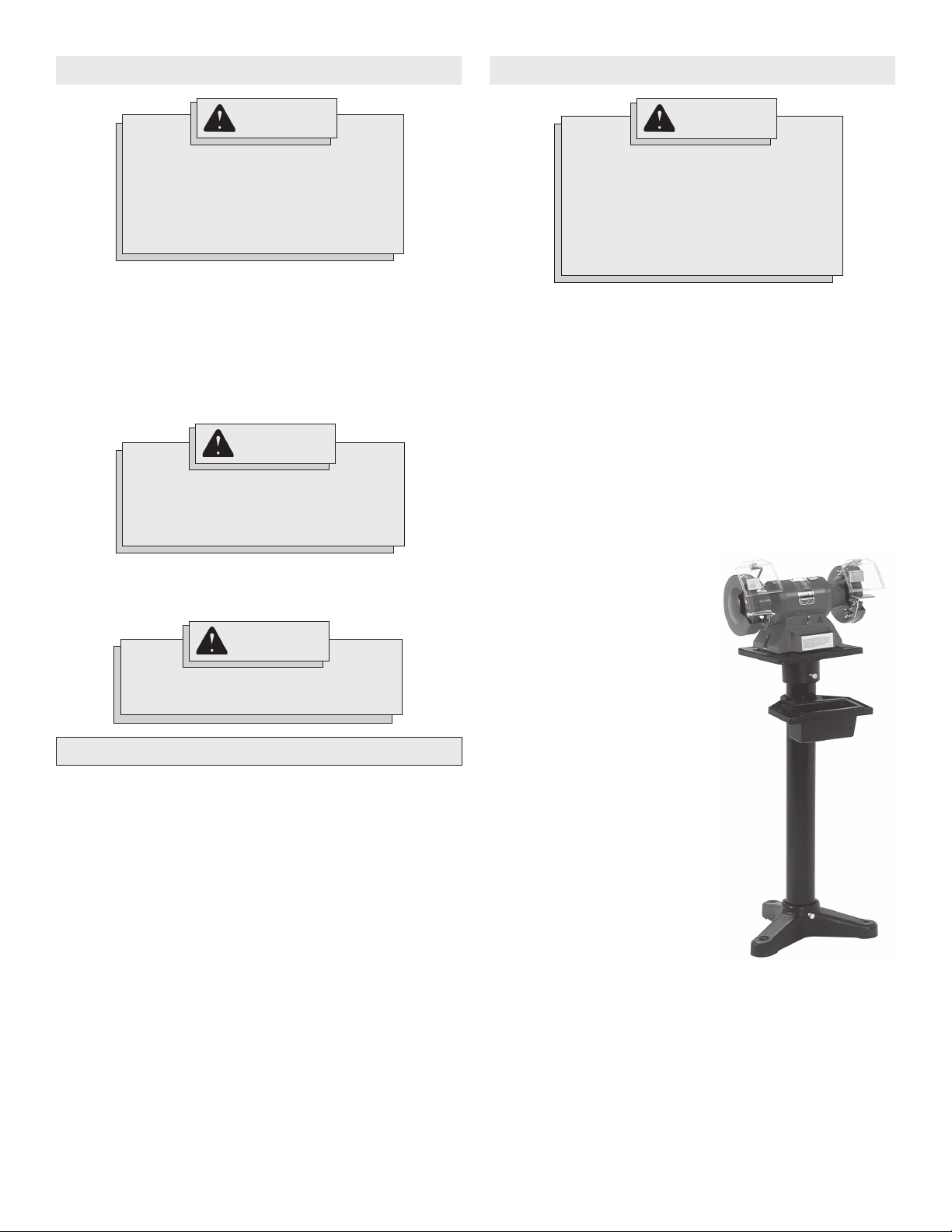

Grinder Pedestal

Heavy grey iron casting with tubular

steel column. Removable water pot.

Adaptable to all models.

MILWAUKEE

Electric

Page 9

Loading...

Loading...