Milwaukee 48-22-8552 Operator's Manual

Cat. No. / No de cat.

48-22-8552

52" MOBILE WORK STATION

POSTE DE TRAVAIL MOBILE DE 1,32 M (52")

ESTACIÓN DE TRABAJO MÓVIL DE 1,32 M (52")

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

2

3

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may result in serious injury. Save all warnings and instructions for future

reference.

•Use the station and accessories in accordance

with these instructions and in the manner intended, taking into account the working conditions.

Use of the station for operations different from those

intended could result in a hazardous situation.

•Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

•Fully assemble the station according to the as-

sembly instructions. Do not leave off any pieces.

•Do not modify the station in any way. Use only

specifically recommended accessories. Drilling

holes or modifying the station will lower the load

capacity, which can cause the station to collapse,

resulting in injury.

•Lock wheels when station is not being moved.

Unlocked wheels can allow the station to move

unexpectedly.

•Keep the station on a level surface. Do not load,

unload, or park station on an incline. The station

may become unbalanced and tip, resulting in injury.

•Always balance the station load to avoid tipping.

Unbalanced stations are more likely to tip when being moved or when using the station work surfaces.

Evenly distribute the weight front to back and side

to side. To help prevent the station from tipping,

load the product starting with the bottom drawers.

• Do not exceed the maximum product weight,

including contents. Do not exceed the maximum

weight for each drawer. Overloaded stations can

tip, collapse, or damage drawer slides.

• Do not open more than one drawer at a time.

Station may tip, causing injury.

•Keep children and bystanders away while load-

ing, unloading, and moving the station. Distrac-

tions can cause you to lose control.

•Only lift the station according to the instructions

in this manual. Other methods may be dangerous,

resulting in injury.

• Only transport the station when empty. Properly

secure when transporting.

• Do not mount the station on a truck bed or any

other moving object.

• Lock all drawers before rolling the station. The

drawers could come open and make the station

unstable and tip.

• Only roll the station short distances by using

the handle provided.

• Secure all items before rolling the station. Loose

items could shift, causing the station to become

unstable.

• Do not use drawers as steps. Do not stand

on the station. Station may tip, causing injury.

• Do not step on side shelf. Shelf may collapse or

break. Station may tip, causing injury.

•Do not use station in explosive atmospheres,

such as in the presence of ammable liquids, gases

or dust. This equipment has internal arcing or spark-

ing parts. Station should not be located in a recessed

area or below oor level.

•Station plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earth (grounded) chest/cabinet power

strips. Unmodied plugs and matching outlets will

reduce risk of electric shock.

•Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

•Maintain station. Check for misalignment or binding wheels, breakage or bending of drawer slides or

other parts and any other condition that may affect

the station's operation. Do not use damaged station.

•Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

•Have your station serviced by a qualied repair

person using only identical replacement parts.

This will ensure that the safety of the station is

maintained.

Federal Communications Commission

WARNING: Changes or modifications to this unit

not expressly approved by the party responsible for

compliance could void the user’s authority to operate

the equipment.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

NOTE: This equipment has been tested and found

to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference in a residential installation. This

equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful

interference to radio communications. However, there

is no guarantee that interference will not occur in a

particular installation. If this equipment does cause

harmful interference to radio or television reception,

which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

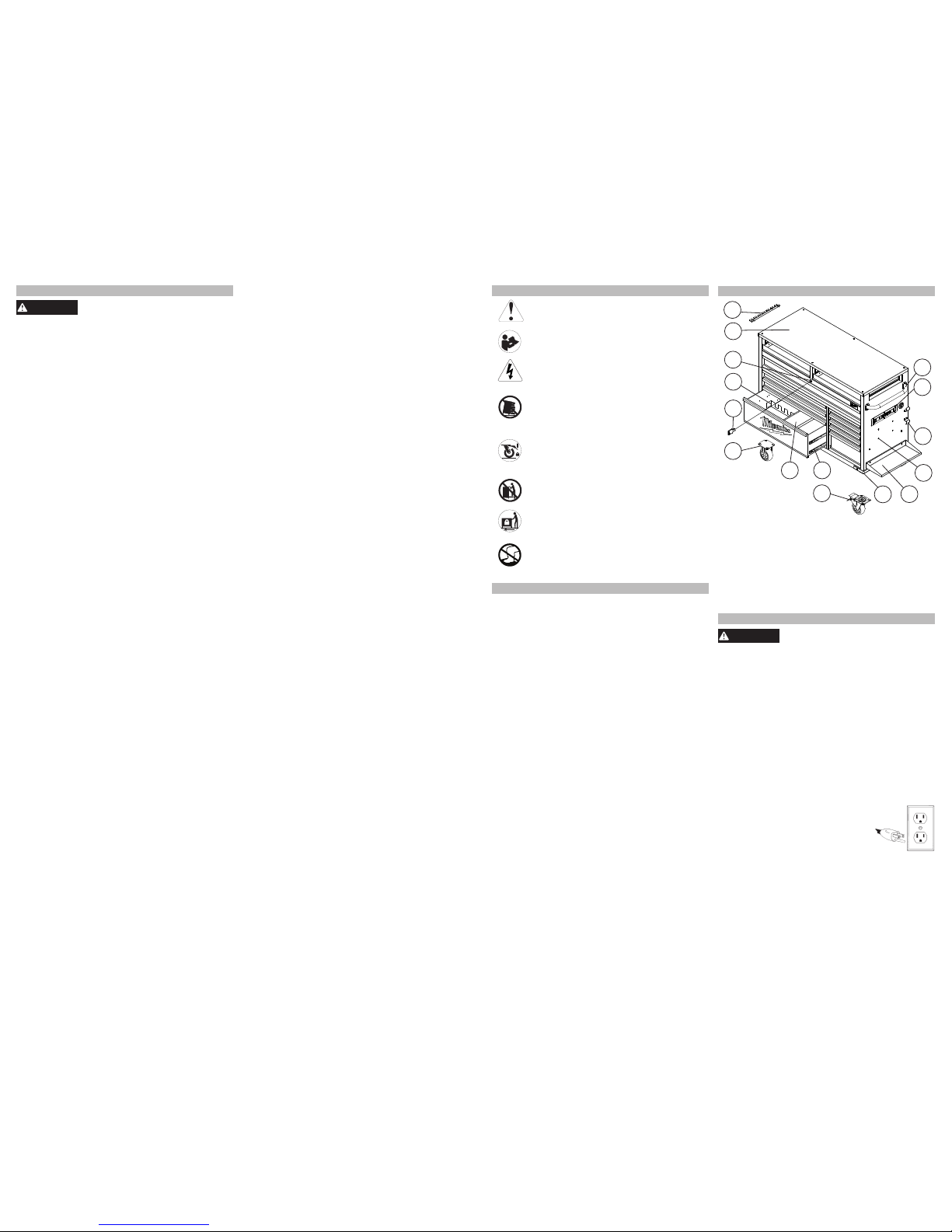

SYMBOLOGY

Warning

Read Operator's Manual

Electrical Shock Hazard

Do not open more than one drawer at a

time. Station may tip, causing injury.

Lock wheels when station is not

being moved. Unlocked wheels can

allow the station to move

unexpectedly.

Do not use drawers as steps. Station

may tip, causing injury.

FPO

Lock all drawers before moving the station.

Do not step on side shelf. Shelf may

collapse or break. Station may tip, causing

injury.

SPECIFICATIONS

Cat. No. ................................................ 48-22-8552

Two-Slide Drawer Capacity .........100 lbs. (45.4 kg)

Four-Slide Drawer Capacity ........200 lbs. (90.7 kg)

Total Capacity .......................... 1800 lbs. (816.5 kg)

AC Input Volts ....................................................120

Hertz ....................................................................60

Amps ...................................................................15

USB Output Volts...................................................5

USB Watts ........................................................10.5

USB Amps ..........................................................2.1

Max Operating Temperature ............221

°F

(105

°C)

FUNCTIONAL DESCRIPTION

14

1

11

10

5

1. Tool hanger

2. Wood work

surface

3. Lock

4. Tool organizer

5. Key

6. Rigid caster

7. Drawer divider

8. Drawer slide

9. Swivel caster

with brake

2

13

12

4

6

10. Bumper

11. Storage shelf

12. Charger mounts

13. Cord storage

brackets

14. Power strip with

USB ports

15. Side handle

7 8

9

15

3

GROUNDING

WARNING

Improperly connecting the grounding wire can result in the risk of

electric shock. Check with a qualied electrician

if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug provided with the station. Never remove the grounding prong from the plug. Do not use the station

if the cord or plug is damaged. If damaged, have

it repaired before use. If the plug will not t the

outlet, have a proper outlet installed by a qualied

electrician.

Stations with Three Prong Plugs

Stations marked “Grounding Required” have a

power strip with a three wire cord and three prong

grounding plug. The plug must be connected to a

properly grounded outlet (See Figure A). If the

power strip should electrically malfunction or break

down, grounding provides a low resistance path to

carry electricity away from the user,

Fig. A

reducing the risk of electric shock.

The grounding prong in the plug is

connected through the green wire

inside the cord to the grounding system in the power strip. The green wire in the cord

must be the only wire connected to the power strip's

grounding system and must never be attached to an

electrically “live” terminal.

Your power strip must be plugged into an appropriate

outlet, properly installed and grounded in accordance

with all codes and ordinances. The plug and outlet

should look like those in Figure A.

4

5

Item Description Quantity

Side handle 1

Tool hanger 1

Swivel caster with

brake

2

Rigid caster 2

Bumper 4

Cord Storage

Bracket

2

NOTE: Begin product assembly close to the nal

intended location of your station. This product is

heavy and may be difcult to move after assembly.

Attaching the Side Handle

Attach the side handle to the station using four bolts

(CC). The side handle can be attached to either side

of the station.

NOTE: The holes in the station are tapped and do

not require nuts.

Installing the Casters

CAUTION

Two people may be required to

complete installation.

CAUTION

Do not overtighten the screws.

1. Ensure all station drawers are securely locked into

place using the key lock on the station.

2. Lay the station on its back. Use the packaging

material to protect the nish.

3. Mount the two swivel casters with brake to the

station using four bolts (EE) and washers (DD)

per caster. The swivel casters with brake should

be installed on the end of the station with the side

handle.

4. Mount the two rigid casters to the opposite end

of the station using four bolts (EE) and washers

(DD) per caster.

5. Tighten all bolts securely with a wrench.

6. Return the station to its upright position.

Installing the Drawer Liners

Place the drawer liners in appropriately sized drawers

to protect the surface.

Installing the Bumpers

Attach the four bumpers to the station using two

screws (FF) per bumper.

ASSEMBLY

CAUTION

Be sure to follow the assembly instructions for the appropriate sta-

tion. Do not use power tools to assemble station.

Tighten bolts with hand wrenches.

Tools Required

Phillips

screwdriver

Safety

goggles

10 mm

Wrench

13 mm

Wrench

Hardware Included

NOTE: Items not shown to actual size.

Hard-

ware Item Description Quantity

AA

Screw M4 x 12L 8

CC Bolt M6 x 16L 8

DD

Washer 16

EE

Bolt M8 x 18L 16

FF Screw M6 x 16L 8

Installing the Cord Storage Brackets

Attach the brackets to the station with two screws

(AA) per bracket. Orient the brackets with one pointed

up and one pointed down so that the power outlet

cord can be wrapped around the brackets for storage.

Attaching the Tool Hanger

Attach the tool hanger to the left end of the station

using two bolts (CC).

Attaching the Storage Shelf

Attach the storage shelf to the station using two bolts

(CC) on either end of the station.

Reversing the Wood Work Surface

The wood work surface comes pre-installed with

the station. After wear and tear, the surface may be

reversed to use the clean bottom surface. To reverse,

remove the six screws from the top of the wood work

surface, ip surface, and reinstall the six screws.

USB Power Outlet

The USB ports on the power outlet can be used to

charge any device that uses less than 2.1A of DC

electrical current.

NOTE: Any device that uses more than 2.1 A of DC

electrical current will trip a self-resetting overload and

disable the output.

OPERATION

WARNING

To avoid injury or property damage,

do not exceed maximum drawer

capacity. Use care when moving the station on

incline or rough surface. Station may tip if weight

is not evenly distributed front to back and side

to side. Place more than half the total load weight

on the bottom drawers when possible.

Locking and Unlocking the Station

NOTE: The drawers must be fully closed before

locking/unlocking the unit.

Insert the key. Turn it fully left to lock, or fully right

to unlock. Always remove the key after locking and

unlocking.

Using the Caster Brakes

To lock the swivel casters,

step down on the levers

marked ON. Be sure to lock

all casters to prevent station

from rolling or swiveling. To

unlock casters, push down

on the levers marked OFF.

Moving the Station on an Incline or

Rough Surface

Take care that the station does not tip or become

unbalanced when moving it on an incline or rough

surface. Do not exceed an incline of 10 degrees.

Lock the station and secure all items before moving.

6

7

Rolling the Station

The station is only intended for rolling short distances.

Only roll the station using the handle. Do not push or

pull station by the frame or product may tip. Do not

modify the station in any way. Drilling holes or modifying the station will lower the load capacity, which

can cause the station to collapse, resulting in injury.

Lock the station and secure all items before rolling.

Lifting the Station

The station is not intended to be lifted. However, if

you need to lift, empty the station and then place

straps or forks inside and next to casters. Do not lift

loaded stations. Be sure all bystanders are moved

away before lifting station.

Mounting Chargers

The station comes equipped with four pre-installed

charger mounting bosses, located below the power

strip. The charger mounts are suitable for holding

MILWAUKEE M18™ & M12™ Multi Voltage chargers

as well as M18™ chargers. To mount a charger,

install a screw (AA) into each boss, then slide the

charger's key-hole slots over the screws. Slide the

charger toward the oor to lock it onto the screws.

Removing the Drawers

1. Fully extend and empty the drawer.

2. Depending on the side, either lift or lower the

release lever on both sides so the slides can ride

over the stops. Pull out to remove.

Release Lever

Installing the Drawers

1. Pull the slides and slide carrier out until fully extended.

2. Hold the slide on the cabinet while aligning it with

the slide on the drawer.

3. Slightly insert one side and repeat for the other

side.

4. Slowly push the drawer until it is fully closed to

engage the slide.

5. Open and close the drawer to verify proper operation.

MAINTENANCE

WARNING

To reduce the risk of injury, contact

MILWAUKEE Corporate After Sales

Service Technical Support for ALL repairs and

replacement parts.

Maintaining the Station

Keep your station in good repair by adopting a regular maintenance program. Before use, examine the

general condition of your station. Check for loose

screws, misalignment, binding of wheels, broken

parts and any other condition that may affect its safe

operation. Do not use a damaged station.

Maintaining the Casters

Grease the casters annually using high quality bearing grease.

Grease

Points

Maintaining the Drawers

1. Periodically clean the drawer with a mild detergent

and water.

2. Remove grease and oil in drawer with a standard,

nonammable cleaning uid.

3. The use of drawer liners is recommended to

protect the nish inside the drawers and make

the drawers easier to clean. Drawer liners can be

cleaned with soap and water.

4. Lubricate the slides semi-annually with general

purpose grease or equivalent.

Grease

Points

Cleaning

This steel product has been coated with industrial

powder coating for a durable nish. To help protect

the powder coated nish, do not allow harsh chemi-

cals (oil, grease or other chemical) to remain on the

powder coating surface. Use a glass cleaner to clean

and maintain all surfaces of powder coating.

Keep the station handles and wheels clean, dry and

free of oil or grease. Use only mild soap and a damp

cloth to clean your station since certain cleaning

agents and solvents are harmful to plastics. Some of

these include: gasoline, turpentine, lacquer thinner,

chlorinated cleaning solvents, ammonia and household detergents containing ammonia. Never use

ammable or combustible solvents around station.

Service

For service and repair information, including the ordering of service parts, call our Corporate After Sales

Service Technical Support line at 1-800-SAWDUST,

or visit our website at www.milwaukeetool.com.

ACCESSORIES

WARNING

Modifying the station to accept

other accessories may be hazardous, resulting in injury or property damage. Use

only specically recommended accessories according to the manufacturer's instructions.

For a complete listing of accessories, go online to

www.milwaukeetool.com or contact a distributor.

SERVICE - UNITED STATES

1-800-SAWDUST (1.800.729.3878)

Monday-Friday, 7:00 AM - 6:30 PM CST

or visit www.milwaukeetool.com

Contact Corporate After Sales Service Technical

Support with technical, service/repair, or warranty

questions.

Email: metproductsupport@milwaukeetool.com

Become a Heavy Duty Club Member at

www.milwaukeetool.com to receive important

notications regarding your tool purchases.

SERVICE - CANADA

Milwaukee Tool (Canada) Ltd

1.800.268.4015

Monday-Friday, 7:00 AM - 4:30 PM CST

or visit www.milwaukeetool.ca

LIMITED WARRANTY

USA & CANADA

Every MILWAUKEE steel storage chest and cabinet are warranted

to the original purchaser only to be free from defects in material and

workmanship. Subject to certain exceptions, MILWAUKEE will repair

or replace any part on a chest or cabinet which, after examination, is

determined by MILWAUKEE to be defective in material or workmanship for a period of three (3) years after the date of purchase. Return

of the chest or cabinet to the place of purchase is required. A copy of

the proof of purchase should be included with the return product. This

warranty does not apply to damage that MILWAUKEE determines to

be from repairs made or attempted by anyone other than MILWAUKEE

authorized personnel, misuse, alterations, abuse, normal wear and

tear, lack of maintenance, or accidents.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE steel storage chest or cabinet. The manufacturing

date of the product will be used to determine the warranty period if no

proof of purchase is provided at the time warranty service is requested.

If you feel your product has a warranty defect, or if you need information

on a service/replacement part, please contact MILWAUKEE at 1.800.

SAWDUST (1.800.729.3878) for instructions.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN IS A CONDITION OF

THE CONTRACT FOR THE PURCHASE OF EVERY MILWAUKEE

PRODUCT. IF YOU DO NOT AGREE TO THIS CONDITION, YOU

SHOULD NOT PURCHASE THE PRODUCT. IN NO EVENT SHALL

MILWAUKEE BE LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES, OR FOR ANY COSTS,

ATTORNEY FEES, EXPENSES, LOSSES OR DELAYS ALLEGED

TO BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF,

OR DEFECT IN ANY PRODUCT INCLUDING, BUT NOT LIMITED

TO, ANY CLAIMS FOR LOSS OF PROFITS. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION

OR EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY

IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES, WRITTEN OR ORAL. TO THE EXTENT PERMITTED

BY LAW, MILWAUKEE DISCLAIMS ANY IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE

OR PURPOSE; TO THE EXTENT SUCH DISCLAIMER IS NOT

PERMITTED BY LAW, SUCH IMPLIED WARRANTIES ARE LIMITED

TO THE DURATION OF THE APPLICABLE EXPRESS WARRANTY

AS DESCRIBED ABOVE. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU, THIS WARRANTY

GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

Please consult the 'Find a Service Center Search' in the Parts &

Service section of MILWAUKEE’s website www.milwaukeetool.com

or call 1.800.SAWDUST (1.800.729.3878) to locate your nearest

MILWAUKEE factory Service Center location.

Loading...

Loading...