OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Cat. No. / No de cat.

3510-20

®

REDLITHIUM

LASER A POINTS USB REDLITHIUM

LÁSER DE PUNTO RECARGABLE MEDIANTE USB

REDLITHIUM

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

USB POINT LASER

®

®

GENERAL POWER

WARNING

WARNING

TOOL SAFETY

WARNINGS

Read and understand all instruc-

listed below, may result in electric shock, re and/or

serious personal injury. Save all warnings and instructions for future reference.

• Save these instructions - This operator's manual

contains important safety and operating instructions.

tions. Failure to follow all instructions

LASER SAFETY

The device produces visible laser

tool.

• This device complies with 21 CFR 1040.10 and

1040.11 except for conformance with IEC 60825-1

Ed. 3., as described in Laser Notice No. 56, dated

May 8, 2019.

•Laser light - Do not stare into beam or view directly with optical instruments. Do not point laser

light at others. Laser light can cause eye damage.

beams, which are emitted from the

WORK AREA SAFETY

• Ensure adequate safeguards at the work site

(e.g. surveying site when measuring on roads,

construction sites, etc.).

• Avoid dangerous environments. Avoid extended

exposure to rain, snow, damp or wet locations. Do

not use in the presence of explosive atmospheres

(gaseous fumes, dust or ammable materials).

PERSONAL SAFETY

• Do not allow persons unfamiliar with the tool,

these safety instructions, and the tool's operator's manual to operate the tool. This tool can be

dangerous in the hands of untrained users.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the tool in unexpected situations.

BATTERY USE

AND CARE

• USE AND CHARGE ONLY REDLITHIUM® USB

BATTERIES IN THIS USB RECHARGEABLE

TOOL. OTHER TYPES OF BATTERIES MAY

CAUSE PERSONAL INJURY AND DAMAGE.

• BEFORE USING THE BATTERY AND TOOL,

READ THIS OPERATOR’S MANUAL AND ALL

LABELS ON THE BATTERY AND TOOL.

• USE ONLY WITH LISTED/CERTIFIED ITE

POWER SUPPLY. Others may result in a risk of re,

electric shock or personal injury.

• CHARGE IN A WELL VENTILATED AREA. Do not

block charger vents. Keep them clear to allow proper

ventilation. Do not allow smoking or open ames

near a charging battery. Vented gases may explode.

• MAINTAIN CORD. When unplugging charger, pull

plug rather than cord to reduce the risk of damage to

the electrical plug and cord. Never carry charger by

its cord. Keep cord from heat, oil and sharp edges.

Make sure cord will not be stepped on, tripped over

or subjected to damage or stress. Do not use charger

with damaged cord or plug. Have a damaged charger

replaced immediately.

• USE ONLY RECOMMENDED ATTACHMENTS. Use

of an attachment not recommended or sold by the

battery charger or battery manufacturer may result in

a risk of re, electric shock or personal injury.

• TO REDUCE THE RISK OF ELECTRIC SHOCK, al-

ways unplug charger before cleaning or maintenance.

• DO NOT BURN OR INCINERATE BATTERY

PACKS. Battery may explode, causing personal

injury or damage. Toxic fumes and materials are

created when batteries are burned.

• DO NOT CRUSH, DROP, OR DAMAGE battery. Do

not use a battery or charger that has received a sharp

blow, been dropped, run over, or damaged in any way

(e.g., pierced with a nail, hit with a hammer, stepped on).

• DO NOT DISASSEMBLE. Incorrect reassembly

may result in the risk of electric shock, re or exposure to battery chemicals. If it is damaged, take it to

a MILWAUKEE service facility.

• BATTERY CHEMICALS CAUSE SERIOUS BURNS.

Never allow contact with skin, eyes, or mouth. If

a damaged battery leaks battery chemicals, use

rubber or neoprene gloves to dispose of it. If skin is

exposed to battery uids, wash with soap and water

and rinse with vinegar. If eyes are exposed to bat-

tery chemicals, immediately ush with water for 20

minutes and seek medical attention. Remove and

dispose of contaminated clothing.

• DO NOT SHORT CIRCUIT. A battery pack will short

circuit if a metal object makes a connection between

the positive and negative contacts on the battery

pack. Do not place a battery pack near anything that

may cause a short circuit, such as coins, keys or

nails in your pocket. Do not allow uids to ow into

battery pack. Corrosive or conductive uids, such as

seawater, certain industrial chemicals, and bleach or

bleach containing products, etc., can cause a short

circuit. A short circuited battery pack may cause re,

personal injury, and product damage.

• STORE YOUR BATTERY AND TOOL in a cool, dry

place. Do not store battery where temperatures may

exceed 120°F (50°C) such as in direct sunlight, a

vehicle or metal building during the summer.

SPECIFIC SAFETY

RULES FOR

LASER LEVELS

•Watch out for erroneous results if the tool is

defective or if it has been dropped, misused or

modied.

•Do not dispose of tool or batteries together with

household waste material! Tool and batteries that

have reached the end of their life must be collected

separately and returned to an environmentally

compatible recycling facility.

•Ensure tool magnets are securely mounted to

a metal surface. Magnet strength may not hold

on thin metal surfaces, causing the tool to fall.

• Always use common sense and be cautious when

using tools. It is not possible to anticipate every

situation that could result in a dangerous outcome.

Do not use this tool if you do not understand these

operating instructions or you feel the work is beyond

your capability; contact Milwaukee Tool or a trained

professional for additional information or training.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact MILWAUKEE for a free replacement.

2

• The device conforms to the most stringent

WARNING

requirements of the relevant Electromagnetic

Compatibility (EMC) Standards and Regulations.

Yet, the possibility of causing interference in other

devices cannot be totally excluded.

CAUTION

than those specied herein may result in hazardous radiation exposure.

• Be sure to power o instrument after use. When

instrument will not be used for a long period, place

it in storage after removing batteries.

proved by the party responsible for compliance could

void the user’s authority to operate the equipment.

This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance

with the instructions, may cause harmful interference

to radio communications.

However, there is no guarantee that interference will

not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning

the equipment o and on, the user is encouraged to

try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Consult the dealer or an experienced radio/TV

technician for help.

Use of controls or adjustments or

performance of procedures other

Federal Communications Commission

Changes or modications to

this unit not expressly ap-

SPECIFICATIONS

Cat. No ...................................................... 3510-20

USB Input Volts .............................................. 5 DC

USB Input Amps ..................................... 0.1 - 2.1 A

Output Volts .................................................... 4 DC

Output Amps ....................................................2.1 A

REDLITHIUM

Volts ................................................................ 4 DC

Power Supply Cat. No. ....................... 48-59-1202

Laser............................................................Class 2

Points Max Power............................... P

Wavelength.......................................... 510-530 nm

Points Beam Divergence .......................... 0.5 mrad

Storage Temp .................................... -4°F to 120°F

Working Range .................................................150'

Accuracy ............................................... ±1/8" @ 33'

Settle Time ......................................... < 3 Seconds

Tripod Mount ...............................................1/4"-20

Ingress Protection............................................ IP54

Drop Rating .......................................................1 m

Leveling ............Auto ±°4 side to side, front to back

Operating Temperature

Battery and Charger ........................ 40°F to 104°F

Battery and Tool ............................... 14°F to 104°F

®

USB Batteries

≤ 1 mW

AVG

FUNCTIONAL

DESCRIPTION

1. Laser apertures

2. Battery compartment

3. On/O dial

4. Adjustable clearance

bracket

1

1

1

8

2

5

7

5. Fuel gauges

6. USB power outlet

7. Threaded insert

8. Magnets

3

4

5

6

SYMBOLOGY

Volts

CLASS 2 LASER PRODUCT

Universal Serial Bus (USB)

Magnets

Read operator’s manual

Direct Current

Amps

LASER RADIATION

DO NOT STARE INTO BEAM

Batteries

3

Properly Recycle

WARNING

WARNING

CAUTION

NOTICE

BATTERY

WARNING

WARNING

WARNING

To reduce the risk of re, personal

a short circuit, never immerse your tool, battery

pack or charger in uid or allow a uid to ow

inside them. Corrosive or conductive uids, such

as seawater, certain industrial chemicals, and

bleach or bleach containing products, etc., can

cause a short circuit.

Do not expose your battery or cordless tools to water or

rain, or allow them to get wet. This could damage the

tool and battery. Do not use oil or solvents to clean or

lubricate your battery. The plastic casing will become

brittle and crack, causing a risk of injury.

Store batteries at room temperature away from mois

ture. Do not store in damp locations where corrosion

of terminals may occur. As with other battery types,

permanent capacity loss can result if the pack is stored

for long periods of time at high temperatures (over 120°

F). MILWAUKEE Li-Ion batteries maintain their charge

during storage longer than other battery types. After

about a year of storage, charge the battery as normal.

battery pack even if it is damaged, dead or completely discharged. When burned, toxic fumes

and materials are created.

Disposing of MILWAUKEE Li-Ion Battery

MILWAUKEE Li-Ion batteries are more environmentally friendly than some other types of power tool

batteries. Always dispose of your battery according

to federal, state and local regulations. Contact a

recycling agency in your area for recycling locations.

Even discharged batteries contain some energy.

Before disposing, use electrical tape to cover the

terminals to prevent the battery from shorting, which

could cause a re or explosion.

The RBRC™ Battery Recycling Seals (see "Symbology") on your batteries indicate that MILWAUKEE

has arranged for the recycling of that battery with

the Rechargeable Battery Recycling Corporation

(RBRC). At the end of your battery's useful life,

return the battery to a MILWAUKEE Branch Oce/

Service Center or the participating retailer nearest

you. For more information, visit the RBRC web site

at www.rbrc.org.

injury, and product damage due to

Maintenance and Storage

To reduce the risk of injury or ex-

plosion, never burn or incinerate a

RBRC Battery Recycling Seals

ASSEMBLY

Use and charge only REDLITHIUM®

chargeable tool. Other types of batteries may

cause personal injury and damage.

1. Twist the battery cap and remove.

2. Line up the arrow on the battery with the arrow in

the compartment and fully insert the battery.

3. Replace the cap and twist to secure.

When the tool is turned on under battery power only, the

remaining battery life is displayed

Green Solid: 50-100% remaining

Yellow Solid: 11-49% remaining

Red Solid: 3-10% remaining

USB batteries in this USB re-

Inserting the Battery

Charging the Battery

:

To indicate low battery level, the laser beams will

blink quickly 3 times, followed by 4 seconds of solid

on (repeating). Charge the battery.

To charge the battery with laser powered o:

1. Plug your USB cable into a power source such as

an AC wall adaptor, computer, or car port.

2. Lift the rubber cover to expose the micro USB port.

Insert the micro USB plug into the micro USB port.

Users may experience longer charge times from

laptops and other power sources.

3. The indicator light will display the charging status:

Pulsing Red: Charging, 0-49% charged

Pulsing Yellow: Charging, 50-99% charged

Solid Green: 100% Charged.

To charge the battery with laser in use, follow

steps1-2 listed in the section above. The indicator

light will display the charging status:

-

Pulsing Red (Continuous)

Upon removal of USB cable, fuel gauge will display current battery life.

Flashing Red/Green: USB cable inserted without

battery installed & Damaged or Faulty Battery. If

the light indicator ashes red and green, check

that the battery is fully seated into the bay. Remove the battery and reinsert. If the light contin-

ues to ash red and green, the battery may be

extremely hot or cold, or wet. Allow the battery to

cool down, warm up, or dry out and then reinsert.

If the problem persists, contact a MILWAUKEE

service facility.

NOTE: When the laser level is charged during

USE, the indicator light will be Pulsing Red (Con-

tinuous). When the USB cable is disconnected,

the fuel gauge will display current battery life.

laser before starting an operation. Injury/damage

may occur if the laser falls.

Mounting/Adjusting the Laser Level

The adjustable clearance bracket can be used to

mount the laser level in multiple ways:

• Use the embedded magnets to secure the laser level

to framing steel studs, steel beams, etc.

• Use the keyhole slot to hang the laser level on the

wall with a nail or screw.

• Set the laser level on a at surface.

• Position the laser and/or wall mount on a stable

surface.

• Use the ¼" - 20 threaded insert to mount on a tripod.

Hold the bracket and adjust the laser up or down until

the desired clearance is achieved.

To reduce the risk of injury or damage, securely mount/attach the

Adjustable Clearance Bracket

OPERATION

To reduce the risk of injury or tem-

look directly into the laser when it is on.

than those specied herein may result in hazardous radiation exposure.

of each new Laser Level and before exposure to

jobsite conditions. See "Accuracy Field Check"

for information.

4

porary eects on vision, do not

Use of controls or adjustments or

performance of procedures other

Perform the Accuracy Field Check

procedure immediately upon unboxing

To turn on the laser and unlock the pendulum, rotate

NOTICE

66'

1'

the On/O dial to the desired position. The remaining

battery life will be displayed. WARNING! Do not look

directly into laser apertures.

ON Turns ON the laser and unlocks the pendu-

OFF Turns OFF the laser and locks the pen-

1. For best results, place the tool on a work surface

that is:

• sturdy

• level (within 4 degrees of true level)

• free of vibrations

• 90° to the work area

2. Turn on the tool.

3. The tool will self-level when placed on surfaces

within 4 degrees of true level.

4. The tool is ready once the emitted points are continuous and no longer moving on the work surface.

5. If the tool cannot achieve a level state (i.e., the

work surface is > 4 degrees o true level), the laser

points will ash rapidly (3 ashes per second).

Relocate or adjust the work surface.

If the tool does not turn on:

• Ensure battery is installed properly. Fuel gauge

should indicate remaining charge when correctly

installed.

• Ensure battery is charged.

• Ensure the tool's internal temperature is within

specied operating ranges. If stored in excessive

heat or cold, allow at least 2 hours to acclimate to

ambient temperature before turning on the tool.

If problem persists, please contact a MILWAUKEE

service facility for support.

Turning On/O

lum to enable self-leveling.

dulum. When not in use, turn o the tool

and store the Laser Level in the protective

carrying case.

Using the Laser Level

Troubleshooting

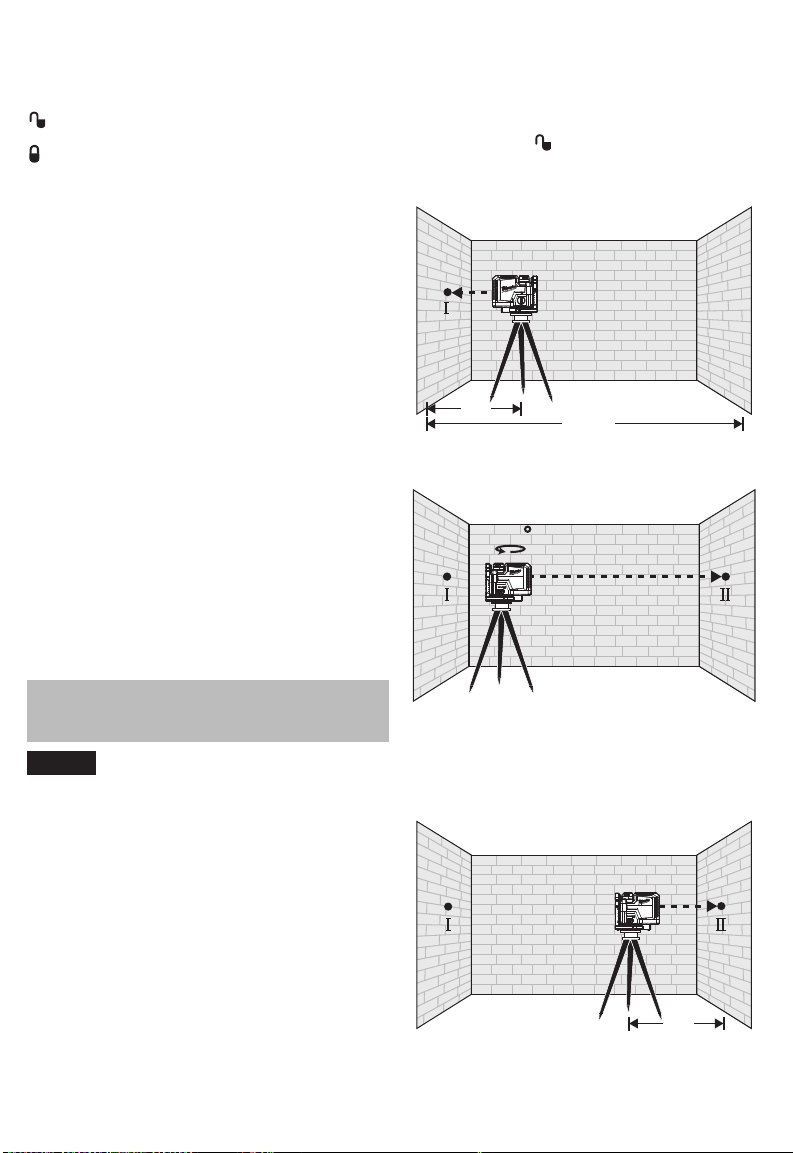

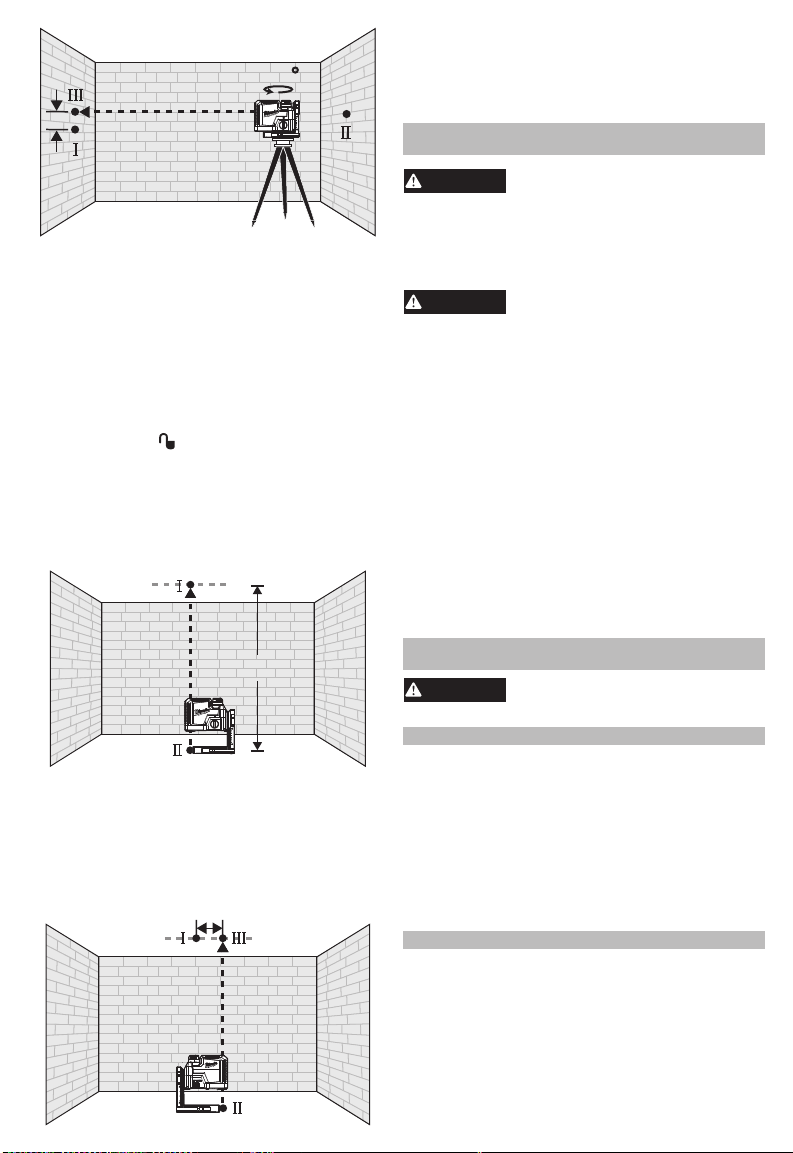

Horizontal Leveling Accuracy

A free measuring distance of approximately 66' on a

rm surface between two walls or structures A and

B is required for this check.

It is also suggested to mount the Laser Level to a

commercially available Tripod for easy adjustment.

1. Securely mount the tool within 1' of wall A.

2. Turn the tool to

3. Direct the front laser beam against the nearest

wall A and allow to self-level. Mark the center of

the laser point on the wall (point I).

ON.

A B

1'

4. Rotate the tool 180° without changing the height,

allow it to self-level, and mark the center point of

the laser point on the opposite wall B (point II).

A B

180

ACCURACY FIELD

CHECK

Perform the Accuracy Field Check

of each new Laser Level and before exposure to

jobsite conditions. See "Accuracy Field Check"

for information. Should any deviation from listed

product accuracy be found, please contact a MILWAUKEE service facility. Failure to do

so could result in rejection of warranty claim.

Ambient temperature gradients can impact laser

accuracy. For accurate and repeatable results, the

following procedure should be conducted with the

laser elevated o the ground and placed in the center

of the working area.

Abusive treatment of the Laser Level, such as excessive impacts from drop, can also lead to deviations

in product accuracy.

Therefore, it is recommended to conduct the Field

Check procedure after any impact or before completing any critical jobs.

procedure immediately upon unboxing

Inuences on Accuracy

5. Move the tool within 1' of wall B. Turn on the tool

and align the front laser point in the general direction of point II on wall B.

6. Adjust the height of the tool (using the tripod or by

adding shims, if required) to align the center point

of the laser beam directly onto point II on wall B.

Allow the tool to self-level.

A B

7. Rotate the tool 180° without changing the height,

allow it to self-level, and mark the center point of

the laser beam on wall A (point III). Point III should

be aligned as vertically above or below point I on

wall A as possible.

5

A

d

WARNING

WARNING

WARNING

d

8. The distance between points I and III on wall A is

the height deviation (d) of the tool. This distance

should not exceed 1/8" (max.) at 33' (1/2" at 132').

For the Measuring distance of 2 x 66' = 132', the maximum allowable deviation (d) is: 132' x ±1/8" ÷ 33' = ±1/2".

A free measuring distance of approximately 16.5'

between oor and ceiling on a rm surface is required

for this check.

1. Draw a straight line on the ceiling to use as a

2. Securely mount the tool within 1' of the oor.

3. Turn the tool to

4. Position the tool so that the bottom plumb point

5. Mark the center of the top plumb point with the refer-

Vertical Leveling Accuracy

reference line.

ON.

can be seen on the oor and the center of the top

plumb point is located on the reference line on the

ceiling. Allow the tool to self-level.

ence line on the ceiling (point I). Also, mark the center of the bottom plumb point on the oor (point II).

180

B

9. The distance between points I and III on the ceiling

is the deviation (d) of the tool. This distance should

not exceed 1/8" (max.) at 33'.

For the Measuring distance of 2 x 16.5' = 33', the

maximum allowable deviation (d) is: 33' x ±1/8"

÷ 33' = ±1/8".

MAINTENANCE

To reduce the risk of injury, always

ing any maintenance. Never disassemble the tool.

Maintain tools. If damaged, have the tool repaired

before use. Accidents may be caused by poorly

maintained tools.

your tool in liquid or allow a liquid to ow inside

them.

Clean dust and debris from any vents. Keep tool

clean, dry and free of oil or grease. Use only mild

soap and a damp cloth to clean, since certain cleaning agents and solvents are harmful to plastics

and other insulated parts. Some of these include

gasoline, turpentine, lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia and

household detergents containing ammonia. Never

use ammable or combustible solvents around tools.

Blow o loose particles with clean compressed air.

Carefully wipe the surface with a cotton swab moistened with water.

For repairs, return the tool, battery pack and charger

to the nearest authorized service center.

remove the battery before perform-

Maintain Laser Level

To reduce the risk of personal injury and damage, never immerse

Cleaning

Cleaning the Lenses

Repairs

16.5'

6. Rotate the tool 180°. Align the center point of the

laser beam directly onto the oor point II.

7. Position the tool to align the center of the top plumb

point onto the reference line on the ceiling. It may

be necessary to rotate the tool slightly to align.

Allow the tool to self-level.

8. Mark the center of the top plumb point on the

reference line on the ceiling (point III).

ACCESSORIES

Use tools only with specifically

any other accessories may create risk of injury.

1-800-SAWDUST (1.800.729.3878)

Monday-Friday, 7:00 AM - 6:30 PM CST

Contact Corporate After Sales Service Technical Support

with technical, service/repair, or warranty questions.

Email: metproductsupport@milwaukeetool.com

Become a Heavy Duty Club Member at

www.milwaukeetool.com to receive important

notications regarding your tool purchases.

Milwaukee Tool (Canada) Ltd

Monday-Friday, 7:00 AM - 4:30 PM CST

6

designated accessories. Use of

SERVICE - UNITED STATES

or visit www.milwaukeetool.com

SERVICE - CANADA

1.800.268.4015

or visit www.milwaukeetool.ca

Loading...

Loading...