Milwaukee 2705-20, 2706-20, 2757-20, 2758-20, 2759-20 Operator's Manual

...

Cat. No. / No de cat.

2705-20, 2706-20

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT Afi n de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

M18™ FUEL™ 1/2" DRILL/DRIVER AND HAMMER DRILL/DRIVER

PERCEUSE-VISSEUSE ET PERCEUSE À PERCUSSION DE

M18™ FUEL™ 13 mm (1/2")

TALADRO DESTORNILLADOR Y TALADRO DE PERCUSIÓN

DE 13 mm (1/2") M18™ FUEL™

2

3

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING

Read all safety warnings, instructions, illustrations and specifi ca-

tions provided with this power tool. Failure to

follow all instructions listed below may result in

electric shock, fi re and/or serious injury. Save all

warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of an GFCI

reduces the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the infl uence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as a dust mask, non-skid safety shoes, hard hat or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your fi nger

on the switch or energizing power tools that have

the switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

• Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage of parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for

operations different from those intended could result

in a hazardous situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

BATTERY TOOL USE AND CARE

• Recharge only with the charger specifi ed by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fi re when used

with another battery pack.

• Use power tools only with specifi cally desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and fi re.

• When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal

to another. Shorting the battery terminals together

may cause burns or a fi re.

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation

or burns.

• Do not use a battery pack or tool that is damaged or modifi ed. Damaged or modifi ed batteries

may exhibit unpredictable behavior resulting in fi re,

explosion or risk of injury.

• Do not expose a battery pack or tool to fi re or

excessive temperature. Exposure to fi re or tem-

perature above 265°F (130°C) may cause explosion.

• Follow all charging instructions and do not

charge the battery pack or tool outside the

temperature range specifi ed in the instructions.

Charging improperly or at temperatures outside

the specifi ed range may damage the battery and

increase the risk of fi re.

SERVICE

• Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

• Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorized service providers.

SPECIFIC SAFETY RULES FOR

DRILLS AND IMPACT DRILLS

• Wear ear protectors when impact drilling. Exposure to noise can cause hearing loss.

• Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

• Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring. Cutting ac-

cessory contacting a “live” wire may make exposed

metal parts of the power tool “live” and could give

the operator an electric shock.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

•

WARNING

Some dust created by power sand-

ing, sawing, grinding, drilling, and

other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals

are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to fi lter out microscopic particles.

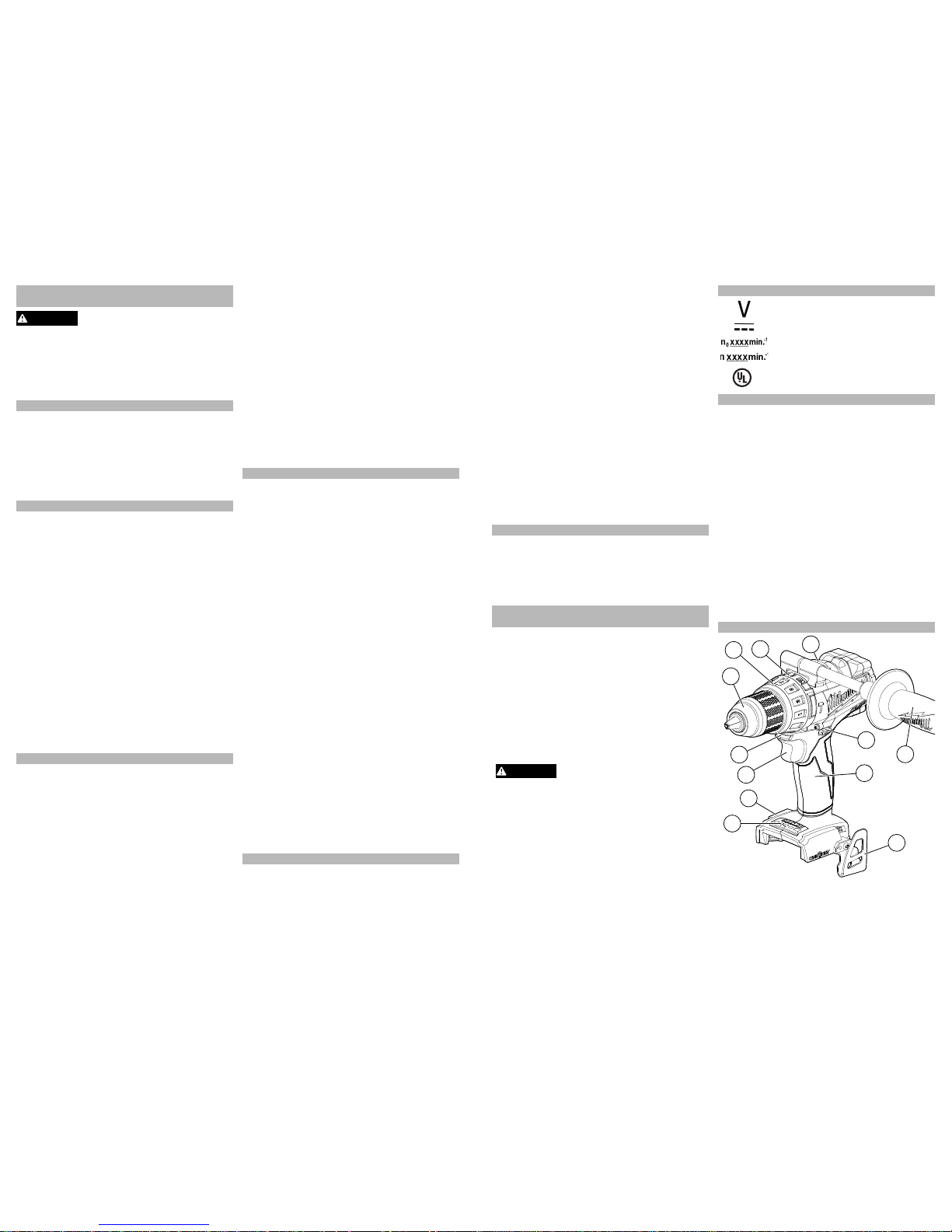

SYMBOLOGY

Volts

Direct Current

No-Load Revolutions per Minute (RPM)

Blows per Minute Under Load (BPM)

C

US

Underwriters Laboratories, Inc.

United States and Canada

SPECIFICATIONS

Cat. No. .....................................................2705-20

Volts ..............................................................18 DC

Battery Type .................................................M18™

Charger Type ................................................M18™

No Load RPM .............Low 0 - 550 / High 0 - 2 000

Steel .................................................................1/2"

Flat Bit in Wood .............................................1-1/2"

Auger Bit in Wood ..........................................1-1/2"

Hole Saw in Wood ...............................................3"

Screws in Wood ............................................ Ø 3/8"

Cat. No. .....................................................2706-20

Volts ..............................................................18 DC

Battery Type .................................................M18™

Charger Type ................................................M18™

No Load RPM .............Low 0 - 550 / High 0 - 2 000

BPM ................................................High 0 - 32,000

Steel .................................................................1/2"

Flat Bit in Wood .............................................1-1/2"

Auger Bit in Wood ..........................................1-1/2"

Hole Saw in Wood ...............................................3"

Screws in Wood ............................................ Ø 3/8"

Masonry ............................................................5/8"

FUNCTIONAL DESCRIPTION

3

4

2

5

6

1

7

8

9

10

11

12

1. Mode selector

2. Bit holder

3. Trigger

4. LED

5. Keyless chuck 9. Side handle

6. Torque selector collar 10. Control switch

7. Application selector collar 11. Handle

8. Speed selector 12. Belt hook

4

5

Allow the tool to come to a complete stop before

changing modes. Press the selector button to

cycle between the settings. Select wireless to

change the default RPM settings via the ONE-KEY

App on your smart device.

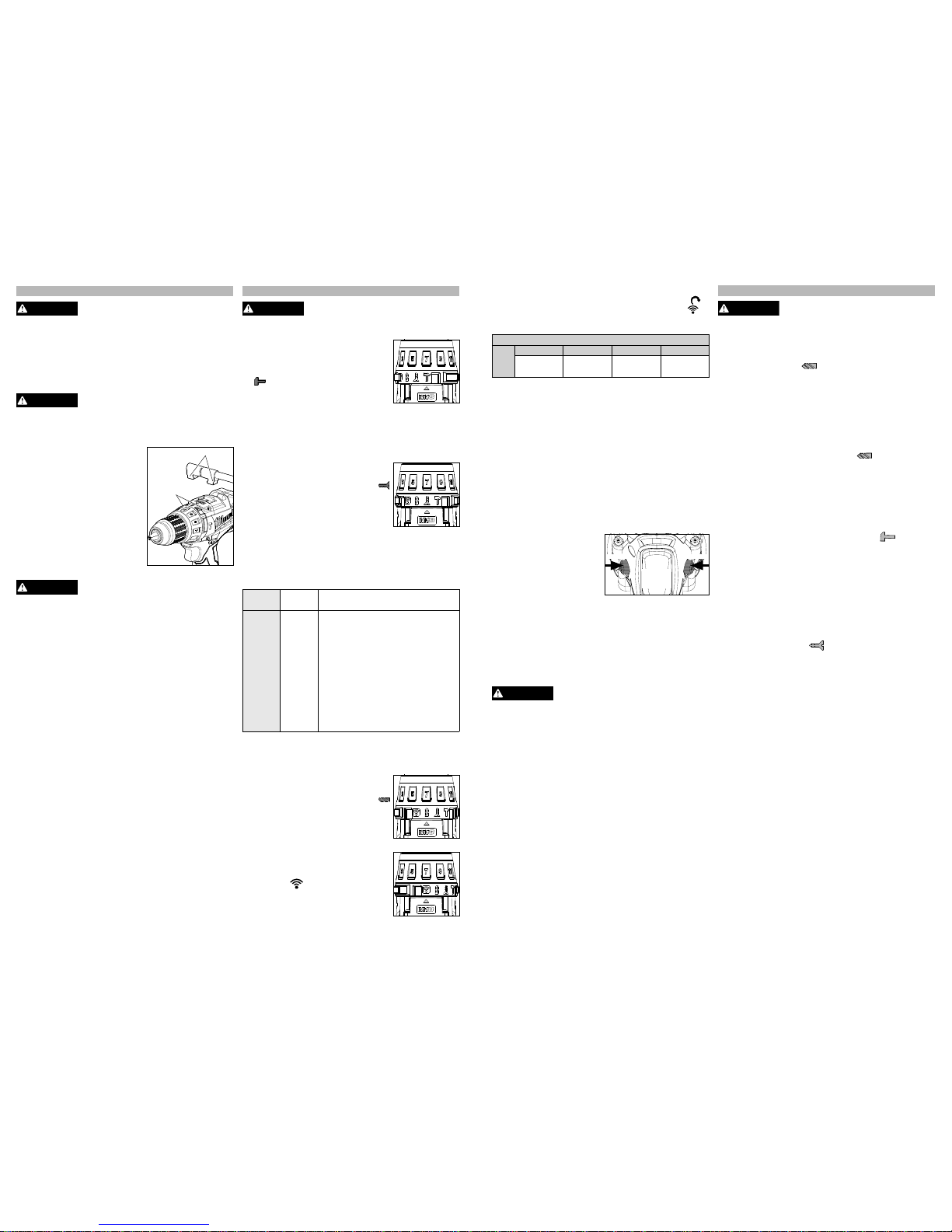

Default Max RPM

High

Low

Setting 1 Setting 2 Setting 3 Setting 4

1 200

300

1 450

375

1 700

425

2 000

500

Selecting Speed

The speed selector is on top of the motor housing.

Allow the tool to come to a complete stop before

changing speeds. See “Applications” for recommended speeds under various conditions.

1. For Low speed, push the speed selector to display

“1”.

2. For High speed, push the speed selector to display

“2”.

Using the Control Switch

The control switch may be set to three positions:

forward, reverse and lock. Due to a lockout mechanism, the control switch can only be adjusted when

the ON/OFF switch is not pressed. Always allow the

motor to come to a complete stop before using the

control switch.

Lock

Push to

CENTER

Reverse

Forward

For forward (clockwise)

rotation, push in the control switch from the right

side of the tool. Check

the direction of rotation

before use.

For reverse (counterclockwise) rotation, push in the

control switch from the left side of the tool. Check

direction of rotation before use.

To lock the trigger, push the control switch to the

center position. The trigger will not work while the

control switch is in the center locked position. Always

lock the trigger or remove the battery pack before

performing maintenance, changing accessories,

storing the tool and any time the tool is not in use.

WARNING

To reduce the risk of injury , always

always hold or brace securely.

Starting, Stopping and Controlling Speed

1. To start the tool, grasp the handles fi rmly and pull

the trigger.

NOTE: An LED is turned on when the trigger is

pulled.

2. To vary the speed, increase or decrease the pres-

sure on the trigger. The further the trigger is pulled,

the greater the speed.

3. To stop the tool, release the trigger. Make sure

the bit comes to a complete stop before laying the

tool down.

Drilling

Place the bit on the work surface and apply fi rm pres-

sure before starting. T oo much pressure will slow the

bit and reduce drilling effi ciency. Too little pressure

will cause the bit to slide over the work area and dull

the point of the bit.

If the tool begins to stall, reduce pressure slightly to

allow the bit to regain speed. If the bit binds, reverse

the motor to free the bit from the workpiece.

ASSEMBLY

WARNING

Recharge only with the charger

specifi ed for the battery. For spe-

cifi c charging instructions, read the operator’s

manual supplied with your charger and battery.

Inserting/Removing the Battery

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body

of the tool. Make sure it latches securely into place.

WARNING

To reduce the risk of injury , always

use a side handle when using this

tool. Always brace or hold securely . Ensure side

handle is tightened securely before each use.

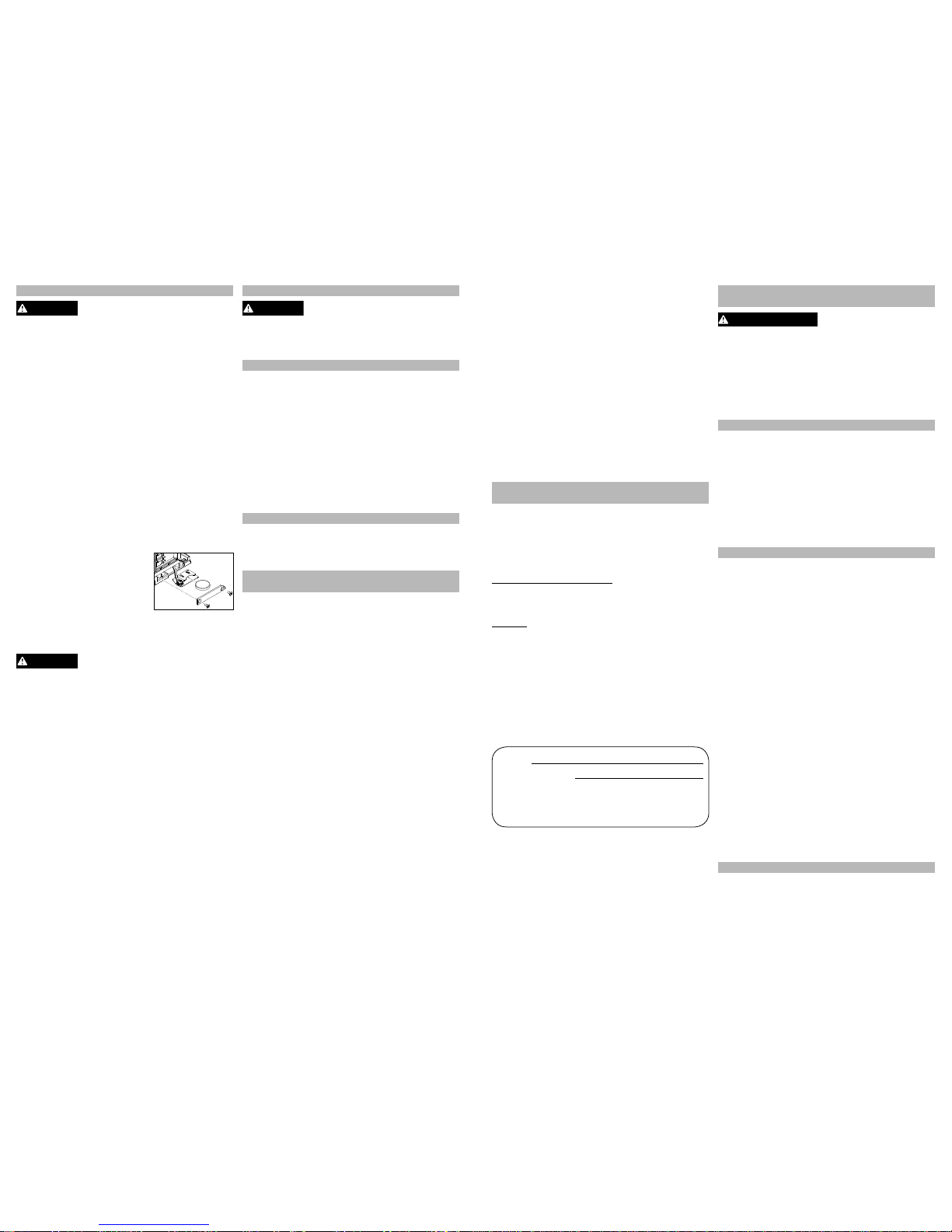

Installing the Side Handle

1. To install the side handle,

Hooks

Slots

loosen the side handle grip

until the hooks are far

enough apart to fi t into the

slots on the gear case ring.

Position the side handle on

the top, pointing to the left or

right. Tighten the side handle grip until it is secure.

2. To remove the side handle,

loosen the side handle grip

until the side handle can be

removed. Reposition and

tighten securely.

WARNING

Always remove battery pack before

changing or removing accessories. Only use accessories specifi cally recom-

mended for this tool. Others may be hazardous.

Installing Bits

Always remove the battery before inserting or removing bits. Select the proper style and size bit for the job.

This tool is equipped with a spindle lock. The chuck

can be tightened with one hand, creating higher grip

strengths on the bit.

1. To open the chuck jaws, turn the sleeve in the

counterclockwise direction.

When using drill bits, allow the bit to strike the

bottom of the chuck. Center the bit in the chuck

jaws and lift it about 1/16” off of the bottom.

When using screwdriver bits, insert the bit far

enough for the chuck jaws to grip the hex of the

bit.

2. To close the chuck jaws, turn the sleeve in the

clockwise direction. The bit is secure when the

chuck makes a ratcheting sound and the sleeve

can not be rotated any further.

3. To remove the bit, turn the sleeve in the counter-

clockwise direction.

NOTE: A ratcheting sound may be heard when the

chuck is opened or closed. This noise is part of the

locking feature, and does not indicate a problem with

the chuck’s operation.

ONE-KEY™

To learn more about the ONE-KEY functionality for

this tool, please reference the Quick Start guide included with this product or go to milwaukeetool.com/

One-Key. To download the ONE-KEY app, visit the

App Store or Google Play from your smart device.

APPLICATIONS

WARNING

To reduce the risk of electric shock,

check work area for hidden pipes

and wires before drilling or driving screws.

Drilling in Wood, Composition

Materials and Plastic

When drilling in wood, composition materials and

plastic, select the

drill-only operating mode.

Start the drill slowly, gradually increasing speed as

you drill. When drilling into wood, use wood augers

or twist drill bits. Always use sharp bits. When using

twist drill bits, pull the bit out of the hole frequently to

clear chips from the bit fl utes. To reduce the chance of

splintering, back work with a piece of scrap wood. Select low speeds for plastics with a low melting point.

Drilling in Metal

When drilling in metal, select the drill-only operating mode. Use high speed steel twist drills or hole

saws. Use a center punch to start the hole. Lubricate

drill bits with cutting oil when drilling in iron or steel.

Use a coolant when drilling in nonferrous metals such

as copper, brass or aluminum. Back the material

to prevent binding and distortion on breakthrough.

Drilling in Masonry

When drilling in masonry, select the hammer

drill operating mode. Use high speed carbidetipped bits. Drilling soft masonry materials such

as cinder block requires little pressure. Hard

materials like concrete require more pressure.

A smooth, even fl ow of dust indicates the proper

drilling rate. Do not let the bit spin in the hole

without cutting. Do not use water to settle dust or

to cool bit. Both actions will damage the carbide.

Driving Screws and Nut Running

Drill a pilot hole when driving screws into thick or hard

materials. Select the driving screws mode. Set

the torque selector collar to the proper position and

set the speed to low. Use the proper style and size

screwdriver bit for the type of screw you are using.

With the screwdriver bit in the screw, place the tip of

the screw on the workpiece and apply fi rm pressure

before pulling the trigger. Screws can be removed

by reversing the motor.

Overloading

Continuous overloading may cause permanent damage to tool or battery pack.

OPERATION

WARNING

To reduce the risk of injury, wear

safety goggles or glasses with side

shields.

Selecting Action

1. To use the hammer-drilling

mode (Cat. No. 2706-20 only),

rotate the application selector

collar until the hammer symbol

appears in line with the arrow.

Apply pressure to the bit to engage the hammering mechanism.

NOTE: The number selected on the torque selec-

tor collar has no effect on operation of the drill in

this mode.

NOTE: When using carbide bits, do not use water

to settle dust. Do not attempt to drill through steel

reinforcing rods. This will damage the carbide bits.

2. To use the driving screws mode

rotate the application selector

collar until the drive symbol

appears in line with the arrow.

Then rotate the torque selector

collar until the desired clutch setting appears in line with the arrow.

The adjustable clutch, when properly adjusted, will

slip at a preset torque to prevent driving the screw

too deep into different materials and to prevent

damage to the screw or tool.

The torque specifi cations shown here are approximate

values obtained with a fully charged battery pack.

Clutch

Setting in. lbs Applications

1

2

3

4

5

6

7

8

9

10

11

12

13

30

35

40

45

50

55

60

65

70

75

80

85

90

Small screws in softwood.

Medium screws in softwood or

small screws in hardwood.

Large screws in softwoods. Medium screws in hardwood or large

screws in hardwood with pilot hole.

NOTE: Because the settings shown in the table are

only a guide, use a piece of scrap material to test

the different clutch settings before driving screws

into the workpiece.

3. To use the drilling only mode,

rotate the application selector

collar until the drill symbol

appears in line with the arrow.

NOTE: The number selected on

the torque selector collar has no

effect on operation of the drill in

this mode.

4. To use the Mode Selector

buttons, rotate the application

selector collar until the wireless

symbol

appears in line with

the arrow.

NOTE: The number selected

on the torque selector collar has

no effect on operation of the drill in this mode.

Hammer-drilling is not available in this mode.

6

7

MAINTENANCE

WARNING

To reduce the risk of injury , always

unplug the charger and remove the

battery pack from the charger or tool before

performing any maintenance. Never disassemble

the tool, battery pack or charger. Contact a

MILWAUKEE service facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

After six months to one year, depending on use,

return the tool, battery pack and charger to A

MILWAUKEE service facility for:

• Lubrication

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (battery pack, charger, motor)

• T esting to assure proper mechanical and electrical

operation

If the tool does not start or operate at full power with

a fully charged battery pack, clean the contacts on

the battery pack. If the tool still does not work properly, return the tool, charger and battery pack, to a

MILWAUKEE service facility for repairs.

Internal Battery

An internal battery is used to facilitate full ONE-KEY™

functionality.

To replace the battery:

1. Remove the battery pack.

+

2. Remove the two screws hold-

ing the battery door.

3. Pull out the battery board and

remove the old battery.

4. Insert the new battery (3V CR2032), with the posi-

tive site away from the board.

5. Slide the board back into the tool and replace the

battery door and screws.

WARNING

To reduce the risk of personal in-

jury and damage, never immerse

your tool, battery pack or charger in liquid or

allow a liquid to fl ow inside them.

Cleaning

Clean dust and debris from charger and tool vents.

Keep tool handles clean, dry and free of oil or grease.

Use only mild soap and a damp cloth to clean the

tool, battery pack and charger since certain cleaning

agents and solvents are harmful to plastics and other

insulated parts. Some of these include gasoline,

turpentine, lacquer thinner, paint thinner , chlorinated

cleaning solvents, ammonia and household detergents containing ammonia. Never use fl ammable or

combustible solvents around tools.

Repairs

For repairs, return the tool, battery pack and charger

to the nearest service center.

ACCESSORIES

WARNING

Always remove battery pack before

changing or removing accessories. Only use accessories specifi cally recom-

mended for this tool. Others may be hazardous.

For a complete listing of accessories, go online to

www.milwaukeetool.com or contact a local distributor .

SERVICE - UNITED STATES

1-800-SAWDUST (1.800.729.3878)

Monday-Friday, 7:00 AM - 6:30 PM CST

or visit www.milwaukeetool.com

Contact Corporate After Sales Service Technical

Support with technical, service/repair, or warranty

questions.

Email: metproductsupport@milwaukeetool.com

Register your tool at www.milwaukeetool.com...

• to receive important notifi cations regarding your

purchase

• to ensure that your tool is protected under the warranty

• to become a Heavy Duty club member

SERVICE - CANADA

Milwaukee Tool (Canada) Ltd

1.800.268.4015

Monday-Friday, 7:00 AM - 4:30 PM CST

or visit www.milwaukeetool.ca

LIMITED W ARRANTY

USA & CANADA

Every MILWAUKEE power tool (including cordless product – tool,

battery pack(s) - see separate & distinct CORDLESS BATTERY

PACK LIMITED WARRANTY statements & battery charger and W ork

Lights*) is warranted to the original purchaser only to be free from

defects in material and workmanship. Subject to certain exceptions,

MILWAUKEE will repair or replace any part on an electric power tool

which, after examination, is determined by MILWAUKEE to be defective in material or workmanship for a period of fi ve (5) years* after the

date of purchase unless otherwise noted. Return of the power tool

to a MILWAUKEE factory Service Center location or MILWAUKEE

Authorized Service Station, freight prepaid and insured, is required.

A copy of the proof of purchase should be included with the return

product. This warranty does not apply to damage that MILWAUKEE

determines to be from repairs made or attempted by anyone other

than MILWAUKEE authorized personnel, misuse, alterations, abuse,

normal wear and tear, lack of maintenance, or accidents.

*The warranty period for, Job Site Radios, M12™ Power Port, M18™

Power Source, Jobsite Fan and Trade Titan™ Industrial Work Carts

is one (1) year from the date of purchase. The warranty period for a

LED Work Light and LED Upgrade Bulb is a limited LIFETIME warranty to the original purchaser only, if during normal use the LED bulb

fails the Work Light or Upgrade Bulb will be replaced free of charge.

*This warranty does not cover Air Nailers & Stapler, Airless Paint

Sprayer, Cordless Battery Packs, Gasoline Driven Portable Power

Generators, Hand Tools, Hoist – Electric, Lever & Hand Chain, M12™

Heated Jackets, Reconditioned product and Test & Measurement

products. There are separate and distinct warranties available for

these products.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE power tool product. The manufacturing date

of the product will be used to determine the warranty period if no proof

of purchase is provided at the time warranty service is requested.

ACCEPTANCE OF THE EXCLUSIVE REP AIR AND REPLACEMENT

REMEDIES DESCRIBED HEREIN IS A CONDITION OF THE CONTRACT FOR THE PURCHASE OF EVERY MIL WAUKEE PRODUCT.

IF YOU DO NOT AGREE TO THIS CONDITION, YOU SHOULD NOT

PURCHASE THE PRODUCT. IN NO EVENT SHALL MIL WAUKEE BE

LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL OR

PUNITIVE DAMAGES, OR FOR ANY COSTS, ATTORNEY FEES,

EXPENSES, LOSSES OR DELAYS ALLEGED TO BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN

ANY PRODUCT INCLUDING, BUT NOT LIMITED TO, ANY CLAIMS

FOR LOSS OF PROFITS. SOME STA TES DO NOT ALLOW THE EXCLUSION OR LIMITA TION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMIT ATION OR EXCLUSION MA Y NOT

APPLY TO YOU. THIS WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER EXPRESS WARRANTIES, WRITTEN OR ORAL.

TO THE EXTENT PERMITTED BY LAW, MILWAUKEE DISCLAIMS

ANY IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR USE OR PURPOSE; TO THE EXTENT SUCH

DISCLAIMER IS NOT PERMITTED BY LAW, SUCH IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THE APPLICABLE

EXPRESS WARRANTY AS DESCRIBED ABOVE. SOME STATES

DO NOT ALLOW LIMIT ATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO

YOU, THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

STA TE T O STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

Please consult the ‘Service Center Search’ in the Parts & Service section of MILWAUKEE’s website www .milwaukeetool.com or call 1.800.

SAWDUST (1.800.729.3878) to locate your nearest service facility for

warranty and non-warranty service on a Milwaukee electric power tool.

LIMITED WARRANTY - MEXICO,

CENTRAL AMERICA & CARIBBEAN

TECHTRONIC INDUSTRIES' warranty is for 5 year since the original

purchase date.

This warranty card covers any defect in material and workmanship

on this Power Tool.

To make this warranty valid, present this warranty card, sealed/

stamped by the distributor or store where you purchased the product,

to the Authorized Service Center (ASC). Or, if this card has not been

sealed/stamped, present the original proof of purchase to the ASC.

Call toll-free 1 800 832 1949 to fi nd the nearest ASC, for service, parts,

accessories or components.

Procedure to make this warranty valid

Take the product to the ASC, along with the warranty card sealed/

stamped by the distributor or store where you purchased the product,

and there any faulty piece or component will be replaced without

cost for you. We will cover all freight costs relative with this warranty

process.

Exceptions

This warranty is not valid in the following situations:

a) When the product is used in a different manners from the end-user

guide or instruction manual.

b) When the conditions of use are not normal.

c) When the product was modifi ed or repaired by people not authorized

by TECHTRONIC INDUSTRIES.

Note: If cord set is damaged, it should be replaced by an Authorized

Service Center to avoid electric risks.

SERVICE AND ATTENTION CENTER:

Av Presidente Mazarik 29 Piso 7, 11570 Chapultepec Morales

Miguel Hidalgo, Distrito Federal, Mexico

Ph. 52 55 4160-3547

IMPORTED AND COMMERCIALIZED BY:

TECHTRONIC INDUSTRIES MEXICO, .S.A. DE C.V.

Av Presidente Mazarik 29 Piso 7, 11570 Chapultepec Morales

Miguel Hidalgo, Distrito Federal, Mexico

Model:

Date of Purchase:

Distributor or Store Stamp:

RÈGLES DE SÉCURITÉ GÉNÉRALES

RELATIVES AUX OUTILS ÉLECTRIQUES

AVERTISSEMENT

Lire toutes les consignes

de sécurité, consignes,

illustrations et spécifi cations fournies avec cet

outil électrique. Ne pas suivre l’ensemble des règles

et instructions peut entraîner une électrocution, un

incendie ou des blessures graves. Conserver les

règles et les instructions à des fi ns de référence

ultérieure. Le terme «outil électrique» fi gurant dans

les avertissements ci-dessous renvoie à l’outil électrique à alimentation par le réseau (à cordon) ou par

batterie (sans fi l).

SÉCURITÉ DU LIEU DE TRAVAIL

• Veillez à ce que l’aire de travail soit propre et

bien éclairée. Le désordre et le manque de lumière

favorisent les accidents.

• Ne pas utiliser d’outils électriques dans des atmosphères explosives, par exemple en présence

de liquides, gaz ou poussières infl ammables.

Les outils électriques produisent des étincelles

risquant d'enfl ammer les poussières ou vapeurs.

• S’assurer que les enfants et les curieux se trouvent à une bonne distance au moment d’utiliser

un outil électrique. Les distractions peuvent causer

une perte de contrôle.

SÉCURITÉ ÉLECTRIQUE

• Les fi ches des outils électriques doivent cor-

respondre à la prise secteur utilisée. Ne jamais

modifi er la fi che, de quelque façon que ce soit.

Ne jamais utiliser d'adaptateurs de fi che avec

des outils mis à la terre. Les fi ches et prises non

modifi ées réduisent le risque de choc électrique.

• Éviter tout contact avec des surfaces mises à

la terre comme des tuyaux, des radiateurs, des

cuisinières et des réfrigérateurs. Le risque de

choc électrique est accru lorsque le corps est mis

à la terre.

• Ne pas exposer les outils électriques à l'eau ou

l'humidité. La pénétration d’eau dans ces outils

accroît le risque de choc électrique.

• Ne pas maltraiter le cordon d'alimentation.

Ne jamais utiliser le cordon d’alimentation

pour transporter l’outil électrique et ne jamais

débrancher ce dernier en tirant sur le cordon.

Garder le cordon à l'écart de la chaleur, de l'huile,

des objets tranchants et des pièces en mouvement. Un cordon endommagé ou emmêlé accroît

le risque de choc électrique.

• Pour les travaux à l’extérieur, utiliser un cordon

spécialement conçu à cet effet. Utiliser un cordon

conçu pour l'usage extérieur réduit les risques de

choc électrique.

• Si l’utilisation d’un outil électrique est inévitable

dans un endroit humide, utiliser une source

d’alimentation munie d’un disjoncteur de fuite

de terre. L’utilisation d’un disjoncteur de fuite de

terre réduit le risque de choc électrique. sécurité

individuelle

SÉCURITÉ INDIVIDUELLE

• Rester attentif, prêter attention au travail et faire

preuve de bon sens lors de l'utilisation de tout

outil électrique. Ne pas utiliser cet appareil en

cas de fatigue ou sous l’infl uence de l’alcool,

de drogues ou de médicaments. Un moment

d’inattention pendant l’utilisation d’un outil électrique

peut entraîner des blessures graves.

Loading...

Loading...