Milwaukee 2738-20 Operator's Manual

Cat. No. / No de cat.

2738-20

M18™ 7" VARIABLE SPEED POLISHER

POLISSEUSE À VITESSE VARIABLE M18™ DE 180 mm (7")

PULIDORA M18™ DE 180 mm (7") DE VELOCIDAD VARIABLE

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

2

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING

Read all safety warnings, instructions, illustrations and specifica-

tions provided with this power tool. Failure to follow

all instructions listed below may result in electric shock,

re and/or serious injury. Save all warnings and in

-

structions for future reference. The

term "power tool"

in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmo

-

spheres, such as in the presence of ammable

liquids,

gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Un

-

modied plugs and matching outlets will reduce

risk

of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi

-

tions. W

ater entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for car

rying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk

of electric shock.

• When operating a power tool outdoors, use an ex

-

tension cord suitable for outdoor use. Us

e of a cord

suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not

use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result

in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as a dust

mask, non-skid safety shoes, hard hat or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your nger on the

switch or energizing power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a ro

-

tating part of the power tool may result in personal injury.

•

Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair can

be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust col

-

lection can reduce dust-related hazards.

•

Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it was designed.

• Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting

the power tool accidentally.

• Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool. Pow

-

er tools are dangerous in the hands of untrained

users.

• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused

by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly main

-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a hazard

-

ous situation.

•

Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles

and grasping surfaces do not allow for safe handling

and control of the tool in unexpected situations.

BATTERY TOOL USE AND CARE

• Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of re when used with

another battery pack.

• Use power tools only with specically designated

battery packs. Use of any other battery packs may

create a risk of injury and re.

• When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys,

nails, screws or other small metal objects, that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause

burns or a re.

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact ac

cidentally occurs, ush with water. If liquid contacts eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

• Do not use a battery pack or tool that is damaged or

modied. Damaged or modied batteries may exhibit

3

unpredictable behavior resulting in re, explosion or

risk of injury.

• Do not expose a battery pack or tool to re or ex

-

cessive temperature. Exposure to re or temperature

above 265°F (130°C) may cause explosion.

• Follow all charging instructions and do not charge

the battery pack or tool outside the temperature

range specied in the instructions. Charging im

-

properly or at temperatures outside the specied range

may damage the battery and increase the risk of re.

SERVICE

• Have your power tool serviced by a qualied repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

• Never service damaged battery packs. Service of

battery packs should only be performed by the manu

-

facturer or authorized service providers.

SPECIFIC SAFETY RULES FOR

POLISHERS

Safety Warnings Common for Polishing:

• This power tool is intended to function as a polish

-

er. Read all safety warnings, instructions, illustra-

tions and specications provided with this power

tool. Failure to follow all instructions listed below

may result in electric shock, re and/or serious injury.

• Operations such as grinding, sanding, wire brush

ing or cutting-off are not recommended to be performed with this power tool. Operations for which

the power tool was not designed may create a hazard

and cause personal injury.

• Do not use accessories which are not specically

designed and recommended by the tool manufac

turer. Just because the accessory can be attached to

your power tool, it does not assure safe operation.

• The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated speed

can break and y apart.

• The outside diameter and the thickness of your

accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories cannot

be adequately guarded or controlled.

• Threaded mounting of accessories must match the

polisher spindle thread. For accessories mounted

by anges, the arbour hole of the accessory must

t the locating diameter of the ange. Accessories

that do not match the mounting hardware of the power

tool will run out of balance, vibrate excessively and may

cause loss of control.

• Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheels for

chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires.

If power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After

inspecting and installing an accessory, position

yourself and bystanders away from the plane of the

rotating accessory and run the power tool at maxi

-

mum no-load speed for one minute. Damaged ac-

cessories will normally break apart during this test time.

• Wear personal protective equipment. Depending

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece

fragments. The eye protection must be capable of

stopping ying debris generated by various operations.

The dust mask or respirator must be capable of ltrating

particles generated by your operation. Prolonged ex

-

posure to high intensity noise may cause hearing loss.

• Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of work

-

piece or of a broken accessory may y away and cause

injury beyond immediate area of operation.

• Never lay the power tool down until the accessory

has come to a complete stop. The spinning acces

-

sory may grab the surface and pull the power tool out

of your control.

• Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could

snag your clothing, pulling the accessory into your body.

• Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause

electrical hazards.

• Do not operate the power tool near ammable

materials. Sparks could ignite these materials.

• Do not use accessories that require liquid cool

-

ants. Using water or other liquid coolants may result

in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other acces

-

sory. Pinching or snagging causes rapid stalling of the

rotating accessory which in turn causes the uncon

-

trolled power tool to be forced in the direction opposite

of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched

by the workpiece, the edge of the wheel that is enter

-

ing into the pinch point can dig into the surface of the

material causing the wheel to climb out or kick out. The

wheel may either jump toward or away from the opera

-

tor, depending on direction of the wheel’s movement at

the point of pinching. Abrasive wheels may also break

under these conditions.

Kickback is the result of power tool misuse and/or in

-

correct operating procedures or conditions and can be

avoided by taking proper precautions as given below.

• Maintain a rm grip on the power tool and position

your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction

during start-up. The operator can control torque reac

-

tions or kickback forces, if proper precautions are taken.

• Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

• Do not position your body in the area where power

tool will move if kickback occurs. Kickback will

propel the tool in direction opposite to the wheel’s

movement at the point of snagging.

• Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the ac

-

cessory. Corners, sharp edges or bouncing have a

tendency to snag the rotating accessory and cause

loss of control or kickback.

• Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety Warnings Specic for Polishing Operations:

• Do not allow any loose portion of the polishing

bonnet or its attachment strings to spin freely.

Tuck away or trim any loose attachment strings.

Loose and spinning attachment strings can entangle

your ngers or snag on the workpiece.

Additional Safety Warnings

• Maintain labels and nameplates. These carry im

-

portant information. If unreadable or missing, contact

a MILWAUKEE service facility for a free replacement.

4

ASSEMBLY

WARNING

Recharge only with the charger

specied for the battery. For specic charging instructions, read the operator’s

manual supplied with your charger and battery.

Removing/Inserting the Battery

To remove the battery, push in the release buttons and

pull the battery pack away from the tool.

WARNING

Always remove battery pack before

changing or removing accessories.

To insert the battery, slide the pack into the body of the

tool. Make sure it latches securely into place.

WARNING

To reduce the risk of injury, always

use a side handle when using this

tool. Hold securely.

Installing Side Handle

The side handle may be installed on either side of

the gear case. Position the side handle in the location which offers best control and guard protection.

To install, thread side handle into handle socket and

tighten securely.

Installing the Bail Handle

1. Remove battery pack.

2. Remove side handle.

3. Position the bail handle in the position (left or right

orientation) that offers best control.

4. Slide the handle around the front of the tool and up

onto the body of the tool.

5. Fit the handle into both handle sockets.

6. Select one of the three angle positions that offers

best control - forward, 90°, or back.

7. Insert the hex cap screws into each side of the bail

handle and tighten securely with the hex wrench

provided.

Installing/Removing/Cleaning

the Dust Screen

Using the dust screen will increase the performance

and extend the life of the tool.

CAUTION Do not use tool without dust screen in-

stalled.

1. To attach the dust screen, snap the screen over the

tool’s handle.

2. To remove the dust screen, insert a at screwdriver

into the notch at the top of the dust screen and pry

away from the tool.

3. To clean the dust screen, tap against a hard surface,

or blow clean with compressed air.

Using the Trigger Lock

The trigger can be locked off for storage and transport,

unlocked for use, or locked on for continuous use.

1. To LOCK OFF the trigger, press the trigger lock from

the locked side of the tool.

2. To UNLOCK the trigger, press the trigger lock from

the unlocked side of the tool.

3. To LOCK ON the trigger for continuous use, pull

the trigger and press in the trigger lock from the

unlocked side of the tool. Release the trigger.

To stop the tool, pull and release the trigger again.

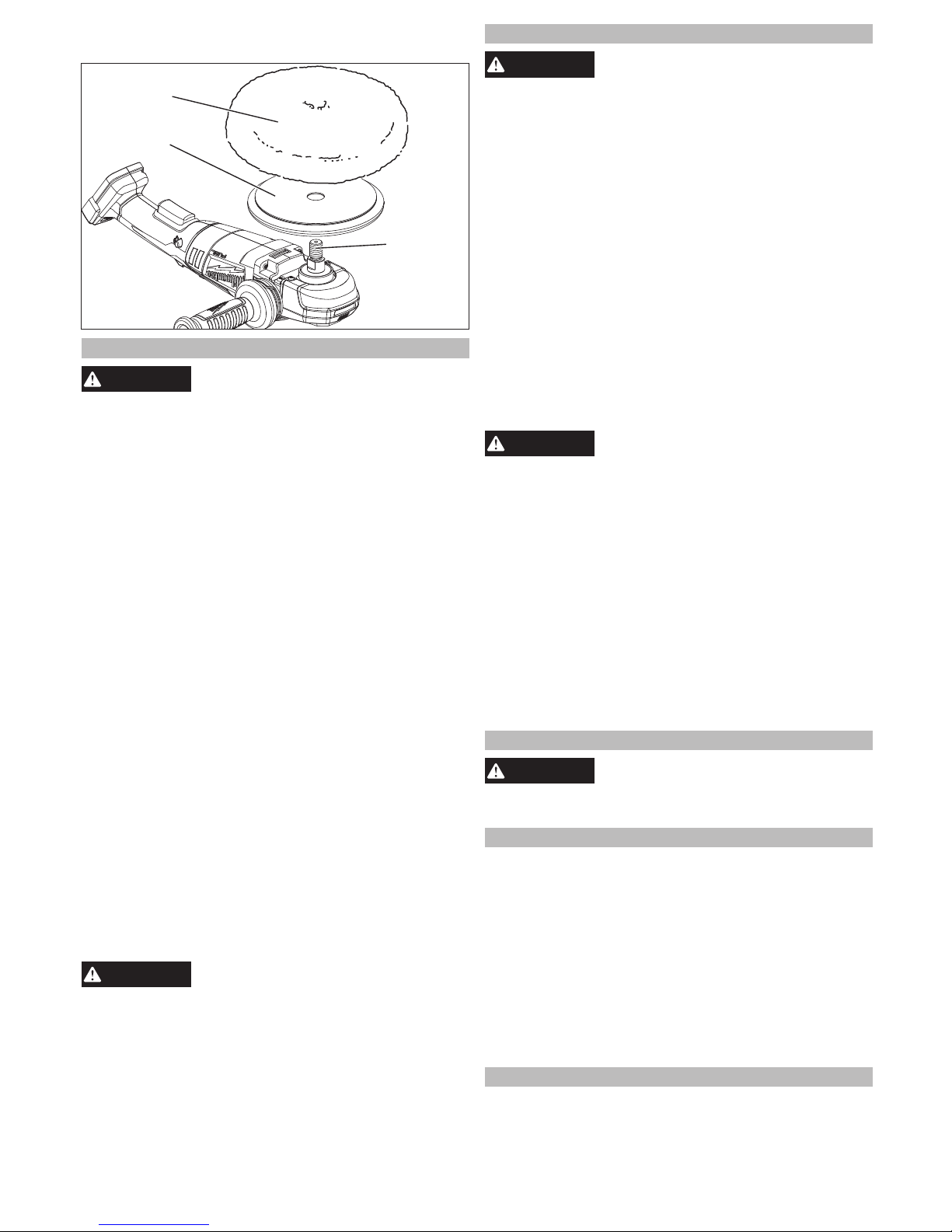

Installing Polishing Pads/ Bonnets

1. To install, remove the battery pack and place the

tool on its tool rest with the spindle upright.

2. Press and hold the spindle lock button.

3. Thread the backing pad onto the spindle. Hand-

tighten securely.

4. Press the polishing pad/bonnet securely onto the

backing pad. Use a centering tool, if provided, to

ensure the pad is aligned for proper balance.

•

WARNING

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

lter out microscopic particles.

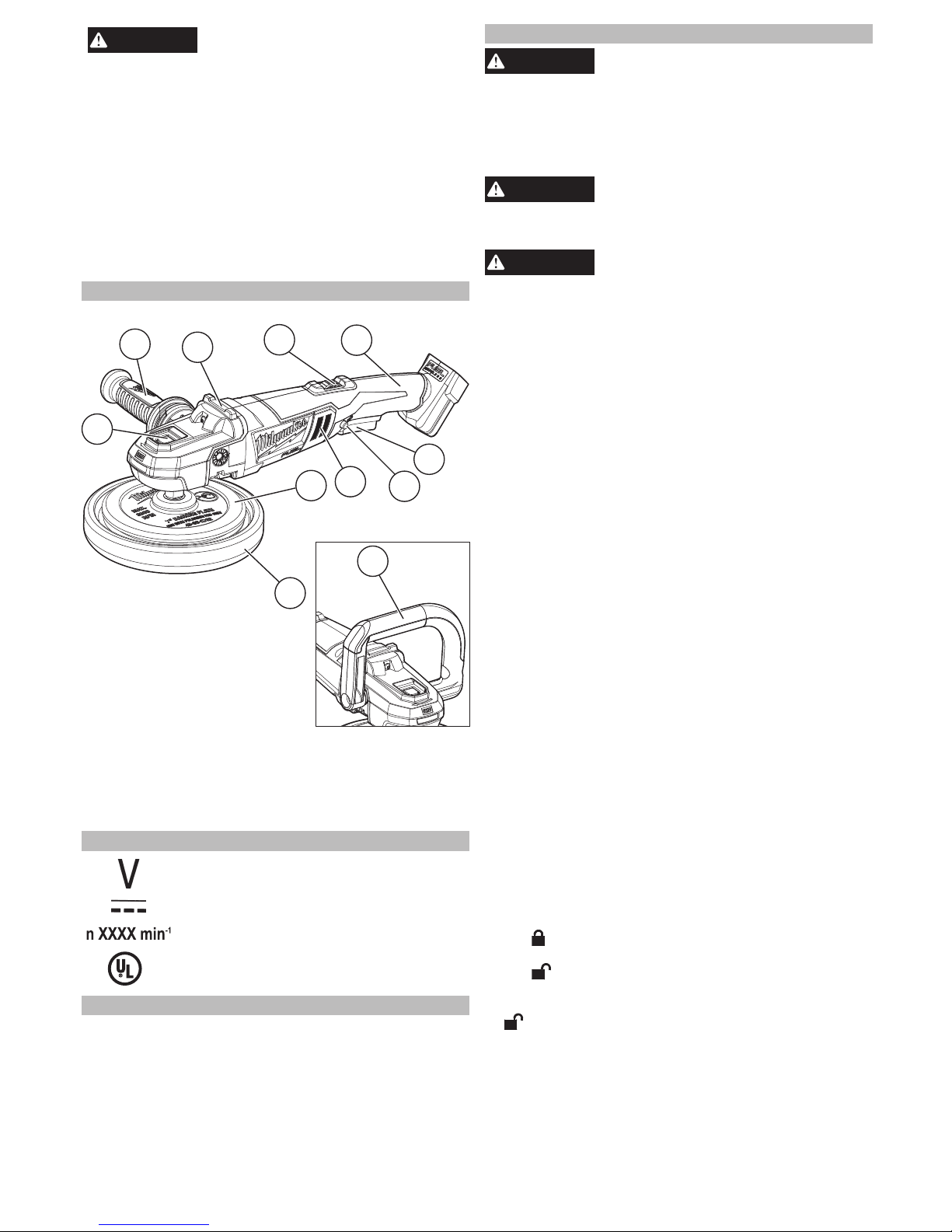

FUNCTIONAL DESCRIPTION

3

8

9

5

10

11

1. Spindle lock button

2. Side handle

3. Tool rest

4. Speed control dial

5. Handle

6. Trigger

7. Trigger lock

8. Dust guard

9. Backing pad

10. Polishing pad

11. Bail handle

4

1

2

6

7

SYMBOLOGY

Volts

Direct Current

Rated Revolutions per Minute (RPM)

C

US

UL Listing Mark for Canada and the U.S

SPECIFICATIONS

Cat. No. ..................................................... 2738-20

Volts .............................................................. 18 DC

Battery Type .................................................M18™

Charger Type ................................................M18™

Rated RPM ................................................ 0 - 2200

Pad Diameter....................................................... 7"

Spindle Thread Size .................................... 5/8"-11

5

5. To uninstall, remove the battery pack and reverse

the procedure.

Polishing pad

Backing pad

Spindle

OPERATION

WARNING

To reduce the risk of injury, always

wear safety goggles or glasses with

side shields.

Starting, Stopping and Controlling Speed

Generally, lower speeds are recommended for tight

work areas and higher speeds are ideal for large

surface areas. Use the speed control dial to set the

maximum speed for the application.

1. Set the speed control dial to the desired maximum

speed.

2. Pull the trigger.

3. Increase or decrease pressure on the trigger to vary

the speed, up to the speed set on the dial.

4. Use the trigger lock to LOCK ON the tool for continu-

ous use, if desired.

5. To stop the tool, release the trigger.

Polishing

Always use side or bail handle for proper control. Move

the polisher back and forth in long, sweeping strokes.

Too much pressure, the wrong angle or improper mo-

tion may cause swirl marks or burning.

For detailed polishing instructions, read the instruc-

tions provided with the nishes, waxes and polishes.

Preventing Burning Through Paint

It is easy to burn through the paint on a surface. This

can occur if you polish at too high a speed or if you

allow the polishing pad to stay in one spot for even a

short period of time. To prevent burning through paint,

use very light pressure and keep the polisher moving

constantly, especially when working near edges or

where there are abrupt changes in the contour of the

work surface.

Be particularly careful when using higher RPM's which

are more likely to burn through paint.

WARNING

To reduce the risk of injury, follow

instructions for preventing snag-

ging. Snagging may cause the tool to kick back

and the operator to suddenly lose control of the

tool. Always use side handle to maintain control.

Preventing Snagging

Snagging occurs when polishing pads get caught on

rough edges of a work surface. Snagging can cause

the tool to suddenly "kick back" and it may cause the

pad to burn through the paint. To reduce the risk of

snagging, use the polisher at low speeds when polish-

ing rough surfaces. For tricky areas such as near trim

or between a mirror and window on a car, do not take

chances with a polisher. Polish these surfaces by hand.

MAINTENANCE

WARNING

To reduce the risk of injury, always

unplug the charger and remove the

battery pack from the charger or tool before performing any maintenance. Never disassemble the

tool, battery pack or charger. Contact a MILWAUKEE

service facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

Inspect your tool for issues such as undue noise,

misalignment or binding of moving parts, breakage of

parts, or any other condition that may affect the tool

operation. Return the tool, battery pack, and charger

to a MILWAUKEE service facility for repair. After six

months to one year, depending on use, return the tool,

battery pack and charger to a MILWAUKEE service

facility for inspection.

If the tool does not start or operate at full power with a

fully charged battery pack, clean the contacts on the

battery pack. If the tool still does not work properly,

return the tool, charger and battery pack, to a MIL-

WAUKEE service facility for repairs.

WARNING

To reduce the risk of personal injury and damage, never immerse

your tool, battery pack or charger in liquid or allow

a liquid to ow inside them.

Cleaning

Clean dust and debris from vents. Keep handles clean,

dry and free of oil or grease. Use only mild soap and

a damp cloth to clean, since certain cleaning agents

and solvents are harmful to plastics and other insulated

parts. Some of these include gasoline, turpentine,

lacquer thinner, paint thinner, chlorinated cleaning

solvents, ammonia and household detergents contain-

ing ammonia. Never use ammable or combustible

solvents around tools.

Repairs

For repairs, return the tool, battery pack and charger

to the nearest service center.

ACCESSORIES

WARNING

Use only recommended accesso-

ries. Others may be hazardous.

For a complete listing of accessories, go online to www.

milwaukeetool.com or contact a distributor.

SERVICE - UNITED STATES

1-800-SAWDUST (1.800.729.3878)

Monday-Friday, 7:00 AM - 6:30 PM CST

or visit www.milwaukeetool.com

Contact Corporate After Sales Service Technical

Support with technical, service/repair, or warranty

questions.

Email: metproductsupport@milwaukeetool.com

Become a Heavy Duty Club Member at

www.milwaukeetool.com to receive important

notications regarding your tool purchases.

SERVICE - CANADA

Milwaukee Tool (Canada) Ltd

1.800.268.4015

Monday-Friday, 7:00 AM - 4:30 PM CST

or visit www.milwaukeetool.ca

Loading...

Loading...