OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Cat. No. / No de cat.

2736-20

M18 FUEL™ 8 1/4" TABLE SAW W/ ONE-KEY™

SCIE A TABLE DE 210 mm (8 1/4") M18 FUEL™

AVEC ONE-KEY™

SIERRA DE MESA DE 210 mm (8 1/4") M18 FUEL™

CON ONE-KEY™

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

GENERAL POWER TOOL

WARNING

SAFETY WARNINGS

Read all safety warnings, instruc-

tions provided with this power tool. Failure to

follow all instructions listed below may result in

electric shock, re and/or serious injury. Save all

warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-oper-

ated (cordless) power tool.

tions, illustrations and specica-

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operat-

ing a power tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the inuence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as a dust mask, non-skid safety shoes, hard hat or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the o-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your nger on

the switch or energizing power tools that have the

switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool

will do the job better and safer at the rate for which

it was designed.

• Do not use the power tool if the switch does not

turn it on and o. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

• Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may aect the power tool’s operation. If damaged,

have the power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations dierent from those intended could

result in a hazardous situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

BATTERY TOOL USE AND CARE

• Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of re when used

with another battery pack.

• Use power tools only with specically designated

battery packs. Use of any other battery packs may

create a risk of injury and re.

2

• When battery pack is not in use, keep it away

DANGER

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal

to another. Shorting the battery terminals together

may cause burns or a re.

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation

or burns.

• Do not use a battery pack or tool that is damaged or modied. Damaged or modied batteries

may exhibit unpredictable behavior resulting in re,

explosion or risk of injury.

• Do not expose a battery pack or tool to re or

excessive temperature. Exposure to re or tem-

perature above 265°F (130°C) may cause explosion.

• Follow all charging instructions and do not charge

the battery pack or tool outside the temperature

range specied in the instructions. Charging

improperly or at temperatures outside the specied

range may damage the battery and increase the risk

of re.

SERVICE

• Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

• Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorized service providers.

SPECIFIC SAFETY RULES FOR

TABLE SAWS

Guarding related warnings

• Keep guards in place. Guards must be in working

order and be properly mounted. A guard that is

loose, damaged, or is not functioning correctly must

be repaired or replaced.

• Always use saw blade guard, riving knife and

anti-kickback device for every through–cutting

operation. For through-cutting operations where the

saw blade cuts completely through the thickness of

the workpiece, the guard and other safety devices

help reduce the risk of injury.

• Immediately reattach the guarding system after

completing an operation (such as rabbeting,

dadoing or resawing cuts) which requires removal

of the guard, riving knife and/or anti-kickback

device. The guard, riving knife, and anti-kickback

device help to reduce the risk of injury.

• Make sure the saw blade is not contacting the

guard, riving knife or the workpiece before the

switch is turned on. Inadvertent contact of these

items with the saw blade could cause a hazardous

condition.

• Adjust the riving knife as described in this

instruction manual. Incorrect spacing, positioning

and alignment can make the riving knife ineective

in reducing the likelihood of kickback.

• For the riving knife and anti-kickback device to

work, they must be engaged in the workpiece.

The riving knife and anti-kickback device are ineffective when cutting workpieces that are too short to

be engaged with the riving knife and anti-kickback

device. Under these conditions a kickback cannot be

prevented by the riving knife and antikickback device.

• Use the appropriate saw blade for the riving

knife. For the riving knife to function properly, the

saw blade diameter must match the appropriate

riving knife and the body of the saw blade must be

thinner than the thickness of the riving knife and the

cutting width of the saw blade must be wider than

the thickness of the riving knife.

Cutting procedures warnings

•

saw blade. A moment of inattention or a slip could

direct your hand towards the saw blade and result

in serious personal injury.

• Feed the workpiece into the saw blade or cutter

only against the direction of rotation. Feeding the

workpiece in the same direction that the saw blade is

rotating above the table may result in the workpiece,

and your hand, being pulled into the saw blade.

• Never use the mitre gauge to feed the workpiece

when ripping and do not use the rip fence as a

length stop when cross cutting with the mitre

gauge. Guiding the workpiece with the rip fence

and the mitre gauge at the same time increases the

likelihood of saw blade binding and kickback.

• When ripping, always apply the workpiece feed-

ing force between the fence and the saw blade.

Use a push stick when the distance between the

fence and the saw blade is less than 150 mm,

and use a push block when this distance is less

than 50 mm. “Work helping” devices will keep your

hand at a safe distance from the saw blade.

• Use only the push stick provided by the manufacturer or constructed in accordance with the

instructions. This push stick provides sucient

distance of the hand from the saw blade.

• Never use a damaged or cut push stick. A damaged

push stick may break causing your hand to slip into

the saw blade.

• Do not perform any operation “freehand”. Always

use either the rip fence or the mitre gauge to

position and guide the workpiece. “Freehand”

means using your hands to support or guide the

workpiece, in lieu of a rip fence or mitre gauge.

Freehand sawing leads to misalignment, binding

and kickback.

• Never reach around or over a rotating saw blade.

Reaching for a workpiece may lead to accidental

contact with the moving saw blade.

• Provide auxiliary workpiece support to the rear

and/or sides of the saw table for long and/or

wide workpieces to keep them level. A long and/

or wide workpiece has a tendency to pivot on the

table’s edge, causing loss of control, saw blade

binding and kickback.

• Feed workpiece at an even pace. Do not bend or

twist the workpiece. If jamming occurs, turn the

tool o immediately, unplug the tool then clear

the jam. Jamming the saw blade by the workpiece

can cause kickback or stall the motor.

• Do not remove pieces of cut-o material while

the saw is running. The material may become

trapped between the fence or inside the saw blade

guard and the saw blade pulling your ngers into the

saw blade. Turn the saw o and wait until the saw

blade stops before removing material.

• Use an auxiliary fence in contact with the table

top when ripping workpieces less than 2 mm

thick. A thin workpiece may wedge under the rip

fence and create a kickback.

3

Never place your ngers or hands

in the vicinity or in line with the

WARNING

WARNING

Kickback causes and related warnings

Kickback is a sudden reaction of the workpiece due

to a pinched, jammed saw blade or misaligned line of

cut in the workpiece with respect to the saw blade or

when a part of the workpiece binds between the saw

blade and the rip fence or other xed object. Most

frequently during kickback, the workpiece is lifted from

the table by the rear portion of the saw blade and is

propelled towards the operator. Kickback is the result

of saw misuse and/or incorrect operating procedures

or conditions and can be avoided by taking proper

precautions as given below.

• Never stand directly in line with the saw blade.

Always position your body on the same side of

the saw blade as the fence. Kickback may propel

the workpiece at high velocity towards anyone

standing in front and in line with the saw blade.

• Never reach over or in back of the saw blade

to pull or to support the workpiece. Accidental

contact with the saw blade may occur or kickback

may drag your ngers into the saw blade.

• Never hold and press the workpiece that is being

cut o against the rotating saw blade. Pressing

the workpiece being cut o against the saw blade

will create a binding condition and kickback.

• Align the fence to be parallel with the saw blade.

A misaligned fence will pinch the workpiece against

the saw blade and create kickback.

• Use a featherboard to guide the workpiece against

the table and fence when making non-through

cuts such as rabbeting, dadoing or resawing

cuts. A featherboard helps to control the workpiece

in the event of a kickback.

• Use extra caution when making a cut into blind

areas of assembled workpieces. The protruding

saw blade may cut objects that can cause kickback.

• Support large panels to minimise the risk of saw

blade pinching and kickback. Large panels tend

to sag under their own weight. Support(s) must be

placed under all portions of the panel overhanging

the table top.

• Use extra caution when cutting a workpiece that

is twisted, knotted, warped or does not have a

straight edge to guide it with a mitre gauge or

along the fence. A warped, knotted, or twisted

workpiece is unstable and causes misalignment of

the kerf with the saw blade, binding and kickback.

• Never cut more than one workpiece, stacked

vertically or horizontally. The saw blade could

pick up one or more pieces and cause kickback.

• When restarting the saw with the saw blade in

the workpiece, centre the saw blade in the kerf so

that the saw teeth are not engaged in the material.

If the saw blade binds, it may lift up the workpiece

and cause kickback when the saw is restarted.

• Keep saw blades clean, sharp, and with sucient

set. Never use warped saw blades or saw blades

with cracked or broken teeth. Sharp and properly set

saw blades minimise binding, stalling and kickback.

Table saw operating procedure warnings

• Turn o the table saw and disconnect the power

cord when removing the table insert, changing

the saw blade or making adjustments to the

riving knife, antikickback device or saw blade

guard, and when the machine is left unattended.

Precautionary measures will avoid accidents.

• Never leave the table saw running unattended.

Turn it o and don’t leave the tool until it comes

to a complete stop. An unattended running saw is

an uncontrolled hazard.

• Locate the table saw in a well-lit and level area

where you can maintain good footing and balance.

It should be installed in an area that provides

enough room to easily handle the size of your

workpiece. Cramped, dark areas, and uneven

slippery oors invite accidents.

• Frequently clean and remove sawdust from

under the saw table and/or the dust collection

device. Accumulated sawdust is combustible and

may self-ignite.

• The table saw must be secured. A table saw that

is not properly secured may move or tip over.

• Remove tools, wood scraps, etc. from the table

before the table saw is turned on. Distraction or

a potential jam can be dangerous.

• Always use saw blades with correct size and

shape (diamond versus round) of arbour holes.

Saw blades that do not match the mounting hardware

of the saw will run o-centre, causing loss of control.

• Never use damaged or incorrect saw blade

mounting means such as anges, saw blade

washers, bolts or nuts. These mounting means were

specially designed for your saw, for safe operation

and optimum performance.

• Never stand on the table saw, do not use it as

a stepping stool. Serious injury could occur if the

tool is tipped or if the cutting tool is accidentally

contacted.

• Make sure that the saw blade is installed to rotate

in the proper direction. Do not use grinding

wheels, wire brushes, or abrasive wheels on a table saw. Improper saw blade installation or use of ac-

cessories not recommended may cause serious injury.

•

erable amount of dust, use an OSHA compliant

dust extraction solution in accordance with the

solution’s operating instructions.

• Always use common sense and be cautious when

using tools. It is not possible to anticipate every

situation that could result in a dangerous outcome.

Do not use this tool if you do not understand these

operating instructions or you feel the work is beyond

your capability; contact Milwaukee Tool or a trained

professional for additional information or training.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

•

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

lter out microscopic particles.

4

To reduce the risk of injury in applications that produce a consid-

Some dust created by power sanding,

sawing, grinding, drilling, and other

SYMBOLOGY

C

US

Volts

Direct Current

No Load Revolutions per Minute (RPM)

Read operator’s manual

Wear eye protection. Use hearing

and respiratory protection.

Keep hands and body out of the path

of the saw blade.

Match kerf width of blade (>1.8 mm)

and blade body thickness (<1.55 mm)

with the marking on the riving knife to

reduce the risk of kickback.

Only use 8-1/4" (210 mm) saw blades

Match the arrow direction on the saw

blade with the arrow direction on the

riving knife.

Cat. No. ..................................................... 2736-20

SPECIFICATIONS

Volts.............................................................. 18 DC

Battery Type .................................................M18™

Charger Type................................................M18™

Module/FCC ID ........BGM220S2/QOQ-BGM220S2

No Load RPM ..................................................6300

Blade Arbor ....................................................... 5/8"

Blade Diameter ..............................8-1/4" (210 mm)

Blade Tilt .................................................. -3° to 47°

Miter gauge angle ......................... 60° Right or Left

Cutting Depth, 0° Bevel .................................... 2.5"

Cutting Depth, 45° Bevel ................................ 1.75"

Blade Kerf ..................................>1.8 mm minimum

.................................<2.2 mm maximum

Blade body thickness..............<1.55 mm maximum

Riving knife thickness ....................1.6 mm (0.063")

Recommended Ambient

Operating Temperature ......................0°F to 125°F

UL Listing for Canada and U.S.

5

FUNCTIONAL DESCRIPTION

1

10

9

8

7

12

13

11

14

6

2

3

4

5

15

16

24

23

17

18

19

22

21

6

20

1. Rip scale indicator

WARNING

WARNING

WARNING

WARNING

2. Rip scale

3. Fence latch

4. Fence adjusting knob

5. Bevel scale

6. Bevel locking lever

7. Height adjusting wheel

8. Switch cover

9. Carrying handle

10. ONE-KEYTM indicator

11. Extending rip fence

12. Rip fence

13. Push stick

14. Blade guard

15. Riving knife and blade guard assembly

16. Anti-kickback pawls

17. Riving knife release lever

18. Anti-kickback pawl storage

19. Dust chute

20. Miter gauge storage

21. Riving knife without guard / riving knife storage

22. Blade wrench / blade wrench storage

23. Miter gauge

24. Fence lock

ASSEMBLY

Recharge only with the charger

cic charging instructions, read the operator’s

manual supplied with your charger and battery.

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body

of the tool. Make sure it latches securely into place.

may be hazardous.

If any parts are damaged or missing, do not operate this tool until the parts are replaced. Use of

this product with damaged or missing parts could

result in serious personal injury.

Do not attempt to modify this tool or create accessories not recommended for use with this tool.

Any such alteration or modication is misuse and

could result in a hazardous condition leading to

possible serious personal injury.

Do not insert to battery pack until assembly is

complete. Failure to comply could result in ac-

cidental starting and possible serious personal

injury.

Do not lift the saw without help. Hold it close to

your body. Keep your knees bent and lift with

your legs, not your back. Ignoring these precautions can result in back injury.

This product requires assembly.

• Carefully lift saw from the carton and place it on a

level work surface.

NOTE: This tool is heavy. To avoid back injury, keep

your knees bent and lift with your legs, not your back,

and get help when needed.

• If tool is shipped with a battery installed, remove

the battery pack.

• Remove any packaging and zip ties.

• Inspect the tool carefully to make sure no breakage

or damage occurred during shipping.

• Do not discard the packing material until you have

carefully inspected the tool, identied all loose parts,

and satisfactorily operated the tool.

For extra stability, mount the table saw to workbench

using the mounting holes in the in the frame. Insert

screws at an angle through the table saw frame.

The Milwaukee Table Saw Stand can also be used.

specied for the battery. For spe-

Removing/Inserting the Battery

Always remove battery pack before

changing or removing accessories.

Only use accessories specically

recommended for this tool. Others

Unpacking

Mounting the Table Saw

Ensure the saw is on a stable,

level surface before use.

7

Understanding the Table Saw

WARNING

NOTICE

WARNING

Before adjusting or operating the saw, have a basic

understanding of table saw use and terminology.

The upper portion of the blade projects up through the

table and is surrounded by an insert called the throat

plate. The height of the blade is set with a wheel on

the front of the cabinet. The rip fence is used to position work for lengthwise cuts. A rip fence scale on the

front rail shows the distance between the rip fence

and the blade. It is very important to use the riving

knife with blade guard and anti-kickback pawls for

all through-sawing operations. Use the miter gauge

for all cross-cut operations.

Detailed instructions are provided in this manual

for making adjustments and basic cuts: cross cuts,

miter cuts, bevel cuts, and compound cuts. This table

saw is designed to cut wood and wood composition

products only. Do not cut metal. Do not cut plastics.

Understand these instructions before continuing.

Selecting, Installing, and Changing Blades

Do not use blades rated less than

heed this warning could result in personal injury.

Use the appropriate saw blade for the riving knife.

Match kerf width of blade (>1.8 mm) and blade

body thickness (<1.55 mm) with the marking on

the riving knife to reduce the risk of kickback.

Failure to heed this warning could result in

personal injury.

Blades are sharp. Wear work gloves when

handling blades.

saw. Failure to heed this warning could cause

damage to the saw blade, the saw, or the workpiece.

Always use clean, sharp blades. Dull blades tend to

overload the tool, bind, and cause pinching. Use only

8-1/4" table saw blades rated at least 6300 RPM.

The blade provided with the saw is a high-quality

combination blade suitable for ripping and cross cut

operations.

Blade kerf width and blade body thickness must be

within the limits stamped on the riving knife. Do not

use metal-cutting blades. Do not cut plastics.

The blade wrench should be stored on the table

saw frame (see "Functional Description" for storage

location).

NOTE: To replace the blade with an accessory blade,

follow the instructions provided with the accessory.

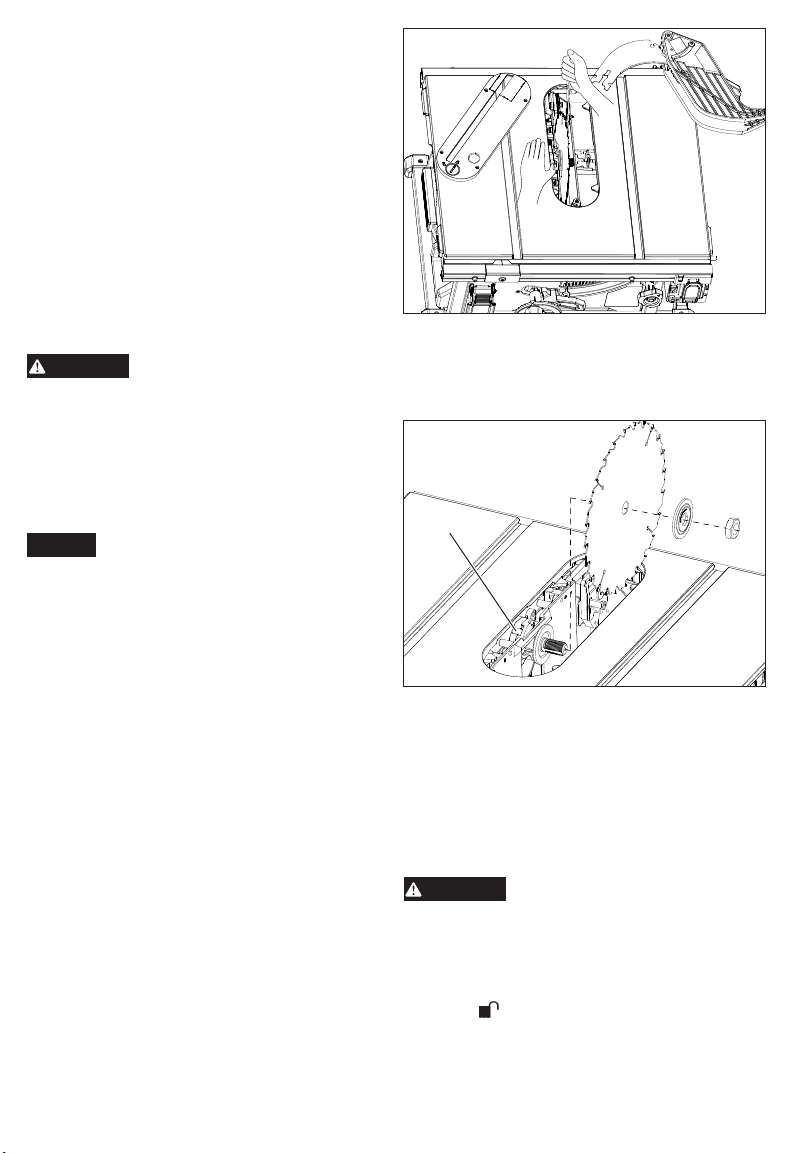

To change the saw blade:

1. Remove the battery pack.

2. Set the blade angle (bevel) to 0° and lock it in

place.

3. Raise the blade by turning the height adjusting

wheel clockwise.

4. Remove the riving knife.

5. Remove the throat plate.

6. Press in the spindle lock and rotate the spindle/

blade until the lock engages.

7. Use the blade wrench to loosen the blade bolt

counterclockwise. Carefully remove the blade

bolt and blade ange by hand. Remove the blade.

Wipe the blade bolt, anges and spindle to remove

dust and debris. Inspect the parts for damage.

Replace if needed.

the speed of this tool. Failure to

To work properly, the saw blade teeth

must point down toward the front of the

8. Match the arrow direction on the replacement saw

blade with the arrow direction on the riving knife.

The teeth should point toward the front of the table

saw. Slide the blade onto the spindle.

9. Install the outer blade ange. The at side of the

ange must rest against the blade.

Spindle lock

10. Hand-thread the blade bolt. Once the spindle

starts to spin, press in the spindle lock and rotate

the blade until the lock engages. Securely tighten

clockwise with the blade wrench.

11. Reinstall the appropriate throat plate, riving knife,

and anti-kickback pawls for the application.

12. Check blade guard and anti-kickback pawls move

freely before starting the saw. Ensure the blade

teeth match the direction of rotation indicated on

the riving knife.

Changing the Throat Plate

Always use the appropriate throat

blades may require dierent throat plates. Never

operate the saw without a throat plate in place.

1. Remove the battery pack.

2. Lower the blade by turning the height adjusting

wheel counterclockwise.

3. To remove a throat plate, turn the throat plate

latch to unlocked.

plate for the operation. Dierent

8

Throat plate

WARNING

WARNING

4. Use the hole to lift the throat plate out.

5. To install a throat plate, slide the back end into the

slot and drop the front into place. Turn the throat

plate latch to locked. The throat plate must be

ush with the saw table.

Throat plate latch

Lift hole

Changing the Riving Knife

Use the appropriate saw blade for

of blade (>1.8 mm) and blade body thickness

(<1.55 mm) with the marking on the riving knife

to reduce the risk of kickback. Failure to heed

this warning could result in personal injury.

Two riving knives are provided with the saw; the

riving knife with guard, and the riving knife without

guard. The riving knife with guard should be used for

through cutting operations for maximum protection

against kickback. When performing an operation

that requires "non-through cutting", use the riving

knife without guard. Do not use any riving knife when

making a dado cut.

Store the riving knife on the table saw frame when not in

use (see "Functional Description" for storage location).

To change the riving knife:

1. Remove the battery pack.

2. Raise the blade by turning the height adjusting

wheel clockwise.

3. Release the riving knife release lever.

4. To remove, pull the riving knife straight up.

5. To install, insert the riving knife into the slot

directly behind the blade until it is rmly seated.

NOTE: if the release lever is not fully open, the

riving knife may not fully seat.

6. Close the riving knife release lever fully.

7. Gently tug on the riving knife to ensure it is locked

into place.

8. When using the riving knife with guard, lift the

guard legs and ensure the move independently

and contact the table top. The guard legs can be

raised to line up the cut, but must be lowered to

contact the table top before starting the saw.

Release

lever

the riving knife. Match kerf width

Installing Anti-kickback Pawls

Always install the anti-kickback

guard when performing "through cutting" operations.

Replace dull or damaged anti-kickback pawls.

Dull or damaged pawls may not stop a kickback

increasing the risk of serious personal injury.

Anti-kickback pawls should only be installed for

through cuts.

1. Remove the battery pack.

2. Raise the blade by turning the height adjusting

wheel clockwise.

3. Install the riving knife with guard.

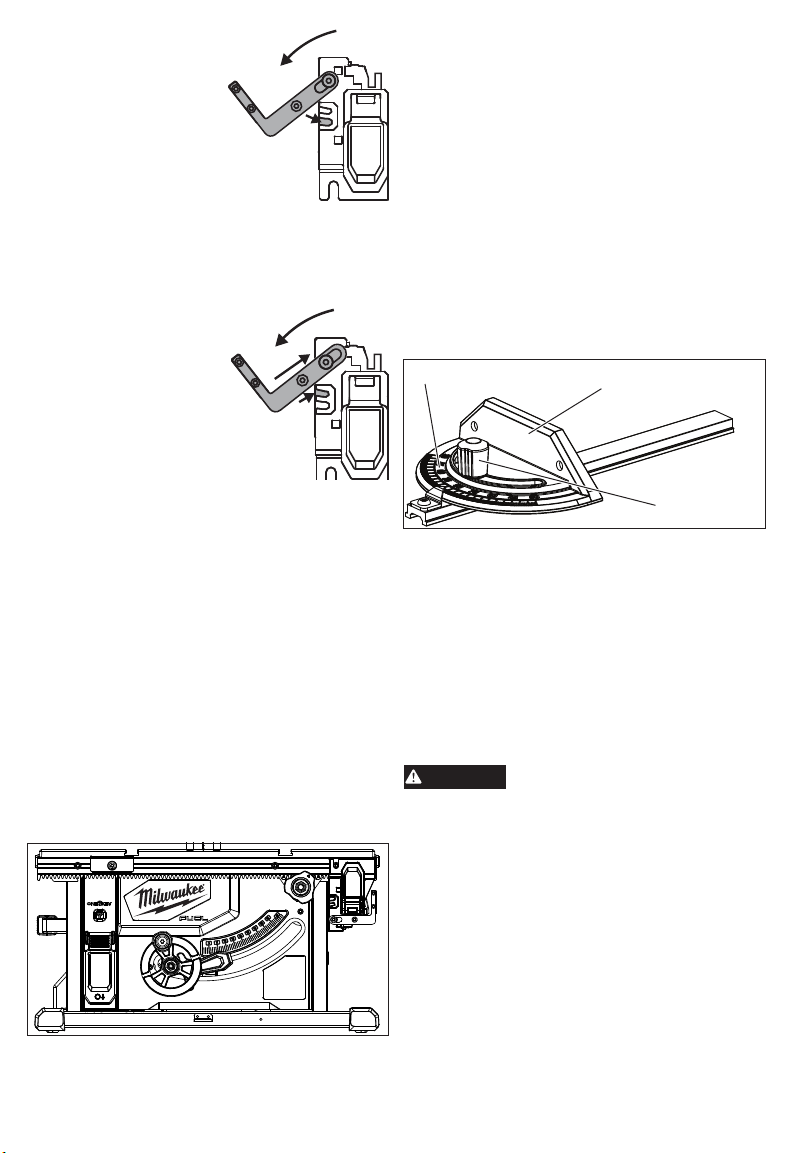

4. Press in the pawl release button and insert the slot

in the pawl joint into the riving knife notch. Press

down on the joint. NOTE: It may be easier to install

the pawls from the front of the saw.

5. Gently tug on the pawl joint to ensure it is locked

into place. Ensure the pawls move freely and are

not engaged in the throat plate slot.

1. Press button

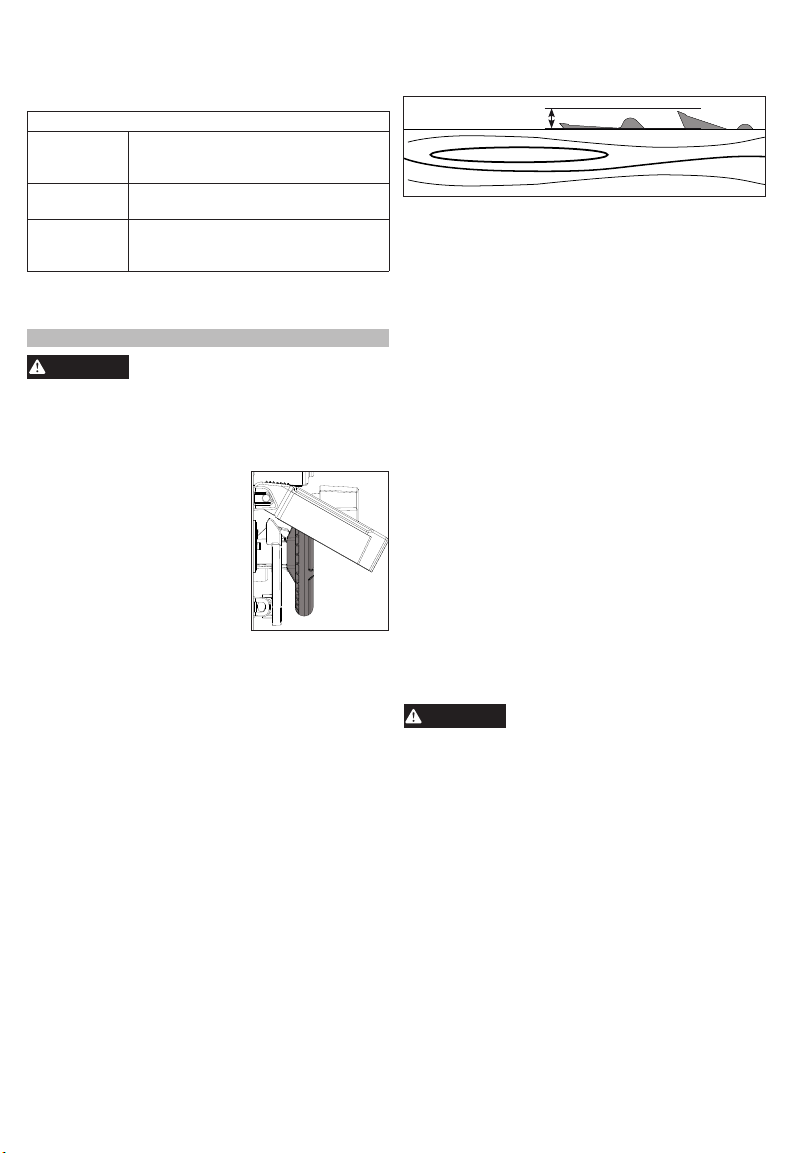

The blade depth should be set so that the outer

points of the blade are higher than the workpiece

by approximately 1/8" to 1/4" but the lowest points

(gullets) are below the top surface.

pawls onto the riving knife with

3. Press down

2. Insert

Changing Blade Depth

1/8" - 1/4"

1. Remove the battery pack.

2. Lower the blade by turning the height adjusting

wheel counterclockwise.

3. Raise the blade by turning the height adjusting

wheel clockwise.

Installing and Moving the Rip Fence

To install the rip fence on one of the fence posts:

1. Open the fence latches.

2. Fit the notches in the fence over the correspond-

ing fence posts.

3. Close the fence latches.

4. Check that the fence is square to the blade (see

"Blade to Fence Adjustment" in Maintenance).

To move the rip fence:

1. Pull the fence lock forward.

2. Use the fence adjusting knob to move the rip

fence left or right.

3. Push the fence lock back.

9

To use the extending rip

WARNING

fence as a table extension:

Use the extending rip fence

to hold the edge of the workpiece when the fence is

moved out past the end of

the table.

1. Pull the fence lock forward.

2. Use the fence adjusting

knob to move the extending rip fence out past the

edge of the table.

3. Flip the fence extension over. The tab on the

extending rip fence will t into the lower slot on

the fence.

4. Adjust the fence as needed and push the fence

lock back.

To use the extending rip

fence when cutting thin

(3/4" or less) workpieces

close to the blade:

NOTE: Only use the extending rip fence in this position

for workpieces 3/4" thick or

less. For thicker workpieces,

use the miter gauge.

Always use a push stick to

keep hands at least 3" away

from the blade.

1. Pull the fence lock forward.

2. Use the fence adjusting knob to move position

the rip fence.

3. Flip the fence extension over. Slide the extending

rip fence back, then push down. The tab on the

extending rip fence will t into the upper slot on

the fence.

4. Adjust the fence as needed and push the fence

lock back.

5. NOTE: If the fence is adjusted close to the blade,

ensure the guard and anti-kickback pawls move

freely. They may rest on top of the fence extension.

WARNING! Never stand directly in line with the

blade. Thin cut-o pieces can be thrown out and

toward the operator when the anti-kickback pawls

are not engaged with the wood.

To store the fence:

When making a cross cut or storing the tool, remove

and store the rip fence, as shown. The fence ts

around the fence lock. NOTE, the fence rail cannot

be adjusted when the fence is in the storage position.

Use an auxiliary fence for cutting thin pieces of wood,

such as veneer panels, that could get pinched under

the rip fence. To create an auxiliary fence, clamp a

1x4 piece of lumber (without beveled edges) to the

rip fence and ush to the table.

NOTE: A 90° cut has a 0° bevel and a 45° cut has

a 45° bevel.

1. Remove the battery pack.

2. Lift the bevel locking lever.

3. Grasp the height adjusting wheel and slide to the

4. Push down the bevel locking lever.

5. Check fence clearance before making a cut. Make

The miter gauge provides greater accuracy in angled

cuts. For very close tolerances, test cuts are recommended.

Miter Gauge

There are two miter gauge grooves, one on either

side of the blade. When making a 90° cross cut, you

can use either miter gauge groove. When making a

beveled cross cut (the blade tilted in relation to the

table) the miter gauge should be located in the groove

on the right so that the blade is tilted away from the

miter gauge and your hands.

The miter gauge can be turned 60° to the right or left.

1. Loosen the lock knob.

2. With the miter gauge in the miter gauge groove,

3. Tighten the lock knob securely.

Using an Auxiliary Fence

Changing Blade Angle (Bevel)

desired bevel angle.

a sample cut before beginning work.

Using the Miter Gauge

Miter Gauge Body

Lock Knob

rotate the gauge until the desired angle is reached

on the scale.

Dust Collection

Collected sawdust from coated

workpieces can self-ignite and cause re. To

reduce the risk of re, empty frequently and

never store or leave a saw without totally emptying sawdust.

The dust chute at the back of the saw can be con-

nected to a vacuum hose (diameter 2.5"/62.6 mm). To

install, push and twist the hose onto the dust chute.

Leave dust chute open to direct dust down into a

garbage can.

Always store all saw parts, such as the fence, miter

gauge, riving knife, riving knife with guard, and blade

wrench, with the saw when transporting and storing.

Lower the blade, remove the battery pack and/or

lock-out the ON/OFF switch before transporting or

storing the saw.

(polyurethanes, linseed oil, etc.)

Transporting and Storing

10

To learn more about the ONE-KEY™ functionality

WARNING

WARNING

for this tool, go to milwaukeetool.com/One-Key. To

download the ONE-KEY™ app, visit the App Store or

Google Play from your smart device.

Solid Blue Wireless mode is active and ready

Blinking Blue Tool is actively communicating with

Blinking Red Tool is in security lockout and can

NOTE: High electronic discharge from the tool may

cause the ONE-KEY™ app to lose connection. Follow the prompts in the app to reconnect.

ONE-KEY™

ONE-KEY™ Indicator

to be congured via the ONE-KEY™

app.

the ONE-KEY™ app.

be unlocked by the owner via the

ONE-KEY™ app.

OPERATION

To reduce the risk of injury, always

to comply with ANSI Z87.1. Wear hearing protection.

When working in dusty situations, wear appropriate respiratory protection or use an OSHA

compliant dust extraction solution.

ALWAYS lock-out the trigger

when the tool is not in use.

Insert a standard padlock or

zip tie behind the switch to

prevent starting by untrained

users.

ALWAYS make sure your

workpiece is not in contact

with the blade before start the

tool. Workpiece contact may

cause the workpiece to be kicked back toward

the operator and result in serious personal injury.

Never stand directly in line with the blade or allow

hands to come closer than 3" to the blade. Do

not reach over or across the blade. Contact with

the blade can result in serious personal injury.

Ensure the saw is on a stable, level surface

before use.

Kickback can occur when the blade stalls or binds,

kicking the workpiece back toward you with great

force and speed. If your hands are near the saw

blade, they may be jerked loose from the workpiece

and may contact the blade. Obviously, kickback

can cause serious injury, and it is well worth using

precautions to avoid the risks.

Kickback can be caused by any action that pinches

the blade in the wood such as:

• Making a cut with incorrect blade depth

• Sawing into knots or nails in the workpiece

• Twisting the wood while making a cut

• Failing to support work

• Forcing a cut

• Cutting warped or wet lumber

• Using the wrong blade for the type of cut

• Not following correct operating procedures

• Misusing the saw

• Failing to use the anti-kickback pawls

• Cutting with a dull, gummed-up, or improperly set blade

wear proper eye protection marked

Causes of Kickback

• Always use the correct blade depth setting. The

top of the blade teeth should clear the workpiece

by 1/8" to 1/4".

Avoiding Kickback

1/8" - 1/4"

• Inspect the work for knots or nails before beginning

a cut. Knock out any loose knots with a hammer.

Never saw into a loose knot or nail.

• Always use the rip fence when rip cutting. Use the

miter gauge when cross cutting. This helps prevent

twisting the wood in the cut.

• Always use clean, sharp, and properly-set blades.

Never make cuts with dull blades.

• To avoid pinching the blade, support the work prop-

erly before beginning a cut.

• When making a cut, use steady, even pressure.

Never force cuts.

• Do not cut wet or warped lumber.

• Use extra caution when cutting some prenished

or composition wood products as the anti-kickback

pawls may not always be eective.

• Always guide your workpiece with both hands or

with push sticks and/or push blocks. Keep your

body in a balanced position to be ready to resist

kickback should it occur. Never stand directly in

line with the blade.

• Use of a featherboard will help hold the workpiece

securely against the saw table or fence.

• Clean the saw, blade guard, under the throat plate,

and any areas where saw dust or scrap workpieces

may gather.

• Use the right type of blade for the cut being made.

• Always use the riving knife for every operation where

it is allowed. The use of this device will greatly reduce the risk of kickback.

Turning Saw ON/OFF

Carefully check and lock all adjust-

revolution to assure proper clearance before

inserting the battery pack. Improper blade clear-

ance and loose adjustments can result in serious

personal injury.

When making a cross cut, make sure the blade

guard is installed and working properly to avoid

serious personal injury.

To reduce the risk of injury, always wear safety

goggles or glasses with side shields. Wear hearing protection and respiratory protection.

Remove zip tie before rst use.

1. Check all adjustments.

2. Insert the battery pack.

3. Line up the workpiece, but do not make contact

with the blade. NOTE: When using the riving knife

with guard, the guard legs can be raised to line up

the cut, but must be lowered to contact the table

top before starting the saw.

4. To turn the saw ON, lift the switch cover and then

lift the switch.

5. To turn the saw OFF, press the switch cover down.

11

ments, and rotate the blade one full

WARNING

Do not allow familiarity with tools

CAUTION

WARNING

2-1/2 in.

3/4 in.

1/4 in.

1/8 in.

1-1/16 in.

12 in.

70°

to make you careless. Remember

that a careless fraction of a second is sucient

to inict severe injury.

Do not use any attachments or accessories not

recommended by the manufacturer of this tool.

The use of attachments or accessories not recommended can result in serious personal injury.

Clearing a Jam/Cleaning the Dust Chute

To clear a jam:

1. Turn OFF the tool.

2. Remove the battery pack.

3. If unable to clear the

jam by removing the

throat plate, remove

the three bolts from the

dust chute and remove

the jam or debris from

the dust compartment.

Clean dust chute com-

pletely.

4. Reinstall all compo-

nents and check all adjustments before restarting work.

Dust

Chute

Bolts

APPLICATIONS

Use this tool for the purposes listed below:

• Straight line cutting operations such as cross cutting,

ripping, mitering, beveling, and compound cutting

• Dado with optional accessories

• Cabinet making and woodworking

NOTE: This table saw is designed to cut wood and

wood composition products only. Do not cut metal.

Do not cut plastics.

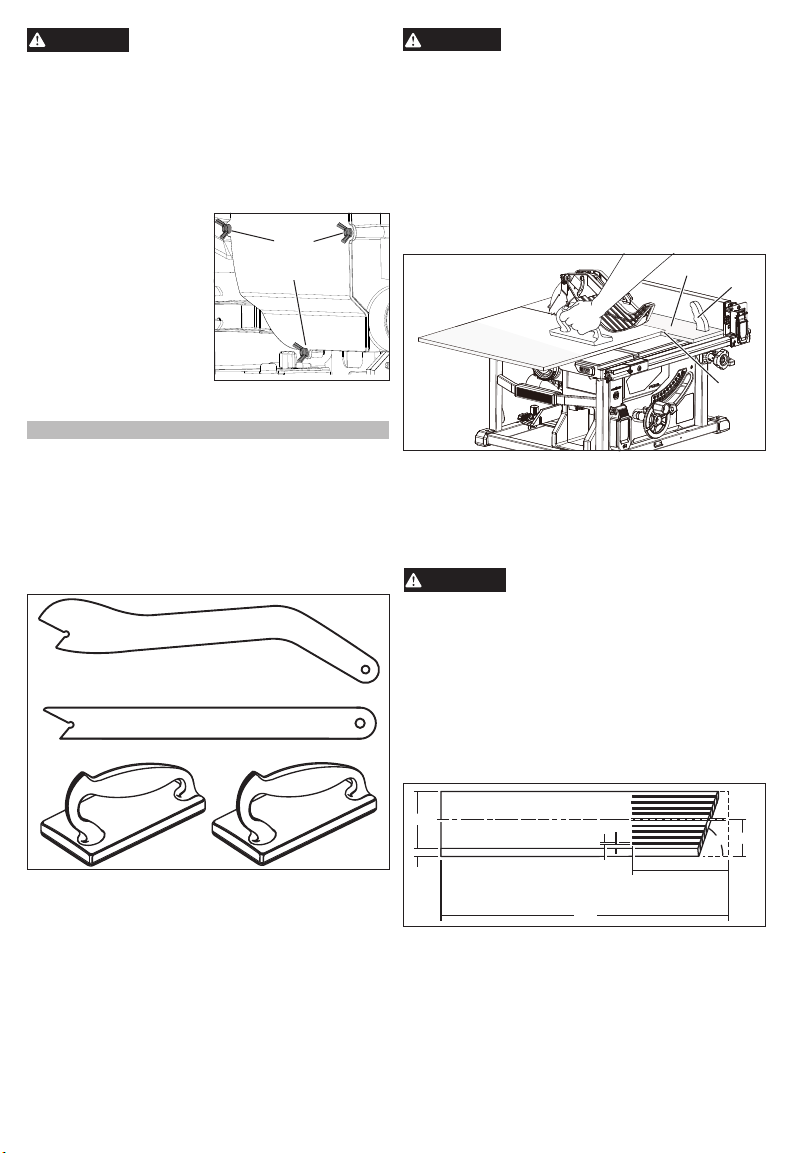

Cutting Aids

Push Sticks

Be sure the screws in a push block

are recessed to avoid damaging the

saw or workpiece.

(For rip cutting narrow workpiece)

If ripping a narrow workpiece places the hands too

close to the blade, it will be necessary to make and

use a jig.

To make a jig:

1. Attach a handle to a long, straight piece of wood

and secure from the underside using recessed

screws.

2. Cut an L-shaped stop in the side of the jig.

How to Make a Jig

Jig

Handle

Stop

To use a jig:

1. Position the workpiece at on the table with the

edge ush against the jig and against the stop.

2. Holding the jig handle and using a push block and/

or push stick, make the rip cut.

Featherboard

Place the featherboard against the

uncut portion of the workpiece to

avoid kickback that could cause serious personal injury.

A featherboard is a device used to help control the

workpiece by holding it securely against the table

or fence. Featherboards are especially useful when

ripping small workpieces and for completing non-

through cuts. The end is angled with a number of

short kerfs to give a friction hold on the workpiece

and locked in place on the table with a C-clamp. Test

to ensure it can resist kickback.

How to Make a Featherboard

Push Blocks

Push sticks are devices that may be used for push-

ing a workpiece through the blade in any rip cut.

When making non-through cuts or ripping narrow

stock, always use a push stick, push block, and/or

featherboard so your hands do not come within 3"

of the saw blade. Use the push stick provided with

the table saw, or they can be made in various sizes

and shapes from scrap wood and used in a specic

project. The stick must be narrower than the workpiece, with a 90˚ notch in one end and shaping for a

grip on the other end.

A push block has a handle fastened by recessed

screws from the underside. Use push blocks for

narrow cuts and all non-through cuts.

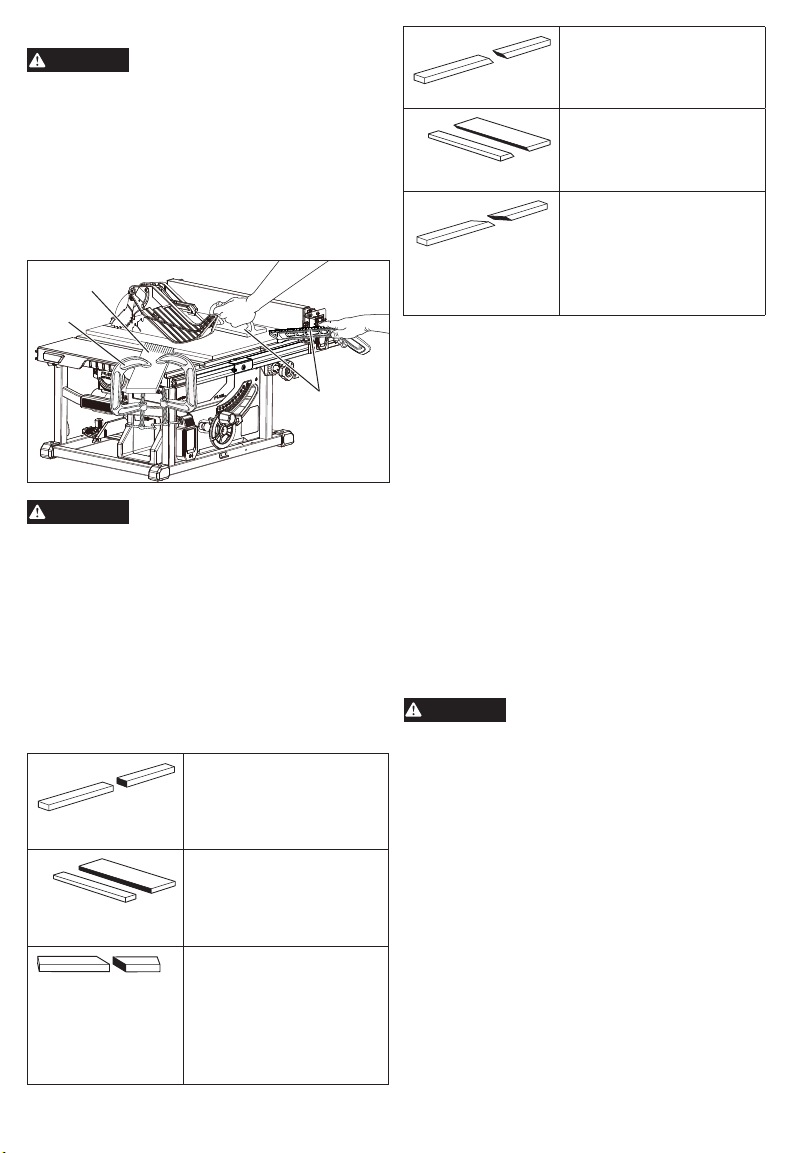

Select a solid piece of lumber approximately 3/4"

thick, 2-1/2" wide and 12" long. Mark the center of the

width on one end of the stock. Miter the width to 70°.

Mark the board from the widest point at four inches.

Prepare the saw for ripping. Set the rip fence to allow

approximately a 1/4" “nger” to be cut in the stock.

Feed the stock only to the mark previously made at

4". Turn the saw OFF and allow the blade to com-

pletely stop rotating before removing the stock. Reset

the rip fence and cut spaced rips into the workpiece

to allow approximately 1/4" ngers and 1/8" spaces

between the ngers.

12

How to Mount a Featherboard

WARNING

WARNING

WARNING

Do not locate the featherboard to

tioned improperly, kickback can result from the

featherboard pinching the workpiece and binding

the blade in the saw kerf. Failure to heed this

warning can result in serious personal injury.

Completely lower the saw blade. Position the rip

fence to the desired adjustment for the cut to be

performed and lock. Place the workpiece against

the fence and over the saw blade area. Adjust the

featherboard to apply resistance to the workpiece

just forward of the blade. Attach C-clamps to further

secure the featherboard to the edge of the saw table.

Featherboard

Clamps

pawls are in place and working properly when

making these cuts to avoid possible injury.

Always use a push stick with small pieces of

wood, and also to nish the cut when ripping a

long narrow piece of wood, to prevent your hands

from getting close to the blade.

There are six basic cuts: the cross cut, the rip cut,

the miter cut, the bevel cross cut, the bevel rip cut,

and the compound (bevel) miter cut. All other cuts

are combinations of these basic six. Operating pro-

cedures for making each kind of cut are given later

in this section.

the rear of the workpiece. If posi-

Push stick

and block

Always make sure the riving knife

with blade guard and anti-kickback

Types of Cuts

Cross Cut - Straight, 90° cuts

made across the grain of the

workpiece. The wood is fed

into the cut at a 90° angle to

the blade, and the blade is

vertical.

Rip Cut - Cuts made with the

grain of the wood. To avoid

kickback while making a rip

cut, make sure one side of the

wood rides rmly against the

rip fence.

Miter Cut - Cuts made with

the wood at any angle to the

blade other than 90°. The

blade is vertical. Miter cuts

tend to “creep” during cut-

ting. This can be controlled

by holding the workpiece

securely against the miter

gauge.

Bevel Cross Cut - Cuts made

with an angled blade. Bevel

cross cuts are across the

wood grain, and bevel rip cuts

are with the grain.

Bevel Rip Cut - Cuts made

with an angled blade. Bevel

cross cuts are across the

wood grain, and bevel rip cuts

are with the grain.

Compound (Bevel) Miter Cut

- Cuts made with an angled

blade on wood that is angled

to the blade. Be thoroughly familiar with making cross cuts,

rip cuts, bevel cuts, and miter

cuts before trying a compound

miter cut.

This table saw can perform a variety of cuts that are

not all mentioned in this manual. DO NOT attempt

to make any cuts not covered here unless you are

thoroughly familiar with the proper procedures and

necessary accessories. Your local library has many

books on table saw usage and specialized wood-

working procedures for your reference.

• Dado and rabbet cuts are non-through cuts which

can be either rip cuts or cross cuts. Carefully read

and understand all sections of this operator’s

manual before attempting these operations.

• The kerf (the cut made by the blade in the wood)

will be wider than the blade to avoid overheating or

binding. Make allowance for the kerf when measuring wood.

• Make sure the kerf is made on the waste side of

the measuring line.

• Cut the wood with the nish side up.

• Knock out any loose knots with a hammer before

making the cut.

• Always provide proper support for the wood as it

comes out of the saw.

Cutting Rules

To reduce the risk of injury from

kickback, check for proper alignment after tool has been stored, dropped or

bumped, or used extensively. A tool that is out

of alignment will cause binding and could result

in serious personal injury. See "Maintenance" for

proper adjustment procedure.

Carefully check and lock all adjustments, and

rotate the blade one full revolution to assure

proper clearance before inserting the battery

pack. Improper blade clearance and loose ad-

justments can result in serious personal injury.

Stand slightly to the side of the blade path to reduce the chance of injury should kickback occur.

Do not use blades rated less than the speed of

this tool. Failure to heed this warning could result

in personal injury.

13

Making a Cross Cut

WARNING

WARNING

WARNING

WARNING

Make sure the blade guard assem-

erly to avoid serious possible injury.

Using the rip fence as a cuto gauge when cross

cutting will result in kickback which can cause

serious personal injury.

1. Remove the battery pack.

2. Remove the rip fence.

3. Set the blade to the correct depth for the workpiece.

4. Set the miter gauge to 0° and tighten the lock knob.

5. Insert the battery pack.

6. Make sure the wood is clear of the blade before

turning on the saw.

NOTE: It is recommended that you place the piece

to be saved on the left side of the blade and that

you make a test cut on scrap wood rst.

7. Turn ON the saw. Allow the saw to come to full

speed.

8. Hold the workpiece rmly with both hands on the

miter gauge and feed the workpiece into the blade.

NOTE: The hand closest to the blade should be

placed on the miter gauge lock knob and the hand

farthest from the blade should be placed on the

workpiece.

9. Turn OFF the saw. Wait for the blade to come to

a complete stop before removing the workpiece.

bly is installed and working prop-

Making a Rip Cut

Make sure the blade guard assem-

erly to avoid serious possible injury.

Taper cuts must only be made with a special jig,

which is commercially available. Do not attempt

a free hand taper cut on this saw. Failure to follow these instructions could result in serious

personal injury.

1. Remove the battery pack.

2. Remove the miter gauge.

3. Install feather board in the appropriate position for

the cut being made.

4. Set the blade to the correct depth for the work-

piece.

5. Position the rip fence the desired distance from

the blade for the cut and lock in place.

6. When ripping a long workpiece, place a support

the same height as the table surface behind the

saw for the cut work.

7. Position the workpiece at on the table with the

edge ush against the rip fence.

8. Insert the battery pack.

9. Make sure the wood is clear of the blade before

turning on the saw.

10. Turn ON the saw. Allow the saw to come to full

speed.

11. Hold the workpiece rmly against the rip fence

and table. WARNING! Keep hands at least 3"

away from the blade at all times! If ripping a

narrow piece, use a push stick and/or push blocks

to move the piece through the cut and past the

blade. Once the blade has made contact with the

workpiece, use the hand closest to the rip fence to

guide it. Make sure the edge of the workpiece remains in solid contact with both the rip fence and

the surface of the table. If ripping a narrow piece,

use a push stick and/or push blocks to move the

piece through the cut and past the blade.

12. Turn OFF the saw. Wait for the blade to come to

a complete stop before removing the workpiece.

bly is installed and working prop-

Making a Miter Cut

Make sure the blade guard assem-

erly to avoid serious possible injury.

Using the rip fence as a cuto gauge when cross

cutting will result in kickback which can cause

serious personal injury.

The miter gauge must be on the right side of the

blade to avoid trapping the wood and causing

kickback. Placement of the miter gauge to the

left of the blade will result in kickback and the

risk of serious personal injury.

1. Remove the battery pack.

2. Remove the rip fence.

3. Set the blade to the correct depth for the work-

piece.

4. Set the miter gauge to the desired angle and

tighten the lock knob.

5. Insert the battery pack.

6. Make sure the wood is clear of the blade before

turning on the saw.

7. Turn ON the saw. Allow the saw to come to full

speed.

8. Hold the workpiece rmly with both hands on the

miter gauge and feed the workpiece into the blade.

NOTE: The hand closest to the blade should be

placed on the miter gauge lock knob and the hand

farthest from the blade should be placed on the

workpiece.

9. Turn OFF the saw. Wait for the blade to come to

a complete stop before removing the workpiece.

bly is installed and working prop-

Making a Bevel Cross Cut

Make sure the blade guard assem-

erly to avoid serious possible injury.

Using the rip fence as a cuto gauge when cross

cutting will result in kickback which can cause

serious personal injury.

The miter gauge must be on the right side of the

blade to avoid trapping the wood and causing

kickback. Placement of the miter gauge to the

left of the blade will result in kickback and the

risk of serious personal injury.

1. Remove the battery pack.

2. Remove the rip fence.

3. Adjust the bevel angle to the desired setting.

4. Set the blade to the correct depth for the work-

piece.

5. Set the miter gauge to 0° and tighten the lock knob.

6. Insert the battery pack.

7. Make sure the wood is clear of the blade before

turning on the saw.

8. Turn ON the saw. Allow the saw to come to full

speed.

9. Hold the workpiece rmly with both hands on

the miter gauge and feed the workpiece into

the blade. NOTE: The hand closest to the blade

should be placed on the miter gauge lock knob

and the hand farthest from the blade should be

placed on the workpiece.

10. Turn OFF the saw. Wait for the blade to come to

a complete stop before removing the workpiece.

14

bly is installed and working prop-

Making a Bevel Rip Cut

WARNING

WARNING

WARNING

WARNING

Make sure the blade guard assem-

erly to avoid serious possible injury.

The rip fence must be on the right side of the

blade to avoid trapping the wood and causing

kickback. Placement of the rip fence to the left

of the blade will result in kickback and the risk

of serious personal injury.

1. Remove the battery pack.

2. Remove the miter gauge.

3. Install feather board in the appropriate position for

the cut being made.

4. Adjust the bevel angle to the desired setting.

5. Set the blade to the correct depth for the workpiece.

6. Position the rip fence the desired distance from

the blade for the cut and lock in place.

7. When ripping a long workpiece, place a support

the same height as the table surface behind the

saw for the cut work.

8. Position the workpiece at on the table with the

edge ush against the rip fence.

9. Insert the battery pack.

10. Make sure the wood is clear of the blade before

turning on the saw.

11. Turn ON the saw. Allow the saw to come to full

speed.

12. Hold the workpiece rmly against the rip fence

and table. WARNING! Keep hands at least 3"

away from the blade at all times! If ripping a

narrow piece, use a push stick and/or push blocks

to move the piece through the cut and past the

blade. Once the blade has made contact with the

workpiece, use the hand closest to the rip fence to

guide it. Make sure the edge of the workpiece remains in solid contact with both the rip fence and

the surface of the table. If ripping a narrow piece,

use a push stick and/or push blocks to move the

piece through the cut and past the blade.

13. Turn OFF the saw. Wait for the blade to come to

a complete stop before removing the workpiece.

bly is installed and working prop-

Making a Compound (Bevel) Miter Cut

Make sure the blade guard assem-

erly to avoid serious possible injury.

The miter gauge must be on the right side of the

blade to avoid trapping the wood and causing

kickback. Placement of the miter gauge to the

left of the blade will result in kickback and the

risk of serious personal injury.

1. Remove the battery pack.

2. Remove the rip fence.

3. Adjust the bevel angle to the desired setting.

4. Set the blade to the correct depth for the workpiece.

5. Set the miter gauge to the desired angle and

tighten the lock knob.

6. Insert the battery pack.

7. Make sure the wood is clear of the blade before

turning on the saw.

8. Turn ON the saw. Allow the saw to come to full speed.

9. Hold the workpiece rmly with both hands on the

miter gauge and feed the workpiece into the blade.

NOTE: The hand closest to the blade should be

placed on the miter gauge lock knob and the hand

farthest from the blade should be placed on the

workpiece.

10. Turn OFF the saw. Wait for the blade to come to

a complete stop before removing the workpiece.

bly is installed and working prop-

Make sure the saw is properly secured to a work sur-

face to avoid tipping from the weight of a large panel.

erly to avoid serious possible injury.

Never make freehand cuts (cuts without the miter

gauge or rip fence). Unguided workpieces can

result in serious injury.

1. Remove the battery pack.

2. Set the blade to the correct depth for the work-

3. Depending on the shape of the panel, use the rip

4. Place a support the same height as the table sur-

5. Install a feather board in the appropriate position

6. Make sure the wood is clear of the blade before

7. Turn ON the saw. Allow the saw to come to full

8. Use proper hand positions for cross cut or rip cut,

9. Turn OFF the saw. Wait for the blade to come to

Non-through cuts can be made with the grain (rip-

ping) or across the grain (cross cut). The use of

a non-through cut is essential to cutting grooves,

rabbets, and dadoes. This is the only type cut that

is made without the riving knife with blade guard

installed. Use the riving knife without blade guard.

Make sure the blade guard assembly is reinstalled

upon completion of this type of cut. Read the appropriate section which describes the type of cut

in addition to this section on non-through or dado

cuts. For example, if your non-through cut is a rip

cut, read and understand the section on rip cuts

before proceeding.

piece during most of the cut. Be alert to the ex-

posed blade at the start and nish of every cut

to reduce the risk of personal injury.

Never feed wood with your hands when making

any non-through cut such as rabbets or dadoes.

To avoid personal injury, always use push blocks,

push sticks, and featherboards.

Do not make complex non-through cuts, such as

plunge cuts, resawing, moulding head cutting,

or plowing.

1. Remove the battery pack.

2. Remove the riving knife with blade guard and

3. Install the riving knife.

4. Adjust the bevel angle to 0°.

5. Set the blade to the correct depth for the workpiece.

6. Depending on the shape and size of the work-

7. Install a feather board in the appropriate position

8. Insert the battery pack.

9. Make sure the wood is clear of the blade before

15

Making a Large Panel Cut

Make sure the blade guard assembly is installed and working prop-

piece.

fence or miter gauge. If the panel is too large to

use either the rip fence or the miter gauge, it is

too large for this saw.

face behind the saw for the cut work. Add supports

to the sides as needed.

for the cut being made.

turning on the saw.

speed.

as necessary.

a complete stop before removing the workpiece.

Making a Non-Through Cut

When making a non-through cut,

the blade is covered by the work-

anti-kickback pawls.

piece, use the rip fence or miter gauge.

for the cut being made.

turning on the saw.

10. Turn ON the saw. Allow the saw to come to full

WARNING

WARNING

speed.

11. Use a push stick and/or push blocks to move the

piece into the cut.

12. Turn OFF the saw. Wait for the blade to come to

a complete stop before removing the workpiece.

13. Once all non-through cuts are complete, remove

the battery pack and reinstall the riving knife with

guard and anti-kickback pawls.

Making a Dado Cut

Blades are sharp. Wear work gloves

Always remove riving knife before

making a dado cut.

An optional dado throat plate is required for this procedure (For a complete listing of accessories, go online to

www.milwaukeetool.com or contact a

distributor). All blades and dado sets must

not be rated less than the speed of this

tool. This saw is designed for use with a 6" stack

dado (up to width of 3/4"). Do not use an adjustable

dado or molding cutters on this saw.

piece during most of the cut. Be alert to the ex-

posed blade at the start and nish of every cut

to reduce the risk of personal injury.

To avoid personal injury, always use push blocks,

push sticks, and featherboards.

1. Remove the battery pack.

2. Remove the riving knife with blade guard and

anti-kickback pawls.

3. Remove the standard blade and install the dado

blade, according to manufacturer instructions,

using the blade and chippers appropriate for the

desired width of cut. NOTE: Always store the throat

plate, blade, ange, and bolt in a secure location.

4. Install the dado throat plate and rotate the blade

by hand to make sure it turns freely then lower

the blade.

5. Depending on the shape and size of the work-

piece, use the rip fence or miter gauge.

6. Install a feather board in the appropriate position

for the cut being made.

7. Insert the battery pack.

8. Make sure the wood is clear of the blade before

turning on the saw.

9. Turn ON the saw. Allow the saw to come to full

speed.

10. Use a push stick and/or push blocks to move the

piece into the cut.

11. Turn OFF the saw. Wait for the blade to come to

a complete stop before removing the workpiece.

12. Once all non-through cuts are complete, remove

the battery pack and reinstall the standard blade,

throat plate, riving knife with guard and anti-

kickback pawls.

when handling blades.

When making a non-through cut,

the blade is covered by the work-

Troubleshooting

Problem Cause Solution

Excess

vibration.

Rip fence

does not

move

smoothly.

Cutting

binds or

burns work.

Wood

edges away

from rip

fence when

ripping.

Saw does

not make

accurate

90˚ or 45˚

cuts.

Height

adjusting

hand-wheel

is hard to

turn.

S

aw does

not start.

Blade

makes poor

cuts.

Motor

labors in rip

cut.

B

lade is out of

balance.

Blade is damaged.

Saw is not mounted

securely.

Work surface is

uneven.

Blade is warped.

Rip fence not

mounted correctly.

Rails are dirty or

sticky.

Blade is dull.

Blade is heeling.

Work is fed too fast.

Rip fence is

misaligned.

Wood is warped.

Riving knife is out of

alignment.

Blade not properly

sharpened or set.

Bevel adjustment is

out of alignment.

Gears or screw post

inside cabinet are

clogged with saw

dust.

Battery pack is at end

of charge.

Battery pack contacts

are dirty.

Blade is dull or dirty.

Blade is wrong type

for cut being made.

Blade is mounted

backwards.

Blade not proper for

rip cut.

Work is fed to fast

into blade.

Replace blade.

Replace blade.

Tighten all

hardware.

Reposition on at

surface. Adjust legs

of optional stand.

Check saw blade

installation.

Replace blade if

necessary.

Remount the rip

fence.

Clean rails.

Replace or sharpen

blade.

See

Blade to Miter

Slot Adjustment

(Heeling)

.

Slow the feed rate.

Align the rip fence.

Replace the wood.

Always cut with

convex side to

table surface.

See Riving Knife

to Saw Blade

Adjustment.

Resharpen or set

blade.

See Bevel

Adjustments at 0°

and 45°

Clean the gears or

screw post.

Charge battery

pack.

Clean battery pack

contacts.

Clean, sharpen, or

replace blade.

Replace with

correct type.

Remount blade.

Change blade; rip

blade typically has

fewer teeth.

Slow feed rate.

16

Saw

WARNING

WARNING

WARNING

WARNING

shuts o

unexpectedly

Battery overtemperature

Allow battery to

cool for 10 minutes

before use.

MAINTENANCE

To reduce the risk of injury, always

battery pack from the charger or tool before

performing any maintenance. Never disassemble

the tool, battery pack or charger. Contact a

MILWAUKEE service facility for ALL repairs.

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

Inspect your tool for issues such as undue noise,

misalignment or binding of moving parts, breakage of

parts, or any other condition that may aect the tool

operation. Return the tool, battery pack, and charger

to a MILWAUKEE service facility for repair. After six

months to one year, depending on use, return the

tool, battery pack and charger to a MILWAUKEE

service facility for inspection.

If the tool does not start or operate at full power with

a fully charged battery pack, clean the contacts on

the battery pack. If the tool still does not work properly, return the tool, charger and battery pack, to a

MILWAUKEE service facility for repairs.

ment after tool has been stored, dropped or

bumped, or used extensively. A tool that is out

of alignment will cause binding and could result

in serious personal injury.

unplug the charger and remove the

Maintaining Tool

To reduce the risk of injury from

kickback, check for proper align-

When making adjustments, follow this

order:

1. Throat Plate Adjustment

2. Blade Angle (Bevel) Adjustments at 0° and 45°

3. Blade to Miter Slot Adjustment

4. Blade to Fence Adjustment

5. Riving Knife to Saw Blade Adjustment

To reduce the risk of injury, always

performing any maintenance or adjustments.

blades may require dierent throat plates. Never

operate the saw without a throat plate in place.

A properly adjusted throat plate is important for a

smooth cut. The front of the throat plate must be

slightly lower or ush with the table top. The back of

the throat plate must be slightly higher than the table

top (0 to 0.027"). Check throat plate each time the

throat plate is changed, and periodically before use.

If the throat plate is not properly adjusted:

1. Remove the battery pack.

2. Remove the riving knife with guard.

3. Lower the blade by turning the height adjusting

wheel counterclockwise.

4. Use the throat plate set screws (2.5 mm) to adjust

the front and back heights.

5. Re-measure and repeat until the throat plate is

properly adjusted.

remove the battery pack before

1. Adjusting the Throat Plate

Always use the appropriate throat

plate for the operation. Dierent

Throat Plate Set Screws

2. Blade Angle (Bevel) Adjustment

The angle settings of the saw have been set at the

factory and, unless damaged in shipping, should not

require setting during assembly. After extensive use,

they should be rechecked and adjusted if necessary.

1. Remove the battery pack.

2. Set the blade angle to 0° and lock into place.

3. Raise the blade by turning the height adjusting

wheel clockwise.

4. Remove the riving knife.

To check for 0°:

5. Place a combination square

beside the blade on the

right. The edge of the

square and the saw blade

should be parallel. NOTE:

Make sure that the square

contacts the at part of the

saw blade, not the blade

teeth.

6. If the blade and square are

not parallel:

• Unlock the bevel locking

lever.

• Loosen the 0° adjustment screw.

0° Adjustment Screw

• Adjust the blade to the 0° position

• Lock the bevel locking lever.

• Rotate the cam until it contacts the bevel

• Tighten the adjustment screw. Check again for

square and continue to adjust if needed.

7. Once square, loosen the pointer screw and adjust

the pointer to 0°.

0° Cam

at 0° and 45°

Pointer

Screw

17

To check for 45°:

WARNING

8. Set the blade angle to 45° and lock into place.

9. Place a combination

square beside the blade

on the right using the 45°

side. The edge of the 45°

side of the square and the

saw blade should be parallel. NOTE: Make sure

that the square contacts

the flat part of the saw

blade, not the blade teeth.

10. If the blade and square

are not parallel:

• Unlock the bevel locking lever.

• Loosen the 45° adjustment screw.

45° Adjustment Screw

45° Cam

• Adjust the blade to the 45° position

• Lock the bevel locking lever.

• Rotate the cam until it contacts the bevel

• Tighten the adjustment screw. Check again for

square and continue to adjust if needed.

11. Make a test cut at both 0° and 45° to check.

3. Blade to Miter Slot Adjustment (Heeling)

1. Remove the battery pack.

2. Set the blade angle (bevel) to 0° and lock into

place.

3. Raise the blade by turning the height adjusting

wheel clockwise.

4. Measure from front of blade to miter slot and back

of blade to miter slot. They must be equal.

5. If the blade is not square to the miter slot,

loosen the front or back blade adjustment screws

(4 mm hex) located from the bottom of the saw.

Blade Adjustment Screws

(from bottom of saw)

6. Slide the blade compartment left or right and

tighten the blade adjustment screws.

7. Recheck the front and back blade to slot measurements again.

8. Repeat until the blade is square to the miter slot.

4. Blade to Fence Adjustment

The rip fence must be parallel to the saw blade and

the miter gauge grooves.

risk of injury, always maintain proper rip fence

alignment.

1. Remove the battery pack.

2. Set the blade angle (bevel) to 0° and lock into

place.

3. Raise the blade by turning the height adjusting

wheel clockwise.

4. Remove the riving knife with guard.

5. Lock the fence onto Post A.

Post C Tape Screw Post A Post B

A misaligned rip fence can cause

kickbacks and jams. To reduce the

6. Slide the fence over to touch blade and lock the

fence lock lever.

18

7. Blade should contact fence evenly, front to back.

8. If not, use a 4 mm hex wrench to loosen the appropriate fence post (front and/or back). Slide the

post left or right as needed, and tighten securely.

9. Repeat until the fence touches the blade evenly.

10. To adjust the rip scale indicator to zero, use a 4

mm hex wrench to loosen the bolt and slide the

indicator to line up with zero on the silver tape.

Retighten the bolt.

11. Lock the fence onto Post B.

12. Measure from front of blade to fence and back

of blade to fence. Both must be 4".

13. If not, use a 4 mm hex wrench to loosen the ap-

propriate fence post (front and/or back). Slide the

post left or right as needed, and tighten securely.

14. Repeat until the fence measures 4" from front of

blade to fence and back of blade to fence. Fence

should rest completely on fence rail with hanging

o the edge of the fence rail.

15. Lock the fence onto Post C.

16. Slide the fence over to touch blade and lock the

fence lock lever.

17. Blade should contact fence evenly, front to back.

18. If not, use a 4 mm hex wrench to loosen the ap-