Milwaukee 2672-20 Operator's Manual

Cat. No. / No de cat.

2672-20

M18™ FORCELOGIC™ CABLE CUTTER

COUPE-CÂBLE M18™ FORCELOGIC™

CORTACABLES M18™ FORCELOGIC™

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

2

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING

Read all safety warnings, instructions, illustrations and specica-

tions provided with this power tool. Failure to follow

all instructions listed below may result in electric shock,

re and/or serious injury. Save all warnings and instructions for future reference. The term "power tool"

in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmo

-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operat

-

ing a power tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Un

-

modied plugs and matching outlets will reduce risk

of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi

-

tions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for car

rying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk

of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A mo

-

ment of inattention while operating power tools may

result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as a dust

mask, non-skid safety shoes, hard hat or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your nger on the

switch or energizing power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left at

-

tached to a rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair can

be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust col

-

lection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

• Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, break

age of parts and any other condition that may affect the power tool’s operation. If damaged, have

the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly main

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a hazard

-

ous situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles

and grasping surfaces do not allow for safe handling

and control of the tool in unexpected situations.

BATTERY TOOL USE AND CARE

• Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of re when used

with another battery pack.

• Use power tools only with specically designated

battery packs. Use of any other battery packs may

create a risk of injury and re.

3

• When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal to

another. Shorting the battery terminals together may

cause burns or a re.

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact ac

cidentally occurs, ush with water. If liquid contacts eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

• Do not use a battery pack or tool that is damaged

or modied. Damaged or modied batteries may

exhibit unpredictable behavior resulting in re, explo

-

sion or risk of injury.

• Do not expose a battery pack or tool to re or ex

-

cessive temperature. Exposure to re or temperature

above 265°F (130°C) may cause explosion.

• Follow all charging instructions and do not charge

the battery pack or tool outside the temperature

range specified in the instructions. Charging

improperly or at temperatures outside the specied

range may damage the battery and increase the risk

of re.

SERVICE

• Have your power tool serviced by a qualied repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

• Never service damaged battery packs. Service of

battery packs should only be performed by the manu

-

facturer or authorized service providers.

SPECIFIC SAFETY RULES FOR

CABLE CUTTER

• Do not use tool without cutting jaws installed.

Fingers could be crushed.

• Blade is sharp. Keep hands away from all cutting

edges and moving parts. Laceration and amputation

can occur.

• To reduce the risk of injury, wear safety goggles

or glasses with side shields when operating or

servicing the tool. Material may crack or shatter.

•

WARNING

To reduce the risk of explosion,

electric shock and property

damage, do not use on live electrical lines.

Tool is NOT insulated. Contact with a live

circuit could result in severe injury or death.

Turn off power before making a cut. Never cut gas

or water lines.

• Maintain labels and nameplates. These carry im

-

portant information. If unreadable or missing, contact

a MILWAUKEE service facility for a free replacement.

•

WARNING

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

lter out microscopic particles.

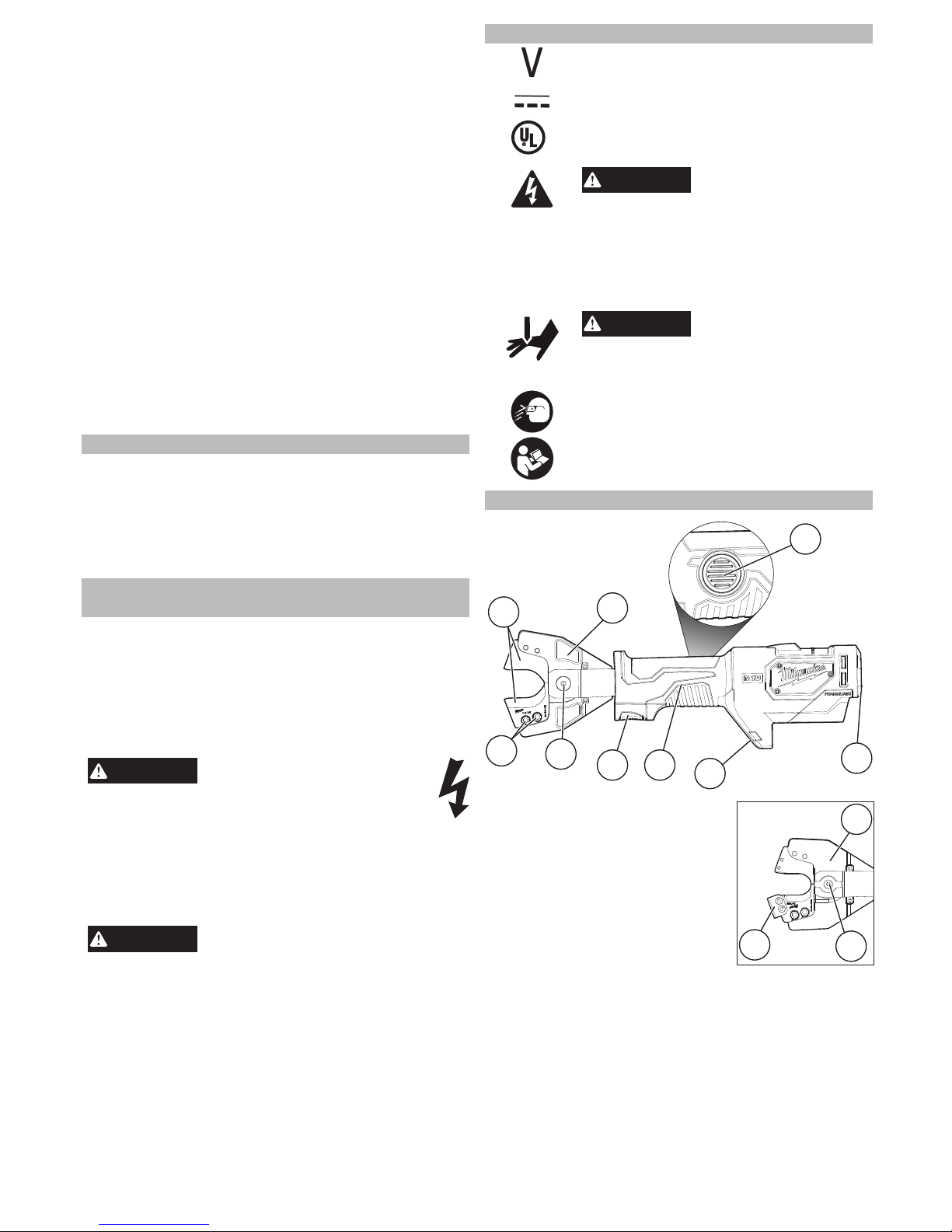

SYMBOLOGY

Volts

Direct Current

C

US

UL Listing for Canada and U.S.

WARNING

To reduce the risk of

explosion, electric

shock and property damage, do not

use on live electrical lines. Tool is

NOT insulated. Contact with a live

circuit could result in severe injury or

death. Turn off power before making a

cut. Never cut gas or water lines.

WARNING

Keep hands away from

all cutting edges and

moving parts. Blade is sharp. Laceration

and amputation can occur.

To reduce the risk of injury, wear safety

goggles or glasses with side shields

when operating or servicing the tool.

Read operator's manual.

FUNCTIONAL DESCRIPTION

1. Backup release valve

2. 750 MCM Cu jaws

3. Blades

4. Socket screws (5 mm)

5. Locking thumb screw

6. Trigger

7. Handle

8. LEDs

9. Hanger

10. 477 ACSR jaws

11. Blade retainer

12. Retaining pin

1

6

4

2

3

7

9

5

8

10

11

12

4

WARNING

Blades are sharp. Keep hands away

from cutting edge. Laceration can

occur.

3. Loosen, do not remove, the socket screws using

a 5 mm hex wrench.

4. Carefully slide the blade out of the jaws, keeping

ngers away from the cutting edge.

5. Insert the new blade, keeping ngers away from

the cutting edge.

6. Securely tighten socket screws to 115 in-lbs.

NOTE: The tightening of the socket screws may

cause the jaws to close. Keep hands and ngers

out of jaws, and away from cutting edges!

7. Repeat for other blade. Always change blades as

a set.

OPERATION

WARNING

To reduce the risk of explosion,

electric shock and property

damage, do not use on live electrical lines.

Tool is NOT insulated. Contact with a live

circuit could result in severe injury or death. Turn

off power before making a cut. Never cut gas or

water lines.

Blade is sharp. Keep hands away from cutting

edges and moving parts. Avoid cutting

short pieces of material that put hands

near blades. Laceration and amputation

can occur.

Always remove battery pack before changing

or removing accessories. Only use accessories

specically recommended for this tool. Others

may be hazardous.

To reduce the risk of injury, wear safety goggles

or glasses with side shields.

Cutting

Before cutting, ensure retaining pin is properly

seated, and blade socket screws are tight.

1. Insert the workpiece squarely between the blades.

Do not attempt to make angled cuts as it will dam-

age the workpiece and blades.

2. Hold the tool rmly and support the workpiece.

Ensure the workpiece is straight and centered in

the jaws. Keep hands away from blades.

3. Pull and hold the trigger through the operation.

When the cut is complete, the blades will separate

and the tool will shut off. Release the trigger.

NOTE: Workpiece may move slightly during the cut.

4. Two LEDs will light when the trigger is pulled.

WARNING

To reduce the risk of injury, only

cut recommended materials for the

jaws (see "Specications"). Do not attempt to cut

other materials.

Cutting Tips

•

Cut farther in from the end of the material to avoid

crooked cuts.

•

Do not attempt angled cuts. It will damage the

blades. Hold the material squarely between the

blades.

•

Cut clean material to extend the blade life. Wipe dirt

and debris from material and blades before begin-

ning the cut.

•

Do not cut 477 ACSR materials with 750 MCM Cu jaws.

Do not cut 750 MCM Cu materials with 477 ACSR

jaws. It could damage the blades, jaws, and tool.

•

When use the 477 ACSR jaws, ensure the blade

retainer is installed.

SPECIFICATIONS

Cat. No. ..................................................... 2672-20

Volts .............................................................. 18 DC

Battery Type .................................................M18™

Charger Type ................................................M18™

Jaw Type .......................................477 ACSR Jaws

(Cat. No. 49-16-2773)

Maximum Capacity ....ACSR: 477 MCM Hen ACSR

Guy Wire: 3/8" Non-EHS

Rebar: 3/8"

Ground Rod: 3/8"

Replacement Blades ..............Cat. No. 48-44-0412

Jaw Type .................................. 750 MCM Cu Jaws

(Cat. No. 49-16-2772)

Maximum Capacity ......... Copper Cable - 750 mcm

Aluminum Cable - 1000 mcm *

Replacement Blades ..............Cat. No. 48-44-0411

* 750 MCM Cu Jaws will cut any aluminum cable

with a diameter less than 1.225"

ASSEMBLY

WARNING

Recharge only with the charger

specied for the battery. For specic charging instructions, read the operator’s

manual supplied with your charger and battery.

Inserting/Removing the Battery

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body

of the tool. Make sure it latches securely into place.

WARNING

Always remove battery pack before

changing or removing accesso-

ries. Only use accessories specically recommended for this tool. Others may be hazardous.

Blades are sharp. Keep hands away from cutting

edge. Laceration can occur.

Inserting/Removing the Cutting Jaws

Use only MILWAUKEE cutting jaws. Do not use with

other jaw types. Other jaw types can cause damage

to the tool.

1. Remove the battery pack.

2. Remove the locking thumb screw (when used)

from the back of the retaining pin.

3. Push in, then rotate the retaining pin counterclock-

wise 90°

. The pin will pop out.

4. Insert the cutting jaws. Line up the center hole with

the retaining pin.

5. Push in the retaining pin, then rotate clockwise

90°

.

6. Insert and hand tighten the locking thumb screw.

NOTE: Use the locking thumb screw to prevent the

retaining pin from being unintentionally loosened.

A loose retaining pin may damage the tool.

7. Rotate the jaws to the desired angle.

CAUTION

To avoid damage to the tool, do not

operate the tool without the retaining pin fully inserted and locked into position.

Damage to the cylinder may occur.

Changing the Blades

Replace the blades when they become dull, rounded,

chipped, or damaged. Always replace blades as a set.

Use only MILWAUKEE blades and cutting jaws. Refer

to Specications for replacement blade numbers.

1. Remove the battery pack.

2. Remove cutting jaws from tool.

5

Backup Release Valve

If the jaws need to be opened without completing the

cycle, press and hold the backup release valve. Hold

tool securely until the cylinder retracts fully.

Jammed Blades

Dirt and debris can cause the blades to become

jammed together after a cut. If the tool shuts off and

the blades are still closed:

1. Press and hold the backup release valve to ensure

the tool has reset.

2. Remove the battery pack.

3. Remove the jaws from the tool.

4. Use a soft mallet to tap the rear of the jaws to

release.

5. Clean any dirt and debris from the blades before

starting another cut.

MAINTENANCE

WARNING

To reduce the risk of injury, always

unplug the charger and remove the

battery pack from the charger or tool before

performing any maintenance. Never disassemble

the tool, battery pack or charger. Contact a

MILWAUKEE service facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

Inspect your tool for issues such as undue noise,

misalignment or binding of moving parts, breakage of

parts, or any other condition that may affect the tool

operation. Return the tool, battery pack, and charger

to a MILWAUKEE service facility for repair. After six

months to one year, depending on use, return the

tool, battery pack and charger to a MILWAUKEE

service facility for inspection.

If the tool does not start or operate at full power with

a fully charged battery pack, clean the contacts on

the battery pack. If the tool still does not work properly, return the tool, charger and battery pack, to a

MILWAUKEE service facility for repairs.

Jaws and Blades

Inspect jaws for cracks or damage. Do not use damaged jaws. Replace the blades when they become

dull, rounded, chipped, or damaged.

Hydraulic Fluid

To extend the life of the tool, return the tool to a

MILWAUKEE service facility for hydraulic uid replacement after 20,000 cuts or 2 years of use.

WARNING

To reduce the risk of personal injury and damage, never immerse

your tool, battery pack or charger in liquid or

allow a liquid to ow inside them.

Cleaning

Clean dust and debris from vents. Keep handles

clean, dry and free of oil or grease. Use only mild

soap and a damp cloth to clean, since certain cleaning agents and solvents are harmful to plastics and

other insulated parts. Some of these harmful agents

include gasoline, turpentine, lacquer thinner, paint

thinner, chlorinated cleaning solvents, ammonia and

household detergents containing ammonia. Never

use ammable or combustible solvents around tools.

Repairs

For repairs, return the tool, battery pack and charger

to the nearest service center.

ACCESSORIES

WARNING

Always remove battery pack before

changing or removing accesso-

ries. Only use accessories specically recommended for this tool. Others may be hazardous.

For a complete listing of accessories, go online to

www.milwaukeetool.com or contact a local distributor.

SERVICE - UNITED STATES

1-800-SAWDUST (1.800.729.3878)

Monday-Friday, 7:00 AM - 6:30 PM CST

or visit www.milwaukeetool.com

Contact Corporate After Sales Service Technical

Support with technical, service/repair, or warranty

questions.

Email: metproductsupport@milwaukeetool.com

Become a Heavy Duty Club Member at

www.milwaukeetool.com to receive important

notications regarding your tool purchases.

SSERVICE - CANADA

Milwaukee Tool (Canada) Ltd

1.800.268.4015

Monday-Friday, 7:00 AM - 4:30 PM CST

or visit www.milwaukeetool.ca

LIMITED WARRANTY

USA & CANADA

Every MILWAUKEE power tool* (see exceptions below) is warranted

to the original purchaser only to be free from defects in material and

workmanship. Subject to certain exceptions, MILWAUKEE will repair

or replace any part on an electric power tool which, after examination,

is determined by MILWAUKEE to be defective in material or workman-

ship for a period of ve (5) years** after the date of purchase unless

otherwise noted. Return of the power tool to a MILWAUKEE factory

Service Center location or MILWAUKEE Authorized Service Station,

freight prepaid and insured, is required. A copy of the proof of purchase

should be included with the return product. This warranty does not

apply to damage that MILWAUKEE determines to be from repairs

made or attempted by anyone other than MILWAUKEE authorized

personnel, misuse, alterations, abuse, normal wear and tear, lack of

maintenance, or accidents.

Normal Wear: Many power tools need periodic parts replacement and

service to achieve best performance. This warranty does not cover

repair when normal use has exhausted the life of a part including,

but not limited to, chucks, brushes, cords, saw shoes, blade clamps,

o-rings, seals, bumpers, driver blades, pistons, strikers, lifters, and

bumper cover washers.

*This warranty does not cover Air Nailers & Staplers; Airless Paint

Sprayer; Cordless Battery Packs; Gasoline Driven Portable Power

Generators; Hand Tools; Hoist – Electric, Lever & Hand Chain;

M12™ Heated Gear; Reconditioned Product; and Test & Measurement Products. There are separate and distinct warranties available

for these products.

**The warranty period for Job Site Radios, M12™ Power Port, M18™

Power Source, Jobsite Fan and Trade Titan™ Industrial Work Carts

is one (1) year from the date of purchase. The warranty period for the

Cables for the Drain Snake is two (2) years from the date of purchase.

The warranty period for the LED in the LED Work Light and the LED

Upgrade Bulb for the Work Light is the lifetime of the product subject

to the limitations above. If during normal use the LED or LED Bulb

fails, the part will be replaced free of charge.

Warranty Registration is not necessary to obtain the applicable war-

ranty on a MILWAUKEE power tool product. The manufacturing date

of the product will be used to determine the warranty period if no proof

of purchase is provided at the time warranty service is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT

REMEDIES DESCRIBED HEREIN IS A CONDITION OF THE CONTRACT FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT.

IF YOU DO NOT AGREE TO THIS CONDITION, YOU SHOULD NOT

PURCHASE THE PRODUCT. IN NO EVENT SHALL MILWAUKEE BE

LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL OR

PUNITIVE DAMAGES, OR FOR ANY COSTS, ATTORNEY FEES,

EXPENSES, LOSSES OR DELAYS ALLEGED TO BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN

ANY PRODUCT INCLUDING, BUT NOT LIMITED TO, ANY CLAIMS

FOR LOSS OF PROFITS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT

Loading...

Loading...