Milwaukee 1-1-1854, 1-1-2404 User Manual

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

1854-1

2404-1

SUPER HOLE SHOOTERS

PERCEUSES HAUTE PERFORMANCE

PERFORADORAS SUPER

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operat-

ing a power tool. Distractions can cause you to lose control.

Protect others in the work area from debris such as chips and

sparks. Provide barriers or shields as needed.

ELECTRICAL SAFETY

4. Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adaptor plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user.

5. Double Insulated tools are equipped with a polarized plug

(one blade is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for

the three wire grounded power cord and grounded power supply

system.

6. Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

7. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

8. Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

9. When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W”. These cords are rated

for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

10. Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in

serious personal injury.

11. Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

12. Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools with the switch on invites accidents.

13. Remove adjusting keys or wrenches before turning on the

tool. A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury.

14. Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

15. Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection must

be used for appropriate conditions.

TOOL USE AND CARE

16. Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

17. Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for which

it is designed.

18. Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and must be

repaired.

19. Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventive safety measures reduce the risk of starting the tool

accidentally.

20. Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

21. Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edge are less likely to

bind and are easier to control. Do not use a damaged tool. Tag

damaged tools “Do not use” until repaired.

22. Check for misalignment or binding of moving parts, break-

age of parts, and any other condition that may affect the

tool’s operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

23. Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for

one tool, may become hazardous when used on another tool.

SERVICE

24. Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified per-

sonnel could result in a risk of injury.

25. When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this

manual. Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

page 2

SPECIFIC SAFETY RULES

1. Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its

own cord. Contact with a “live” wire will make exposed metal parts of tool “live” and shock the operator.

2. Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a

replacement.

3. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such as those dust masks that are specifically designed to filter out

microscopic particles.

MILWAUKEE

service facility for a free

Symbology

Underwriters Laboratories Inc.

Canadian Standards Association

Mexican Approvals Marking

Volts Direct Current or

Alternating Current

No Load Revolutions Per Minute

Amperes

10

Specifications

Steel

Steel

Bits

3/4"

1-1/4"

Hole

Saws

6"

6"

Wood

Auger

Bits

1-1/2"

1-1/2"

Ship

Auger

Bits

1-1/2"

1-1/2"

Selfeed

4-5/8"

4-5/8"

Tool

Flat

No

Cat. No.

1854-1

2404-1*

* To adapt a 3/4" capacity chuck to Cat. No. 2404-1 drill with No. 3 Internal Morse

Taper Socket specify Chuck Kit No. 49-22-1550. Kit consists of Chuck No.

48-66-2000 and Arbor No. 48-07-0100.

Volts

AC/DC

120

120

Load

RPM

350

250

Boring

Bits

1-1/2"

1-1/2"

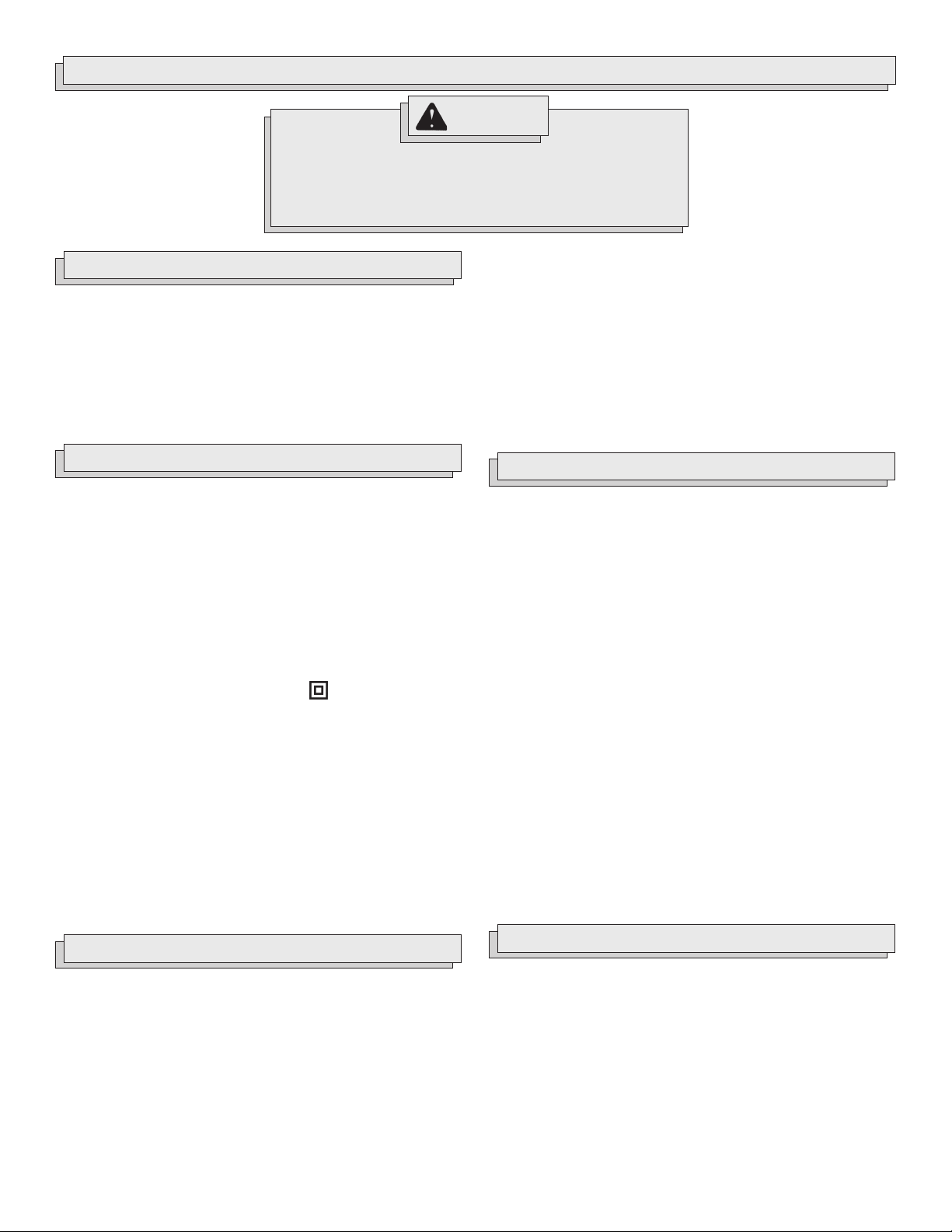

FUNCTIONAL DESCRIPTION

Bit

Masonry

Carbide

Tip Bit

1-1/2"

1-1/2"

10

10

1. Pipe handle

9

7

10

6

1

3

4

5

2. Chuck

(Cat. No. 1854-1)

3. Morse Taper Socket

(Cat. No. 2404-1)

4. Reversing switch

5. Trigger switch

6. Switch handle

7. Motor housing

8. Nameplate

9. Spade handle

10. Insulated gripping surfaces

9

8

10

7

10

6

1

2

8

5

4

page 3

GROUNDING EXTENSION CORDS

WARNING!

Improperly connecting the grounding wire can

result in the risk of electric shock. Check with a

qualified electrician if you are in doubt as to

whether the outlet is properly grounded. Do not

modify the plug provided with the tool. Never

remove the grounding prong from the plug. Do

not use the tool if the cord or plug is damaged. If

damaged, have it repaired by a

service facility before use. If the plug will not fit

the outlet, have a proper outlet installed by a

qualified electrician.

MILWAUKEE

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a

serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

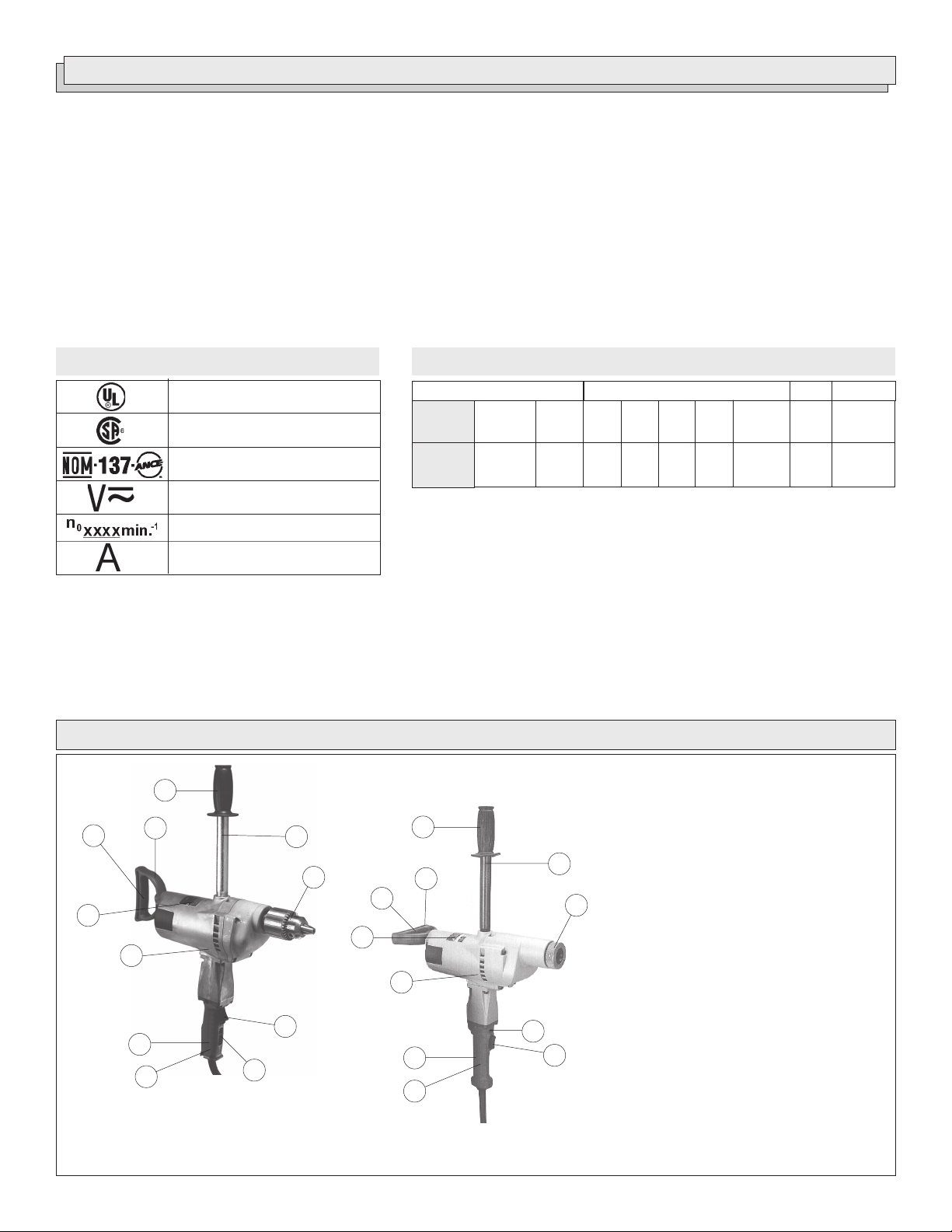

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required”

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break

down, grounding provides a low resistance path to carry electricity

away from the user, reducing the risk

of electric shock.

The grounding prong in the plug is connected through the green wire

inside the cord to the grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's grounding system and

must never be attached to an electrically “live” terminal.

Your tool must be plugged into an appropriate outlet, properly installed

and grounded in accordance with all codes and ordinances. The plug

and outlet should look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do

not require grounding. They have a

special double insulation system

which satisfies OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association and the National Electrical Code. Double Insulated tools may

be used in either of the 120 volt outlets shown in Figures B and C.

Fig. A

Fig. B

Fig. C

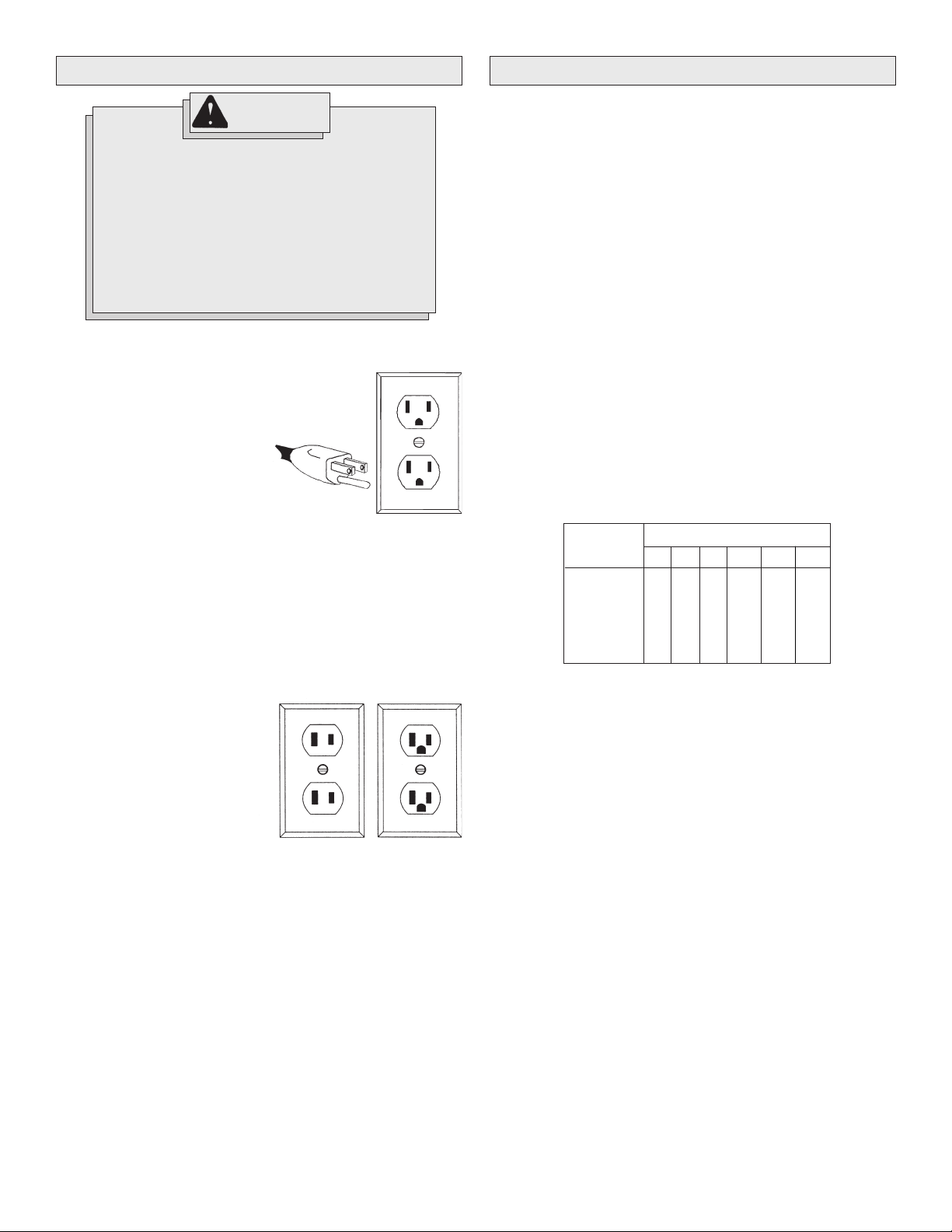

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked

with the suffix “W-A” (“W” in Canada) to indicate that it is acceptable

for outdoor use.

• Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it

repaired by a qualified person before using it.

• Protect your extension cords from sharp objects, excessive heat

and damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

5.1 - 8

16

16

14

12

10

Extension Cord Length

100'

50'

16

16

14

12

10

75'

16

14

12

10

10

14

12

10

10

150'

12

10

--

--

--

--

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

page 4

TOOL ASSEMBLY

OPERATION

WARNING!

To reduce the risk of injury, always unplug

tool before attaching or removing accessories

or making adjustments. Use only specifically

recommended accessories. Others may be

hazardous.

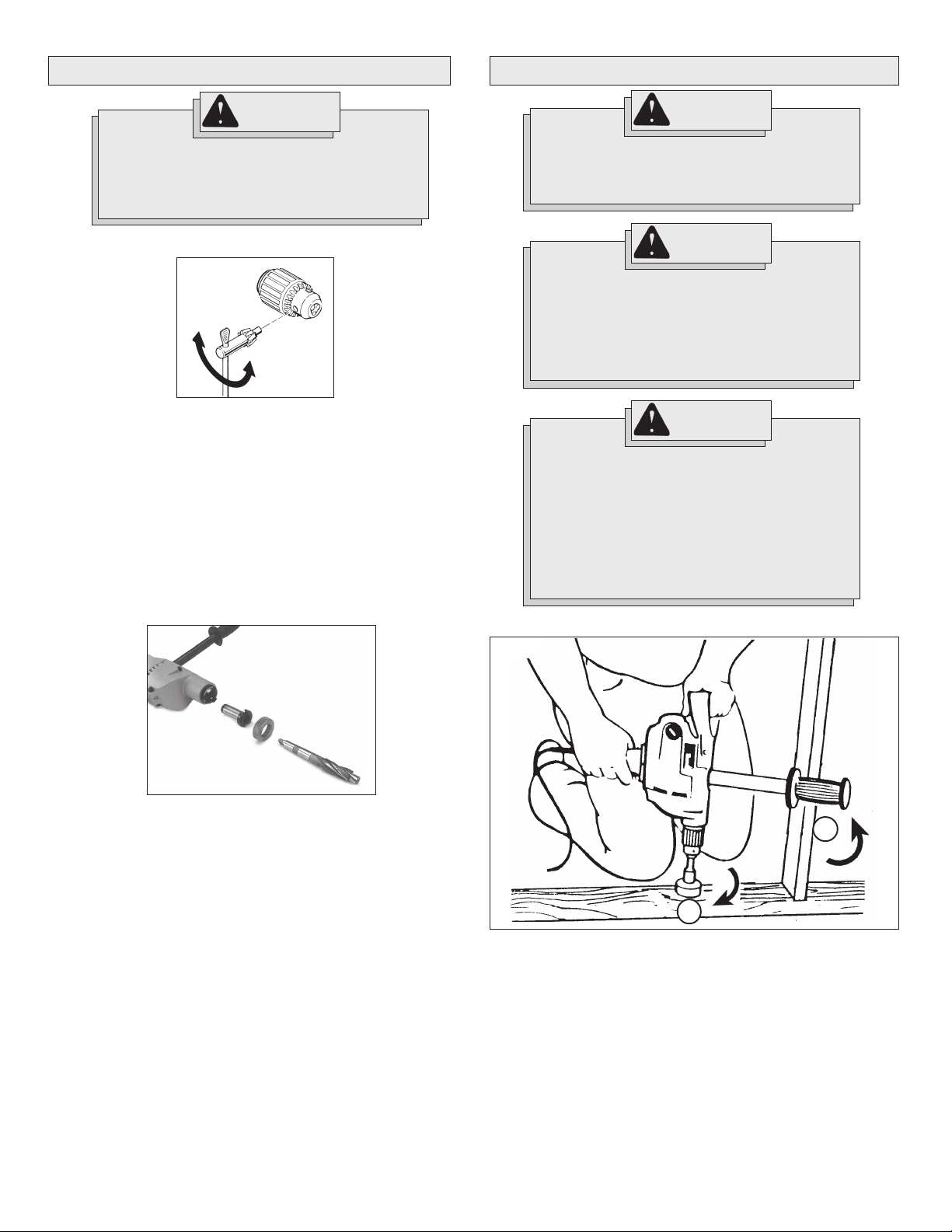

Installing Bits into Keyed Chucks (Fig. 1)

Fig. 1

1. Unplug tool.

2. Open the chuck jaws wide enough to insert the bit. Be sure the bit

shank and chuck jaws are clean. Dirt particles may prevent the bit

from lining up properly.

3. Insert the bit into the chuck. Center the bit in the chuck jaws and lift

it about 1/16" off of the bottom. Then, tighten the chuck jaws by

hand to align the bit.

4. Place the chuck key in each of the three holes in the chuck, turning

it clockwise as shown. Tighten securely.

5. To remove the bit, insert the chuck key into one of the holes in the

chuck and turn it counterclockwise.

Installing Bits into Morse Taper Sockets (Fig. 2)

Fig. 2

WARNING!

To reduce the risk of injury, wear safety goggles

or glasses with side shields. Unplug the tool

before changing accessories or making adjustments.

WARNING!

To reduce the risk of personal injury when

drilling, always hold tool by the insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring

or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and

shock the operator.

WARNING!

When drilling, always brace the drill against a

solid fixed object (such as a stud) in preparation

for a sudden reaction.

When drilling, never use your body to brace drill.

Never put your hands (or other body parts)

between the part of the drill being braced and the

object it is being braced against. Hands (or other

body parts) that are in the path of the reaction can

be pinched, crushed or broken.

Bit binding (Fig. 3)

Fig. 3

A No. 3 Morse Taper Socket is furnished as standard equipment on

Super Hole-Shooter Cat. No. 2404-1. Before inserting the drill bit, be

sure its taper matches the socket taper. To insert drill bit, push the shank

of the bit firmly into the socket. This is all that is necessary to properly

seat the bit for drilling. Always keep the taper shanks clean, free of

nicks and coated with a film of oil.

To remove the bit from the socket, unscrew the knurled taper socket

cap and pull out the bit and the socket. Once removed, the bit can be

gently knocked free with a soft metal mallet. Replace the socket and the

knurled cap.

Bit Selection

• Use sharp bits. Sharp bits are less likely to bind when drilling.

• Use the proper bit for the job. There are many types of bits designed

for specific purposes. Check the information on the bit's packaging

for proper usage.

• Do not use bits larger than the rated capacity of the drill. Gear

damage or motor overload may result (see "Specifications").

Pipe Handle

Thread pipe handle into the threaded hole in the motor housing.

B

A

If the bit binds, the drill will suddenly react in the opposite direction of the

rotation of the bit. Figure 3 shows the path of reaction, (B) if the drill bit

binds while being driven in forward (A).The operator should reduce the

chances of a sudden reaction by following the instructions listed below.

The operator should also prepare for a sudden reaction by holding

securely using the pipe handle or bracing against a solid fixed object.

page 5

To reduce the chance of bit binding:

• Use sharp bits. Sharp bits are less likely to bind when drilling.

• Use the proper bit for the job. There are many types of bits designed

for specific purposes.

• Avoid drilling warped, wet, knotty, and or pitchy material if possible.

• Avoid drilling in material that you suspect contains hidden nails or

other things that may cause the bit to bind.

The direction of reaction is always opposite of the direction of bit rotation.

Reaction is even more likely to occur when enlarging already existing

holes and at the point when the bit breaks through the other side of the

material.

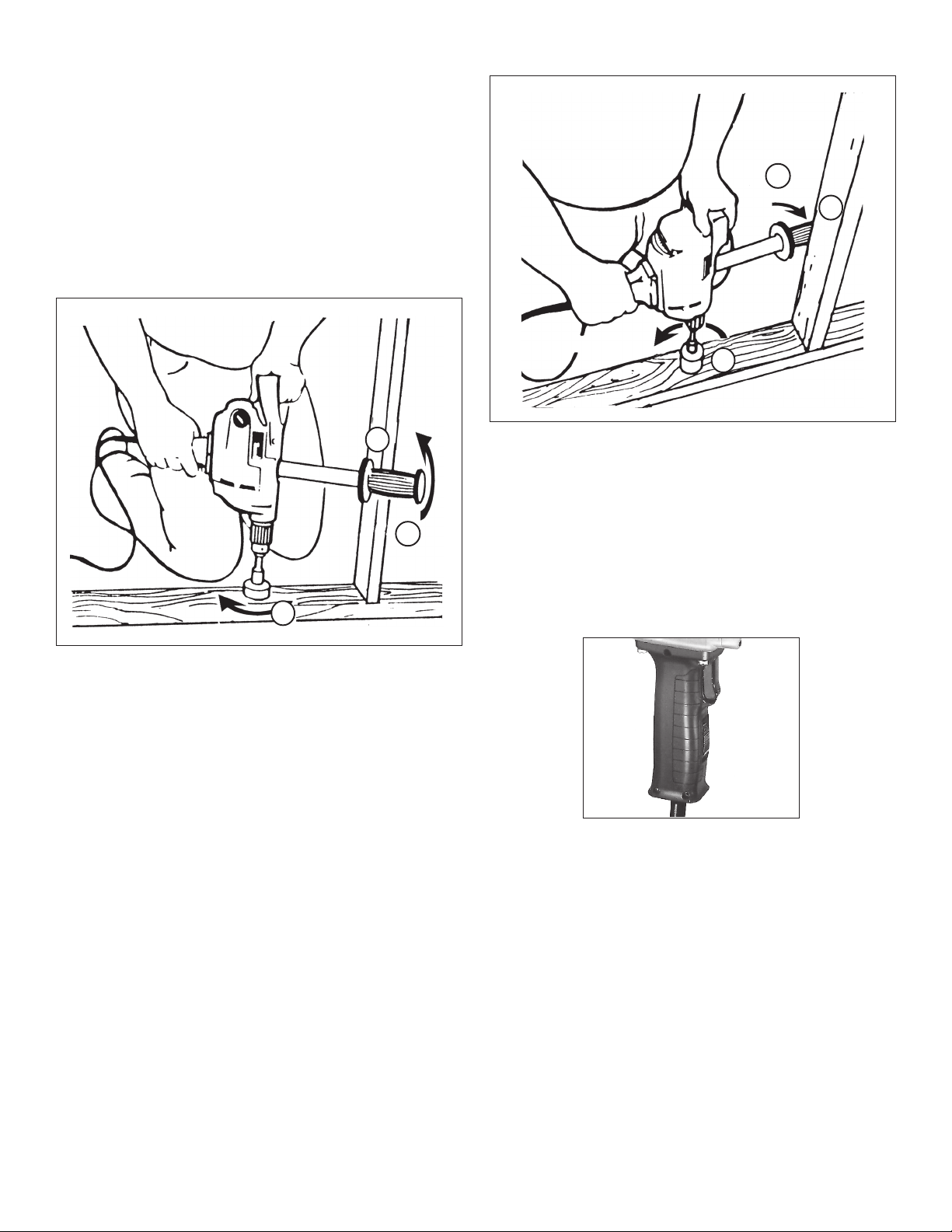

Bracing for forward rotation (Fig. 4)

Fig. 4

Bracing for reverse rotation (Fig. 5)

Fig. 5

B

C

A

C

B

A

When drilling in forward, the bit will rotate in a clockwise direction. If the

bit binds in the hole, the bit will come to a sudden stop and drill will

suddenly react in a counterclockwise direction.

Figure 4 shows an example of a Super Hole-Shooter properly braced for

forward rotation.

A. Forward (clockwise) rotation

B. Reaction

C. Brace drill with pipe handle here

If the bit binds, the pipe handle or the motor housing braced against the

stud will hold the drill in position.

When drilling in reverse, the bit will rotate in a counterclockwise direction. If the bit binds in the hole, the bit will come to a sudden stop and the

drill will suddenly react in a clockwise direction.

Figure 5 shows an example of the Super Hole-Shooter properly braced

for reverse rotation.

A. Reverse (counterclockwise) rotation

B. Reaction

C. Brace drill with pipe handle here

If the bit binds, the pipe handle or the motor housing braced against the

stud will hold the drill in position.

Reversing (Fig. 6)

Fig. 6

A reversing switch is located below the trigger switch for removal of

bits from holes. Permit the motor to come to a complete stop before

reversing. Reversing the tool with the gears in motion may cause severe

damage. When removing selfeed bits from partially drilled holes, a flick of

the trigger switch will free the threaded pilot screw. When the threads

are loose, lift the bit from the workpiece with the motor stopped.

page 6

Drilling

Before drilling, clamp the material down securely. A poorly secured piece

of material may result in personal injury or inaccurate drilling. When

drilling in light gauge metal or wood, use a wooden block to back up the

material to prevent damage to the workpiece.

Mark the center of the hole to be drilled with a center punch to give the bit

a start and to prevent it from "walking." Lubricate the drill bit with cutting

oil when drilling iron or steel. Use a coolant when drilling nonferrous

metals such as copper, brass or aluminum.

Loading...

Loading...