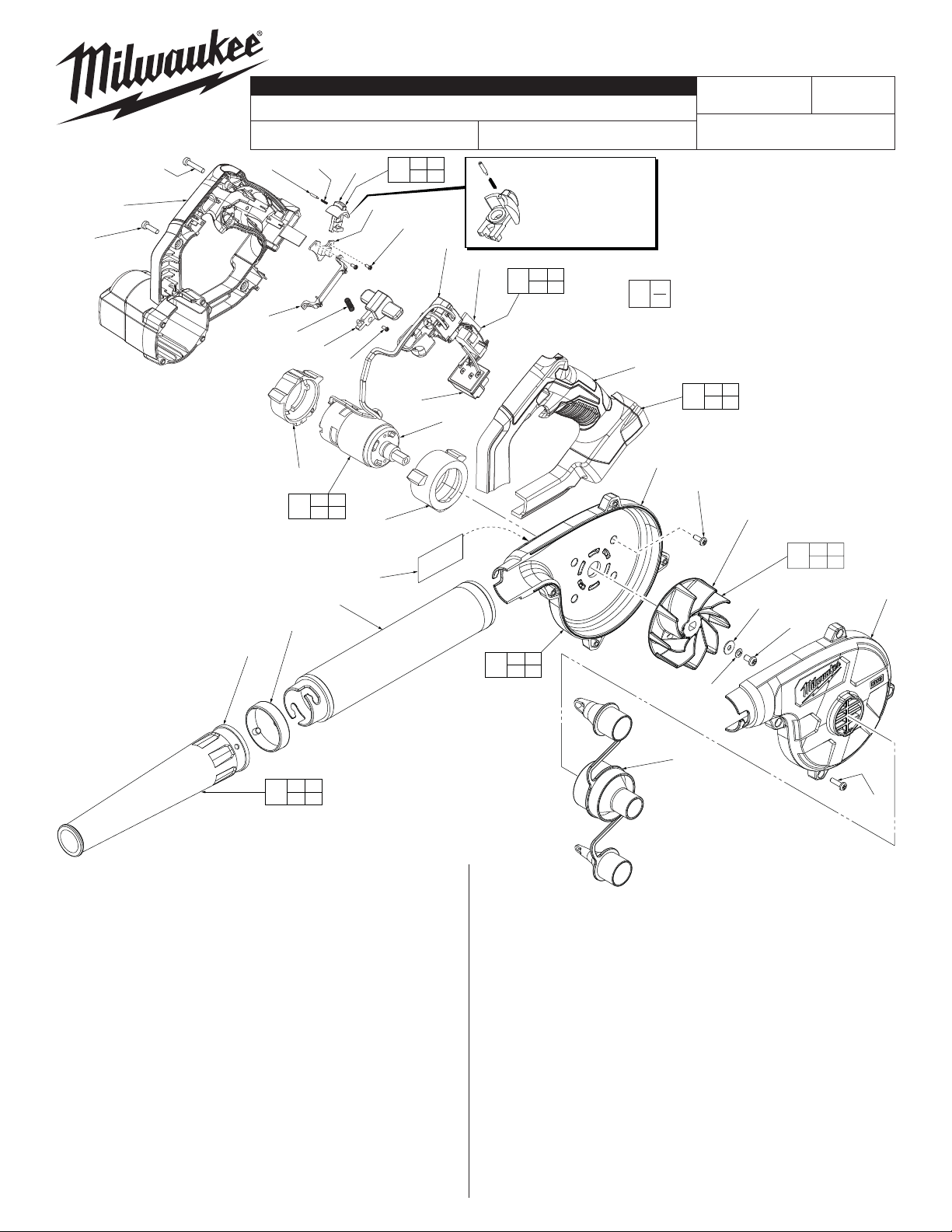

Page 1

1

(7x)

BULLETIN NO.

SERVICE PARTS LIST

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS

CORDLESS M18™ COMPACT BLOWER

35

14

STARTING

SERIAL NO.

NOTE: Place a little grease

on the Spring #10 and the

Pin #9 to help retain

the parts in the small

cavity of the Speed

37

41

35 36

37 38

F74A

Button

00

12

0

CATALOG NO.

9

33

(1x)

2

10

3

7

6

11

8

0884-20

9 10

39

11

38

4(2x)

36

REVISED BULLETIN

EXAMPLE:

Component Parts (Small #) Are Included

When Ordering The Assembly (Large #).

1 2

40

12 33

54-05-0805

DATE

Nov. 2013

WIRING INSTRUCTION

See Page 2

13

13 14

42

15

17

16

16 17

45

19

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

1 06-81-0016 M3 x 9 Pan Hd. Plastite T-10 Screw (7)

2 --------------- Handle/Motor Housing Halve-Right (1)

3 31-17-0130 Wire Trap (1)

4 06-81-0026 M2.3 x 6 Pan Hd. Plastite Phillips Screw (2)

6 42-42-0805 Switch Lock Button (1)

7 40-50-0206 Switch Lock Spring (1)

8 06-81-0046 M2.3 x 6 Pan Hd. Washer Screw-Phillips (1)

9 --------------- Speed Button Detent Pin (1)

10 --------------- Speed Button Spring (1)

11 --------------- Speed Button (1)

12 --------------- Handle Housing Halve-Left (1)

13 44-34-0450 Lower Motor Support (1)

14 --------------- Motor with Spindle (1)

15 44-34-0455 Upper Motor Support (1)

16 43-24-0510 Nozzle (1)

17 44-90-1040 Nozzle Ring (1)

19 43-24-0155 Extension Tube (1)

20 45-80-0020 Infl ator/Defl ator Valves (1)

21 06-81-0056 M4 x 18 Pan Hd. Plastite T-20 Screw (4)

22 --------------- Fan Housing Halve-Left (1)

23 05-83-0400 M5.0 x 8 Pan Hd. Phillips Machine Screw (1)

24 45-88-0013 Washer (1)

25 --------------- Fan (1)

15

31

19

27

26(4x)

25

23 24

44

25 32

24

23

21 22

43

27 31

32

20

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

26 06-81-0066 M4.0 x 10 Pan Hd. Plastite Phillips Screw (4)

27 --------------- Fan Housing Halve-Right (1)

31 12-20-0884 Service Nameplate (1)

32 06-97-0040 Lock Washer (1)

33 06-81-0017 M3 x 15 Pan Hd. Plastite T-10 Screw (1)

35 --------------- On-Off Switch (1)

36 --------------- Battery Connector Block (1)

37 --------------- Main PCBA (1)

38 --------------- Switch PCBA (1)

39 31-01-1010 Blower Speed Button Assembly (1)

40 14-34-1025 Handle/Motor Housing Assembly (1)

41 14-20-2000 Electronics Assembly

Consists of On-Off Switch, Main PCBA,

PCBA Switch, Battery Terminal Block (1)

42 14-50-1300 Motor Assembly with Spindle (1)

43 14-38-1010 Fan Housing Assembly (1)

44 22-84-0080 Blower Fan Kit (1)

45 43-24-0520 Nozzle/Extension Assembly (1)

MILWAUKEE ELECTRIC TOOL CORPORATION

13135 W. LISBON RD., BROOKFIELD, WI 53005

22

21

(4x)

Drwg. 3

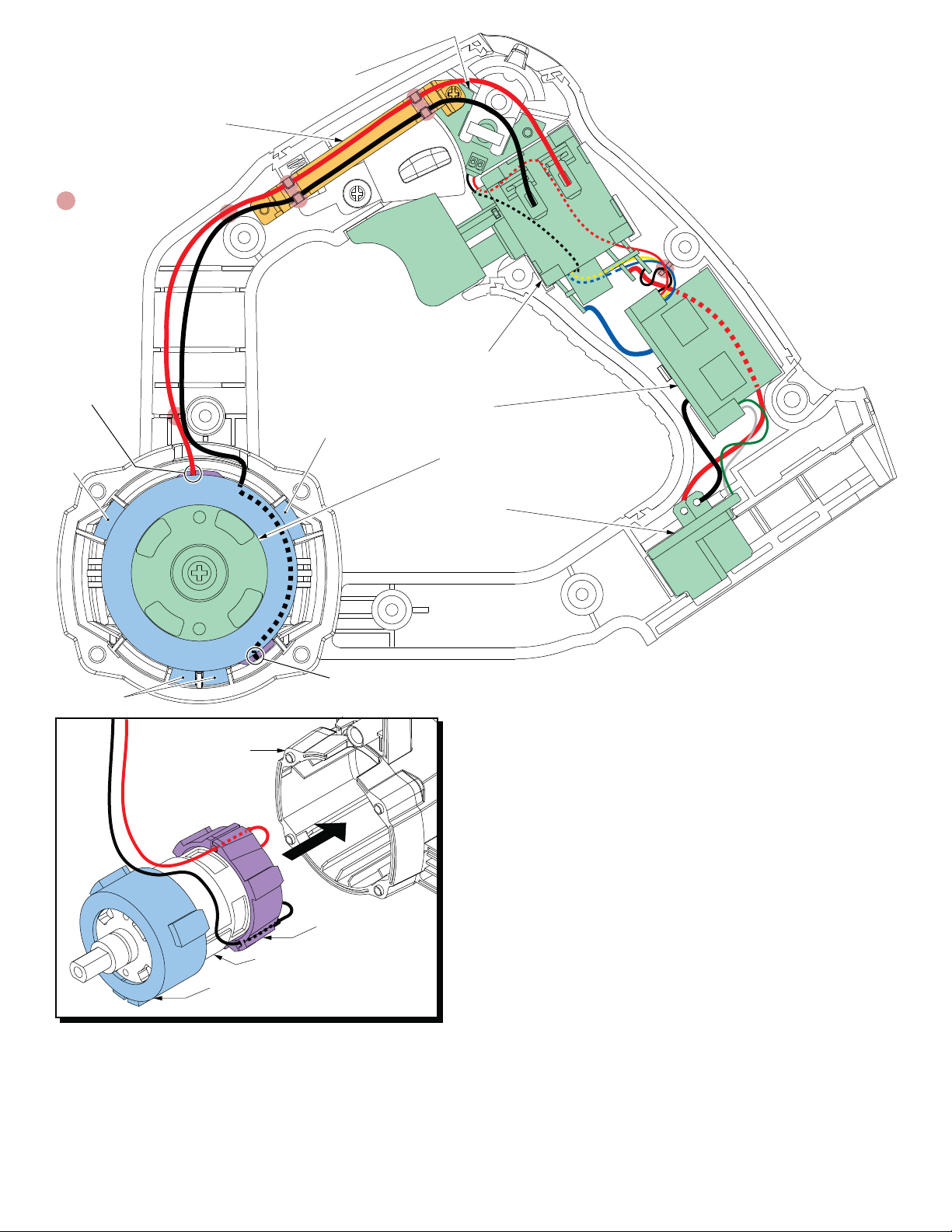

Page 2

Wire Trap #3

= WIRE TRAPS

or GUIDES

Switch PCBA

AS AN AID TO REASSEMBLY, TAKE

NOTICE OF WIRE ROUTING AND

POSITION IN WIRE GUIDES AND

TRAPS WHILE DISMANTLING TOOL.

BE CAREFUL AND AVOID PINCHING

WIRES BETWEEN HANDLE HALVES

WHEN ASSEMBLING.

Channel in

Lower Motor

Support for

red motor wire

Rubber

lugs

Rubber lugs

#2 Handle/Motor

Housing Halve

#15 Upper

Motor Support

Rubber lugs

#14 Motor

On-Off Switch

Main PCBA

Motor

Battery Terminal

Block

Channel in Lower Motor

Support for black motor wire

#13 Lower

Motor Support

When reinstalling a new Motor Assembly, be sure that the red and black motor

leads are fed through the large opening in the back of the Lower Motor Support

before soldering wires to the On-Off Switch.

Slide the lower motor support onto the rear of the motor, orienting it as shown

and making sure it is firmly pressed into place.

Be sure that the Upper Motor Support is oriented as shown and firmly seated on

the spindle end of the Motor.

Press the motor leads into the channels of the lower motor support and remove

most of the slack from the rear of the motor. Line up the rubber lugs of the upper

and lower motor supports with the channels in the motor cavity of the Handle/

Motor Housing Halve. Install the assembly into the handle/motor housing halve.

NOTE:

For ease of installation, the upper motor support can be left off the spindle end

of the motor until the lower motor support and motor are pressed into place. At

that time, the upper motor support can be assembled onto the motor, orienting

the rubber lugs with the corresponding channels in the motor cavity and firmly

seated.

Loading...

Loading...