Milwaukee 0566-1 Operator's Manual

HEAVY-DUTY DRAIN CLEANER WITH TRIGGER

SPEED CONTROL

DÉBOUCHOIR EXTRA ROBUSTE À VITESSE VARIABLE

HERRAMIENT A PARA T AREAS PESADAS DE LIMPIEZA DE

CAÑOS CON DISPARADOR PARA CONTROLAR LA

VELOCIDAD

TO REDUCE THE RISK OF INJURY , USER MUST READ AND UNDERSTAND

OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE

ET BIEN COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y

ENTENDER EL MANUAL DEL OPERADOR.

Catalog No.

No de Cat.

Catálog No.

0566-1

OPERATOR'S MANUAL

MANUEL DE L'UTILISATEUR

MANUAL DEL OPERADOR

32

POWER TOOL USE AND CARE

16. Do not force the power tool. Use

the correct power tool for your

application. The correct power tool

will do the job better and safer at the

rate for which it was designed.

17. Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

18. Disconnect the plug from the

power source and/or the battery

pack from the power tool before

making any adjustments, changing accessories, or storing

power tools. Such preventive safety

measures reduce the risk of starting

the tool accidentally.

19. Store idle power tools out of the

reach of children and do not allow persons unfamiliar with the

power tools or these instructions

to operate power tools. Power

tools are dangerous in the hands of

untrained users.

20. Maintain power tools. Check for

misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool's operation. If

damaged, have the power tool

repaired before use. Many acci-

dents are caused by poorly maintained

power tools.

21. Keep cutting tools sharp and

clean. Properly maintained cutting

tools with sharp cutting edges are less

likely to bind and are easier to control.

SERVICE

23. Have your power tool serviced by

a qualified repair person using

only identical replacement parts.

This will ensure that the safety of the

power tool is maintained.

WORK AREA SAFETY

ELECTRICAL SAFETY

PERSONAL SAFETY

WARNING!

READ ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in electric shock, fire

and/or serious injury. The term "power tool" in all of the warnings listed

below refers to your mains-operated (corded) power tool or batteryopearted (cordless) power tool.

SAVE THESE INSTRUCTIONS

GENERAL SAFETY RULES-FOR ALL POWER TOOLS

1. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2. Do not operate power tools in ex-

plosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the

dust or fumes.

3. Keep children and bystanders

away while operating a power

tool. Distractions can cause you to

lose control.

4. Power tool plugs must match the

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with earthed (grounded)

power tools. Unmodified plugs and

matching outlets will reduce risk of

electric shock.

5. Avoid body contact with earthed

or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is

earthed or grounded.

6. Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of

electric shock.

7. Do not abuse the cord. Never use

the cord for carrying, pulling, or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges, or moving parts. Damaged

or entangled cords increase the risk

of electric shock.

9. Stay alert, watch what you are do-

ing and use common sense when

operating a power tool. Do not use

a power tool while you are tired

or under the influence of drugs,

alcohol or medication. A moment

of inattention while operating power

tools may result in serious personal

injury.

10. Use safety equipment. Always

wear eye protection. Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

11. Avoid accidental starting. Ensure

the switch is in the off-position

before plugging in. Carrying tools

with your finger on the switch or plugging in power tools that have the

switch on invites accidents.

12. Remove any adjusting key or

wrench before turning the power

tool on. A wrench or a key left at-

tached to a rotating part of the power

tool may result in personal injury.

13. Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the

power tool in unexpected situations.

8. When operating a power tool out-

doors, use an extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the

risk of electric shock.

14. Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away

from moving parts. Loose clothes,

jewellery, or long hair can be caught in

moving parts.

15. If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dustrelated hazards.

22. Use the power tool, accessories

and tool bits etc., in accordance

with these instructions and in the

manner intended for the particular type of power tool, taking into

account the working conditions

and the work to be performed.

Use of the power tool for operations

different from those intended could result in a hazardous situation.

54

The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool.

The green wire in the cord must be the

only wire connected to the tool's grounding system and must never be attached to

an electrically “live” terminal.

Your tool must be plugged into an appropriate outlet, properly installed and

grounded in accordance with all codes and

ordinances. The plug and outlet should look

like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require grounding. They have a special

double insulation system which satisfies

OSHA requirements and complies with the

applicable standards of Underwriters Laboratories, Inc., the Canadian Standard Association and the National Electrical Code.

Double Insulated tools may be used in either of the 120 volt outlets shown in

Figures B and C.

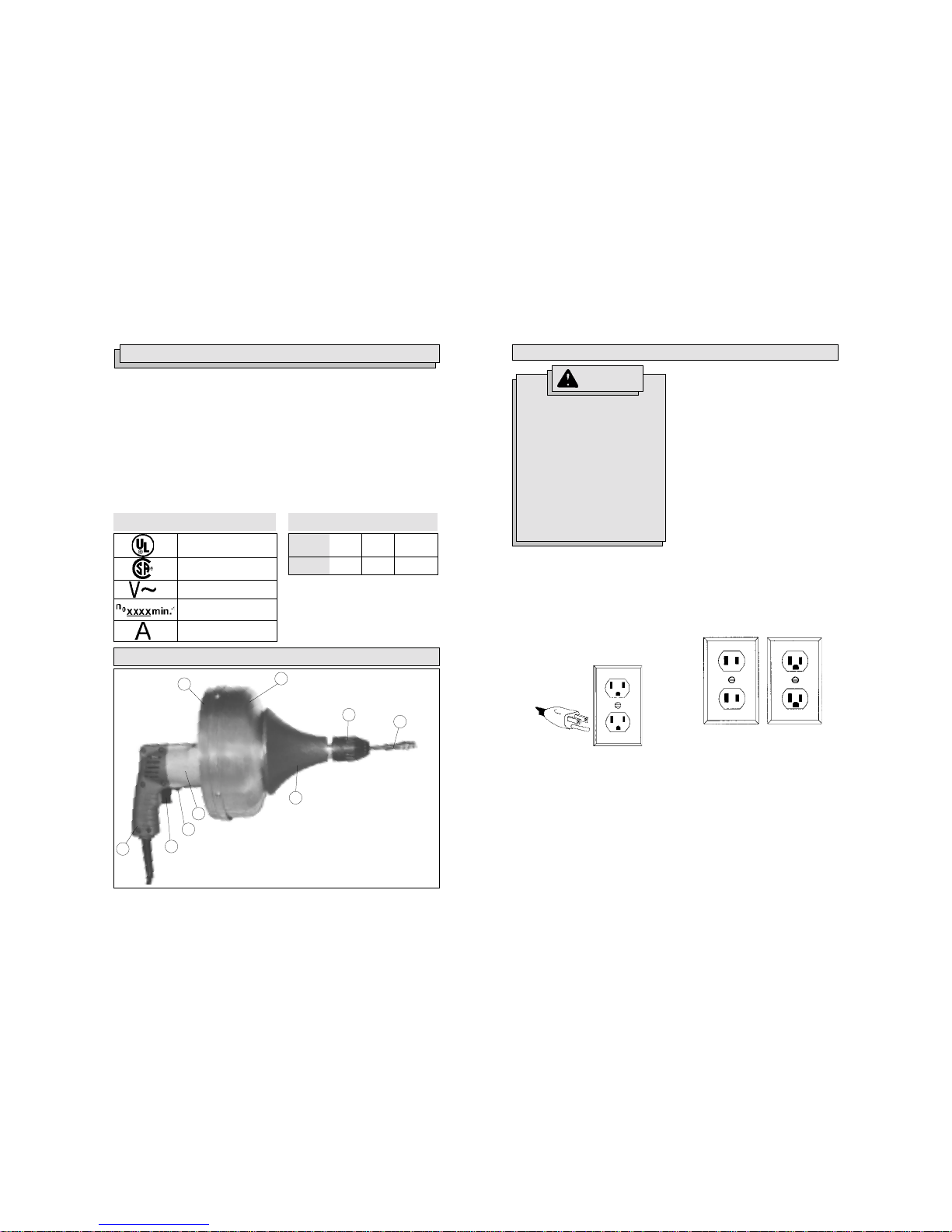

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required” have

a three wire cord and three prong grounding plug. The plug must be connected to a

properly grounded outlet (See Figure A). If

the tool should electrically malfunction or

break down, grounding provides a low resistance path to carry electricity away from

the user, reducing the risk of electric shock.

Fig. B

Fig. C

Fig. A

Improperly connecting the

grounding wire can result in the

risk of electric shock. Check

with a qualified electrician if you

are in doubt as to whether the

outlet is properly grounded. Do

not modify the plug provided

with the tool. Never remove the

grounding prong from the plug.

Do not use the tool if the cord or

plug is damaged. If damaged,

have it repaired by a MILWAUKEE

service facility before use. If the

plug will not fit the outlet, have a

proper outlet installed by a qualified electrician.

GROUNDING

WARNING!

Symbology

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates. These carry important information. If unreadable

or missing, contact a MILWAUKEE service facility for a free replacement.

2. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as those dust masks that are specifically designed to filter out microscopic particles.

Amps

1.6

No Load

RPM

0 - 450

Volts

120

Catalog

Number

0566-1

Specifications

Amperes

Canadian Standards

Association

Underwriters

Laboratories, Inc.

Volts Alternating Current

No Load Revolutions

per Minute (RPM)

FUNCTIONAL DESCRIPTION

1. Rear drum half

2. Front drum half

3. Jacobs

™

keyless chuck

4. Steel cable

5. Hand grip

6. Motor housing

7. Forward/reverse switch

8. Trigger switch

9. Handle

7

8

1

2

3

4

5

6

9

76

NOTE: To prevent damage to the cable, do not exceed the recommended pipe diameters.

Cable installation

Inserting cable into drum (Fig. 1 & 2)

1. Make a 15° to 30° bend approximately

1 inch from the tail end of the cable

(See Fig. 1). This will aid in seating

the cable into the drum.

Fig. 2

Cable

Size

1/4"

5/16"

5/16"

3/8"

Pipe

Dia.

1 1/4"-1 1/2"

1 1/4"-1 1/2"

1 1/4"-1 1/2"

1 1/2" -2"

Selecting the proper cable

Cable

Style

Steel Coreless

Steel Coreless

Steel Inner-core

Steel Inner Core

Additional Applications

Trap & Drain Lines

Trap & Drain Lines

Trap & Drain Lines"

Drain lines & Boiler Tube Cleaning

TOOL ASSEMBLY

2. Hold the drain cleaner firmly. Loosen

the chuck and insert the cable approximately 10 to 12 inches into the drum

(See Fig. 2). To prevent kinking, insert

the complete cable into the drum, 10 to

12 inches at a time, leaving only the

bulb or the enlarge head exposed.

Fig. 1

1"

15° to 30°

To reduce the risk of injury, always unplug the tool before attaching or removing accessories.

Use only specifically recommended accessories. Others may

be hazardous.

WARNING!

Grounded tools require a three wire extension cord. Double insulated tools can

use either a two or three wire extension

cord. As the distance from the supply outlet increases, you must use a heavier

gauge extension cord. Using extension

cords with inadequately sized wire causes

a serious drop in voltage, resulting in loss

of power and possible tool damage. Refer

to the table shown to determine the required minimum wire size.

The smaller the gauge number of the wire,

the greater the capacity of the cord. For

example, a 14 gauge cord can carry a

higher current than a 16 gauge cord. When

using more than one extension cord to make

up the total length, be sure each cord contains at least the minimum wire size required. If you are using one extension cord

for more than one tool, add the nameplate

amperes and use the sum to determine the

required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked with the

suffix “W-A” (“W” in Canada) to indicate that it is acceptable for outdoor

use.

• Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged

extension cord or have it repaired by

a qualified person before using it.

• Protect your extension cords from

sharp objects, excessive heat and

damp or wet areas.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE.

Recommended Minimum Wire

Gauge for Extension Cords*

Extension Cord Length

* Based on limiting the line voltage drop to

five volts at 150% of the rated amperes.

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

25'

18

18

18

18

16

14

12

75'

18

18

16

14

12

10

100'

18

16

14

12

10

150'

16

14

12

12

50'

18

18

18

16

14

12

10

EXTENSION CORDS

98

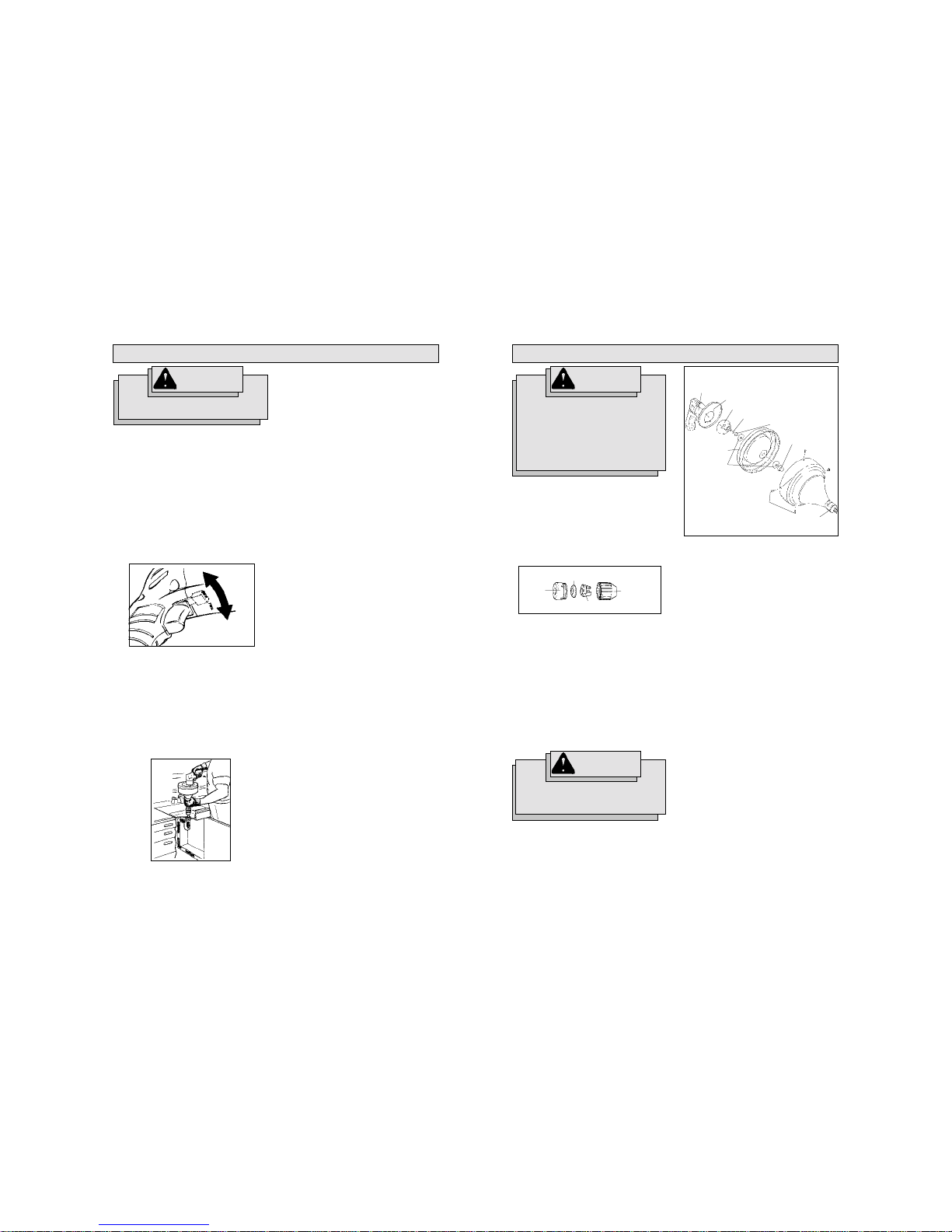

Chuck Maintenance (Fig. 5)

The chuck should be taken apart and

cleaned periodically. Collets should be replaced when worn to assure proper gripping of the cable. Do not use a wrench to

tighten the chuck. If the chuck fails to grip

the cable, either a thorough cleaning job or

a new collet is required.

Lubrication (Fig. 6)

Proper and regular lubrication is an important factor in determining the useful life of

your MILWAUKEE Drain Cleaner.The tool

has been lubricated at the factory and this

lubrication should be sufficient for six

months to one year depending upon the

amount of use the tool receives. Tools used

consistently on heavy duty production jobs

require lubrication more often. Tools that

have not been used for extended periods

of time should be relubricated before being put back into service.

WARNING!

To reduce the risk of injury, always

unplug your tool before

performing any maintenance.

Never disassemble the tool or try

to do any rewiring on the tool's

electrical system. Contact a

MILWAUKEE service facility for

ALL repairs.

To lubricate:

1. Unplug the tool and remove the steel

cable through the chuck.

2. Remove the four perimeter screws

from the drum.

3. Carefully pull the drum halves apart by

grasping the motor housing and the

chuck spindle. Set aside the front drum

half.

4. Remove the 3/8"-24 crown nut, “D”

hole hex washer and the rear drum

half. Set aside the rear drum half and

the parts.

5. Remove the three screws from the

gearcase.

6. With the tool resting on the motor housing, hold the diaphragm firmly against

the motor housing and lightly tap the

gearcase to loosen. If the gearcase

will not dislodge, use two screwdrivers opposite each other to gently pry

apart. If the diaphragm pulls free of

the motor housing, the armature may

dislodge, permitting the brushes to slip

off the commutator. Should this occur,

return the entire tool and all parts to

the nearest MILWAUKEE Service

Center or Authorized Service Station.

7. Clean out old grease and repack the

gearcase two-thirds full with

MILWAUKEE Type “A” grease - 1 lb.

can (Cat. No. 49-08-4121).

8. To assemble, reverse the procedure

described above.

WARNING!

Coiled cable can cause injury and

must be removed before drum is

opened.

MAINTENANCE

Body

Thrust plug

Collet

Sleeve

Fig. 5

Flat washer

Shield

Gear case

Spindle washer

Chuck

spindle

Drum screw

Crown nut

“D” hole

hex washer

Rear drum

half

Motor

housing

Fig. 6

Starting, stopping and controlling

speed

These tools may be used at any speed

from 0 RPM to full speed.

1. To start the tool, pull the trigger.

2. To vary the driving speed, increase or

decrease pressure on the trigger. The

further the trigger is pulled, the greater

the speed.

3. To stop the tool, release the trigger.

Using forward/reverse switch (Fig. 3)

1. For forward (clockwise) rotation,

push the forward/reverse switch to

the left.

2. For reverse (counterclockwise) rotation, push the forward/reverse

switch to the right. Although an interlock prevents reversing the tool while

the motor is running, allow the motor

to come to a full stop before reversing.

Inserting cable into drain (Fig. 4)

1. Set the forward/reverse switch to the

forward position

2. Loosen the chuck and remove 10 to

12 inches of the cable from the drum.

3. Tighten the chuck by hand.

4. Operate the tool at low speed. Continue to feed the cable (steps 2 and 3)

into the drain using a back and forth

motion until the obstruction is cleared.

This procedure keeps the cable rotating and will prevent binding.

NOTE: If the tool binds, stop it immediately.

To unbind drain cleaner

1. Withdraw the tool a few inches while

in reverse to free the cable.

2. Stop the tool.

3. After the tool has come to a complete

stop, switch back to the forward direction.

CAUTION: Extended operation of the tool

in reverse can cause damage to the cable

and accessories.

Removing cable from drain

1. Tighten the chuck. With the tool running slowly in the forward direction,

remove 10 to 12 inches of the cable.

2. Stop the tool. Wash and wipe the exposed cable with a rag. Loosen the

chuck and push the exposed cable into

the drum and retighten the chuck. Repeat steps 1 and 2 as necessary until

all the cable is free of the drain.

3. Before storing the drain cleaner, remove the full length of the cable. Coil it

loosely. Then wash and wipe it with

an oiled rag before returning it to the

drum.

To reduce the risk of injury,

always wear eye protection.

WARNING!

Fig. 4

OPERATION

Reverse

Forward

Fig. 3

1110

WARNING!

To reduce the risk of injury,

electric shock and damage to the

tool, never immerse your tool in

liquid or allow a liquid to flow inside the tool.

Maintaining tools

Keep your tool in good repair by adopting a

regular maintenance program. Before use,

examine the general condition of your tool.

Inspect guards, switches, tool cord set and

extension cord for damage. Check for

loose screws, misalignment, binding of

moving parts, improper mounting, broken

parts and any other condition that may affect its safe operation. If abnormal noise

or vibration occurs, turn the tool off immediately and have the problem corrected before further use. Do not use a damaged

tool. Tag damaged tools “DO NOT USE” until

repaired (see “Repairs”).

Under normal conditions, relubrication is

not necessary until the motor brushes

need to be replaced. After six months to

one year, depending on use, return your

tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

• Electrical inspection (switch,cord,

armature, etc.)

• Testing to assure proper mechanical

and electrical operation

Cleaning

Clean dust and debris from vents. Keep

the tool handles clean, dry and free of oil

or grease. Use only mild soap and a damp

cloth to clean your tool since certain cleaning agents and solvents are harmful to plastics and other insulated parts. Some of

these include: gasoline, turpentine, lacquer

thinner, paint thinner, chlorinated cleaning

solvents, ammonia and household detergents containing ammonia. Never use flammable or combustible solvents around

tools.

Drill size and depth of drill to be used

in removing plasticore

Repairing kinked or broken cables

(Fig. 7)

Installing replacement bulbs on steel

cables

If the cable becomes kinked, it can be repaired by cutting off the damaged portion

and attaching a replacement bulb.

Core Size

3/8"

5/16"

Drill No.

#206

#33

Depth

(.430)

(.437)

Steel cable

Replacement bulb

Fig. 7

1. To install the replacement bulbs, cut

the cable off below the kinked portion.

2. Grind or file off all burrs remaining on

the cable.

3. Using a screwdriver, slightly spread

apart the coils on the cable. This will

make it easier to thread on the replacement bulb.

4. Manually screw on the replacement

bulb. The bulb end must be facing

away from the coil.

5. Tighten the replacement bulb onto the

steel cable using a pliers or a vice

grips. It is not necessary to weld the

bulb onto the cable since it is a right

hand coiled cable. When pressure is

applied during pipe cleaning, the bulb

tightens on to the cable.

Installing replacement couplings on

core cables

1. Make sure the end of the cable is

ground flat.

2. Place the end of the cable into a vice

so that it extends beyond the vise jaws

by 2 inches. Tighten securely.

3. Drill out the plasticore center using the

proper drill bit (see Drill Size Chart ).

Operate drill with a fast “in and out”

motion until the center of the cable is

clear of plastic to the specified depth

and diameter (see Drill Size Chart).

This generally takes 25-30 seconds.

When clear, tap the end of the cable

several times to knock out any plastic

or metal wire chips.

4. Using a vise grip, thread the coupling

into the drill hole until the shoulder on

the coupling is snug against the face

of the cable.

NOTE: Do not over torque. A flush fit is

all that is required.

FIVE YEAR TOOL

LIMITED WARRANTY

Every MILWAUKEE tool is tested before

leaving the factory and is warranted to be

free from defects in material and workmanship. MILWAUKEE will repair or replace (at MILWAUKEE’s discretion), with-

out charge, any tool (including battery

chargers) which examination proves to be

defective in material or workmanship from

five (5) years after the date of purchase.

Return the tool and a copy of the purchase

receipt or other proof of purchase to a

MILWAUKEE Factory Service/Sales Support Branch location or MILWAUKEE Authorized Service Station, freight prepaid

and insured. This warranty does not cover

damage from repairs made or attempted

by other than MILWAUKEE authorized personnel, abuse, normal wear and tear, lack

of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are

warranted for one (1) year from the date

of purchase.

THE REPAIR AND REPLACEMENT REMEDIES

DESCRIBED HEREIN ARE EXCLUSIVE. IN NO

EVENT SHALL MILWAUKEE BE LIABLE

FOR ANY INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING LOSS

OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES, OR

CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR

PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal

rights. You may also have other rights that

vary from state to state and province to

province. In those states that do not allow

the exclusion of implied warranties or limitation of incidental or consequential damages, the above limitations or exclusions

may not apply to you. This warranty applies to the United States, Canada, and

Mexico only.

For a complete listing of accessories refer

to your MILWAUKEE Electric Tool catalog

or go on-line to www.milwaukeetool.com.

To obtain a catalog, contact your local distributor or a service center.

Repairs

If your tool is damaged, return the entire

tool to the nearest service center.

Loading...

Loading...