Page 1

MILROYAL® D Drive With

Packed Plunger Liquid End

Instruction Manual

Manual No : 53941

Rev. : 00

Rev. Date : 01/2016

Page 2

PRECAUTIONS

The following precautions should be taken when working with metering pumps.

Please read this section carefully prior to installation.

Protective Clothing

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working on or

near your metering pump. Additional precautions should be taken depending on the solution

being pumped. Refer to Safety Data Sheets for the solution being pumped.

Hearing Protection

It is recommended that hearing protection be used if the pump is in an environment where the

time- weighted average sound level (TWA) of 85 decibels is exceeded. (as measured on the

A scale - slow response)

Electrical Safety

• Remove power and ensure that it remains off while maintaining pump.

• DO NOT FORGET TO CONNECT THE PUMP TO EARTH/ GROUND.

• Electric protection of the motor (Thermal protection or by means of fuses) is to correspond

to the rated current indicated on the motor data plate.

Liquid Compatibility

Verify if the materials of construction of the wetted components of your pump are

recommended for the solution (chemical) to be pumped.

Pumps Water “Primed”

All pumps are tested with water at the factory. If your process solution is not compatible with

water, ush the Pump Head Assembly with an appropriate solution before introducing the

process solution.

Plumbing and Electrical Connections

Always adhere to your local plumbing and electrical codes.

Line Depressurization

To reduce the risk of chemical contact during disassembly or maintenance, the suction and

discharge lines should be depressurized before servicing.

Over Pressure Protection

To ensure safe operation of the system it is recommended that some type of safety/pressurerelief valve be installed to protect the piping and other system components from damage due

to over- pressure.

Lifting

This manual should be used as a guide only - Follow your company’s recommended lifting

procedures. It is not intended to replace or take precedence over recommendations, policies

and procedures judged as safe due to the local environment than what is contained herein.

Use lifting equipment that is rated for the weight of the equipment to be lifted.

ii Instruction Manual

Page 3

TABLE OF CONTENTS

SECTION 1 - INSTALLATION ................................................................1

1.1 INTRODUCTION .................................................................1

1.2 UNPACKING .................................................................... 1

1.3 MOUNTING ..................................................................... 1

1.4 PIPING ....................................................................... 1

1.4.1 General Information ............................................................. 1

1.4.2 Suction Piping .................................................................. 2

1.4.3 Discharge Piping................................................................ 2

1.5 SERVICE CONNECTIONS .........................................................2

1.5.1 Pump Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5.2 Auxiliary (Accessory) Equipment.................................................... 3

1.5.3 Drains ....................................................................... 3

SECTION 2 - OPERATION .................................................................. 4

2.1 PRINCIPLES OF OPERATION ...................................................... 4

2.2 OPERATION .................................................................... 4

2.2.1 Pre- Operational Inspection ....................................................... 4

2.2.2 Capacity Adjustment: Stroke Length................................................. 4

2.2.3 Capacity Adjustment: Stroke Speed .................................................5

2.3 START-UP ...................................................................... 5

2.3.1 General.......................................................................5

2.3.2 Packing.......................................................................5

2.3.3 Capacity Calibration .............................................................5

SECTION 3 - MAINTENANCE INSTRUCTIONS- DRIVE SECTION................................... 6

3.1 LUBRICATION................................................................... 6

3.2 SPARE PARTS .................................................................. 6

3.3 RETURNING PUMPS TO THE FACTORY ............................................. 6

3.4 REPLACING SPARE PARTS........................................................ 7

3.4.1 Removal of Gear Cage ...........................................................7

3.4.2 Removal of Crosshead ........................................................... 7

3.4.3 Assembly and Installation of Crosshead.............................................. 7

3.4.4 Assembly of Gear cage into Pump Housing ...........................................8

SECTION 4 - MAINTENANCE INSTRUCTIONS- LIQUID END 1/8” and 1/4” DIAMETER PLUNGERS...... 10

4.1 SPARE PARTS ................................................................. 10

4.2 RETURNING PUMPS TO THE FACTORY ............................................ 10

4.3 LUBRICATION.................................................................. 11

4.4 CHECK VALVE MAINTENANCE .................................................... 11

4.5 PACKING ADJUSTMENT, START- UP AND REPLACEMENT ............................. 11

4.5.1 Replacing Packing ............................................................. 11

iiiInstruction Manual

Page 4

SECTION 5 - MAINTENANCE INSTRUCTIONS- LIQUID END 7/16” and 5/8” DIAMETER PLUNGERS .... 13

5.1 SPARE PARTS ................................................................. 13

5.2 RETURNING PUMPS TO THE FACTORY ............................................ 13

5.3 LUBRICATION.................................................................. 14

5.4 CHECK VALVE MAINTENANCE ....................................................14

5.5 PACKING ADJUSTMENT, START- UP AND REPLACEMENT ............................. 14

5.5.1 Types of Packing............................................................... 15

5.5.2 Replacing Packing ............................................................. 15

SECTION 6 - TROUBLESHOOTING .......................................................... 17

LIST OF ILLUSTRATIONS

FIGURE 1. Pump dimensions ................................................................ 18

FIGURE 2. Polar Crank Mechanism ........................................................... 19

FIGURE 3. Basic Drive Assembly Drawing (102-2906-0001) ........................................ 20

FIGURE 4.1/8” and 1/4” Liquid Ends Assembly Drawing (102-290-600-015) ............................23

FIGURE 5. 7/16” and 5/8” Liquid Ends Assembly Drawing (102-290-600-012)........................... 25

LIST OF TABLES

TABLE 1. Drive Spare Parts .................................................................. 6

TABLE 2. Spare Parts for Liquid Ends with 1/8” and 1/4” Diameter Plunger. ............................ 10

TABLE 3. Spare Parts for Liquid Ends with 7/16” and 5/8” Diameter Plunger. ........................... 13

TABLE 4. Basic Drive Assembly Drawing Location Reference Chart .................................. 21

TABLE 5. 1/8” and 1/4” Liquid Ends Assembly Drawing Location Reference Chart ....................... 24

TABLE 6. 7/16” and 5/8” Liquid Ends Assembly Drawing Location Reference Chart ......................26

iv Instruction Manual

Page 5

SECTION 1 - INSTALLATION

1.1 INTRODUCTION

The MILROYAL® D Controlled Volume Pump is a

reciprocating plunger, positive displacement pump

designed to deliver accurately measured liquid

volumes against a positive differential pressure

(or head) between pump suction and discharge.

Precision built, the pump performs this function with

a repetitive accuracy of plus or minus one percent

of mean delivered volume.

Basically, the pump consists of a drive unit, plunger

and displacement chamber or liquid end in which

the plunger reciprocates. The pump delivers a

controlled volume of liquid with each discharge

stroke.

Pump capacity is adjustable by changing plunger

stroking speed and / or length. Capacity adjustment

can be made manually or automatically by

signal from remote process control instruments.

Selection of capacity control methods is determined

by the nature of the application.

1.3 MOUNTING (Refer to Figure 1)

Support the pump rmly in a level position on a

solid foundation, preferable with the base above

floor level to protect it from wash downs and

provide easier access for service. This model

pump is provided with three tie-down points to

accommodate anchor bolts. Table-top operation

is possible without need for tie-down with 1/8” or

1/4” plunger diameter liquid end, but tie-down is

necessary for 7/16” and 5/8” plunger diameter liquid

ends. Up to six units can be easily multiplexed to

a single standard motor without special support.

1.4 PIPING

1.4.1 General Information

1. Use piping materials that are resistant to

corrosion by the liquid being pumped. Use

care in selection of materials to avoid galvanic

corrosion at points of connection to the pump

liquid end.

1.2 UNPACKING

Pumps are shipped Free on Board (FOB) from

the factory and title passes to the customer

when carrier signs for receipt of it. The customer,

therefore, must le damage claims with the carrier.

The shipping crate should be carefully examined

upon receipt from carrier to be sure there is no

obvious damage to the contents. Open the crate

carefully, as there are sometimes accessory items

fastened to the inside of the crate which may be

lost or damaged. Examine all material inside crate

and check against packing list to be sure that all

items are accounted for and undamaged.

2. Use piping sufficiently heavy to withstand

maximum pressures.

3. Blow out all lines before making nal connections

to pump.

4. Provide for pipe expansion when hot uids are to

be pumped. Support piping so that pipe weight

is not placed on the pump. Never spring piping

to make connections.

5. Piping should be sloped in a manner to prevent

trapping of vapor pockets. Vapor present in liquid

end will cause inaccurate pump delivery.

1Instruction Manual

Page 6

SECTION 1 - INSTALLATION

1.4.2 Suction Piping

1. If possible use metal or plastic tubing for the

suction line because tubing has a smooth inner

surface and can be formed into sweep bends,

thus decreasing frictional ow losses.

2. Suction piping must be absolutely air tight to

insure accurate pumping. After installation, test

suction piping with air and soap solution for

leaks.

3. A strainer should be used in the suction line to

prevent foreign particles from entering the liquid

end. Any measures which prevent foreign matter

from entering and fouling the ball checks will

give increased maintenance free service.

4. It is preferable to have the suction of the pump

ooded by having the liquid end located below

the level of the uid in the supply tank.

5. When pumping liquids at temperatures near the

boiling point, provide sufcient suction head to

prevent “ashing’’ of the liquid into vapor when

it enters the liquid end on the suction stroke.

6. Suction piping need to be one or two sizes larger

than the liquid end suction tting, ensure NPIP

(Net Positive Inlet Pressure).

7. Sealed piping, sufficient suction pressure,

and properly adjusted packing are absolutely

necessary for accurate and stable pump

operation.

1.4.3 Discharge Piping

1. Install adequate size pump to prevent excessive

pressure losses on the discharge stroke of the

pump. Maximum pressure at the discharge

fitting on the liquid end must be kept at or

below the maximum pressure rating as shown

on the pump data plate. The peak flow of

this type pump during the discharge stroke is

approximately three times the average ow rate

(because of harmonic motion of the plunger) and

discharge piping should be sized accordingly.

2. The pump will not deliver a controlled ow if

the discharge pressure is less than the suction

pressure. Piping should be arranged to provide

at least 5 psi (34.5 kPa) positive pressure

differential from the discharge side to the suction

side. There are a number of ways to create an

articial discharge pressure, such as the use of

a vented riser or a back pressure valve.

1.5 SERVICE CONNECTIONS

1.5.1 Pump Drive

1. Check the nameplate data on the pump drive

(motor) and insure proper power supply is

available before making any connections.

2. Preferred motor shaft rotation is marked on the

drive side ange of the pump. Although severe

immediate damage will not occur if motor

rotation is incorrect, preferred rotation should

be observed. (See Maintenance Instructions,

Assembly of Gear Cage into Pump Housing.)

Where possible, correct drive rotation will be

established at shipment by the factory.

2

3. For drives other than constant speed electric

motors, refer to complete manufacturer’s

instructions and service information included

with pump.

Instruction Manual

Page 7

SECTION 1 - INSTALLATION

1.5.2 Auxiliary (Accessory) Equipment

1. Service connections for auxiliary or accessory

electrical equipment should be determined

by reference to wiring diagrams, instruction

manuals, and data plate requirements furnished

with the equipment.

2. Air operated equipment will normally require

two sources of air supply. A standard 60 psig

(414 kPa) (80-100 psi (552-690 kPa) at

compressor) plant air supply will usually

be satisfactory for the power elements.

An instrument air signal is required for control

instruments.

1.5.3 Drains

Provide drains convenient to the pump so that any

leakage may be easily removed. The pump catchall

area is provided with a cast hole which may be

drilled and tapped or otherwise altered to receive

desired piping for drainage.

3Instruction Manual

Page 8

SECTION 2 - OPERATION

2.1 PRINCIPLES OF OPERATION

MILROYAL® D Pumps consist of two basic

mechanisms; the drive system and the liquid

end. The drive mechanism (Figure 1) is unique

and operates on a patented polar crank principle

(Figure 2). Essentially, a crank driven by a worm

gear reduction system rotates on a plane whose

slope is variable.

As the slope of the plane is changed OFF the

vertical, a link transmits the resulting reciprocating

motion from the crank to the plunger. Stroke length

of the pump is increased from zero to maximum

by adjusting the slope of the plane from vertical.

As the plunger reciprocates in the liquid end,

the pumped liquid is alternately drawn into

and discharged from the liquid end. On the

suction (rearward) stroke the liquid follows

the plunger, unseating the double suction ball

checks and seating the discharge ball checks

(Figure 4 or 5). The discharge ball checks prevent

back-ow of liquid into the displacement chamber.

On the discharge stroke (plunger moving forward)

the plunger exerts pressure on the liquid, causing

the discharge ball checks to rise, allowing liquid

to flow out of the displacement chamber and

seating the suction ball checks. Thus, by repetitive

reciprocating plunger strokes, liquid is caused to

ow in only one direction from the suction port,

through the displacement chamber, and out the

discharge port.

2.2 OPERATION

2.2.1 Pre-Operational Inspection

After the pump is installed, but before it is started for

the rst time, a number of checks should be made:

1. Be sure all tie down bolts are tight, piping is

installed properly, and the discharge line is

open.

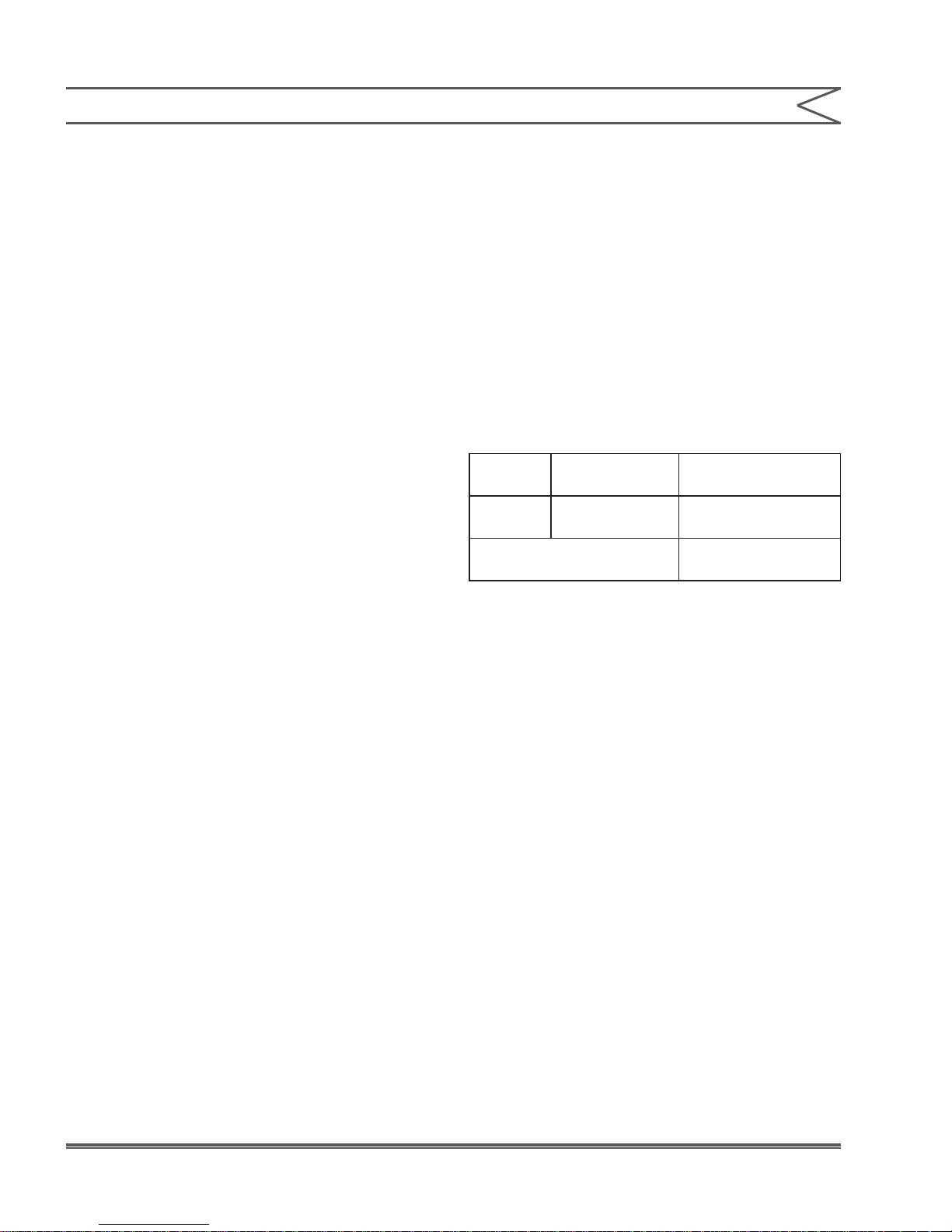

2. Check the pump housing and ll to the correct

level with the recommended lubricant listed in

the table below. The nominal capacity of the

MILROYAL® D housing is 1 pint. Fill to the level

of the drain plug.

Liquid

End

Packed

Plunger

2.2.2 Capacity Adjustment: Stroke Length

Pump capacity is adjusted by turning the micrometer

type stroke adjustment knob clockwise to decrease

or counterclockwise to increase the capacity

as required. The adjustment scale is marked in

percent of full stroke, with calibration lines on

the knob at 1.0% intervals. There is a friction

plug and setscrew threaded into the side of the

boss enclosed by the stroke adjustment knob.

Periodic adjustment (tightening) may be required

to provide enough friction to keep the stroke

adjustment from creeping. The nylon friction plug

should be replaced when worn to keep from bearing

the steel setscrew against the stroke adjustment

screw threads and damaging this part.

Operating Oil

Temperature

15°F to 125°F

(-9°C to 52°C)

Type Oil

AGMA No. 7

Compounded

Nevastane SL 100,

Food Grade

4

Instruction Manual

Page 9

SECTION 2 - OPERATION

2.2.3 Capacity Adjustment: Stroke Speed

Capacity of the MILROYAL® D Pump is

directly proportional to the input drive speed.

Most pumps are supplied with a constant speed

electric motor as the input power source. With a

constant speed input power source, the stroking

speed is established by the worm and worm gear

set installed in the pump housing, and may be

changed only by changing this gear set. The use

of a variable speed input power source, however,

allows continuous variation of stroking speed and,

therefore, output ow rate variation over a broader

range.

2.3 START- UP

2.3.1 General

All pumps are thoroughly tested under simulated

operating conditions before they leave the factory

to verify the pump capacity and to check the drive

motor for satisfactory operation at maximum rated

pressure. With the pump housing lled to the proper

oil level and all piping and electrical connections

made, the pump is now ready for start- up.

2.3.2 Packing

New packing, installed and shipped from the factory

in a complete pump or liquid end, has been “set’’

and run-in during production quality assurance

testing and requires no further breaking in for

start- up. During operation, if leakage does occur,

the gland nut should be tightened a little at a time

(1/6 turn or less) until leakage is minimized or

stopped. The packing should be allowed to resettle

at least ve minutes between adjustments. If it is

possible to tolerate a little leakage at the gland,

the leaking liquid will help to lubricate and cool

the packing and plunger, greatly extending the life

of both.

2.3.3 Capacity Calibration

After the initial break-in period and adjustment of

the packing, test runs should be made to determine

the exact capacity of these controlled volume pump

under the specic operating conditions for various

stroke length settings. Usually it is necessary to

calibrate the pump at only three stroke length

settings to determine its characteristics throughout

the entire range. The settings normally used are

full stroke (100%), 50%, and 20% stroke length.

Two methods of measuring the capacity in a given

time limit can be used:

1. Measure the drop in liquid level from calibrated

vessel (preferred).

2. Measure the quantity collected from the

discharge side of the pump.

It is essential that the suction lines of controlled

volume pumps be absolutely free of entrapped

air or vapor to prevent gas movement into the

liquid end. Milton Roy liquid ends are designed

to rapidly discharge any small bubbles which

may enter. However, any large amounts of gas

in the liquid end is alternately compressed and

expanded with each plunger stroke and causes

inaccuracies in pumping. In severe case the liquid

end may become vapor bound and cease pumping

altogether.

5Instruction Manual

Page 10

SECTION 3 - MAINTENANCE INSTRUCTIONS-DRIVE SECTION

The MILROYAL® D Pump has been carefully

designed, manufactured, assembled, and tested

to give reliable service with a minimum amount

of maintenance. However, in normal operation,

a periodic check of the pump is recommended to

visually conrm proper operation of the pump.

3.1 LUBRICATION

Fill the gear section of the MILROYAL® D housing

with recommended gear lubricant (see page 8 for

oil type) to the oil level plug hole. The oil should be

changed every 2500 hours of operation or every

six months, whichever comes rst. This can often

be scheduled with winter and summer oil change.

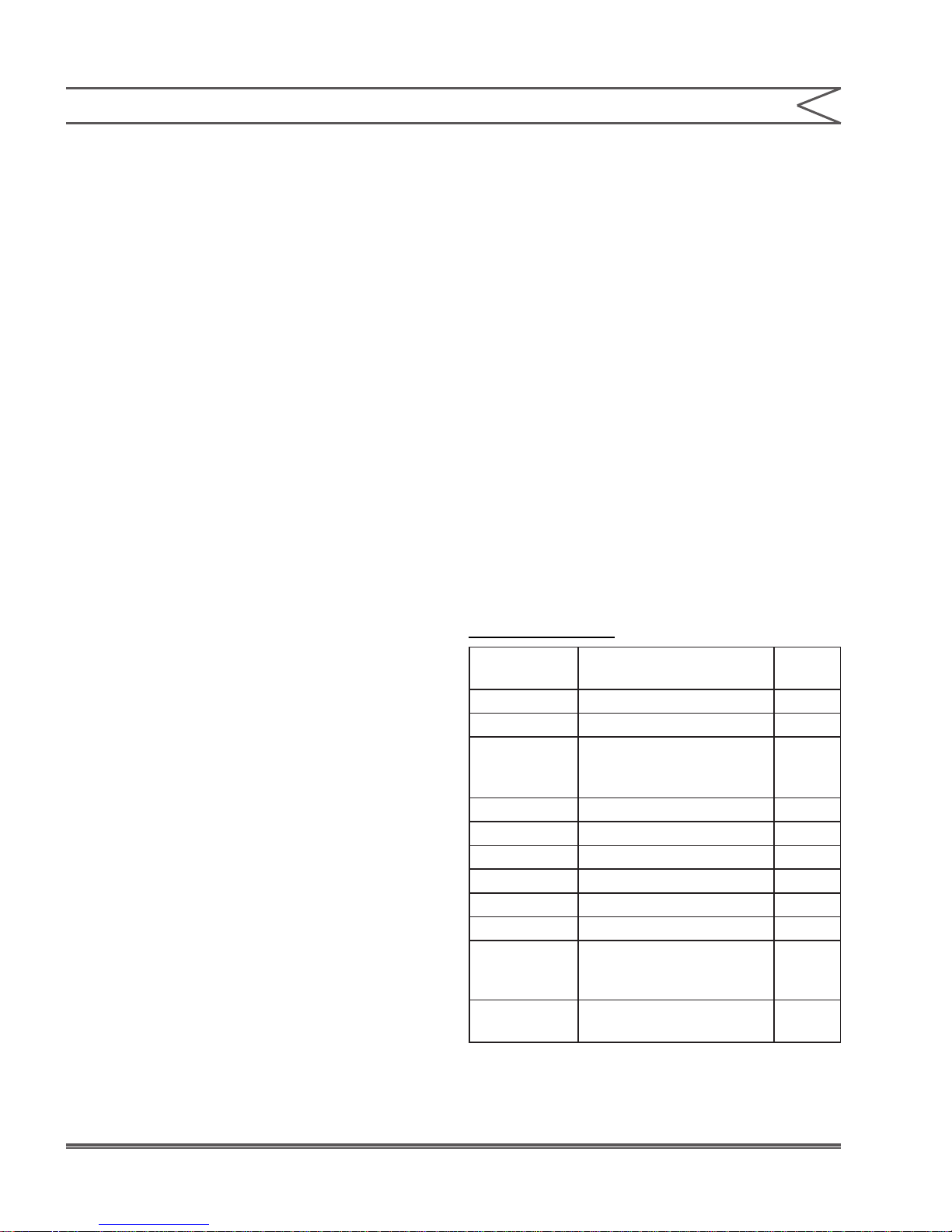

3.2 SPARE PARTS (Figure 3)

It is recommended that a standard group of spare

parts (shown in Table 4) be kept on hand at all times

to prevent serious delays in repairs. The following

list of spare parts represents those which should

be kept on hand for each pump drive (see liquid

end section for spare parts for liquid end).

Parts orders must include the following information:

1. Quantity required.*

2. Part number.*

3. Part description.*

4. Pump serial number (include in all

correspondence regarding the pump).**

5. Full model number.**

* Found in this manual.

** Found on pump nameplate.

EXAMPLE:

Two No. 200 Clevis Pins for model DB2-C-175R,

serial number IP-0009 Milton Roy Pump.

3.3 RETURNING PUMPS TO THE FACTORY

Pumps will not be accepted for repair without a

Return Material Authorization, available from the

Factory Repair Department. Pumps returned to

the Factory for repairs should be clearly labeled

to indicate the liquid being pumped. Process liquid

should be ushed from the pump liquid end and oil

should be drained from the pump housing before

the pump is shipped.

Note:

Federal law prohibits handling of equipment that

is not accompanied by an OSHA Safety Data

Sheet (SDS). A completed SDS must be packed

in the shipping crate with any pump returned to

the factory. These safety precautions will aid

the troubleshooting and repair procedure and

preclude serious injury to repair personnel from

hazardous residue in pump liquid end. A Safety

Data Sheet must accompany all returns.

All inquiries or parts orders should be addressed

to your local Milton Roy representative or sent to:

www.miltonroy.com.

Item

Number

160 Crank Pin 1

165 Crank Pin Shoulder 1

142

270 Friction Plug 2

152 Dowel Pin 1

210 Snap Ring 2

40 Shaft Oil Seal 4

112 Worm Shaft Bearing 2

211-0042-006 Journal Nut Tool 1

None

Part Name Qty

Connecting Rod

Assembly (Includes

Spherical Bearing)

Coupling Insert for

300 Coupling

1

1

6

None LOCTITETM Grade 222

Instruction Manual

0.10 cc

tube

Table 1. Drive Spare Parts.

Page 11

SECTION 3 - MAINTENANCE INSTRUCTIONS-DRIVE SECTION

3.4 REPLACING SPARE PARTS (Figure 3)

3.4.1 Removal of Gear Cage

1. Remove pump housing assembly from No. 272

motor mounting adapter.

2. Remove No. 290 shaft cover.

3. Remove No. 25 oil drain plug and drain oil from

housing.

Note:

At this point the entire pump body should be

securely held in a comfortable working position,

such as in a large vise.

4. Remove No. 300 coupling from worm shaft.

5. Turn stroke control to 100%. Using journal nut

tool, unscrew No. 100 journal nut (right hand

thread) from housing.

Note:

The journal nut can be removed more easily by

applying a steady force on the wrench rather

than by attempting to hammer the wrench to

break the nut free.

6. Unscrew the journal nut and pull it OFF the

shaft. Bearing No. 112 should come out with

the journal nut.

7. Remove worm shaft from housing.

8. Unscrew and remove crankpin and crankpin

shoulder, No. 160 & 165.

9. Remove No. 210 snap rings and push clevis

pin No. 200 aside to disengage stroke adjusting

screw.

10. Lift gear cage out of housing. The remaining

bearing should come out with the cage.

The cage cannot be removed unless this

bearing is in place in the cage.

11. Remove nut No. 100 and worm gear from the

crank. Take care not to lose the key which pins

worm gear to crank.

3.4.2 Removal of Crosshead (Figures 4 & 5)

1. The above disassembly procedure for removal

of Gear Cage must be accomplished prior to

removal of Crosshead.

2. Unscrew Plunger Adapter Nut No. 235 until the

thread is free of the Crosshead.

3. Pull Crosshead out of its bore from the rear,

taking care not to lose Thrust Washer No. 245

if it remains in Crosshead when Nut No. 235 is

removed.

4. Use a drift pin to remove No. 152 Dowel

Pin joining Crosshead and Connecting Rod

Assembly No. 142.

CONNECTING ROD ASSEMBLY

MAY BE OF TWO PIECE

CONSTRUCTION, HAVING A THREADED SHANK SPHERICAL

BEARING SCREWED INTO CONNECTING ROD. IF SO, DO NOT

CHANGE THE RELATIONSHIP OF CONNECTING ROD AND

SPHERICAL BEARING HOLES BY SCREWING THE BEARING IN

OR OUT. IF THE RELATIONSHIP IS CHANGED, DAMAGE TO

THE PUMP WILL OCCUR WHEN PUT BACK INTO OPERATION.

3.4.3 Assembly & Installation of Crosshead

1. Support Crosshead in a “V” block of soft

material to protect Crosshead outside nish.

Insert No. 142 Connecting Rod Assembly into

Crosshead slot so the dog-leg of the Connecting

Rod points the Spherical Bearing to the open

side of the slot.

2. Push No. 152 Dowel Pin into Crosshead

(slip fit) and tap pin through hole in the

Connecting Rod (force t). Make sure Dowel

Pin ends are not sticking out either side of

Crosshead and that connecting rod oscillates

freely without binding.

3. Insert assembled Crosshead into Pump

Housing, gently working it forward through

No. 52 Oil Seal.

12. Bronze bearing No. 72 must be pressed onto

crank if replacement of bearing is required.

7Instruction Manual

Page 12

SECTION 3 - MAINTENANCE INSTRUCTIONS-DRIVE SECTION

3.4.4 Assembly of Gear cage into

Pump Housing

Before assembly, several of the parts may need

special preparation.

The Journal Nut threads (on nut and housing),

Crankpin and Crankpin Shoulder, Worm Shaft,

Crank threads, Crank Nut, and if bearings or oil

seals are removed the outside of bearings and

seals and inside of mating housing surfaces must

be thoroughly cleaned of oil and foreign matter.

This will require scraping of parts to remove

original lm of LOCTITETM and use of solvent for

degreasing.

DO NOT IMMERSE SEALS IN

SOLVENT AS THIS MAY CAUSE

SEVERE SWELLING OF SEAL MATERIAL.

The following special tools and equipment

are required: MILROYAL® D Journal Nut Tool

No. 211-0042-006, and LOCTITETM Grade 222.

1. Replace Oil Drain Plug No. 25.

2. If bearings and / or oil seals have been removed

for replacement:

c. After the bearings are installed, lightly

coat the outside of Shaft Oil Seals with

LOCTITETM Grade 222 and press into place

until ush with bearing recess. Be sure seal

lips are facing toward the bearings. When all

bearings and shaft seals are installed there

should be one seal in the drive side of the

Housing, one bearing in the drive side of

the Gear Cage, and a bearing and oil seal

in the Journal Nut, all LOCTITED ™ sealed

in place.

3. Insert Crank No. 216 with its pressed-on Bearing

No. 72 through bore in Gear Cage, and insert

No. 90 Key into key way. Slide Worm Gear onto

Crank with side of Worm Gear having stamped

identication numbers facing stroke adjustment

end of pump. Apply 2 to 3 drops of LOCTITETM

Grade 222 to crank threads and tighten nut No.

100 to 125-130 Inch-pounds (46-48 N). Check to

insure free rotation of Crank and Worm Gear.

4. Insert Clevis Pins No. 200 into holes in Gear

Cage with tongs pointed inward.

a. Crosshead Oil Seal No. 52 should be installed

with sealing lip facing stroke adjustment end

of pump. Apply a thin coat of LOCTITETM

Grade 222 to outside of Seal Casing and

press in Seal until it is rmly seated in the

bottom of its recess.

b. The motor-side Shaft Bearing should

be pressed into its recess with grade

HV LOCTITETM. Seat the Bearing into

the recess as far as it will go. The same

procedure should be followed for installing

the other bearing into the Journal Nut.

5. Place Gear Cage into housing. Position driveside bearing into its recess in housing.

6. Insert Shaft and Worm through Cage and

Bearing. Apply 3 to 4 drops of LOCTITE™

Grade 222 to a single thread of Journal Nut

about mid-way on the Nut, coating the thread

for an entire revolution.

7. Slip Journal Nut over Shaft and screw it nger

tight into Housing. Make sure both shaft bearings

are seated in their recesses. Using Journal Nut

Tool, tighten Journal Nut to approximately

30 inch-pounds (11 N) torque.

8

Instruction Manual

Page 13

SECTION 3 - MAINTENANCE INSTRUCTIONS-DRIVE SECTION

8. Adjust stroke adjustment screw to 10% and

pull Gear Cage to align No. 200 Clevis Pins

with groove in stroke adjustment screw. Slide

Clevis Pins into the groove and install No. 220

“E” Rings so concave sides of rings bear against

cage.

9. Pin No. 142 Connecting Rod Bearing to

No. 216 Crank using No. 160 and No. 165 Crank

Pin and Crank Pin Shoulder in the following

manner. Determine operating direction of

rotation of crank. Place a drop of LOCTITETM

Grade 222 on threaded section of No. 160

Crank Pin. Insert No. 165 Crank Pin Shoulder

through leading side hole of crank and No. 160

Crank Pin through following side hole of crank.

This allows the solid crank pin to perform

the heavy duty cycle portion of the pumping

stroke.

10. If applicable, assemble Liquid End and Plunger

into Pump Body as outlined in Liquid End

Maintenance section.

9Instruction Manual

Page 14

SECTION 4 - MAINTENANCE INSTRUCTIONS-LIQUID END 1/8” AND 1/4” DIAMETER PLUNGERS

4.1 SPARE PARTS (Figure 4)

It is recommended that a standard group of spare

parts be kept on hand at all times to prevent serious

delays in repairs. The following list of spare parts

represents those which should be kept on hand for

each liquid end (see pump drive section for spare

parts for pump drive).

Parts orders must include the following information:

1. Quantity required.*

2. Part number.*

3. Part description.*

4. Pump serial number (include in all

correspondence regarding the pump).**

5. Full model number.**

* Found in this manual.

** Found on pump nameplate.

EXAMPLE:

Four No. 384 Clevis Pins for model DB2-C-175R,

serial number IP-0009 Milton Roy Pump.

NOTE:

Unless otherwise specied, plunger size and

materials of construction of spare parts will be

the same as specied on the original pump

order.

NOTE:

Federal law prohibits handling of equipment that

is not accompanied by an OSHA Safety Data

Sheet (SDS). A completed SDS must be packed

in the shipping crate with any pump returned to

the factory. These safety precautions will aid

the troubleshooting and repair procedure and

preclude serious injury to repair personnel from

hazardous residue in pump liquid end. A Safety

Data Sheet must accompany all returns.

All inquiries or parts orders should be addressed

to your local Milton Roy representative or sent to:

www.miltonroy.com.

Item

Number

383 Ball Seat 4

385 Cap Gasket 6

222 Plunger Assembly 1

245 Thrust Washer 1

250 Thrust Washer Ring 1

384 Ball Check 1

425 Packing 2 Sets

Part Name Qty

Table 2. Spare Parts for Liquid Ends with

1/8” and 1/4” Diameter Plunger.

4.2 RETURNING PUMPS TO THE FACTORY

Pumps will not be accepted for repair without a

Return Material Authorization, available from the

Factory Repair Department. Pumps returned to

the Factory for repairs should be dearly labeled to

indicate the liquid being pumped. Process liquid

should be ushed from the pump liquid end and oil

should be drained from the pump housing before

the pump is shipped.

10

Instruction Manual

Page 15

SECTION 4 - MAINTENANCE INSTRUCTIONS-LIQUID END 1/8” AND 1/4” DIAMETER PLUNGERS

4.3 LUBRICATION

No lubrication is required. All sliding surfaces which

would normally require lubrication are in contact

with a self- lubricating uorocarbon material.

4.4 CHECK VALVE MAINTENANCE

Suction and discharge cartridge assembly

405 are designed to be self cleaning and should

give long, trouble free service. If the check valves

do become fouled, a hot detergent solution

cleaning will usually remove all but the most

stubborn contaminants. Prepare a hot detergent

solution and pump it freely through the pump for

10 to 15 minutes. Flush with hot water and return

the pump to normal service.

If ushing does not prove adequate, remove the

cartridges and inspect for chemical damage.

A cotton swab is often helpful in cleaning the

seat area. Replace cartridge assembly with Ball

Checks, Seats, and Gaskets in the order shown on

Figure 4. This cartridge design depends on

compression of the Cap Gaskets (No. 385) to

prohibit leakage from around outside of Ball Seats

and exterior thread of No. 381 Caps; therefore, on

reassembly tighten Caps down rmly.

4.5 PACKING ADJUSTMENT, START- UP

AND REPLACEMENT

New Packing, installed and shipped from the

factory in a complete pump or liquid end, has been

“set” and run-in during production quality assurance

testing and requires no further breaking in for startup. If, during operation, leakage does occur, Gland

Nut No. 430 should be tightened a little at a time

(1/6 turn or less) until leakage is minimized or

stopped. Wait at least five minutes between

adjustments to allow packing to resettle. If it is

possible to tolerate a little leakage at the Gland, the

leaking liquid will help to lubricate and cool Packing

and Plunger, greatly extending the life of both.

4.5.1 Replacing Packing

1. To replace packing it is necessary to remove

liquid end from the pump.

2. Loosen No. 430 Gland Cap.

3. Remove two screws which retain No. 410

Adapter to Pump Housing and pull liquid end

straight forward, taking care not to bend plunger.

Inspect plunger for scoring or pitting and replace

if necessary.

4. With liquid end OFF pump, remove gland cap

and packing follower.

5. Remove old packing with a small hook

(do not scratch stufng box) and thoroughly

clean stufng of any foreign material.

6. Install new packing with female portions facing

forward so they may react with applied hydraulic

pressure and expand against stufng box walls

and plunger to effect a good seal.

7. Replace packing follower and screw gland cap

on lightly.

8. Install plunger if it has been removed, making

sure the two thrust washers are replaced. If

necessary, moisten solid washer with a drop

of clean light oil to insure it remains seated in

plunger adapter nut during installation.

9. After tightening plunger adapter nut, loosen it

1/8 turn (no more or thrust washer may

unseat).

10. Carefully slide entire liquid end over plunger

and back onto pump and secure it with the two

screws.

11. Tighten gland cap nger tight to center plunger,

then tighten plunger adapter nut rmly.

12. Tighten No. 430 gland cap 1/4 turn past nger

tight and hold packing under this compression

for 10 minutes to allow packing to settle in

stufng box.

11Instruction Manual

Page 16

SECTION 4 - MAINTENANCE INSTRUCTIONS-LIQUID END 1/8” AND 1/4” DIAMETER PLUNGERS

13. Loosen gland cap and retighten 1/6 turn

(one HEX at) past nger tight.

14. Start pump at 100% stroke length but without

pumping load. It is permissible to run liquid end

dry, or pump uid to atmospheric pressure.

Run for about 1/2 hour.

15. At end of this break-in period put pump into

full operation against normal pumping load.

Adjust capacity to the desired chemical

feed.

16. Adjust packing as explained under “Packing

Adjustment, Start- Up and Replacement”.

12

Instruction Manual

Page 17

SECTION 5 - MAINTENANCE INSTRUCTIONS-LIQUID END 7/16” AND 5/8” DIAMETER PLUNGERS

5.1 SPARE PARTS (Figure 5)

It is recommended that a standard group of spare

parts be kept on hand at all times to prevent serious

delays in repairs. The following list of spare parts

represents those which should be kept on hand for

each liquid end (see pump drive section for spare

parts for pump drive).

Parts orders must include the following information:

1. Quantity required.*

2. Part number.*

3. Part description.*

4. Pump serial number (include in all

correspondence regarding the pump).**

5. Full model number.**

* Found in this manual.

** Found on pump nameplate.

EXAMPLE

Four No. 435 Clevis Pins for model DB2-C-175R,

serial number IP-0009 Milton Roy Pump.

5.2 RETURNING PUMPS TO THE FACTORY

Pumps will not be accepted for repair without a

Return Material Authorization, available from the

Factory Repair Department. Pumps returned to

the Factory for repairs should be clearly labeled

to indicate the liquid being pumped. Process liquid

should be ushed from the pump liquid end and oil

should be drained from the pump housing before

the pump is shipped.

NOTE:

Federal law prohibits handling of equipment that

is not accompanied by an OSHA Safety Data

Sheet (SDS). A completed SDS must be packed

in the shipping crate with any pump returned to

the factory. These safety precautions will aid

the troubleshooting and repair procedure and

preclude serious injury to repair personnel from

hazardous residue in pump liquid end. A Safety

Data Sheet must accompany all returns.

All inquiries or parts orders should be addressed

to your local Milton Roy representative or sent to:

www.miltonroy.com.

NOTE:

Unless otherwise specied, plunger size and

materials of construction of spare parts will be

the same as specied on the original pump

order.

Item

Number

222 Plunger Assembly 1

250 Thrust Washer 1

250 Thrust Washer Ring 1

9001 Ball Check Cartridge Assembly 2

428 Gland Bearing Liner 2

425 Packing 2 Sets

Part Name Qty

Table 3. Spare Parts for Liquid Ends with

7/16” and 5/8” Diameter Plunger.

13Instruction Manual

Page 18

SECTION 5 - MAINTENANCE INSTRUCTIONS-LIQUID END 7/16” AND 5/8” DIAMETER PLUNGERS

5.3 LUBRICATION

Once each day lubricate the packing lightly with

lubricant recommended on pump data face sheet

(front of manual). A grease tting located on the

liquid end is provided for this purpose.

5.4 CHECK VALVE MAINTENANCE

The ball check cartridge assemblies, each with

double ball checks are designed to give long,

trouble- free service. If the check valves do become

fouled, cleaning with a hot detergent solution

will usually remove all but the most stubborn

contaminants. Prepare a hot detergent solution and

pump freely through the pump for 10 to 15 minutes.

Flush with hot water and return to normal service.

If ushing does not prove adequate, remove and

disassemble cartridges to inspect for chemical

damage. To remove balls and seats from cartridge,

perform the following:

1. Using a 5/16” (7.93 mm) diameter pin, push out

No. 383 seats and No. 386 ring insert from small

end of No. 381 body.

2. Using a 1/16” (1.59 mm) diameter pin, push out

No. 385 limit pin from seat.

3. Remove No. 384 ball check and inspect ball

and seat for marks, pits and scratches. The

important portion of the seat is where ball

contacts edge of the hole. This area should

be a smooth bright band when viewed under

10X magnication. Any imperfections in either

ball or seat is cause for replacement.

4. It is recommended that No. 382 O-ring and

No. 386 ring insert be replaced after

disassembly.

5. After cleaning all parts, reassemble as shown in

gure 5. Make sure O-ring end of seat is placed

into body rst, and that the entire assemblies

are screwed into liquid end with arrows on body

pointing upward.

ONE OF THE FOLLOWING WILL

RESULT FROM INCORRECT

BALL CHECK CARTRIDGE ASSEMBLY: (A) IMMEDIATE SEVERE

DAMAGE TO PUMP MECHANISM, (B) NO PUMPING, (C)

REVERSE PUMPING ACTION (FROM DISCHARGE LINE INTO

SUCTION LINE).

6. Threads on cartridges should be prepared with

sparing amount of pipe dope or, preferably,

with a thread sealant tape to prevent air or uid

leakage past threads.

5.5 PACKING ADJUSTMENT, START- UP

AND REPLACEMENT

New packing, installed and shipped from the factory

in a complete pump or liquid end has been set

and run-in during Production Quality Assurance

and requires no further break-in prior to full load

start- up.

If, during operation, leakage does occur, gland

cap no. 403 should be tightened a little at a time

(1/6 turn or less) until leakage is minimized or

stopped. Wait at least five minutes between

adjustments to allow packing to resettle. If it is

possible to tolerate a little leakage at Gland Cap,

the leaking liquid will help to lubricate and cool

packing and plunger, greatly extending the life of

both.

14

Instruction Manual

Page 19

SECTION 5 - MAINTENANCE INSTRUCTIONS-LIQUID END 7/16” AND 5/8” DIAMETER PLUNGERS

5.5.1 Types of Packing

There are two general types of packing used in this

pump, automatic and compression.

Automatic type packing is made up of a series of

shaped rings which have sealing lips that react

with applied hydraulic pressure to form a good uid

seal against both the moving plunger and walls

of the stufng box. This type packing is generally

preferred over the compression type because of

its lower friction against plunger and somewhat

self-adjusting characteristics which allow it to

compensate for wear and maintain good sealing.

Automatic packing must never be adjusted so

tightly that it loses its capability to properly ex

during operation. It is seldom necessary to adjust

this type of packing any more than nger tight.

Packings of square or round cross section which

must be rmly compressed in the stufng box are

known as compression types. These are available

in many materials, and are usually used only

when the somewhat limited materials of automatic

type are not compatible with the pumped uid.

They depend on mechanical compression in stufng

b o x b y t h e f o l l o w e r a n d g l a n d c a p f o r u i d s e a l i n g .

If compression type packing is too tightly

compressed against the moving plunger, frictional

force will be reflected back through the drive

mechanism as an overload, or develop sufcient

localized heat to destroy sealing surfaces of both

plunger and packing.

Compression type packing is very dependent on

proper break-in to develop a good sealing surface.

5.5.2 Replacing Packing

1. To properly replace packing, it is necessary to

remove liquid end from pump.

2. Loosen No. 430 Gland Cap (do not remove).

3. Remove the two No. 270 screws which attach

liquid end to pump housing.

4. Pull liquid end straight OFF pump and plunger,

taking care not to damage plunger by bending.

Inspect plunger for scoring or pitting and replace

if necessary.

5. Remove No. 430 Gland Cap and No. 427 Gland

follower. Inspect No. 428 gland bearing liner

and replace if worn. Remove rear section of

packing with a small hook or corkscrew device,

taking care not to scratch wall of stufng box.

Remove No. 419 lantern ring, remaining forward

section of packing and No. 418 neck ring.

Thoroughly clean lantern ring, neck ring, and

stufng box of all foreign matter.

6. Refer to gure 5. It can be seen that the total

packing set consists of a neck ring, a lantern

ring, a gland follower, and two separate sets of

packing material. The forward set of packing

(nearest check valves) is intended to seal

against pumped uid. The rear set is intended

to seal lubricant in and force lubricant to ow

forward at injection. A new packing set should

be made up to the following dimensions with a

tolerance of +0 to -1 packing ring.

a. Length of neck ring and front set of packing

(automatic packing to include one male and

one female adapter) 1 1/2” (38 mm).

b. Total overall length of both front and rear

packing sets, neck ring, and lantern ring

(including adapters for automatic type

packing) 2 3/4” (70 mm).

15Instruction Manual

Page 20

SECTION 5 - MAINTENANCE INSTRUCTIONS-LIQUID END 7/16” AND 5/8” DIAMETER PLUNGERS

7. To install packing, coat each piece with

recommended lubricant and install in order

shown in gure 5. Place each piece into stufng

box individually, insuring each piece is rmly

seated. Automatic packing should be installed

with lips facing forward; if rings are split, locate

the joints so they are not in line.

8. Install No. 427 gland follower with it No. 428 liner

in place. Install follower with its bore lip facing

away from packing.

9. Screw No. 430 gland cap loosely onto liquid

end.

10. To replace thrust washer, adjust pump stroke

length setting to 0%. Unscrew No. 245 oating

plunger nut from crosshead and remove

plunger assembly. Replace worn rings if

necessary.

11. With plunger installed, carefully slip liquid end

back over plunger and onto pump body with

grease tting up and secure with washers

and bolts. Observe to ow direction arrows

stamped onto No. 9001 ball check cartridge

assembly; arrows should both be pointing

up.

12. After new packing is installed and liquid end

is mounted on pump, the new packing must

be broken in to develop a reliable sealing

surface and insure long, trouble free packing

life. Tighten gland cap 1/4 turn past nger tight

and hold packing under this compression for

at least 10 minutes. While under compression,

inject a small amount of recommended

lubricant into tting provided.

13. Loosen gland cap and retighten 1/6 past nger

tight.

14. Start pump at 100% stroke length but without

pressure load. It is permissible to operate liquid

end dry, or to pump clear uid to atmospheric

pressure. Run for about 1/2 hour.

NOTE:

Often, compression type packings will expand

due to frictional heat generated during initial

break-in. If gland cap becomes uncomfortably

hot to touch during break-in, gland cap should

be loosened slightly (by less than 1/6 turn) to

relieve excessive frictional force.

15. At the end of this break-in period, put pump

into full operation against normal operating

load.

16

Instruction Manual

Page 21

Pump mechanism will not operate

Pump does not deliver rated ow

Motor and pump body hot

Noisy operation

Pump is not at zero stroke when

adjustment reads zero

Leaking oil

Stroke knob “creeps” OFF setting

SECTION 6 - TROUBLESHOOTING

• Incorrect or inoperative electrical circuit to motor. Check and

repair / reset power supply, fuses, thermal overload protectors,

wiring.

• Incorrect or inoperative electrical circuit to motor. Correct controlling

devices such as liquid level, speed control, etc.

• Discharge line blocked. Remove blockage (open valve,thaw

discharge lines).

• Discharge line blocked. Check maximum pressure rating of pump

from data plate.

• Fluid vapor in liquid end. Eliminate suction line leaks, tighten line

ttings, increase available suction head by increasing suction line

size; decrease suction line length; heat uid to decrease its viscosity

or cool uid farther away from its boiling point.

• Suction or discharge check valves fouled. Clean per liquid end

maintenance instructions or replace.

• Capacity adjustment improperly set or pump not operating at proper

speed. Adjust capacity and insure electrical requirements of motor

are available .

• Packing leaking excessively. Adjust or replace per liquid end

maintenance instructions.

• Normal operating temperature of both motor and pump body is

frequently uncomfortable to the touch. However, neither should

exceed 200°F (93°C).

• Power supply does not match electrical requirement of motor.

Insure proper matching of power supply and motor.

• Pump being operated at greater than rated performance. Reduce

pressure or stroke speed. If this is not practical, contact factory.

• Pump improperly lubricated. Drain oil and rell with proper amount

of recommended lubricant.

• Check valves may emit a clicking sound in normal operation.

• In pump housing- Insure proper lubrication, replace worn bearings,

clevis pins, or gears.

• Stroke adjustment knob is set incorrectly (a normal pump may not

be able to obtain absolute zero stroke at any setting). Minimum

obtainable stroke should not exceed 0.015” (0.381 mm). Adjust

pump to minimum stroke obtainable, loosen knob set- screw, reset

to zero indication, and retighten knob wet- screw. Adjust pump to

minimum stroke obtainable, loosen knob setscrew reset to zero

indication, re- tighten knob setscrew.

• Worn crosshead oil seal. Replace seal, inspect crosshead for

scoring, replace if necessary.

• Worm shaft seals. Clean and inspect oil seal bushings, replace

seals, bushings, and O-rings as necessary.

• Loose friction plug. Tighten friction plug setscrew, replace plug if

necessary.

17Instruction Manual

Page 22

20” with

largest

motor

75/16

41/16

37/16

121/4

57/8

(3) 7/16 dia.

43/8

71/2

103/4

Typ

11/8

(4) 7/16 dia. when

supplied with

HPD liquid end

13

41/8

33/4

41/4

(REF)

15/8

TYP

Top View

79/32

CLLiquid end

53/32

93/8

21/2

5

103/4

14

Side View

Figure 1. Pump dimensions.

18 Instruction Manual

Page 23

Figure 2. Polar Crank Mechanism.

19Instruction Manual

Page 24

0310

0295

0296

0020

0330

0190

0200

0325

0210

0200

6060

0300

0040

6065

0112

0080

APPLY LOCTITE

TO O.D. OF BEARING

APPLY LOCTITE

THREADS & O.D. OF

0100

0042

0270

0275

910

0295

0290

0280

OIL LEVEL

0250

0260

TM

TM

TO

APPLY LOCTITE

TO THREADS

0040

TM

6030

0020

0025

0296

0240

0170

0165

LOCATETM ON THIS SIDE.

APPLY LOCTITE ON THREADS

0160

0230

0220

6050

0142

6070

Figure 3. Basic Drive Assembly Drawing (102-2906-0001).

20 Instruction Manual

0152

0132

0060

0072

0100

0055

0090

0052

0010

Page 25

Drawing Location

Reference

20 A/R Loctite™ #242

220 1 Stop Collar Set Screw #8-32 NC

275 1 Friction Plug Set Screw 1/4-20 NC

250 2 Knob Set Screw #8-32 NC

190 1 Stroke Adjusting Screw

260 1 Knob Stroke Adjustment

240 1 Stroke Scale

270 1 Friction Plug

230 1 Stroke Stop Collar

300 1 Coupling (mounting to pump)

330 4 Motor Screw 3/8-16 NC

295 4 Shaft Cover Lock Washer 1/4

325 4 Motor Lock Washer 3/8

290 1 Shaft Cover

272 1 Motor Mountin Adapter (NEMA 56 C Flange)

80 1 Gear Set (specify gear ratio)

170 1 Crank Pin Retaining Ring

72 1 Crank Bronze Bearing

112 2 Worm Shaft Bearing

52 1 Crosshead Oil Seal

40 2 Shaft Oil Seal

100 1 Crank Nut 7/16-14 NC 2

296 4 Motor Adapter Screw 1/4 20 NC

6060 4 Drive Cover Screw #10-24 NC

20 4 Nameplate Drive Screw

90 1 Crank Key 1/8 Sq

210 2 Clevis Pin Samp Ring

6065 4 Drive Cover Lock Washer #10

295 4 Motor Adapter Lock Washer 1/4

25 2 Plug

152 1 Dowell Pin

55 1 Gear Cage

6070 1 Catchall Cover Assembly

6050 1 Drive Cover

Quantity Required Description

Table 4. Basic Drive Assembly Drawing Location Reference Chart.

21Instruction Manual

Page 26

Drawing Location

Reference

10 1 Housing

6030 1 Nameplate

100 1 Journal Nut

280 1 Cover Gasket

142 1 Connecting Rod Assembly

165 1 Crank Pin Shoulder

160 1 Crank Pin

200 2 Clevis Pin

132 1 Cross head

Table 4. Basic Drive Assembly Drawing Location Reference Chart Contd.

Quantity Required Description

22 Instruction Manual

Page 27

DISCHARGE

384

402

LIQUID END BODY ASS’Y

405

LIQUID END BODY ASS’Y

384

385

385

381

385

381

383

383

383

385

385

385

SUCTION

384

383

410

408

425

415

PUMP HOUSING

384

270

280

430

426

427

222

235

245

250

Figure 4. 1/8" and 1/4" Liquid Ends Assembly Drawing (102-290-600-015).

23Instruction Manual

Page 28

Drawing Location

Reference

222 1 Plunger Assembly

235 1 Floating Plunger Nut

245 1 Thrust Washer

250 1 Thrust Washer Ring

402 1 Liquid End Body Assembly Consist of:

405 1 Discharge cartridge Assembly Consist of:

381 1 Cap

383 2 Ball Seat

385 3 Cap Gasket

384 2 Ball Check

405 1 Suction Cartridge Assembly consisting of:

381 1 Cap

383 2 Ball Seat

385 3 Cap Gasket

384 2 Ball Check

405 1 Liquid End Body

426 1 Packing

427 1 Packing Follower

430 1 Gland Cap

415 1 Liquid End Nut

410 1 Adapter Liquid End Mounting

408 1 Key Pin

270 2 Cap Screw 1/4-20

280 2 Lock Washer 1/4

384 A/R Loctite™

Quantity Required Description

Table 5. 1/8” and 1/4” Liquid Ends Assembly Drawing Location Reference Chart.

24 Instruction Manual

Page 29

384

385

386

280

270

382

383

381

405

222

222

9001

*AVAILABLE ONLY AS ASSEMBLY

435

419

425

418

PUMP HOUSING (REF)

430

235

245

250

250

427

428

Figure 5. 7/16” and 5/8” Liquid Ends Assembly Drawing (102-290-600-012).

25Instruction Manual

Page 30

Drawing Location Reference Description

222 Plunger Assembly Consisting of:

222 Plunger

250 Thrust Washer (Ring)

245 Plunger Adapter

235 Nut, Floating Plunger

9001 Ball Check Cartridge Assembly Consisting of:

381 Body

383 Seat

382 O-Ring

385 Limit Pin

384 Ball Check

386 Ring Insert

419 Lantern Ring

418 Neck Ring

430 Gland Cap

250 Thrust Washer (Solid)

405 Liquid End

428 Liner, Gland Bearing

427 Gland Follower

280 Washer

270 Liquid End Bolts

435 Grease Fitting

425 Packing

Table 6. 7/16” and 5/8” Liquid Ends Assembly Drawing Location Reference Chart.

26 Instruction Manual

Page 31

Page 32

We are a proud member of Accudyne Industries, a leading

global provider of precision-engineered, process-critical,

and technologically advanced ow control systems and

industrial compressors. Delivering consistently high levels

of performance, we enable customers in the most important

industries and harshest environments around the world

to accomplish their missions.

Info@miltonroy.com

www.miltonroy.com

MILROYAL® is a registered trademark of Milton Roy, LLC.

© 2015 Milton Roy, LLC.

Loading...

Loading...