Page 1

Primeroyal / Milroyal® Critical

Service HPD Liquid End

Instruction Manual

Manual No : 54261

Rev. : 0

Rev. Date : 05/2019

1

Page 2

PRECAUTIONS

The following precautions should be taken when working with metering pumps.

Please read this section carefully prior to installation.

Protective Clothing

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working on or

near your metering pump. Additional precautions should be taken depending on the solution

being pumped. Refer to Safety Data Sheets for the solution being pumped.

Hearing Protection

It is recommended that hearing protection be used if the pump is in an environment where the

time - weighted average sound level (TWA) of 85 decibels is exceeded. (as measured on the

A scale - slow response)

Electrical Safety

• Remove power and ensure that it remains OFF while maintaining pump.

• DO NOT FORGET TO CONNECT THE PUMP TO EARTH / GROUND.

• Electric protection of the motor (Thermal protection or by means of fuses) is to correspond

to the rated current indicated on the motor data plate.

Liquid Compatibility

Verify if the materials of construction of the wetted components of your pump are

recommended for the solution (chemical) to be pumped.

Pumps Water “Primed”

All pumps are tested with water at the factory. If your process solution is not compatible with

water, ush the Pump Head Assembly with an appropriate solution before introducing the

process solution.

Plumbing and Electrical Connections

Always adhere to your local plumbing and electrical codes.

Line Depressurization

To reduce the risk of chemical contact during disassembly or maintenance, the suction and

discharge lines should be depressurized before servicing.

Over Pressure Protection

To ensure safe operation of the system it is recommended that some type of safety /

pressure- relief valve be installed to protect the piping and other system components from

damage due to over-pressure.

2 Instruction Manual

Page 3

Lifting

This manual should be used as a guide only - Follow your company’s recommended lifting

procedures. It is not intended to replace or take precedence over recommendations, policies

and procedures judged as safe due to the local environment than what is contained herein.

Use lifting equipment that is rated for the weight of the equipment to be lifted.

3Instruction Manual

Page 4

TABLE OF CONTENTS

SECTION 1 - DESCRIPTION................................................................. 5

1.1 SPECIFICATIONS ................................................................5

SECTION 2 - INSTALLATION ................................................................ 6

2.1 UNPACKING ....................................................................6

2.2 SAFETY PRECAUTIONS ..........................................................6

2.3 MOUNTING ..................................................................... 6

2.4 PIPING CONNECTIONS .......................................................... 6

2.4.1 General....................................................................... 6

2.5 NPSH CONSIDERATIONS ......................................................... 7

2.6 TYPICAL PIPING................................................................. 7

SECTION 3 - OPERATION .................................................................. 8

3.1 PUMP START-UP PROCEDURE (VARIABLE STROKE PUMPS) ........................... 8

3.2 RELIEF VALVE ADJUSTMENT ..................................................... 10

SECTION 4 - MAINTENANCE............................................................... 11

4.1 DIAPHRAGM REPLACEMENT (FIGURE 2, SHEET 1 & 2) ............................... 11

4.2 HYDRAULIC OIL REPLACEMENT .................................................. 12

4.3 MARS REFILL VALVE (400) .......................................................12

4.4 RETURNING UNITS TO THE FACTORY ............................................. 12

4.5 RECOMMENDED SPARE PARTS .................................................. 12

4.6 ROUTINE PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.7 HYDRAULIC OIL REPLACEMENT .................................................. 13

4.8 CHECK VALVE MAINTENANCE ................................................... 13

4.8.1 Disassembly .................................................................. 13

4.8.2 Re-assembly.................................................................. 13

4.9 CORRECTIVE MAINTENANCE .................................................... 14

4.9.1 Relief Valve Assembly........................................................... 14

SECTION 5 - LEAK DETECTION (PRESSURE SENSING SYSTEM) ................................ 15

5.1 DESCRIPTION. ........... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 PRINCIPLE OF OPERATION . .......... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 SPECIFICATIONS ............ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SECTION 6 - INSTALLATION & OPERATION (PRESSURE SENSING SYSTEM) ...................... 16

6.1 UNPACKING ................................................................... 16

6.2 SAFETY PRECAUTIONS ......................................................... 16

6.3 DISASSEMBLY / ASSEMBLY ...................................................... 16

6.4 ELECTRICAL CONNECTIONS .................................................... 17

6.5 NEMA 4 PRESSURE SWITCH WIRING ............................................. 17

6.5.1 Wiring ...................................................................... 17

6.6 EXPLOSION PROOF PRESSURE SWITCH WIRING ................................... 18

6.7 START-UP ..................................................................... 18

SECTION 7 - PARTS ...................................................................... 19

4 Instruction Manual

Page 5

SECTION 1 - DESCRIPTION

Milton Roy’s High Performance Diaphragm

(HPD) liquid end overcomes the Net Positive

Suction Head (NPSH) restrictions associated with

conventional disc diaphragm metering pumps.

This is accomplished by a patented Mechanically

Actuated Rell System (MARS) that eliminates the

process side support plate.

The MARS also does away with the need for eld

adjustment of the rell mechanism by automatically

compensating for process liquid modications.

This, combined with removable check valves,

makes the HPD an ideal choice for any process

in which downtime is critical. The HPD features a

diaphragm that is compatible with a wide range of

process liquids and chemicals.

The HPD liquid end is particularly suitable for

pumping costly, aggressive or hazardous liquids

without leakage.

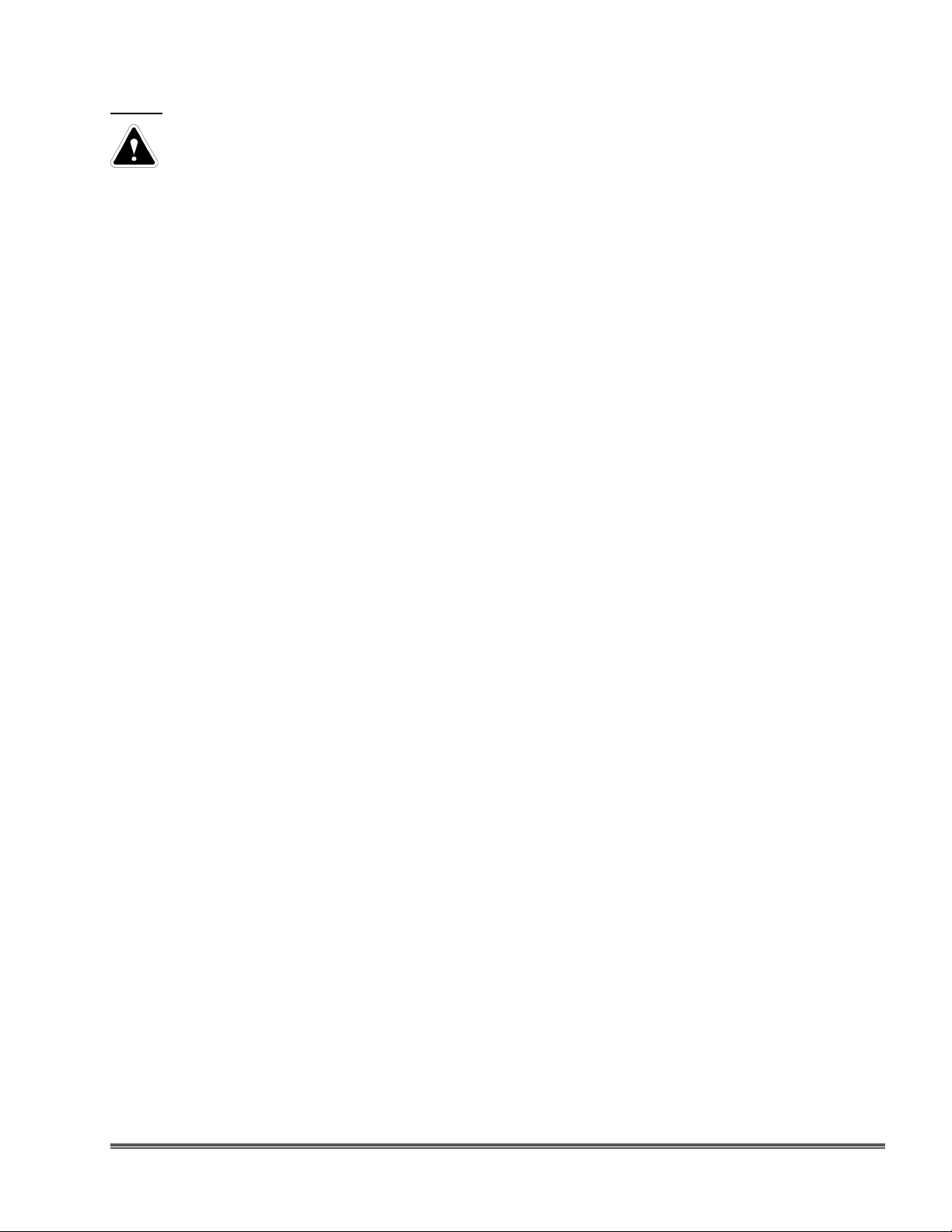

1.1 SPECIFICATIONS

Steady State

Accuracy / Turndown

Liquid Temperature:

Minimum Suction

Pressure:

Minimum Discharge

Back Pressure:

Hydraulic Fluid:

Ball Checks:

Gear Lubricant

Ratio: + 1% over 10:1

Turndown ratio.

+20°F to 250°F

3 PSIA minimum

(12 psi maximum vacuum).

35 psi above suction

pressure.

Mobile SHC-524 or

Equivalent.

Double ball checks in

suction and discharge.

SHC-634 or Equivalent.

5Instruction Manual

Page 6

SECTION 2 - INSTALLATION

2.1 UNPACKING

Pumps are shipped Free on Board (FOB) from the

factory and the title passes to the customer when

the carrier signs for receipt of it. The customer,

therefore, must le damage claims with the carrier.

The shipping crate should be carefully examined

upon receipt from the carrier to be sure there is no

obvious damage to the contents. Open the crate

carefully, as there are sometimes accessory items

fastened to the inside of the crate that may be lost

or damaged. Examine all material inside crate and

check against the packing list to be sure that all

items are accounted for and undamaged.

2.2 SAFETY PRECAUTIONS

When installing, operating, and maintaining an

HPD pump, keep safety considerations foremost.

Use proper tools, protective clothing, and eye

protection when working on the equipment and

install the equipment with a view toward ensuring

safe operation. Follow the instructions in this

manual and take additional safety measures

appropriate to the liquid being pumped.

Be extremely careful in the presence of hazardous

substances, (e.g. corrosives, toxics, solvents,

acids, caustics, ammables etc.).

2.3 MOUNTING

The HPD liquid end is shipped already mounted

to the appropriate pump. Mounting, therefore, is

simply a matter of securing the pump to a safe,

level surface. For further information on proper

pump mounting, see the appropriate pump

instruction manual.

2.4 PIPING CONNECTIONS

2.4.1 General

General piping instructions are given in the pump

drive instruction manual. No reciprocating plunger

pump can be expected to perform satisfactorily

unless those recommendations are followed.

Pay particular attention to plastic liquid ends,

as these units are relatively fragile and can be

damaged by the installation. For best results, avoid

straining the liquid end by installing a very short

section of exible tubing between rigid, xed piping

and suction and discharge cartridges on plastic

liquid ends.

NOTE:

Maximum safety and reliability may be ensured

by protecting liquid ends and piping with an

external relief valve installed in the system

discharge line.

6

Instruction Manual

Page 7

SECTION 2 - INSTALLATION

2.5 NPSH CONSIDERATIONS

The HPD liquid end is far superior to conventional

diaphragm liquid ends for suction lift and many

other NPSH critical applications. It’s patented

diaphragm and advanced design rell mechanism

give this liquid end truly high performance in these

applications.

For more NPSH information, refer to Milton Roy

web site (www.miltonroy.com) for aid in evaluating

applications for this liquid end.

2.6 TYPICAL PIPING

In order to adjust the HPD relief valve, it is

necessary to have a pressure gauge and a

shut OFF valve installed in the discharge line.

The pressure gauge must have a higher range than

the desired pump relief pressure, and should be

installed as close to the pump discharge connection

as possible. The shut OFF valve should be installed

downstream of the pressure gauge. These items

are not required for normal operation, but for

ease of pump maintenance and adjustment, it is

suggested that they be permanently piped into

the line.

Also see the instructions in the appropriate pump

instruction manual for additional typical piping

instructions.

7Instruction Manual

Page 8

SECTION 3 - OPERATION

3.1 PUMP START-UP PROCEDURE

(VARIABLE STROKE PUMPS)

DO NOT RUN THE MOTOR UNTIL

ALL START UP STEPS HAVE

BEEN COMPLETED. YOU COULD DAMAGE THE PUMP IF YOU

RUN THE MOTOR BEFORE ALL OF THE STEPS HAVE BEEN

COMPLETED. IT MAY BE NECESSARY TO TEST THE MOTOR

OFF THE PUMP TO INSURE PROPER DIRECTION AND

OPERATION. THE MOTOR DIRECTION IS CRITICAL. WIRE THE

MOTOR SO THAT IT ROTATES IN THE DIRECTION OF THE

ARROW CAST ON THE MOTOR MOUNT FLANGE. CONSULT

MANUFACTURER DOCUMENTATION FOR MOTOR START UP

RECOMMENDATIONS.

1. Follow the motor mounting procedure before

attempting to start your pumps. On some

pumps, the motor is mounted at the factory.

2. Make the proper electrical connections to the

motor per the manufacturer’s recommendations.

Make sure the motor is properly grounded.

3. Make sure that all of the mounting holes for the

pump base are used to securely tighten the base

to the mounting area.

8. Remove all of the tubing connecting the air bleed

valve (at the top of the displacement chamber

behind the discharge check valve). There is a

compression tting at the point where the tubing

enters the front catchall reservoir. Loosen the

nut and remove the tubing from this tting.

There is a tting connected to the air bleed

valve that needs to be removed. Remove all air

bleed valves from the top of the displacement

chamber.

9. The displacement chamber must be lled with,

ISO-32 (SHC-524) through the air bleed port.

If pump equipped with leak detection see

Section 5.

IF THE DISPLACEMENT

CHAMBER IS FILLED WITH THE

PLUNGER FULLY REARWARD, THE DIAPHRAGM COULD

RUPTURE AT START-UP. TO PROPERLY FILL THE

DISPLACEMENT CHAMBER, THE PLUNGER MUST BE

POSITIONED SO THAT IT IS TOP DEAD CENTER IN THE

DISPLACEMENT CHAMBER.

4. Do not run the motor until ALL start up steps

have been completed.

5. Remove the gear drive ll cap (the chamber

closest to the motor).

6. Fill the gear drive chamber with appropriate

gear lubricant (SHC-634). This oil was shipped

with the pump. Fill this chamber so that the oil

level is even with the midpoint of the sight glass.

Do not overll.

7. Remove the catchall chamber cover (closest to

the process liquid end of the pump) revealing

the plunger and bleed valve. Fill this chamber

with hydraulic oil, ISO -32 (SHC-524). This oil

was shipped with your pump, and is a lower

viscosity compared to the gear oil. The hydraulic

uid must ll the catchall chamber so that the

oil level is even with the midpoint of the sight

glass. Do not overll.

NOTE:

Two types of oils have been provided. They must

be added at the proper location.

10. With the plunger fully engaged in the

displacement chamber (pump at TDC, Top

Dead Center) adjust the stroke adjustment

mechanism until the indicating needle reads

100%. Either turn the hand wheel on a

micrometer, apply a 15-PSI supply signal

for a Pneumatic, or apply a 20-mA signal for

an Electronic actuator. In order to ll each

displacement chamber and fully purge the air

from the oil, rotate the motor either by hand

(by removing the fan cover and spinning the fan

by hand), or by rotating the motor electrically.

The motor may be jogged by turning the power

ON and OFF very quickly. (During this process

watch for air bubbles escaping the oil)

IT IS VERY IMPORTANT NOT TO

ROTATE THE MOTOR AT HIGH

SPEED, BECAUSE HYDRAULIC FLUID WILL BE FORCED FROM

THE AIR BLEED PORT AT A VERY HIGH VELOCITY.

8

Instruction Manual

Page 9

SECTION 3 - OPERATION

11. Rotate the motor shaft again so that the pump

is back at TDC (fully extended plunger into the

displacement chamber). Fill this chamber with

ISO-32 oil and check that no air bubbles are

present.

12. Replace the air bleed valve and tighten.

Use a pipe thread sealant to seal the threads.

Be very careful not to get any sealant into the

displacement chamber air bleed port. Place the

end of the tubing into the compression tting

and tighten the lock nut to secure the tubing.

13. On multiplex units, repeat these two steps for

each pump to insure proper hydraulic ll in

each displacement chamber.

14. Recheck the oil level in the catchall reservoir

and install the cover, screws and lock washers.

The gaskets have an adhesive backing that

should be removed and the gaskets should

be rmly attached to the covers using this

adhesive.

15. Make sure that all oil ll caps are securely

tightened to prevent oil leakage.

ALWAYS WEAR THE PROPER

PROTECTIVE GEAR WHEN

WORKING ON THE PUMP LIQUID END.

18. It is advisable to test the pump for proper

operation by testing it with water before you

use a process uid. Now ll the process liquid

ends with process uid.

TAKE ADDITIONAL SAFETY

MEASURES APPROPRIATE TO

THE LIQUID BEING PUMPED. BE EXTREMELY CAREFUL IN

THE PRESENCE OF HAZARDOUS SUB-STANCES

(CORROSIVES, TOXINS, SOLVENTS, ACIDS, CAUSTICS, AND

FLAMMABLES).

19. Loosen each process bleeder barb, if so

equipped, on each pump to bleed any air from

the liquid end. Connect a hose to this barb and

use caution if you are pumping a hazardous

chemical. After all process liquid ends have

been purged of air, you can tighten all bleeder

barbs to prevent leakage.

20. Now the motor can be started if and only if all

steps have been followed.

A. For constant speed motors, adjust the stroke

adjustment mechanism so that the indication

needle reads 25-30%. Gradually increase

the capacity adjustment mechanism and

increase back-pressure to insure that the

pump has time to purge all air from the

system.

16. Connect suction and discharge piping

manifolds. Use the proper gaskets and tighten

each ange per specication. Check that all

connections are tight including the check

valves, anges, air bleed valves and the motor

mount bolts.

17. Make sure the process bleeder barb, if so

equipped, is tight. It is located on the front

face of the pump directly under the discharge

check valve. This tting is used to purge any

air that is trapped in the process liquid end.

If this tting is loose when you ll the pump, a

stream of process uid will come out and create

a hazardous condition.

B. For a variable speed drive, the motor

should be run at a very slow speed between

75-100 revolutions per minute, and the pump

should have minimal process back pressure

for initial start-up. Gradually increase the

motor speed and increase back-pressure

to insure that the pump time to purge all air

from the system.

NOTE:

This concludes the start-up procedure. Please

follow these steps to insure start-up success

and reduce any risk of damage to the pump.

9Instruction Manual

Page 10

SECTION 3 - OPERATION

3.2 RELIEF VALVE ADJUSTMENT

THE PRESSURE RELIEF VALVE

IS FACTORY SET TO OPEN AT A

PRESSURE SLIGHTLY ABOVE THE PUMP MAXIMUM

OPERATING DISCHARGE PRESSURE; NEVER SET THE VALVE

AT ANY GREATER PRESSURE.

All HPD liquid ends have a built in relief valve that

allows hydraulic uid to return to the hydraulic uid

reservoir if excessive pressure builds up in the

discharge line. This effectively stops the pump from

pumping, since the forward stroke of the piston

will not displace the hydraulic uid and force the

diaphragm to ex.

The HPD liquid end relief valve may be adjusted

to operating conditions by the following procedure.

Adjust the relief valve after rst installing the pump

and after any maintenance procedures.

1. A pressure gauge and shut OFF valve must be

installed in the discharge line to complete this

procedure. If the necessary equipment is not

installed, refer to the “Typical Piping” instructions

in Section 2.

2. Make sure shut OFF valve is open. Start pump

and pump process liquid to drain or other safe

point to establish proper pumping action.

3. Set capacity control at 30%.

4. Close shut OFF valve slowly (“dead head” the

pump) and closely watch the pressure increase

on the pressure gauge. If pressure exceeds

desired value, quickly open shut OFF valve to

relieve pressure in line.

5. With shut OFF valve still closed, loosen relief

valve adjusting screw located on top of valve

until the maximum pressure gauge reading

reaches and maintains the relief valve pressure

setting desired.

6. After setting relief valve, make sure shut OFF

valve is fully open. Remove pressure gauge

from line or leave in place, as desired, and place

pump in routine service.

NEVER OPEN THE AIR PURGE

VALVE (IF EQUIPPED 0261)

DURING PRESSURIZED PUMP OPERATION.

7. The diaphragm head is equipped with an

air bleed purge valve built in just below the

discharge port. (Item 0350). The purpose of

this device is to vent entrapped air from the

diaphragm head during priming and start-up.

This end of this tting will accept exible tubing

in order to pipe OFF the solution to a non-

hazardous location. Immediately after priming,

the tting should be tightened.

KEEP HANDS AWAY FROM

RECIPROCATING PLUNGER

AND CROSSHEAD. DO NOT LEAVE PUMP OPERATING

UNATTENDED WITH SHUT OFF VALVE CLOSED. EXCESSIVE

PRESSURE CAN BUILD QUICKLY, POSSIBLY CAUSING

SEVERE DAMAGE TO PUMP AND / OR PIPING. SINCE THE

RELIEF VALVE IS NOT YET PROPERLY ADJUSTED, IT CAN NOT

BE RELIED ON TO LIMIT EXCESSIVE PRESSURE BUILD-UP. BE

SURE TO WATCH PRESSURE GAUGE VERY CAREFULLY AND

OPEN SHUT OFF VALVE IMMEDIATELY IF EXCESSIVE

PRESSURE DEVELOPS.

10

Instruction Manual

Page 11

SECTION 4 - MAINTENANCE

4.1 DIAPHRAGM REPLACEMENT

(FIGURE 2, SHEET 1 & 2)

The HPD diaphragm is extremely durable and often

lasts for many years of service. As a preventive

measure, however, Milton Roy recommends that

the diaphragms be replaced yearly to coincide

with annual check valve replacement. The liquid

end must be removed from the pump to replace

the diaphragm. The following is the diaphragm

replacement procedure:

1. Stop pump and relieve all pressure from system.

Isolate the liquid end from all sources of process

liquid with appropriate valving and purge liquid

end of all process uid.

2. Disconnect both the suction inlet and discharge

outlet from the piping system.

NOTE:

Approximately one pint of oil will still be present

in the contour plate area which will be released

when the diaphragm is removed. Prepare your

work area accordingly.

3. Remove the catchall cover and drain catchall of

hydraulic oil by removing pipe plug at bottom of

casing.

4. Completely loosen the piston rod retention nut

(1750) located inside the catchall.

5. Disconnect all tubing that connects the liquid

end to the pump body.

NOTE:

The liquid end is very heavy (150 lbs. or more).

A hoist is required to move it.

7. Remove relieve valve (1040) and rell valve

(400) from displacement chamber.

8. Place liquid end, diaphragm head up

(bolts (710) on top), on a bench or other clean,

at, and convenient working area.

9. Once the diaphragm head is adequately

supported, the diaphragm head bolts (710)

can be removed. Carefully pull the diaphragm

head (700) away from the displacement

chamber. The diaphragm (670) may pull OFF

with the diaphragm head or remain with the

displacement chamber. Remove diaphragm

(670). (When equipped with leak detection

(See Section 5) remove two diaphragms,

leak detection ring A (8080), leak detection

ring B (8081), and leak detection ring spacer

(8082). Leak detection rings A, leak detection

rings B, and leak detection ring spacer can be

reused).

10. Clean all sealing surfaces and install new

diaphragm (670). (When equipped with

leak detection (See Section 5) install two

diaphragms, leak detection ring A (8080), leak

detection ring B (8081), and leak detection

ring spacer (8082) removed previously.

Apply a small amount of mineral oil between

the diaphragms. Stacked diaphragms and

rings may be aligned using the three small

holes as a guide).

NOTE:

Apply anti-seize thread lubricant to the bolts.

6. Support liquid end with a hoist and unscrew

nuts (980) that hold the displacement chamber

(630) to the pump body. Pull liquid end and

plunger assembly (2000) OFF, being careful

to protect the plunger from damage. Carefully

raise liquid end and plunger over catchall and

pull plunger from liquid end, allowing hydraulic

uid to drain back into catchall. Pull plunger

rmly but carefully, being careful not to bend or

otherwise damage the plunger.

11. Reinstall liquid end on catchall, using the bolts

as a guide.

NOTE:

The bolt torque value stamped on the head only

applies to the material grade supplied with the

pump.

11Instruction Manual

Page 12

SECTION 4 - MAINTENANCE

12. Torque bolts in sequence to one half of the nal

torque value stamped on the head. Follow the

bolt torque pattern as stamped on the head.

Repeat the torque sequence until bolts are

tightened to nal torque value.

13. Reconnect suction inlet and discharge outlet to

piping system. Follow Section 5 if your pump

is equipped with leak detection.

14. Fill the liquid end with hydraulic oil (refer to

above “INITIAL START-UP” procedure).

4.2 HYDRAULIC OIL REPLACEMENT

Inspect and replace hydraulic oil on same schedule

as the pumps gear drive lubricant (or whenever

diaphragm is replaced). Annual replacement is

recommended.

4.3 MARS REFILL VALVE (400)

The MARS rell valve (400) requires no periodic

maintenance. Clean hydraulic oil is critical for

proper operation.

Strainer service: while replacing the hydraulic

oil, it is also recommended that the hydraulic oil

strainer be replaced. The strainer, (390) which

screws into the displacement chamber can become

fouled or clogged over time.

NOTE:

Federal law prohibits handling of equipment that

is not accompanied by an OSHA Safety Data

Sheet (SDS). A completed SDS must be packed

in the ship-ping crate with any pump returned

to the factory. These safety precautions will aid

the troubleshooting and repair procedure and

preclude serious injury to repair personnel from

hazardous residue in pump liquid end. A Safety

Data Sheet must accompany all returns.

4.5 RECOMMENDED SPARE PARTS

Be Prepared. To avoid delays in repairs, the

following spare parts should be ordered for each

pump:

One Routine Preventive Maintenance Kit, which

contains replacements for those parts which

are subject to wear; specically the ball checks,

check valve seats, gaskets, and the hydraulic uid

strainer. Replacing these parts annually with an

RPM kit can reduce the possibility of unexpected

downtime and will help to extend pump life.

Parts orders must include the following information:

1. Serial number (found on nameplate)

2. Model number (found on nameplate)

3. Quantity required

4. Part number

Screw the valve back into the chamber. If the valve

is damaged or broken, replace the entire assembly.

4.4 RETURNING UNITS TO THE FACTORY

Pumps will not be accepted for repair without a

Return Material Authorization, available from the

factory or other authorized Customer Service

Department. Pumps returned to the factory for

repairs should be clearly labeled to indicate the

liquid being pumped. Process liquid should be

ushed from the pump liquid end before the pump

is shipped.

12

Instruction Manual

5. Part description

Always include the serial and model numbers in all

correspondence regarding the unit.

Page 13

SECTION 4 - MAINTENANCE

4.6 ROUTINE PREVENTIVE MAINTENANCE

BEFORE ANY MAINTENANCE,

RELIEVE ALL PRESSURE FROM

SYSTEM, ISOLATE LIQUID END FROM ALL SOURCES OF

PROCESS LIQUID WITH APPROPRIATE VALVING, AND PURGE

LIQUID END OF ALL PROCESS LIQUID.

All inquiries on part order should be addressed to

your local Milton Roy sales representative or sent

to: www.miltonroy.com.

4.7 HYDRAULIC OIL REPLACEMENT

Inspect and replace hydraulic oil on the same

schedule as the pump’s gear drive lubricant

(see the appropriate pump drive instruction manual

for this information). Semiannual replacement is

recommended, and can be scheduled to coincide

with season oil changes.

To replace the hydraulic oil:

1. Remove the catchall cover by unscrewing the

four screws, which hold it on.

2. Place a container under the pump catchall to

catch the oil and unscrew the catchall drain

plug.

3. When oil has finished draining, make sure

that the area around the drain hole is clean.

Screw drain plug back in securely.

4. Fill the catchall to the top of the oil seal that

surrounds the crosshead with new, clean oil.

Use hydraulic oil or any good quality type A

automobile transmission uid.

5. Replace the catchall cover the screw rmly in

place.

NOTE:

It is not necessary to purge the liquid end

displacement chamber of oil during annual oil

replacement.

6. Dispose of oil according to federal, state, or local

codes that may apply.

4.8 CHECK VALVE MAINTENANCE

4.8.1 Disassembly

BEFORE PERFORMING ANY

MAINTENANCE ON THE CHECK

VALVES, RELIVE ALL PRESSURE FROM SYSTEM, ISOLATE

LIQUID END FROM ALL SOURCES OF PROCESS LIQUID WITH

APPROPRIATE VALVING, AND PURGE LIQUID END OF ALL

PROCESS FLUID.

After insuring that all system pressure has been

relieved and that all hazardous process liquids

have been ushed from the liquid end, disconnect

both the suction inlet and discharge outlet from the

system piping.

1. Loosen the retaining nut, then remove.

Once disassembled, the O-rings should be

discarded.

2. Check valves may be removed. A compressed

O-ring provides the seal to the head.

Inspect the balls carefully. If they are smooth,

round and free of deposits or pits, then they

are suitable for continued use. Examine the

check valve seats. The area of the seat where

it meets the ball (the un-chamfered side) must

be in near perfect condition for continued use.

Any imperfection visible on the seating surface

(pits, erosion, cracks, or a ball shaped contour

greater than 0.030 deep) makes the seat

unusable. If both the balls and seats are in good

condition, then the length of time between parts

replacement may be lengthened. If the balls and

seats are severely damaged, then the length

of time between parts replacement should be

shortened.

4.8.2 Re-assembly

1. Replace O-ring on the check valves.

Lubricate the O-rings and check valve threads

before assembly.

2. Attach port adapter and tighten retaining nut.

13Instruction Manual

Page 14

SECTION 4 - MAINTENANCE

4.9 CORRECTIVE MAINTENANCE

4.9.1 Relief Valve Assembly

The relief valve assembly operates in filtered

hydraulic oil and should require maintenance

only if unusual circumstances occur, such

as if corrosive media contaminates the fluid.

Assembly and disassembly is straightforward.

Field servicing should be limited to inspection and

cleaning only. Repairs of this critical component

should only be carried out by an authorized

Milton Roy repair facility.

14

Instruction Manual

Page 15

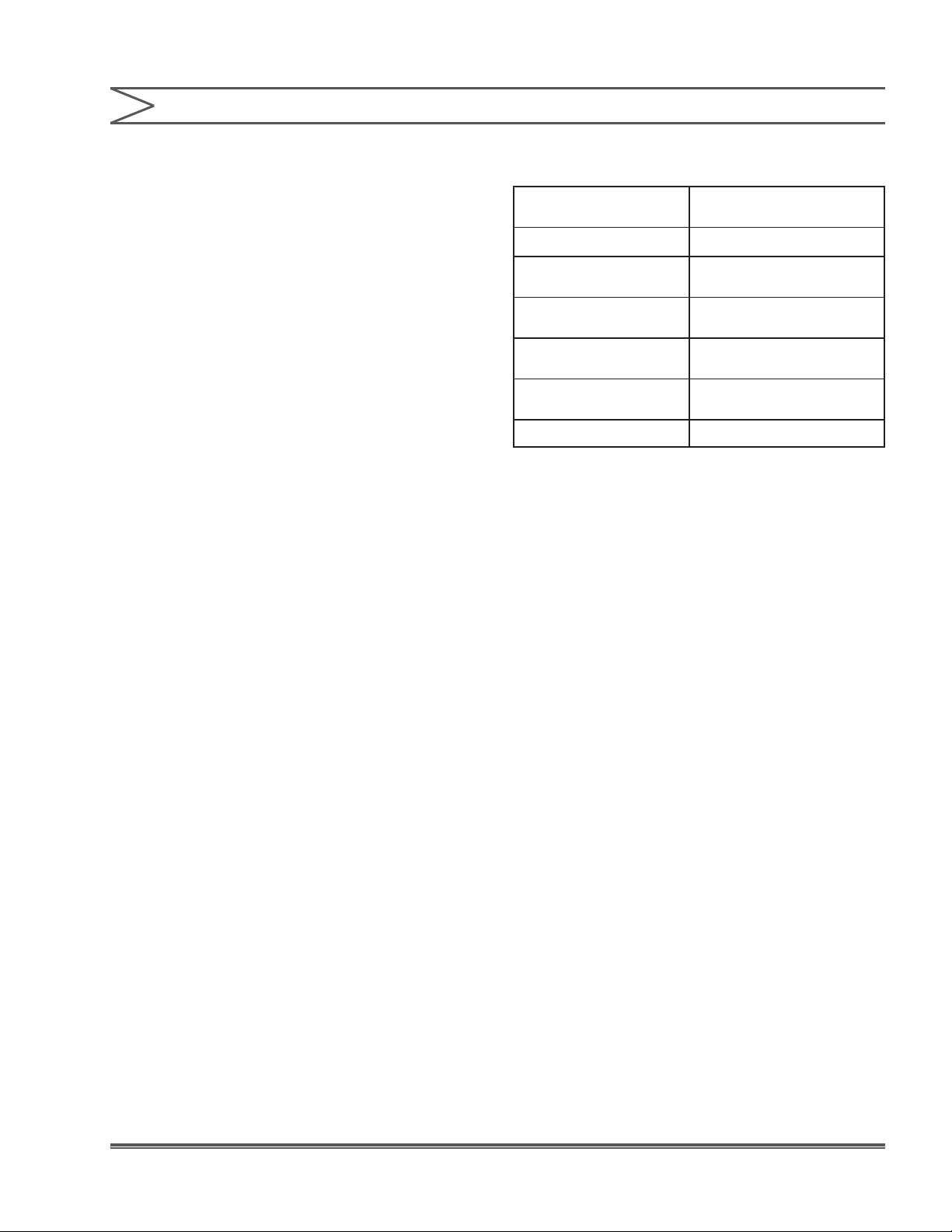

SECTION 5 - LEAK DETECTION (PRESSURE SENSING SYSTEM)

5.1 DESCRIPTION

(FIGURE 2, SHEET 1 & 2)

Milton Roy’s pumps are, by design, leakproof

and durable. In some applications, however,

added assurance is desired to protect the pump

from hostile chemicals, or protect the process

from contamination by hydraulic uids. For these

situations, Milton Roy has developed a highly

reliable diaphragm rupture detection system.

The diaphragm rupture detection system is an

optional feature, available on the Critical Service

line of metering pumps, which is used to detect

and signal if a hole or tear occurs in one or both

diaphragms. The system consists of two PTFE

diaphragms separated by four leak detection

rings (two A rings (8080) & two B rings (8081)).

Pressure in the four leak detection rings between

the diaphragms is monitored via a pressure

gauge. A machined port in the displacement

chamber at (5021) connects the diaphragms and

rings with tubing, gauge, and or pressure switch.

A low cracking pressure check valve (5000) and

a bleed valve (5100) are located between the

displacement chamber and the pressure gauge.

5.2 PRINCIPLE OF OPERATION

The system consists of two separate diaphragms,

four leak detection rings, leak detection ring

spacer (8082), and a pressure gauge (5030) or

switch (1250). During normal operation, the two

diaphragms are pushed tightly together and are

separated only around their outside edge by the

rings. Because there is no uid and very little air

between the two diaphragms, the system does not

experience pressure from the process when both

diaphragms are intact. The pressure is therefore

at atmospheric pressure, and the pressure gauge

displays 0 psi. The rupture detection system

senses process pressure only when one of the

diaphragms rupture. In the event of a rupture in

either diaphragm, uid rushes into the rings, and

the pressure at the ring rises rapidly to the pump’s

operating pressure. This pressure will be displayed

directly on the pressure gauge for visual indication.

An optional pressure switch is also available to

shut down the pump or provide an alarm signal.

The pressurized uid trapped between the pressure

gauge and the check valve can be relieved via the

bleed valve after the pump is shut down and system

pressure relieved.

5.3 SPECIFICATIONS

Maximum

Pressure Ratings:

Materials:

Flow Rate:

Accessories:

Same as pump rating.

Diaphragms: PTFE

Leak Detection Ring /

Tubing: Steel 304SS or

316SS

Derate ow by 5% on all

pumps

Pressure Gauge: 316SS

liquid lled (Standard)

Pressure Switch

W/Gauge : NEMA 4 or

Explosion Proof (optional)

15Instruction Manual

Page 16

SECTION 6 - INSTALLATION & OPERATION (PRESSURE SENSING SYSTEM)

The Diaphragm Rupture Detection System is

usually shipped already mounted to the pump.

Installation, therefore, is usually only a matter of

piping in the pump, and wiring the pressure switch

if one is provided.

6.1 UNPACKING

Units are shipped Free on Board (FOB) factory

and the title passes to the customer when the

carrier signs for receipt of the unit. In the event

that damages occur during shipment, it is the

responsibility of the customer to notify the

carrier immediately and to le a damage claim.

Carefully examine the shipping crate upon receipt

from the carrier to be sure there is no obvious

damage to the contents. Open the crate carefully so

accessory items fastened to the inside of the crate

will not be damaged or lost. Examine all material

inside crate and check against packing list to be

sure that all items are accounted for and intact.

6.2 SAFETY PRECAUTIONS

6.3 DISASSEMBLY / ASSEMBLY

(REFER TO DRAWING 1029026000,

FIGURE 2, SHEET 1 & 2)

LOOSENING ANY HYDRAULIC

CONNECTIONS OR OPENING

ANY VALVES COULD CAUSE PROCESS LIQUID TO BE

RELEASED UNDER PRESSURE. CAREFULLY DISCONNECT

PUMP FROM ALL ELECTRICAL AND HYDRAULIC SERVICE

BEFORE PERFORMING ANY MAINTENANCE.

1. After shutting down the pump and relieving

system pressure, disconnect all hydraulic

connections.

2. Drain the oil from the catchall.

3. Disassemble the diaphragm head from the

pump body following the instructions in

Section 4.

4. Remove diaphragms (670) and discard along

with four leak detection rings (8080 and

(8081), and leak detection ring spacer (8082).

Items (8080, 8081, and 8082) can be reused

if not damaged by process fluid. Refer to

Figure 2, Sheet 2, Detail C as needed.

When installing, operating, and maintaining a

Critical Service pump with Diaphragm Rupture

Detection, keep safety considerations foremost.

Use proper tools, protective clothing, and eye

protection when working on the equipment

and install the equipment with a view toward

ensuring safe operation. Follow the instructions

in this manual and take additional safety

measures appropriate to the liquid being pumped.

Be extremely careful in the presence of hazardous

substances (e.g., corrosives, toxics, solvents,

acids, caustics, ammables etc.).

IF THE PROCESS FLUID IS

HYDROGEN PEROXIDE OR

ANOTHER STRONG OXIDIZING AGENT, MINERAL OIL SHOULD

NOT BE USED BETWEEN THE DIAPHRAGMS. SUBSTITUTE

WITH A CHLOROTRIFLUOROETHYLENE POLY-MER FLUID

SUCH AS FLOUROLUBE.

5. Clean all sealing surfaces and install new

diaphragms (670), leak detection ring A (8080),

leak detection ring B (8081), and leak detection

ring spacer (8082), leak detection ring A (8080),

leak detection ring B (8081) removed previously

(Figure 2, Sheet 1, Detail C). Apply a small

amount of mineral oil between the diaphragms.

Stacked diaphragms and rings may be aligned

using the three small holes as a guide.

Make sure diaphragms (670) t into pocket on

diaphragm head (700).

16

Instruction Manual

Page 17

SECTION 6 - INSTALLATION & OPERATION (PRESSURE SENSING SYSTEM)

6. Reassemble diaphragm head following

Section 4.

7. Once the suction inlet and discharge outlets are

connected to piping system mount the switch

bracket (5090, Figure 2 Sheet 2) then the

remaining components should be tted nger

tight and oriented as shown.

NOTE:

Check the ow direction arrow on the check

valve. The check valve must be assembled with

the arrow pointed toward the pressure gauge

or pressure switch as shown in the gures.

Improper operation will result if the check valve

is not installed correctly.

8. Check all threaded and tube connections to

make sure they are tight.

IMPORTANT

9. Remove the pipe plug(s) and open the bleed-

valve(s). Follow the oil ll and start up procedure

in manual.

10. Leaving the bleed valve(s) open, run the

pump at 100% capacity and normal operating

pressure for 10 minutes. This procedure

purges any excess air and oil from in between

the diaphragms. If too much mineral oil was

placed between the diaphragms in step 5,

some will leak out from the bleed valve(s) at

this point. Lubricant leakage is acceptable.

6.4 ELECTRICAL CONNECTIONS

THIS SECTION ONLY APPLIES TO MODELS

EQUIPPED WITH THE PRESSURE SWITCH

ALARM OPTION.

The diaphragm leak detection system can be

equipped with a pressure switch which can be

wired to activate an alarm or shut down the pump

in the event of a diaphragm failure. This switch is

either NEMA 4 (indoor / outdoor, weather and dust

proof) or Explosion Proof (for hazardous locations).

In both cases the switch relay is single-pole double-

throw (SPDT), normally open or normally closed

and rated for 15 amps, 125/240/480 VAC resistive.

6.5 NEMA 4 PRESSURE SWITCH WIRING

The switch terminals are accessed by removing the

two screws retaining the cover and cover gasket.

A 1/2” NPT conduit connection is provided in the

switch enclosure.

6.5.1 Wiring

Unscrew the switch cover to access the wiring

connections. A 3/4” NPT conduit connection

is provided in the switch enclosure. Replacing

the cover hand tight (5 full threads engaged) is

sufcient to maintain proper protection. Additional

tightening may be required to fully engage the

O-ring and seal enclosure for rain tight protection.

11. Close the bleed valve(s) and replace the pipe

plug(s). The leak detector assembly is now

complete.

12. Additional oil may need to be purged again.

Return to step 10.

17Instruction Manual

Page 18

SECTION 6 - INSTALLATION & OPERATION (PRESSURE SENSING SYSTEM)

6.6 EXPLOSION PROOF PRESSURE

SWITCH

ALWAYS WIRE IN ACCORDANCE

WITH LOCAL OR NATIONAL

CODES. BE SURE ALL LIVE SUPPLY CIRCUITS ARE

DISCONNECTED BEFORE WIRING TO THE SWITCH. MAXIMUM

RECOMMENDED WIRE SIZE IS #14 AWG.

The three switch terminals are clearly labeled

“Com” (common), “NO” (normally open), and

“NC” (normally closed). A grounding screw is

also provided. Keep wires as short as possible

to prevent interference with the plunger and

differential switch wheel inside the switch.

Customer Connections

COM

NO

NC

6.7 START-UP

1. Refer to the manual for pump installation and

start-up instructions.

2. During the initial installation, following any

disassembly of the leak detection system, or if

the pump has not been operated for a prolonged

period, a short break-in procedure for the leak

detector system is required. On duplex pumps,

be sure to follow directions on both sides of the

pump.

a. Open the bleed valve(s) on the leak detection

system.

b. Operate the pump at 100% capacity and

normal system operating pressure. Air and a

small amount of oil may leak from the bleed

valve(s).

c. After a minimum of ten minutes of operation,

close the bleed valve(s).

(Violet)

(Blue)

NC

NO

Internal SPDT Switch Rated

15A, 120/240/480 VAC

(Black)

COM

Figure 1. Pressure Switch Wiring Diagram

IMPORTANT

Connections must always be made through cable

connectors which maintain the integrity of the

NEMA 4 switch or Explosion Proof enclosure.

The break-in operation purges any air and excess

oil which may be trapped in the intermediate ring(s).

The leak detection system is now operational.

18

Instruction Manual

Page 19

1. Please refer to the Bill of Material and assembly

for spare parts.

2. Use the drawing to identify the sequence for the

part.

3. The sequence number is used on the drawing

and Bill of Material.

4. Parts should be ordered by the “Part Number”

listed in the Bill of Material.

5. Also reference the sequence number of the part,

since component upgrades occur.

SECTION 7 - PARTS

19Instruction Manual

Page 20

20 Instruction Manual

Page 21

21Instruction Manual

Page 22

BILL OF MATERIAL

FOR

MCB2418GPCCDEAV6H311C522

MR SO #2441959 / PO6019493

MILROYAL® C

MODEL # MCB241

TAG # 41-67-2011, 41-67-2012

ITEM

NUMBER

261 20352 BARB,AIR BLEED 316/316LSS 1 EA

262 A5-1007 OR -007 VITON 1 EA

300 40538 ‘O’ RING 2-176 VITON 1 EA

350 30342 AIR BLEED VALVE HI TEMP 1 EA

351 21801 PLUG, AIR BLEED VALVE 1 EA

352 V-112 POPPET O-RING / VITON STD. 1 EA

390 2450021000 STRAINER FITTING HPD 1 EA

400 20749 REFILL VALVE BODY 1 EA

420 L10626 BALL, 1/4” 440C SS 1 EA

430 20024 SPRING MARS CS 1 EA

440 60668 FLATWASHER M4 ZINC PLT 1 EA

441 40605 RETAINING RING #RCLBHO0037STPA 1 EA

630 21269 DISP. CHMBR ‘116’ SLEEVED 1 EA

643 20663 MARS BUTTON 1 EA

644 60677 SPRING, MARS BUTTON 1 EA

645 60673 POPPET MARS VALVE 1 EA

646 40570 WALDES RETAINING RING X5133-31 1 EA

647 4020095011 PLUG 1/8 NPT SOCKET HEX HEAD 1 EA

648 4050025144 SOC HD SCR #10-24X1-1/2 STL 2 EA

649 4080068015 O-RING 2-111 VITON / USE V-111 1 EA

650 20658 CONTOUR PLATE 7.50 MILC BAR 1 EA

670 40515 DIAPHRAGM - GYLON 8.730 X .060 2 EA

700 20747 DIAPHRAGM HEAD ‘116’BAR ASTM A479 1 EA

710 40525-G7 SOC HD CAP SCR 1 1/4-7 X 5 1/2 12 EA

711 40893 WASHER, FLAT 1 1/4 NARROW 12 EA

790 20684 CAGE - 1-1/2” BALL CHECKS 316SS 4 EA

800 40564 O-RING , TFE ENC VITON,V-133 4 EA

805 20683 SEAT - 1-1/2” BALL CHECKS 316SS 4 EA

810 4070014272-G7 BALL 1-1/2 316SS 4 EA

815 20680 CHECK VALVE BODY - 1-1/2” 2 EA

816 40565 O-RING, TFE ENC VITON, V-142 4 EA

820 53720 FLANGE WELD ASSY 1” 600# VERT 2 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

22 Instruction Manual

Page 23

ITEM

NUMBER

870 40791 ‘O’RING 2-230 NITRILE 70 DURO 1 EA

880 21268 SLEEVE, PLUNGER BORE 1.50 DIA 1 EA

881 4050020136 HEX HD SCR 1/2-13X1-1/4 ULTRA 5 EA

950 2190063006 HALF MOON STEEL MILROY HPD ALL 2 EA

960 2720026406 PLUNGER ADAPTER 7/8 HOLE CRS 1 EA

968 2250028099 GASKET 5-1/2ID LE TO DRIVE HSG 1 EA

970 4040044022 SPRING LOCK WASHER 5/8 18.8SS 4 EA

980 4050021151 HEX HD SCR 5/8-11X1-3/4STL GR2 4 EA

990 4020001124 HXPIPEBSHG 1X1/2 304SS 1 EA

1000 4020052012 NIPTHRDSCH40 1/2X1-1/8 304SS 1 EA

1005 42170 TEE3000#THRD 1/2 304SS 1 EA

1010 4020001054 HXPIPEBSHG 1/2X1/4 304SS 1 EA

1020 4020553152 MALE ELBOW 1/2 NPT X 3/8 TUBE 1 EA

1021 A1-0013 MELBOW 1/4T 1/4P SS 1 EA

1030 C7-0028 3/8” 316 SEAMLESS .035W 12 IN

1031 C7-0027 1/4” 316 SEAMLESS .035W 24 IN

1040 4070177051 RELIEF VALVE 50/2500 PSI 1 EA

1051 A1-0007 MCONN 3/8T 1/4NPT SS 1 EA

1052 A1-0003 MCONN 1/4T 1/8P SS 1 EA

2000 53744 PLUNGER ASSEMBLY 1 1/2” 1 EA

4040 4070317020 MINERAL OIL-NOT FOR RESALE 1 OZ

4990 C7-0044 1/8” 316 SEAMLESS .035W 24 IN

5000 40065 CHECK VALVE 1/8TUBE 1/3PSI 316SS 1 EA

5020 40061 TUBE CONN 1/8 TUBEX 1/8NPT 316SS 2 EA

5030 53716 GAUGE, PRES, 2.5”, ASHCRO, 2000PSI 1 EA

5031 4050263050 PAN HD SCR #4-40X1/2 ZNCR 3 EA

5032 4040095023 SPRING LOCK WASHER #4 18.8SS 3 EA

5033 C0-0051 4-40 NUT SS 3 EA

5050 40062 TEE 1/8NPT FEMALE 316SS 1 EA

5070 40067 RED ADAPTER 1/4F X1/8M NPT 316SS 1 EA

5090 21094 SUPPORT BRACKET,SWITCH / GAGE 1 EA

5092 4050016095 HEX HD SCR 1/4-20X3/4 18.8SS 2 EA

5100 40063 BLEED VALVE 1/8 NPT 316SS 1 EA

8080 40610 LEAK DETECTION RING ‘A’ 2 EA

8081 40611 LEAK DETECTION RING ‘B’ 2 EA

8082 40609 SPACER RING ‘116’ RUP. DET. 1 EA

8083 40790 O-RING, TFE ENC VITON, 2-178 1 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

23Instruction Manual

Page 24

BILL OF MATERIAL

FOR

MCB2018JPCCCEAV6H311C522

MR SO #2441959 / PO6019493

MILROYAL® C

MODEL # MCB201

TAG # 40-67-3316 A/B, 40-67-3326 A/B, 40-67-3336 A/B, 40-67-3346 A/B

ITEM

NUMBER

261 20352 BARB,AIR BLEED 316/316LSS 1 EA

262 A5-1007 OR -007 VITON 1 EA

300 40538 ‘O’ RING 2-176 VITON 1 EA

350 30342 AIR BLEED VALVE HI TEMP 1 EA

351 21801 PLUG, AIR BLEED VALVE 1 EA

352 V-112 POPPET O-RING / VITON STD. 1 EA

390 2450021000 STRAINER FITTING HPD 1 EA

400 20749 REFILL VALVE BODY 1 EA

420 L10626 BALL, 1/4” 440C SS 1 EA

430 20024 SPRING MARS CS 1 EA

440 60668 FLATWASHER M4 ZINC PLT 1 EA

441 40605 RETAINING RING #RCLBHO0037STPA 1 EA

630 21269 DISP. CHMBR ‘116’ SLEEVED 1 EA

643 20663 MARS BUTTON 1 EA

644 60677 SPRING, MARS BUTTON 1 EA

645 60673 POPPET MARS VALVE 1 EA

646 40570 WALDES RETAINING RING X5133-31 1 EA

647 4020095011 PLUG 1/8 NPT SOCKET HEX HEAD 1 EA

648 4050025134 SOC HD SCR #10-24X1-1/4 STL 2 EA

649 4080068015 O-RING 2-111 VITON / USE V-111 1 EA

650 20658 CONTOUR PLATE 7.50 MILC BAR 1 EA

670 40515 DIAPHRAGM - GYLON 8.730 X .060 2 EA

700 20747 DIAPHRAGM HEAD ‘116’BAR ASTM A479 1 EA

710 40524 WASHER SAE HI STRENGTH 1 1/4 12 EA

711 40525-G7 SOC HD CAP SCR 1 1/4-7 X 5 1/2 12 EA

790 20684 CAGE - 1-1/2” BALL CHECKS 316SS 4 EA

800 40564 O-RING , TFE ENC VITON,V-133 4 EA

805 20683 SEAT - 1-1/2” BALL CHECKS 316SS 4 EA

810 4070014272-G7 BALL 1-1/2 316SS 4 EA

815 20680 CHECK VALVE BODY - 1-1/2” 2 EA

816 40565 O-RING, TFE ENC VITON, V-142 4 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

24 Instruction Manual

Page 25

ITEM

NUMBER

820 53720 FLANGE WELD ASSY 1” 600# VERT 2 EA

870 4080095215 O-RING 2-230 VITON 1 EA

880 22731 SLEEVE, PLUNGER BORE 1.25 DIA 1 EA

881 4050020136 HEX HD SCR 1/2-13X1-1/4 ULTRA 5 EA

950 2190063006 HALF MOON STEEL MILROY HPD ALL 2 EA

960 2720026406 PLUNGER ADAPTER 7/8 HOLE CRS 1 EA

968 2250028099 GASKET 5-1/2ID LE TO DRIVE HSG 1 EA

970 4040044022 SPRING LOCK WASHER 5/8 18.8SS 4 EA

980 4050021151 HEX HD SCR 5/8-11X1-3/4STL GR2 4 EA

990 4020001124 HXPIPEBSHG 1X1/2 304SS 1 EA

1000 4020052012 NIPTHRDSCH40 1/2X1-1/8 304SS 1 EA

1005 42170 TEE3000#THRD 1/2 304SS 1 EA

1010 4020001054 HXPIPEBSHG 1/2X1/4 304SS 1 EA

1020 4020553152 MALE ELBOW 1/2 NPT X 3/8 TUBE 1 EA

1021 A1-0013 MELBOW 1/4T 1/4P SS 1 EA

1030 C7-0028 3/8” 316 SEAMLESS .035W 12 IN

1031 C7-0027 1/4” 316 SEAMLESS .035W 12 IN

1040 4070177051 RELIEF VALVE 50/2500 PSI 1 EA

1051 A1-0007 MCONN 3/8T 1/4NPT SS 1 EA

1052 A1-0003 MCONN 1/4T 1/8P SS 1 EA

2000 53719 PLUNGER ASSEMBLY 1 1/4” 1 EA

4040 4070317020 MINERAL OIL-NOT FOR RESALE 1 OZ

4990 C7-0044 1/8” 316 SEAMLESS .035W 12 IN

5000 40065 CHECK VALVE 1/8TUBE 1/3PSI 316SS 1 EA

5020 40061 TUBE CONN 1/8 TUBEX 1/8NPT 316SS 1 EA

5030 53716 GAUGE,PRES,2.5”,ASHCRO,2000PSI 1 EA

5031 4050263050 PAN HD SCR #4-40X1/2 ZNCR 3 EA

5032 4040095023 SPRING LOCK WASHER #4 18.8SS 3 EA

5033 C0-0051 4-40 NUT SS 3 EA

5050 40062 TEE 1/8NPT FEMALE 316SS 1 EA

5070 40067 RED ADAPTER 1/4F X1/8M NPT 316SS 1 EA

5090 21386 BRACKET, LEK DET, GAGE MCB 1 EA

5092 40710 SCREW 3/8-16X3/4 SHCS, 18.8SS 2 EA

5100 40063 BLEED VALVE 1/8 NPT 316SS 1 EA

8080 40611 LEAK DETECTION RING ‘B’ 2 EA

8081 40610 LEAK DETECTION RING ‘A’ 2 EA

8082 40609 SPACER RING ‘116’ RUP. DET. 1 EA

8083 40790 O-RING, TFE ENC VITON, 2-178 1 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

25Instruction Manual

Page 26

BILL OF MATERIAL

FOR

MCB1418BPBCDEAV6ST33C5C2

MR SO #2441959 / PO6019493

MILROYAL® C

MODEL # MCB141

TAG # 40-67-3111 A/B/C/D

ITEM

NUMBER

261 20352-G7 BARB,AIR BLEED 316SS 1 EA

262 A5-1007 OR -007 VITON 1 EA

300 40780 O-RING, TFE ENC VITON, V-167 1 EA

350 30342 AIR BLEED VALVE HI TEMP 1 EA

351 21801 PLUG, AIR BLEED VALVE 1 EA

352 V-112 POPPET O-RING/VITON STD. 1 EA

390 2450021000 STRAINER FITTING HPD 1 EA

400 20749 REFILL VALVE BODY 1 EA

420 L10626 BALL, 1/4” 440C SS 1 EA

430 20024 SPRING MARS CS 1 EA

440 60668 FLATWASHER M4 ZINC PLT 1 EA

441 40605 RETAINING RING #RCLBHO0037STPA 1 EA

630 53777 DISP. CHMBR .875 ‘72’ MIL C 1 EA

643 20663 MARS BUTTON 1 EA

644 60677 SPRING, MARS BUTTON 1 EA

645 60673 POPPET MARS VALVE 1 EA

646 40570 WALDES RETAINING RING X5133-31 1 EA

647 OS601 PLUG - 1/8” NPT, SOC HEX HD 1 EA

648 4050025134 SOC HD SCR #10-24X1-1/4 STL 2 EA

649 40534 ‘O’ RING 2-109 NITRILE 1 EA

650 20659 CONTOUR PLATE 4.50 MILC BAR 1 EA

670 40516 DIAPHRAGM -6” OD X .030 THK 2 EA

700 21092 DIAPHRAGM HEAD ‘72’ L/D 1 EA

710 43195-G7 SOC HD SCR 7/8-9X4-1/2 ST XYLN 10 EA

711 40749 WASHER 7/8 AN 960 C ULTRA COAT 10 EA

790 22710-G7 CAGE 3/4 BALL, SLURRY SERVICE 4 EA

800 2250043075 SEAL .915ID 1.197OD .141THK 4 EA

805 41054-G7 SEAT,HARDENED INSERT ASSEMBLY 4 EA

810 4070015191 BALL 3/4 CERAMIC AD995 4 EA

815 20678-G7 CHECK VALVE BODY - 1” 2 EA

816 40566 O-RING, TFE ENC VITON,M V-128 4 EA

820 52861 FLANGE WELD ASSY 1/2” 600#VERT 2 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

26 Instruction Manual

Page 27

ITEM

NUMBER

950 2190063006 HALF MOON STEEL MILROY HPD ALL 2 EA

960 2720026406 PLUNGER ADAPTER 7/8 HOLE CRS 1 EA

968 2250028099 GASKET 5-1/2ID LE TO DRIVE HSG 1 EA

970 4040044022 SPRING LOCK WASHER 5/8 18.8SS 4 EA

980 4050032164 SOC HD SCR 5/8-11X2 ULTRA COAT 4 EA

990 A2-0066 BUSHING RED 1 X 1/4 SS 1 EA

1000 HN1414304 SS-4-HN 1 EA

1005 A2-0115 TEE 1/4 SS 1 EA

1020 L11439 ELBOW 3/8ODTX1/4MPT 316SS 1 EA

1021 A1-0013 MELBOW 1/4T 1/4P SS 1 EA

1030 41028 TUBE MECH 3/8 ODX.035WALL 317L 18 IN

1031 41027 TUBE MECH 1/4 ODX.035WALL 317L 24 IN

1040 53779 RELIEF VLV ASSY 1500-2250 PSIG 1 EA

1051 A1-0007 MCONN 3/8T 1/4NPT SS 2 EA

1052 A1-0003 MCONN 1/4T 1/8P SS 1 EA

2000 2120062110 PLUNGER ASSEMBLY 7/8” 1 EA

4040 4070317020 MINERAL OIL-NOT FOR RESALE 1 OZ

4990 C7-0044 1/8” 316 SEAMLESS .035W 12 IN

5000 40065 CHECK VALVE 1/8TUBE 1/3PSI 316SS 1 EA

5020 40061 TUBE CONN 1/8 TUBEX 1/8NPT 316SS 1 EA

5030 53716 GAUGE,PRES,2.5”,ASHCRO,2000PSI 1 EA

5031 4050263050 PAN HD SCR #4-40X1/2 ZNCR 3 EA

5032 4040095023 SPRING LOCK WASHER #4 18.8SS 3 EA

5033 C0-0051 4-40 NUT SS 3 EA

5050 40062 TEE 1/8NPT FEMALE 316SS 2 EA

5070 40067 RED ADAPTER 1/4F X1/8M NPT 316SS 1 EA

5090 21094 SUPPORT BRACKET,SWITCH / GAGE 1 EA

5092 40710 SCREW 3/8-16X3/4 SHCS, 18.8SS 2 EA

5100 40063 BLEED VALVE 1/8 NPT 316SS 1 EA

8080 20847 LEAK DETECTION RING ‘A’ 2 EA

8081 20848 LEAK DETECTION RING ‘B’ 2 EA

8082 53965 MOD. SPACER RING’72’ 316SS 1 EA

8083 40781 O-RING, TFE ENC VITON, V-165 1 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

27Instruction Manual

Page 28

DRILL 1/4” O THRU AS

BREATHER HOLE FOR PISTON

2020

2030

2050

1040

2.25

OIL LEVEL

330

340

990

2010

SEALS INSTALLED

BACK TO BACK

10

REF

DETAIL

925

FOR HPD

HOUSING

810

820

830

840

780

760

790

800

1075

1076

1070

720

1060

635

1080

710

670

700

650

640

630

3010

3000

28 Instruction Manual

Page 29

5033

5032

5031

5090

5030

5040

5050

5094

5100

5096

5097

5000

4990

4980

5092

5091

5020

5010

5093

0670

8081

8080

8082

8083

ENLARGED SECTION

29Instruction Manual

Page 30

BILL OF MATERIAL

FOR

MBH0918JPECCEAS6ST11C522

MR SO #2441959 / PO6019493

MILROYAL® B

MODEL # MBH091

TAG # 40-67-3610, 40-67-3611, 40-67-3612

ITEM

NUMBER

10 2810047001 HOUSING MIL B 1 EA

330 4080031020 OIL SEAL- CROSSHEAD 2 EA

340 4020009024 SQHDPLPIPE150#THRD 1 304SS 1 EA

630 20391 DISP CHMBR 9/16 LO FLO HPD STL 1 EA

635 4080109415 O-RING 2-044 VITON 70 DURO 1 EA

640 20021 BODY MARS CS 1 EA

650 20079 CONTOUR PLT ASS’Y CS-USE 30616 1 EA

670 20493 DIAPHRAGM LO FLOW HPD DBL DIA 2 EA

700 20319 DIAPHRAGM HEAD LOFLO HPD 6”D A479 1 EA

710 53768-G7 SOC HD SCR 1/2-13X3-1/4 XYLAN 8 EA

720 4040151033 FLAT WASHER SAE 1/2 NOM ULTRA 8 EA

760 4050160143-G7 STUD 3/8-16UNCX4-1/2 300SS 8 EA

780 2250075075-G7 GASKET TEFLON 3/8 BALL 106 HPD 10 EA

790 2920054016-G7 GUIDE 3/8 BALL 316SS HPD 4 EA

800 2240099016-G7 SEAT 3/8 BALL 316SS HPD 4 EA

810 4070014112-G7 BALL 3/8 316/316LSS 4 EA

820 2710060000-G7 FLANGE PORT ADAPTER WELD ASSY 2 EA

830 4050066012-G7 HEX NUT 3/8-16NC 18.8SS 8 EA

840 4040041022-G7 SPRING LOCK WASHER 3/8 316SS 8 EA

925 4080095231 O-RING 2-232 NITRILE 70 DURO 1 EA

990 2450021000 STRAINER FITTING HPD 1 EA

1040 1010021306 RELIEF VALVE ASSY MAX 1780 PSI 1 EA

1060 4040040028 SPRING LOCK WASHER 5/16 Z PL 2 EA

1070 4050028194 SOC HD SCR 5/16-18X2-3/4 ALY 2 EA

1075 20352 BARB,AIR BLEED 316/316LSS 1 EA

1076 A5-1007 OR -007 VITON 1 EA

2010 2250035199 GASKET 1 EA

2020 2720026406 PLUNGER ADAPTER 7/8 HOLE CRS 1 EA

2030 20390 PLUNGER ASSY. 9/16 LO FLO HPD 1 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

30 Instruction Manual

Page 31

ITEM

NUMBER

2050 4050018136 HEX HD SCR 3/8-16X1-1/4 ULTRA 4 EA

3000 4020503182 ELL 1/2 NPT 3/4 ID TUBE NYLON 1 EA

3010 4020296171 TUBING 1”OD X 3/4”ID-1/8” WALL 1 FT

4980 A1-0100 MELBOW 1/8T X 1/8P SS 2 EA

4990 20495 TUBE HEAD TO VALVE 1 EA

5000 40065 CHECK VALVE 1/8TUBE 1/3PSI 316SS 1 EA

5010 52425 TUBE, STRAIGHT, VALVE TO GAUGE 1 EA

5020 40061 TUBE CONN 1/8 TUBEX 1/8NPT 316SS 1 EA

5030 53716 GAUGE,PRES,2.5”,ASHCRO,2000PSI 1 EA

5031 4050263050 PAN HD SCR #4-40X1/2 ZNCR 3 EA

5032 4040095023 SPRING LOCK WASHER #4 18.8SS 3 EA

5033 C0-0051 4-40 NUT SS 3 EA

5040 40067 RED ADAPTER 1/4F X1/8M NPT 316SS 1 EA

5050 40062 TEE 1/8NPT FEMALE 316SS 1 EA

5090 20428 SUPPORT BRACKET LOW FLOW HPD 1 EA

5091 4050017091 HEX HD SCR 5/16-18X3/4 STL GR5 4 EA

5092 4040040028 SPRING LOCK WASHER 5/16 Z PL 4 EA

5093 22222 SUPPORT BRACKET LK DET MIL B 1 EA

5094 40415 HEX HD SCR 1/4-20 X 5/8 316SS 2 EA

5096 C0-0062 1/4” FLAT WASHER SS 2 EA

5097 C0-0095 1/4-20 HEX NUT SS 2 EA

5100 40063 BLEED VALVE 1/8 NPT 316SS 1 EA

8080 20431 INTERMEDIATE RING MIL-BLOWFLOW 2 EA

8081 20429 INTERMEDIATE RING MIL-BLOWFLOW 2 EA

8082 20430 SPACER RING MIL-BLOW FLOW 1 EA

8083 4080109425 O-RING 2-045 VITON 70 DURO 1 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

31Instruction Manual

Page 32

BILL OF MATERIAL

FOR

MBH0718KPECCEAS6ST11C522

MR SO #2441959 / PO6019493

MILROYAL® B

MODEL # MBH071

TAG # 41-67-3620, 41-67-3621, 41-67-3622

ITEM

NUMBER

10 2810047001 HOUSING MIL B 1 EA

330 4080031020 OIL SEAL- CROSSHEAD 2 EA

340 4020009024 SQHDPLPIPE150#THRD 1 304SS 1 EA

630 20317 DISP CHMBR 7/16 LO FLO HPD STL 1 EA

635 4080109415 O-RING 2-044 VITON 70 DURO 1 EA

640 20021 BODY MARS CS 1 EA

650 20079 CONTOUR PLT ASS’Y CS-USE 30616 1 EA

670 20493 DIAPHRAGM LO FLOW HPD DBL DIA 2 EA

700 20319 DIAPHRAGM HEAD LOFLO HPD 6”D A479 1 EA

710 53768-G7 SOC HD SCR 1/2-13X3-1/4 XYLAN 8 EA

720 4040151033 FLAT WASHER SAE 1/2 NOM ULTRA 8 EA

760 4050160143-G7 STUD 3/8-16UNCX4-1/2 300SS 8 EA

780 2250075075-G7 GASKET TEFLON 3/8 BALL 106 HPD 10 EA

790 2920054016-G7 GUIDE 3/8 BALL 316SS HPD 4 EA

800 2240099016-G7 SEAT 3/8 BALL 316SS HPD 4 EA

810 4070014112-G7 BALL 3/8 316/316LSS 4 EA

820 2710060000-G7 FLANGE PORT ADAPTER WELD ASSY 2 EA

830 4050066012-G7 HEX NUT 3/8-16NC 18.8SS 8 EA

840 4040041022-G7 SPRING LOCK WASHER 3/8 316SS 8 EA

925 4080095231 O-RING 2-232 NITRILE 70 DURO 1 EA

990 2450021000 STRAINER FITTING HPD 1 EA

1040 1010021306 RELIEF VALVE ASSY MAX 1780 PSI 1 EA

1060 4040040028 SPRING LOCK WASHER 5/16 Z PL 2 EA

1070 4050028194 SOC HD SCR 5/16-18X2-3/4 ALY 2 EA

1075 20352 BARB,AIR BLEED 316/316LSS 1 EA

1076 A5-1007 OR -007 VITON 1 EA

2010 2250035199 GASKET 1 EA

2020 2720026406 PLUNGER ADAPTER 7/8 HOLE CRS 1 EA

2030 20321 PLUNGER ASSY, 7/16 LO FLO HPD 1 EA

2050 4050018136 HEX HD SCR 3/8-16X1-1/4 ULTRA 4 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

32 Instruction Manual

Page 33

ITEM

NUMBER

3000 4020503182 ELL 1/2 NPT 3/4 ID TUBE NYLON 1 EA

3010 4020296171 TUBING 1”OD X 3/4”ID-1/8” WALL 1 FT

4980 A1-0100 MELBOW 1/8T X 1/8P SS 2 EA

4990 20495 TUBE HEAD TO VALVE 1 EA

5000 40065 CHECK VALVE 1/8TUBE 1/3PSI 316SS 1 EA

5010 52425 TUBE, STRAIGHT, VALVE TO GAUGE 1 EA

5020 40061 TUBE CONN 1/8 TUBEX 1/8NPT 316SS 1 EA

5030 53716 GAUGE,PRES,2.5”,ASHCRO,2000PSI 1 EA

5031 4050263050 PAN HD SCR #4-40X1/2 ZNCR 3 EA

5032 4040095023 SPRING LOCK WASHER #4 18.8SS 3 EA

5033 C0-0051 4-40 NUT SS 3 EA

5040 40067 RED ADAPTER 1/4F X1/8M NPT 316SS 1 EA

5050 40062 TEE 1/8NPT FEMALE 316SS 1 EA

5090 20428 SUPPORT BRACKET LOW FLOW HPD 1 EA

5091 4050017091 HEX HD SCR 5/16-18X3/4 STL GR5 4 EA

5092 4040040028 SPRING LOCK WASHER 5/16 Z PL 4 EA

5093 22222 SUPPORT BRACKET LK DET MIL B 1 EA

5094 40415 HEX HD SCR 1/4-20 X 5/8 316SS 2 EA

5096 C0-0062 1/4” FLAT WASHER SS 2 EA

5097 C0-0095 1/4-20 HEX NUT SS 2 EA

5100 40063 BLEED VALVE 1/8 NPT 316SS 1 EA

8080 20431 INTERMEDIATE RING MIL-BLOWFLOW 2 EA

8081 20429 INTERMEDIATE RING MIL-BLOWFLOW 2 EA

8082 20430 SPACER RING MIL-BLOW FLOW 1 EA

8083 4080109425 O-RING 2-045 VITON 70 DURO 1 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

33Instruction Manual

Page 34

BILL OF MATERIAL

FOR

MBH0718JPECCEAS6ST11C522

MR SO #2441959 / PO6019493

MILROYAL® B

MODEL # MBH071

TAG # 40-67-3620 A/B, 41-67-3630, 41-67-3631, 41-67-3632

ITEM

NUMBER

10 2810047001 HOUSING MIL B 1 EA

330 4080031020 OIL SEAL- CROSSHEAD 2 EA

340 4020009024 SQHDPLPIPE150#THRD 1 304SS 1 EA

630 20317 DISP CHMBR 7/16 LO FLO HPD STL 1 EA

635 4080109415 O-RING 2-044 VITON 70 DURO 1 EA

640 20021 BODY MARS CS 1 EA

650 20079 CONTOUR PLT ASS’Y CS-USE 30616 1 EA

670 20493 DIAPHRAGM LO FLOW HPD DBL DIA 2 EA

700 20319 DIAPHRAGM HEAD LOFLO HPD 6”D A479 1 EA

710 53768-G7 SOC HD SCR 1/2-13X3-1/4 XYLAN 8 EA

720 4040151033 FLAT WASHER SAE 1/2 NOM ULTRA 8 EA

760 4050160143-G7 STUD 3/8-16UNCX4-1/2 300SS 8 EA

780 2250075075-G7 GASKET TEFLON 3/8BALL 106 HPD 10 EA

790 2920054016-G7 GUIDE 3/8 BALL 316SS HPD 4 EA

800 2240099016-G7 SEAT 3/8 BALL 316SS HPD 4 EA

810 4070014112-G7 BALL 3/8 316/316LSS 4 EA

820 2710060000-G7 FLANGE PORT ADAPTER WELD ASSY 2 EA

830 4050066012-G7 HEX NUT 3/8-16NC 18.8SS 8 EA

840 4040041022-G7 SPRING LOCK WASHER 3/8 316SS 8 EA

925 4080095231 O-RING 2-232 NITRILE 70 DURO 1 EA

990 2450021000 STRAINER FITTING HPD 1 EA

1040 1010021306 RELIEF VALVE ASSY MAX 1780 PSI 1 EA

1060 4040040028 SPRING LOCK WASHER 5/16 Z PL 2 EA

1070 4050028194 SOC HD SCR 5/16-18X2-3/4 ALY 2 EA

1075 20352 BARB,AIR BLEED 316/316LSS 1 EA

1076 A5-1007 OR -007 VITON 1 EA

2010 2250035199 GASKET 1 EA

2020 2720026406 PLUNGER ADAPTER 7/8 HOLE CRS 1 EA

2030 20321 PLUNGER ASSY, 7/16 LO FLO HPD 1 EA

2050 4050018136 HEX HD SCR 3/8-16X1-1/4 ULTRA 4 EA

3000 4020503182 ELL 1/2 NPT 3/4 ID TUBE NYLON 1 EA

3010 4020296171 TUBING 1”OD X 3/4”ID-1/8” WALL 1 FT

PART NUMBER NOMENCLATURE QUANTITY U/I

34 Instruction Manual

Page 35

ITEM

NUMBER

4980 A1-0100 MELBOW 1/8T X 1/8P SS 2 EA

4990 20495 TUBE HEAD TO VALVE 1 EA

5000 40065 CHECK VALVE 1/8TUBE 1/3PSI 316SS 1 EA

5010 52425 TUBE, STRAIGHT, VALVE TO GAUGE 1 EA

5020 40061 TUBE CONN 1/8 TUBEX 1/8NPT 316SS 1 EA

5030 53716 GAUGE,PRES,2.5”,ASHCRO,2000PSI 1 EA

5031 4050263050 PAN HD SCR #4-40X1/2 ZNCR 3 EA

5032 4040095023 SPRING LOCK WASHER #4 18.8SS 3 EA

5033 C0-0051 4-40 NUT SS 3 EA

5040 40067 RED ADAPTER 1/4F X1/8M NPT 316SS 1 EA

5050 40062 TEE 1/8NPT FEMALE 316SS 1 EA

5090 20428 SUPPORT BRACKET LOW FLOW HPD 1 EA

5091 4050017091 HEX HD SCR 5/16-18X3/4 STL GR5 4 EA

5092 4040040028 SPRING LOCK WASHER 5/16 Z PL 4 EA

5093 22222 SUPPORT BRACKET LK DET MIL B 1 EA

5094 40415 HEX HD SCR 1/4-20 X 5/8 316SS 2 EA

5096 C0-0062 1/4” FLAT WASHER SS 2 EA

5097 C0-0095 1/4-20 HEX NUT SS 2 EA

5100 40063 BLEED VALVE 1/8 NPT 316SS 1 EA

8080 20431 INTERMEDIATE RING MIL-BLOWFLOW 2 EA

8081 20429 INTERMEDIATE RING MIL-BLOWFLOW 2 EA

8082 20430 SPACER RING MIL-BLOW FLOW 1 EA

8083 4080109425 O-RING 2-045 VITON 70 DURO 1 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

35Instruction Manual

Page 36

816

TO DRIVE

820

816

805

815

790

810

800

350

SEE DETAIL“A”

630

630

634

635

632

1040

TO AIR BLEED

2030

2027

2025

VALV E

1052

1031

MILROYAL DRIVE ASSY

REF. DWG # 10220950001

1021

1010

HOUSING

5020

700

710

SEE

DETAIL

“B”

711

650

674

8082

648

649

636

4040

1070

SEE

DETAIL

“C”

400

970

1071

420

633

430

441

1075

643

2020

REFILL FILTER

INTO SIDE OF

DRIVE HSG.

CUT AWAY SIDE.

1074

390

1073

1071

644

645

646

670

300

DETAIL “C”

NOTE:

1. UNLESS OTHERWISE SPECIFIED, BREAK ALL

OUTSIDE CORNERS WITH A 0.005/0.015 x 45 CHAMFER

AND ALL INSIDE RADII WITH A 0.20R MAX.

8083

670

8081

DETAIL “A”

8080

36 Instruction Manual

440

DETAIL “B”

Page 37

37Instruction Manual

Page 38

BILL OF MATERIAL

FOR

MBB1618BPECCEAV6H233C5C2

MR SO #2441959 / PO6019493

MILROYAL® B

MODEL # MBB161

TAG # 40-67-3211 A/B, 41-67-3110, 41-67-3111, 41-67-3112, 41-67-3210,

41-67-3211, 41-67-3212

ITEM

NUMBER

300 40780 O-RING, TFE ENC VITON, V-167 1 EA

350 30342 AIR BLEED VALVE HI TEMP 1 EA

390 2450021000 STRAINER FITTING HPD 1 EA

400 20749 REFILL VALVE BODY 1 EA

420 L10626 BALL, 1/4” 440C SS 1 EA

430 20024 SPRING MARS CS 1 EA

440 60668 FLATWASHER M4 ZINC PLT 1 EA

441 40605 RETAINING RING #RCLBHO0037STPA 1 EA

630 52851 DISP. CHMBR ‘72’ SLEEVED MIL B 1 EA

632 2250035199 GASKET 1 EA

633 52849 SLEEVE, BORE 1.00 DIA MB (72) 1 EA

634 53650 FLAT WASHER 5/16 ID 1/2 OD 1 EA

635 MC600-06 5/16-18X1 SHCS SS 92185A583 1 EA

636 4080095131 O-RING PARKER 2-222 BUNA N 1 EA

643 20663 MARS BUTTON 1 EA

644 60677 SPRING, MARS BUTTON 1 EA

645 60673 POPPET MARS VALVE 1 EA

646 40570 WALDES RETAINING RING X5133-31 1 EA

647 4020095011 PLUG 1/8 NPT SOCKET HEX HEAD 1 EA

648 4050025134 SOC HD SCR #10-24X1-1/4 STL 2 EA

649 40534 ‘O’ RING 2-109 NITRILE 1 EA

650 52856 CONTOUR PLATE 4.50 MILC CS 1 EA

670 40516 DIAPHRAGM -6” OD X .030 THK 2 EA

700 21092 DIAPHRAGM HEAD ‘72’ L/D 1 EA

710 43195-G7 SOC HD SCR 7/8-9X4-1/2 ST XYLN 10 EA

711 40749 WASHER 7/8 AN 960 C ULTRA COAT 10 EA

790 22710-G7 CAGE 3/4 BALL, SLURRY SERVICE 4 EA

800 2250043075 SEAL .915ID 1.197OD .141THK 1 EA

805 41054-G7 SEAT,HARDENED INSERT ASSEMBLY 4 EA

810 4070015191 BALL 3/4 CERAMIC AD995 4 EA

815 20678-G7 CHECK VALVE BODY - 1” 2 EA

816 40566 O-RING, TFE ENC VITON,M V-128 4 EA

820 52861 FLANGE WELD ASSY 1/2” 600#VERT 2 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

38 Instruction Manual

Page 39

ITEM

NUMBER

970 4050018136 HEX HD SCR 3/8-16X1-1/4 ULTRA 4 EA

1010 4020001054 HXPIPEBSHG 1/2X1/4 304SS 1 EA

1021 A1-0013 MELBOW 1/4T 1/4P SS 2 EA

1031 C7-0027 1/4” 316 SEAMLESS .035W 1 IN

1040 1010013002 RELIEF VALVE 1 EA

1052 A1-0003 MCONN 1/4T 1/8P SS 1 EA

1070 40927 FEMALE ELBOW, SWAGELOK 1 EA

1071 C7-0028 3/8” 316 SEAMLESS .035W 12 IN

1072 40683 UNION ELBOW SWAGELOK SS-600-9 1 EA

1073 L11439 ELBOW 3/8ODTX1/4MPT 316SS 1 EA

1074 4020001044 HXPIPEBSHG 1/2X3/8 304SS 1 EA

1075 4020095066 PLUG 1 NPT HEX SOCKET 18.8SS 1 EA

2020 2720026406 PLUNGER ADAPTER 7/8 HOLE CRS 1 EA

2025 2720062306 PLUNGER ADAPTER 1 EA

2027 2680024539 PLUNGER ROD 3/8 DIA 7-5/16 LG 1 EA

2030 20882 PLUNGER 1.0 HI PERF DISC MIL B 1 EA

4040 4070317020 MINERAL OIL-NOT FOR RESALE 1 OZ

4980 A1-0100 MELBOW 1/8T X 1/8P SS 1 EA

4990 C7-0044 1/8” 316 SEAMLESS .035W 12 IN

5000 40065 CHECK VALVE 1/8TUBE 1/3PSI 316SS 1 EA

5020 4020095012 PIPE PLUG HEX SOCKET 1/8 NPT 1 EA

5020 40061 TUBE CONN 1/8 TUBEX 1/8NPT 316SS 2 EA

5030 53716 GAUGE,PRES,2.5”,ASHCRO,2000PSI 1 EA

5031 4050263050 PAN HD SCR #4-40X1/2 ZNCR 3 EA

5032 4040095023 SPRING LOCK WASHER #4 18.8SS 3 EA

5033 C0-0051 4-40 NUT SS 3 EA

5050 40062 TEE 1/8NPT FEMALE 316SS 2 EA

5070 40067 RED ADAPTER 1/4F X1/8M NPT 316SS 1 EA

5090 21094 SUPPORT BRACKET,SWITCH / GAGE 1 EA

5092 40710 SCREW 3/8-16X3/4 SHCS, 18.8SS 2 EA

5100 40063 BLEED VALVE 1/8 NPT 316SS 1 EA

8080 20847 LEAK DETECTION RING ‘A’ 2 EA

8081 20848 LEAK DETECTION RING ‘B’ 2 EA

8082 20846 SPACER RING ‘72’ 304/316SS 1 EA

8083 40781 O-RING, TFE ENC VITON, V-165 1 EA

PART NUMBER NOMENCLATURE QUANTITY U/I

39Instruction Manual

Page 40

Ingersoll Rand (NYSE:IR) advances the quality of life by creating comfortable, sustainable and efficient environments. Our

people and our family of brands— including Club Car®, Ingersoll Rand®, Thermo King® and Trane®—work together to

enhance the quality and comfort of air in homes and buildings; transport and protect food and perishables; and increase

industrial productivity and efficiency. We are committed to a world of sustainable progress and enduring results.

Info@miltonroy.com

www.miltonroy.com

MILROYAL® is a registered trademark of Milton Roy, LLC.

© 2019 Milton Roy, LLC.

Loading...

Loading...