Page 1

LMI ELECTRONIC DOSING PUMPS

Code : P1

Basic manual

Instruction supplement

Spare parts list for drive assembly

Declaration « CE » of conformity

List of « Technical assistance » and « spare parts » departments

07/98

Page 2

INSTRUCTION MANUAL

FOR INSTALLATION,

OPERATING,

AND MAINTENANCE.

LMI ELECTRONIC DOSING PUMPS

Diaphragm liquid end

Basic manual

This manual should be made available to the person responsible for installation,

operating and maintenance.

Date : 02/2012 Ref : 160.0101

.001 Rev. D

Replaces Rev. 0 09/98

Page 3

Page 4

LMI, Doseur à membrane, L001, Rev.B, 1098

CONTENTS

I – DESCRIPTION

I – 1. Unpacking

I – 2. Description

I – 3. Accessories

I – 4. Precautions

II – INSTALLATION

II – 1. Hydraulic installation

II – 2. Electrical installation

III – START UP

III – 1. Priming

III – 2. Output adjustment controls

III – 3. Calibration

III – 4. Volumetric calibration in external mode

III – 5. Pressure control

IV – MAINTENANCE

IV – 1. Spare parts replacements

IV – 2. Checking pump for proper zeroing (stroke knob)

IV – 3. Troubleshooting

IV – 4. EPU Resistance chart

Page 5

0.0 Precautions

The pump described here may be used for the dosing of liquid products in connection with the applications set out in this

manual.

The following precautions should be taken when working with LMI metering pumps. Please read this section carefully prior to

installation.

Storage precautions

- Storage period of less than six months:

The product should preferably be stored in its original packing and be protected from bad weather.

- Storage period of more than six months:

Store the pump in its original packing. It should be stored covered by a heat-sealing plastic cover and desiccant bags

should be used (quantity dependent on volume and planned storage period). Store away from the influence of bad

weather.

Protective Clothing

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working on or near your metering

pump. Additional precautions should be taken depending on the solution being pumped. Refer to MSDS precautions

from your solution supplier.

Water Pre-Prime

All LMI pumps are pre-primed with water when shipped from the factory. If your solution is not compatible with water,

disassemble the Pump Head Assembly. Thoroughly dry the pump head, valves, seal rings, balls and Liquifram™

(diaphragm). Reassemble head assembly tightening screws in a crisscross pattern. Refill the pump head with the

solution to be pumped before priming the pump. (This will aid in priming.)

Solution Compatibility

Determine if the materials of construction included in the liquid handling portion of your pump are adequate for the

solution (chemical) to be pumped. Always refer to the solution supplier and the LMI Chemical Resistance Chart for

compatibility of your specific LMI metering pump. Contact your local MRE distributor for further information.

Tubing Connections

Inlet and outlet tubing or pipe sizes must not be reduced. Outlet tubing size must not be increased. Make certain that

any tubing is SECURELY ATTACHED to fittings prior to start-up (see Section ., Tubing Connections). ALWAYS use

LMI supplied tubing with your pump, as the tubing is specifically designed for use with the pump fittings. It is

recommended that all tubing be shielded and secure to prevent possible injury in case of rupture or accidental damage.

If tubing is exposed to sunlight, black UV resistant tubing should be installed. Check tubing frequently for cracks and

replace as necessary.

Vinyl Tubing

Your carton may contain a roll of clear vinyl tubing; this is only for connection to the return line of the FastPrime™ Head

and must not be used as discharge tubing.

Connectors

All connectors shall be tightened by hand. An additional turn of 1/8 to 1/4 might be necessary to ensure tightness. Any

excessive tightening or using a toolmight damage the connecting device and the seals or the liquid end.

All LMI pumps have straight screw machine threads on the head and fittings and are sealed by the O-rings. DO NOT

use Teflon® tape or pipe dope to seal threads. Teflon® Tape may only be used on the 1/2" NPT thread side of the

Injection Check Valve, the stainless steel liquid end connections, or if piping is directly connected to the pipe threads of

the suction or discharge fittings.

Installation

Always comply with local regulations and requirements. Always adhere to your local plumbing codes and requirements.

Be sure installation does not constitute a cross connection. Check local plumbing codes for guidelines. Milton Roy

Europe is not responsible for improper installations.

Back Pressure/Anti-syphon valve

If you are pumping downhill or into low or no pressure system, a back pressure/antisyphon device such as LMI’s FourFunction Valve should be installed to prevent over pumping or siphoning. Contact your distributor for further

information..

Electrical Connections

WARNING: To reduce the risk of electrical shock, the metering pump must be plugged into a properly grounded

grounding-type receptacle with ratings conforming to the data on the pump nameplate.. Do not use adapters! All wiring

must conform to local electrical codes. If the supply cord is damaged, it must be replaced by the manufacturer, stocking

distributor, or authorized repair centre in order to avoid a hazard..

Environment

The ambient temperature must be less than 50°C. Avoid direct exposure to sunlight. The pump must be accessible and

situated in a ventilated room.

Page 6

Noise

The noise level of your equipment is less than 65 dB (A).

Maintenance

CAUTION - ELECTRICAL RISK:

Before performing any maintenance work, deactivate the pump and make sure that all electrical connections are

disconnected.

CAUTION: : DISCHARGE LINE DEPRESSURIZATION

If you are pumping downhill or into low or no pressure system, a back pressure / antisyphon device such as LMI’s

Four-Function Valve should be installed to prevent over pumping or siphoning. Contact your LMI distributor for further

information.

CAUTION: CHEMICAL AND INFLAMMABLE PRODUCTS:

Take all the precautions necessary when performing work on equipment that is dosing chemical and/or inflammable

products. Contact your local Milton Roy Europe distributor for more information.

Earth leakage protection

CAUTION:

It is essential to install an earth leakage circuit breaker calibrated on the basis of the electrical values noted on the

equipment plate.

Cleaning

Make sure that your equipment is clean at all times and that no external items interfere with its functioning.

Page 7

I - 1

LMI, Doseur à membrane, L001, Rev.B, 1098

PART I – DESCRIPTION

This manual addresses the installation, maintenance and troubleshooting procedures for electronic dosing pumps. An

instruction supplement and a liquid end sheet complete this manual.

Please read them carefully before installing your pump.

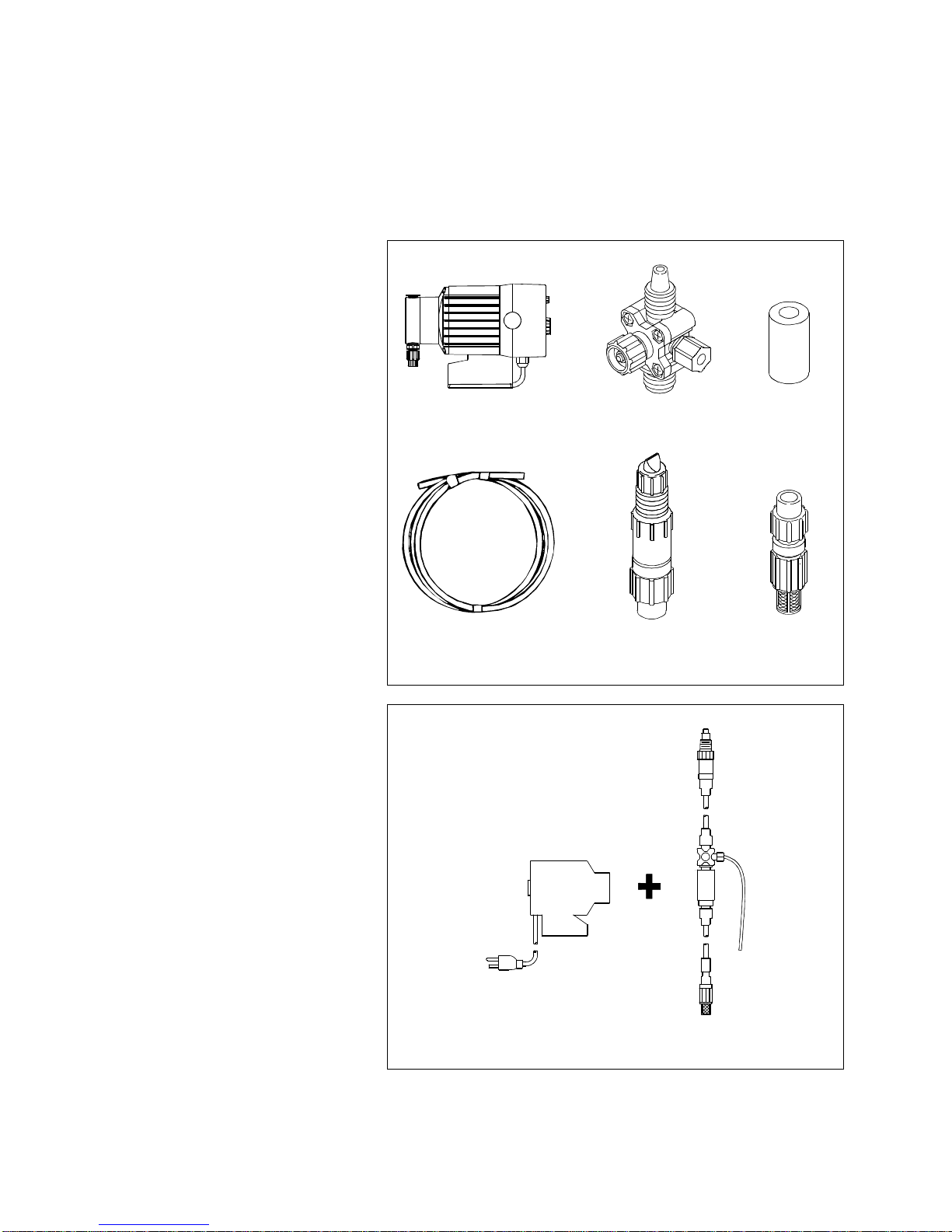

I – 1. UNPACKING

The packaging must be carefully

examined on receipt in order to

ensure that the contents have not

sustained any obvious damage.

The carton contains the items

necessary to a proper installation.

I - 2 - DESCRIPTION

Your pump consists of two parts :

1. The drive assembly

2. The liquid handling assembly

The pump code which appears on

the packaging and on the

identification plate consists of two

codes according to drive assembly

type and liquid handling assembly

type.

Dosing pump Function valve * Ceramic weight*

Tubing Injection check valve* Foot valve*

* depending on model

DRIVE

A753

LIQUID HANDLING ASSY

352SM

Page 8

I - 2

LMI, Doseur à membrane, L001, Rev.B, 1098

Output adjustment controls

According to pump type, output adjustment controls are

available :

• Stroke adjustment

Each pump is equipped with a stroke adjustment.

Stroke control provides adjustment of percent of

maximum diaphragm travel.

Note : For B & C Series, stroke adjustment only when

pump is running.

• Speed adjustment

A1, A7, B1, B7, C1, C7, J5, P1 Series pumps are

equipped with a speed adjustment. Speed control

provides adjustment of the percent of maximum strokes

per minute.

• Pressure control adjustment

B7 and C7 Series Pumps are equipped with a pressure

control adjustment. Pressure control provides the

adjustment of the pump’s pressure capability and power

consumption, reducing heat, pipe shock and pulsation.

For more details, refer to Instruction supplement

I - 3. ACCESSORIES

4-Function valve

This accessory is supplied as standard equipment or as

option. The functions are :

1. Anti-syphon (automatic)

Prevents syphoning when pumping downhill or into a

vacuum.

2. Back pressure (automatic)

Supply approximately 1,7 bar back pressure to prevent

over pumping when little or no system back pressure is

present.

3. Priming (manual)

Prime your pump while it is connected to a pressurized

line.

4. Line depressurization (manual)

By pulling both knobs (yellow and black) the discharge

line will drain back to your supply tank.

3-Function valve

This accessory is supplied as standard equipment or as

option (according to Series 300 models). The functions

are :

1. Priming (manual)

Prime your pump while it is connected to a pressurized

line.

2. Pressure relief (automatic)

Provides protection against excessive system pressure.

3. Line depressurization (manual)

By opening the relief valve, the discharge line will

depressurize without having loosen or disconnect

discharge tubing.

Bleed/4-Function valve

This accessory is supplied as standard equipment or as

option (according to Series 300 models). The functions

are :

1. Anti-syphon (automatic)

Prevents syphoning when pumping downhill or

into a vacuum.

2. Back pressure (automatic)

Supply approximately 1,7 bar back pressure to

prevent over pumping when little or no system

back pressure is present.

3. Continuous bleed (automatic)

This valve is designed to permit an adjustable,

continuous bleed or degasing or entrapped

vapors. It is ideal for pumping small volumes of

solutions having low vapor pressures.

4. Line depressurization (manual)

By opening bleed port, the discharge lline will

depressurize, without having to loosen tubing or

fittings.

Foot valve

(Accessory available according to the model)

The foot valve makes easier priming and keep the

pump primed in suction lift applications.

The strainer prevents sediment to pass through and

valves to clog.

Injection check valveCanne d’injection

The injection check valve prevents backflow from a

treated line.

I – 4. PRECAUTIONS

Always wear protective clothing, face shield, safety

glasses and gloves when working on or near your

metering pump.

All LMI pumps are shipped from factory with water

in pump head to make easier priming.

If the pump head is empty, refill it with water or

solution compatible with pumped solution before

starting up the pump (see note on the Liquid End

Sheet).

Solution compatibility

Verify that the liquid handling components are

compatible with the pumped solution (refer to Liquid

End Sheet).

Make certain that all tubing is securely attached to

fittings prior to start-up.

Tubing supplied allows to match with pump

maximum specifications.

All fittings should be hand tightened.Overtightening

or use of a pipe wrench can cause damage to the

fittings, causing the pump to lose prime or not

function.

All LMI pumps have straight ¾’’- 16N or 7/8 ’’- 14N

or 1"- 12 N machine threads on the head and

fittings.

The seal rings prevent leaks. Do not use Teflon tape

between fittings and pump head.

Page 9

II - 1

LMI, Doseur à membrane, L001, Rev.B, 1098

PART II – INSTALLATION

II – 1. HYDRAULIC INSTALLATION

The pump can be mounted in one of two ways :

• Flooded suction (ideal installation).

• Suction lift – when suction lift is less than 1,5 m for

solutions having a specific gravity of water. Your

LMI metering pump must be mounted so that the

suction and discharge valves are vertical.

Flooded suction

The pump is mounted at the base of the storage tank.

This installation is the most trouble-free, and is

recommended for very low outputs, solutions that

gasify, and high viscosity solutions. (Install shut off

valve on the tank).

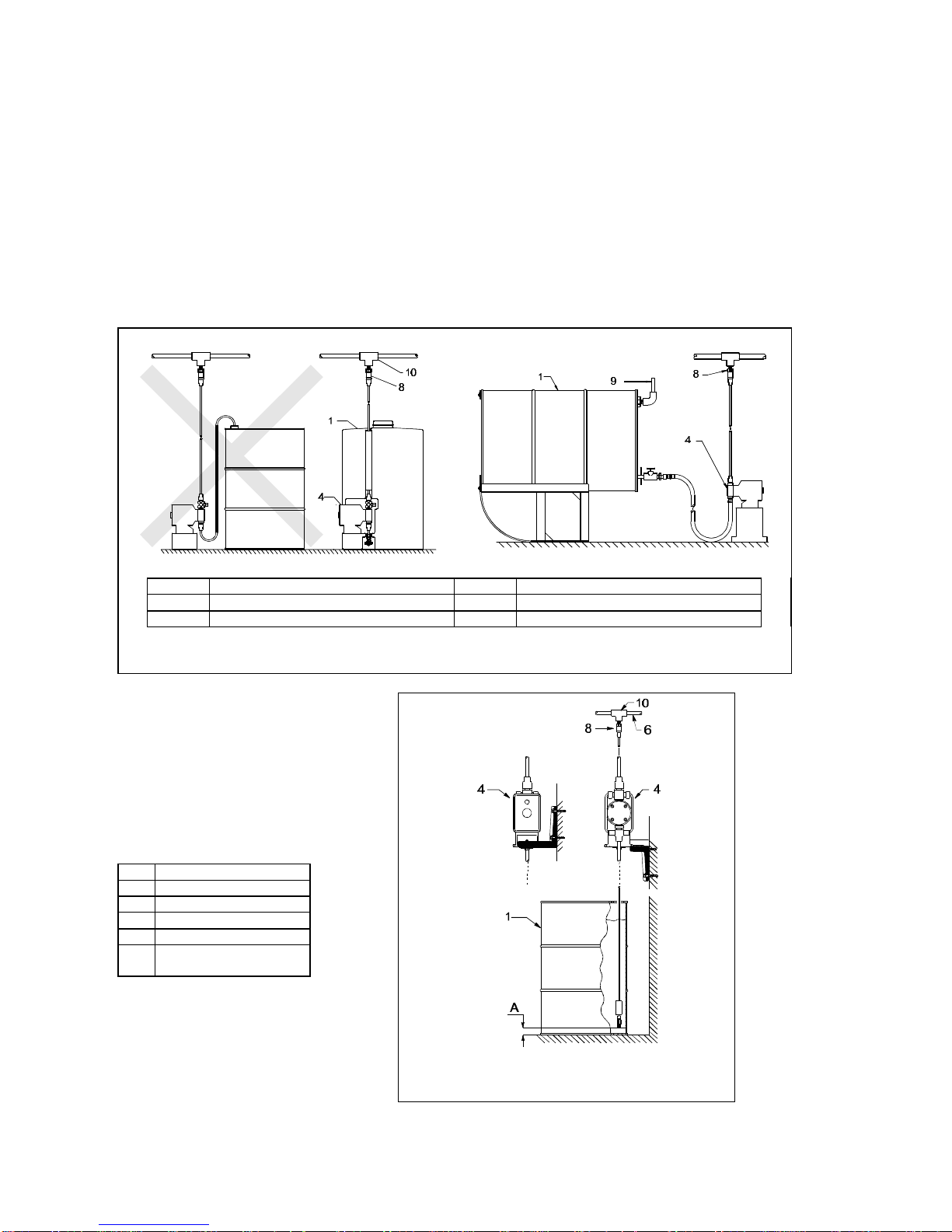

1 Solution tank 9 Vent

4 Pump 10 Tee

8 Injection check valve

Fig. 2.1a : Flooded suction

Suction lift

• Wall bracket mount. The pump

may be mounted directly above the

solution tank. A pump mounted in

this manner allows for easy

changing of solution tank.

1 Solution tank

4 Pump

6 Pressure line

8 Injection check valve

10 Tee

A 50 mm space for

sediment accumulation

Fig. 2.1b : Suction lift

Page 10

II - 2

LMI, Doseur à membrane, L001, Rev.B, 1098

• Tank mount. The pump may be

mounted on a molded tank. Tanks

from 60 to 1000 liters are available

for this utilisation.

1 Solution tank

2 Foot valve (equipped

with strainer)

4 Pump

6 Flow

8 Injection check valve

10 Te

11 Ceramic weight

A 50 mm space for

sediment accumulation

• Shelf mount (customer supplied).

The pump may be mounted on a

shelf. An LMI mounting kit is

available for securing the pump to

a shelf. (Series A , B, C).

1 Solution tank

2 Foot valve (equipped

with strainer)

4 Pump

6 Flow

8 Injection check valve

10 Te

11 Ceramic weight

A 50 mm space for

sediment accumulation

Fig. 2.1c : Tank mount

Fig. 2.1d : Shelf mount

Page 11

II - 10

LMI, Doseur à membrane, L002, Rev.B, 1098

Pump location

Locate pump in an area convenient to solution tank and

electrical supply.

The pump should not be subjected to ambient

temperatures above 50°C. Avoid exposing to direct

sunlight the pump.

Tubing connections

• For installation and trouble-free running, use

only recommended tubing size (refer to spare parts

list).

• Do not use clear vinyl tubing on the discharge

side of the pump. The pressure created by the

pump can rupture the vinyl tubing.

• Before installation, all tubing must be cut with

a clean square end.

• Remove the plugs which protect the head

connections and valves.

• Do not use pliers or pipe wrench on coupling

nuts or fittings.

Refer also to the Liquid End Sheet.

Foot valve/Ceramic weight

The foot valve must be sit in a vertical position at the

bottom.

Position approximately 50 mm off the bottom if the tank

or drum contains sediment.

The ceramic weight positions the foot valve in a vertical

position.

Refer to the Liquid End Sheet for details of connections

1

Solution tank

4

Pump

2

Foot valve

11

Ceramic weight

Fig. 2.2a : Foot valve/Ceramic weight

Injection check valveCanne d’injection

Connect the injection check valve to your discharge

(outlet) line (refer to the Liquid End Sheet).

For in-line injection, use fitting or pipe tee with reducing

bushing to ½’’ (12x17).

Use Teflon tape or pipe dope to seal the pipe threads

only.

When installing the injection check valve, be sure to

position it so that the valve enters the botton of your

pipe in a vertical position (see fig. 2.2b).

Variations left and right within 30° are acceptable.

For low pressure (under 1,7 bar) or open tank use, the

injection nozzle prevents siphoning but not flow

increase.

In this case,we recommend the use of a 4-Function

valve.

Refer to the Liquid End Sheet for details of

connections.

Page 12

II - 4

LMI, Doseur à membrane, L001, Rev.B, 1098

8 Injection check valve B Use Teflon tape

10 Tee C Do not use Teflon tape

12 Reducing bushing ½ ‘’ D

± 30° variation acceptable

13 Pipe cross section

Fig. 2.2b : Injection check valve

II – 2. ELECTRICAL INSTALLATION

Check the specifications of the pump and compare

them with the voltage available on your installation

before making connections.

WARNING :

To reduce the risk of electrical shock, the metering

pump must be plugged into a fused grounded outlet

with ratings conforming to the pump specification chart

(see Technical characteristics : refer to peak power to

determine the appropriate fuse size).

DO NOT USE ADAPTERS.

All wiring must be conform to local electrical codes.

OVER-VOLTAGE

LMI pumps include a Varistor vonnected on the supply

voltage terminals.

This device is an over-voltage protection. It will burn if

the supply voltage exceeds 150 V for 115 V rated

pumps or 275 V for 230 V rated pumps to protect the

pulser.

As soon as it happends, it means the pump got a too

high voltage peak. After supply voltage control, replace

the Varistor and the pump will run again.

Page 13

III - 1

LMI, Doseur à membrane, L001, Rev.B, 1098

PART III – START UP

Pumps are shipped from the factory with water in the

pump head to aid in priming. After a long storage, refill

the pump head with water or solution compatible with

pumped solution (see note on the Liquid End Sheet).

III – 1. PRIMING

After connecting the pump, plug in or switch the pump

on. While the pump is running, set the speed knob at

80% and the stroke knob at 100%. If the pump is

equipped with a pressure control knob (B7, C7), set the

switch on « INTERNAL » and turn the pressure control

knob fully clockwise.

III – 2. OUTPUT ADJUSTMENT

CONTROLS

Once the pump has been primed, an appropriate output

adjustment must be made.

The identification plate indicates the output at max.

stroke and max. speed (100%) and max. pressure. The

graduations of stroke knob and speed knob correspond

to percentage of this max. output.

Note : P0 pumps have no stroke adjustment.

Example :

Use max. output = 2,3 L/H. If the pump is set at 40%

speed and 60% stroke lenght, the appropriate pump out

put is 2,3 L/H x 0.40 x 0.60 = 0,55 L/H.

Note : Remember that 6x8 tubing is 0,22 ml/cm which is

0,8 % wrong for 1 l measuring pot.

III – 3. CALIBRATION

Once installation is complete and the approximate

output has been determined, the pump should be

calibrated to adjust speed and stroke for your actual

desired output.

1. If equipped (B7 – C7 series), make certain Pressure

control knob is turned fully clockwise.

2. Be sure the pump is in normal service (i.e. including

factors such as injection pressure, fluid viscosity,

suction lift …).

3. Place the foot valve in a graduated container.

4. Start the pump at maximum frequency and let it run

to remove air trapped in suction line (bleed valve

open when using a 4FV). Close bleed after priming.

5. Turn the pump off. Refill graduated container to a

level strarting point.

6. Using a stopwatch or timer, turn the pump on for a

measured amount of time (50 pump strokes

minimum). The longer the time period, the more

confident you can be of the results.

7. The volume and the time unit are known. Calculate

the output. If the output is too low or too great, adjust

speed and or stroke, estimating required correction.

8. Adjust stroke length knob to desired value refering to

calibration.

2 Foot valve 10 Tee

4 Pump 14 Graduate container

(1 l min.)

6 Pressure line E Suction lift

8 Inj. check valve

Fig. 3.2a : Calibration

Page 14

III - 2

LMI, Doseur à membrane, L001, Rev.B, 1098

III – 4. VOLUMETRIC CALIBRATION IN

EXTERNAL MODE

1. Since pump output is governed by an external device

such as Flowmeter-pulser, Liquitron Current-tofrequency converter or 4-20 mA DC signal from an

instrument with an LMI Analog-to-digital converter,

only the ouptut per stroke may be calibrated.

2. With pump primed and discharge tubin connected to

the injection point as it would be in normal service,

place foot valve in a graduated container.

3. Swtch pump to Internal mode with speed knob set at

100 until air is exhausted from suction line and pump

head.

4. Adjust control pressure (B7 – C7 series).

5. Turn the pump off. Refill graduated container to a

level strarting point.

6. Switch pump on and count the number of strokes.

For a good accuracy, count at least 100 strokes.

Switch pump off.

7. Note the volume pumped during the calibration

period and the number of strokes. Divide into the

volume the number of strokes to determine the

volume of solution pumped per stroke.

8. Adjust stroke length knob to desired value refering to

calibration.

III – 5. PRESSURE CONTROL

Adjust pressure control (B7 - C7 series) : while unit is

running, turn pressure control knob fully clockwise then

turn slowly counter-clockwise until unit just begins to

stall. This is the optimmum pressure control setting for

your installation. Adjust pressure control to prolong

pump life.

Increase setting if back pressure is increased.

F : Excess pressure

Fig. 3.3a : Control pressure

Note : On series A9, B9, C9, this setting is in the main

menu.

Page 15

IV - 1

IV – MAINTENANCE

IV – 1. SPARE PARTS REPLACEMENTS

WARNING : Always wera protective clothing, face

shield, safety glasses and gloves when performing any

maintenance or replacement on your pump. LMI

metering pumps are designed for trouble-free

operation, yet routine maintenance of elastomeric parts

is essential for optimmum performance.

Refer to the spare parts list.

Replacements frequency will depend on your particular

application. We recommend replacing these parts at

least one a year.

Diaphragm replacement

1. Depressurize the pump (see Liquid End Sheet).

2. Place the foot valve into a container of water or

other neutralizing solution.

Turn the pump on to flush the head assembly. Lift the

foot valve out of the solution and continue to pump air

into the pump head until the pump head is purged of

water or neutralizing solution. If the liquid cannot be

pumped due to diaphragm rupture, using protective

gloves, carefully disconnect the suction and discharge

tubing. Remove the screws to the head and immerse

the head in water or other neutralizing solution.

3. While running, set the stroke knob to zero and turn

the pump off.

4. Dismantle the liquid end. Unscrew the diaphragm.

Clean the diaphragm recess and the disk. Check the

size of replacement diaphragm, the code (0,5 - 0,9 1,8 - 3,0- 6,0) is indicated on the diaphragm and the

disk or spacer (see fig. 4.1a).

5. Reinstall the disk (A, J, P series).

6. Start the pump and turn the stroke knob to the

setting indicated on stroke setting chart which matches

the pump model number located on the pump

dataplate. Stop the pump.

7. Grasp the outer edge of the diaphragm and adjust

by screwing it in or out so that the center of the

diaphragm is flush with the outside of the spacer edge

(see fig. 4.1b). Once the diaphragm is properly

positionned, remount the pump head to the spacer

using the screws. Tighten in a crisscross pattern.

For the diaphragm size 3.0 (show on the diaphragm)

put the glue (loctite 221) on the fixing screws.

Screw the liquid end’s screws at 0.6N.m then tighten

them at 3.5N.m

Note : Tighten the liquid end’s screws diametrically

opposite

AFTER ONE WEEK OF OPERATION, RECHECK

THE SCREWS AND TIGHTEN IF NECESSARY.

16 Diaphragm 18 Code

17 Spacer

Fig. 4.1a : Diaphragm identification

15 Straight edge G Gap

16 Diaphragm H No gap

17 Spacer

Fig. 4.1b : Diaphragm fitting

Pump series

Stroke knob setting

AA - A – B – J – P (tous

modèles)

Cx0 – Cx1 – Cx2

Ex0 – Ex1 – Ex2

90 %

Cx3 – Cx4 – Cx5

Ex3 – Ex4

70 %

Page 16

IV - 2

LMI, Doseur à membrane, L001, Rev.B, 1098

Ball, seal ring and injection check valve spring

replacement or set of cartridges replacement

(depending on model)

Refer to the spare parts list for the proper sparte parts

kit number.

1. Depressurize the pump (see Liquid End Sheet).

2. Flush and purg the pump head before dismantling

(see above).

3.During dismantling, note the orientation of each item.

4. Dismantling the injection check valve. Unscrew the

valve body and replace the spring, the ball and the

seal ring. Refer to the spare parts list drawing.

5. Replace the seal rings and balls in the pump head

and the foot valve. Order of assembly changes

depending on valve location.

6. In case of cartridge liquid end, see spare parts list

drawing to identify the orientation of each item.

IV – 2. CHECKING PUMP FOR PROPER

ZEROING (STROKE KNOB)

1. With pump running, turn stroke knob counterclockwise toward zero or end of black or red band.

2. Listen to the clicking as the pump is running. The

pump shoukd operate quietly at the zero position (no

clicking). If the pump continues to click at zero or

stops clicking before zero is reached, the pump zero

must be reset.

Push on knob

1. Remove stroke knob from the pump by grasping the

knob firmly and pulling it toward you.

2. Pry off the yellow cap.

3. Place the knob on a flat surface.

4. Using needle nose pliers, squeeze the inner section

together while lifting the outer section up.

5. Push the inner section back onto the « D » shaped

stroke shaft.

6. With the pump running, zero the pump by turning the

inner sectionof the knob counter-clockwise until the

pump stops clicking.

7. Position the outer section of the knob so that the

pointer aligns with zero on the nameplate or end of

the black or red band.

8. Push down on the outer section (a snap sound

indicates parts are locked together).

9. Replace the yellow cap over the outer section of the

knob, aligning the tabs on the cap with the slots

inside the knob.

20 Shaft 22 Knob base

21 Knob pointer 24 Knob pointer

Fig. 4.2a : Push on knob

Page 17

IV - 3

LMI, Doseur à membrane, L001, Rev.B, 1098

IV – 3. TROUBLESHOOTING

Pump will not prime

• Pump not turned on or plugged in.

Turn on pump/plug in pump.

• Output dials not set properly.

Always prime pump with speed at 80 % and stroke

at 100 %.

• Foot valve not in vertical position on bottom of tank.

See Chapter II – 1. Section Foot valve/ceramic

weight.

• Pump suction lift too high.

Maximum suction lift is 1,5 m. Pump with High

viscosity liquid handling assemblies require flooded

suction.

• Suction tubing is curved or coiled in tank.

Suction tubing must be vertical. Use ceramic weight

supplied with pump. (see Chapter II – 1. Section

Foot valve/ceramic weight).

• Fittings are over tightened.

Do not overtighten fittings. This causes seal rings to

distort and not seat propertly which causes pump to

leak back or lose prime.

• Air trap in suction valve tubing.

Suction tubing should be as vertical as possible.

AVOID FALSE FLOODED SUCTION (see Chapter

II – 1. Section Flooded suction).

• Too much pressure at discharge (pump without 4function valve).

Shut off valves in pressurized line. Disconnect

tubing at injection check valve (see Chapter III – 1.

Priming). When pump is primed, reconnect

discharge tubing.

Pump loses prime

• Solution container ran dry.

Refill container with solution and reprime (see Part

III).

• Foot valve not in vertical position on bottom of tank.

See Chapter II – 1. Section Foot valve/ceramic

weight.

• Pump suction lift too high.

Maximum suction lift is 1,5 m. Pump with High

viscosity liquid handling assemblies require flooded

suction.

• Suction tubing is curved or coiled in tank.

Suction tubing must be vertical. Use ceramic weight

supplied with pump. (see Chapter II – 1. Section

Foot valve/ceramic weight).

• Fittings are over tightened.

Do not overtighten fittings. This causes seal rings to

distort and not seat propertly which causes pump to

leak back or lose prime.

• Air trap in suction valve tubing.

Suction tubing should be as vertical as possible.

AVOID FALSE FLOODED SUCTION (see Chapter

II – 1. Section Flooded suction).

• Air leak on suction side.

Check for pinholes, cracks. Replace if necessary.

Leakage at tubing

• Worn tubing ends.

Cut tubing about 25 mm (1’’) off tubing and then

replace as before.

• Loose or crack fitting.

Replace fitting if cracked. Carefully hand tighten

fittings. Do not use pipe wrench. Once fitting comes

into contact with seal ring, tighten an additional 1/8

or ¼ turn.

• Worn seal rings.

Replace balls and seal rings (see part IV).

• Solution attacking Liquid handling assembly

material.

Consult Technical Assistance Department for

alternate materials compatible with the pumped

solution.

Low output or failure to pump against

pressure

• Pump’s maximum pressure rating is exceeded by

injection pressure.

Injection pressure cannot exceed pump’s maximum

pressure. See pump data plate.

• Worn seal rings.

Replace them : see Chapter IV –1.

• Ruptured diaphragm.

Replace diaphragm : see Chapter IV –1. Section

Diaphragm replacement.

• Incorrect stroke length.

Check zero on pump/Re-zero pump (See Chapter

IV – 2.).

• Tubing run on discharge may be too long.

Longer tubing runs may create frictional losses

sufficient to reduce pump’s pressure rating.

• Clogged foot valve strainer.

Remove foot valve strainer when pumping slurries

or when solution particles cause strainer to clog.

Failure to run

• Pump not turned on or plugged in.

Turn on or plug in pump. Check also programming

(A9, B9, C9 Series).

• EPU failure.

Disassemble pump and measure the resistance of

the EPU across the EPU wires. Resistance reading

should be in accordance to the table (see Chapter

IV – 4.). Also check EPU leads to ground.

• Pulser failure.

The pulser should be replaced if EPU checks out

OK.

Page 18

IV - 4

LMI, Doseur à membrane, L001, Rev.B, 1098

Excessive pump output

• Syphoning. Pumping downhill without a 4-FV.

Move injection point to a pressurized location or

install an 4-FV.

• Little or no pressure at injection point.

If pressure at injection point is less than 1,5 bar (25

psi), an 4-FV should be installed.

• Excessive strokes per minute.

Replace pulser or control panel.

IV – 4. EPU RESISTANCE CHART

Pump series Voltage Coil resistance (ohms)

20° C (68°F)

Ax4, Ax5, Ax6 115 V 76 – 87

Px4, Px5, Px6, Px8

H9

230 V 307 – 353

Ax7, Ax8 115 V 152 – 176

Px2, Px3 230 V 583 – 671

Bx1, Bx2, Bx3, Bx4 115 V 43 –49

230 V 167 – 193

Cx0, Cx1, Cx2, Cx3, Cx4, Cx5 115 V 22.8 – 26,2

E70, E71, E72, E73, E74 230 V 91 – 105

J54D, J55D, J56D 12VDC 1.1 – 1.3

Page 19

Instruction Supplement

LMI PUMP SERIES P1

Date : 10.98

Replaces Rev. 0 , 07.98

REF. : 161.5304.001 Rev. A

1 Foot valve 9 Injection check valve

2 Ceramic weight 10 Discharge tubing

3 Suction tubing 11 Spacer E.P.U.

4 Suction fitting 12 Metering pump housing

5 Return line (pressure relief) 13 Speed knob

6 Pump head 14 Stroke knob

7 4-Function valve (option) 15 Power cord

8 Coupling nut

Metering pump component diagram

Page 20

LMI PUMP SERIES P1

2/3

Control panel detail

Wiring diagram

1 Identification plate

2 Stroke knob

3 Speed knob

4 Stroke light

1 Potentiometer

2 Stroke led

3 Pulser assembly

4 Power cord

5 Mov/cap assembly

6 EPU assembly

23 P12x, P13x : cut 1 resistor

Other P1 : leave both resistors

BLU Blue

BRN Brown

GRN/YEL Green/yellow

YEL Yellow

Page 21

LMI PUMP SERIES P1

3/3

TECHNICAL CHARACTERISTICS

P12x P13x P14x P15x P16x P18x

Output

- max. (l/h)

- min (ml/h)

0.75

2.25

1.6

4.8

2.2

4.4

3.8

7.6

7.6

15.2

12

24

Max. pressure (bar) 10.3 7.6 17.3 7.6 3.5 1.5

Stroke capacity (ml)

- min.

- max.

0.07

0.22

0.13

0.44

0.07

0.37

0.13

0.63

0.25

1.27

0.40

2.00

Stroke frequency (cps/mn)

- min.

- max.

1

60

1

60

1

100

1

100

1

100

1

100

Diaphragm size (in2) 0.5 0.9 0.5 0.9 1.8 1.8

Min. recommanded stroke lenght (%) 30 30 20 20 20 20

Peak power (W) 75 75 150 150 150 150

Average power (Wh) 11 11 22 22 22 22

Note :

The « x » which appears in the code designates both voltage and power cord/plug type.

Page 22

Pipe Thread Connection 1/4" or 1/2"

Typical injection check valve installation

Liquid End Sheet

1 ”pipe tee

Reduction*

1 ”to ½ ”NPT

injection

check valve

CORRECT

Use Teflon tape on

the thread only

CORRECT

Do NOT use

Teflon tape on

machined thread

injection

check

valve

Flow

Flow

40°Variation

acceptable

* customer supplied

NPT pipe

connection

DO NOT USE CLEAR VINYL TUBING ON

THE DISCHARGE SIDE OF THE PUMP.

(Pressure can rupture tubing.)

DO NOT USE PLIERS OR PIPE WRENCH

ON COUPLING NUTS OR FITTINGS.

Tubing Connections

Your pump will be supplied with one of the following

tubing connections. Before installation, all tubing must

be cutted with a clean square end. Valve and head

connections from the factory may be capped. Remove

and discard these caps before connecting the tubing.

Apply Teflon© tape.

(Customer supplied pipe

connections)

Injection Check Valve and

Discharge Tubing Installation

The Injection Check Valve prevents backflow from a

treated line. Connect the Injection Check Valve to your

“DISCHARGE” (outlet) line. An NPTF fitting or pipe tee

with a reducing bushing to 1/2" NPTF will

accept the injectioncheck valve. Use Teflon® tape or

pipe dope to seal the pipe threads only.

When installing the Injection Check Valve, be sure to

position it so that the valve enters the bottom of your

pipe in a vertical position. Variations left and right within

40° are acceptable (see illustration below).

After cutting an appropriate length of discharge tubing,

connect tubing to the injection check valve then back

discharge

Make sure it does not crimp or come into contact with

hot or sharp surface (see Tubing Connections).

When pumping solutions, make certain that all tubing is securely attached to the fittings. It is

recommended that tubing or pipe lines be shielded to prevent possible injury in case of rupture or accidental

damage. Always wear protective clothing and face shield when working on or near your metering pump.

Flexible pipe connection with connection Nozzle

A : Nut C : Connection Nozzle

B : End fitting D : Connection

Encase properly pipe into connection nozzle as shown in

the drawing

Flexible connection without connection Nozzle

Mounting Steps : Manual mounting

1

At the startup of the pump check that the assembly does not

leak

2

: Fit the part 3 on

the part 4 in

mechanical stop

3

Pull on the part 3 for

checking the

assembly

Page 23

Use Ceramic

Weight

pump pump

Foot Valve

Must Reamin

Vertical

CORRECTINCORRECT

2.0in (50mm) for Sediment

Accumulation

solution

tank

Foot Valve Tilted Sideways

Foot Valve Tubing Connection

WILL NOT PRIME

Foot Valve/Suction Tubing

Installation

The Foot Valve acts as a check valve to keep the pump

primed in suction lift applications.

The foot valve is designed to be submersed in the

solution tank or drum and must sit in a vertical position

at the bottom. Position approximately 2 inches (50mm)

off the bottom if the tank or drum contains sediment.

The ceramic weight, when installed, positions the foot

valve in a vertical position.

NOTE: Pump models equipped with high-viscosity

liquid end s are not equipped with foot valves. Flooded

suction is recommended A 1/2" NPT connector is

included for flooded suction installations.

1. Cut a piece of suction tubing to a length so that the

foot valve hangs just above the bottom of the

solution container. Maximum recommended

vertical suction lift is 5 feet (1.5 m).

2. Attach the foot valve to one end of the suction

tubing.

3. Slide the ceramic weight over the tubing end until

it contacts the top of the foot valve coupling nut.

4. Place foot valve and tubing into the solution tank.

Check that the foot valve is vertical and

approximately 2 inches (50 mm) from the bottom

of the tank or drum(see ullustration). Connect the

Connect the other end of the tubing to the suction

side (bottom side) of the pump head (see Tubing

Connections).

Multi-Function Valve Installation

To install the multi-function valve, remove the yellow

screw cap on the top of the pump head and screw in

the valve so that it contacts the seal ring. An additional

1/8 – 1/4 turn may be necessary to prevent leakage.

1/4" O.D. tubing connects to the side of the valve and

acts as a return line to the solution tank. To ensure

priming, this tubing must NOT be submerged in the

solution.

This return line tubing must be secured to ensure

pumped solution will safely return to supply tank.

Depressurizing Discharge Line

(pumps equipped with multi-function

valves)

It is possible to depressurize the discharge line and

pump head without removal of tubing or loosening of

fittings.

1. Be sure injection check valve is properly installed

and is operating. If a gate valve or globe valve has

been installed downstream of injection check

valve, it should be closed. Be certain relief tubing

from the multi-function valve is connected and run

to solution reservoir.

2. Turn Pressure Relief knob 1/4 turn.

3. Open the anti-syphon valve, if equipped

4. The discharge line is now depressurized.

5. If injection check valve is of higher elevation than

pump head, disconnecting tubing at the injection

check valve end will allow air to enter and cause

solution to drain back to tank.

Discharge

To Pump Head

¼ ” Tubing

Coupling nut

To solution Tank

Bottom Tubing

in Fitting

Push and hold while

tightening connector.

1 Inch

(25 mm)

Multi-Function Valve Tubing Connection

Page 24

1 Flapper valve

2 Injection check valve body

3 Injection check valve spring

4 Check valve ball

5 Seal ring

6 Cartridge valve

7 Cartridge valve o-ring

8 Cartridge valve washer

9 Valve seat

10 Clamp ring

11 Ferrule

12 Clamp sleeve

13 Tubing adapter

14 Coupling nut

15 Discharge tubing

16 Valve housing

17 Multi-function valve

18 High-viscosity spring

19 Liquifram

20 Pump head

21 Pump head screw

22 Suction tubing

23 Foot valve seat

24 Foot valve screen

25 High-viscosity valve seat

26 H.V. tubing clamp

27 H.V. suction tubing

28 H.V. Tubing x 1/2 NPT connector

29 Injection check valve assembly

30 Discharge valve assembly

31 Suction valve assembly

32 Pump head assembly

33 Foot valve assembly

34 Injection Seat PTFE

35 Ceramic Weight

36 Return Line

37 Cap ASM (Black Knob)

38 Cap ASM (Yellow Knob)

39 Multi-Function Valve Body

40 Nut Multi-Function Valve

41 Screw Multi-Function Valve

42 Return Line Coupling Nut

43 Adjustment Screw B/4-FV

44 Cap B/4-FV

45 Plug B/4-FV

46 Gasket B/4-FV

47 Small O-Ring B/4-FV

48 Large O-Ring B/4-FV

Liquid End Parts List

NOTE: This illustration is a visual

representation of all LE components.

Liquid ends will not include all parts

shown.

40

42

40

36

38

39

48

47

46

45

44

41

43

41

42

36

41

39

37

17

17

17

37

39

38

40

42

36

3FV

B/4FV

4FV

Page 25

Bleed 4-FV

Start-Up/Priming for Pump

Supplied with Multi-Function

Valve

Read this entire section completely before

proceeding.

When all precautionary steps have been taken, the

pump is mounted, and the tubing is securely attached,

you may now start priming the pump.

1. Plug in or switch the pump on.

2. While the pump is running, set the speed knob at

80 %and the stroke knob at 100%.

If the pump is equipped with pressure control, turn fully

clockwise.

3. 1/4 turn open the relief side (black knob) of the

multi-function valve.

3A. (Bleed 4FV only) With screwdriver rotate bleed

adjustement screw counter-clockwise 2 full turns.

When solution begins to flow through translucent

bleed return tubing, the pump is primed. Stop

pump.

4. The suction tubing should begin to fill with solution

from the tank.

5. A small amount of solution will begin to discharge

out the return line of the multi-function valve. Once

this happens,1/4 turn or release the knob and

SHUT THE PUMP OFF. (If pump is not equipped

with an on/off switch, or disconnect the power

cord.)

6. The pump is now primed.

6A. (Bleed 4FV only)

a. Start pump and let pump inject solution into

the discharge line.

b. Close the bleed adjustment screw by rotating

it clock-wise with a screwdriver.

c. Now adjust the pump stroke length and/or

speed (frequency) to a range approximately

25% higher than you would normally want for

the process.

d. Slowly rotate bleed adjustment screw counter-

clockwise until just a small amount of solution

begins to trickle down inside the bleed return

tubing. A small amount of solution pumped

back to the tank with each stroke of the pump

will allow gas and air to escape without air or

gas locking in the pump head.

NOTE: If the pump does not self-prime, remove the

multi-function valve on the discharge side of the pump

head. Remove the check valve and pour water or

solution into the port until the head is filled. Replace

valve, then follow start-up/priming steps.

Start-Up/Priming without MultiFunction Valve

Read this entire section completely before

proceeding.

When all precautionary steps have been taken, the

pump is mounted, and the tubing is securely attached,

you may now prime the pump.

1. Plug in or switch on the pump.

2. While the pump is running, set the speed knob at

80% and the stroke knob at 100%.

If the pump is equipped with pressure control, turn fully

clockwise.

3. The suction tubing should begin to fill with solution

from the tank.

4. Once the solution begins to exit the pump head on

the dis-charge side, SHUT THE PUMP OFF. (If

pump is not equipped with an on/off switch,

disconnect the power cord).

5. The pump is now primed.

NOTE: If the pump does not self-prime, remove the

fitting on the discharge side of the pump head. Remove

the ball and pour water or solution into the port until the

head is filled. Replace valve, then follow start-up/

priming steps.

Rotate clockwise

to close Bleed

Adjustment Screw

Anti-Syphon

Knob

Negative pressure

at discharge closes

diaphragm and

prevents syphoning.

Bleed

(Relief) Port

Space open

to drain

Pump discharge stroke

lifts diaphragm to allow

for fluid flow.

Page 26

F

DECLARATION "CE" DE CONFORMITE

Nous, déclarons que le matériel désigné ci-après a été conçu et fabriqué suivant les directives et spécifications suivantes :

Directive basse tension 2006/95/EEC

Directive CEM 2004/108/EEC

GB

"EC" DECLARATION OF CONFORMITY

We, certify that the equipment designated below has been designed and manufactured in accordance with the specifications

of the following :

Low voltage Directive 2006/95/EEC

EMC Directive 2004/108/EEC

D

EG-KONFORMITÄTSERKLÄRUNG

Wir, verklären, daß die nachgestehend bezeichneten Gerätschaften im Einklang mit folgenden Richtlinien und Spezifikationen

geplant und hergestellt wurden :

EG-Richtlinie 2006/95 für Niederspannung

EG-Richtlinie 2004/108 zur elektromagnetischen Verträglichkeit

NL

EG FABRIKANTENCONFORMVERKLARING

De ondergetekenden, verklaren geheel onder eigen verantwoor delijkheid dat het produkt waarop deze verklaring betrekking

heeft in overeenstemming is met:

Richtlijn 2006/95/EEG inzake elektrisch materiaal bestemd voor gebruik binnen b epaalde spanningsgrenzen;

Richtlijn 2004/108/EEG inzake elektromagnetische compatibiliteit.

I

DICHIARAZIONE DI CONFORMITA' "CE"

La società, Dichiara che il materiale sotto specificato è stato progettato e realizzato in conformità con l e seguenti direttive e

specifiche:

Direttiva bassa tensione 2006/95/EEC

Direttiva CEM 2004/108/EEC

E

DECLARACION "CE" DE CONFORMIDAD

Nosotros, declaramos que el material detallado a continuación está diseñado y fabricado de acuerdo a la siguientes

directivas y normas :

Directiva basa tensión 2006/95/EEC

Directiva EMC 2004/108/EEC

TYPE / TYP / TIPO

LMI : AA7.. / AA9.. / B1.. / B7.. / B9.. / C1.. / C7.. / C9.. / H9.. / J5.. / P0.. / P1.. / P5../ E7

Alain LAMPERIER

Le Directeur Production

Production Manager

AQFORM 289

10/2010

Page 1/1

Page 27

PS-GARANTIE /1

1

GUARANTEE

The vendor guarantees his products according to the Milton Roy Europe . general conditions

of sale.

The guarantee for components and sub-assemblies not fabricated by the vendor is limited

tothat given by the supplier.

The vendor’s guarantee only covers the replacement or the repair, at his cost and in his

factory, of all parts acknowledged by his technical services as being defective due to an error

in conception, of material or of execution.

It is the purchasers responsability to prove the said defects. The guarantee does not cover

the replacement of wear parts mentioned in part V - Preventive Maintenance.

The vendor reserves the right to modify all or part of his products in order to satisfy the

guarantee. The guarantee does not cover charges arising from dismantling, assembly,

transport and movements.

The replacement of one or several parts, for whatever reason, does not prolong the period of

guarantee.

The guarantee is not applicable notably in the following cases :

installation not in accordance with standard current practice.

deterioration or accident resulting from negligence.

lack of surveillance or maintenance.

modifications to conditions of use.

chemical corrosive or erosive attack. The proposed materials of construction are

recommendations subject in all cases to verification and acceptance by the client. The

recommendations, based on the experience of the vendor and the best available information,

do not guarantee against wear or chemical action.

The guarantee ceases :

if the storage of the material, outwith the vendors factory, does not conform to his

recommendations or to current standard practices.

in case of work or dismantling of the material by someone who does not respect written

recommendations of the instruction manual (when replacing wear parts).

if parts from another origin are substituted for the original parts supplied by the

manufacturer.

The purchaser cannot call on guarantee claims to justify differing payments.

INDUSTRIAL OWNERSHIP

This manual can only be used by the purchaser or the user. It cannot be distributed,

published, reproduced (partially or totally) or generally communicated to third parties without

the advance, formal written authorisation of the vendor.

Any breach of these rules may result in legel action being taken.

Page 28

FRANCE

Tel.: +33.(0)2.32.68.30.00 / Fax: +33.(0)2.32.68.30.93

E-mail: contact@miltonroy-europe.com

Assistance technique / Technical assistance: ?el.: +33.(0.2.32.68.30.02 - Fax: +33.(0)2.32.68.3 0.96

Pièces de rechange / Spare parts: ?el.: +33 (0)2.32.68.30.01 - Fax: +33.(0)2.32.68.30.92

E-mail: quote.sp@miltonroy-europe.com

10 Grande Rue 27360 Pont-Saint-Pierre - FRANCE

www.miltonroy

-europe.com

ESPANA / PORTUGAL

Sistemas de Dosificación y Mezcla de Fluidos, S.L.

Tel.: +34 91 4741914 - Fax : +34. 91 3459707 - E-mail: info@sdm-sistemas.com

C/ Embajadores, 100

28012 Madrid - ESPANA

www.sdm

-sistemas.com

ITALIA / MALTA

Milton Roy Italia Srl

Tel.: +39.(0)39.65.78.505 - Fax: +39 (0)39 60.56.906

E-mail: sergio.testa@miltonroy-europe.com

Centro Direzionale Colleoni Via Paracelso, 16

Palazzo Andromeda Ingresso 2

20041 Agrate Brianza (Ml) - ITALIA

www.miltonroy

-europe.com

UNITED-KINGDOM / NORTHERN EUROPE

Milton Roy UK, Ltd

TECHNICAL ASSISTANCE AND SPARE PARTS :

Tel.: +44 (0)191.5375.256 - Fax: +44.(0)191.5490.911

E-mail: victoria.richardson@miltonroy-europe.com

North Hylton Road

Sunderland, SR5 3JD - UNITED-KINGDOM

www.miltonroy

-europe.com

NORTH AND SOUTH AMERICA

LMI Milton Roy Milton Roy Company

Tel.: 215.293.0401 - Fax: 215.293.0445 Tel.: 215.441.0800 - Fax: 215.441.8620

E-mail: info@lmipumps.com E-mail: info@miltonroy.com

201 Ivyland Road 201 Ivyland Road

Ivyland, PA 18974 - USA Ivyland, PA 18974 - USA

www.lmipumps.com

www.miltonroy.com

FOR OTHER COUNTRIES:

Visit our web site at www.miltonroy-europe.com for a complete list of our distributors network around the world.

For further details you can contact our headquarter located in France at contact@miltonroy-europe.com.

Loading...

Loading...