Page 1

I N S T R U C T I O N M A N U A L

B E A M O P E R A T E D P L U N G E R

LINC82 Series Chemical Metering Pump

Beam Operated Plunger

Page 2

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

To Order, Call 800.455.LINC

Or FAX your order anytime to

215.293.0498

For the Nearest Authorized

Representative:

By Telephone: 800.455.LINC for

the US & Canada, 215.293.0465 or

215.441.0800 for International

customers

By Fax: 215.293.0498

E-mail:

LINCORDERS@MILTONROY.com

Technical Support

By Telephone: 800.455.LINC or

215.293.0498

By E-mail:

INFO@LINCPUMPS.com

Convenient Hours

Our phone lines are open Monday

– Friday 8:00 AM – 4:45 PM (EST)

LINC Warranty

Three year limited warranty on all our

products against defects in materials.

LINC Technical Support

Technical service and support

begins with an easy toll-free call.

Many times, our experienced

customer service reps can isolate

and resolve problems over the

phone or provide a referral to our

authorized representatives nationwide. We also offer factory repair

services with facilities in Ivyland,

PA. if a warranty issue that cannot

be resolved locally.

Purchase Orders

All mail-in purchase orders must

be signed by an authorized

person. When ordering please list:

• Quantity

• Description of Items

• Shipping Address

• Billing Address

• Purchase Order Number

Request for Quotation – RFQs

Please send RFQs to:

By Mail:

Linc Milton Roy

Attn: Customer Service

201 Ivyland Road

Ivyland, PA 18974

USA

By Fax:

1.215.293.0498

By E-mail:

Lincorders@miltonroy.com

Freight Charges

All shipments are F.O.B., Ivyland,

PA, USA. Shipping and handling

are included on the invoice,

prepay and add.

Terms

With credit approval, net 30 days.

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800 Page 2

LINC 82 ver. 04102003 - pn 15104

Page 3

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

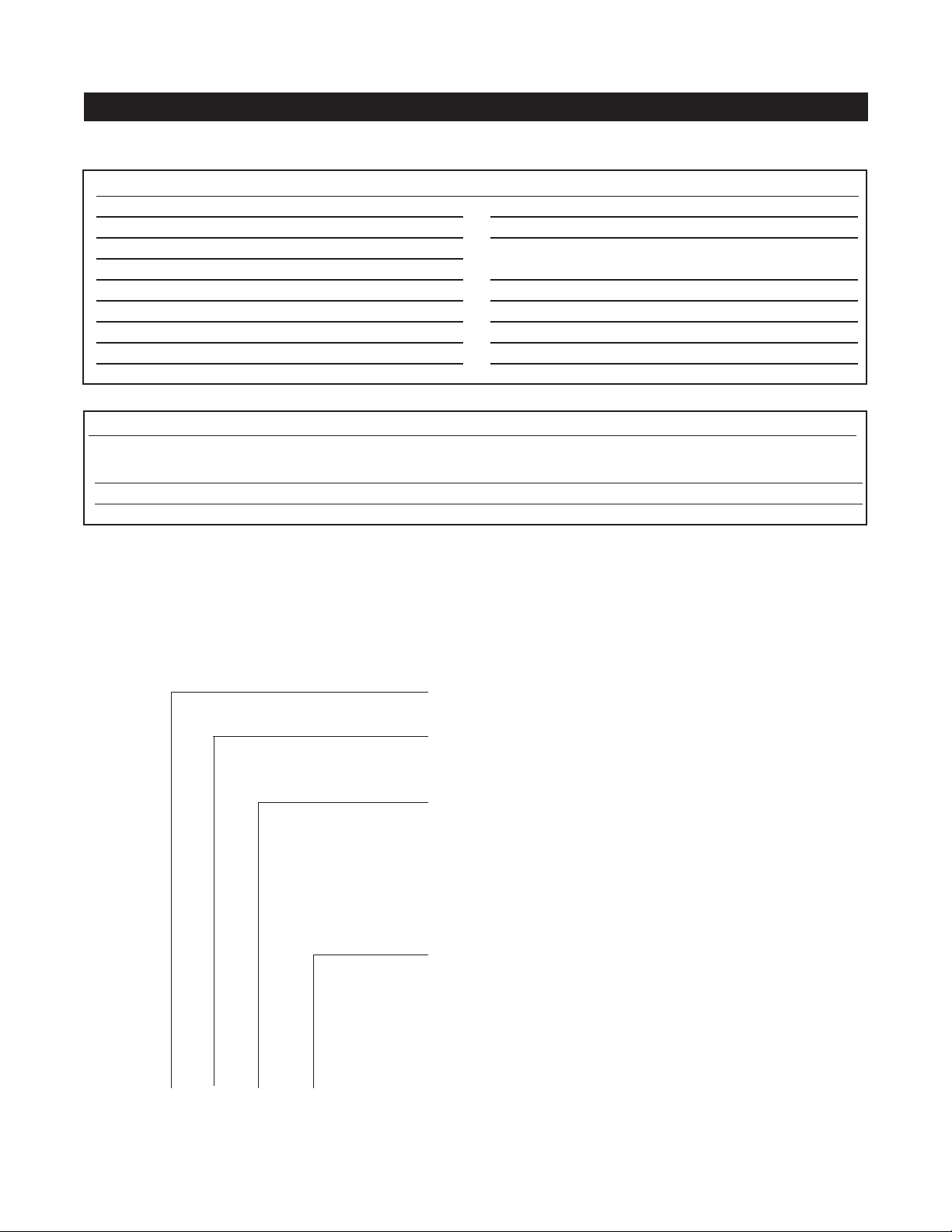

Contents 82 Pump Manual ............................................................................................................... Page

General Specifications ........................................................................................................................ 4

Selection Chart ................................................................................................................................... 4

Ordering Chart .................................................................................................................................... 4

Scope Of This Manual ........................................................................................................................ 5

Installation ........................................................................................................................................... 5

Start Up ............................................................................................................................................... 5

Maintenance........................................................................................................................................ 5

Suction Check Valve ........................................................................................................................... 5

Discharge Check Valve ....................................................................................................................... 6

Plunger and Plunger Seal .................................................................................................................. 6

Plunger and Plunger Seal Lubricant ................................................................................................. 6

Assembly Drawings & Parts Lists

Figure 1, 82 Assembly Drawing ........................................................................................................ 7

Pump Assembly Parts List: 82 ......................................................................................................... 8

Mounting Kit Parts List ...................................................................................................................... 8

Figure 2, Disharge Check Valve Assembly Drawing & Parts List .................................................. 9

Figure 3, Suction Check Valve Assembly Drawing .......................................................................... 9

Plunger Seal Assembly Selection Chart .......................................................................................... 9

Suction Check Valves Parts Lists .................................................................................................... 10

Figure 4, Capacity for 1/4" Plunger Pump ........................................................................................ 11

Figure 5, Capacity for 1/2" Plunger Pump ........................................................................................ 11

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800

LINC 82 ver. 04102003 - pn 15104

Page 3

Page 4

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

General Specifications: 82 Series Beam-Operated Plunger Pumps

Wetted Parts:

Pump Body: 316 Stainless Steel

Plunger: 17-4 PH Stainless Steel

Plunger Seal: Refer to Ordering Chart

Check Valves :

Body: 316 Stainless Steel

Ball: 316 Stainless Steel

Spring - Discharge: 316 Stainless Steel

Seat: TFE, Standard

The LINC 82 Series: Beam-Operated Plunger Pump Selection Chart

Model Plunger Maximum Maximum Minimum Minimum Maximum Maximum Volume Stroke

Number Diameter Rate Rate Rate Rate Pressure Pressure Per Length

Gal/24Hr Liter/24Hr Gal/24Hr Liter/24Hr PSI Bar Stroke

82-11 1/4" 5.00 19.0 0.25 1.0 3,000 207 0.8 cc 1"

82-12 1/2" 20.0 76.0 1.00 4.0 1,500 103 3.2 cc 1"

Plunger Sizes: 1/4" & 1/2" plunger diameters

Pressure: To 3,000 psi, maximum

Optional Materials: 316 Stainless Steel, Hastelloy,

Monel, & Titanium

Notes:

1. Pump rate is dependent on beam actuation frequency.

2. One beam turnbuckle is included as standard 82 Series equipment.

Ordering Chart: LINC 82 Series

Beam Operated Plunger Pump

Series:

82 - Pneumatic, plunger-type metering pump

Plunger:

11 - 1/4" plunger diameter

12 - 1/2" plunger diameter

Seal Materials:

4 - Packing mechanical seal - TFE/Graphite, wetted o-rings - TFE

5 - Specify your requirements

6 - Packing mechanical seal - Ultra High Molecular Weight

7 - O-rings packing seal - Fluorocarbon, wetted o-rings -

8 - O-rings packing seal - Nitrile, wetted o-rings - Nitrile

9 - O-rings packing seal - Kalrez, wetted o-rings - Kalrez

Option Number:

0 - Standard unit

5 - Specify your requirements

6 - 316 ss wetted parts

7 - Mounting Kit

Polyethylene, wetted o-rings - TFE

Fluorocarbon

LINC ____- _____-_____ ( )

Example: LINC 82-11-40 Beam-Operated Injection Pump

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800 Page 4

LINC 82 ver. 04102003 - pn 15104

Page 5

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

Scope Of This Manual:

This manual describes the

LINC82 Chemical Metering Pump,

which is a beam-operated plunger

pump.

Installation:

This pump requires a flooded

suction and must be located lower

than the chemical supply tank.

Vertical installation of the pump

body is required.

1. Bolt or weld the pump

mounting bracket from the

mounting kit to the steel

base of the pumping unit. It

is recommended that the

chemical pump is mounted

so that the cable (wire rope)

is as close to vertical as

possible.

2. Attach the cable assembly

from the mounting kit to the

walking beam near the

fulcrum point of the pumping unit with the beam

clamp provided. Ensure

that the cable does not

interfere with the walking

beam supports. Refer to

Figures 4 or 5 of this manual

for desired stroke length.

3. Attach the cable to the

turnbuckle of the chemical

pump using the cable clamp

provided (fig. 1, item 23).

4. Adjust the cable length to

obtain desired approximate

plunger stroke length. Final

adjustment of the stroke may

be obtained with the turnbuckle.

5. Secure the turnbuckle

position with locknuts (fig. 1,

items 22 & 24).

Caution: Care must be exercised

to assure that the cable is of sufficient length and is attached to the

walking beam at a point so that the

plunger stroke does not exceed 1".

6. Connect the suction line from

the chemical drum through a

filter or strainer to the suction

check valve (fig. 1, item 14).

7. Connect the discharge line

from the discharge check

valve to the desired location

(fig. 1, item 15).

Note: An inline check valve at

the point of injection is recommended to prevent back flow to the

pump during shutdown or servicing.

Start-Up:

1. To prime the pump, loosen

the bleed screw to vent the

trapped air allowing the liquid

(chemical) to flow into the

pump chamber (fig. 1, item

12). Tighten the bleed screw.

2. Start the pump and run for a

minimum of one minute.

Then, open the bleed screw

again to evacuate all the

remaining air or gas from the

pump chamber.

Refer to Figures 4 or 5 for desired

injection rate. Determine the stroke

length by adjusting the cable and

turnbuckle. Stroke length must be

adjusted when changes are made to

the pumping unit cycles per minute

to maintain a fixed rate of flow.

If a drum gauge has been installed, depress test level on drum

gauge to cause the pump suction

to be drawn from the gauge glass.

With a stop watch, note the change

of liquid level on drum gauge glass

for one minute. Most drum gauge

scales are calibrated directly in

quarts per day for one minute of

operation. The liquid level remaining in the drum is displayed on the

gauge with the test level released.

Maintenance:

Pump parts are subject to normal

wear and must be inspected and replaced as necessary. Inspection and

maintenance frequency depends on

severity of service conditions. Instructions are given in this section

for maintaining the pump as units;

i.e. suction check valve, discharge

check valve and plunger packing.

Suction Check Valve,

Figure 1, item 14 & Figure 3:

1. Assure that the pump is

isolated from the rest of the

system.

2. Disconnect the piping from

the check valve.

3. Unscrew the check valve

body (fig. 3, item 1) from the

pump lower housing (fig. 1,

item 13).

4. Remove and discard the

o-rings (fig. 3, items 3 & 4).

5. Inspect the ball for damage

(fig. 3, item 2). Replace if

necessary. Reassemble the

check valve using new o-rings.

If the seat o-ring is Teflon,

install it into the check valve

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800

LINC 82 ver. 04102003 - pn 15104

Page 5

Page 6

M E T E R I N G P U M P S

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

body (fig. 3, item 1) and "peen"

the ball onto the seat to

ensure proper sealing.

6. Install the repaired suction

check valve into the pump

body. Tighten securely.

7. Reconnect the suction piping.

Discharge Check Valve,

Figure 1, item 15 & Figure 2:

1. Assure that the pump is

isolated from the rest of the

system.

2. Disconnect the piping from

the check valve.

3. Unscrew the check valve

body (fig. 2, item 1) from the

pump lower housing (fig. 1,

item 13).

4. Remove and discard the

o-rings (fig. 2, items 4 & 5).

5. Inspect the ball and spring

(fig. 2, items 2 & 3) for damage. Replace if necessary.

Reassemble the check valve

using new o-rings. If the seat

o-ring is Teflon, install in into

the pump lower housing (fig.

1, item 13) and "peen" the

ball onto the seat to ensure

proper sealing.

6. Install the repaired discharge

check valve into the pump

lower housing. Place the ball

on the o-ring seat followed by

the spring (small end of the

spring toward the ball) and

screw the discharge check

valve body into the pump

lower housing. Tighten

securely.

7. Reconnect the discharge

piping.

Plunger and Plunger Seal,

Figure 1, item 6 & 16:

1. Assure that the pump is

isolated from the rest of the

system.

2. Remove the pin retainer and

pins separating the plunger

assembly from the beam (fig.

1, items 4 & 5). Remove the

retaining ring and loosen the

set screw and separate the

swivel ring (fig. 1, items 7, 9

& 8) from the packing block.

3. Grasp the plunger assembly

(fig. 1, item 6) and pull up out

of the packing block (fig. 1,

item 11) to remove. Inspect

the plunger for wear, especially longitudinal grooves.

Replace the plunger assembly

if necessary.

4. With a pipe or strap wrench

separate the packing block

(fig. 1, item 11) from the lower

housing (fig. 1, item 13).

5. Remove the plunger seal and

seal back-ups, where used,

from the lower housing (fig.

1, items 16 & 13). Carefully

remove the seal back-up and

seal. Inspect for wear or

deterioration from being

attacked by the chemical the

pump is pumping.

6. Replace the plunger seal and

plunger seal back-ups if

needed (see parts lists on

page 9). If the plunger seal

is the o-ring type, it should

be installed with a plunger

seal back-up on each side of

the o-ring. If the plunger seal

is of the Uniseal type, it

should be installed with the

expander ring down toward

the lower housing. Extreme

care should be taken not to

scratch or distort these parts.

7. After the seal has been

replaced, lubricate with a light

oil to protect against possible

damage during assembly.

8. Screw the packing block onto

the lower housing and tighten

securely. Slide the plunger

assembly into the packing

block and down into place.

Install the swivel ring with the

retaining ring and beam with

the pin and pin retainer. See

step 2 above under this section.

9. If the bleed screw has been

removed, install and tighten

securely.

Plunger and Plunger Seal

Lubrication:

1. Remove the plug from the

pump body (fig. 1, item 10).

2. Add silicone base lubricant

(Dow Corning DC-7, part

#10354) or equal into the port

where the plug was removed.

Approximately 0.5cc will be

required for each refill.

Replace the plug.

Note: Do not use a grease gun

or any metal tool to insert the lubricant into the pump to prevent damage to the plunger or plunger seal.

3. Silicone lubricant should be

added every 4 - 6 weeks

depending upon operation

conditions.

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800 Page 6

LINC 82 ver. 04102003 - pn 15104

Page 7

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

24

Figure 1, LINC82 Series Pump

E

D

F

1

2

3

5

4

C

9

10

11

6

7

8

60°

17

16

15

20

1918

23

22

21

12

13

14

H

B

Model 82-11 82-12

A ............................ 2 1/8" ..................... 2 1/4"

B ............................ 3" ........................... 3 3/4"

C ........................... 12 3/4" ................... 13 1/2"

D ........................... 13/16" .................... 13/16"

E ............................ 9" ........................... 9"

G

A

F ............................ 10 3/8" ................... 10 3/8"

GSuction ................ 1/4" NPTM ............. 1/2" NPTM

H Discharge ........... 1/4" NPTF .............. 1/4" NPTF

MODEL 82 -12-70

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800

LINC 82 ver. 04102003 - pn 15104

Page 7

Page 8

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

LINC82 Series Parts List

82 Pump Assembly

Model 82-11 82-12

Plunger Size 1/4" 1/2"

Item Part# Part# Description Material Qty

1 ......................... 21891 .......... 21891 .......... Pin ................................................................. 303 ss .............................. 1

2 ......................... 10915 .......... 10915 .......... Pin Retainer .................................................. 15-7 PH ............................ 1

3 ......................... 21895 .......... 21895 .......... Connecting Rod ............................................ 303 ss .............................. 1

4 ......................... 21891 .......... 21891 .......... Pin ................................................................. 303 ss .............................. 1

5 ......................... 10915 .......... 10915 .......... Pin Retainer .................................................. 15-7 PH ............................ 1

6 ......................... 23307 .......... 21979 .......... Plunger Assembly ......................................... 17-4 PH ............................ 1

7 ......................... 10916 .......... 10916 .......... Retaining Ring............................................... 15-7 PH ............................ 1

8 ......................... 23465 .......... 23465 .......... Swivel Ring ................................................... 303 ss .............................. 1

9 ......................... 11461 ...........11461 .......... Set Screw ...................................................... 18-8 ss ............................. 1

10 ....................... 10278 .......... 10278 .......... Plug ............................................................... 304 ss .............................. 1

11 ....................... 30999 .......... 31021 .......... Packing Block ............................................... 304 ss .............................. 1

12 ....................... 20460 .......... 20460 .......... Bleed Screw .................................................. 316 ss .............................. 1

13 ....................... 30811 ............30820 ........... Lower Housing ................................................ 316 ss ............................... 1

14 ....................... See page 10 .................... Suction Check Valve Assembly ................... 316 ss ..............................

15 ....................... See page 9 ...................... Discharge Check Valve Assembly ............... 316 ss ..............................

16 ....................... See page 9 ...................... Seal Assembly .........................................................................................

17 ....................... 10655 .......... 10655 .......... Roll Pin .......................................................... 15-7 PH ............................ 1

18 ....................... 10941 .......... 10941 .......... Name Plate ................................................... 18-8 ss ............................. 1

19 ....................... 10324 .......... 10324 .......... Drive Screw ................................................... 18-8 ss ............................. 2

20 ....................... 31000 .......... 31000 .......... Beam............................................................. 304 ss .............................. 1

21 ....................... 10940 .......... 10940 .......... Shackle ......................................................... Galvanized ....................... 1

22 ....................... 10934 .......... 10934 .......... Jam Nut (Left Handed).................................. Plated ............................... 1

23 ....................... 10936 .......... 10936 .......... Turnbuckle ..................................................... Aluminum ......................... 1

24 ....................... 10555 .......... 10555 .......... Jam Nut (Right Handed) ............................... Plated ............................... 1

24 .............................................22201 .......... Beam Weight (Not Shown) ........................... Steel ................................. 1

24 .............................................11167 .......... Set Screw (Not Shown) ................................ 18-8 ss ............................. 2

Model 82-11 82-12

Assembly 23423 23607 Mounting Kit

Item Part# Part# Description Material Qty

1 ......................... 10846.......... 10486 ......... Beam Clamp ................................................. Steel ................................. 1

2 ......................... 10928 .......... 10928 .......... Eye-Bolt ........................................................ Galvanized ....................... 1

3 ......................... 10926 .......... 11607 .......... Pump U-Bolts ................................................ Galvanized ....................... 1

4 ......................... 10938 .......... 10938 .......... Wire Rope (1/3") ........................................... Galvanized ....................... 1

5 ......................... 10937 .......... 10937 .......... Rope Clips ..................................................... Galvanized ....................... 1

6 ......................... 21981 .......... 21981 .......... Bracket .......................................................... Steel ................................. 1

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800 Page 8

LINC 82 ver. 04102003 - pn 15104

Page 9

P N E U M A T I C B E L L O W S

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

Figure 2, Discharge Check Valve

Reference fig. 1, item 15

Part # See Below

Figure 3, Suction Check Valve,

Reference fig. 1, item 14

Part # See Next Page

Assembly 22624 22625 22626 Discharge Check Valve Port Size 1/4" NPTF

One Piece Body

Item Part # Part # Part # Description Material Qty

1 .................. 20570 .......... 20570 .......... 20570 ................. Body .......................... 316 ss ............................... 1

2 .................. 10283 .......... 10283 .......... 10283 ................. Ball............................. Carbide ............................. 1

3 .................. 10068 .......... 10068 .......... 10068 ................. Spring ........................ 316 ss ............................... 1

4 .................. 10312 ............................................................. Seat ........................... Fluorocarbon .................... 1

......................................... 10328 ....................................... Seat ........................... Nitrile ................................ 1

............................................................... 10317 ................. Seat ........................... TFE ................................... 1

5 .................. 10482 ............................................................. Seal ........................... Fluorocarbon .................... 1

......................................... 10124 ....................................... Seal ........................... Nitrile ................................ 1

............................................................... 10481 ................. Seal ........................... TFE................................... 1

Seal Assembly

Model 82-11 82-12

Item # Part # Part # Material

16 ................ 23350 .......... 23351 .......... Fluorocarbon

16 ................ 23391 .......... 23392 .......... Nitrile

16 ................ 23390 .......... 23393 .......... Kalrez

16 ................ 11821 .......... 11822 .......... TFE/Graphite

16 ................ 13007 .......... 13008 .......... UHMWPE

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800

LINC 82 ver. 04102003 - pn 15104

Page 9

Page 10

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

Suction Check Valves - One Piece Body

Part Number 24773 Port Size 1/4" NPTM

Item Description Part # Material Qty

1 ....................................... Inlet Body .......................... 24789 .........................316 ss ........................................ 1

2 ....................................... Ball ....................................10283 ......................... Carbide ...................................... 1

3 ....................................... Seat ..................................10365 .........................TFE ............................................ 1

4 ....................................... Seal ................................... 10280 ......................... Fluorocarbon .............................. 1

Part Number 24774 Port Size 1/4" NPTM

Item Description Part # Material Qty

1 ....................................... Inlet Body .......................... 24789 .........................316 ss ........................................ 1

2 ....................................... Ball ....................................10283 ......................... Carbide ...................................... 1

3 ....................................... Seat ..................................10282 .........................Fluorocarbon .............................. 1

4 ....................................... Seal ................................... 10280 ......................... Fluorocarbon .............................. 1

Part Number 24775 Port Size 1/4" NPTM

Item Description Part # Material Qty

1 ....................................... Inlet Body .......................... 24789 .........................316 ss ........................................ 1

2 ....................................... Ball ....................................10283 ......................... Carbide ...................................... 1

3 ....................................... Seat ..................................10365 .........................TFE ............................................ 1

4 ....................................... Seal ................................... 10122 ......................... Nitrile ......................................... 1

Part Number 24776 Port Size 1/4" NPTM

Item Description Part # Material Qty

1 ....................................... Inlet Body .......................... 24789 .........................316 ss ........................................ 1

2 ....................................... Ball ....................................10283 ......................... Carbide ...................................... 1

3 ....................................... Seat .................................. 10110 ......................... Nitrile ......................................... 1

4 ....................................... Seal ................................... 10122 ......................... Nitrile ......................................... 1

Part Number 24778 Port Size 1/2" NPTM

Item Description Part # Material Qty

1 ....................................... Inlet Body .......................... 24787 .........................316 ss ........................................ 1

2 ....................................... Ball ....................................10529 ......................... Carbide ...................................... 1

3 ....................................... Seat ..................................10469 .........................TFE ............................................ 1

4 ....................................... Seal ................................... 10467 ......................... TFE ............................................1

Part Number 24779 Port Size 1/2" NPTM

Item Description Part # Material Qty

1 ....................................... Inlet Body .......................... 24787 .........................316 ss ........................................ 1

2 ....................................... Ball ....................................10529 ......................... Carbide ...................................... 1

3 ....................................... Seat ..................................10337 .........................Fluorocarbon .............................. 1

4 ....................................... Seal ................................... 10466 ......................... Fluorocarbon .............................. 1

Part Number 24780 Port Size 1/2" NPTM

Item Description Part # Material Qty

1 ....................................... Inlet Body .......................... 24787 .........................316 ss ........................................ 1

2 ....................................... Ball ....................................10529 ......................... Carbide ...................................... 1

3 ....................................... Seat ..................................10121 .........................Nitrile ......................................... 1

4 ....................................... Seal ................................... 10468 ......................... Nitrile ......................................... 1

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800 Page 10

LINC 82 ver. 04102003 - pn 15104

Page 11

M E T E R I N G P U M P S

B E A M O P E R A T E D P L U N G E R

Figure 4

20

1/4" 1/2" 3/4" 1"

15

10

STROKES/MINUTE

5

0 5 10 15 20 25

Strokes vs. Quarts at Various Stroke Lengths

20

15

10

STROKES/MINUTE

5

0 20 40 60 80 100

QUARTS / DAY

1/4" Plunger

Figure 5

1/4" 1/2" 3/4" 1"

QUARTS / DAY

Strokes vs. Quarts at Various Stroke Lengths

1/2" Plunger

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800

LINC 82 ver. 04102003 - pn 15104

Page 11

Page 12

M E T E R I N G P U M P S

N O T E S

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800 Page 12

LINC 82 ver. 04102003 - pn 15104

Page 13

M E T E R I N G P U M P S

N O T E S

LINC MILTON ROY 201 IVYLAND ROAD IVYLAND PA, 18974 USA TEL. 215.441.0800

LINC 82 ver. 04102003 - pn 15104

Page 13

Page 14

LINC Milton Roy. represents and warrants that for a period of 3 years from receipt of the product: (1) the product will be free from defects in materials and workmanship; and (2)

the product will perform substantially in accordance with product manuals, literature, or documentation. Any written or oral information or advice given by LINC Milton Roy

representatives, agents, or employees will in no way increase the scope of this warranty. If the product fails to comply with the warranty set forth herein, LINC Milton Roy's entire

liability and the customer's exclusive remedy will be replacement of the product(s) or, at LINC Milton Roy's option, LINC Milton Roy's reasonable effort to make the product meet the

warranty set forth herein.

purpose, with respect to the product. This limited warranty gives you specific legal rights. You may have others, which vary from state to state. These remedies are not available outside

of the United States and Canada. In no event shall LINC Milton Roy or its suppliers be liable for any damages whatsoever (including, without limitation, damages for loss of profits,

business interruption, loss of information, or other pecuniary loss) arising out of the use of or inability to use the product, even if LINC Milton Roy has been advised of the possibility

of such damages. Information contained in this document is subject to change without notice and does not represent a commitment on the part of LINC Milton Roy. All prices quoted

are in U.S. dollars, F.O.B. Ivyland, PA. LINC, LINC Chemical Pumps, and LINC Level & Flow Switches are trademarks of LINC Milton Roy. All other product names and/or registered

trademarks are the property of their respective holders. LINC Milton Roy support services are subject to LINC Milton Roy's then-current prices, terms, and conditions, which are

subject to change without notice. All prices and specifications, if published, are subject to change without notice.

LINC Milton Roy disclaims all other warranties, either expressed or implied, including but not limited to, implied warranties or merchantability and fitness for a particular

Loading...

Loading...