Page 1

®

EXCEL

EXCEL

XR™

XR

Metering Pump

EFFICIENT • RESPONSIVE • INTELLIGENT • CONTROL

Manual, Enhanced, and Communications Models

The EXCEL® XR metering pump is a mechanically actuated diaphragm pump

driven by advanced variable speed technology to provide the most accurate and

reliable performance in the industry. This proven technology is easy to maintain

and will provide years of maximum up-time service. Available in three control

configurations, Manual, Enhanced, and Communications Models, the EXCEL XR

pump fits seamlessly into the process control requirements of every application.

The Manual model is the entry level model with two digital inputs, the Enhanced

model provides a full range of capabilities, and the Communications model offers

Profibus DP or Modbus RTU communication protocols for 2-way communication.

All models come standard with a color backlit display, multilanguage options and

remote operation options. The EXCEL XR metering pump provides everything you

need for complete control of your process.

Applications

Whatever your application, the EXCEL XR metering pump can provide the performance

you need. Designed for the specific requirements of municipal and industrial water and

waste treatment, the EXCEL XR pump is suitable for a wide range of applications.

DATA SHEET

• Water treatment

• Waste water treatment

• General industry

• Agricultural

• Chemical

• Oil & gas

• Power generation

• Pulp & paper

• Textiles

• Other (contact your local authorized representative)

Performance Specifications

Turndown Ratio: Up to 1000:1

Steady State Accuracy: +/- 1.0%

Repetitive Accuracy: +/- 3.0%

Linearity: +/- 3.0%

Duty Rating: Continuous

Features and Benefits

• Intuitive user interface with backlit color display makes setup and customization simple.

• Wide range of control and input/output options to meet the demanding needs of most applications.

• Universal power supply providing maximum flexibility to power your pump: 100-240V, 50/60 Hz

• Multi-language navigation (English, French, Spanish, Portuguese and Chinese) for convenient operation anywhere in the field.

• Innovative drive system creates superior +/- 1% steady state accuracy over 1000:1 turndown ratio for greater flexibility of

handling difficult chemicals.

• Optional liquid-end materials to maximize the life of the pump in challenging environments: polypropylene, PVDF,

and 316L Stainless Steel.

• Mechanically actuated diaphragms for simple maintenance and reliable operation.

• Rugged construction with NEMA 4X/IP 65 housing and protective cover for the harshest environments.

Literature #IR-59261.04 Rev 2/2020

©2018 Milton Roy, LLC. All rights reserved.

1

Page 2

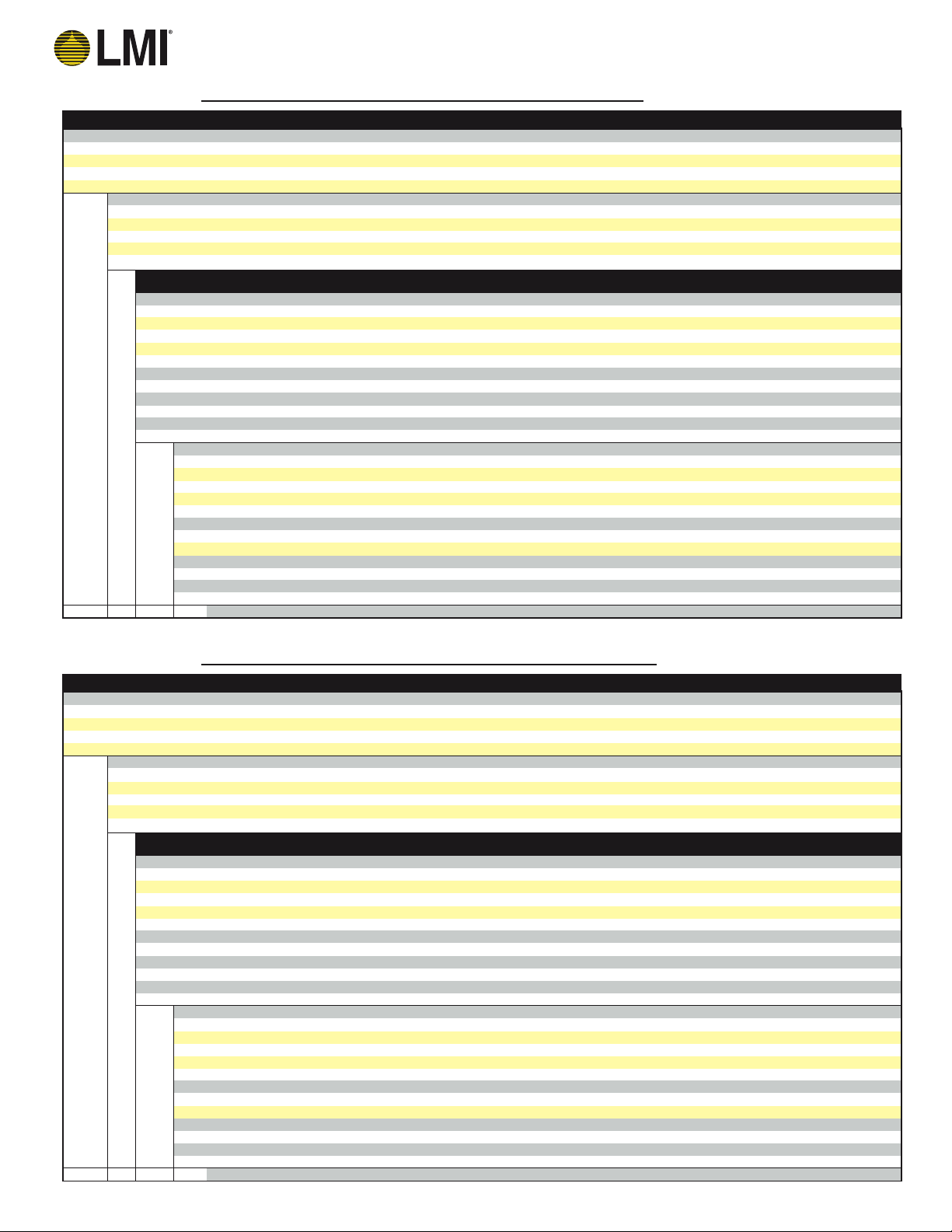

EXCEL® XR Series Code Selection Tables

OUTPUT CODE 2

Drive End Note: Cordsets from the accessories table may be required for the customer to connect to desired input/output.

Control Description Cordset Included Part Number

XRD12 Manual Control - - See Note

XRD92 Enhanced Control 4 Pin Cordset 54711

XRDP2 Enhanced Control with ProfiBus 4 Pin, 5 Pin Cordset 54711, 55199

XRDM2 Enhanced Control with ModBus 4 Pin, 5 Pin Cordset 54711, 55199

Power Code Voltage Plug

1 110/240V 110 - 120 VAC 1 Phase US Plug

2 220/240V 220 - 240 VAC 1 Phase US Plug

3 220/240V 220 - 240 VAC 1 Phase DIN Plug

5 220/240V 220 - 240 VAC 1 Phase UK Plug

6 220/240V 220 - 240 VAC 1 Phase Australia / New Zealand Plug

Liquid End Head Seat Balls Check Valve Body Max Turndown Ratio Standard DN15 Conn.

Standard Plastic

A44AC PP TFE/P Ceramic PVDF 1000:1 RPM54771 RPM54772

A44A1 PP TFE/P 316L PVDF 1000:1 RPM54778 RPM54779

A44AT PP TFE/P PTFE PVDF 1000:1 RPM56409 RPM56410

A74TC PVDF PTFE Ceramic PVDF 200:1 RPM54773 RPM54774

A74AT PVDF TFE/P PTFE PVDF 1000:1 RPM56409 RPM56410

Standard Metallic

A1411 316L 316L 316L 316L 1000:1 see below

Slurry

S1414 316L 316L 440C 316L 1000:1 RPM54776

High Viscosity PE Tubing limited to 150 psi (10.3) Bar

V44T1 PP PTFE 316L PP 1000:1 RPM54777

Standard Plastic Diaphragm O-Rings Fittings Connections Tubing Kit RPM Kit

A7T1 PTFE/PVDF TFE/P PVDF Imperial Tube 1 A7PN PTFE/PVDF TFE/P PVDF 1/2” NPT/BSP - A7M2 PTFE/PVDF TFE/P PVDF Metric Tube 2 A2FN PTFE/PVDF TFE/P PVDF/PVC DN 15 Female - see above

A7DN (PVDF heads only) PTFE/PVDF TFE/P PVDF DN 15 Male - see above

Standard Metallic

A1PN PTFE/316L TFE/P 316L 1/2” NPT/BSP - RPM56407

V1PN PTFE/316L FKM 316L 1/2” NPT/BSP - RPM54775

Slurry

V1PN PTFE/316L FKM 316L 1/2” NPT/BSP - High Viscosity

N4T3 PTFE/PVDF - PP Imperial Tube 3 XRD12 1 A44AC A7T1

5.6 GPH (21.2 LPH); 175 psi (12 bar)

RPM Kit

OUTPUT CODE 3

Drive End Note: Cordsets from the accessories table may be required for the customer to connect to desired input/output.

Control Description Cordset Included Part Number

XRD13 Manual Control - - See Note

XRD93 Enhanced Control 4 Pin Cordset 54711

XRDP3 Enhanced Control with ProfiBus 4 Pin, 5 Pin Cordset 54711, 55199

XRDM3 Enhanced Control with ModBus 4 Pin, 5 Pin Cordset 54711, 55199

Power Code Voltage Plug

1 110/240V 110 - 120 VAC 1 Phase US Plug

2 220/240V 220 - 240 VAC 1 Phase US Plug

3 220/240V 220 - 240 VAC 1 Phase DIN Plug

5 220/240V 220 - 240 VAC 1 Phase UK Plug

6 220/240V 220 - 240 VAC 1 Phase Australia / New Zealand Plug

Liquid End Head Seat Balls Check Valve Body Max Turndown Ratio Standard DN15 Conn.

Standard Plastic

A44AC PP TFE/P Ceramic PVDF 1000:1 RPM54771 RPM54772

A44A1 PP TFE/P 316L PVDF 1000:1 RPM54778 RPM54779

A44AT PP TFE/P PTFE PVDF 1000:1 RPM56409 RPM56410

A74TC PVDF PTFE Ceramic PVDF 200:1 RPM54773 RPM54774

A74AT PVDF TFE/P PTFE PVDF 1000:1 RPM56409 RPM56410

Standard Metallic

A1411 316L 316L 316L 316L 1000:1 see below

Slurry

S1414 316L 316L 440C 316L 1000:1 RPM54776

High Viscosity

V44T1 PP PTFE 316L PP 1000:1 RPM54777

Standard Plastic Diaphragm O-Rings Fittings Connections Tubing Kit RPM Kit

A7T1 PTFE/PVDF TFE/P PVDF Imperial Tube 1 A7PN PTFE/PVDF TFE/P PVDF 1/2” NPT/BSP - A7M2 PTFE/PVDF TFE/P PVDF Metric Tube 2 A2FN PTFE/PVDF TFE/P PVDF/PVC DN15 Female - see above

A7DN PVDF heads only PTFE/PVDF TFE/P PVDF DN15 Male - see above

Standard Metallic

A1PN PTFE/316L TFE/P 316L 1/2” NPT/BSP - RPM56407

V1PN PTFE/316L FKM 316L 1/2” NPT/BSP - RPM54775

Slurry

V1PN PTFE/316L FKM 316L 1/2” NPT/BSP - High Viscosity

N4T3 PTFE/PVDF - PP Imperial Tube 3 XRD13 1 A44AC A7T1

14.0 GPH (53.0 LPH); 75 psi (5 bar)

Literature #IR-59261.04 Rev 2/2020

©2018 Milton Roy, LLC. All rights reserved.

RPM Kit

2

Page 3

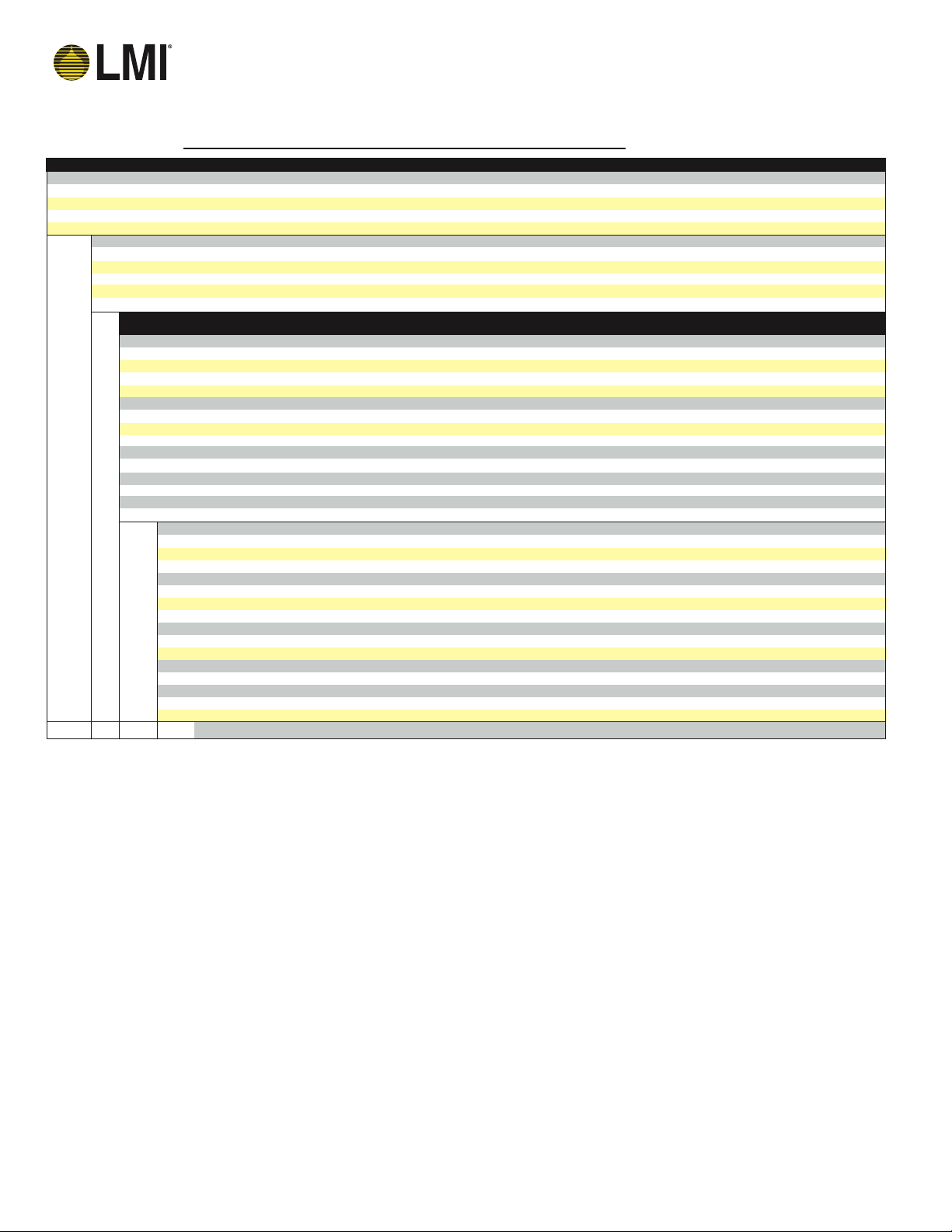

EXCEL® XR Series Code Selection Tables

OUTPUT CODE 4

Drive End Note: Cordsets from the accessories table may be required for the customer to connect to desired input/output.

Control Description Cordset Included Part Number

XRD14 Manual Control - - See Note

XRD94 Enhanced Control 4 Pin Cordset 54711

XRDP4 Enhanced Control with ProfiBus 4 Pin, 5 Pin Cordset 54711, 55199

XRDM4 Enhanced Control with ModBus 4 Pin, 5 Pin Cordset 54711, 55199

Power Code Voltage Plug

1 110/240V 110 - 120 VAC 1 Phase US Plug

2 220/240V 220 - 240 VAC 1 Phase US Plug

3 220/240V 220 - 240 VAC 1 Phase DIN Plug

5 220/240V 220 - 240 VAC 1 Phase UK Plug

6 220/240V 220 - 240 VAC 1 Phase Australia / New Zealand Plug

Liquid End Head Seat Balls Check Valve Body Diaphragm Max Turndown Ratio RPM Kit

Standard PP

A46VC PP FKM Ceramic PP PTFE 500:1 RPM54780

A46V1 PP FKM 316L PP PTFE 500:1 RPM54784

A46AC PP TFE/P Ceramic PP PTFE 500:1 RPM56405

A46A1 PP TFE/P 316L PP PTFE 500:1 RPM56406

Standard PVDF

A76VC PVDF FKM Ceramic PVDF PTFE 500:1 RPM54780

A76AT PVDF TFE/P PTFE PVDF PTFE 500:1 RPM56411

A76AC PVDF TFE/P Ceramic PVDF PTFE 500:1 RPM56405

Standard Metallic

A1611 316L 316L 316L 316L PTFE 1000:1 see below

Slurry

S1614 316L 316L 440C 316L PTFE 1000:1 RPM54783

High Viscosity

V46T1 PVC PTFE 316L PP PTFE 1000:1 RPM54782

Standard PP O-Rings Fittings Connections Tubing Kit RPM Kit

N4PN - PP 1/2” NPT/BSP - N4TN - PP Imperial Tube - N2FN - PP/PVC DN15 Female - Standard PVDF N2FN - PVDF/PVC DN15 Female - N7PN - PVDF 1/2” NPT/BSP - N7TN - PVDF Imperial Tube - Standard Metallic

A1PN TFE/P 316L 1/2” NPT/BSP - RPM56408

V1PN FKM 316L 1/2” NPT/BSP - RPM54781

Slurry

V1PN FKM 316L 1/2” NPT/BSP - High Viscosity

N4P4 - PP 1/2” NPT/BSP 4 N4T4 - PP Imperial Tube 4 -

XRD14 1 A46AC N4PN

18.0 GPH (68.1 LPH); 50 psi (3.5 bar)

Literature #IR-59261.04 Rev 2/2020

©2018 Milton Roy, LLC. All rights reserved.

3

Page 4

EXCEL® XR Series Code Selection Tables

OUTPUT CODE 2

Drive End Note: Cordsets from the accessories table may be required for the customer to connect to desired input/output.

Control Description Cordset Included Part Number

XRE12 Manual Control - - See Note

XRE92 Enhanced Control 4 Pin Cordset 54711

XREP2 Enhanced Control with ProfiBus 4 Pin, 5 Pin Cordset 54711, 55199

XREM2 Enhanced Control with ModBus 4 Pin, 5 Pin Cordset 54711, 55199

Power Code Voltage Plug

1 110/240V 110 - 120 VAC 1 Phase US Plug

2 220/240V 220 - 240 VAC 1 Phase US Plug

3 220/240V 220 - 240 VAC 1 Phase DIN Plug

5 220/240V 220 - 240 VAC 1 Phase UK Plug

6 220/240V 220 - 240 VAC 1 Phase Australia / New Zealand Plug

Liquid End Head Seat Balls Check Valve Body Max Turndown Ratio Standard DN15 Conn.

Standard Plastic

A44A1 PP TFE/P 316L PVDF 1000:1 RPM54778 RPM54779

A44AC PP TFE/P Ceramic PVDF 1000:1 RPM54771 RPM54772

A44AT PP TFE/P PTFE PVDF 1000:1 RPM56409 RPM56410

A74AT PVDF TFE/P PTFE PVDF 1000:1 RPM56419 RPM56410

A74TC PVDF PTFE Ceramic PVDF 200:1 RPM54773 RPM54774

Standard Metallic

A1411 316L 316L 316L 316L 1000:1 see below

Slurry

S1414 316L 316L 440C 316L 1000:1 see below

High Viscosity

V44T1 PP PTFE 316L PP 1000:1 see below

Standard Plastic Diaphragm O-Rings Fittings Connections Tubing Kit RPM Kit

A2FN PTFE/PVDF TFE/P PVDF/PVC DN 15 Female - A7M2 PTFE/PVDF TFE/P PVDF Metric Tube 2 A7PN PTFE/PVDF TFE/P PVDF 1/2” NPT/BSP - A7T1 PTFE/PVDF TFE/P PVDF Imperial Tube 1 A7DN (PVDF heads only) PTFE/PVDF TFE/P PVDF DN 15 Male - -

Standard Metallic

A1PN PTFE/316L TFE/P 316L 1/2” FNPT - RPM56407

V1PN PTFE/316L FKM 316L 1/2” FNPT - RPM54775

Slurry

V1PN PTFE/316L FKM 316L 1/2” FNPT - RPM54776

High Viscosity

N4T3 PTFE/PVDF - PP Imperial Tube 3 RPM54777

XRE12 1 A44AC A7T1

16 GPH (60.6 LPH); 150 psi (10.3 bar)

RPM Kit

OUTPUT CODE 3

Drive End Note: Cordsets from the accessories table may be required for the customer to connect to desired input/output.

Control Description Cordset Included Part Number

XRE13 Manual Control - - See Note

XRE93 Enhanced Control 4 Pin Cordset 54711

XREP3 Enhanced Control with ProfiBus 4 Pin, 5 Pin Cordset 54711, 55199

XREM3 Enhanced Control with ModBus 4 Pin, 5 Pin Cordset 54711, 55199

Power Code Voltage Plug

1 110/120V 110 - 120 VAC 1 Phase US Plug

2 220/240V 220 - 240 VAC 1 Phase US Plug

3 220/240V 220 - 240 VAC 1 Phase DIN Plug

5 220/240V 220 - 240 VAC 1 Phase UK Plug

6 220/240V 220 - 240 VAC 1 Phase Australia / New Zealand Plug

Liquid End Head Seat Balls Check Valve Body Max Turndown Ratio

Standard PP

A46A1 PP TFE/P 316L PP 500:1 RPM56406

A46AC PP TFE/P Ceramic PP 500:1 RPM56405

A46V1 PP FKM 316L PP 500:1 RPM54784

A46VC PP FKM Ceramic PP 500:1 RPM54780

Standard PVDF

A76AC PVDF TFE/P Ceramic PVDF 500:1 RPM56405

A76AT PVDF TFE/P PTFE PVDF 500:1 RPM56411

A76VC PVDF FKM Ceramic PVDF 500:1 RPM54780

Standard Metallic

A1611 316L 316L 316L 316L 1000:1 see below

Slurry

S1614 316L 316L 440C 316L 1000:1 RPM54783

High Viscosity

V46T1 PP PTFE 316L PP 1000:1 RPM54782

Standard PP Diaphragm O-Rings Fittings Connections Tubing Kit RPM Kit

N4PN PTFE - PP 1/2” MNPT - N2FN PTFE - PP/PVC DN15 Female - -

Standard PVDF

N2FN PTFE - PP/PVC DN15 Female - -

N7PN PTFE - PVDF 1/2” MNPT - Standard Metallic

A1PN PTFE TFE/P 316L 1/2” FNPT - RPM56408

V1PN PTFE FKM 316L 1/2” FNPT - RPM54781

Slurry

V1PN PTFE FKM 316L 1/2” FNPT - -

High Viscosity

N4P4 PTFE - PP 1/2” MNPT 4 XRE13 1 A46VC N4PN

32 GPH (121.1 LPH); 100 psi (6.9 bar)

Literature #IR-59261.04 Rev 2/2020

©2018 Milton Roy, LLC. All rights reserved.

RPM Kit

4

Page 5

OUTPUT CODE 4

Drive End Note: Cordsets from the accessories table may be required for the customer to connect to desired input/output.

Control Description Cordset Included Part Number

XRE14 Manual Control - - See Note

XRE94 Enhanced Control 4 Pin Cordset 54711

XREP4 Enhanced Control with ProfiBus 4 Pin, 5 Pin Cordset 54711, 55199

XREM4 Enhanced Control with ModBus 4 Pin, 5 Pin Cordset 54711, 55199

Power Code Voltage Plug

1 110/120V 110 - 120 VAC 1 Phase US Plug

2 220/240V 220 - 240 VAC 1 Phase US Plug

3 220/240V 220 - 240 VAC 1 Phase DIN Plug

5 220/240V 220 - 240 VAC 1 Phase UK Plug

6 220/240V 220 - 240 VAC 1 Phase Australia / New Zealand Plug

Liquid End Head Seat Balls Check Valve Body Max Turndown Ratio RPM Kit

Standard PP

A46A1 PP TFE/P 316L PVDF 500:1 RPM56406

A46AC PP TFE/P Ceramic PVDF 500:1 RPM56405

A46V1 PP FKM 316L PVDF 500:1 RPM54784

A46VC PP FKM Ceramic PVDF 500:1 RPM54780

Standard PVDF

A76AC PVDF TFE/P Ceramic PVDF 500:1 RPM56405

A76AT PVDF TFE/P PTFE PVDF 500:1 RPM56411

A76VC PVDF FKM Ceramic PVDF 500:1 RPM54780

Standard Metallic

A1611 316L 316L 316L 316L 1000:1 see below

Slurry

S1614 316L 316L 440C 316L 1000:1 RPM54783

High Viscosity

V46T1 PP PTFE 316L PP 1000:1 RPM54782

Standard PP Diaphragm O-Rings Fittings Connections Tubing Kit RPM Kit

N7NN PTFE - PVDF 3/4” MNPT - N2GN PTFE - PVDF/PVC DN20 Female - Standard PVDF

N7NN PTFE - PVDF 3/4” MNPT - N2GN PTFE - PVDF/PVC DN20 Female - Standard Metallic

A1NN PTFE TFE/P 316L 3/4” MNPT - RPM56408

V1NN PTFE FKM 316L 3/4” MNPT - RPM54781

Slurry

V1NN PTFE FKM 316L 3/4” MNPT - High Viscosity

N4N5 PTFE - PP 3/4” MNPT 5 -

XRE14 1 A46VC N7NN

53 GPH (200.6 LPH); 60 psi (4.1 bar)

Tubing Kits (included in select pump configurations)

Tubing Kit 1

• Injection Valve

• Foot Valve

• 1 Weight (Suction Tubing)

• 16’ PE Tube 3/8”

• 20” Reinforced PVC Hose 1/4” x 1/2”

Tubing Kit 2

• Injection Valve

• Foot Valve

• 1 Weight (Suction Tubing)

• Metric Ferrules 6x12mm

• 6m Reinforced PVC Hose 6x12mm

Tubing Kit 3

• Injection Valve

• 2m Reinforced PVC hose 15x23mm

(Suction)

• 3m PE Tube 1/2” (Discharge)

• 1 Suction hose fitting (1/2” FNPT x

15x23 hose) & 2 hose clamps

Output Code XRDx2, XRDx3, XREx2

Imperial Connections Metric Connections

Part Number Description Part Number Description

58982 Injection Valve, PTFE 58982 Injection Valve, PTFE

58987 Foot Valve, Mixed 58987 Foot Valve, Mixed

59008 Connection Kit, 0.375 and 0.25 x 0.5 59009 Connection Kit, 6x12

Tubing Kit, includes: Tubing Kit, includes:

10342-10 3/8” TUBE x 10 FT 36181-6M 8mm TUBE X 6m

54342-20 1/4” x 1/2” HOSE x 20 FT 70121-6M 6x12mm HOSE X 6m

58983 Injection Valve, Mixed 58983 Injection Valve, Mixed

58985 Foot Valve, Aflas 58985 Foot Valve, Aflas

59008 Connection Kit, 0.375 and 0.25 x 0.5 59009 Connection Kit, 6x12

Tubing Kit, includes: Tubing Kit, includes:

10342-10 3/8” TUBE X 10 FT 36181-6M 8mm TUBE X 6m

54342-20 1/4” x 1/2” HOSE x 20 FT 70121-6M 6x12mm HOSE X 6m

58983 Injection Valve, Mixed 58983 Injection Valve, Mixed

58986 Foot Valve, PTFE 58986 Foot Valve, PTFE

59008 Connection Kit, 0.375 and 0.25 x 0.5 59009 Connection Kit, 6x12

Tubing Kit, includes: Tubing Kit, includes:

10342-10 3/8” TUBE X 10 FT 36181-6M 8mm TUBE X 6m

54342-20 1/4” x 1/2” HOSE x 20 FT 70121-6M 6x12mm HOSE X 6m

High Viscosity

58984 Injection Valve, HV

59010 Connection Kit, Hose Clamp

59013 Tubing Kit, HV

Literature #IR-59261.04 Rev 2/2020

©2018 Milton Roy, LLC. All rights reserved.

PP Head, 316 SS Balls

PP Head, Ceramic Balls

PVDF Head, Ceramic Balls

Tubing Kit 4

• 2m Reinforced PVC hose 15x23mm

(Suction)

• 1 Suction hose fitting (1/2” FNPT x

15x23 hose) & 2 hose clamps

Tubing Kit 5

• 6.5ft Reinforced PVC hose 0.75”

x 1.031” (Suction)

• 1 Suction hose fitting (3/4” MNPT x

0.75” x 1.031” hose) & 2 hose clamps

Output Code XRDx4 (all kits), XREx3 (NPT Connections only)

Imperial Connections Metric Connections

Part No Description Part No Description

PP Head

26758 Injection Valve, 0.5” Tube, PP, PTFE, Cer 26710 Injection Valve, NPT, PP, PTFE, Cer

25154 Foot Valve, 0.5” Tube, PP, PTFE, Cer 26015 Foot Valve, NPT, PP, PTFE, Cer

77384 Connection Kit, 0.5” Tubing

PVDF Head

33481 Injec. Valve, 0.5” Tube, PVDF, PTFE, Cer 38270 Injec. Valve, NPT, PVDF, PTFE, Cer

33480 Foot Valve, 0.5” Tube, PVDF, PTFE, Cer 38271 Foot Valve, NPT, PVDF, PTFE, Cer

77384 Connection Kit, 0.5” Tubing

High Viscocity

56912 Inject. Valve 0.5” MNPT, PVDF, PTFE, Cer

Input/Output Cordsets

Part No. Description Application Notes

48414 CORDSET, 5 PIN, 2 M / 6.6 FT (J2) Digital output

49035 CORDSET, 6 PIN, 2 M / 6.6 FT (J1 & J4) Digital input & Analog output

54711 CORDSET, 4 PIN, 2 M / 6.6 FT (J3) Analog input

55199 CORDSET, 5 PIN, 2 M / 6.6 FT (C) ProfiBus/ModBus Communicaton

Extension Cable Assembles - 5 Pin

Part No. Description

50503-6 Extension Cable, 6 M / 19.7 Ft

50503-15 Extension Cable, 15 M / 49.2 Ft

Extension Cable Assembles - 6 Pin

Part No. Description

50684-6 Extension Cable, 6 M / 19.7 Ft

50684-30 Extension Cable, 30 M / 98.4 Ft

5

Page 6

Electronic control by model

Control Version Control Version

Manual model

Enhanced model

User Interface

Four Color Backlit graphical display

Flow rate or volume display (GPH, L/hr)

Capacity setting display

Start/Stop button

Mode/Select button

Full capacity (100%) button

Prime button

Active operation mode indication on display

Active alarm indication on display

Calibration status indication on display

Operation Modes

Manual (Internal)

Analog [0/4-20 mA] (External)

Pulse [volume/pulse] (External)

Batch (External)

Cycle Timer (Internal)

Timed event (Internal)

Control Input

Programmable digital contacts

User 1

User 2

User 3

Single level float switch

Dual low level float switch

Pulse control

Remote start/stop

Remote internal/external mode selection

Programmable analog inputs

Pacing

Tank level

Control Protocol

Modbus RTU*

Profibus DP*

* Must order pump configured for your control protocol

(See section table).

Literature #IR-59261.04 Rev 2/2020

©2018 Milton Roy, LLC. All rights reserved.

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• •

• •

• •

• •

• •

1 4 4

• •

• •

• •

• • •

• •

• •

• • •

• •

0 2 2

• •

• •

•

•

Model Selection Guide

Communications model

Control Output

Programmable digital contacts

Pump running

Pump standby/stopped [not pumping but ready]

Alarm status

User alarm status

Internal/External mode indication

Pump stopped

Stroke pulse

Timed event running

Programmable analog output

Flow rate [4-20 mA correlates to 0 - max capacity]

Mirror analog input 1

Mirror analog input 2

Power supply for remote device [24V] (eg. Flow sensor)

Operation functions

Capacity control by motor speed variation

Variable stroke profile (variable discharge speed/constant suction speed)

Slow suction mode for viscous or degassing media

Calibration function (single point)

Prime feature (max capacity) button, timer

Totalizer (strokes, volume, hours motor operation, number of power cycles)

Keypad lock (software driven with password)

Clock feature (date and 12 hour time)

Diaphragm replacement mode (sets stroke to extended position)

Display firmware revision

Load factory defaults

Battery to maintain date and time settings when main power is removed

EEPROM nonvolatile memory (configurations saved/powers up in last used mode)

Internal/External input control mode configuration

Alarm output mask configuration (configure which events trigger alarm output relay)

Analog input response curve customization

Input pulse width setting

Start/Stop via remote signal

Pump switch off on tank empty

Modus RTU / Profibus DP protocol

StayPrime Degassing Technology

Alarm Log

Manual model

Enhanced model

Communications model

0 2 2

• •

• •

• •

• •

• •

• •

• •

• •

0 1 1

• •

• •

• •

0 1 1

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• •

• •

• • •

• • •

•

• • •

• • •

6

Page 7

Drive Sizes: XRDx2x, XREx2x & XRDx3x

Drive Size: XRDx4x, XREx3x & XREx4x

Literature #IR-59261.04 Rev 2/2020

©2018 Milton Roy, LLC. All rights reserved.

Mounting Information

(All drive sizes)

DRIVE LIQUID END

“TUBE CONNECTIONS:

CODE A44, A74”

“DN PIPE CONNECTIONS:

XRDx2x

CODE A44, A74”

XRDx3x

“STAINLESS HEAD AND SLURRY HEAD:

XREx2x

CODE A14, S14”

“HIGH VISCOSITY HEAD:

CODE V44”

“NPT CONNECTIONS:

CODE A46, A76”

“TUBE CONNECTIONS:

CODE A46, A76”

“DN PIPE CONNECTIONS:

XRDx4x

CODE A46, A76”

XREx3x

“STAINLESS HEAD AND SLURRY HEAD:

XREx4x

CODE A16, S16”

“HIGH VISCOSITY HEAD (NPT DISCHARGE):

CODE V46”

“HIGH VISCOSITY HEAD (TUBE DISCHARGE):

CODE V46”

A B C D

INCH [mm] INCH [mm] INCH [mm] INCH [mm]

1.44 36.7 2.03 51.7 4.09 103.9 7.25 184.2

1.44 36.7 2.00 50.7 2.45 62.2 10.54 267.7

1.38 35.0 2.01 51.0 3.70 94.0 8.03 204.0

1.61 40.8 2.30 58.3 4.32 109.8 7.63 193.7

2.33 59.3 2.96 75.3 3.45 87.6 8.58 218.0

2.33 59.3 2.96 75.3 2.82 71.6 9.84 250.0

2.33 59.3 3.13 79.5 2.05 52.1 11.38 289.0

2.42 61.4 3.28 83.4 2.98 75.6 9.49 241.0

2.33 59.3 2.95 74.9 3.73 94.8 8.30 210.8

2.33 59.3 2.95 74.9 3.73 94.8 8.93 226.8

Note: Tube connections A46 and A76 aren’t available on XRE, neither is the V46

high viscosity tube option.

7

Page 8

LMI® is a brand of Ingersoll Rand.

Contact your local representative to find out more about EXCEL® XR

the intelligent pump that’s making a name for itself.

www.lmipumps.com

www.excelxrpumps.com

EXCEL® is a registered trademark of Milton Roy, LLC

©2018 Milton Roy, LLC. All rights reserved.

Literature #IR-59261.04 Rev 2/2020

8

Loading...

Loading...