M I L - R A M T E C H N O L O G Y

TA-2102

Two Wire Loop Powered

smarter Transmitter

Instruction Manual

Detection Range:

Operating Voltage: 10-30 VDC

Arsine, AsH3 Tungsten Hexafluoride, WF

Phosphine, PH3 Tetrachlorosilane, SiCl4

Diborane, B2H

Hydrazine, N

Silane, SiH

4

6

2H4

Many More Gases

Ammonia, NH3

Boron Trichloride, BCl

Bromine, Br2

Carbon Monoxide, CO

Chlorine, Cl2

Chlorine Dioxide, ClO2

Dichlorosilane, SiH2Cl

Fluorine, F2

Hydrogen Bromide, HBr

Hydrogen Chloride, HCl

Hydrogen Cyanide, HCN

Hydrogen Fluoride, HF

Hydrogen Iodide, HI

Hydrogen Peroxide, H

Hydrogen Sulfide, H

Nitric Acid Vapors, HNO3

Nitrogen Dioxide, NO

Oxygen, O

Ozone, O

Sulfur Dioxide

Silicon Tetrafluoride, SiF

Sulfur Dioxide, SO2

Sulfuric Acid Vapors, H

6

2

3

5423 Central Avenue Suite 1

Mil-Ram Technology, Inc.

2

S

2

3

2

2O2

2SO4

4

no false alarms

Newark, CA 94560

Ph (510) 818-0200

Fax (510) 818-0300

Web: www.mil-ram.com

Table of Contents

I. Description ............................................................................... 1

II. Smarter Features ..................................................................... 1

III. Installation ............................................................................... 2

IV. Transmitter Wiring ................................................................ 4

V. Transmitter Operation........................................................... 5

A. Main Information Mode.................................................... 6

B. Loop Test............................................................................. 9

VI. Diagnostic Messages............................................................. 11

VII. Rain/Splash/RF Shield (optional)....................................... 12

IIX. Sensor Calibration ............................................................... 13

A. Zero Calibration ............................................................ 14

B. Span Calibration ............................................................ 15

IX. Off-Site Sensor Calibration................................................ 16

X. Self-Calibration .................................................................... 17

XI. Remaining Sensor Life........................................................ 17

Installation Drawings

Warranty

I. Description:

The model TA-2102 smarter Transmitter provides remote detection of a specific toxic gas

using Mil-Ram’s patented no false alarms electrochemical sensor technology. The

transmitter is two-wire loop powered and transmits a standard 4-20mA signal. The smarter

transmitter operates on 10-30 VDC.

II. Smarter Features:

• 2-Wire Loop Powered – operates on 10-30 VDC and generates a standard 4-20mA

signal

• Self-Calibration – unattended span calibration adjustments performed every 30 days

based on life curve for sensor

• Auto-Calibration – non-intrusive calibrations using a magnet to activate zero and span

switches located behind glass window of explosion-proof junction box – no mechanical

adjustments required

• LCD Display – 12 character x 2 line display provides meter readings, calculated values

and diagnostic messages

• Life Remaining – sensor life remaining based on calibration history, life curve for sensor

and electrical characteristics of sensor

• Peak Value/15-min. TWA/Number of days since last gas calibration—Transmitter

displays this information on demand

• Loop Test – Output 4/8/12/16/20mA to verify readings and alarms at controller

electronics

• Calibration Mode Alarm Inhibit – during span calibration and for a period of 5 minutes

after calibration, the transmitter outputs 4.0mA

• Diagnostics – continuous diagnostics related to both hardware and software operation

with auto reset of micro-controller in the event of software failure – provide messages

including Replace Sensor, Remaining Sensor Life and Sensor Disconnected

2-Wire Toxic Smarter Transmitter

22May2002 Page 1

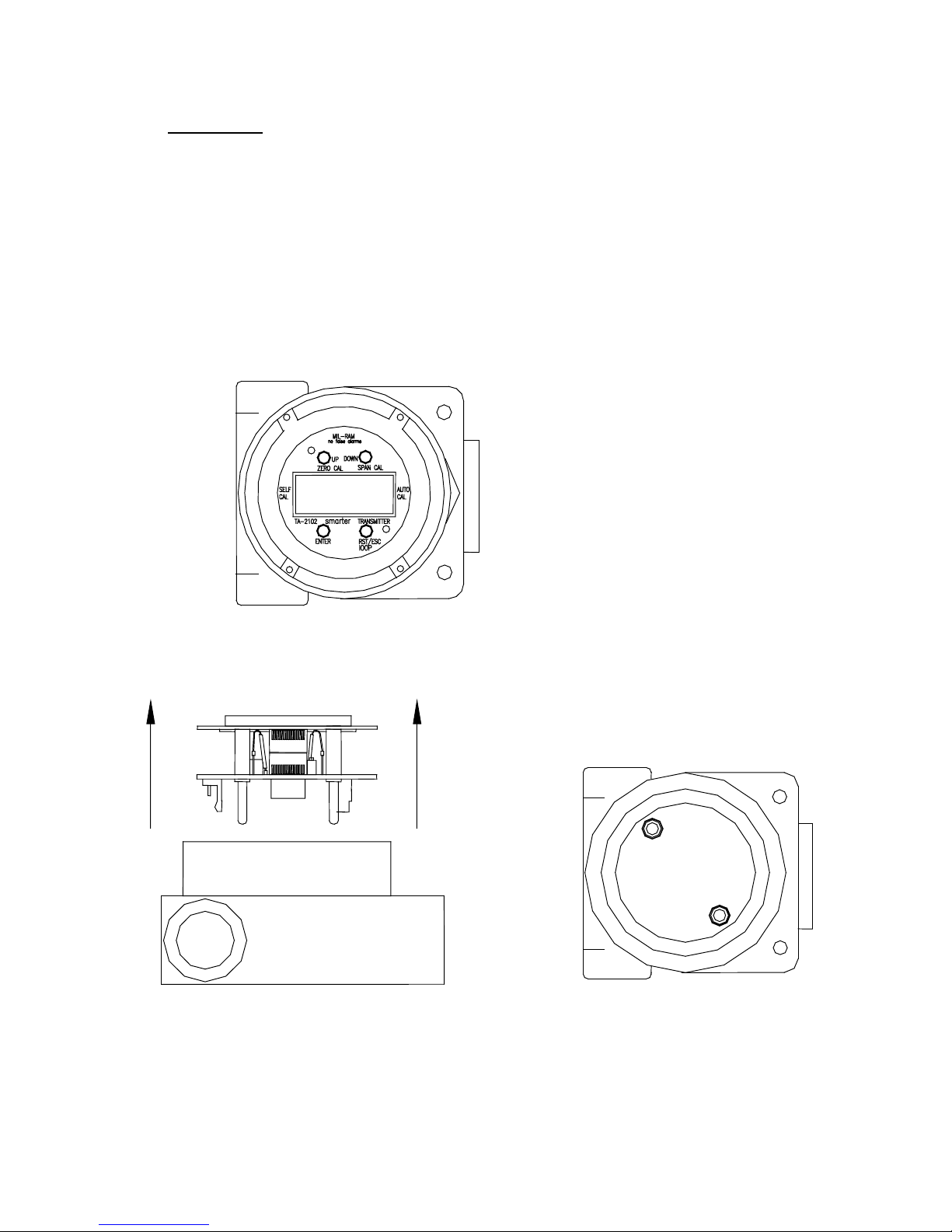

III. Installation:

The sensor is provided with ¾’ NPT external threads opposite the sensing end of the device.

The sensor screws into an explosion-proof junction box which houses the smarter

electronics. The sensor/smarter electronics/junction box assembly constitutes the

transmitter.

Install transmitter as follows:

1. Unscrew cover (with glass window) from junction box.

Junction Box with cover/glass

window removed

Removal of LCD display/main circuit

board assembly from junction box

22May2002 Page 2

Junction box with banana

sockets

2. Remove LCD display/main circuit board assembly by pulling up on face plate at two

locations marked PULL (banana jacks secure the assembly in the junction box).

Carefully lift assembly from junction box.

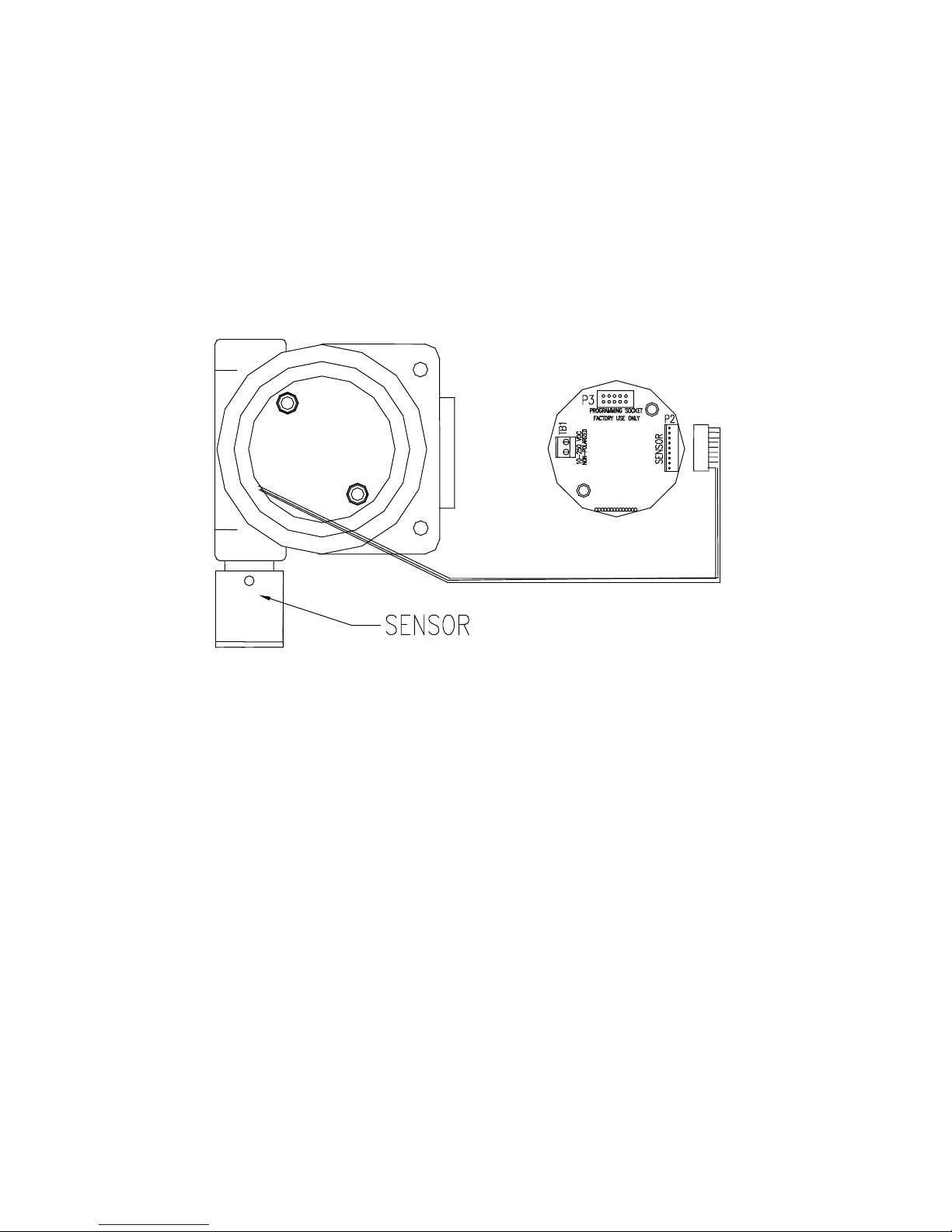

3. Carefully guide brown sensor cable connector through opening in bottom of junction

box. Screw sensor into junction box hand tight. Attach sensor connector to bottom of

main circuit board at 9-pin brown connector marked SENSOR. Seat the sensor

connector fully to lock in place.

4. Install LCD display/main circuit board assembly in junction box by carefully aligning

banana plugs on bottom of main circuit board with sockets in junction box. Gently push

(directly above face-plate screws) until banana plugs seat fully in sockets.

5. Replace cover on junction box.

6. Mount junction box to a vertical surface with the perforated end of the sensor

pointing downward.

Note: It is generally recommended that the sensor be installed at a location as close as

possible to the source of gas.

22May2002 Page 3

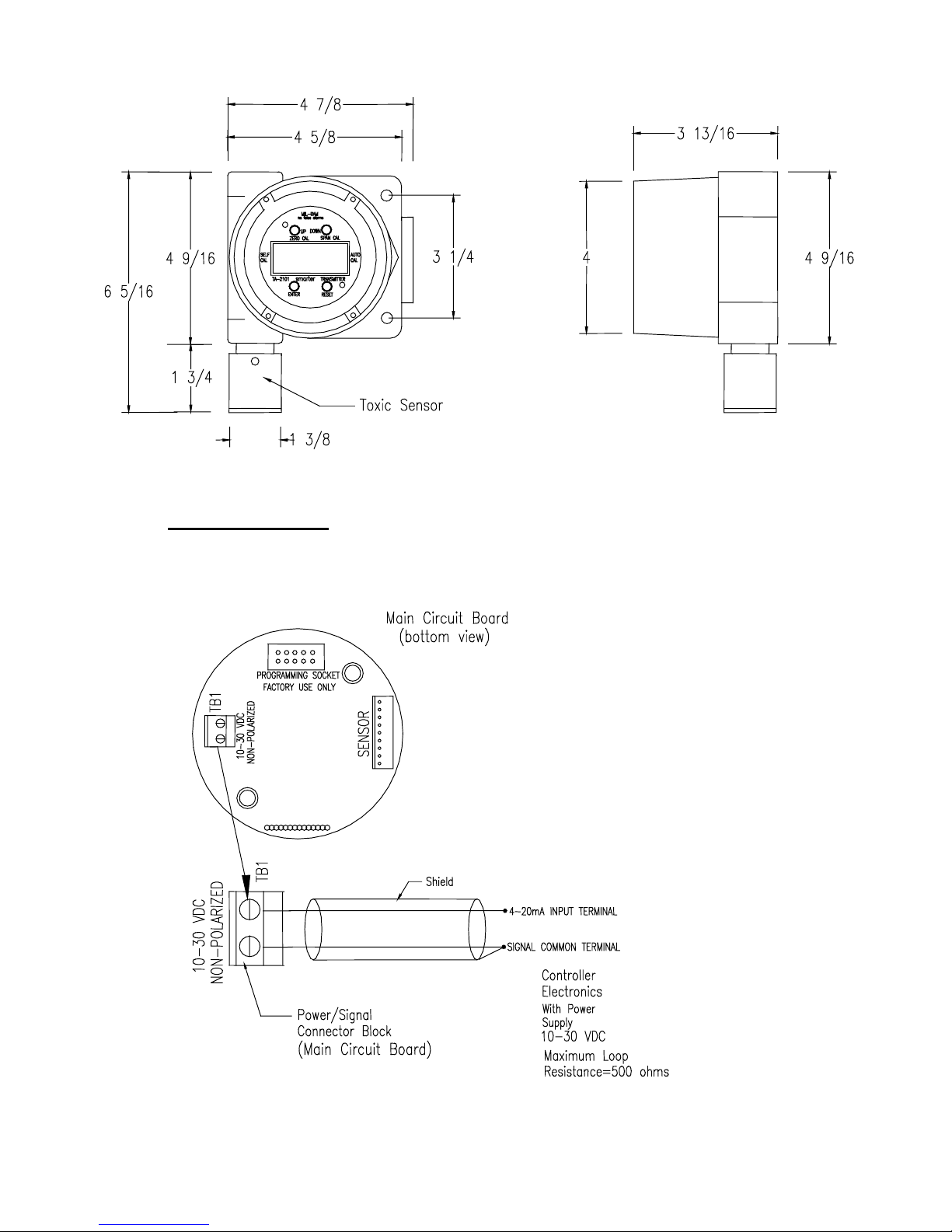

IV. Transmitter Wiring:

The smarter transmitter is 2-wire loop powered and operates on 10-30 VDC. Make

connections as follows:

22May2002 Page 4

Run two wires from the controller 4-20mA Input and signal common to the power/signal

terminals located on the bottom of the main circuit board. The power/signal terminals are

non-polarized.

NOTE: The two power/signal wires must be isolated from other wires and should therefore

be shielded or run in metal conduit to avoid electrical pick-up. If a shield is used it

should run continuously from the controller electronics to the inside of the

transmitter junction box. The shield should be terminated at the controller signal

common but left floating (do not attach to anything) inside the transmitter junction

box to avoid ground loop interference. Apply electrical tape to exposed shield

inside junction box.

The smarter transmitter can be located up to several thousand feet (max. total loop

resistance = 500 ohms) from the controller electronics using 18 AWG standard copper wire.

V. Transmitter Operation:

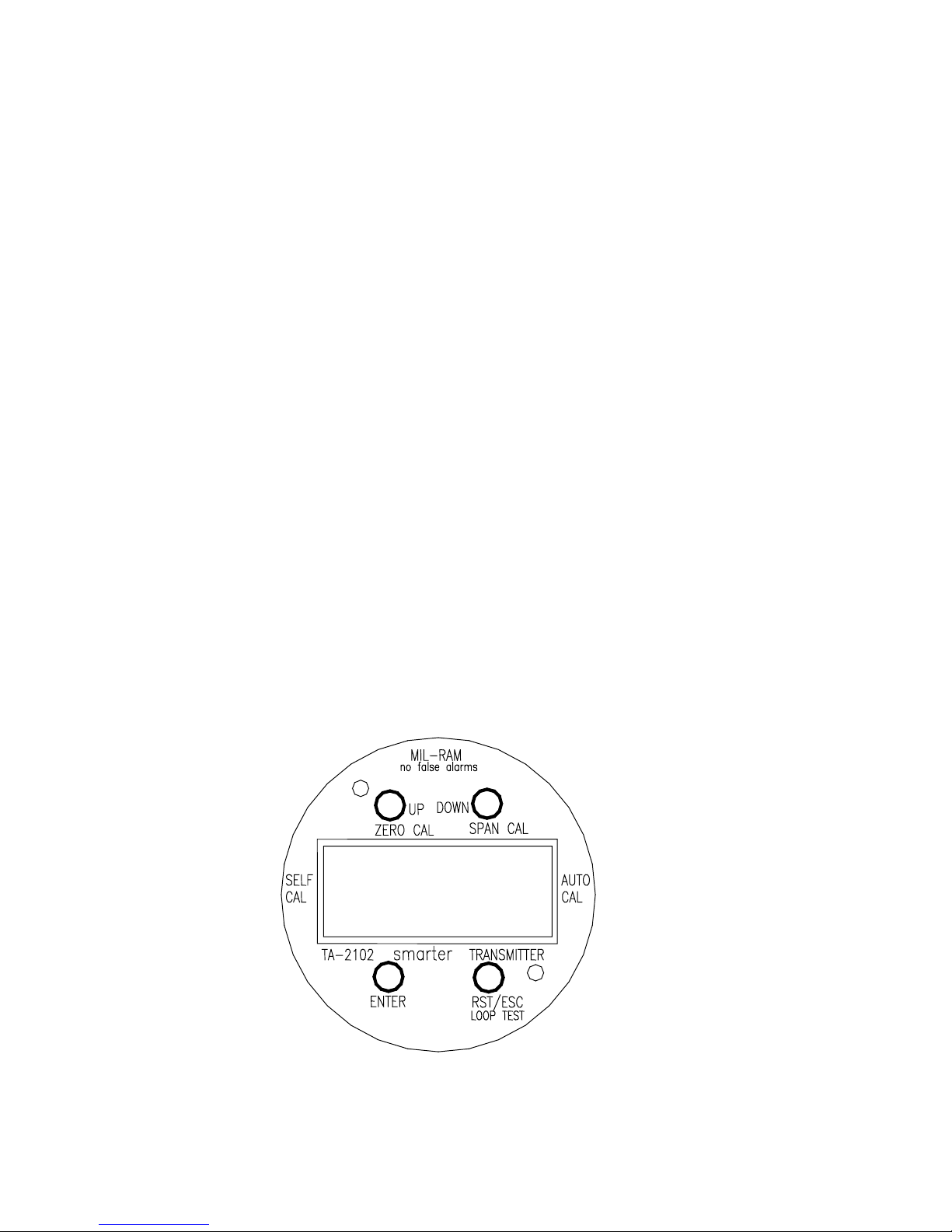

The smarter transmitter provides four magnetic switches to access information, test the

loop and calibrate the toxic sensor. The switches are activated using a magnet held directly

over the switch outside the junction box glass window.

22May2002 Page 5

The switches are designated as follows:

ENTER: A magnetic switch used to enter the main Information Routine to view

Peak Value, Remaining Sensor Life, 15-Min. TWA (Time Weighted

Average) and Ambient Temperature (degrees C). ENTER switch is also

used to escape Loop Test in progress.

UP: A magnetic switch used to enter Zero Calibration mode and increment

span calibration gas concentration. The UP switch is also used to proceed

with the Loop Test.

DOWN: A magnetic switch used to enter Span Calibration mode and decrement

span calibration gas concentration. The DOWN switch is also used to exit

Loop Test before generating any output.

RESET: A magnetic switch used to reset Peak Value and escape Span Calibration

mode without performing calibration.

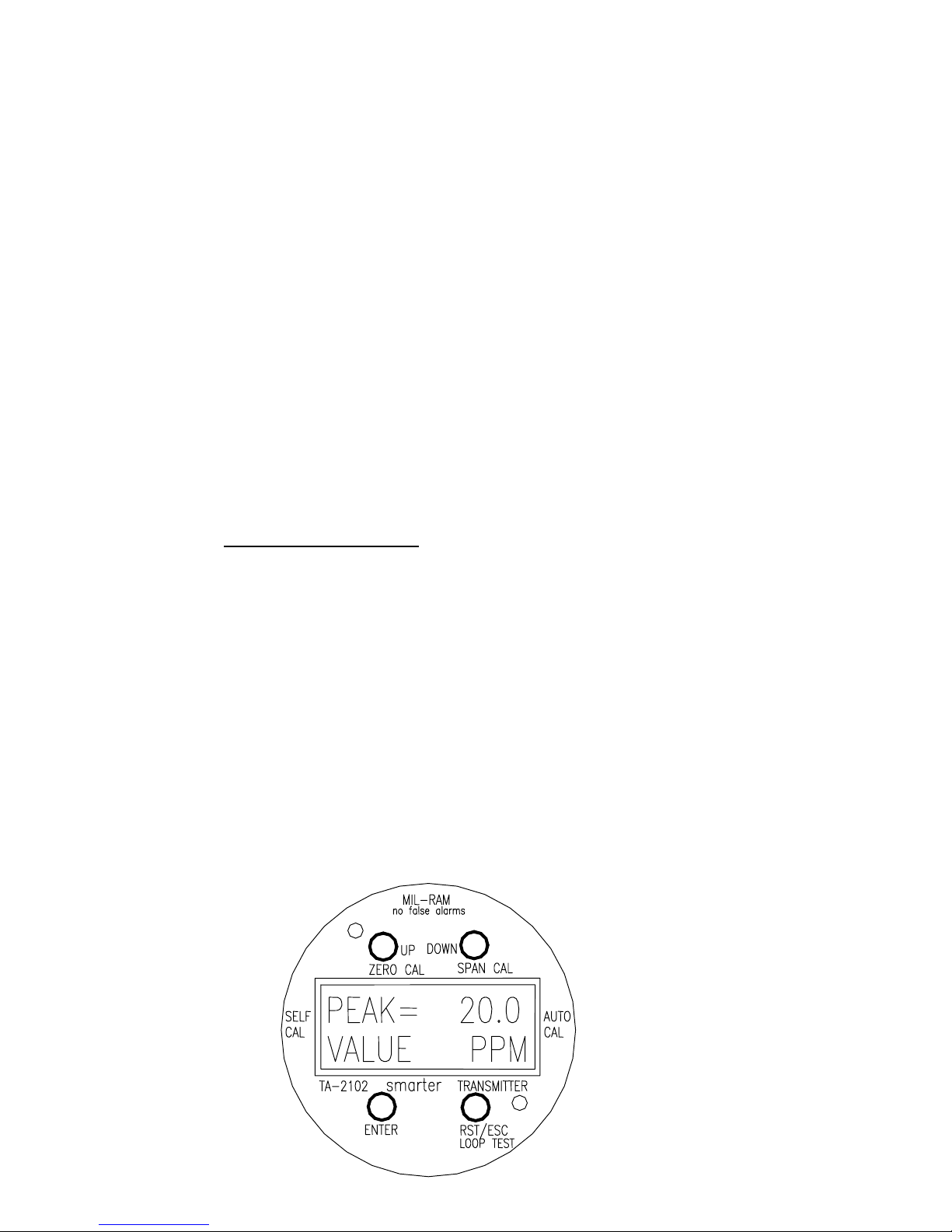

A. Main Information Mode:

The smarter transmitter displays the following parameters when the Information Mode is

entered:

• Peak Value

• Remaining Sensor Life

• 15-Min. TWA (time weighted average)

• Ambient Temperature (degrees C)

Upon entering the Information Mode the LCD display will automatically sequence through

the parameters.

To enter Information Mode, momentarily hold magnet directly over ENTER

switch until LCD display shows the Peak Value

22May2002 Page 6

Note: While Peak Value is displayed, the value can be reset by momentarily holding magnet

directly over RESET switch. A successful reset provides the following message on the

LCD display

Following Peak Value the LCD will automatically proceed to Remaining Sensor

Life

22May2002 Page 7

Next, the LCD will proceed to 15-Min. TWA (Time Weighted Average)

Next, the LCD will proceed to Ambient Temperature

After approximately 5 sec. LCD display will return to normal operating mode to

provide gas readings

22May2002 Page 8

B. Loop Test

The smarter transmitter provides a built-in loop test whereby the transmitter outputs

4/8/12/16/20 mA on demand. The generated output signal can be used to verify

readings/alarms at the Controller electronics and loop integrity.

To enter loop test, hold magnet directly over RESET switch until LCD display

shows

22May2002 Page 9

To escape loop test without generating any output, hold magnet directly over DOWN

switch until LCD display returns to normal operating mode

To proceed with loop test, hold magnet directly over UP switch until LCD display

shows

To increment Signal Output, hold magnet directly over UP switch until LCD

Increments Output Value. When Output reaches 20 mA the next increment will

roll-over to 4 mA.

22May2002

Page 10

To decrement Signal Output, hold magnet directly over DOWN switch until LCD

display decrements Output Value. When Output reaches 4 mA the next decrement

will roll-over to 20 mA.

To exit LOOP TEST, hold magnet directly over ENTER switch to return to normal

operating mode.

VI. Diagnostic Messages:

The LCD display provides the following fault messages during normal operation

Sensor cannot be calibrated—Requires

immediate replacement

Sensor has been disconnected from main

circuit board—transmitter outputs

2.4mA— install sensor as described in

Section III, steps 1-6, above

Relay Definitions:

The 2-Wire smarter Transmitter does not provide local relay outputs. However, external

relays are often used at the controller electronics to provide appropriate alarms at pre-set

alarm points. The following definitions are provided for general information.

Non-latching: when alarm set point is reached and exceeded, relay is activated (open

contacts close and closed contacts open). When gas concentration falls

22May2002 Page 11

below alarm set point, relay automatically resets to original state.

Latching: when alarm set point is reached and exceeded, relay is activated (i.e. open

contacts close and closed contacts open). When gas concentration falls

below alarm set point, relay does not reset to original state. The relay

must be manually reset using a switch.

Energized: Power is normally applied to relay such that normally open contacts are

closed and normally closed contacts are open. When the alarm set point is

reached or exceeded, the relay changes to the power down state.

Non- Energized: Power is normally not applied to relay such that normally open contacts are

open and normally closed contacts are closed. When alarm set point is

reached or exceeded, the relay changes state.

VII. Rain/Splash/RF Shield (Optional)

A black anodized aluminum shield offers protection to the sensor from rain, splashing,

radio frequency (RF) and mechanical shock.

The upper portion of the housing is provided with internal and external 3/4” NPT threads.

The external threads screw into the explosion-proof junction box which houses the

remote amplifier. The sensor screws into the 3/4” NPT internal threads.

The lower portion of the housing consists of a cylinder with bottom plate; the housing is

perforated to allow gas entry. The cylinder is secured to the upper housing with four set

screws.

Install the shield as follows:

1. Screw upper portion of housing into junction box.

2. Carefully guide brown sensor cable connector through housing

into junction box. Screw sensor into housing hand tight. Attach

sensor connector to bottom of main circuit board at connector

marked SENSOR. Seat the sensor connector fully to lock in place.

22May2002

Page 12

3. Position lower portion of housing (cylinder) around sensor. Push

upper edge of cylinder over upper housing. Tighten four set screws

to secure cylinder.

VIII. SENSOR CALIBRATION:

NOTE: A routine program of calibration should be employed to ensure proper

operation/performance of the sensor and system. Although the sensors are normally

quite stable, it is generally recommended that calibration be performed monthly in

the interest of safety.

Sensor calibration is performed at the smarter transmitter using a gas sample of known

concentration. To calibrate the sensor, follow the steps outlined below.

NOTE: The sensors are factory calibrated with gas prior to delivery. Field calibrations

must be performed with an appropriated gas sample of known concentration.

22May2002 Page 13

A. Zero Calibration:

1. In clean gas-free air, momentarily hold magnet over ZERO CAL switch until LCD

display shows

When zero calibration is complete, the transmitter will return to normal operation to

provide meter readings.

Note: If ambient air is not known to be gas-free, apply zero air (cylinder) using calibration

Cup

22May2002 Page 14

B. Span Calibration:

1. Momentarily hold magnet over SPAN CAL switch until LCD display shows

Note: To exit span calibration mode without performing calibration, momentarily hold

Magnet directly overt RESET switch.

2. Momentarily hold magnet directly over UP or Down switch to increment or

decrement calibration gas concentration. When proper gas concentration is

displayed, hold magnet directly over ENTER switch to advance to next display

22May2002 Page 15

3. Apply span calibration gas of exact concentration shown on LCD display using

calibration cup.

4. When span calibration is complete, the transmitter will return to normal operation to

provide meter readings. Note: during span calibration and for a period of 5 minutes

after calibration, the smarter transmitter outputs 4.0mA to prevent activation of

alarms at the controller electronics.

5. Remove calibration cup and allow sensor to recover. LCD display will show recovery of sensor to zero.

22May2002 Page 16

IX. Off-Site Sensor Calibration:

The smarter transmitter Toxic gas sensors include an EEprom encapsulated inside the

sensor housing. The EEprom retains all set-up parameters (alarm set points, relay

operation/function, etc.) and sensor calibration factors. Therefore, the sensors can be

calibrated in the instrument shop (i.e. off-site) with Mil-Ram Remote Calibration

Electronics (contact factory) and the sensors re-installed in the field without further

calibration. Upon installing the sensors, the field installed transmitter electronics

automatically up-loads the calibration data to properly configure the transmitter.

X. Self-Calibration:

The smarter transmitter provides unattended self-calibration features whereby every 30

days the micro-controller electronics increments the span calibration based on the typical

life curve for the sensor type. When a field calibration is performed with a gas sample of

known concentration, the life curve is re-extrapolated based on actual calibration data.

Note: The self-calibration feature is intended to supplement and not replace a regular

calibration program using a certified gas sample of known concentration. Although

the sensors are normally quite stable, it is generally recommended that calibration be

performed monthly in the interest of safety. Unusually harsh or severe environments may require more frequent calibration checks.

XI. Remaining Sensor Life:

The smarter transmitter determines Remaining Sensor Life based on actual field

calibration data, sensor life curve and specific electrical characteristics of the sensor. The

remaining sensor life is an approximation and does not replace a regular calibration

program using a certified gas sample of known concentration to validate sensor response.

Near the end of sensor service life, the transmitter will indicate Replace Sensor. At that

time the sensor must be replaced with a new sensor to ensure proper calibration.

22May2002 Page 17

MIL-RAM TECHNOLOGY, INC.

TOXIC GAS DETECTION INSTRUMENTS AND SENSORS - WARRANTY

Mil-Ram Technology, Inc., warrants toxic gas alarm equipment manufactured and sold by it to be free

from defects in materials, workmanship, and performance for a period of one year from date of shipment

from Mil-Ram Technology, Inc. Any parts found defective within that period will be repaired or

replaced, at its option, free of charge, f.o.b. factory. This warranty does not apply to items which by

their nature are subject to deterioration or consumption in normal service, and which must be cleaned,

repaired, or replaced on a routine basis. Items included, but not limited to, are:

1. Absorbent cartridges

2. Batteries

3. Filter element

4. Lamp bulbs and fuses

5. Pump diaphragms and valves

6. Sensors - electrochemical sensors for Tox-Array 1000

Portable Monitors are covered by a warranty of 24 months.

7. Sensors - electrochemical sensors for Fixed Systems and Transmitter are

covered by a warranty of 12 months.

Warranty is voided by abuse, including rough handling, mechanical damage, alteration or repair by an

unqualified person and/or procedures not in accordance with the corresponding instruction manuals and

specifications. This warranty indicates the full extent of our liability, and we are not responsible for

removal or replacement costs, local repair costs, transportation costs, or contingent expenses incurred

without our prior written approval.

Mil-Ram Technology, Inc.’s obligation under this warranty shall be limited to repairing or replacing and

returning any product which Mil-Ram Technology, Inc., upon a detailed examination by Mil-Ram

Technology, Inc., shall disclose to have been defective. To receive warranty consideration, all products

must be returned to Mil-Ram Technology, Inc., at its manufacturing facilities with transportation

charges prepaid.

This warranty is expressly in lieu of any and all other warranties and representations, express or implied,

and all other obligations or liabilities on the part of Mil-Ram Technology, Inc., including, but not limited

to, the warranty of fitness for a particular purpose. In no event shall Mil-Ram Technology, Inc., be

liable for direct, incidental, or consequential loss or damage of any kind connected with the use of its

products or failure of its products to function or operate properly.

This warranty covers instruments and parts sold (to users) only by authorized distributors, dealers and

representatives as appointed by Mil-Ram Technology, Inc.

Loading...

Loading...