Page 1

Page 2

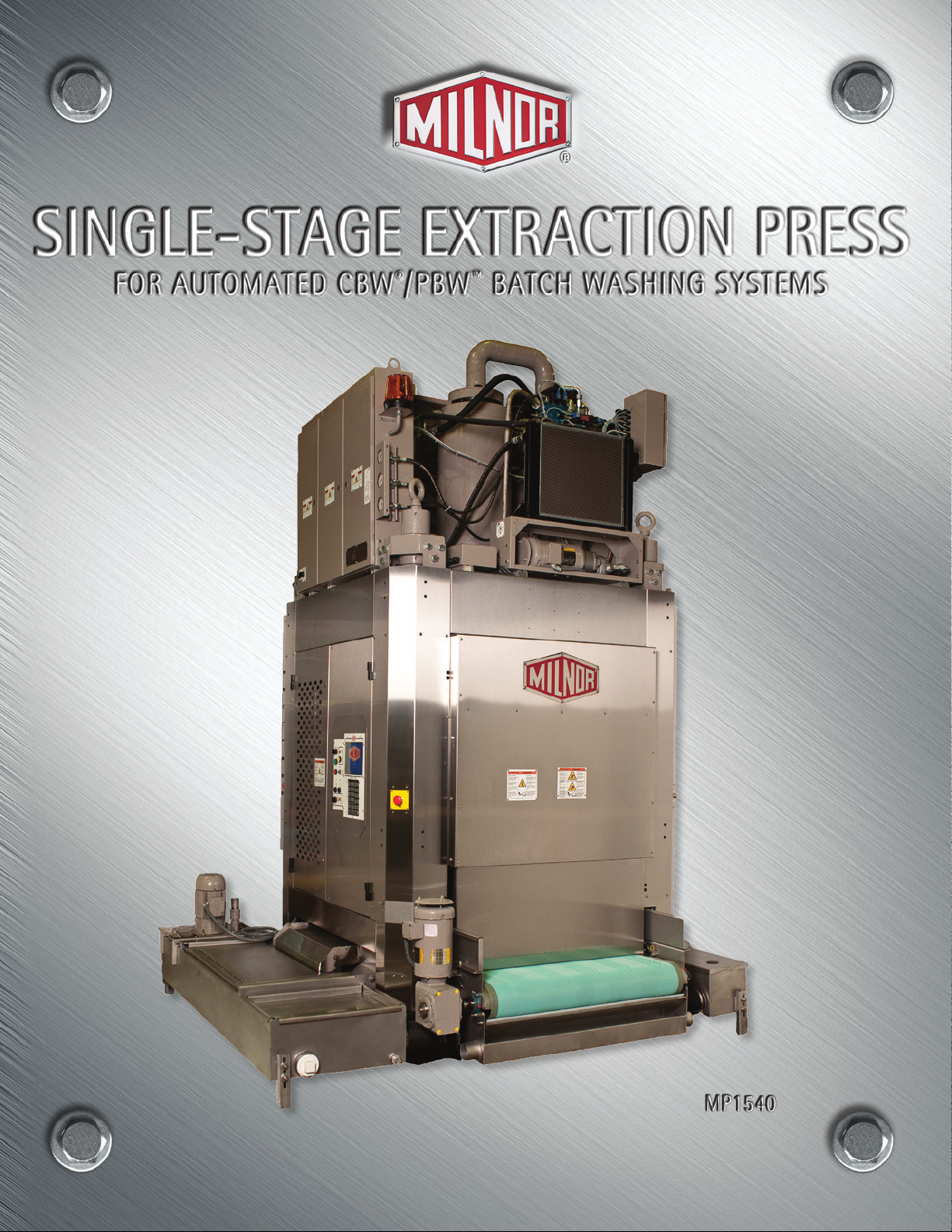

Another extraction alternative

for Milnor tunnel systems!

Milnor’s single-stage membrane press makes it

even easier to tailor a continuous batch system to

your needs. You can meet production and space

requirements in the way that suits you best.

Extracts wide variety of goods.

This single-station press can process 100% polyester,

blends, and all-cotton effectively. Several

features provide careful treatment while exerting

pressure appropriate for the goods. To remove water

pockets and minimize hydroburst, goods can be tamped

by the membrane before final pressure. Ram movement

and pressure (up to 56 bar) are programmable.

Waterless membrane: This standard feature

prevents puncturing and promotes longevity.

Designed for easy service: Hinged

press water return pump simplifies

press maintenance.

Hygienic Processing Environment

Milnor’s stainless steel cosmetics and antimicrobial

paint for structural components promote a hygienic

environment within the machine.

Saves space.

Compact design requires less space. And the press

can be ordered for various installation

arrangements – in-line or 90º angle in either

direction – to fit your laundry’s size and shape.

Single-stage press: This membrane press

processes almost any type of goods in one station.

It’s a good choice when space is tight.

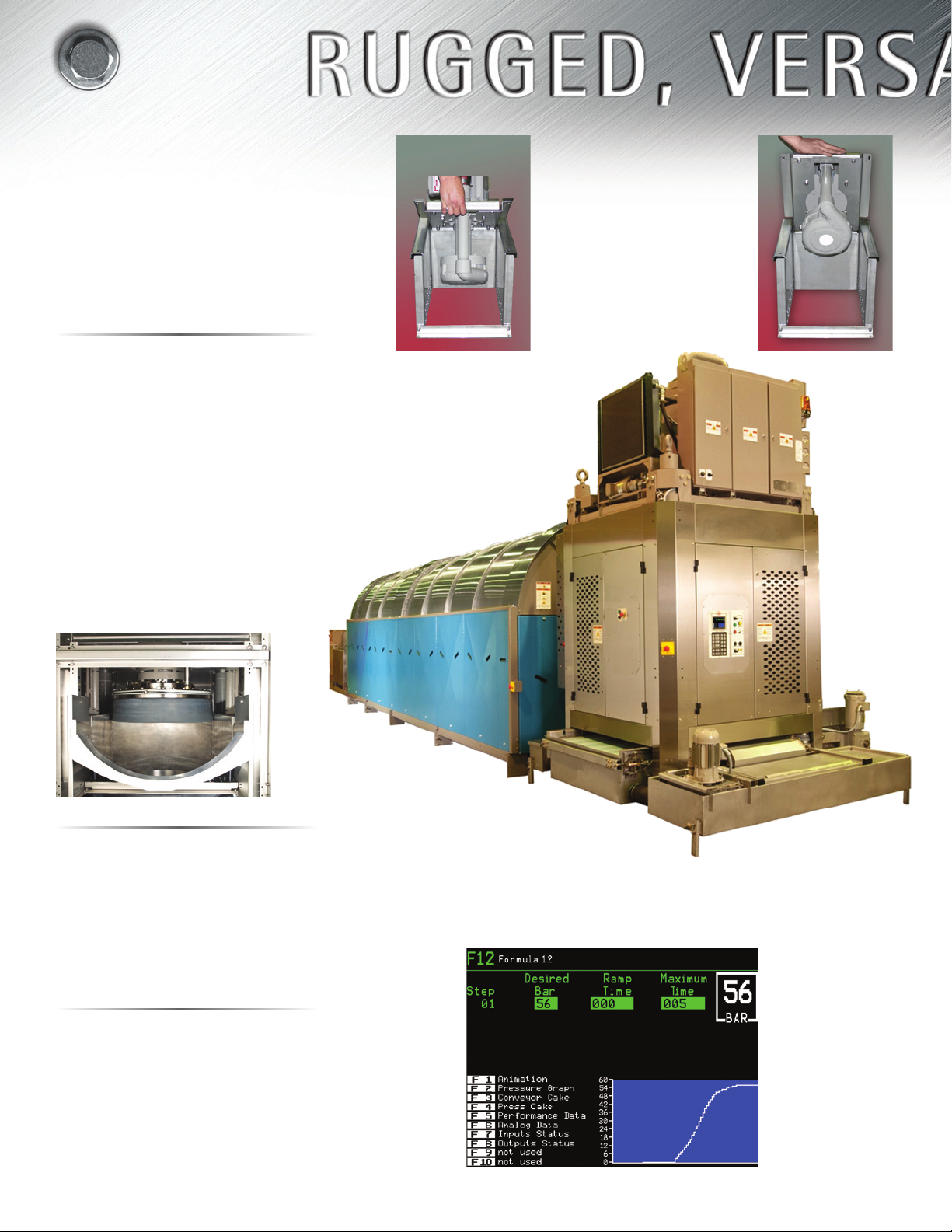

Run Screen

control

Easy-to-read and easyto-program. The operator

can monitor the press in

real-time with this 10.4"

LCD display.

©2010 Pellerin Milnor Corporation

Page 3

Moisture Retention: These graphs illustrate how much moisture can be expelled in terry towels and poly-cotton sheets in Milnor's presses. The more moisture removed,

the more money you save in dryer fuel costs.

Ratcheting Ram.

The diaphragm is rotated 10 degrees by a patentpending actuator as the hydraulic ram retracts at

the end of every press cycle. The service life of the

diaphragm is greatly increased with this standard

feature.

It’s productive and efficient.

Stainless steel press basket accomodates up to 110 lbs.

(50 kg), 150 lbs. (68 kg), or 250 lbs. (115 kg) of

standard cotton sheets. The basket’s large diameter

keeps the cake relatively flat for fast drainage.

Extracted water is pumped to the CBW washer for

reuse. After completion of a cycle, two hydraulic

cylinders lift the basket and an integral conveyor

(which helps keep the cake intact) moves the cake to

the next position for conditioning or drying. A special

unloading sequence prevents the cake from sticking.

Ruggedly built.

Rigid structure absorbs stress for long life. A thick,

solid steel platform supports the hydraulic press

cylinder and pressure system. It is linked to the

bottom plate by four steel columns, using massive,

specially designed locknuts. The hydraulic system uses

an elastomer interfaced connection to prevent leaks.

Its separate recirculation/air cooling loop (standard)

provides both optimum fluid filtration and cooling

for reliability and long life. Easy cleaning

helps enhance plant hygiene.

*XML Tag compatible

Control is versatile, simple.

Proven microprocessor control provides 16

programmable extraction sequences. 10.4" graphic

display tells operating status – including time

remaining in extraction cycle, loading status,

and status for receiving another load. It also

shows production and accounting data, plus

fault recognition with error statements. Control

components are interchangeable with those of other

Milnor machines, to simplify inventory. Control

can be linked to the Mildata® computer system for

central programming, data collection, and system

monitoring.

Page 4

SPECIFICATIONS

SINGLE-STAGE EXTRACTION PRESS MP1540 MP1556 MP1640 MP1656 MP1A50

Batch Size – lbs. (kg) 90-110 (41-50) 90-110 (41-50) 110-150 (50-68) 110-150 (50-68) 250 (115)

Nominal cake diameter – ins. (mm) 35.4 (900) 35.4 (900) 39.37 (1000) 39.37 (1000) 48 (1219)

Standard minimum cycle time – secs 75 — 75 — 75 — 75 — 75 —

Maximum pressure – psi (bar) 580 (40) 812 (56) 580 (40) 812 (56) 725 (50)

Hydraulic pump motor – HP (kW) 15 (11.18) 15 (11.18) 15 (11.18) 30 (22.4) 40 (29.8)

Booster Pump – HP (kW) n/a n/a 11 (8.2) n/a n/a 11 (8.2) 11 (8.2)

Recirculation motor – HP (kW) 1.5 (1.12) 1.5 (1.12) 1.5 (1.12) 1.5 (1.12) 1.5 (1.12)

Conveyor motor – HP (kW) 1 (.75) 1 (.75) 1 (.75) 1 (.75) 1 (.75)

Approx. overall width* – ins. (mm) 108 (2744) 108 (2744) 108 (2744) 108 (2744) 116.5 (2959)

Approx. overall depth* – ins. (mm) 91.94 (2335) 91.94 (2335) 91.94 (2335) 91.94 (2335) 115 (2921)

Approx. overall height* – ins. (mm) 150.5 (3823) 150.75 (3829) 150.75 (3829) 150.75 (3829) 178.25 (4540)

Approx. net weight* – lbs. (kg) 24,400 (11068) 25,000 (11340) 29,600 (13426) 36,000 (16330) 49,500 (22452)

Specifications and appearance subject to change without notice. Contact factory for acoustics data and exact specifications.

All dimensions are Center discharge models unless otherwise noted. *With standard accessories.

Another Milnor extraction option:

Centrifugal extractor: Excellent for garments, dust

mats, 100% polyester textiles (including surgery and

barrier cloth items), plus cottons and blends.

Also available:

Ram Command™ press ram

option for single stage presses:

This feature enhances the control over the ram’s descent into the can. It

also allows the ram to descend at a slower rate (programmable for goods

type) when pressing delicate goods. For example, high thread-count

cotton sheets or barrier material that are subject to fabric microbursting

would benefit from this unique feature.

Material Handling Devices also available:

Printed in U.S.A.

© Pellerin Milnor Corporation

B2 2S L8 902 6/ 124 93

Pellerin Milnor Corporation

P.O. Box 400, Kenner, LA 70063-0400 USA

504-712-7656 • 800-469-8780

Fax: 504-468-3094

E-mail: milnorinfo@milnor.com

www.milnor.com

Loading...

Loading...