Milnor M9V48040 User Manual

Extract even the most delicate and difficult-to-handle fabrics

automatically in a CBW®/PBW™ batch washing system

Milnor’s centrifugal extractor – teamed with a CBW®/PBW™ batch washer – brings full automation to

processing all types of linen, even the most delicate and difficult-to-handle fabrics. With its inherent savings, a

continuous batch washer broadens a laundry's processing opportunities.

The extractor can be paired with any size Milnor tunnel washer. With cycle times as low as 2 ¼ minutes, depending

upon goods and programming, Milnor’s centrifugal extractor can produce over 25 loads per hour (polycotton).

Single motor inverter produces a full range of speeds.

Automatic loading and unloading.

The hydraulic system of Milnor’s centrifugal extractor is

designed to tilt quickly for fast turnaround between loads.

Extracts polycottons and barrier

cloth with ease.

Milnor’s centrifugal extractor works especially well

with polycotton goods, such as uniforms. Low moisture

retention – without setting wrinkles – allows these

uniforms to go directly to a steam finishing tunnel. The

result is faster, higher output plus a superior finish. The

machine’s ability to remove water gently and efficiently

also allows extraction of multifilament or membranetype barrier cloth for operating rooms – as well as 100%

polyester napery. Maximum moisture removal reduces

drying times and saves fuel.

A variety of configurations.

This versatile centrifugal extractor can be built and engaged

in a variety of configurations:

• One centrifugal extractor can receive discharged goods

immediately from a tunnel washer and discharge them directly

into carts or onto a shuttle that loads automatic dryers.

• Multiple centrifugal extractors can be used with a single

CBW/PBW batch washer in higher-production plants.

• A combination of centrifugal and membrane press

extractors can be configured for mixed-goods plants.

• 4 programmable extract speeds.

Reduces mat post-processing.

Low moisture retention is achieved with either cotton

or synthetic mats – even up to 4’ x 10’. That minimizes

post-processing requirements. Benefits are time, labor,

and fuel savings. During extraction, the machine

automatically distributes mats evenly inside the cylinder.

Moreover, the machine’s optional split extract cycle helps

minimize hydroburst since sudden pressure is not applied

to pockets of water common with some types of goods.

With a steady stream of easily-handled batches of mats,

continuous production is achieved.

Other features...

• Microprocessor control links to washer and dryer

controls for completely automated system.

• Suspension system isolates vibration for high speed operation.

• Bearing housing supported 360° by massive ring-of-

steel design.

• Dynamic braking shortens turnaround time.

(No wearable discs or pads.)

• Links to Mildata® computer system for total plant

management (ask us for a brochure).

• Flat back design eases maintenance and simplies

service.

SPECIFICATIONS

Maximum extract speed - RPM (G force)

Dry weight capacity - lbs. (kg)

Cylinder diameter - ins. (mm)

Cylinder depth - ins. (mm)

Gross cylinder volume - cu. ft. (L)

Drive Motor - HP (kW)

Hydraulic Motor - HP (kW)

Overall Width - ins. (mm) +

Overall Depth - ins. (mm)

Stationary Overall Height - ins. (mm)

Unloading Overall Height - ins. (mm)

Approximate net weight - lbs. (kg)

+ Add 36 ins. (914 mm) for freestanding controls.

Specifications are approximate. Dimensions for 76039 with standard conveyor.

Specifications and appearance are subject to change without notice.

1000 (600)

up to 150 (68)

42 (1067)

32 (813)

25.7 (728)

30 (22)

15 (11)

106.63 (2708)

128.87 (3273)

103.25 (2622)

135.81 (3450)

13,240 (6019)

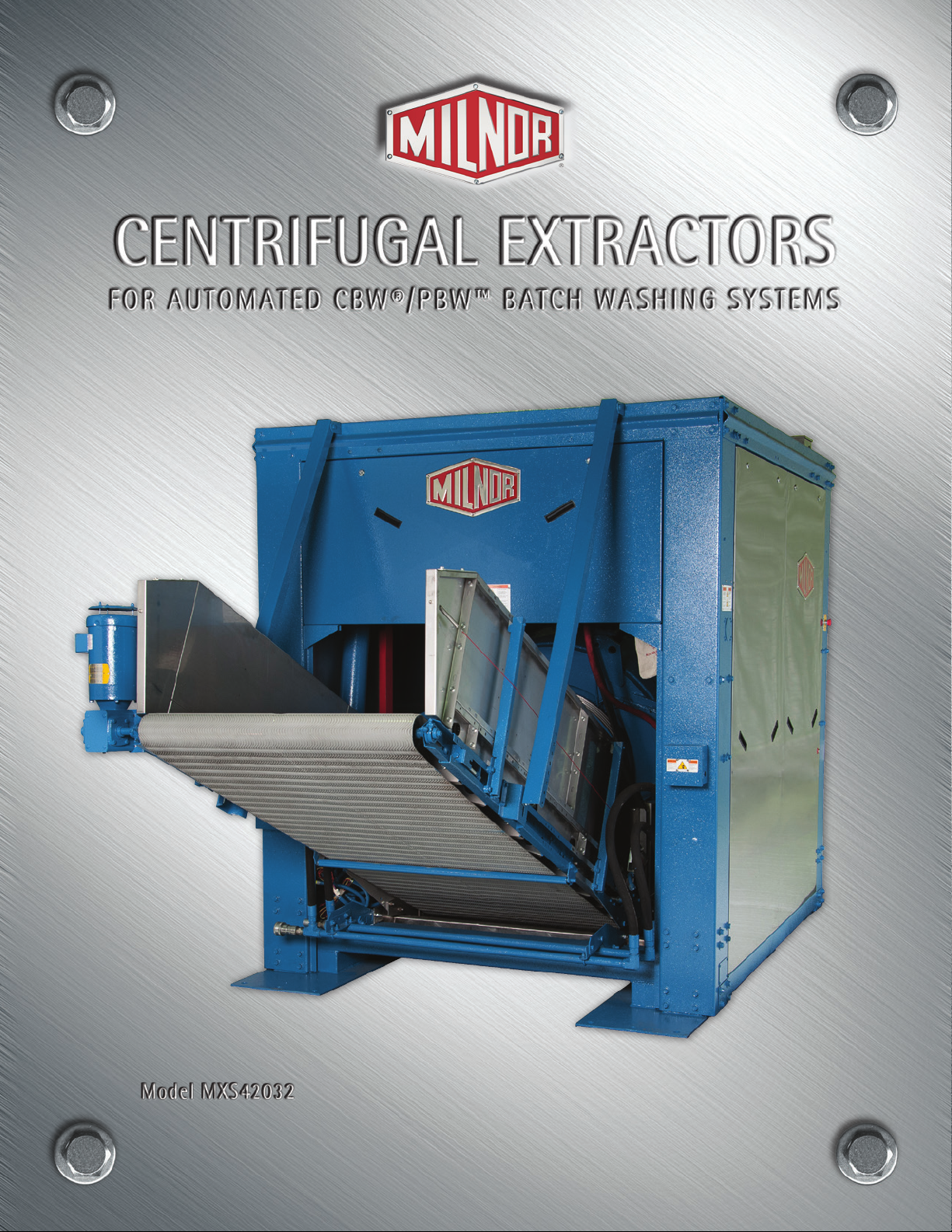

Centrifugal Extractor.

Milnor’s centrifugal extractor has cylinder speeds

up to 1000 RPM, producing 600 Gs for excellent

moisture removal. Pre-extract load distribution

speed minimizes out-of-balance conditions. Singlemotor inverter produces a full range of speeds.

Paired with a Milnor tunnel washer, the centrifugal

extractor combines versatility with automation.

MXS42032 M9V48040

840 (480)

up to 250 (115)

48 (1219)

40 (1016)

41.9 (1186)

60 (45)

15 (11)

122.43 (3110)

166.4 (4227)

113.87 (2892)

159.68 (4055)

18,250 (8278)

Printed in U.S.A.

© Pellerin Milnor Corporation

Class 5-9 Brochure B22SL00005/13183

Pellerin Milnor Corporation

P.O. Box 400, Kenner, LA 70063-0400 USA

504-712-7656 • 800-469-8780

Fax: 504-468-3094

E-mail: milnorinfo@milnor.com

www.milnor.com

Loading...

Loading...