Milnor M35ED User Manual

M35ED

35-lb Capacity Dryer

Standard Features:

• 35-lb. Capacity

• Residual Moisture Control

• Self-Diagnostic Microprocessor Control

• 100% Axial Airflow

• Completely Sealed Basket

• Non-Perforated Ribs and Basket

• Dual-Paned Door Glass

• Four-Point Roller Support System

• High Capacity Lint Drawer

• F.S.S. (Fire Suppression System)

Optional Features:

• Stainless Steel Front, Cabinet & Basket

• Single Phase Reversing

OPL

Why Purchase Milnor EcoDry?

100% Axial Airflow (standard)

EcoDry tumblers incorporate a 100% axial airflow design with a completely sealed basket. This ensures the most

efficient drying available on the market today without sacrificing dry times.

Four-Point Roller Support System (standard)

EcoDryers are designed with a four-point roller support system, eliminating costly repairs and downtime due to

trunnion failures.

Residual Moisture Control (standard)

EcoDry utilizes a unique Residual Moisture Control (RMC) sensing system to measure the presence of moisture in the load. The

patented system senses when the load is dry, shutting the unit down to prevent over-drying. This saves time, utility costs as

well as prolongs the life of dried items.

Available Option: Single Phase Reversing

Single Phase Reversing is an optional feature on the M35ED. What once was an expensive option requiring an upgrade

from single phase to three phase electrical service is now available in single phase. A reversing tumbler ensures that the

load doesn’t “rope” or “ball up”, providing a quicker, more even drying process.

Your local Milnor independent authorized dealer.

M35ED OPL Dryer

www.milnor.com

M35ED

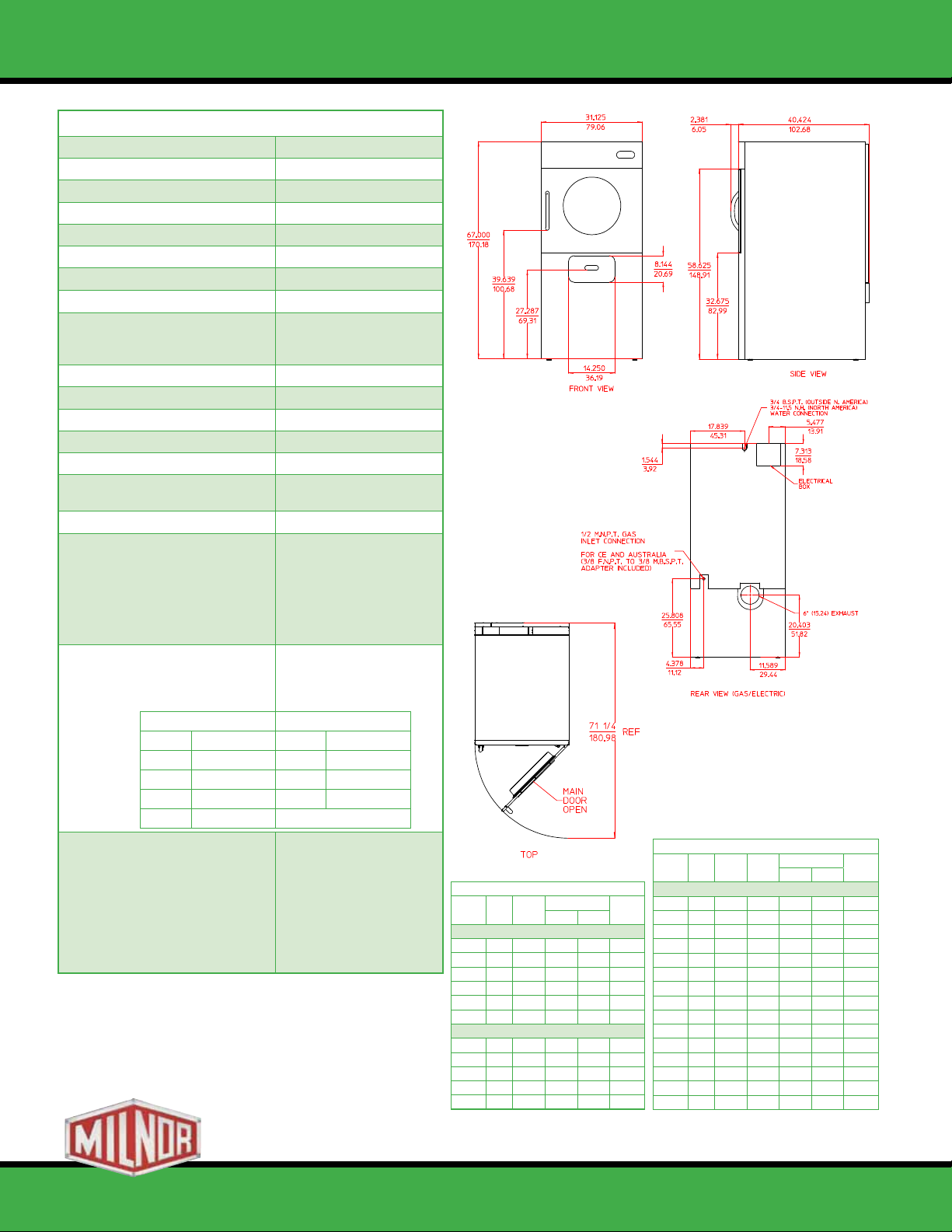

M35ED Specifications

Tumbler Capacity (dry weight) 35 lbs. (15.88 kg)

Tumbler Diameter 30” (76.20 cm)

Tumbler Depth 30” (76.20 cm)

Tumbler Volume 12.27 cu ft (347.44 L)

Tumbler/Drive Motor 1/4 hp (0.19 kW)

Blower/Fan Motor 1/2 hp (0.37 kW )

Door Opening

Door Sill Height 37” (93.98 cm)

F.S.S. Water Connection

North America

Outside North America

Dryers per 20’/40’ Container 14 / 28

Dryers per 53’ Truck 36

Width 31.125” (79.06 cm)

Depth 40.424” (102.68 cm)

Height 67” (170.18 cm)

Airflow 60 Hz

gas/electric/steam 50 Hz

Exhaust Connection 6” (15.24 cm)

GAS MODEL:

50 Hz

ELECTRICAL MODEL:

STEAM MODEL:

* Specications in parentheses are metric equivalents.

(Diameter) 19-3/8” (49.21 cm)

3/4”-11.5 NH

3/4” B.S.P.T.

319 cfm (9.03 cmm)

266 cfm (7.53 cmm)

Approx. Net Wt.

Approx. Ship Wt.

Heat Input 60 Hz

Inlet Pipe Connection

(CE and Australia Only)

Approx. Net Wt.

Approx. Ship Wt.

Exhaust Connection (Diameter)

Oven Size per pocket Oven Size per pocket

kW Btu/hr (kcal/hr) kW Btu/hr (kcal/hr)

7.9 26,962 (6,794) 12.4 42,320 (10,665)

8.3 28,327 (7,138) 12.5 42,661 (10,751)

9.0 30,716 (7,740) 13.5 46,074 (11,611)

11.3 38,566 (9,719)

Approx. Net Wt.

Approx. Ship Wt.

Steam Consumption

Operating Steam Pressure

Exhaust Connection

(Diameter)

Boiler Horsepower (Normal Load)

Supply Connection

Return Connection

462 lbs (209.6 kg)

492 lbs (223.2 kg)

64,000 btu/hr (16,128 kcal/hr)

55,000 btu/hr (13,860 kcal/hr)

1/2” M.N.P.T.

3/8” M.B.S.P.T.

462 lbs (209.6 kg)

492 lbs (223.2 kg)

6” (15.24 cm)

462 lbs (209.6 kg)

492 lbs (223.2 kg)

63 lb/hr (28.58 kg/hr)

150 psi max (10.34 bar)

6” (15.24 cm)

1.75 Bhp

1/2” F.N.P.T.

1/2” M.N.P.T.

1/21/10

Electrical Service Specifications

SERVICE

PHASE

VOLTAGE

120 1ø 2 10.3 -- 15

200 1ø 2 8.7 8.8 15

208 1ø 2 8.4 -- 15

220 1ø 2 8.1 8.1 15

230 1ø 2 -- 7.4 15

240 1ø 2 7.7 7.0 15

120 1ø 2 9.3 -- 15

208 1ø 2 6.2 6.0 15

220 1ø 2 5.6 5.5 15

230 1ø 2 -- 5.4 15

240 1ø 2 5.1 -- 15

WIRE

SERVICE

APPROX AMP DRAW

60 Hz 50 Hz

GAS

STEAM

CIRCUIT

BREAKER

Electrical Service Specifications

SERVICE

VOLTAGE

200 1ø 2 12.5 68.4 67.7 90

208 1ø 2 7.9 43.8 -- 60

208 1ø 2 13.5 70.7 -- 90

220 1ø 2 7.5 36.9 -- 40

230 1ø 2 8.3 -- 41.3 60

230 1ø 2 12.4 -- 59.1 80

240 1ø 2 9.0 42.7 -- 60

240 1ø 2 13.5 61.5 -- 80

208 3ø 3 13.5 43.3 -- 60

220 3ø 3 11.3 35.3 -- 50

230 3ø 3 12.4 -- 36.5 50

240 3ø 3 13.5 37.7 -- 50

380 3ø 4 11.3 22.8 22.6 40

400 3ø 4 12.4 -- 23.1 40

416 3ø 4 13.5 -- 23.7 40

PHASE

WIRE

SERVICE

OVEN kW

ELECTRIC

APPROX AMP DRAW

60 Hz 50 Hz

CIRCUIT

BREAKER

Pellerin Milnor Corporation, PO Box 400, Kenner, LA 70063 USA,

Phone 504.712.7656 Toll Free: 800.469.8780 Fax: 504.468.3094

www.milnor.com

Loading...

Loading...