Page 1

Published Manual Number/ECN: H28 0010/2001074N

• Publishing System: TPAS

• Access date: 2/14/01

• Document ECN's: Latest Available

Kit Instruction—

K28 0010

K36 0005

K36 0005R

PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063-0400, U.S.A.

Page 2

Please Read

About the Manual Identifying Information on the Cover

The front cover displays pertinent identifying information for this manual. Most important, are

the published manual number (part number) /ECN (date code). Generally, when a replacement

manual is furnished, it will have the same published manual number, but the latest available ECN.

This provides the user with the latest information applicable to his machine. Similarly all

documents comprising the manual will be the latest available as of the date the manual was

printed, even though older ECN dates for those documents may be listed in the table of

contents.

When communicating with the Milnor factory regarding this manual, please also provide the

other identifying information shown on the cover, including the publishing system, access date,

and whether the document ECN’s are the latest available or exact.

References to Yellow Troubleshooting Pages

This manual may contain references to “yellow pages.” Although the pages containing

troubleshooting procedures are no longer printed on yellow paper, troubleshooting instructions, if

any, will be contained in the easily located “Troubleshooting” chapter or section. See the table of

contents.

Trademarks of Pellerin Milnor Corporation

The following, some of which may be used in this manual, are trademarks of Pellerin Milnor

Corporation:

®

Ampsaver

Autolint

®

Auto-Purge

Autovac E-P OneTouch® Mildata

®

CBW

Dye-Extractor® Gear Guardian

Dyextractor® Hands-Off

®

E-P Express® Hydro-Cushion

E-P Plus

®

®

®

®

®

®

Milnet

Milnor

®

Staph-Guard

System 4

Miltrac System 7

Miltron Totaltrol

®

®

®

®

Comments and Suggestions

Help us to improve this manual by sending your comments to:

Pellerin Milnor Corporation

Attn: Technical Publications

P. O. Box 400

Kenner, LA 70063-0400

Fax: (504) 469-1849

Page 3

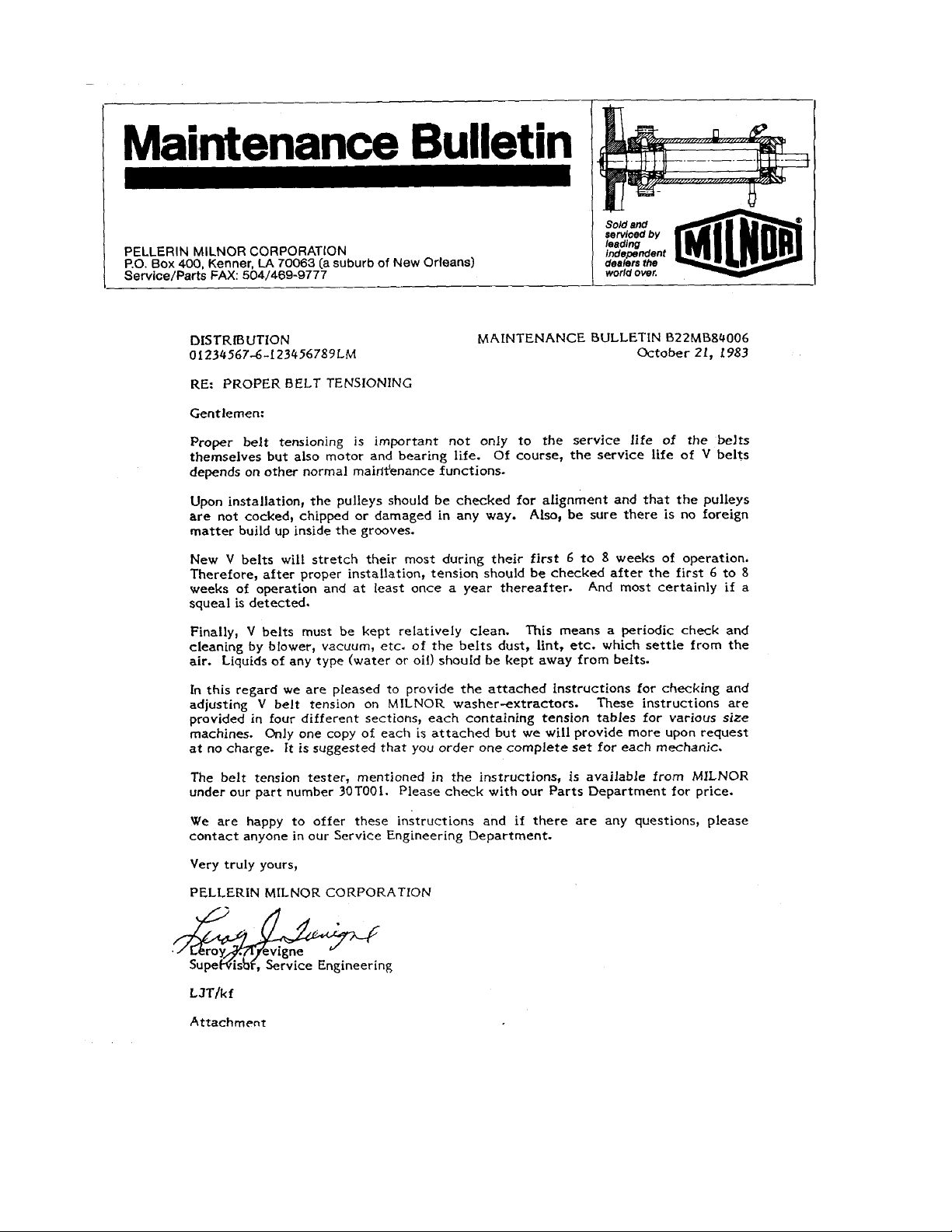

1

Page 4

MN

2

Initial

Initial

Belt

Initial

Initial

Tension

(lbs.) (ref.)

Tension

(lbs.) (ref.)

(IN)

Deflect

Tension

(lbs.) (ref.)

Tension

Initial

Tension

7.4 – 10.0

(lbs.) (ref.)

MP3

Initial

Tension

6.6 – 9.2 KP3 5.1 – 7.1 KN

11/64

Belt

Initial

(lbs.) (ref.)

(IN)

Deflect

(ref.)

Tension (lbs.)

11/32 9.6 – 13.0

EP2 2.4 – 3.4 EN

2.8 – 4.0

MP3 7.4 – 10.0 MN

1/4

6.6 – 9.2

Final Tension

(lbs.) (ref.)

Initial Tension

(lbs.) (ref.)

Ï42026QHE, QTG, QTH

Initial

Tension

Belt Defl.

19/64 9.62 – 13.0 MP3 7.4 – 10.0 MN

(inches)

19/64 8.0 – 11.0 LP 3 6.2 – 8.5 LN

4. If the reading on the tension tester is less than the range shown in the table, the belt is too loose and must be

tightened. If the reading is greater than the range shown in the table, the belt is too tight and must be loos-

(lbs.) (ref.)

Belt

Deflect.

(inches)

Ï30016BWE 36021BWE

50C 5/16 6.6 – 9.2 KP3 5.1 – 7.1 KN 13/32 2.4 – 2.8 DP2 2 – 2.4 DN

60C 11/32 2.4 – 2.84 DP2 2.0 – 2.4 DN 13/32 2.4 – 2.8 DP2 2 – 2.4 DN

60C 11/32 2.8 – 4.0 EP2 2.4 – 3.37 EN 13/ 32 2.8 – 4.0 EP2 2.4 – 3.4 EN

50C 25/64 10.5 – 14.3 NP3 8.1 – 11.0 NN 27/64 10.5 – 14.3 NP3 8.1 – 11.0 NN

60C 25/64 8.0 – 11.0 LP3 6.2 – 8.5 LN 27/64 9.6 – 13.0 MP3 7.4 – 10.0 MN

50C 11/64

9.0 – 13.0 MP3 7.4 – 10.0 MN

60C 5/32 11/64

Ï36026QWE 42026QWE

(lbs.) (ref.)

2.4 – 2.84 DP2 2.0 – 2.4 DN

Belt

Deflect.

(inches)

60C 13/32 23/64

50C 13/32

60C 13/32 2.8 – 4.0 EP2 2.4 – 3.34 EN 23/ 64 10. 5 – 14.3

ened. Adjust the belt until the reading falls within the acceptable range in the table.

WASH/ 2

SPEED WASH

DRAIN 50C 5/16 9.6 – 13.0 MP3 7.4 – 10.0 MN 25/ 64 9.6 – 13.0 MP3 7.4 – 10.0 MN

Deflection

Force Scale

HIGH

SPEED

EXTRACT

(Read Down)

Deflection Dis-

tance Scale

LOW

SPEED

(Read Up)

EXTRACT

WASH/ 2

DRAIN 50C 25/64 9.6 – 13.0 MP3 7.4 – 10.0 MN 23/64

SPEED WASH

50C 7/16 9.6 – 13.0 MP3 7.4 – 10.0 MN 7/16 9. 6 – 13 .0 NP3 8.1 – 11.0 NN

60C 7/16 8.0 – 11.0 LP3 6.2 – 8.5 LN 7/16 9.6 – 13.0 MP3 7.4 – 10.0 MN

HIGH

SPEED

9.6 – 13.0 MP3 7.4 – 10.0 MN

WASH/

2 SPEED WASH

DRAIN 5/32 10.5 – 14.3 8.1 – 11.0

50C 3/16

60C 3/16 1/4 KP3 5.1 – 7.1 KN

EXTRACT

LOW

SPEED

EXTRACT

60C 15/32

MAIN 50C 31/64 10.5 – 14.3 NP3 8.1 – 11.0 NN

OPTIONAL LOW

SPEED EXRACT

MSSM0204AE/8332BV (1 of 1)

Upper

o-ring

Lower

part number 30T001) and a straight

®

o-ring

(MSSM0204AE)

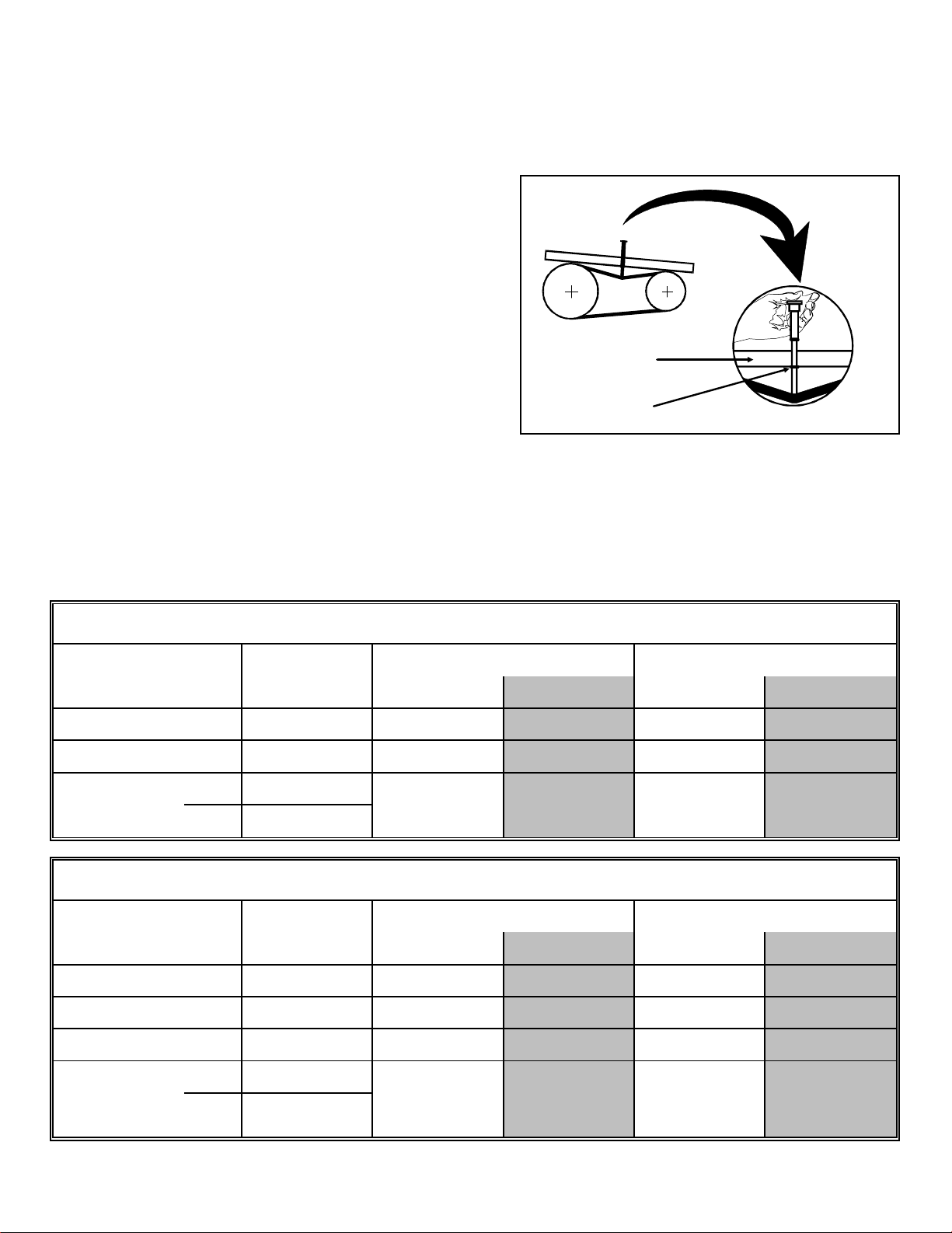

ÎFIGURE 1

ÎTension Tester Scales

Straight

Edge

Lower

o-ring

(MSSM0204AE)

Tension Tester

ÎFIGURE 2

ÎTaking Measurements with the

This instruction is to be used for adjus ting the belt tens ion on the followi ng

ÈV-BELT TENSION ADJUSTMENTS FOR 30" AND 36" B-TYPE

MACHINES AND 42" Q-TYPE MACHINES

30016BWE 42026QHE

machine modes:

36021BWE 42026QTG

42026QWE

360326QWE 42026QTH

A belt tension testing device (Milnor

edge are required when using these instructions.

ÊTension Settings

Set the o-rings on the tension testing device (see FIGURE 1) as follows:

edge of the cap.

1. Move the upper o-ring to the topmost position, resting against the bottom

2. Find the proper belt deflection setting (by machine model and belt function) in the appropriate table below.

3. Move the lower o-ring on the tension tester to this deflection setting on the inches scale.

NOTE 1: The tension testing device is marked on the one side in inches and pounds and on the other side in cen-

timeters and kilograms. All values in the tables are marked.

NOTE 2: The instruction sheet provided with the tension testing device should not be used. Use only the instruc-

tions provided herein.

NOTE 3: The reference (ref.) codes shown in the tables are for factory use

only.

it spans both pulleys. Place the tension tester in the center of the belt

and press and down on the cap until the lower o-ring is in line with

the straight edge, as shown.

ËBelt Tension Measurements

1. Place a straight edge along the top edge of the belt to be tested so that

tester.

2. Read the setting of the upper o-ring on the LBS scale of the tension

3. Compare this value with the acceptable range in the appropriate table.

If the belt is brand new (has never been run), use the range in the In-

itial Tension column. If the belt is not brand new, locate the accept-

able range in the Final Tension column.

Page 5

MSSM0301AE/9126BV

3

ÈV-BELT TENSION ADJUSTMENTS

This instruction is to be used for adjusting the belt tension on the following machine models:

42031WE2 42031SG2 42031WE3 42031SG3

42044WE2 42044SG2 42044WE3 42044SG3

A belt tension testing device (Milnor® part number 30T001) and a straight edge are required when using these

instructions.

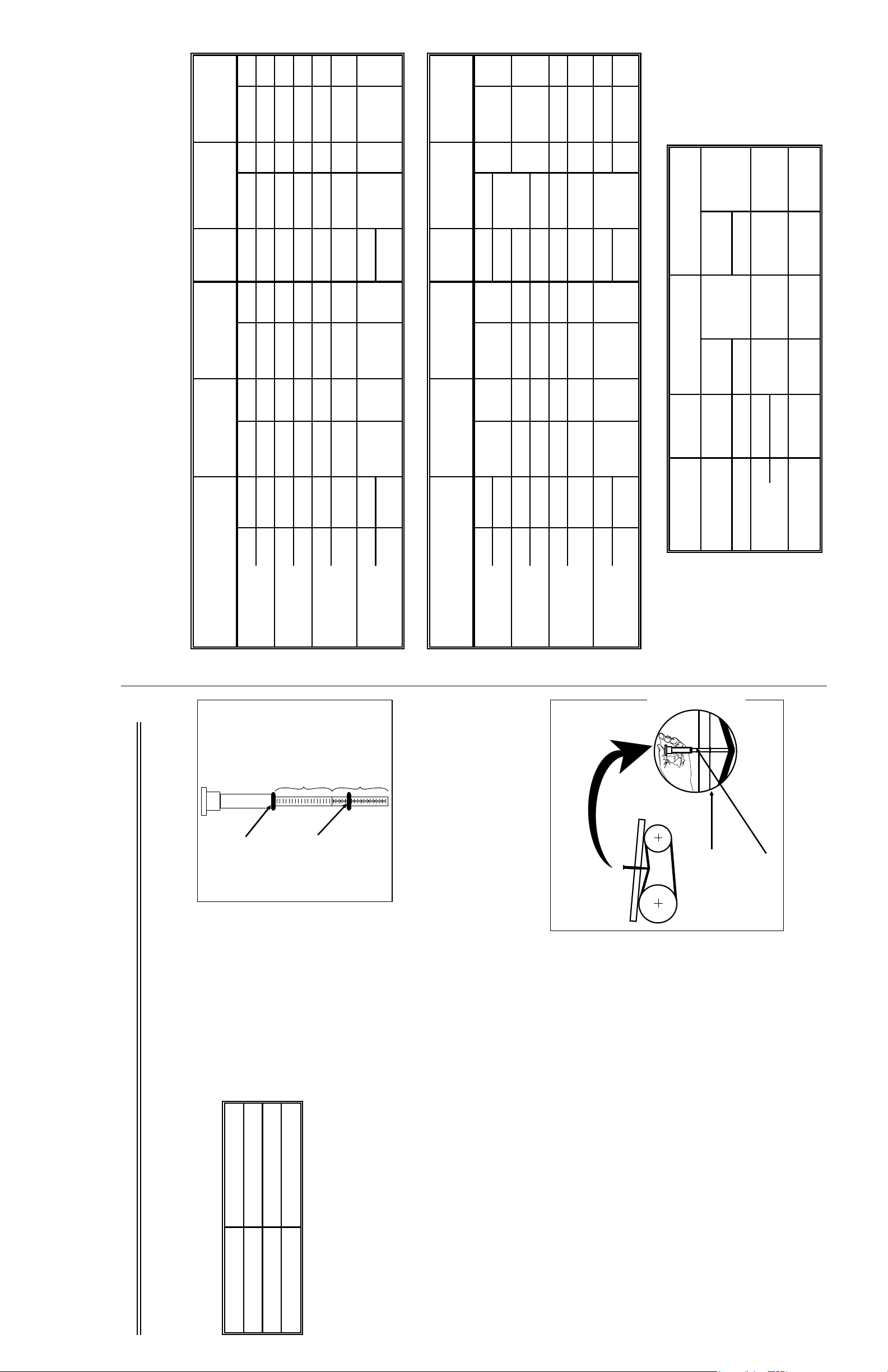

ÊTension Settings

Set the o-rings on the tension testing device (FIGURE 1) as follows:

1. Move the upper o-ring to the topmost position, resting against the

bottom edge of the cap.

2. Find the proper Belt Deflection setting (by machine model and belt

function) in the appropriate table in this section.

3. Move the lower o-ring on the tension tester to this deflection setting

on the inches scale.

NOTE 1: The tension testing device is marked on one side in inches

and pounds and on the other side in centimeters and kilograms. All

values in the tables are in inches (in) and pounds (lbs).

NOTE 2: The instruction sheet provided with the tension testing

device should not be used. Use only the instructions provided herein.

NOTE 3: The reference (ref) codes shown in the tables are for factory

use only.

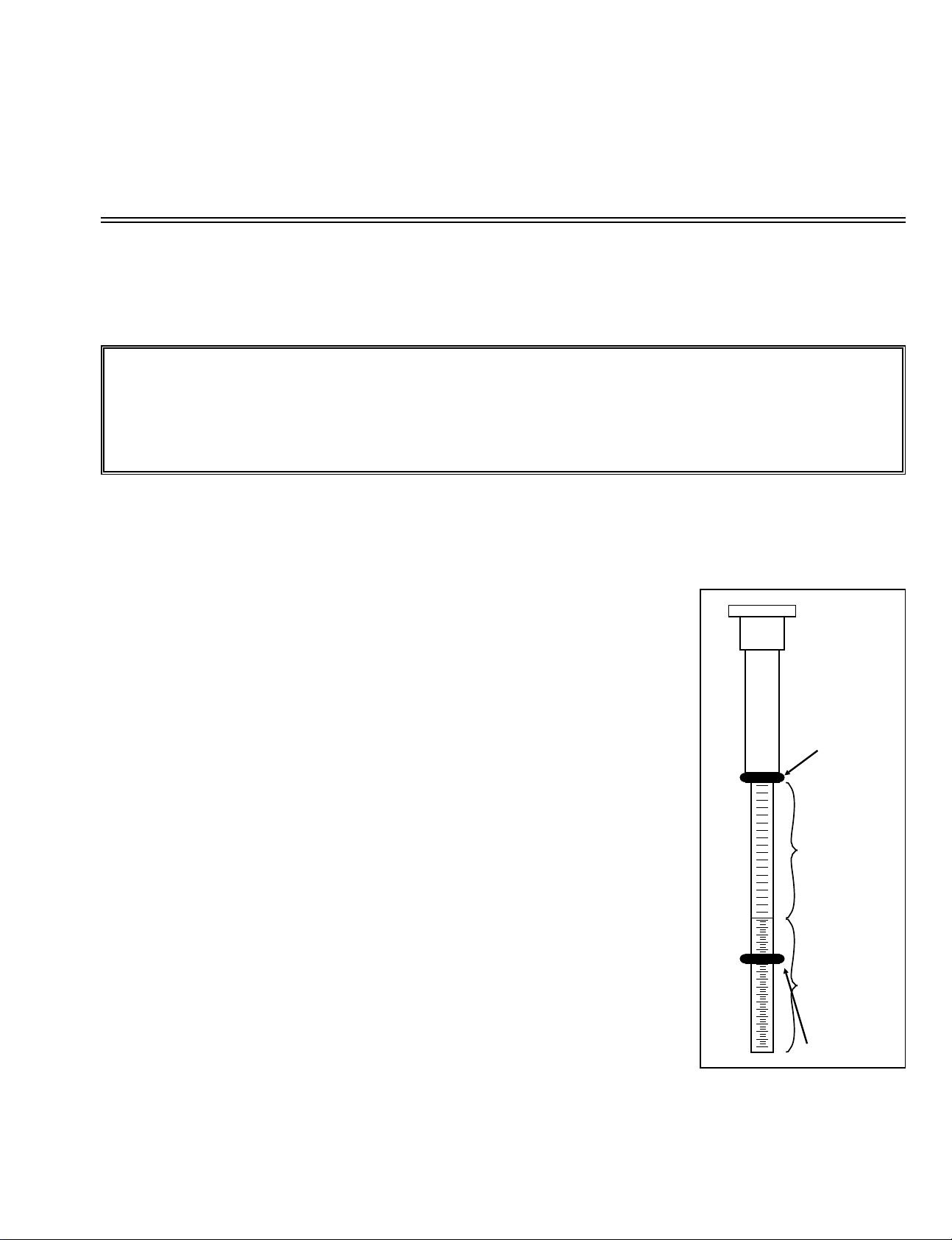

Upper o-ring

Deflection

force scale

(read down)

Lower o-ring

Deflection

distance scale

(read up)

ÎFIGURE 1 (MSSM0301AE)

ÎTension Tester Scales

Page 6

ÊBelt Tension Measurements

4

1. Place a straight edge along the top edge of the belt to be

tested so that it spans both pulleys. Place the tension

tester in the center of the belt and press down on the cap

until the lower o-ring is in line with the straight edge, as

shown.

2. Read the setting of the upper o-ring on the lbs scale of the

tension tester.

3. Compare this value with the acceptable range in the ap-

propriate table. If the belt is brand new (has never been

run), use the range in the Initial Tension column. If the

belt is not brand new, locate the acceptable range in the

Final Tension column.

4. If the reading on the tension tester is less than the range

shown in the table, the belt is too loose and must be tightened. If the reading is greater than the range shown

in the table, the belt is too tight and must be loosened. Adjust the belt until the reading falls within the acceptable range in the table.

Straight edge

Lower o-ring

ÎFIGURE 2 (MSSM0301AE)

ÎTaking Measurements with

the Tension Tester

Ï42031WE2/WE3 and 42044WE2/WE3 Belt Tension Measurements

Belt Deflection

(inches)

Wash/2-Speed Wash 11/64 9.6-13.0 MP3 7.4-10.0 MN

Drain 3/8 8.0-11.0 LP3 6.2-8.5 LN

50Hz 9/16

Main

60Hz 37/64

10.5-14.3 NP3 8.1-11.0 NN

Initial Tension Final Tension

(LBS) (REF) (LBS) (REF)

Wash/2-Speed Wash 11/64 9.6-13.0 MP3 7.4-10.0 MN

Upper Jackshaft

Lower Jackshaft

Ï42031SG2/SG3 and 42044SG2/SG3 Belt Tension Measurements

Belt Deflection

(inches)

Drain 3/8 8.0-11.0 LP3 6.2-8.5 LN

E1 (optional) 11/32 9.6-13.0 MP3 7.4-10.0 MN

50Hz 13/16

to

60Hz 13/16

10.5-14.3 NP3 8.1-11.0 NN

Initial Tension Final Tension

(LBS) (REF) (LBS) (REF)

Page 7

MSSMA405AE/8737BV

5

ÈV-BELT TENSION ADJUSTMENTS

FOR 48", 52", 60" AND 72" WASHER-EXTRACTORS

This instruction is to be used for adjusting the belt tension on the following machine models:

48032BHE 48032BTG 48032BTH 48036QHE 48036QTG 48036QTH

52038WE1 52038WTF 52038WTB 52038WTG 52038WTH

60036WE2 60036WE3 60036SG2 60036SG3 60044WE2 60044WE3 60044SG2 60044SG3

72044SG2 72044SG3 72044WE2 72044WE3 72044WTB 72044WTG 72044WTH

A belt tension testing device (Milnor® part number 30T001) and a straight edge are required when tensioning

unbanded belts.

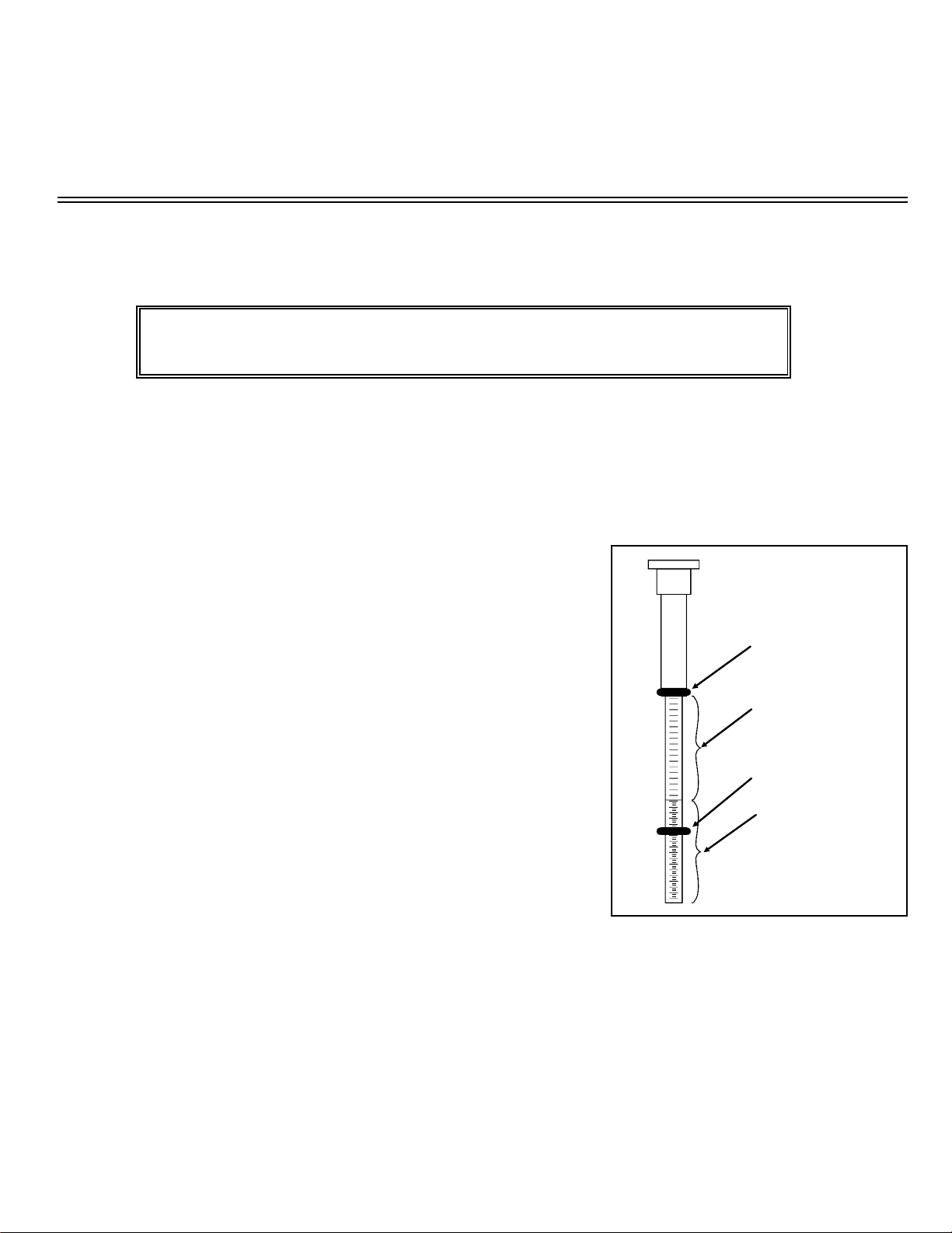

ÊTension Settings—Unbanded Belts

Set the o-rings on the tension testing device (see FIGURE 1) as follows:

1. Move the upper o-ring to the topmost position, resting against the bottom edge

of the cap.

2. Find the proper belt deflection setting (by machine model and belt function) in

the appropriate table below.

3. Move the lower o-ring on the tension tester to this deflection setting on the in-

ches scale.

NOTE 1: The tension testing device is marked on one side in inches and pounds

and on the other side in centimeters and kilograms. All values in the tables are in

inches (in.) and pounds (lbs.).

NOTE 2: The instruction sheet provided with the tension testing device should

not be used. Use only the instructions provided herein.

NOTE 3: The reference (ref.) code shown in the tables are for factory use only.

Upper o-ring

Deflection

force scale

(read down)

Deflection

distance

scale

(read up)

Lower o-ring

ÎFIGURE 1 (MSSMA405AE)

ÎTension Settings

Page 8

ÊBelt Tension Measurements

6

ËUnbanded Belts

1. Place a straight edge along the top edge of the belt to be tested so that it spans both pulleys. Place the tension

tester in the center of the belt and press down on the cap until the lower o-ring is in line with the straight

edge, as shown.

2. Read the setting of the upper o-ring on the lbs scale of the tension tester.

3. Compare this value with the acceptable range in the appropriate table. If the belt is brand new (has never been

run), use the range in the Initial Tension column. If the belt is not brand new, locate the acceptable range in

the Final Tension column.

4. If the reading on the tension tester is less than the range shown in the table, the belt is too loose and must be

tightened. If the reading is greater than the range shown in the table, the belt is too tight and must be

loosened. Adjust the belt until the reading falls within the acceptable range in the table.

Straight edge

Lower o-ring

ÎFIGURE 2 (MSSMA405AE)

ÎMeasuring Belt Tension

Page 9

ËTensioning Banded Belts

7

Ï48032BHE, BTG, BTH 48036QHE, QTG, QT

Belt

Deflect.

(inches)

Initial

Tension

(lbs.) (ref.)

Initial

Tension

(lbs.) (ref.)

Belt

Deflect

(in.)

Initial

Tension

(lbs.) (ref.)

Initial

Tension

(lbs.) (ref.)

WASH/

2 SPEED

9/32 6.6 - 9.2 KP3 5.1 - 7.1 KN 5/16 5.7 - 7.6 JP3 4.4 - 5.9 JN

WASH

DRAIN 5/32 5.7 - 7.6 JP3 4.4 - 5.9 JN 5/32 6.6 - 9.2 KP3 5.1 - 7.1 KN

. 50C

MAIN

. 60C

35/64

17/32

10.5 - 14.3 NP3 8.1 - 11.0 NN

17/32

10.5 - 14.3 NP3 8.1 - 11.0 NN

17/32

LOW

SPEED

13/64 6.6 - 9.2 KP3 5.1 - 7.1 KN 3/16 9.62 - 13.0 MP3 7.4 - 10.0 MN

EXTRACT

Ï52038WE1, WTF, WTB, WTG, WTH 60036 + 60044WE2 + WE3

Belt

Deflect.

(inches)

Initial

Tension

(lbs.) (ref.)

Initial

Tension

(lbs.) (ref.)

Belt

Deflect

(in.)

Initial

Tension

(lbs.) (ref.)

Initial

Tension

(lbs.) (ref.)

WASH/

2 SPEED

25/64 10.5 - 14.3 NP3 8.1 - 11.0 NN 3/16 5.7 - 7.6 JP3 4.4 - 5.9 JN

WASH

DRAIN 5/32 10.5 - 14.3 NP3 8.1 - 11.0 NN 13/32 6.6 - 9.2 KP3 5.1 - 7.1 KN

E1 1/4 6.6 - 9.2 KP3 5.1 - 7.1 KN 17/64 6.6 - 9.2 KP3 5.1 - 7.1 KN

E2 1/2 6.6 - 9.2 KP3 5.1 - 7.1 KN 11/32 6.6 - 9.2 KP3 5.1 - 7.1 KN

50C 11/16 18.2 - 26.0 SP3 14.0 - 20.0 SN 43/64

MAIN

60C 23/32 16.9 - 20.8 RP3 13.0 -16.0 RN 45/64

16.9 - 20.8 RP3 13.0 - 16.0 RN

Page 10

Ï

8

Ï48032BHE, BTG, BTH 48036QHE, QTG, QT

Belt

Deflect.

(inches)

WASH/

2 SPEED

WASH

DRAIN 3/64 6.6 - 9.2 KP3 5.1 - 7.1 KN 33/64 6.6 - 9.2 KP3 5.1 - 7.1 KN

E-1 9/32 6.6 - 9.2 KP3 5.1 - 7.1 KN 17/64 6.6 - 9.2 KP3 5.1 - 7.1 KN

E-2 39/64 6.6 - 9.2 KP3 5.1 - 7.1 KN 5/8 6.6 - 9.2 KP3 5.1 - 7.1 KN

UPPER JACK

TO

LOWER JACK

LOWER JACK

TO

UPPER JACK

1/4 5.7 - 7.6 JP3 4.4 - 5.9 JN 17/64 5.7 - 7.6 JP3 4.4 - 5.9 JN

Initial

Tension

(lbs.) (ref.)

BANDED

BELTS

NEED

SPECIAL

INSTRUCTIONS

Initial

Tension

(lbs.) (ref.)

Belt

Deflect

(in.)

Initial

Tension

(lbs.) (ref.)

BANDED

BELTS

NEED

SPECIAL

INSTRUCTIONS

Initial

Tension

(lbs.) (ref.)

Ï52038WE1, WTF, WTB, WTG, WTH 60036 + 60044WE2 + WE3

Belt

Deflect.

(inches)

Initial

Tension

(lbs.) (ref.)

Initial

Tension

(lbs.) (ref.)

Belt

Deflect

(in.)

Initial

Tension

(lbs.) (ref.)

Initial

Tension

(lbs.) (ref.)

WASH/

2 SPEED

WASH

DRAIN 13/32 6.6 - 9.2 KP3 5.1 - 7.1 KN 25/64 6.6 - 9.2 KP3 5.1 - 7.1 KN

E1 17/64 6.6 - 9.2 KP3 5.1 - 7.1 KN 17/64 6.6 - 9.2 KP3 5.1 - 7.1 KN

E2 5/16 6.6 - 9.2 KP3 5.1 - 7.1 KN 5/16 6.6 - 9.2 KP3 5.1 - 7.1 KN

50C 45/64 16.9 - 20.8 RP3 13.0 -16.0 RN 3/4 16.9 - 20.8 RP3 13.0 - 16.0 RN

MAIN

60C 11/16 16.9 - 20.8 RP3 13.0 -16.0 RN 23/32 16.9 - 20.8 RP3 13.0 - 16.0 RN

15/64 5.7 - 7.6 JP3 4.4 - 5.9 JN 15/64 5.7 - 7.6 JP3 4.4 - 5.9 JN

Page 11

9

Page 12

MSSM0303AE/8451BV

10

ÈMAIN BEARING AND SEAL REPLACEMENT

FOR DIVIDED CYLINDER MACHINES

This section applies to the front and rear cylinder shaft bearings of all divided cylinder machines (Rapid Load,

Staph-guard®, dye machines, etc.). It does not apply to jackshaft bearings, idler shaft bearings or bearings on open

pocket machines.

The bearings covered by this section are double row, spherical roller, self aligning bearings; Koya, SKF, FMC,

Torrington or equal. Referring to FIGURE 1, the rear (clean side on Staph-guard® models) bearing is firmly held

in the bearing housing (bearing and seal carrier) by the shaft seal holder, preventing axial movement. The front (soil

side on Staph-guard® models) bearing is free to move axially in the bearing housing to accommodate thermal

expansion of the shaft during operation and is thus the “floating” bearing. Both bearings are held in place on the

tapered portion of the shaft by a bearing lockwasher and locknut.

The front and rear bearings are each protected from contamination from wash water by three spring loaded,

lip type seals and a shaft seal leak-off cavity (that carries off any water that leaks past the main water seals) as shown

in FIGURE 1.

Cap

Bolt

Bearing

Housing

(Bearing and

Seal Carrier)

Bearing Cover

Bearing

Lock-nut

Bearing

Lock-washer

Front Bearing

(floating)

Front Bearing Assembly

Shell

Front

Bearing and Seal

Cavity Leak-offs

Seal Sleeves

Shaft

Seals

Shaft Seal

Leak-off

Cavities

Rear Bearing Assembly

Shell

Rear

Bearing and Seal

Cavity Leak-offs

Cap Bolt

Bearing

Housing

(Bearing and

Seal Carrier)

Seal

Shaft Seal

Holder

Rear Bearing

(fixed)

ÎFigure 1 (MSSM0303AE)

ÎCross Section View of Front and Rear Bearing Assemblies

(Bearing Assembly for 60" and 72" WED Shown. Others similar.)

Page 13

Access to the bearings and seals for lubrication is provided by the various grease passages. Excess lubricant is

11

excreted through the bearing and seal cavity leak-offs as shown on FIGURE 1. The bearings and seals must be

lubricated regularly and the leak-off cavities flushed out periodically through the plugged cleanout connections, in

strict accordance with the preventive maintenance procedures elsewhere.

If bearing replacement becomes necessary due to wear, it is essential that the bearings and seals are replaced.

Seal replacement requires removal of the bearing housing and seal sleeve. (In rare instances where the seals are

known to be in good condition, it is not necessary to remove the bearing housing, seals or seal sleeve when a bearing

is replaced.) A pulling fixture is required to remove the bearing housing. A set of guide rods, a seal sleeve

setting fixture and a bearing setting fixture are required for reinstallation of the housing. These tools are

available for rental or purchase from the Milnor® factory and are pictured elsewhere in this section. Contact the

factory two weeks in advance of repairs, when ordering these tools.

This maintenance is performed in the following order:

1. Remove old bearing(s). When removing both bearings, remove the front (soil side) bearing first.

2. Remove bearing housings, seal sleeves, and seals.

3. If both bearings were removed, install the bearing housing, seal sleeve, seals, and new bearing on the rear

(clean side).

4. Install the bearing housing, seal sleeve, seals, and new bearing on the front (soil side).

5. Tighten bearing(s).

See the Main Bearing Assembly drawing for your machine for bearing component part numbers.

ÊRemoving the Bearing (Front or Rear)

1. Loosen, then remove the main drive belts and

cylinder shaft pulley (if applicable) by lowering the

drive base with the jacking bolts. Do not attempt to

pry belts off with a pry bar or by rolling the sheave.

Remove the bearing cover (or shaft seal holder) to

expose the bearing.

2. Bend back the locking tang on the bearing lock-

washer then remove the locknut and lockwasher.

3. The center tapped hole in the shaft end is an oil pas-

sage through which oil may be forced between the

tapered shaft and the bearing inner race. Install a

pipe fitting into this tapped hole as shown in figure

to the right. Using a “Porto-Power” or similar hand

operated hydraulic pump, force fluid into the passage. Pump hard to build up fluid pressure. This

pressure will cause the inner race to expand slightly; just enough to free the tapered surfaces and

allow the bearing to slip off easily. If the bearing is

not readily removed, remove the front water level

ÎConnection From Hydraulic Pump to

ÎFIGURE 2 (MSSM0303AE)

Assist in Bearing Removal

Page 14

inspection plate and use a timber to pry up the cylinder to remove cylinder weight from the bearings. Once

12

the bearing is removed, the cylinder drops only approximately 1/32" before the shaft comes to rest on the

shaft support.

4. Slide the bearing off of the shaft and if it is to be reused, place it on a clean surface and cover with a clean,

lint free cloth.

ÊRemoving the Bearing Housing (Bearing and Seal

Carrier), Seal Sleeve, and Seals (Front or Rear)

These procedures require the use of a pulling fixture and guide rods available from the Milnor® factory. With

the bearing cover (or shaft seal holder) and the bearing removed, proceed as follows:

1. Remove the three bearing housing cap bolts and the grease lines from the bearing housing front plate. Install

guide rods in two of the bolt holes, as shown in FIGURE 3.

2. Install the pulling fixture as shown in FIGURE 4, by placing each of the four threaded rods through a hole in

the steel plate with hexnuts to the outside of the plate then screwing each rod into the appropriate tapped

hole in the bearing housing (same holes as used to mount the bearing cover or shaft seal holder).

ÎFIGURE 3 (MSSM0303AE)

ÎTwo Bearing Housing Guide

Rods in Position

ÎFIGURE 4 (MSSM0303AE)

ÎBearing Housing Pulling

Fixture in Position

Page 15

NOTE: Step 2a or 2b below wil l cause the bearing housing to sli de away from the shell. Shi ms were placed

13

under one or more of the three bearing housing pads during factory assembly to align the housing and insure

its being exactly parallel with the shaft. When removing the bearing housing, be sure to keep these shims

separate and identified so that they may be returned to their proper location, otherwise the bearing

and seal will be out of line and may be damaged after a short operating period. As a precaution in case

the shims are lost during disassembly, you will find stamped next to the bearing housing the proper thickness

of shims required (if any) under each adjacent bearing housing pad. The stamped number indicates the shim

thickness in thousandths of an inch. For example, the number “38” indicates that 38/1000 (.038") shims

would be required under this pad.

2a. Tighten all four hexnuts on the threaded rods such that the pulling fixture plate is pressed against the shaft

end. With an impact wrench, tighten down on the center bolt until the housing slides out, or

2b. If no impact wrench is available, simply continue to tighten down on each of the four hexnuts behind the

pulling fixture plate, alternately and progressively, until the housing slides out. It may be necessary to place

a spacer (approx. two inches long) between the plate and the shaft to provide enough clearance between the

plate and the bearing housing.

3. Once the bearing housing is free of the shell, carefully slide it off of the guide rods and place on a clean work

surface.

4. The seal sleeve will almost always remain on the shaft when the housing is removed. Remove the seal sleeve

taking care not to damage or scar it and place it on a clean work surface.

ÊPrecautions for Bearing Replacement

The most important ingredient in successful bearing and seal installation is cleanliness. The bearing housing

must be free of all foreign matter. The grease and leak-off passages must be blown clear and all foreign matter

removed. You must have a clean work area. Keep your hands and tools free from grit and grime. Wash your hands

before starting and as required during these procedures. Foreign matter is, without doubt, the most frequent cause

of bearing failure, and one over which the manufacturer has no control.

Where cleaning is required, bearings, bearing housings and seal sleeves may be cleaned with the following

solvents or cleaning agents (in strict accordance with the manufacturer’s recommendations as such substances are

generally toxic and/or explosive under certain conditions):

Benzene

Chlorethane

Freons

Do not, however, expose any components to the above substances for more than 24 hours and only use at room

temperature. Never use the following solvents or cleaning agents: alcohols, cresols, phenols, flouro propanols, or

other similar chemicals or mixtures.

NOTE: Hammer blows, overheating, or improper use of force can damage precision parts.

Gasoline

Kerosene

Mineral Spirts

Naptha

Tricholorethylene

Page 16

ÊReplacing the Bearing Housing, Seal Sleeve,

14

and Seals (Front or Rear)

1. With the seal sleeve removed, press all old seals out of the bearing housing. Remove the large o-ring from the

outside of the housing. Thoroughly clean the bearing housing and flush out all grease passages to make certain they are unblocked. Remove the o-rings from the inside of the seal sleeve and clean the seal sleeve.

2. While the bearing housing is dissassembled, charge all grease passages with grease. This will assure that there

are no blockages.

3. Replace the o-rings in the seal sleeve and the large o-ring on the outside of the bearing housing. Replace with

new o-rings if the old ones are worn.

4. Press new seals into the bearing housing. You may gently work the seals in with a mallet and metal drift as

shown in FIGURE 5.

Each seal must be of the proper material and face the proper direction. The type of material

and direction the seal faces may differ from one seal to another within the same bearing

housing and also from one type of machine to another. It is essential to consult the Main

Bearing Assembly drawing for your machine for the proper part number and direction to

face each seal.

5. Slip the seal sleeve into the bearing housing as shown in FIGURE 6 below right, using care not to damage or

fold under any of the seal lips. Be sure to insert the sleeve in the proper direction (see Bearing Assembly drawing).

ÎFIGURE 5 (MSSM0303AE)

ÎInstalling Seals in

Bearing Housing

ÎFIGURE 6 (MSSM0303AE)

ÎInstalling Seal Sleeve in

Bearing Housing

NOTE: If both housings are being installed, install the rear housing first.

Page 17

6. With two of the three temporary guide rods in position on the shell, place the bearing housing onto the guide

15

rods and install the seal sleeve setting fixture on to the bearing housing as shown in FIGURE 7. The seal

sleeve setting fixture prevents the seal sleeve from being pushed out of the housing as the housing is inserted into the shell. Note that the seal sleeve setting fixture and the bearing setting fixture are very similar,

but the seal sleeve setting fixture has a longer hub.

7. With a clean, lint free cloth, apply a coating of light machine oil to the outside of the housing, to assist in in-

stallation. Push the housing into the shell as shown in FIGURE 8. Once the housing is far enough into the

shell to support itself, place any shims back into position between the housing and the shell. Remove, then

replace guide rods if required to place shims under bearing housing pads.

ÎFIGURE 7 (MSSM0303AE)

ÎInstalling the Bearing Housing Setting

Fixture onto Housing (42" machine shown)

8. Install the third guide rod, spacers if required, and hex-

nuts, using these to seat the housing fully, as shown

in FIGURE 9. Remove the seal sleeve setting fixture.

9. Remove the guide rods and install the bearing housing

cap bolts. See “BOLT TORQUE REQUIREMENTS” elsewhere, for proper torques.

10. With the grease gun, pump grease into the inner por-

tion of the bearing cavity, such that when the bearing is installed, the space between the bearing and

the seals will be approximately 1/3 full of grease.

11 Proceed to “Measuring Unmounted Clearance . . .”

below, even if both the front and rear bearings are

being replaced. Once the rear bearing is installed,

the bearing housing replacement procedures may

then be repeated for the front (soil side) bearing housing.

ÎFIGURE 8 (MSSM0303AE)

ÎPushing the Bearing Housing into the

Shell (60" Rapid-load machine shown)

ÎFIGURE 9 (MSSM0303AE)

ÎTightening the Bearing Housing

into the Shell (42" machine shown)

Page 18

ÊMeasuring Unmounted Clearance and

16

Setting Bearing (Front or Rear)

The bearings used on Milnor® washer and dye extractors are the very best anti-friction devices available for

these applications. However, the anti-frictional charact eristics of the bearings will be r educed if they are not properly installed. It is of cr itical impor tance when installing these t apered roller bearings, to accomplish t he following ( A

step by step procedure follows this synopsis):

1. Accurately measure the unmounted internal clearance of the bearing (gap between the rollers and outer race

before the bearing is installed). This is an essential quality control measure.

2. Calculate the final internal clearance by subtracting the specified clearance reduction (amount that the internal

clearance must be reduced when the bearing is tightened onto the tapered shaft) from the unmounted

clearance.

3. Tighten the bearing onto the shaft until the final internal clearance as calculated is achieved and verified by

measurement.

These measurements are taken in thousandths of an inch. Although this requires precise work, attention to

detail and a good set of feeler gauges, it is the only way to insure that the bearing will be tightened onto the shaft to

precisely the right tension. If you have any questions on performing the measurements or adjustments described

below, your local bearing supplier or the Milnor® factory can assist you. Although these procedures require

precision over and above that normally required for laundry room maintenance, they are standard in bearing installation and absolutely essential:

NOTE: Step 1 which follows, requires a good set of feeler

gauges including .001" through .010" in thousandths of an inch

increments. Contact your local bearing supplier.

1. When you are ready to proceed (and not before) remove the

new bearing from it’s box or protective wrapping. Do not attempt to clean the bearing or wash out the preservative coating. On a clean work surface, stand the bearing on edge and

insert a .003 feeler gauge into the bearing as shown in FIGURE 10, at right. The gauge should be inserted just inside

the outer race between two rollers and worked through to the

opposite row of rollers. Rotate the inner race of the opposite

row so that the end of the feeler gauge is caught between a

roller and the outer race.

ÎFIGURE 10 (MSSM0303AE)

2. Try to pull the gauge straight out. If it comes out, increase the

size of the gauge by .001". If it does not come out, decrease

the gauge by .001". The thickest feeler gauge that will come

out is the unmounted internal clearance of the bearing.

3. Compare the measured clearance with the “Unmounted Clearance” in the table below. If the measured

clearance is not within the range shown, do not use the bearing. Contact your bearing supplier for an exchange.

(bridge for 42" machine shown)

ÎMeasuring Bearing

Unmounted Clearance

Page 19

NOTE 1: The clearances listed in the chart are industry standards and therefore apply to all brands of

17

bearings supplied by Milnor®. If other sources of bearings are used, refer to the manufactur er’s instr uctions

for proper clearances.

NOTE 2: To locate your bearing on the chart, match the first five characters of the manufacturer’s part

number (not the Milnor® part number) with those in the chart. For example, for a manufacturer’s part

number 22217LBK, find under “Manufacturer Part Number” the line “22217 . . .”

ÏTable of Bearing Clearances

Unmounted Clearance Clearance Reduction

Manufacturer Part Number

22330 . . . .0071 .0091 .002 .003

22213 . . . .0030 .0039 .001 .002

22216 . . . .0028 .0037 .001 .002

22217 . . . .0044 .0057 .0015 .0025

22312 . . . .0030 .0039 .001 .002

22316 . . . .0037 .0049 .001 .002

22320 . . . .0044 .0057 .0015 .0025

Minimum Maximum Minimum Maximum

22328 . . . .0063 .0081 .002 .003

23220 . . . .0044 .0057 .0015 .0025

4. Calculate and record the final internal clearance by deducting the “Clearance Reduction” for your bearing (see

above chart) from the measured clearance. For example, if you measured .004 and the clearance reduction is

.001 to .002, then the final internal clearance should be between .002 and .003.

5. Hand pack the bearing with grease by rotating the inner race and rollers, forcing grease between all rollers.

NOTE: The bearing will be set into position in Step 6. If both front and rear bearings are being installed,

the rear (clean side on Staph-guard® models) bearing should be set in position first because it is the fixed

bearing.

6. Set the bearing into the housing (with the taper facing the proper direction) and seat the bearing using the bearing setting fixture. This fixture is installed in similar fashion to the seal sleeve setting fixture. If you have

just set the rear bearing and the front bearing housing is yet to be installed, leave the bearing setting fixture

in place for now.

7. If you have just set the rear bearing and the front bearing housing is yet to be installed, repeat all steps in bearing housing installation, measuring unmounted clearance and setting bearing, for the front bearing and housing. The bearing setting fixture should not be removed from the rear housing until it is needed to seat the

front bearing. This will prevent rear bearing components from being pushed out of position by the shaft as

the front housing components are seated. Remove the bearing setting fixture from the front housing once the

bearing is seated.

Page 20

ÊTightening Bearing(s) (Front and/or Rear)

18

1. Once both bearings are seated, or if only one bearing was replaced, install the bearing lockwasher(s) and locknut(s). Use a hammer and a metal drift as shown in FIGURE 11, to tighten the locknut. It is imperative to

only tap lightly and to assure that metal chips from the drift or locknut do not fall off and contaminate the bearing. If both bearings are being tightened, work between the front and rear bearings and

turn the basket by hand periodically, while tightening the locknut(s).

2. After tightening the bearing(s) onto the tapered shaft, check the internal clearance as pictured in FIGURE 12,

by working a feeler gauge between the outer race and a roller of the outer row then between the outer race

and a roller of the inner row.

NOTE: Sometimes, when setting the bearings, all the load is taken by onl y one row of rollers (al though the

load would quickly equalize on both rows after the machine has run for only a few minutes). If all the load

is taken by one row, you will get an erroneous clearance reading. It is therefore, necessary to use the feeler

gauge to measure the clearance of both rows of rollers. With the bearing in place on the machine it is

admittedly rather difficult to get a feeler gauge back past the first row of rollers to measure the second but it

must be done.

3. If one row of rollers is tight but the other has measurable clearance, tap lightly on the end of the shaft nearest

the tight row of rollers to cause the shaft to shift axially and equalize the roller loading. Adjust the bearing

tightness to achieve the internal clearance previously calculated.

4. When the proper internal clearance has been attained, lock the nut by bending over the matching tang on the

lockwasher, making sure that all unused tangs are bent as near the nut as possible so that they will not rub

against the bearing roller cage.

Check each unused tab individually to insure this.

ÎFIGURE 11 (MSSM0303AE)

ÎTightening the Bearing

Locknut (42" machine shown)

ÎFIGURE 12 (MSSM0303AE)

ÎMeasuring the Mounted Internal

Clearance of the Bearing

(42" machine shown)

Page 21

5. With the grease gun, fill the space between the bearing and the front of the housing 1/3 full of grease.

19

6. Install the bearing cover plate or shaft seal holder, as appropriate. When installing the shaft seal holder, take

care not to damage the seal as it is gently pushed over the shaft. Cover the keyway on the end of the shaft

with tape to prevent the sharp corners of the keyway from cutting the seal lip. Also, make sure that the seal

lip does not turn over as it passes over rough areas.

Loading...

Loading...