Page 1

Published Manual Number/ECN: MAT30C4AAE/2002115N

• Publishing System: TPAS

• Access date: 03/14/2002

• Document ECN's: Latest Available

Technical Reference—

Operating and

Troubleshooting the C4A

Electronic Coin WasherExtractor

PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063-0400, U.S.A.

Page 2

Please Read

About the Manual Identifying Information on the Cover

The front cover displays pertinent identifying information for this manual. Most important, are

the published manual number (part number) /ECN (date code). Generally, when a replacement

manual is furnished, it will have the same published manual number, but the latest available ECN.

This provides the user with the latest information applicable to his machine. Similarly all

documents comprising the manual will be the latest available as of the date the manual was

printed, even though older ECN dates for those documents may be listed in the table of

contents.

When communicating with the Milnor factory regarding this manual, please also provide the

other identifying information shown on the cover, including the publishing system, access date,

and whether the document ECN’s are the latest available or exact.

References to Yellow Troubleshooting Pages

This manual may contain references to “yellow pages.” Although the pages containing

troubleshooting procedures are no longer printed on yellow paper, troubleshooting instructions, if

any, will be contained in the easily located “Troubleshooting” chapter or section. See the table of

contents.

Trademarks of Pellerin Milnor Corporation

The following, some of which may be used in this manual, are trademarks of Pellerin Milnor

Corporation:

®

Ampsaver

Autolint

®

Auto-Purge

Autovac E-P OneTouch® Mildata

®

CBW

Dye-Extractor® Gear Guardian

Dyextractor® Hands-Off

®

E-P Express® Hydro-Cushion

E-P Plus

®

®

®

®

®

®

Milnet

Milnor

®

Staph-Guard

System 4

Miltrac System 7

Miltron Totaltrol

®

®

®

®

Comments and Suggestions

Help us to improve this manual by sending your comments to:

Pellerin Milnor Corporation

Attn: Technical Publications

P. O. Box 400

Kenner, LA 70063-0400

Fax: (504) 469-1849

Page 3

Table of Contents

for MAT30C4AAE/2002115N

Operating and Troubleshooting the C4A Electronic Coin Washer-Extractor

Page Description Document/ECN

1 About This Manual MHT30C4AAE/9274AV

2 Safety for Coin Operated Washer-Extractors BIRMCS01/20020312

9 Section 1: Commissioning

10 The C4A Electronic Coin Washer-Extractor Control MSOP0503AE/9274AV

11 Section 2: Operating

12 Operation of C4A Electronic Coin Washer-Extractor MSOP0502AE/9274AV

15 How to Set Required Number of Coins MSIN0501AE/9274AV

17 Section 3: Troubleshooting

18 Testing Display, Inputs, and Outputs on the Electronic

Coin Washer-Extractor MSTS0501AE/9274AV

23 How to Correct Errors with the C4A Control MSTS0502AE/9274AV

25 Section 4: Supplemental Information

26 The Hardware in C4A Electronic Coin Washer-

Extractor Controls MSFD0503AE/9274AV

28 How to Change EPROMS in Microprocessors

and Where to Check the DC Voltages MSSM0217AE/9020IV

Page 4

Page 5

MHT30C4AAE/9274AV (1 of 1)

ABOUT THIS MANUAL

ËScope—This instruction manual is intended to provide operating and troubleshooting instructions for the

C4A electronic coin washer-extractor control. Refer to the INSTALLATION AND SERVICE manual for

information on machine installation procedures, mechanical requirements, preventive maintenance, service

procedures, and mechanical parts identification. Refer to the SCHEMATIC MANUAL for electrical parts

identification and electrical troubleshooting.

ËThe Power Up Sequence—Verify that the machine behaves as described in “OPERATION OF

C4A . . . ” (see Table of Contents). Any other display indicates an error condition which must be corrected

before the machine will operate. See “HOW TO CORRECT ERRORS WITH THE C4A CONTROL.”

ËQuick Reference Tabs—The tabs along the right edge of the manual mark vital information.

SAFETY—READ FIRST—Safety instructions must be read before operating machine.

COMMISSIONING—Commissioning instructions ensure proper start up.

CONTENTS—See Table of Contents for section/page numbers of cross references used herein.

CHANGES/NEW MATERIALS—These, if any, will be found in an envelope inside the rear

cover.

ËManual Number/Date Code (When To Discard or Save)—The manual number/date

code is located on the inside front cover, upper right corner just above the manual name. Whenever the

manual is reprinted with new information, part of this number changes. If the date code after the “/”

changes, the new version applies to all machines covered by the old version, but is improved— thus

the old version can be discarded. If the manual number before the “/” changes, the new manual covers

only n ew machines. Example: Discard MATMODELAE/8739CV when MATMODE LAE/8739DV is

received (minor improvements). Also, discard MATMODELAE/8739DV when MAT-

MODELAE/8746AV is received (major improvements). But keep MATMODELAE/8746FV when MAT-

MODELBE/8815AV is received, since the new manual no longer applies to machines originally shipped

with the old manual.

ËDocuments and Change Bars—The individual documents comprising this manual use the same

revisio n criteria as the manual. Text documents als o display change bars. Example: When section

MSOP0599AE/9135BV becomes MSOP0599AE/9135CV, change bars with the letter “C” appear next to

all changes for this revision. For a major rewrite (e.g., MSOP0599AE/9226AV), all change bars are deleted.

ËTrademarks of Pellerin Milnor Corporation—The following, some of which may be used in

this publication, are trademarks of Pellerin Milnor Corporation:

Ampsaver

®

Autolint

®

Auto-Purge

®

Autovac

CBW

®

Dye-Extractor

®

Dyextractor

®

E-P Plus

®

Gear Guardian

®

Hands-Off

®

Hydro-Cushion

®

Mildata

®

Milnet

®

Milnor

®

Miltrac

Miltron

Staph-Guard

®

System 4

®

System 7

®

Totaltrol

®

Page 6

CQVUdi V_b 3_Y^ ?`UbQdUT GQcXUb5hdbQSd_bc

29B=3C ! @eR\YcXUT 2__[ c`USc 4QdUc* " " #!" " " #!" " " #!" <Q^W* 5>7 ! 1``\YS* B=3

BPUTchU^a2^X]>_TaPcTSFPbWTa4gcaPRc^ab

6T]TaP[BPUTchAT`dXaT\T]cbb_TRXUXRfPa]X]Vb]Tgc_PVTP]S

cWa^dVW^dc\P]dP[

Incorrect installation, neglected preventive maintenance, abuse, and/or improper repairs, or

changes to the machine can cause unsafe operation and personal injuries, such as multiple

fractures, amputations, or death. The owner or his selected representative (owner/user) is

responsible for understanding and ensuring the proper operation and maintenance of the machine.

The owner/user must familiarize himself with the contents of all machine instruction manuals.

The owner/user should direct any questions about these instructions to a Milnor® dealer or the

Milnor® Service department.

Most regulatory authorities (including OSHA in the USA and CE in Europe) hold the owner/user

ultimately responsible for maintaining a safe working environment. Therefore, the owner/user

must do or ensure the following:

• recognize all foreseeable safety hazards within his facility and take actions to protect his

personnel, equipment, and facility;

• work equipment is suitable, properly adapted, can be used without risks to health or safety,

and is adequately maintained;

• personnel are familiar with all functional and safety aspects of the machine, and where

specific hazards are likely to be inv olv ed, access to the equipment is restricted to those

employees given the task of using it;

• only specifically designated workers carry out repairs, modifications, maintenance, or

servicing;

• info rm ation, ins tru ction, and tra in ing is provided ;

• workers and/or their representatives are consulted.

Work equipment must comply with the requirements listed below. The owner/user must verify

that installation and maintenance of equipment is performed in such a way as to support these

requirements:

• control devices must be visible, identifiable, and marked; be located outside dangerous zones;

and not give rise to a hazard due to unintentional operation;

• control systems must be safe and breakdown/damage must not result in danger;

• work equipment is to be stabilized;

• protection against rupture or disintegration of work equipment;

• guarding, to prevent access to danger zones or to stop movements of dangerous parts before

the danger zones are reached. Guards to be robust; not give rise to any additional hazards; not

be easily removed or rendered inoperative; situated at a sufficient distance from the danger

zone; not restrict view of operating cycle; allow fitting, replacing, or maintenance by

restricting access to relevant area and without removal of guard/protection device;

• suitable lighting for working and maintenance areas;

• maintenance to be possible when work equipment is shut down. If not possible, then

protection measures to be carried out outside danger zones;

• work equipment must be appropriate for preventing the risk of fire or overheating; discharges

of gas, dust, liquid, vapor, other substances; explosion of the equipment or substances in it.

@5<<5B9> =9<>?B 3?B@?B1D9?>

Page 7

CQVUdi V_b 3_Y^ ?`UbQdUT GQcXUb5hdbQSd_bc

;Pd]Sah5PRX[Xch

—Provide a supporting floor that is strong and rigid enough to support–with

a reasonable safety factor and without undue or objectionable deflection–the weight of the fully

loaded machine and the forces transmitted by it during operation. Provide sufficient clearance for

machine movement. Provide any safety guards, fences, restraints, devices, and verbal and/or

posted restrictions necessary to prevent personnel, machines, or other moving machinery from

accessing the machine or its path. Provide adequate ventilation to carry away heat and vapors.

Ensure service connections to installed machines meet local and national safety standards,

especially regarding the electrical disconnect (see the National Electric Code). Prominently post

safety information, including signs showing the source of electrical disconnect.

!

?Tab^]]T[

—Train personnel what to do in case of emergencies. Inform personnel about

hazard avoidance and the importance of care and common sense. Provide personnel with the

safety and operating instructions that apply to them. Verify that personnel use proper safety and

operating procedures. Verify that personnel understand and abide by the warnings on the

machine and precautions in the instruction manuals.

"

BPUTch3TeXRTb

—Ensure that no one eliminates or disables any safety device on the machine

or in the facility. Do not allow machine to be used with any missing guard, cover, panel or door.

Service any failing or malfunctioning device before operating the machine.

#

<PX]cT]P]RT

—Ensure the machine is inspected and serviced in accordance with the norms of

good practice and with the preventive maintenance schedule. Replace belts, pulleys, brake

shoes/disks, clutch plates/tires, rollers, seals, alignment guides, etc. before they are severely

worn. Immediately investigate any evidence of impending failure and make needed repairs (e.g.,

cylinder, shell, or frame cracks; drive components such as motors, gear boxes, bearings, etc.,

whining, grinding, smoking, or becoming abnormally hot; bending or cracking of cylinder, shell,

frame, etc.; leaking seals, hoses, valves, etc.) Do not permit service or maintenance by

unqualified personnel.

!

CWT3P]VTa5a^\PA^cPcX]V2h[X]STa

A tremendous amount of potential energy is stored in the rotating cylinder of any washerextractor (even at slow speed). Washer-extractors are equipped with a

door interlock

designed to

prevent the door from being opened if the cylinder is turning and to prevent the machine from

starting unless the door is closed and locked.

Some coin machine models permit the door to be opened only during the first few minutes of the

formula and only while the machine is rotating in wash speed. If the door is opened, the drain

valve opens immediately, the machine stops, and (provided the machine still has electric power),

on most models a brake is immediately applied.

30=64A ) 4]cP]V[T P]S BTeTa 7PiPaSb

—Contact with goods being processed can

cause the goods to wrap around your body or limbs and dismember you. The goods are normally

isolated by the locked cylinder door.

• Do not put any part of your body in the machine while it is moving.

• Do not operate the machine with the door open.

• Do not attempt to open the door or reach into the cylinder until the cylinder is stopped.

• Do not touch goods inside or hanging partially outside the turning cylinder.

• Do not open the cylinder door with water in the cylinder.

• Do not tamper with or disable any safety device or operate the machine with a

malfunctioning safety device. Request authorized service.

@5<<5B9> =9<>?B 3?B@?B1D9?>

Page 8

CQVUdi V_b 3_Y^ ?`UbQdUT GQcXUb5hdbQSd_bc

• Do not operate the machine with a malfunctioning door interlock.

30=64A ! ) 4g_[^bX^] 7PiPaSb

—Cylinder—A damaged cylinder can rip apart during

extraction, puncturing the shell and discharging metal fragments at high speed.

• Do not operate the machine with any evidence of damage or malfunction.

"

CWT3P]VTa5a^\?a^RTbbX]VFXcW5[P\\PQ[T<PcTaXP[b

Washer-extractors are manufactured specifically for use with water,

nor with any other material that might be fla mm able

. They are not suitable for any type of

not with any type solvent

solvent cleaning process.

30=64A " ) 4g_[^bX^] P]S 5XaT 7PiPaSb

—Flammable substances can explode or ignite

in the cylinder, drain trough, or sewer. The machine is designed for washing with water, not any

other solvent. Processing can cause solvent-containing goods to give off flammable vapors.

• Do not use flammable solvents in processing.

• Do not load machine with goods containing dry cleaning materials.

• Do not use the machine in the presence of solvent fumes.

#

CWT3P]VTa5a^\>_TaPcX]VFXcW6dPaSb^a2^eTabAT\^eTS

Like other types of industrial equipment, Milnor® washer-extractors utilize

electrical power

to drive a wide variety of

moving parts

. Even with external power completely

high voltage

removed, the machine may contain energy such as tensioned springs and heavy parts that may fall

if released. As previously stated, the washer cylinder acquires tremendous potential energy during

extract, which must be absorbed by the brake or permitted sufficient time to dissipate.

Every

guard, side panel, and door on the machine exists to isolate energized or moving parts from

laundry personnel and must be securely in place for safe operation.

30=64A # ) 4[TRca^RdcX^] P]S 4[TRcaXRP[ 1da] 7PiPaSb

—Contact with high voltage

will electrocute or burn you. Power switches on the machine and the control box do not eliminate

these hazards. High voltage is present at the machine unless the main machine power disconnect

is off.

• Do not unlock or open electric box doors.

• Do not remove guards, covers, or panels.

• Do not reach into the machine housing or frame.

• Do not service machine unless qualified and authorized.

• Know the location of the main machine disconnect and use it in an emergency to remove

all electric power from the machine.

30=64A $ ) 4]cP]V[T P]S 2adbW 7PiPaSb

—Contact with moving components normally

isolated by guards, covers, and panels, can entangle and crush your limbs. These components

move automatically.

• Do not remove guards, covers, or panels.

• Do not reach into the machine housing or frame.

• Do not operate a damaged or malfunctioning machine. Request authorized service.

• Do not service machine unless qualified and authorized.

• Ensure that all personnel are clear of the machine before starting it.

@5<<5B9> =9<>?B 3?B@?B1D9?>

Page 9

CQVUdi V_b 3_Y^ ?`UbQdUT GQcXUb5hdbQSd_bc

$

CWT3P]VTa^U4]caP_\T]cX]P2^X]<PRWX]T

30=64A % ) 4]caP_\T]c 7PiPaS

—A locking cylinder door can entrap anyone who enters

the cylinder. The person can be killed or seriously injured.

Most modern coin operated washer-extractors have a door interlock which, for safety, locks the

door when the cycle starts (or a short time later). The door is unlocked when the cycle ends. If

power is lost, the door unlocks so that goods may be removed if desired. When power is restored

and the door is closed, most machines resume the interrupted cycle without additional coins and

the door is again locked.

In a tragic incident, a small child was placed, climbed, or was helped to climb into a front

loaded coin machine and the door was then closed behind him. The door locked, the

machine started running and the child was scalded to death.

The laundry owner/operator must guard against entrapping anyone in a washer-extractor by doing

the following:

$

8]bcP[[3XbR^]]TRcBfXcRWTb

—The National Electric Code (article 430-112) requires a

clearly marked electric disconnect switch in sight and no more than 50 feet from each machine.

(Local codes may have additional requirements.) Make disconnect switches readily accessible,

but not so accessible as to provide an attractive nuisance for playful children.

You are urged to consult your licensed electrician and take immediate steps to comply if

your installation does not now meet the National Electric Code requirement.

$!

8]U^a\cWT2dbc^\Ta

—Post signs prominently in the laundry or use whatever additional

effective means are available to inform the customer of the entrapment hazard, and how to

minimize the hazard, including but not necessarily limited to the following:

1. that children must not be placed inside, nor be allowed to operate or play in or around any

machine,

2. the location of the disconnect switch for each machine, and

3. what to do in the event of an emergency.

$"

CTbc3^^a8]cTa[^RZP]S2^X]2^d]cTa>_TaPcX^]

interlock is functioning properly. Verify

any means other than inserting the proper number of coins with the door closed (see

accompanying document “How To Test Your Milnor Coin Operated Washer-Extractor's

Electronic Coin Counter and Locking-type Door Interlock”).

$#

4]bdaT2hR[T2^\_[TcX^]

close the doors on all coin machines and complete the cycles of any machines which start up.

Unattended stores must develop a procedure to address this circumstance.

%

7^fC^CTbcH^da<X[]^a2^X]>_TaPcTSFPbWTa4gcaPRc^ab

4[TRca^]XR2^X]2^d]cTaP]S;^RZX]VCh_T3^^a8]cTa[^RZ

J3^Rd\T]c 18A<2B!L

=^cXRT & ) 4]bdaT BPUT >_TaPcX^]

monthly

• To test

@5<<5B9> =9<>?B 3?B@?B1D9?>

, both the coin counter

the locking-type door interlock (daily), perform Step 6 and 7.

only

monthly

—Verify

that the machine cannot be made to operate by

that the door

daily

—After a power loss and subsequent restoration, immediately

—Confirm

the door interlock function.

and

, the door interlock function. Confirm

daily

Page 10

CQVUdi V_b 3_Y^ ?`UbQdUT GQcXUb5hdbQSd_bc

• To test the electronic coin counter

all of the following steps, in order.

Step 1.

Step 2.

Make sure that power is ON to your machine.

Close the door.

If the machine starts, let it run to the end of the cycle, then proceed to Step 3. (This may

a.

Do not insert coins.

the locking-type door interlock (monthly), perform

and

Do not skip any step.

have been simply a restart in mid cycle—when electric power is restored after a power

interruption while the machine was

=^cT )

possibility of a free wash when electric power is restored after a power interruption while the machine

was

If the machine does not start, proceed to step 3.

b.

Step 3.

Open the door. Now verify that the machine will not accept coins with the door open.

If the machine accepts coins when the door is open,

a.

and fix whatever is wrong.

Step 4 tests the possibility of a free wash simply by closing the door and Step 5 tests the

running.

not

(Perhaps the door switch is bad or the door switch actuator is

running

jammed making the switch think the door is closed.)

).

take it out of service, determine why,

Do not return the machine to service

until it successfully passes all seven steps described herein.

If the machine does not accept coins with the door open, proceed to Step 4.

b.

Step 4.

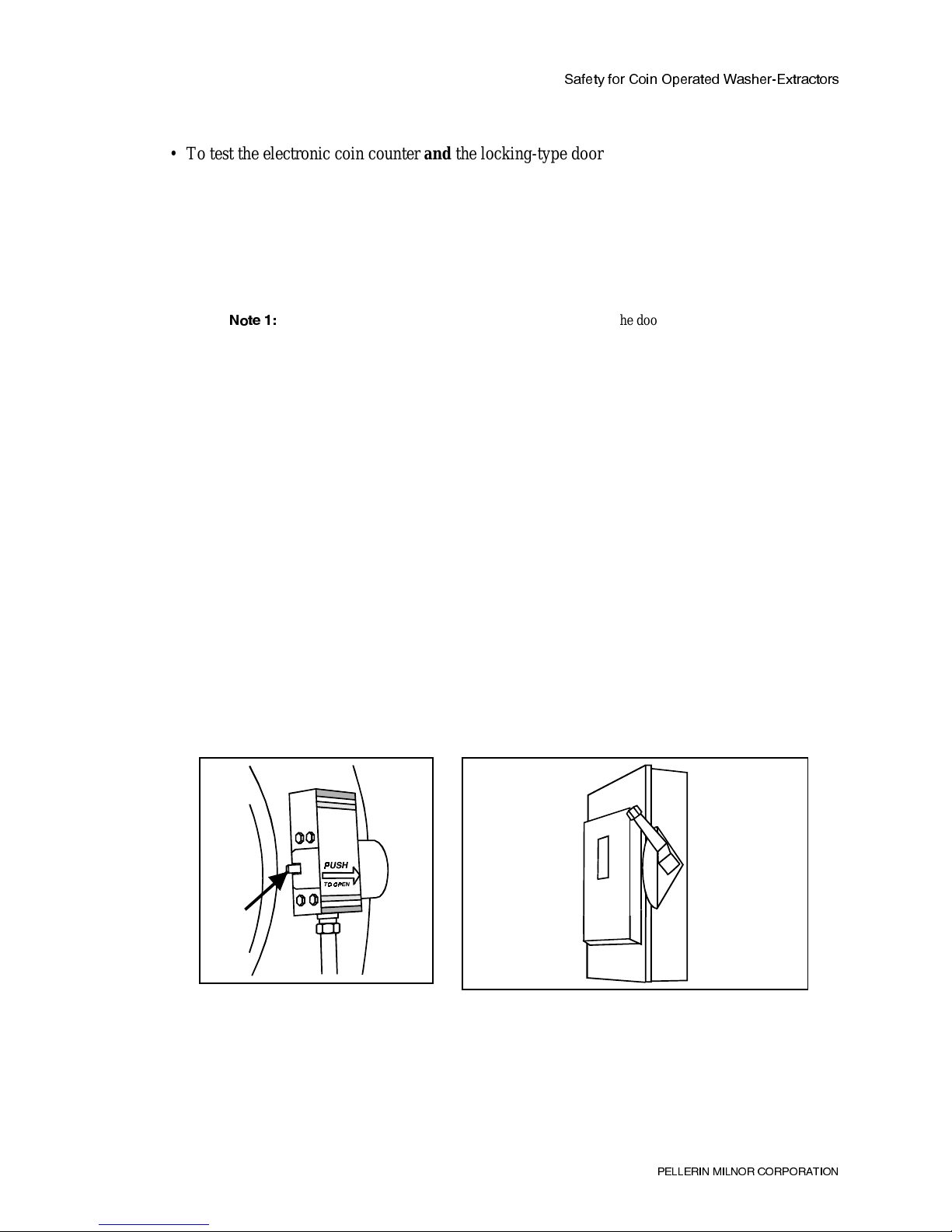

With the door open, manually operate the door switch actuator 100 times (Figure 1).

Operate the actuator for one second ON (depressed), then one second OFF (released). If the

machine completed steps 1, 2, and 3 successfully, this tests if simply closing the door will permit

a free wash.

If the machine starts while the door switch actuator is depressed,

a.

immediately take your

hand off the door switch actuator and take the machine out of service until the coin

counter has been changed. Do not return the machine to service until it successfully

passes all seven steps described herein.

If the machine does not start, proceed to Step 5.

b.

Figure 1: Door Switch Actuator Figure 2: Wall Mounted Power Disconnect Switch

Step 5.

With the door closed and the machine still in the “unarmed” condition (it has not yet

accepted coins), turn the power ON and OFF 25 times at the wall-mounted power disconnect

switch (Figure 2) or external circuit breaker. Turn power ON for five seconds, then OFF for five

seconds). Observe if the machine starts at any time the power is turned ON. This tests if the coin

counter will give a free wash when electric power is restored after power interruption while the

machine was

running.

not

@5<<5B9> =9<>?B 3?B@?B1D9?>

Page 11

CQVUdi V_b 3_Y^ ?`UbQdUT GQcXUb5hdbQSd_bc

If the machine starts without coins at any time as power is turned ON,

a.

take the machine

out of service until the coin counter has been changed. Do not return the machine to

service until it successfully passes all seven steps described herein.

If the machine does not start without coins at any time power was turned ON and OFF 25

b.

times, you probably have a good coin counter. Proceed to step 6.

Step 6.

Insert the proper number of coins. Verify that:

• the machine starts only after the last coin is accepted, and

• the machine will then accept no more coins.

If the machine starts before the last coin is accepted or accepts more than the proper

a.

number of coins,

take the machine out of service until you determine and fix what is

wrong. Do not return the machine to service until it successfully passes all seven steps

described herein.

If the coin counter functions properly and the machine starts,

b.

wait a full 2.5 minutes

proceed to step 7.

20DC8>= ' ) BRP[S 7PiPaSb

—Contact with hot bath liquor can scald you.

• During following step, hold the door firmly closed, as shown in Figure 3, to prevent door

from springing open if the latch retracts during this test.

Figure 3: Hold Door Shut When Testing the Door

Interlock

, then

Step 7.

After the machine has been running at least 2.5 minutes, and while manually holding the

door closed (Figure 3), attempt to depress the door unlock handle.

If the latch retracts,

a.

fixed. Do not return the machine to service until it successfully passes all seven steps

described herein.

If the latch does not retract, it is OK to return the machine to service (provided it also

b.

passes all other tests described herein).

=^cXRT ( ) 4]bdaT BPUT >_TaPcX^]

monthly

• To test

, both the coin counter

the locking-type door interlock (daily), perform Step 6 and 7.

only

• To test the electronic coin counter

all of the following steps, in order.

@5<<5B9> =9<>?B 3?B@?B1D9?>

take the machine out of service until the problem is diagnosed and

—Confirm

the door interlock function.

and

the locking-type door interlock (monthly), perform

and

, the door interlock function. Confirm

daily

Do not skip any step.

— End of BIRMCS01 —

Page 12

Page 13

Section 1

Commissioning

Page 14

MSOP0503AE/9274AV (1 of 1)

ÈTHE C4A ELECTRONIC COIN

WASHER-EXTRACTOR CONTROL

All controls and displays for operation of the C4A are visible on the front panel (FIGURE 1). Controls

and indicator lights for the M4A (single formula, non-coin) machine are shown in FIGURE

Detailed explanations of the following items are given throughout this manual.

ÊNameplate Controls

ËRun/Test Keyswitch—When this keyswitch and the Run/Attendant keyswitch are set to “Run,” the

machine operates normally. When this keyswitch is set to “Test” and the Run/Attendant keyswitch is set to

“Attendant,” a qualified service technician may view the software version and troubleshoot certain machine

functions by actuating displays, inputs, outputs, and functional tests.

ËTest Button—Depress this button to scroll among available tests (displays, inputs, and outputs) when

the Run/Test keyswitch and the Run/Attendant keyswitch are set to “Test” and “Attendant,” respectively.

ËRun/Attendant Keyswitch—When set to “Run,” the machine operates normally, requiring coins

for starting. When set to “Attendant,” the optional push-button (START button) operation is enabled. This

keyswitch must be set to “Attendant” to access the testing and troubleshooting functions of the control.

ËTO REDUCE SUDS Button—Used during normal operation to reduce the level of suds in the

machine to a level below the “Suds Level” line on the loading door glass, thus increasing washing efficiency.

During output testing, this button is used to toggle individual outputs and functional tests ON and OFF.

ËSTART Button (optional)—This button (optional, not shown) is enabled when the Run/Attendant

keyswitch is set to “Attendant.” It allows an attendant to operate the machine without coins.

ËSelect Temperature Buttons—These three buttons allow the user to select the appropriate first

bath water temperature for the goods loaded.

ÊDisplay

ËDeposit Coins Display—When the machine is ready for normal operation (not running a wash

cycle), these two digits display the number of coins required to start the machine. When the machine is

running a wash cycle, this display is dark. In Test mode, this display is dark except for two flashing decimals.

ËTime Remaining Display—During normal operation, this display shows the number of minutes

remaining in the current wash cycle. When the machine is in Test mode, the individual segments of this

display represent inputs, and illuminate as inputs are made.

ËMachine Status Display—During normal operatio n, this display shows which step of the wash

cycle the machine is currently performing. When the machine is in Test mode, this display is dark except for

a single flashing decimal.

ÎFIGURE 1 (MSOP0503AE)

ÎNameplate of C4A Models

Page 15

Section 2

Operating

Page 16

MSOP0502AE/9274AV (1 of 3)

ÈOPERATION OF C4A ELECTRONIC COIN WASHER-EXTRACTOR

ENTANGLEMENT HAZARD—The linen inside or hanging partially outside a

turning cylinder can suddenly wrap around you hand, arm, or body and twist

off/sever it. You can be killed or seriously injured.

ÊThe Power Up Sequence

Control circuit is

energized when power

is applied

Software version (20003) is displayed for 80 seconds after

power is applied. This safety delay prevents operation during

this time.

After 80-second

safety delay

The display flashes the number of coins (example: 15) required.

“C” (Close Door) flashes if door is open. See “HOW TO SET

REQUIRED NUMBER OF COINS” (see Table of Contents).

ÊHow To Start a Wash Cycle

Load machine

and close door

Load machine at or near rated capacity. Overloading or underloading may reduce efficiency.

Select bath

temperature

Select water temperature according to the goods loaded.

NOTE: As a factory-supplied option, the machine may be

equipped for second and third baths to be cold only, regardless

of the temperature selected.

Deposit coins Operation begins when last coin is accepted. When first coin

is accepted, display stops flashing and counts down number of

coins inserted. Coins are rejected if the door is open. The

door locks 1 minute after the machine accepts the last coin.

ËHow To Counteract Oversuds—If the suds level in the machine exceeds the “Suds Level” line on the

loading door, reduce the suds level.

Press “TO REDUCE

SUDS” button on

control panel

The drain opens for 10 seconds, then closes. Machine refills

after drain closes.

NOTE: Suds reduction can be used a maximum of three times

during each bath step.

ËHow To Start by Pushbutton (optional)—Pushbutton start is available as an option on all current coin

machine models. The following procedure applies only if your machine is equipped with this option.

Set Run/Attendant keyswitch to “Attendant”

position, and press the Start button.

Pushbutton start feature does not affect normal coin-start

operation, which works with keyswitch in either position.

Page 17

ÊDescription of Wash Formula

FIGURE 1 shows timing and operation of the standard wash cycle. During operation, the Deposit Coins dis-

play is blank and the Time Remaining display counts down minutes. The decimal flashes when the timer is counting.

ÏWash Formula for 30015C4A and 30020C4A Models

Operation Time Coast Time

Selected Temperature

Hot Warm Cold

Bleach/Suds bath 6:00 1:00 Hot Split Cold

Low-speed extract 1:00 0:30 — — —

Rinse 2:00 1:00 Split Split Cold

Low-speed extract 1:00 0:30 — — —

Softener bath 2:00 1:00 Cold Split Cold

High-speed extract 6:00 1:20 — — —

Total Time 18 :00 + 5:20 = 23:20 As a factory option, second and third baths may be

cold only.

ÎFIGURE 1 (MSOP0502AE)

ÎWash Cycle Timing for C4A Models

OPERA TION OF C4A ELE C TRONI C COI N W ASHER-EXT RACTO R MSOP0502AE/9274AV (2 of 3)

Page 18

ÊThe Power Restoration Sequence

ËIf Machine Memory Is Corrupt—If the machine lose s power while a wash cycle is runnin g and

microprocessor memory is corrupt (current wash cycle is not retained), the machine resets as shown in “The Power

Up Sequence” in this section. The microprocessor memory will remain intact approximately 24 hours without

power.

ËIf Machine Memory Is Intact AND Door Is Closed—If the machine loses power while a wash cycle

is running, and the wash cycle in progress is retained by the microprocessor, the control checks the status of the door

latch when power is restored. If the control detects that the door is closed, the wash cycle resumes—after an

80-second safety delay—at the beginning of the step in which power was lost. If the control detects that the

door is open, the machine resets as shown in “The Power Up Sequence” in this section.

The drain opens as soon as the machine loses power, but if the power outage is brief, the liquor level may not

fall enough to open the level switch. If the level switch is made when power is restored, the display indicates a Level

Switch Fault (E3) until the liquor level in the cylinder falls enough to open the level switch. When the level switch

opens, the machine clears the error and resumes the wash cycle at the beginning of the step in which power was lost.

If the error does not clear automatically, see “TESTING THE INPUTS, OUTPUTS, AND THE DISPLAY ON THE

C4A ELECTRONIC COIN WASHER-EXTRACTOR.”

If power is lost during extract, the machine executes a recycle sequence shown below when power is restored:

1. Basket rotates clockwise at wash speed for 18.5 seconds.

2. Basket accelerates to distribution speed and maintains speed for 60 seconds.

3. Timer starts and basket accelerates to extract speed. If the interrupted step is a low-speed extract, the wash

cycle proceeds normally. If the interrupted step is a final (high-speed) extract, the machine maintains

low extract speed for 100 seconds, then accelerates to high extract speed.

ÊAccessing the Formula Count Accumulator

ËOperation—The Formula Count Accumulator (FIGURE 2) tracks the number of

times the wash cycle has been run. This cumulative counter automatically increments each time the final extract step begins. The accumulator may be viewed and

compared to previous readings to determine the number of wash cycles, up to 999.

After 999 counts, the accumulator resets to 000 when next incremented.

Because the accumulator is maintained in capacitor-backed memory, a brief

power loss should not affect the count. However, a power loss of more than 24 hours

may cause memory loss, in which case an Accumulator Warning message (E1) appears on the display to indicate that accumulator memory was corrupted and reset to

0. Clear this error as described in “Viewing and Clearing Counter” in this section.

ËViewing and Clearing Accumulator—The accumulator may be viewed only when a wash cycle is not

in progress and the machine is not in Attendant mode. To view the counter, open the door and turn the keyswitch to

“Attendant.”

To clear the accumulator or an accumulator error, open the door, turn the keyswitch to “Attendant” and press

OVERSUDS three times. The accumulator displays “000” until a wash cycle is run. Always check accumulator if

power has been off for several days.

ÎFIGURE 2 (MSOP0502AE)

ÎAccumulator Display

OPERA TION OF C4A ELE C TRONI C COI N W ASHER-EXT RACTO R MSOP0502AE/9274AV (3 of 3)

Page 19

MSIN0501AE/9274AV (1 of 2)

ÈHOW TO SET REQUIRED NUMBER OF COINS

For all electronic coin washer extractors, the number of coins required to start the wash cycle is determined by

a six-position DIP switch (SW1) on the processor board (see FIGURE 1). Each position of the DIP switch (numbered 1-6) represents a specific number of coins, as shown in the Table of Sample Coin Count Settings in this

section. The total number of coins required to operate the machine for one wash cycle may be set from one to 63,

inclusive. The required count is represented by the total of all switches set to the ON position.

SHOCK HAZARD may cause severe injury.

☞ Lock OFF and tag out machine power at wall disconnect before removing

panels.

Using a small insulated screwdriver or wooden pencil, set the DIP switch for the desired number of coins. See

the Table of Sample Coin Count Settings in this section for available settings.

NOTE: The processor board to which the DIP switch is mounted is normally concealed by a dust cover.

This dust cover must be removed to gain access to the DIP switch, and must be replaced to prevent dust

accumulation on the processor board.

ÎFIGURE 1 (MSIN0501AE)

ÎDIP Switch (Positions 2 and 4 ON=10 coins)

Page 20

ÏT able of Sample Coin Count Settings

Coin Count

Switch Position and Number of Coins Represented

Position 1

(1 coin)

Position 2

(2 coins)

Position 3

(4 coins)

Position 4

(8 coins)

Position 5

(16 coins)

Position 6

(32 coins)

1 coin ✔

6 coins ✔✔

8 coins ✔

10 coins ✔✔

12 coins ✔✔

16 coins ✔

18 coins ✔✔

20 coins ✔✔

24 coins ✔✔

30 coins ✔✔✔✔

36 coins ✔✔

42 coins ✔✔✔

48 coins ✔✔

51 coins ✔✔ ✔✔

63 coins ✔✔✔✔✔✔

HOW TO SET REQUIRED NUMBER OF COINS MSIN0501AE/9274AV (2 of 2)

Page 21

Section 3

Troubleshooting

Page 22

MSTS0501AE/9274AV (1 of 5)

ÈTESTING DISPLAY, INPUTS, AND OUTPUTS

ON THE ELECTRONIC COIN WASHER-EXTRACTOR

The C4A electronic coin washer-extractor control includes several diagnostic features to aid in troubleshoot-

ing equipment problems. Procedures for using the following diagnostics are explained in this section:

1. How To View the Software Version—allows verification of software version and machine configuration

2. How To Exit the Testing Procedure—ends the testing procedure from any test.

3. How To Test the Displays—verifies that display is fully operational

4. How To Test the Microprocessor Inputs—verifies ON/OFF condition of inputs, and

5. How To Test the Outputs—allows manual operation of machine outputs.

CRUSHING AND ENTANGLEMENT HAZARD may result in loss of fingers or

limbs.

☞ DO N OT operate t his machine wi thout all pane ls securely in pl ace. The

panels prevent access to the drive mechanism and hot components, including motors and solenoids.

☞ Ensure that all personnel are clear of the machine before restarting after

service.

SHOCK HAZARD may result in serious injury.

☞ Lock OFF and tag out machine power at wall disconnect.

☞ NEVER remove panels without turning OFF all power to the machine.

Page 23

ÊHow To View the Software Version

As MILNOR®makes improvements to the software which controls these machines, the software version num-

ber changes. This information is often very helpful in troubleshooting errors and malfunctions.

ËViewing Software Version During Power Up—When power is first applied to the machine, the dis-

play will appear similar to FIGURE 1. This number is the software version; it will remain on the display for 80

seconds, then the normal operating display will appear.

ËViewing Software Version After Power Up—The software version can also be viewed after the

power up sequence has finished provided the machine is not running a wash cycle.

1. Set the Attendant keyswitch to

“Attendant.”

2. Set the Run/Test keyswitch to

“Test.”

The software version will

remain on the display until the Test

button is pressed.

ËHow To Interpret the

Software Version

—The first

digit in the Deposit Coins display

represents the machine class. In the

case of 30015C4A and 30020C4A

models, this number is “2.” The

second digit in the Deposit Coins display is ignored for these models. The two digits in the Time Remaining display,

along with the single digit in the Machine Status display, make up the revision of the software.

NOTE: If the first digit in the Time Remaining display is an alphabetic character (A-Z), the software is

non-standard; therefore, the wash cycle may not be the same as that described in “OPERATION OF C4A

ELECTRONIC COIN WASHER-EXTRACTOR” (see Table of Contents).

ÊHow To Exit the Testing Procedure

The machine may be returned to Automatic mode at any time during testing by switching the Run/Test and

Attendant keyswitches to “Run.”

ÎFIGURE 1 (MSTS0501AE)

ÎSoftware Version Display (Typical)

TESTING DISPLAY, INPUTS, AND OUTPUTS

ON THE ELECTRONIC COIN WASHER-EXTRACTOR MSTS0501AE/9274AV (2 of 5)

Page 24

ÊHow To Test the Displays

C4A models are equipped with a Test button beneath the Run/Test keyswitch, as shown in FIGURE 2. Press

this button once to begin testing the light emitting diode (LED) displays. All five digits will simultaneously display

“1,” then “2,” etc., counting upward then repeating the

sequence. All digits should be identical at any time.

Press Test to end the Display Test and start the Input

Test.

ÊHow To Test the

Microprocessor Inputs

During this test each input signal to the

microprocessor lights a specific segment of the Time

Remaining display (see Figure 3 and Table of

Microprocessor Inputs in this section).

In Test mode with the input test active, the

Deposit Coins display is dark except for two flashing

decimal points (DP1 and DP2). Likewise, the Machine

Status display is dark except for the flashing decimal.

If no inputs other than Test Mode are made, the Time Remaining

display appears as shown in Figure 3 immediately upon beginning the

input test sequence. Segment A2 corresponds to Test Mode; when this

segment lit, the machine is functioning normally in Test mode. Other

segments of the display represent other microprocessor inputs, as listed

in the Table of Microprocessor Inputs in this section. Manually actuate

each input for testing, and verify that the corresponding segment of the

Time Remaining display illuminates.

Segment A1 (OFF) represents the status of the Test button. Because the Test button scrolls the con trol through the available tests,

pressing it after the input test is selected will advance the control to the

output test without lighting segment A1. Assume that the Test button is

operating correctly if the control switched from the display test to the

input test when the Test button was pressed.

Alternatively, press and HOLD the Test button while in the display test. Segment A1 will remain illuminated as long as the Test button

is held.

ÎFIGURE 2 (MSTS0501AE)

ÎTesting Controls—C4A Models

ÎFIGURE 3 (MSTS0501AE)

ÎTime Remaining Display

(Input Test Mode)

TESTING DISPLAY, INPUTS, AND OUTPUTS

ON THE ELECTRONIC COIN WASHER-EXTRACTOR MSTS0501AE/9274AV (3 of 5)

Page 25

ÏTable of Microprocessor Inputs

Segment

Illuminated Input Name

Connector-

Pin

Input Status when

Illuminated

A1 Test Button (SHPS) MTA4-6 Test button depressed. (This input can be

tested only if the Test button is HELD

DEPRESSED while in the display test.)

B1 Door Interlock (CRDL) MTA4-5 Door is closed.

C1 Run/Attendant Keyswitch (SK01) MTA4-4 Keyswitch set to “Attendant.”

D1 not used — —

E1 Low Water Level Switch(SPLL) MTA4-2 Low level switch (SPLL) is made.

F1 Start Button (SHS+; optional) MTA4-1 Optional Start button is depressed

G1 not used — —

A2 Run/Test Keyswitch (SKM0) MTA5-6 Machine is in Test mode.

B2 Oversuds Button (SHDR) MTA5-5 Oversuds button is depressed.

C2 not used MTA5-4 —

D2 Normally-open Coin Switch

(SMS$; 1-7)

MTA5-3 Normally-open contact on coin mechanism

is closed.

E2 not used — —

F2 Normally-closed Coin Switch

(SMS$; 4-7)

MTA5-1 Normally-closed contact on the coin

mechanism is open.

G2 not used — —

ÊHow To Test the Outputs

Press the Test button to enter the output test from the input

test. When the output test is active, the Deposit Coins display

flashes “00.”

The Table of Manual Outputs in this section lists the tests

of output relays and systems. Press the Test button to scroll the

appropriate test (see Table of Manual Outputs) into the Time

Remaining display. Press TO REDU CE SUDS to toggle the

ON/OFF status of the output or functional test. Press the Test

button to turn the output OFF and advance to the next output or

functional test.

In Test mode, the door locks when either motor is energized, and remains locked for 10 seconds after the motor is deenergized. When the door is closed, certain relays operate in

combination; all relays function individually when the door is

open. Functional tests 17 and 18 are not available when the door

is open.

ÎFIGURE 4 (MSTS0501AE)

ÎTime Remaining Display Segments

TESTING DISPLAY, INPUTS, AND OUTPUTS

ON THE ELECTRONIC COIN WASHER-EXTRACTOR MSTS0501AE/9274AV (4 of 5)

Page 26

ÏT able of Manual Outputs

Test

Number

Output Relay Relay Name or

Functions Tested

Result or Test Sequence

Relay/Test status shown in “Machine Status”

01 K0 Clutch 0=engage extract clutch 1=engage wash clutch

02 K1 Cold water valve 0=close cold water valve 1=open cold water valve

03 K2 Hot water valve 0=close hot water valve 1=open hot water valve

04 K3 Coin rejector solenoid 0=accept subsequent

coins

1=reject subsequent

coins

05 K4 Not used None

06 K5 Not used None

07 K6 Not used None

08 K7 Not used None

09 K8 Extract Basket turns clockwise. Energize clockwise wash

relay (CRWAC) and engage extract clutch.

10 K9 Distribution Basket turns clockwise. Energize extract relay

(CREX) energized and engage wash clutch.

11 K10 Clockwise wash Basket turns clockwise. Clockwise wash relay

(CRWAC) energized and wash clutch engaged.

12 K11 Counter-clockwise wash Basket turns counter-clockwise. Energize

counter-clockwise wash relay (CRWAA) and

engage wash clutch.

13 K12 Not used None

14 K13 Not used None

15 K14 Drain solenoid 0=open drain valve 1=close drain valve

16 K15 Door interlock 0=unlock door 1=lock door

17 Functional test Water valves, drain

solenoid, level switch,

and reversing wash

speed

Door must be closed for this test.

• Engage wash clutch and open water valve(s).

• Basket reverses; water shuts off at level

• Open drain if oversuds pressed, machine

refills when released.

18 Functional test Extract speeds and vibra-

tion switch

Door must be closed for this test.

• Energize clockwise wash relay and energize

clutch for 20-second clockwise wash speed

• Energize distribution relay for 20-second

distribution speed

• De-energize clutch and distribution relay, and

energize CRWAC for 20-second low extract

• De-energize CRWAC and energize CREX for

high extract

• If vibration switch is manually tripped during

high extract, CRWAC replaces CREX in circuit,

yielding low extract

TESTING DISPLAY, INPUTS, AND OUTPUTS

ON THE ELECTRONIC COIN WASHER-EXTRACTOR MSTS0501AE/9274AV (5 of 5)

Page 27

MSTS0502AE/9274AV (1 of 2)

ÈHOW TO CORRECT ERRORS

WITH THE C4A CONTROL

ÊLoading Door Open During Operation

If the loading door should open during operation, the basket stops, the

program timer stops, and the drain opens. The Machine Status display shows

“C” (Close Door), as shown in FIGURE 1. When the door is closed, operation

resumes from where it was interrupted.

ÊOther Error Conditions

If an error other than “Loading Door Open” occurs, the Time Remaining display flashes an error code corresponding to the error, and the Machine Status display alternately flashes “E” (Error) and “U” (Unload).

Ë“Accumulator” Warning

formula count

accumulator memory

was corrupted and

accumulator was reset

to “000”

This error may be caused by a protracted lack of power to the processor

board, or when the machine is first started after the processor board is

replaced (see “Accessing the Formula Count Accumulator” in “OPERATION OF C4A ELECTRONIC COIN WASHER-EXTRACTOR” (see

Table of Contents)). Manually clear the accumulator to correct this error:

1. Open loading door, and set Run/Attendant keyswitch to “Attendant.”

2. Press “To Reduce Suds” button three times.

3. Return keyswitch to “Run.”

Ë“Coin Switch” Fault

coin switch not

responding properly,

subsequent coins are

rejected

1. Check for sticking for faulty coin switch.

2. Check input wiring and connections.

3. Correct error.

4. Turn Run/Attendant keyswitch to “Attendant” then to “Run” to clear

display.

Time

Remaining

Machine

Status

Time

Remaining

Machine

Status

Time

Remaining

Machine

Status

USE

QUARTERS

ÎFIGURE 1 (MSTS0502AE)

ÎDoor Open Error Display

Page 28

Ë“Level Switch” Fault

level switch normally

open contact is

CLOSED.

Check for faulty level switch. Replace if necessary.

Ë“Too Long to Fill” Error

maximum fill time

(10 minutes)

exceeded

Software Date Codes before 20003: Operation terminates. Door unlocks after 15 seconds with operation disabled during delay.

Software Date Codes 20003 and later: Machine continues to fill with

water, basket reverses at wash speed. Error clears without manual intervention when level is achieved.

Corrective Action: Check inlet water pressure, and check debris screens

on inlet tubing.

Ë“Too Long to Drain” Error

maximum drain time

(40 seconds) exceeded

Operation terminates, door unlocks after 15 seconds with operation disabled during delay. Check for clogged drain line or stuck drain valve.

Corrective Action: Turn Run/Attendant keyswitch to “Attendant” then

back to “Run” to clear display.

Time

Remaining

Machine

Status

Time

Remaining

Machine

Status

Time

Remaining

Machine

Status

HOW TO CORRECT ERRORS

WITH THE C4A CONTROL MSTS0502AE/9274AV (2 of 2)

Page 29

Section 4

Supplemental Information

Page 30

MSFD0503AE/9274AV (1 of 2)

ÈTHE HARDWARE IN C4A ELECTRONIC COIN

WASHER-EXTRACTOR CONTROLS

ÊGeneral

The MILNOR® C4A microprocessor control is designed specifically for MILNOR machines. Along with

certain external electromechanical relay logic and sensing devices, they control all machine and system functions.

Not every microprocessor includes all the following components.

ÊThe Microprocessor Components

Ë1. Keyswitches—The RUN/ATTE NDANT keyswitch and the RUN/TEST keyswitch allow access to the

RUN and TEST modes only by authorized personnel. The RUN/ATTENDANT key may be removed only in RUN,

and the RUN/TEST key may be removed only in RUN. Never leave keys accessible to unauthorized personnel.

Ë2. Display—The display is light emitting diode (LED).

Ë3. Power Supply—Converts control circuit AC voltage to +12VDC, -12VDC, and +5VDC for the CPU board.

The power supply is auto switchable between 120VAC and 240VAC.

Although the +12VDC and -12VDC are not adjustable, the +5VDC is rather sensitive and the power supply

must be adjusted most accurately, so that the actual voltage at the Power Supply and at the CPU board is

between 5.04 VDC and 5.06VDC as measured by an accurate digital voltmeter; otherwise the machine will

likely malfunction.

Ë4. CPU Processor Board—The Central Processing Unit (CPU) processes data received from the various

inputs, stores information, and responds to each pushbutton entry with the appropriate action. Data is stored in three

microprocessor chips, which reside on the CPU.

E-PROM—contains fixed instructions programmed by MILNOR® (software) that dete rmine how the

machine functions. Also contains the standard formulas for all industries.

S-RAM—stores the accumulator (formula count) data so long as the machine has power, or via a capacitor

for approximately 48 hours with power off. Also stores where machine was last when power is turned off at

machine.

Page 31

Ë5. Output Board—The 16 output relays are socket-mounted SPDT electromechanical relays with contacts

capable of faithfully conducting a maximum of 25VA (0.1 ampere or 100 milliamperes at 220/240VAC, or 0.2

amperes or 200 milliamperes at a maximum of 110/120VAC). The output will be either 220/240VAC or

110/120VAC depending on the machine model/type.

These outputs and their power source are intended only to drive another relay with higher contact ratings that,

in turn, may drive a pump, valve, solenoid, etc., from a separate power source. Never use these outputs to

directly drive a pump, valve, or solenoid unless the maximum current required never exceeds the above

values. Higher ampere or VA loads will burn out traces on the printed circuit board or possibly overload and

damage the control circuit transformer.

THE HARDWARE IN C4A ELECTRONIC COIN WASHER-EXTRACTOR CONTROLS MSFD0503AE/9274AV (2 of 2)

Page 32

MSSM0217AE/9020IV (1 of 5)

ÈHOW TO CHANGE EPROMS IN MICROPROCESSORS

AND WHERE TO CHECK THE DC VOLTAGES

Occasionally, software enhancements become available. Depending upon the software change, the new software EPROMs (Erasable, Programmable, Read-Only Memory) may be offered for sale or for no charge to the

customer. When a set of EPROMs is changed in the field, ensure that the software version being installed matches

the machine hardware and that EPROMs are installed in the proper socket positions and orientation.

ÊHow To Change EPROMs

SHOCK HAZARD—Electrical components on the machine conduct high voltage

that will kill or seriously injure you on contact.

☞ Lock OFF and tag out electrical power at the main (wall) disconnect before

beginning this procedure.

1. Make sure all power to the machine is off.

2. Locate the EPROMs as described in “Location of EPROMs on Proces-

sor Board” in this section. Note the orientation of the EPROMs as

shown in FIGURES 3, 5, 7, and 9.

D

G

B

E

3. Slip a small flat tool underneath the EPROM, and carefully remove

each old EPROM from its base, taking note of their numerical order

(see FIGURES 3 and 7) and orientation to the key notch on the socket.

4. Install new EPROMs, making sure the key notch on the EPROM is

properly oriented and that all pins enter the proper holes in the socket

(FIGURE 1). If necessary, slightly bend the pins on the EPROMs to

align them in the socket. After inserting each EPROM, verify that all

ÎFIGURE 1

ÎProperly Seating the EPROM

(MSSM0217AE)

pins are seated in the socket.

COMPONENT DAMAGE HAZARD—Incorrectly installing any EPROM may

cause EPROM burn out, machine failure, or display error.

☞ Match each EPROM with its corresponding socket. Each EPROM will

only one socket, although it may physically

fit

in others.

work

in

☞ Align EPROM so every pin mates with the correct hole in the socket.

ËVerifying Proper EPROM Installation

—After installing new EPROMs, apply power to the machine

and turn the machine on. If the EPROMs are properly installed, the display will continue with the normal display

sequence when powering up. If the display is blank or appears unusual, turn the machine off at once and check the

orientation of the EPROMs.

F

F

Page 33

HOW TO CHANGE EPROMS IN MICROPROCESSORS

AND WHERE TO CHECK THE DC VOLTAGES MSSM0217AE/9020IV (2 of 5)

B

C

ÊLocation of EPROMs on Processor Board

Depending on machine model and type, the CPU chip can be an Intel 8085 or an Intel 8088. Each microprocessor board requires at least one EPROM for proper operation, but the EPROMs are located differently, depending

upon the type of board. This information describes the location and arrangement of the EPROM chips on each type

of board. It also describes where to check the voltages required by the processor board.

Ë8085 Processor Boards,

NOT Coin Machine

—See FIGURE 3. Install EPROM #1 at the end of the

row, then #2, #3, and #4. Chip #4 goes next to the two soldered chips on the board. See FIGURE 2 for where to

check voltages.

ÎFIGURE 2

(MSSM0217AE)

ÎMTA-31 on 8085 Processor Board

(wires not shown for clarity)

ÎFIGURE 3

(MSSM0217AE)

Î8085 Processor Board (NOT Coin Machine)

Page 34

HOW TO CHANGE EPROMS IN MICROPROCESSORS

AND WHERE TO CHECK THE DC VOLTAGES MSSM0217AE/9020IV (3 of 5)

Ë8085

Coin Machine

Processor Boards

—See FIGURE 5. Install the single

EPROM in socket IC7 below connector W34. These boards have no battery.

DIP switch

ÎFIGURE 4

8085 chip

EPROM in

socket IC-7

MTA connectors

Chassis ground

(MSSM0217AE)

ÎMTA-1 in 8085 Coin Machine

(wires not shown for clarity)

ÎFIGURE 5

Î8085 Coin Machine Processor Board

H

Capacitor

(MSSM0217AE)

Page 35

HOW TO CHANGE EPROMS IN MICROPROCESSORS

AND WHERE TO CHECK THE DC VOLTAGES MSSM0217AE/9020IV (4 of 5)

B

Ë8088 Processor Boards

C

Without Memory Expansion Board

—See the table of EPROM loca-

tions (below) and FIGURE 7. If the set consists of only one EPROM, install it in socket A of FIGURE 7. If two

EPROMs comprise the set, install EPROM #2 in socket A and EPROM #1 in socket B. Always install highest

numbered EPROM in socket A. If the set consists of more than two EPROMs, a Memory Expansion Board must

be present in the machine along with the processor board.

Ë8088 Processor Boards

With Memory Expansion Board

—See the table of EPROM locations

below and FIGURE 7. If the EPROM set consists of three or more EPROMs, install the two highest numbered

EPROMs (e.g., EPROMs #3 and #4 of a four-chip set) on the processor board, with the highest numbered E-PROM

(EPROM #4 of a four-chip set) in socket A, and the EPROM with the second highest number (EPROM #3 of a

four-chip set) in socket B. Install the remaining EPROM(s) on the Memory Expansion Board with the highest

numbered of the remaining EPROMs (e.g., EPROM #2 of a four-chip set) in socket IC-1 on the Memory Expansion

Board and EPROM #1 in socket IC-2.

EPROM Locations on 8088 Processor Board

and Memory Expansion Board

E-PROM Location by Socket

(see FIGURE 4)

EPROMS in Set A B IC-1 IC-2

4-chip set 4321

3-chip set 3 2 1 —

2-chip set 2 1 ——

1-chip set 1 ———

ÎFIGURE 6

Î1MTA-31 on 8088 Board

(MSSM0217AE)

(wires not shown for clarity)

Î8088 Processor Board and Optional Memory Expansion Board

ÎFIGURE 7

(MSSM0217AE)

Page 36

R

HOW TO CHANGE EPROMS IN MICROPROCESSORS

AND WHERE TO CHECK THE DC VOLTAGES MSSM0217AE/9020IV (5 of 5)

Ë80186 Processor Boards

—This processor board

is used on all Milnor system controllers (Miltron, Mildata,

etc.) equipped with a color monitor, and on textile processing machines with software versions 95000 and later. The

single EPROM on this board is located in socket IC-2.

Chassis Ground

IMTA28

ÎFIGURE 8

(MSSM0217AE)

Î1MTA-31 on 80186 Board

1MTA31

Capacitor

2MTA31

1MTA32

1MTA33

(wires not shown for clarity)

1MTA34

1MTA29

MTA30

I

80186 Processor

ROM socket

(empty except

for Japan)

EPROM in

socket IC-2

MTA35

ÎFIGURE 9

MTA40

(MSSM0217AE)

MTA37

MTA36

MTA38

MTA39

Î80186 Processor Board

Loading...

Loading...