Milnor BICWUT01 User Manual

Published Document Number: BICWUT01

• Specified Date: 20050118

• As-of Date: 20050118

• Access Date: 20050118

• Depth: detail

• Applicability: CWU

• Language Code: ENG01, Purpose: publication, Format: 1colA

Document—

Troubleshooting Basket

Speed Errors on Singlemotor Washerextractors

PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063 - 0400, U.S.A.

BICWUT01 (Published) Book specs- Dates: 20050118 / 20050118 / 20050118 Lang: ENG01 Applic: CWU

Troubleshooting Basket Speed Errors on Single-motor Washerextractors

This document describes the proper procedure for troubleshooting errors related to basket motor

speed on machines equipped with a single motor, an inverter, and a digital-to-analog (D-to-A)

board.

1. As the basket rotates, a photoeye sees each spoke of the main drive pulley. The photoeye

sends a pulse representing each pulley spoke to an input/output board (I/O #1).

2. I/O #1 determines the time between pulses and communicates this to the machine processor

board.

3. The processor board calculate the RPM and compares this value to the digital value

corresponding to the programmed basket speed. If the speed is incorrect, the processor board

signals the digital-to-analog (D-to-A) board to slightly increase or decrease the basket speed.

4. The D-to-A board converts the digital signal from the processor board to an analog voltage of

0 to 10 volts and sends it to the inverter. The speed at which the inverter drives the motor is

directly related to the voltage output of the D-to-A board.

5. The inverter interprets the voltage from the D-to-A board and adjusts the voltage and

frequency of the motor supply to drive the motor at a different speed.

6. The motor speed changes, causing the spokes on the main pulley to pass the photoeye at a

different rate, and the speed control circuit is complete.

The most common indicator of a problem somewhere in the speed control circuit is that the

basket does not turn at the desired speed, or does not turn at all. The chart in Figure 1

describes the overview of the troubleshooting process.

WARNING 1 : Electrocution and Electrical Burn Hazards—Hazardous voltages can

cause sever injury or death.

• Whenever possible, lock all power sources feeding the inverter in the “OFF” position.

• The status indicator LEDs and the inverter display will be extinguished when the DC

voltage inside the inverter is below 50VDC. Wait at least one additional minute for

voltages to further dissipate.

PELLERIN MILNOR CORPORATION

Troubleshooting Basket Speed Errors on Single-motor Washer-extractors

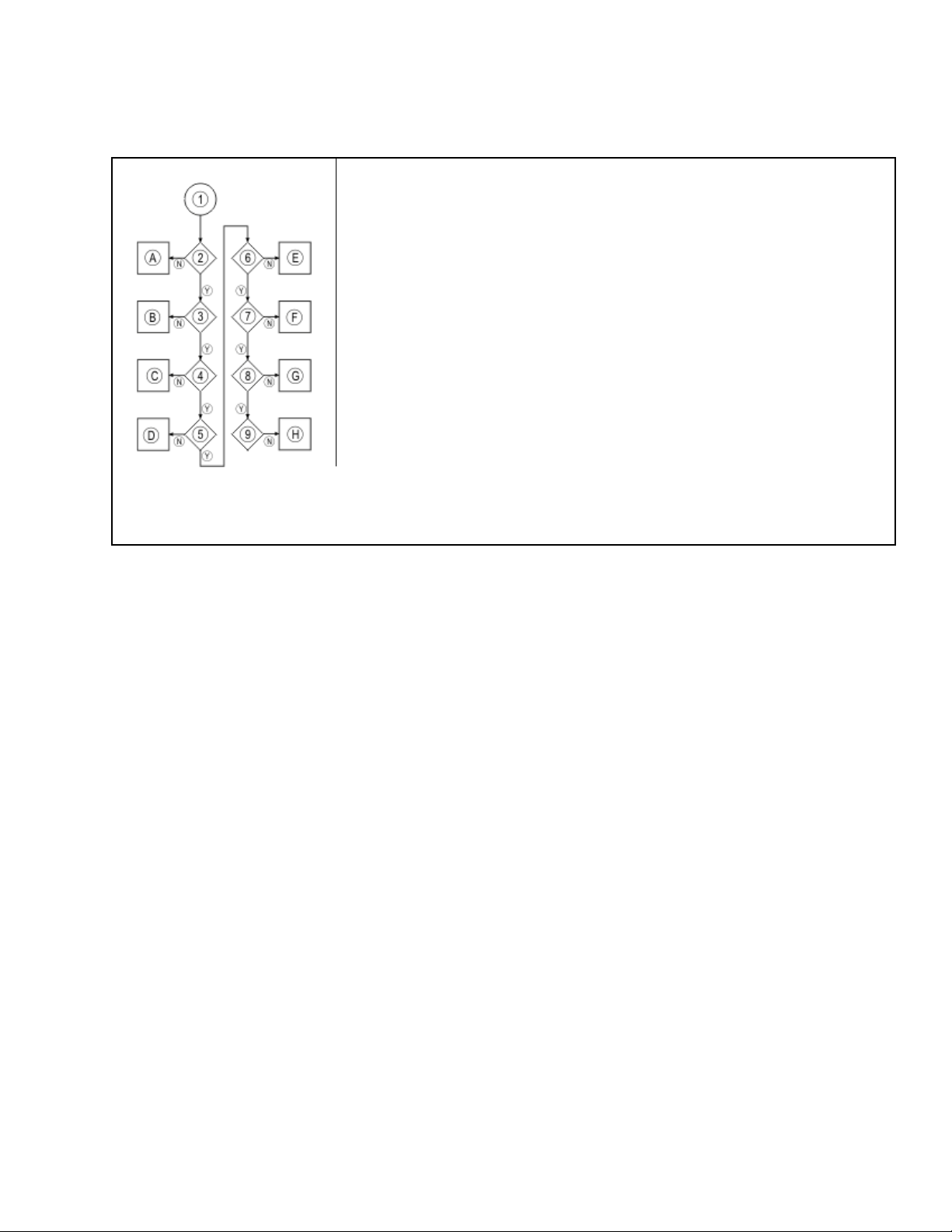

Figure 1: Troubleshooting Speed Errors

Process Chart Legend

Y. Yes

N. No

1. Machine does not run at desired speed.

2. Section 1: Is desired speed programmed in wash formula?

A. Edit wash formula.

3. Section 2: Are inverter parameters correct for this machine model?

B. Contact Milnor, and correct inverter parameters.

4. Section 3: Does digital counts value match desired speed?

C. Contact Milnor for updated software.

5. Section 4: Does D-to-A output voltage at D-to-A board match desired speed?

D. Replace D-to-A board.

6. Section 4: Does D-to-A voltage at inverter match desired speed?

E. Check wiring from D-to-A board to inverter.

7. Section 5.1: Does inverter output frequency match input voltage?

.

F. Review inverter parameters, and contact Milnor Customer Service.

8. Section 5.2: Is inverter output amperage within normal limits?

G. Contact Milnor Customer Service before repairing or replacing inverter.

9. Section 6: Does motor test within normal limits?

H. Contact Milnor Customer Service before repairing or replacing motor.

PELLERIN MILNOR CORPORATION

Loading...

Loading...