Milnor 76032 User Manual

CBW® PulseFlow™ Batch Washers

On very rare occasions

an evolution takes place that

makes everyone stop and notice.

Revolutionizing Tunnel Technology. Again.

CBW® PulseFlow

™

Batch Washers

The History

Since their introduction in the 1960s, tunnel washers

have saved water, energy, and loads of labor. Since 1979,

the Milnor CBW

in tunnel washing. With innovations such as True Top

Transfer, Solid Welded Partitions, Double Drum

Construction, and High Mechanical Action, our

productive and efficient equipment is unrivaled.

As a world-leading manufacturer of laundry

equipment since 1947, Milnor knows laundry

processing. And we’ve revolutionized tunnel

washing... Again.

®

washer has been a worldwide leader

Pellerin Milnor

05: PulseFlow Technology

18: True Top Transfer

20: Solid Welded Partitions

22: Double Drum Throughout

24: High Mechanical Action

26: Compare

28: Control Systems

30: System Equipment

PulseFlow™ Benefits

Pellerin Milnor has developed

a revolutionary, patent-pending

system—PulseFlow Technology—

which has been successfully

implemented in numerous locations

in the USA and Europe. The soil

removal and rinsing performance

of PulseFlow Technology has been

verified by an independent testing

laboratory. PulseFlow Technology in a

new Milnor CBW

®

washer offers:

Introducing Milnor’s CBW® PulseFlow™ Technology.

• Lowest Water Consumption

• Enhanced Chemical Performance

• Low Energy Usage

• Faster Washing

05: PulseFlow™

PulseFlow™ Technology

The new Milnor PulseFlow™ Technology system offers a

major breakthrough in batch washing technology. This patent-

pending innovation retains all the proven features that have

made the Milnor CBW

and improves upon that technology with increased productivity,

reduced utilities and more efficient use of chemical energy.

PulseFlow

with a standing bath and counterflow to occur in every module

except the last. For the greatest part of each cycle, “PulseFlow”

without counterflow, creates standing baths, so that chemicals

are allowed to do their job better without being diluted. Then,

for a very short portion of each cycle, high-velocity counterflow

™

Technology combines traditional “True Top Transfer”

®

washer the market leader for over 30 years,

Technology

A: The Innovation

B: Lowest Water

Consumption

C: Enhanced Chemical

Performance

D: Low Energy Usage

E: Faster Washing

is initiated—PulseFlow—thus providing the required dilution

very quickly with less water compared to full-time counterflow.

Dedicated rinse modules are not required, meaning more

production from fewer modules.

How Does It Work?

Standing Bath (SB)

Standing Bath (SB)

Extra

Chemical

Extra Time

for Chemicals

NEW PulseFlow™ Technology (PFT)

(Vigorous, High-Flow-Rate

PulseFlow

Top

Transfer (TT)

PFT

TT

SB

PFT

TT

PREVIOUS 100%

Continuous Counter Flow (CF)

A. The Innovation

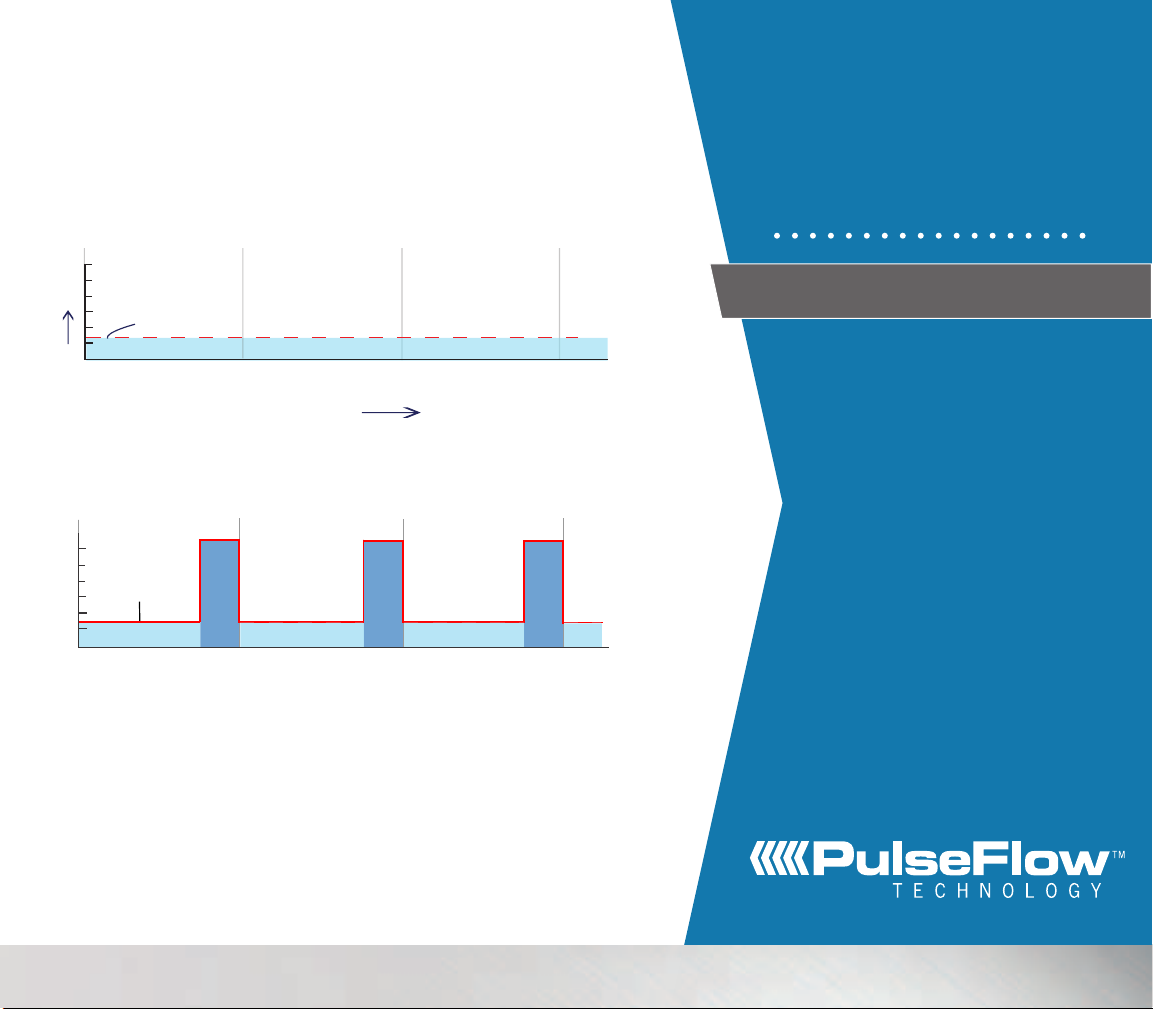

Milnor’s new PulseFlow™ Technolgy is a unique but simple

solution for faster and more water-efficient washing in a

Continuous Batch Washer.

Previous Counter Flow

PREVIOUS 100%

Counter Flow (CF)

(GPM)

Module A Module B

Time (Modules)

Proven Milnor Top Transfer (TT) design still “leaves the dirty water

behind” for immediate dilution upon each transfer.

New PulseFlow

Water Level

(GPM)

Water Flow Rate

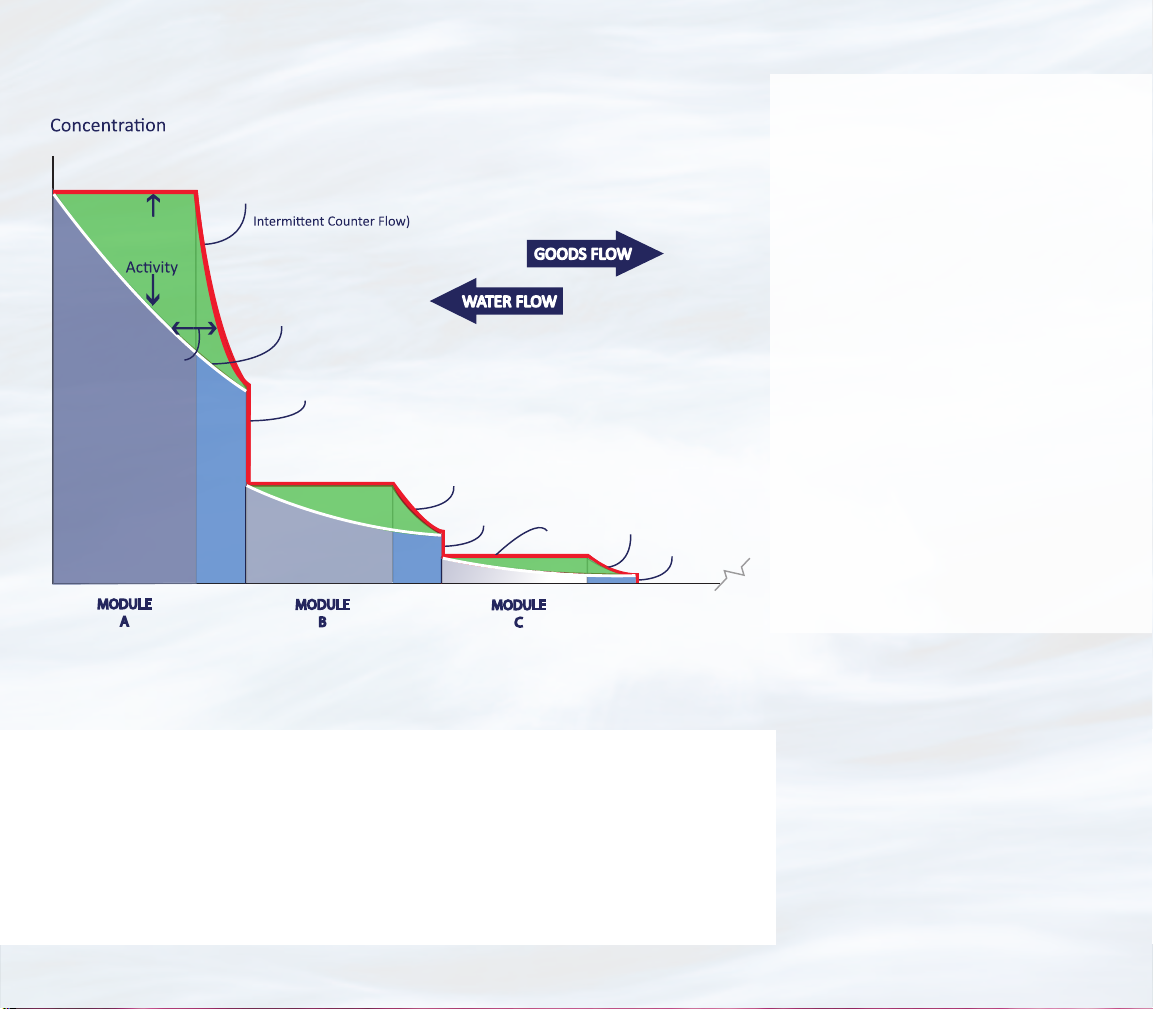

The Milnor CBW® washer with New PulseFlow™

MODULE A

Technology offers users the best of all worlds:

• The new system creates a Standing-Bath (SB) without flow for the

major portion of each bath allowing the chemicals time to reach full

equilibrium and work more effectively.

• PulseFlow™ Technology feature retains full Counterflow (CF)

(universally accepted as the most effective rinsing method for

tunnels), using controlled, high-velocity, intermittent pumps.

™

Technology

PulseFlow

MODULE B MODULE C

Time (Modules)

PulseFlow

Module C

PulseFlow

06: PulseFlow™

Technology

A: The Innovation

B: Lowest Water

Consumption

C: Enhanced Chemical

Performance

D: Low Energy Usage

E: Faster Washing

How Does It Work?

Standing Bath (SB)

Extra

Chemical

NEW PulseFlow™ Technology (PFT)

(Vigorous, High-Flow-Rate

How Does it Work?

®

The Milnor CBW

Continuous Batch Washer

™

with PFT

washes faster

PREVIOUS 100%

Continuous Counter Flow (CF)

Extra Time

for Chemicals

Top

Transfer (TT)

Standing Bath (SB)

PulseFlow

Now, with Milnor’s new PulseFlow™ Technology, we simply stop the counterflow

completely for the first 65-75% of each transfer cycle and then pump the entire

amount of counterflow water at a very fast rate in the 25-35% of time remaining

(see diagram above). The pumps are high-velocity, inverter driven variable speed

so that both GPM and duration can be varied based on goods being processed.

The high-speed flow gives better wash action and uses far less water.

PFT

TT

SB

PFT

TT

(same lbs/hr in less

modules), uses less water

(as little as 0.3 US gals.

lb

or 2.5 l/kg), uses less fuel

to heat water; and lets

the wash chemicals work

more effectively. All of

which creates unsurpassed

customer value.

B. Lowest Water Consumption

Milnor CBW® washers with new PulseFlow™ Technology wash

and rinse linen at a rate of 0.6 - 0.8 gallons per pound (5 - 6.7

liters per kilogram) with a fresh water replenishment rate as low

as 0.3 gallons per pound (2.5 liters per kilogram) for light soil

processing and 0.5 gallons per pound (4.2 liters per kilogram) for

heavy soil processing.

PulseFlow™ Technology saves water with these features:

• Interrupted Counterflow: water only flows about 25-35% of each cycle.

• Pumped Counterflow: water is delivered by high-volume inverter pumps

with vigorous flow that remove soil and chemistry faster with less water.

• Dual-Use Modules: each module is used for both standing chemical baths

AND counterflow rinsing.

• Eliminates Rinse Modules: single-purpose rinse modules are eliminated.

• Better Use of Chemistry: Reduced chemicals require less water to rinse.

• Controlled Flow: inverter pumps utilize programmable time and flow

rates, keeping water use low.

08: PulseFlow™

Technology

A: The Innovation

B: Lowest Water

Consumption

C: Enhanced Chemical

Performance

D: Low Energy Usage

E: Faster Washing

• Recycled Wet-down Water: high-volume pump circulates bath water

for quicker loading and wet down.

• Full Water Availability: fresh water and recycled press water are

collected in a single tank mounted within the washer frame (under

the load scoop). No external tanks exist.

Lint Removal Screen

The 430 micron wedgewire

screen removes lint and

other solids from the

process water.

Loading...

Loading...