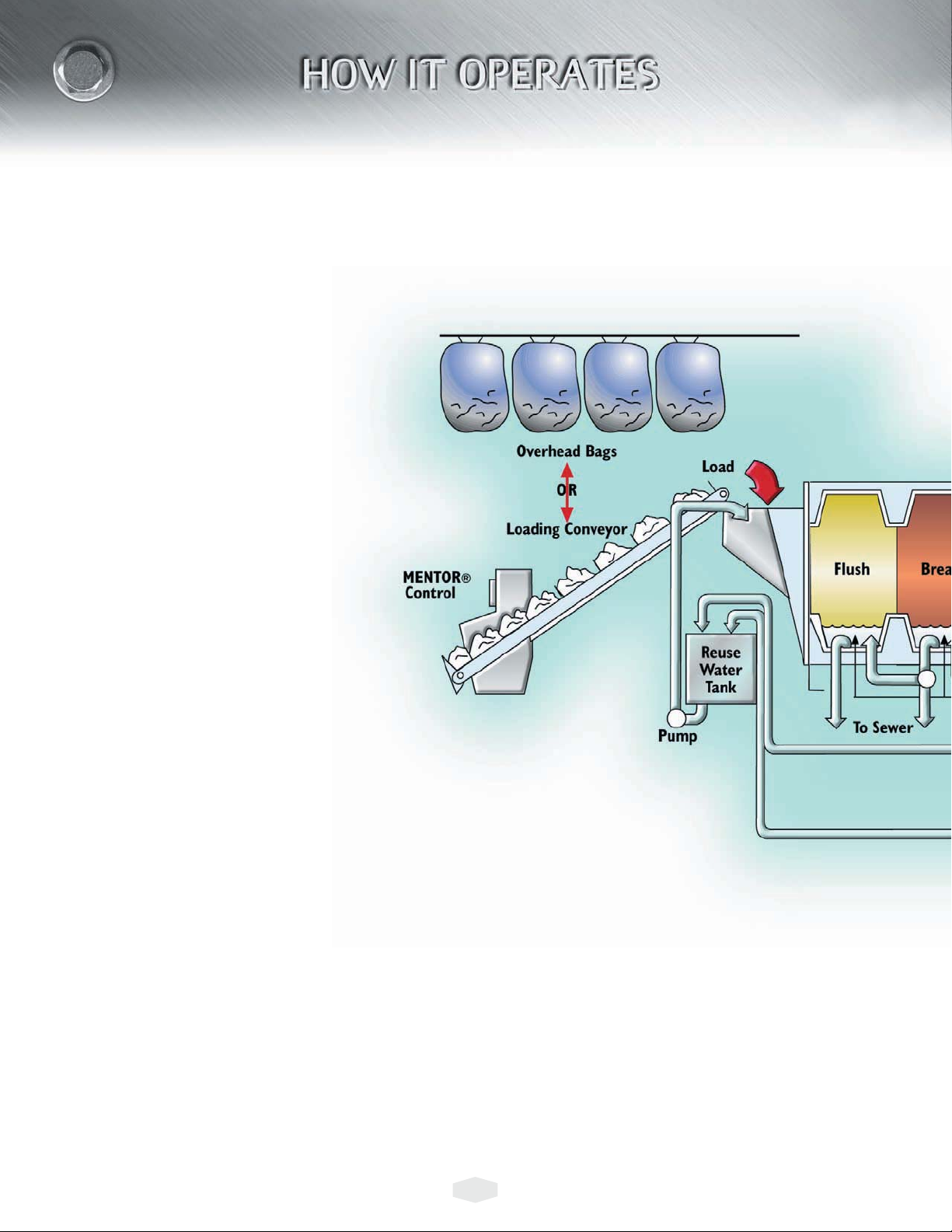

A variety of arrangements.

Each Milnor CBW washer is custom-made for the

customer’s specific needs. More modules give greater

production. Water inlets and drain valves give

greater flexibility. Mentor control allows

predetermined temperature and chemical levels for

each individual bath.

Mentor®Control.

The operator puts a batch in line for loading, then

enters the goods classification number into the

Mentor control. This automatically selects the

processing formula which follows the batch until it’s

automatically unloaded from the dryer and delivered

to its finishing destination.

Loading.

A conveyor or overhead bag system may feed the

load chute.

Washing.

Each module has a stationary shell – to hold the

wash bath – and a rotating, perforated inner

cylinder. Each module can be used for different

baths. Goods proceed through the formula by

traveling from module to module, via a perforated

top transfer scoop. There are no stops and starts for

draining and filling after each bath. This saves time,

compared to conventional washing machinery.

Temperature controls.

Any module can be equipped with a steam inlet

and temperature probe.

Supplies.

Supply inlets can be placed in each module.

The Mentor control dictates the amount of supplies

and when – or if – they are added to the specific

goods in each module during the wash cycle.

Post-wash.

The MultiTrac system relays each batch’s

post-wash requirements to other parts of the system

– extractor, shuttle, dryers, and conveyors.

A CRT display identifies batch location and status.

Where multiple-batch dryers are used, the control

system prevents mixing of incompatible batches in

the same dryer.

1

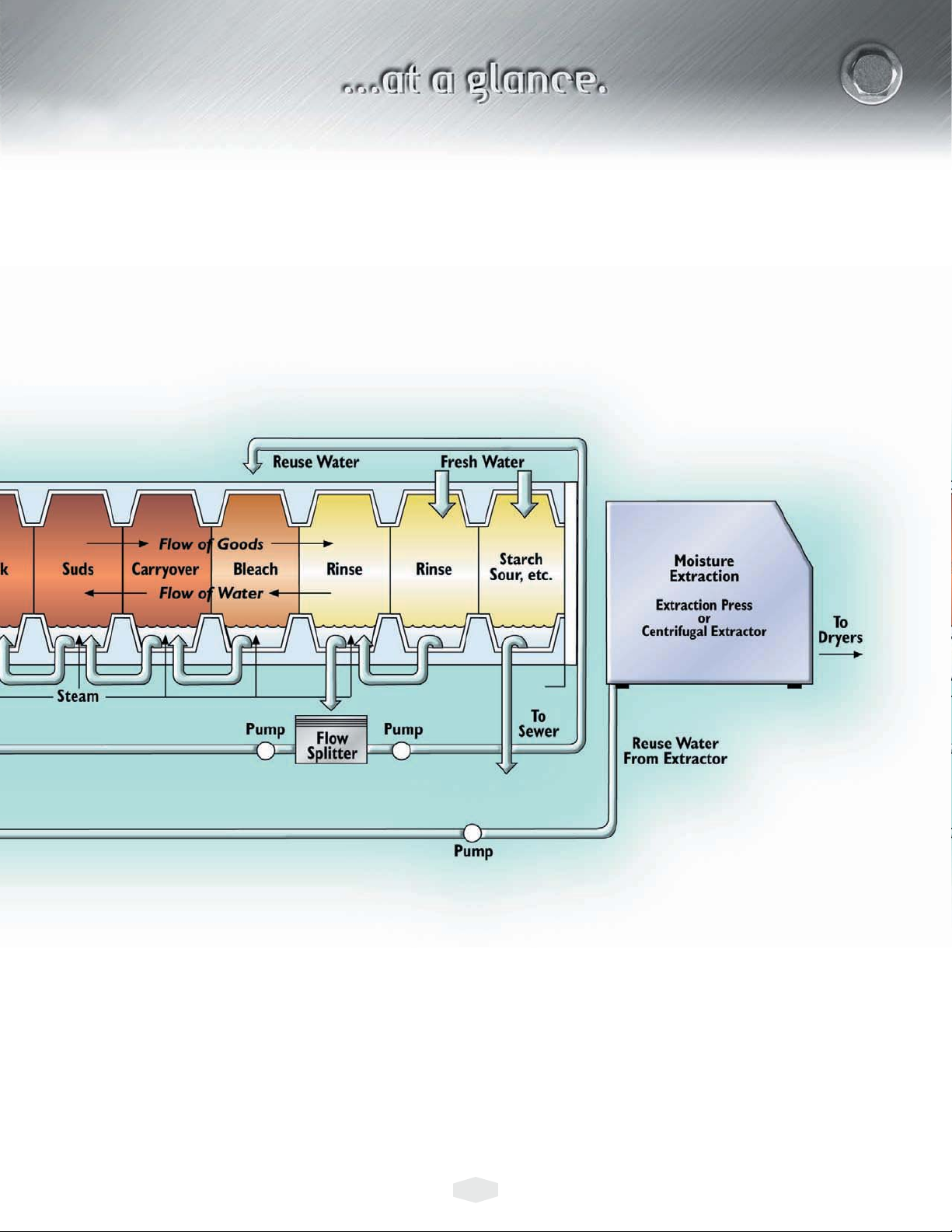

Tunnel washers were developed to save water, energy

and labor, and to expedite the flow of goods through

the laundry. Since they entered the market in the

1960s, they’ve all done this to some degree.

Early tunnel washers were bottom transfer machines.

To move the goods from one stage of the washing

process to the next, they transferred the goods and

ALL the water along the bottom. Even the first

batch

successful

tunnels did this. And today, the

same is still true of some tunnel washers made by

others.

But the Milnor CBW washer has taken tunnel

washing another step forward. This is a top transfer

machine. It lifts and drains the goods before

transferring them into the next processing stage.

This results in a high level of wash quality for

a range of goods – everything from light hospitality

2

linen to heavy-soil industrial goods can be laundered

in a Milnor CBW washer.

There are other features that set a Milnor CBW

washer apart from other tunnels – such as modular

construction and double drum characteristics

throughout. What distinguishes a Milnor tunnel

washer from the competition are better dilution,

higher wash quality and more rugged construction.

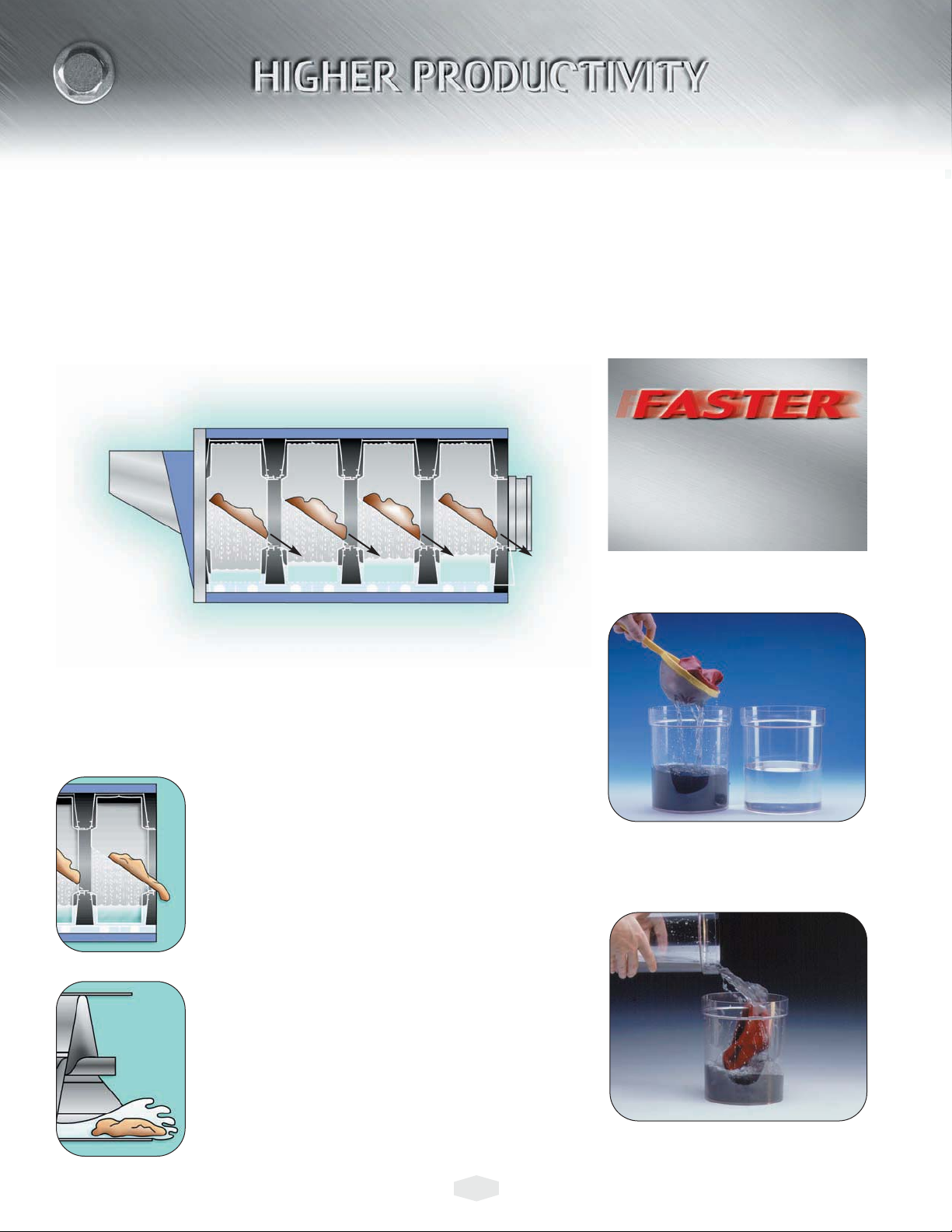

Top transfer increases productivity.

Milnor top transfer CBW washers have proven higher productivity in more than 1,300 installations worldwide. They wash faster than other tunnel washers due

to superior dilution – which means better soil removal. This yields two major advantages:

B More production in a given number of compartments, or…

C Fewer compartments to achieve the same production. Both of these advantages save wear and tear on the goods.

’s better washing quality – and higher productivity – result from:

Milnor

•Better dilution. •Better wash liquor penetration. •Better mechanical action. •More cylinder space.

Better dilution means

processing.

The proven result of all of this:

Dilution is far greater in a Milnor than in other tunnels.

That’s the main reason Milnor can wash and rinse more quickly,

and why Milnor can also wash heavily soiled goods so well.

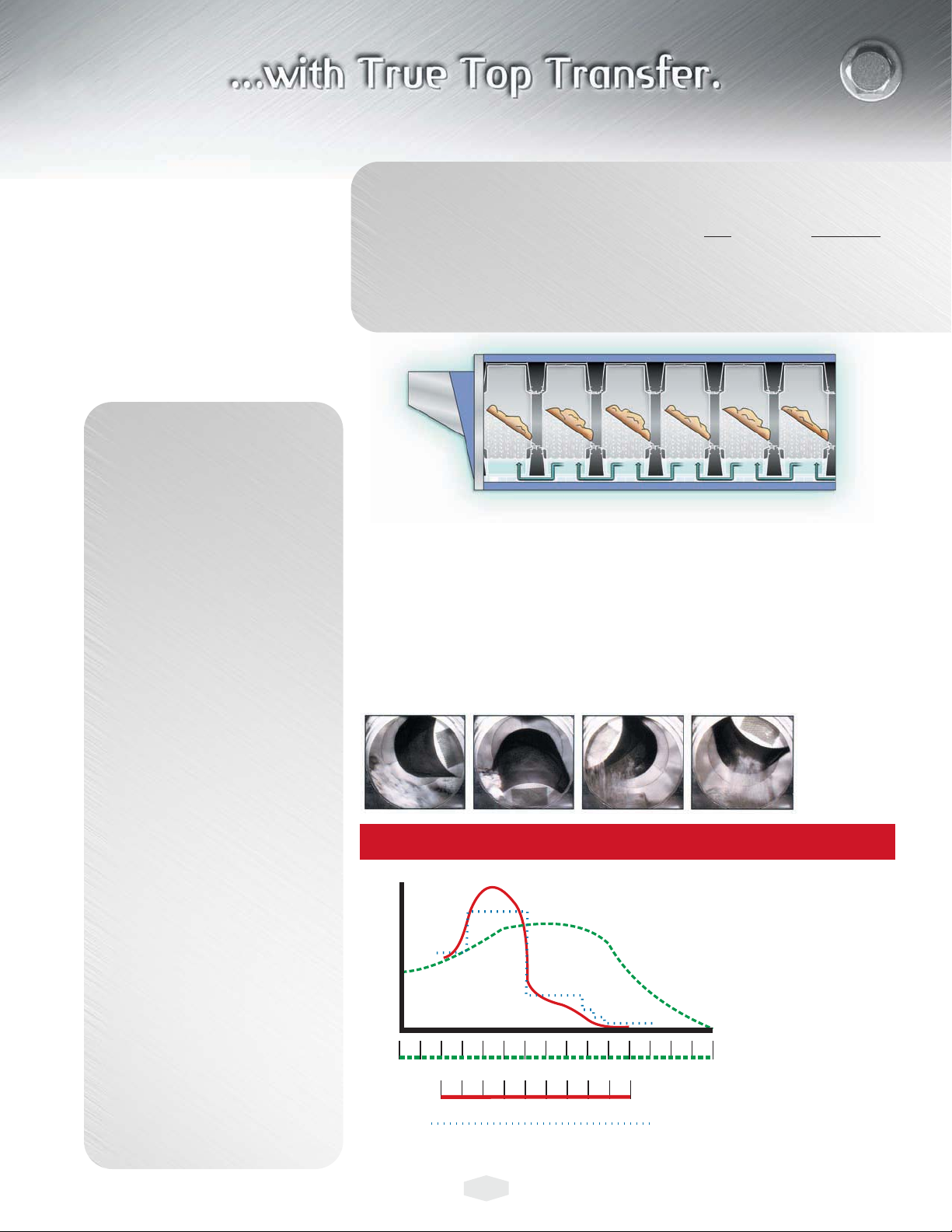

Why Goods Get Cleaner Faster

With Total Top Transfer.

Linen see cleaner water in the next bath - for better dilution. Note bath separation.

Milnor’s perforated top transfer scoop leaves dirty water behind.

How transfer affects dilution.

A tunnel washer’s transfer method is critical, because it’s the way the machine

introduces each batch of goods to its next bath. And, of course, dilution will be

best served if the next bath has cleaner water.

Milnor transfers each batch by lifting the goods out of the water, draining the

free water, then sliding the goods into the next compartment. Goods are

immediately exposed to cleaner water. Only the water trapped in the goods moves

forward – most dirty water is left behind. Milnor leaves back approximately half

of the total water in each compartment.

Other tunnels transfer by forcing the goods and the dirty water forward, generally

along the bottom of the tunnel. Instead of a cleaner bath upon transfer, goods

are exposed to the same dirty water that was in the previous bath!

That’s why, at the unload end of a Milnor CBW washer, there’s hardly any free

water when the goods transfer into the press. Other tunnels have a wave of water

splashing into the press, along with the goods. And what happens at the end

happens in every other compartment of the machine, as well.

3

You can see the effect of total top transfer vs. other

methods by using buckets of water to simulate

different compartments. A Milnor loading scoop lifts

the goods, drains them, and deposits them into

cleaner water.

Other tunnels send dirty water into the next

compartment, along with the goods.There’s no

dilution as the whole compartment moves forward.

MILNOR’S DILUTION ADVANTAGE

Top transfer gives better

control of chemicals.

Milnor’s top transfer feature assures bath integrity.

Baths are truly independent, so the washing formula

can work as planned.

Because water is not pumped forward with each

transfer, chemicals are better targeted to the

proper baths. They don’t migrate uncontrollably to

subsequent baths. Titrations show that with a Milnor,

it is far easier to control pH.

What is

“True Top

Transfer”?

To acheive all of the benefits

of True Top Transfer,

a tunnel washer must include:

1. A scoop that lifts each batch out of the

water and transfers it to the next chamber.

2. Perforations in the lifting scoop that allow

almost all of the “free water” (the water not

trapped in the goods) to flow back into the

original module and not be carried forward

with the load.

The results are clear.

Dilution is the way goods are washed. It’s always been

true of conventional washers and washer-extractors.

It’s also true of tunnel washers. Time, temperature,

chemicals and mechanical action are essential

elements of the washing process. These four things

loosen soil from the goods and dissolve/suspend

What about counterflow?

Counterflow – water moving against the direction of

the goods – also achieves dilution. With counterflow,

a tunnel washer would get almost the same dilution

as a washer-extractor gets with one dump and fill,

using reuse water. This is true of both the Milnor top

transfer washer and other tunnels. But a Milnor

CBW washer, with its perforated top transfer scoop,

the soil in water. But these four catalysts can only

remove soil if water

– successive baths, each with cleaner water,

each replacing dirtier water. Without dilution, the

dirt cannot be removed from the linen.

goes a big step further. The goods change baths upon

transferring. So, again except for reusing the water

over and over in each module, Milnor achieves

approximately the equivalent of a second dump

and fill – and about twice the dilution of some other

tunnels.

TOP TRANSFER AT WORK:

washes it away. That’s dilution

This video

sequence shows

how Milnor

leaves dirty

water behind.

3. A solid partition between modules

to completely separate chemical baths.

4. No perforations in the partitions so bath

integrity is maintained at all times.

5. The partition should be fixed to the outer

drum so that no sliding seals are required

to completely separate baths.

6. All flow between modules should be

external, so flows can be changed on

command when necessary and proper water

levels can be maintained.

Compare Titrations

HIGH

Chemical Concentrations

LOW

123456789101112131415

15-Compartment Bottom Transfer Tunnel

123456789

9-Module Milnor CBW Washer

Washer-Extractors

4

Note the similarity between titration curves

of a washer-extractor and a Milnor CBW washer.

In both, chemical concentrations are high where

soil is heaviest. Then, concentrations drop sharply

in the next stage of the formula as soil is removed.

Compare this to a bottom transfer tunnel’s

flatter curve: Lower peak concentration

where chemicals are added

(because so much water has

been transferred from previous compartments),

and spillover of chemicals in subsequent stages

(where a washer-extractor and a Milnor CBW

washer have already removed most chemicals).

Loading...

Loading...