Milnor 72044 WP2 User Manual

y

72044 WP2

700LB. (318KG) CAPACITY

IVIDED-CYLINDER WASHER-EXTRACTOR

D

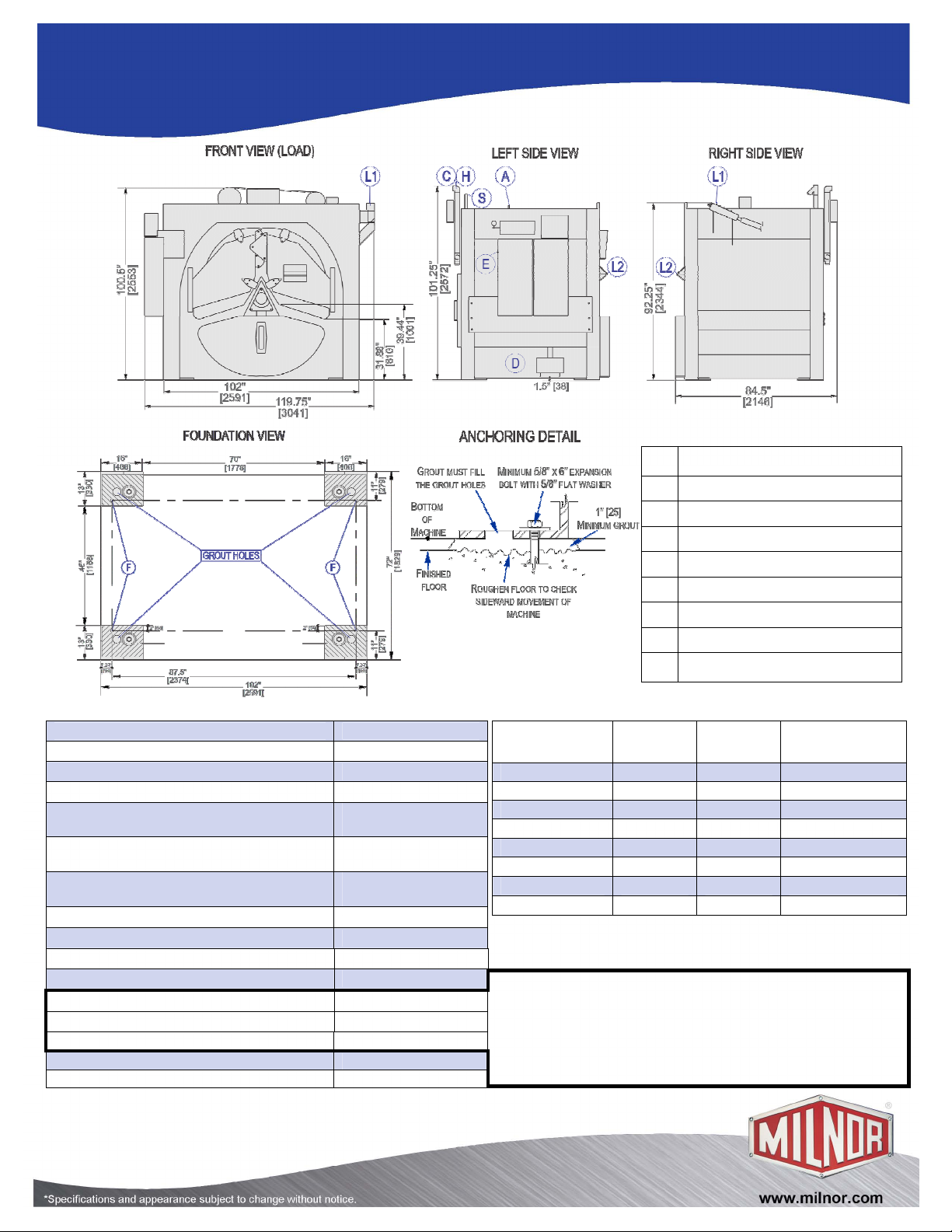

Capacity – lbs (kg) 700 (318)

Cylinder Diameter x Depth – ins (mm) 72 x 44 (1829x1118)

Cylinder Door Area – sq. in. (sq. cm) 850 (5484)

Cylinder Volume – cu. ft. (L) 104 (2936)

Machine Dimensions

(W x D x H) – ins (mm)

Shipping Dimensions

(W x D x H) – ins (mm)

Motors – HP (kW)

Wash Speed – RPM 26

Distribution Speed – RPM 38

Extraction Speeds – RPM 220-535

Extraction G-Force 292

Static Weight – lbs (kg)

Max. Dynamic Load RMS - lbs (kg)

Frequency (Hz) 8.92

Water Pressure

Water Valve Cv Rating – gal/min (L/min) 110 (416.4)

MECHANICAL SPECIFICATIONS ELECTRICAL SPECIFICATIONS

119.75x84.5x100.5

(3041x2146x2553)

91 x 127 x 110

(2311x322x2794)

10, 7.5, 20, 15 (7.45,

5.59, 14.91, 11.18)

21,951 (9956.7)

2675.37 (1213.52)

(Required)

– psi (bar) 30-65 (2.06-4.48)

B22SL10041/10534 Page 1 of 2

SPECIFICATION SHEET

LEGEND

Compressed air inlet connection .25”

A

(6 mm) NPT

C Cold water inlet 2” (51 mm) NPT

D Drain valve 10” (254 mm) diameter

E Electrical connection

F Anchor bolt holes 1.06” (27 mm)

H Hot water inlet 2” (51 mm) GHT

L1 Peristaltic supply manifold

L2 Soap chute

Steam supply connection 1.25” (32

S

mm) NPT

Voltage Running

Amps

208/3/60 60 FRN110 200

220/3/50-60 56.5 FRN100 200

240/3/60 51.5 FRN100 200

380/3/50-60 33 FRS60 125

400/3/50 31 FRS60 125

415/3/50 30 FRS60 100

480/3/60 26 FRS50 90

600/3/60 21 FRS40 70

See Fuse and Wire Size manual MAEFUSE1BE for safety information.

Fuse

(Amps)

Circuit Breaker

(Amps)

▼ See dimensional drawing for complete details.

It is the sole responsibility of the owner/user to assure that the floor and/or any

other supporting structure exceeds not only all applicable building codes, but also

that the floor and/or any other supporting structure for each washer-extractor or

group of washer-extractors has sufficient strength and rigidity (i.e., a natural or

resonant frequency many times greater than the rotational machine speed with a

reasonable factor

including the weight of the water and goods, and including the published 360º

rotating sinusoidal RMS forces that are transmitted by the machine(s). Contact the

factory for additional machine data for use by a structural engineer.

of safety) to support the weight of all the fully loaded machine(s)

W

72044 WP2

700LB. (318KG) CAPACITY

IVIDED-CYLINDER WASHER-EXTRACTOR

D

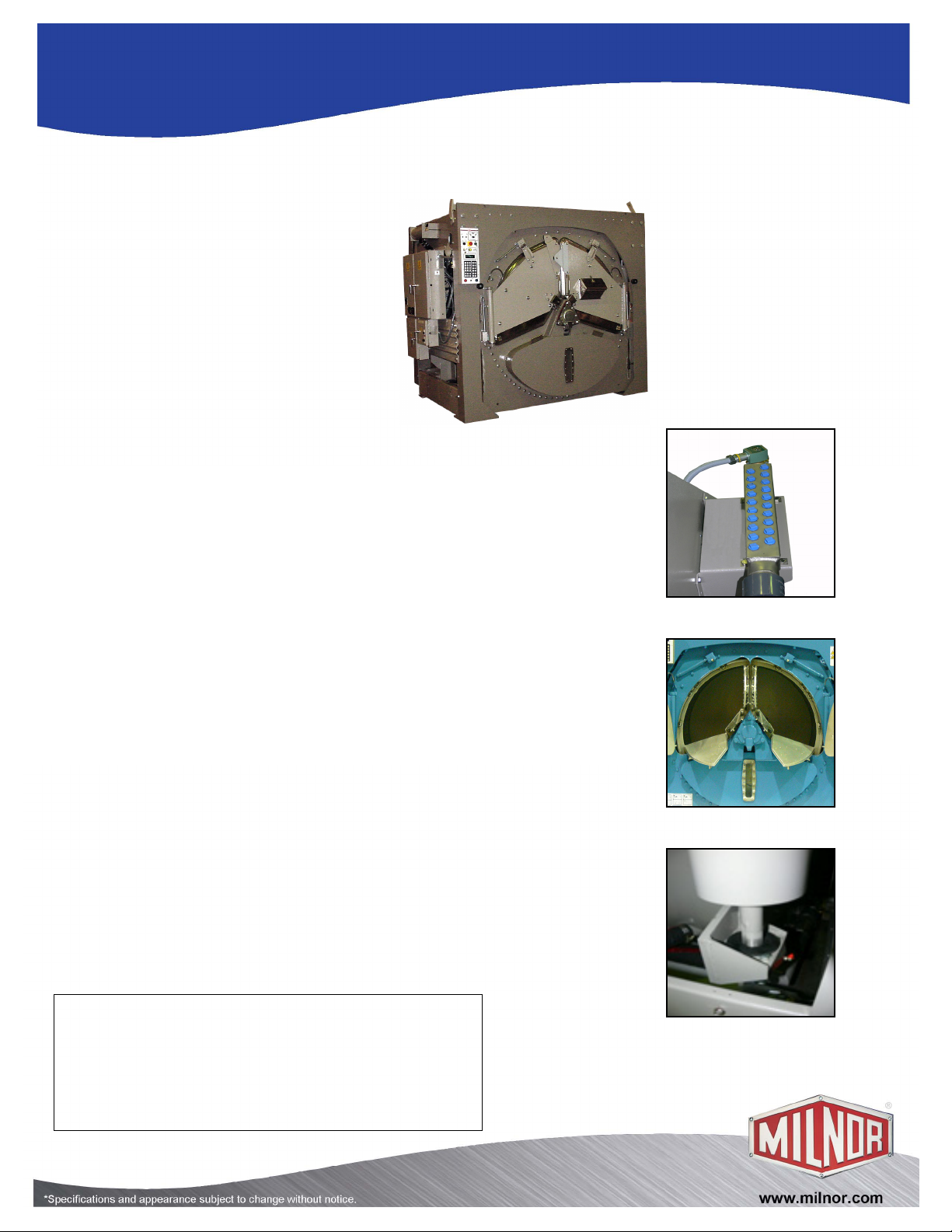

Standard Features:

• Rapid Load split pocket cylinder

• AUTOSPOT™ cylinder positioner

• MarkVI programmable controller

• Color graphic display

• Single-motor inverter drive

• Air-operated valves

• Programmable overnight bath soak

• Programmable water temperature for each bath

• Hydro-Cushion™ suspension

• Spherical roller bearings

• Large cylinder perforations

• Twenty (20) liquid chemical injection ports

• Control reads in English/second language

• 5-year limited warranty on frame, cylinder & shell

hy Purchase Milnor?

• With Rapid Load split pocket cylinder (only a single partition), both pockets are

open at one time for loading. BENEFIT: Faster loading and greater lift and

drop action for outstanding soil removal.

• MarkVI Controller with color graphic display allows operator to choose formulas

from real words, not codes. Standard controller features English/Spanish (other

languages optional). Controller also provides diagnostic and error messages.

Shortens training time of new employees.

BENEFIT: Fewer operator errors.

• 292-G high extract provides excellent moisture removal. Lower extract speeds

are available for uniforms, delicate textiles and blended fabrics.

BENEFIT: Better extraction saves dryer fuel.

• 20 liquid chemical ports, 15 signals, and optional 5 compartment supply injector.

BENEFIT: Promotes consistency and allows flexibility.

• Larger cylinder perforated-area generates better wash quality, better rinsing and

better extraction. BENEFIT: Better extraction saves dryer fuel.

• Faster process times reduce fabric wear, promoting longer linen life!

BENEFIT: Saves linen replacement costs.

• Superior product support through local, highly-skilled dealers.

BENEFIT: Faster repairs mean less downtime.

Contact Milnor for your local, authorized dealer:

Pellerin Milnor Corporation

P.O. Box 400 ● Kenner, LA 70063

t: 504-467-9591 ● f: 504-468-3094

SPECIFICATION SHEET

Optional Features:

• 5 compartment flushing

supply injector

• Programmable Air-

Operated steam

injection

Safe chemical injection

Superior cylinder design

Hydro-Cushion™ suspension

B22SL10041/10534 Page 2 of 2

Loading...

Loading...