Page 1

Page 2

75.6 cu. ft. cylinder handles

popular batch sizes.

High extraction saves

finishing time.

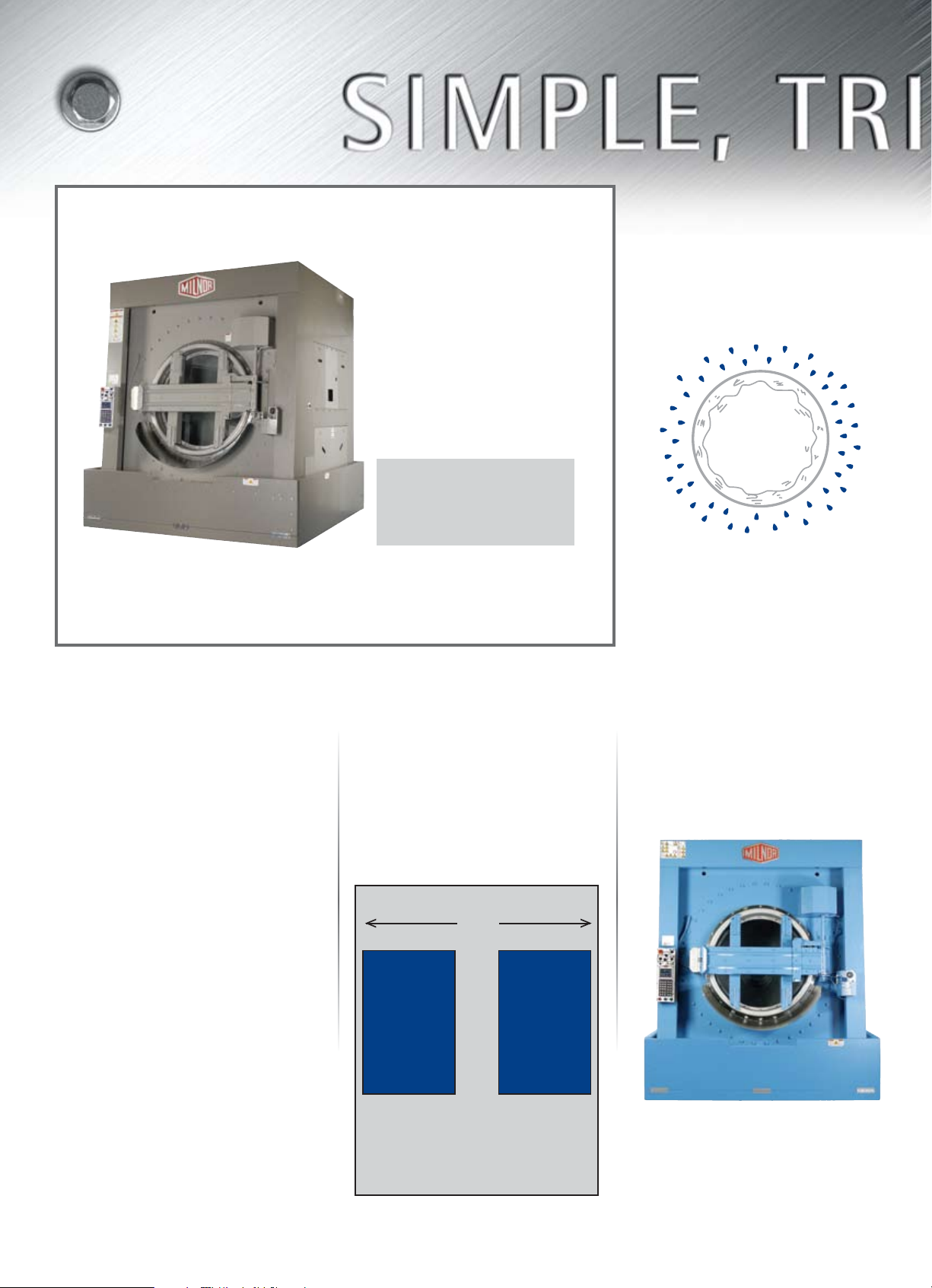

Milnor’s 68036 F5N washer-extractor features open pocket

cylinder, two-way tilt, simple design, and a trim footprint.

Open pocket cylinder enhances

quality, saves time.

Large, open pocket wash cylinder provides an

unobstructed drop for outstanding washing

action. It’s ideal for bulky goods such as mats and heavily

soiled items such as uniforms, mops, and shop towels.

Turnaround is faster because there’s only one door to open

for unloading/loading – and no need for cylinder-inching.

Milnor’s 68036 F5N washer-extractor

is ideally sized for large laundries. Its

75.6 cu. ft. (2141 L) open pocket cylinder

processes the 400–500 lb. (182–227 kg) load

sizes that mesh well with operations in many

plants. This allows upgrade capability without

changing existing batch sizes.

5.29 lbs./cu. ft. @ 400 lbs.

5.95 lbs./cu. ft. @ 450 lbs.

6.61 lbs./cu. ft. @ 500 lbs.

Trim footprint conserves space.

New design results in a machine that’s only 94” (2387 mm)

wide, requiring less than 63.26 sq. ft. (5.87 sq. m)

of space. Only 24” (609 mm) is needed between

machines. Efficient use of space aids plant layout

whether you’re replacing existing machines or building

from scratch.

Final extraction is 300 Gs (558 RPM). Motor is sized for

long-lasting performance.

300 Gs

Streamlined design,

rugged components, easy

maintenance access.

The structure is just as robust as you’d expect. But

simpler design results in fewer parts, so there is less

to maintain. Frame, shell front and back, as well

as other components are rugged enough to withstand

multiple shifts for many years. Open-access simplifies

maintenance. Electrical control boxes, too, are uncluttered.

Excellent ergonomics with

gravity-assist.

Two-way tilt makes loading and unloading faster and

easier. This boosts productivity while minimizing

fatigue and risk of back injuries. Door height is within

easy reach for sling- or manual-loading. It’s also ideal

for unloading onto a shuttle conveyor or even into carts.

Large 48” (1219 mm) opening with hydraulic door allows

work to pass through with ease.

Tilt angles via air-bag system are up to 22˚ for

loading, and up to 22˚ for unloading.

212”

94” W

x 97” D

24”

94” W

x 97” D

High productivity

in minimal space.

Streamlined design results in more

uptime, higher production.

Page 3

How to get long bearing life – even under severe conditions.

1. Keep bearings dry with an

air-barrier plus seals.

An air jet combines with an excluder seal and two

additional water seals to keep contaminants away

from bearings. Air is injected between the excluder

seal and front water seal forcing water back inside

the shell. The air jet functions continuously during

machine operation.

2. Make servicing easy, so it

will get done.

Both seals and seal sleeves can be replaced

through the cylinder – without bearing removal

– allowing the machine to return to service

quickly. Removable hub can be swung away from

the shaft, providing easy access. Unique design

makes it more likely service will be performed

when needed.

3. Make sure the machine is

prepared for almost anything!

What if adverse conditions – metal shavings,

etc. – should happen to wear seals before they

can be replaced? Milnor’s advanced design still

protects bearings. Water passing through the

worn seal is channeled away from the bearings

in all directions, into a cavity. It then exits freely

through three large ports at the rear.

Smooth operation helps prevent costly delays.

Milnor’s dynamically tuned suspension puts the center of mass where

an imbalance would occur. The result is outstanding vibration-dampening for

less wear and tear. Dynamic forces are evenly applied for minimum vibration,

which also means greater output because it prevents stopping-and-recycling.

Innovative “smooth coil” rubber springs reduce vibration.

Rubber spring suspension.

Microprocessor control is

flexible and functional.

Milnor designs and builds its own microprocessor.

This is not an off-the-shelf control designed for

general use by non-laundry people. You get the

functionality you need.

And 100 formulas (98 programmable) give the

flexibility you want for today and tomorrow.

The control can even print production

reports (standard) to help you maintain high

productivity. It’s easy to operate and to program,

and it provides self-diagnostics.

Supply injection choices include automatic liquid

connections or five-compartment flushing injector.

Additional chemical injection signals (for up to 15

total) are also available.

A control designed specifically

for laundries.

Page 4

68036 F5N SPECIFICATIONS

Cylinder Size

Cylinder diameter – ins. (mm) 68 (1727)

Cylinder depth – ins. (mm) 36 (914)

Cylinder volume – cu. ft. (L) 75.6 (2141)

Loading (filling) factor – lbs./cu.ft. (L/kg)*

@ 400 lbs. (182 kg) 5.29 (11.76)

@ 450 lbs. (205 kg) 5.95 (10.44)

@ 500 lbs. (227 kg) 6.61 (9.43)

TilT angleS

Load – degrees up to: 22

Unload – degrees up to: 22

dimenSionS+

Machine footprint – ins. (mm):

Width 94 (2387)

Depth 97 (2463)

Machine height – ins. (mm):

Run 118 (2997)

Max. tilt height 137 (3479)

Min. distance between machines – ins. (mm) 24 (609)

Door lip height – ins. (mm):

Load 57 (1448)

Unload 31 (787)

Door opening – ins. (mm) 48 (1219)

SpeedS and aCCeleraTion

Wash speed – RPM 25–32**

Distribution speed – RPM 48

Extract speed – RPM 200–558**

Max. centrifugal acceleration – Gs 300

moTor

Motor – HP (kW) 40 (29.82)

ConneCTion Sizing

Water valves – ins. (mm) 2 (51)

Steam valve – ins. (mm) 1.25 (31.75)

Compressed air – ins. (mm) 0.25 (6.35)

Drain valve – ins. (mm) 8 (203)

WeighT+

Weight – lbs. (kg) 15,500 (7031)

Specifications and appearance subject to change without notice.

* Depending on density and soil weight of goods.

** Programmable Range.

+With standard accessories. Contact factory for acoustics data.

Milnor is a stable, reliable company with extensive design and

manufacturing capabilities.

You’re buying the company

behind the machine, too.

One of the most important components in a Milnor washer-extractor is the company

behind the product. In an era of “where are they now?” manufacturers, Milnor

stands apart for stability. That’s important when you buy a machine you plan to

keep as long as you keep a Milnor washer-extractor. Three generations of consistent

ownership says as much for our future as for our past. And it says a lot about

your ability to get what you need when you need it. Milnor is stable, accountable

– and highly capable. We design and build our machines from the ground up

at our 400,000 sq. ft. (37,160 sq. m) factory in suburban New Orleans. Product

development is so important that almost 50% of our office staffers are engineers or

engineering-support personnel. Computer integration facilitates advanced product

design and precise manufacturing of components and finished machines.

When you buy a new, open pocket washer-extractor, remember that you’re buying

the company behind it, too.

Features at a glance.

• Popular size – 75.6 cu. ft. (2141 L) cylinder.

• Trim footprint.

• Robust construction.

• Innovative bearing design keeps water away (even if seals wear).

• Through-the-cylinder seal and seal sleeve replacement facilitates maintenance.

• Simple machine design with easy access to components.

• 300 G extraction.

• Dynamically tuned suspension.

• Flexible microprocessor designed specically for laundry use.

• Automatic supply injection.

Printed in U.S.A.

© Pellerin Milnor Corporation

B22SL03005/08202

Pellerin Milnor Corporation

P.O. Box 400, Kenner, LA 70063-0400 USA

504-712-7656 • 800-469-8780

Fax: 504-468-3094

E-mail: mktg@milnor.com

www.milnor.com

Loading...

Loading...