Milnor 60044WP3 Service Manual

Published Manual Number/ECN: MPP60WE3AE/2001044N

• Publishing System: TPAS

• Access date: 01/23/2001

• Document ECN's: Exact

Service—

60044WP3 Washer-Extractors

PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063-0400, U.S.A.

Please Read

About the Manual Identifying Information on the Cover

The front cover displays pertinent identifying information for this manual. Most important, are

the published manual number (part number) /ECN (date code). Generally, when a replacement

manual is furnished, it will have the same published manual number, but the latest available ECN.

This provides the user with the latest information applicable to his machine. Similarly all

documents comprising the manual will be the latest available as of the date the manual was

printed, even though older ECN dates for those documents may be listed in the table of

contents.

When communicating with the Milnor factory regarding this manual, please also provide the

other identifying information shown on the cover, including the publishing system, access date,

and whether the document ECN’s are the latest available or exact.

References to Yellow Troubleshooting Pages

This manual may contain references to “yellow pages.” Although the pages containing

troubleshooting procedures are no longer printed on yellow paper, troubleshooting instructions, if

any, will be contained in the easily located “Troubleshooting” chapter or section. See the table of

contents.

Trademarks of Pellerin Milnor Corporation

The following, some of which may be used in this manual, are trademarks of Pellerin Milnor

Corporation:

®

Ampsaver

Autolint

®

Auto-Purge

Autovac E-P OneTouch® Mildata

®

CBW

Dye-Extractor® Gear Guardian

Dyextractor® Hands-Off

®

E-P Express® Hydro-Cushion

E-P Plus

®

®

®

®

®

®

Milnet

Milnor

®

Staph-Guard

System 4

Miltrac System 7

Miltron Totaltrol

®

®

®

®

Comments and Suggestions

Help us to improve this manual by sending your comments to:

Pellerin Milnor Corporation

Attn: Technical Publications

P. O. Box 400

Kenner, LA 70063-0400

Fax: (504) 469-1849

Table of Contents

for MPP60WE3AE/2001044N

60044WP3 Washer-Extractors

Page Description Document/ECN

1 About This Manual MHPHYDROAE/9541AV

3 Warranty BMP720097/92732A

4 How to Order Parts BMP720097R/72332A

5 Installation and Service Safety for Suspended

Washer-Extractors and Centrifugal Extractors MSINA405AE/2000215V

10 About the Forces Transmitted by Milnor Washer-Extractors BIWUUI02/20001108

12 Glossary of Tag Illustrations - Suspended Washer-

Extractors MSIUPUTGAE/9808AV

17 Section 1: Service and Maintenance

18 Lubrication and Preventive Maintenance for Hydro-

Cushion Machines MSSM0201CE/9840AV

29 Lubricants for Milnor Machines MSSM0132AE/9903AV

30 Baldor Motor Maintenance MSSM0274AE/9731AV

34 Lubrication Points for 42" Hydro-Cushion Washer-Extractor BMP701174/2069371A

35 Lubrication Points for 42" Hydro-Cushion Washer-Extractor BMP701174R/2069367

36 Lubrication Chart BMP701226/74113A

37 Lubrication Chart BMP701226R/74113A

38 Fastener Torque Requirements MSSM0101CE/9906AV

57 Section 2: Shell and Door Assemblies

58 Door Seal Replacement on Rapid Load Models MSSMA413AE/8530BV

62 Shell Door Assembly BMP700402/70316

63 Parts List - Shell Door Assembly BMP700402R/70121V

64 Cylinder Door Installation - 6036 & 6044 3-Pocket

Staph-Guard & Hydrocushion BMP970080/97402V

65 Cylinder Door Assembly - 6036 & 6044 3-Pocket

Staph-Guard & Hydrocushion BMP970081/97402V

67 Interlock Plunger Assembly BMP700630/94087V

68 60" WE3 & SG3 Door Assembly BMP800183/80323B

69 Parts List - Door Assembly, 60" SG3, WE3 BMP800183R/98301V

71 Section 3: Drive Assemblies

72 Drive Base Components on Hydro-Cushion Machines MSSMA407BE/85047V

82 Jackshaft Bearing Assembly - 5238, 6036, 6044,

6442 & 7244 BMP820109/89253C

83 Parts List - Jackshaft Bearing Assembly (52, 60, 64, 72) BMP820109R/89253A

85 Drive Assembly - 6036WE2, WE3 & 6044WE2, WE3 BMP840021/91107D

86 Parts List - Drive Assembly, 60036 & 60044 WE2/WE3 BMP840021R/98446V

87 Reducer Air Seal BMP700392/93376V

88 Autospot Drive Assembly BMP701411/2000133V

90 Air Operated Autospot Assembly - 60044WP2/WP3

and 72044WP2/WP3 BMP710043/96216V

Table of Contents, cont.

Page Description Document/ECN

91 Sensing Unit = Airop Autospot BMP710042/76143D

92 Parts List - Sensing Unit, Airop Autospot BMP710042R/85353A

93 Brake Installation - 6036 & 6044 BMP760001/76022B

94 Parts List - Brake Installation (60WED) BMP760001R/85341A

95 Centrifugal Switch Assembly BMP701195/2000242V

97 Centrifugal Switch Operation BMP701196/81271A

98 Brake Assembly - 60044 & 72044 WP2/WP3 BMP710022/99512V

99 V-Belt Tension Adjustments for 48", 52", 60"

and 72" Washer-Extractors MSSMA405AE/8737BV

103 Section 4: Bearing Assemblies

104 Main Bearing and Seal Replacement for Divided

Cylinder Machines MSSM0303AE/8451BV

114 Main Bearing Assembly - 60036, 60044 & 72044

WE2, WE3, SG2, SG3 & DA3 BMP840039/84336D

115 Parts List - Main Bearing Assembly BMP840039R/96142V

117 Section 5: Frame, Pivots and Suspension

118 Hold Down Adjustments 60" & 72" Rapid Load

& Staph-Guard Washer-Extractors BMP701672/71051

119 Hold Down Adjustments - 60" & 72" Rapid Load

and Staph-Guard BMP701672R/71051

120 Suspension Adjustments for Divided Cylinder Machines MSSM0302AE/8414BV

126 Suspension Cylinder Assemblies - 42031, 42044,

52038, 60044 & 72044 BMP701408/2000133V

128 Parts List - Suspension Cylinder Assembly BMP701408R/97266V

129 Suspension Cylinder Locations BMP701235/2000133V

130 Push Down Assembly BMP701671/70526

131 Parts List - Push Down Assembly BMP701671R/70526

133 Section 6: Control and Sensing Assemblies

134 Vibration Safety Switch Adjustments MSSMA408BE/9273BV

136 Vibration Switch Assembly BMP700613/83211A

137 Parts List - Vibration Switch Assembly BMP700613R/83211A

138 Maintenance - Vib Safety Switch BMP750047/81307A

139 Section 7: Chemical Supply Devices

140 Rules for the Field Installation of Pumped-Type

Liquid Supply Systems MSSM0213AE/89457V

142 Supply Injector - 6036, 6044 & 5238 BMP700940/97287V

145 Section 8: Water and Steam Piping and

Assemblies

146 Ball Valve Water Inlet Assembly BMP701539/89113D

147 Parts List - Water Inlet Assembly BMP701539R/71521A

148 Universal Actuators & Mounting Hardware for

Watts Ball Valves - New Pivot BMP920005/96067V

151 Watts Ball Valves and Repair Kits BMP920007/96066V

Table of Contents, cont.

Page Description Document/ECN

153 Pressure Regulators BMP900031/96081V

155 Water Level Float Chamber Assembly BMP810111/83404C

156 Parts List - Water Level Float Chamber Assembly BMP810111R/89256A

158 Water Level Switch Assembly BMP800186/93192V

159 8" & 10" Stainless Dump Valve BMP780095/2000133V

160 Burket Steam Valve BMP800020/96066V

161 Steam Sparger Assemblies BMP900001/96132V

163 Section 9: Pneumatic Piping and Assemblies

164 3 Way Pilot Valves BMP900032/91182V

165 Asco 3-way Solenoid Valves BMP701359/97086V

167 ½" ASCO N.C. Valve Assembly BMP701394/71463A

168 Parts List - ½" ASCO N.C. Valve BMP701394R/81377A

169 Universal Airvalve Box Assembly BMP780088/83457C

170 Parts List - Universal Airvalve Box BMP780088R/93046N

172 Air Valves & Mounting Hardware BMP780087/83457B

173 Parts List - Air Valves & Mounting Hardware BMP780087R/83457A

175 Quick Exhaust Valves BMP701406/98296V

177 Air Cylinder Assemblies BMP830078/2000133V

180 Air Cylinders for 2"Watts Ball Valves BMP920006/2000133V

MHPHYDROAE/9541AV (1 of 1)

ÈABOUT THIS MANUAL

ËScope—This instruction manual is intended to provide preventive maintenance, service procedures, an d

mechanical parts identification for your machine. See the safety manual for safety instructions before installing,

servicing, or operating this machine. See the installation guide for facility requirements, installation instructions,

and assembly instructions. See the operator guide for operator instructions. See the reference manual for programming, operating, and troubleshooting instructions. See the schematic manual for electrical parts identification and

electrical troubleshooting.

ËManual Number/Date Code (When To Discard or Save)—The manual number/date code is lo-

cated on the inside front cover, upper right corner just above the manual name. Whenever the manual is reprinted

with new information, part of this number changes. If the date code after the “/” changes, the new version applies

to all machines covered by the old version, but is improved— thus the old version can be discarded. If the

manual number before the “/” changes, the new manual covers only new machines. Example: Discard MAT-

MODELAE/8739CV when MATMODELAE/8739DV is received (minor improvements). Also, discard MATMODELAE/8739DV when MATMODELAE/8746AV is received (major improvements). But keep

MATMODELAE/8746FV when MATMODELBE/8815AV is received, since the new manual no longer applies to

machines originally shipped with the old manual.

ËDocuments and Change Bars —The individual documents comprising this manual use the same revision

criteria as the manual. Text documents also display change bars. Example: When section MSOP0599AE/9135BV

becomes MSOP0599AE/9135CV, change bars with the letter “C” appear next to all changes for this revision. For

a major rewrite (e.g., MSOP0599AE/9226AV), all change bars are deleted.

ËTrademarks of Pellerin Milnor Corporation—The following, some of which may be used in this pub-

lication, are trademarks of Pellerin Milnor Corporation:

Ampsaver

®

Autolint

®

Auto-Purge

®

Autovac

CBW

®

Dye-Extractor

®

Dyextractor

®

E-P Plus

®

Gear Guardian

®

Hands-Off

®

Hydro-Cushion

®

Mildata

®

Milnet

®

Milnor

®

Miltrac

Miltron

Staph-Guard

®

System 4

®

System 7

®

Totaltrol

®

ËFor Assistance—Please call:

Pellerin Milnor Corporation

Attn: Service Department

P. O. Box 400

Kenner, LA 70063-0400

Phone: (504) 467-9591

Fax: (504) 467-9777

3(//(5,10,/125&25325$7,21

/,0,7('67$1'$5':$55$17<

We warrant to the original purchaser that MILNOR machines including electronic

hardware/software (hereafter referred to as “equipment”), will be free from defects in material

and workmanship for a period of one year from the date of shipment from our factory with no

operating hour limitation. This warranty is contingent upon the equipment being installed,

operated and serviced as specified in the operating manual supplied with the equipment, and

operated under normal conditions by competent operators.

Providing we receive written notification of a warranted defect within 30 days of its discovery,

we will – at our option – repair or replace the defective part or parts, FOB our factory. We

retain the right to require inspection of the parts claimed defective in our factory prior to

repairing or replacing same. We will not be responsible, or in any way liable, for unauthorized

repairs or service to our equipment, and this warranty shall be void if the equipment is repaired

or altered in any way without MILNOR’s written consent.

Parts which require routine replacement due to normal wear – such as gaskets, contact points,

brake and clutch linings and similar parts – are not covered by this warranty, nor are parts

damaged by exposure to weather or to chemicals.

We reserve the right to make changes in the design and/or construction of our equipment

(including purchased components) without obligation to change any equipment previously

supplied.

ANY SALE OR FURNISHING OF ANY EQUIPMENT BY MILNOR IS MADE ONLY UPON

THE EXPRESS UNDERSTANDING THAT MILNOR MAKES NO EXPRESSED OR IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR USE OR

PURPOSE. MILNOR WILL NOT BE RESPONSIBLE FOR ANY COSTS OR DAMAGES

ACTUALLY INCURRED OR REQUIRED AS A RESULT OF: THE FAILURE OF ANY OTHER

PERSON OR ENTITY TO PERFORM ITS RESPONSIBILITIES, FIRE OR OTHER HAZARD,

ACCIDENT, IMPROPER STORAGE, MISUSE, NEGLECT, POWER OR ENVIRONMENTAL

CONTROL MALFUNCTIONS, DAMAGE FROM LIQUIDS, OR ANY OTHER CAUSE BEYOND

THE NORMAL RANGE OF USE. REGARDLESS OF HOW CAUSED, IN NO EVENT SHALL

MILNOR BE LIABLE FOR SPECIAL, INDIRECT, PUNITIVE, LIQUIDATED, OR

CONSEQUENTIAL COSTS OR DAMAGES, OR ANY COSTS OR DAMAGES WHATSOEVER

WHICH EXCEED THE PRICE PAID TO MILNOR FOR THE EQUIPMENT IT SELLS OR

FURNISHES.

WE NEITHER ASSUME, NOR AUTHORIZE ANY EMPLOYEE OR OTHER PERSON TO

ASSUME FOR US, ANY OTHER RESPONSIBILITY AND/OR LIABILITY IN CONNECTION

WITH THE SALE OR FURNISHING OF OUR EQUIPMENT TO ANY BUYER.

BMP720097

92732A

How to order repair parts

Repair parts may be ordered either from the authorized dealer who sold you this

machine, or directly from the MILNOR factory. In most cases, your dealer will

have these parts in stock.

When ordering parts, please be sure to give us the following in formation:

1. Model and serial number of the machine for which the parts are required

2. Part number

3. Name of the part

4. Quantity needed

5. Method of shipment des ired

6. In correspondence regarding motors or electrical controls, please include all

nameplate data, including wiring diagram number and the make or

manufacturer of the motor or controls.

All parts will be shipped C.O.D. transportation charges collect on ly.

Please read this manual

It is strongly recommended that you read the installation and operating manual

before attempting to install or operate your machine. We suggest that this manual

be kept in your business office so that it will not become lo st.

PELLERIN MILNOR CORPORATION

32%2;.(11(5/$ 86$

FAX: Administration 504/468-9307, Engineering 504/469-1849, Service 504/469-9777

BMP720097R

72332A

MSINA405AE/2000215V

ÈINSTALLATION AND SERVICE SAFETY FOR SUSPENDED

WASHER-EXTRACTORS AND CENTRIFUGAL EXTRACTORS

ÊGeneral Safety Requirements

(specific warnings, next page and throughout manual)

Incorrect installation, neglected preventive maintenance, abuse, and/or improper repairs or changes to the

machine can cause unsafe operation and personal injuries, such as multiple fractures, amputations, or death. The

owner or his selected representative ( owner/user) is responsible for underst anding and ensuring the proper operation

and maintenance of the machine. The owner/user must familiarize himself with the contents of all machine instruction manuals. The owner/user should direct any questions about these instructions to a Milnor® dealer or the Milnor® Service department.

Most regulatory authorities (including OSHA in the USA) hold the owner/user ultimately responsible for

maintaining a safe working environment. Therefore, the owner/user must do the following:

• recognize all foreseeable safety hazards within his facility and take actions to protect his personnel,

equipment, and facility

• require that personnel are familiar with all functional and safety aspects of the machine

• ensure safety devices installed on the machine are in place and properly maintained

• ensure all machine parts and assemblies are properly maintained.

ËLaundry Facility

—Provide a supporting floor that is strong and rigid enough to support--with a reasonable

safety factor and without undue or objectionable deflection--the weight of the fully loaded machine and the forces

transmitted by it during operation. (For washer-extractors, see “ABOUT THE FORCES TRANSMITTED BY MILNOR® WASHER-EXTRACTORS.”) Provide sufficient clearance for machine movement. Provide any safety

guards, fences, restraints, devices, and verbal and/or posted restrictions necessary to prevent personnel, machines,

or other moving machinery from accessing the machine or its path. Provide adequate ventilation to carry away heat

and vapors. Ensure service connections to installed machines meet local and national safet y standards, especially

regarding the electrical disconnect (see the National Electric Code). Prom inently post s afety informati on, including

signs showing the source of electrical disconnect.

ËPersonnel

—Inform personnel about hazard avoidance and the importance of care and common sense. Provide

personnel with the safety and operating instructions that apply to them. Verify that pers onnel use proper safety and

operating procedures. Verify that personnel understand and abide by point-of-hazard tags on the machine and procedure-specific precautions in the instruction manuals.

ËSafety Devices

—Ensure that no one eliminates or disables any safety device on t he machine or in this facilit y.

Do not allow machine to be used with any missing guard or cover. Service any failing or malfunctioning device

before operating the machine.

ËMaintenance

—Ensure the machine is inspected and serviced in accordance with the norms of good practice and

with the preventive maintenance schedule. Replace belts, pulleys, brake shoes/disks, clutch plates/tires, rollers,

seals, alignment guides, etc. before they are severely worn. Immediately investigate any evidence of impending

failure and make needed repairs (e.g., cylinder, shell, or frame cracks; drive components such as motors, gear boxes,

bearings, etc., whining, grinding, smoking, or becoming abnormally hot; bending or cracking of cylinder, shell,

frame, etc.; leaking seals, hoses, valves, etc.) Do not permit service or maintenance by unqualified personnel.

READ BEFORE INSTALLING MACHINE!

ÊHazards During Installation

ELECTROCUTION HAZARD—Contact with high voltages can kill or seriously

injure you.

☞ All electrical connections must be made by a competent electrician.

EQUIPMENT DAMAGE HAZARD—Machine can be damaged if shipping restraints are improperly utilized. These include various bolts, brackets, and

safety stands (painted red), brake blocks and the vibration safety switch (tie

wrapped).

☞ DO NOT remove shipping restraints until installation is complete.

☞ DO remove all shipping restraints before operating machine.

ÊHazards During Service and Maintenance

ELECTROCUTION HAZARD—High voltage is present inside electric boxes, motors and many other components. Power switches on machine control panels

disable only control circuit power in certain boxes. You can be killed or seriously injured on contact with high voltage.

☞ Lock OFF and tag out power at the wall di sconnect before ser vici ng, except w her e spe-

cifically instructed otherwise in this manual.

ENTANGLE AND CRUSH HAZARD—Belts and pulleys can entangle and crush

body parts.

☞ Lock OFF and tag out power at the wall disconnect before servicing, except

where specifical ly instr ucte d otherwis e in this manua l.

☞ Insure belt guards are in place during service procedures.

MULTIPLE HAZARDS—Failure to maintain machine in proper working order can result in

fatal or serious injury to operators and/or damage to property. DO NOT permit operation

under any of the following circumstances:

☞ Malfunctioning door interlock mechanism.

☞ Malfunctioning limit switches.

☞ Malfunctioning two hand inching.

☞ Any evidence of cylinder damage.

☞ Missing or removed guards, covers, or side panels.

☞ Malfunctioning tilting components, including but not limited to safety limit switches,

electrical interlocks, and operator controls.

☞ If any of these conditions occur:

• The machine makes a sound like skidding automobile tires as it comes out of extract.

• The wash or drain clutch does not disengage or it reengages during extract.

• V-belt s jum p off at the start of, during, or at the end of extract.

• A strange whining sound occurs at any time during extract.

BURN HAZARD — Machines equipped with heat exchangers and their associated piping may be hot enough to burn body parts on contact.

☞ Provide safety guards, fences, restraints, or covers as required to isolate hot

surfaces.

ÊAdditional Hazards During Tilting Machine Maintenance

CRUSH/SEVER HAZARD—Tilting mechanisms can crush or sever parts of your

body caught in them.

☞ Install the safety stands before performing maintenance under a tilted ma-

chine.

☞ NEVER test or operate (manually or automatically) any machine function

with any portion of a person’s body under the tilted machine—even if the

safety stands are ins tal led.

CRUSH/SEVER HAZARD—Tilting machines with tilt wheels/cradles may lunge forward or rearward and even fall ove r if the tilt wheels at the non-tilted end are r aised

out of their cradles—killing/ injuri ng personnel and/or damaging property.

☞ NEVER manually tilt (lift) both ends of the machine at the same time. One end must

always be seated in it s cradle.

☞ ALWAYS visually inspect the tilt wheels to be sure they are all fully seated in their cra-

dles before each manual tilt up.

☞ Hydraulic valve manual operation must be done by trained competent maintenance per-

sonnel who thoroughly understand the system and all the consequences of manual

operations.

☞ ALWAYS understand beforehand all the consequences of manually operating hydraul ic

valves.

☞ NEVER permit operation with malfunctioning tilt limit switches.

NOTE: Shipping brackets, (not shown

here) are also painted red. These may

be retained in the event the machine

must be moved.

Safety Stands or Brackets

Safety Stands or Brackets

These stands or brackets, painted red

and shown to the right, must be retained,

and used to support the machine during

servicing.

Read all safety instructions before performing maintenance.

Tall safety stands

Tall safety stands

Short safety stands

48032, 48036, 52038, and 72044

(dual pivot tilting washer-extractor models)

All except J2N models

64040, 64042, 64046, 72046, 72058 and 72075

(single pivot tilting washer-extractor models)

J2N models

Centrifugal extractor models

Short safety stands

48040

(dual pivot tilting washer-extractor model)

About the Forces Transmitted by Milnor® Washer-extractors

2

8

8

8

U

About the Forces Transmitted by Milnor

Washer-extractors

During washing and extracting, all washer-extractors transmit both static and dynamic

(cyclic) forces to the floor, foundation, or any other supporting structure. During washing, the

impact of the goods as they drop imparts forces which are quite difficult to quantify. Size for size,

both rigid and flexibly-mounted machines transmit approximately the same forces during

washing. During extracting, rigid machines transmit forces up to 30 times greater than equivalent

flexibly-mounted models. The actual magnitude of these forces vary according to several factors:

• machine size,

• final extraction speed,

• amount, condition, and type of goods being processed,

• the liquor level and chemical conditions in the bath preceding extraction, and

• other miscellaneous factors.

Estimates of the maximum force normally encountered are available for each Milnor

and size upon request. Floor or foundation sizes shown on any Milnor

on-grade situations based only on previous experience without implying any warranty, obligation,

or responsibility on our part.

1.

Rigid Machines

Size for size, rigid washer-extractors naturally require a stronger, more rigid floor,

foundation, or other supporting structure than flexibly-mounted models. If the supporting soil

under the slab is itself strong and rigid enough and has not subsided to leave the floor slab

suspended without support, on grade installations can often be made directly to an existing floor

slab if it has enough strength and rigidity to safely withstand our published forces without

transmitting undue vibration. If the subsoil has subsided, or if the floor slab itself has insufficient

strength and rigidity, a deeper foundation, poured as to become monolithic with the floor slab,

may be required. Support pilings may even be required if the subsoil itself is “springy” (i.e., if its

resonant frequency is near the operating speed of the machine). Above-grade installations of rigid

machines also require a sufficiently strong and rigid floor or other supporting structure as

described below.

®

Document..................... BIWUUI0

Specified Date.................2000110

As-of Date.......................2000110

Access Date..................... 2000110

Applicability...........................WU

®

®

document are only for

model

2.

Flexibly-mounted Machines

Size for size, flexibly-mounted machines generally do not require as strong a floor,

foundation, or other supporting structure as do rigid machines. However, a floor or other

supporting structure having sufficient strength and rigidity, as described in section 3, is

nonetheless vitally important for these models as well.

3.

How Strong and Rigid?

Many building codes in the U.S.A. specify that laundry floors must have a minimum live

load capacity of 150 pounds per square foot (732 kilograms per square meter). However, even

compliance with this or any other standard does not necessarily guarantee sufficient rigidity. In

any event, it is the sole responsibility of the owner/user to assure that the floor and/or any other

supporting structure exceeds not only all applicable building codes, but also that the floor and/or

any other supporting structure for each washer-extractor or group of washer-extractors actually

has sufficient strength and rigidity, plus a reasonable factor of safety for both, to support the

weight of all the fully loaded machine(s) including the weight of the water and goods, and

including the published 360º rotating sinusoidal RMS forces that are transmitted by the

machine(s). Moreover, the floor, foundation, or other supporting structure must have sufficient

rigidity (i.e., a natural or resonant frequency many times greater than the machine speed with a

reasonable factor of safety); oth erwise, the m enti oned 360º ro ta ting sinuso ida l RMS forces can be

multiplied and magnified many times. It is especially important to consider all potential vibration

problems that might occur due to all possible combinations of forcing frequencies (rotating

speeds) of the machine(s) compared to the natural frequencies of the floor and/or any other

supporting structure(s). A qualified soil and/or structural engineer must be engaged for this

purpose.

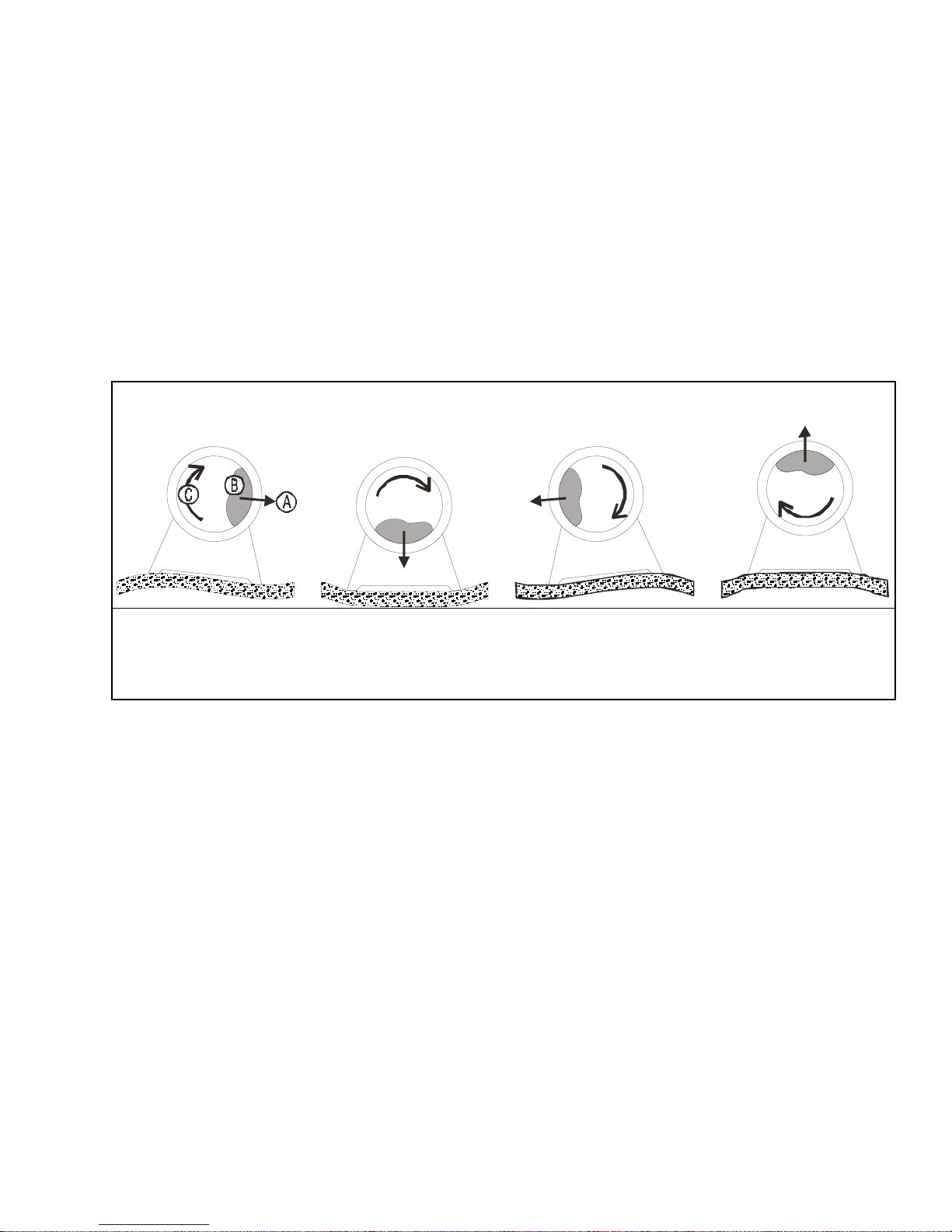

Figure 1: How Rotating Forces Act on the Foundation

Typical Machine

A.

Direction of force

B.

Load

C.

Rotation (Frequency = RPM / 60)

Figure 1 above is intended to depict both on-grade and above-grade installations and is

equally applicable to flexibly-mounted washer-extractors, as well as to rigid models installed

either directly on a floor slab or on a foundation poured integrally with the slab. Current machine

data is available from Milnor

have changed since last printed. It is the sole responsibility of every potential owner to obtain

written confirmation that any data furnished by Milnor

number(s) of the specific machines.

Legend

®

upon request. All data is subject to change without notice and may

®

applies for the model(s) and serial

— End of BIWUUI02 —

<B8D?DC604(''0E

7\_ccQbi_VDQW9\\ecdbQdY_^c±

Cec`U^TUTGQcXUb5hdbQSd_bc

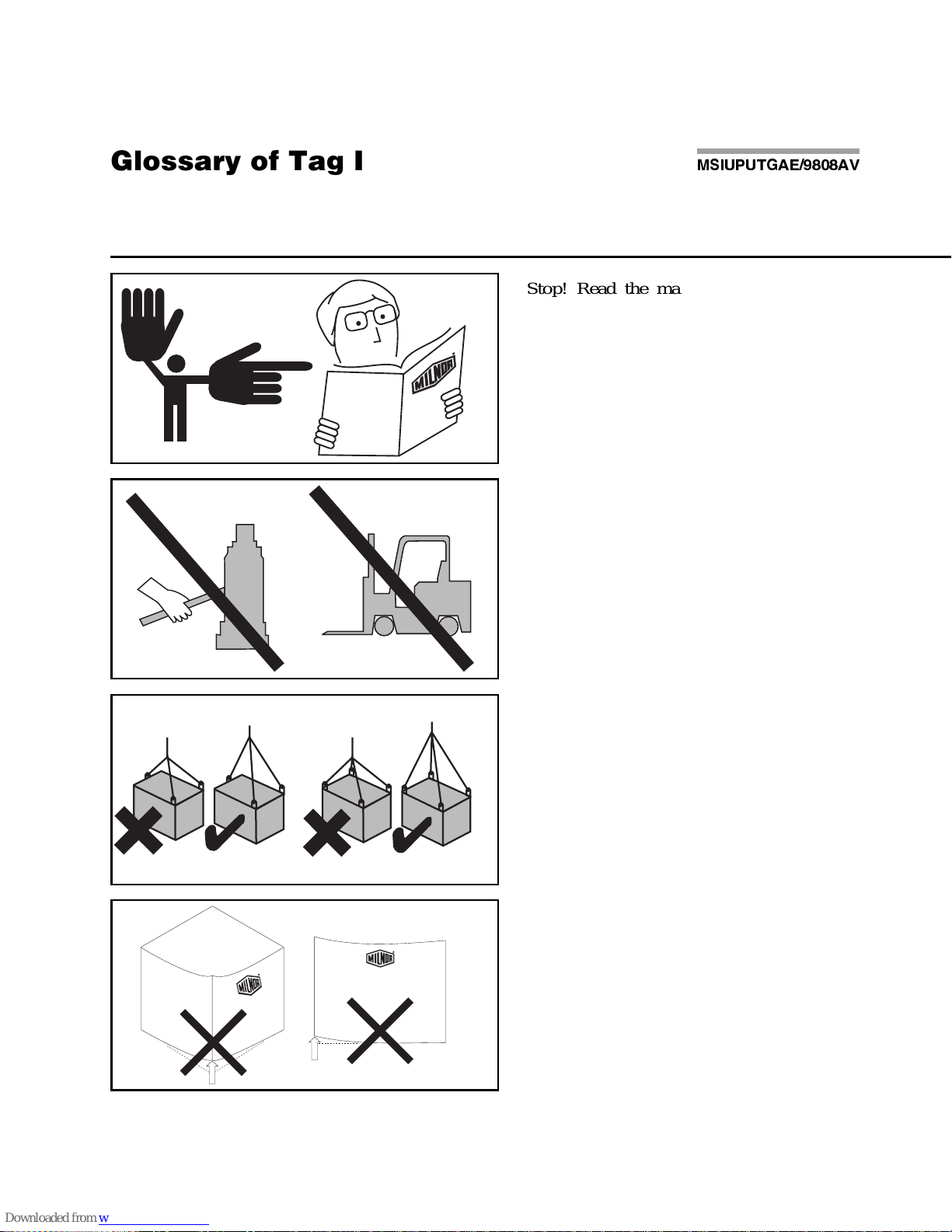

Illustration Explanation Illustration Explanation

Stop! Read the manual first for complete

instructions before continuing.

Do not jack the machine here.

Do not lift the machine here.

Use three point or four point lifting as

determined by the lifting eyes furnished. Rig

the load using lifting cables of sufficient size

and length to ensure cables are not

over-stressed.

Do not lift the machine from one corner or one

side edge.

Do not start this machine until the packing

materials, lifting brackets, etc. with this tag

attached or behind this panel are removed.

These materials are painted red. Safety stands

or brackets (also painted red) may be provided

with this machine. Do not discard safety

stands or brackets

Do not step or stand on this machine part.

Maintain a 25 mm. (1") minimum clearance

between float clips. Set "low level" so that the

bottom of the float is always at least 25mm

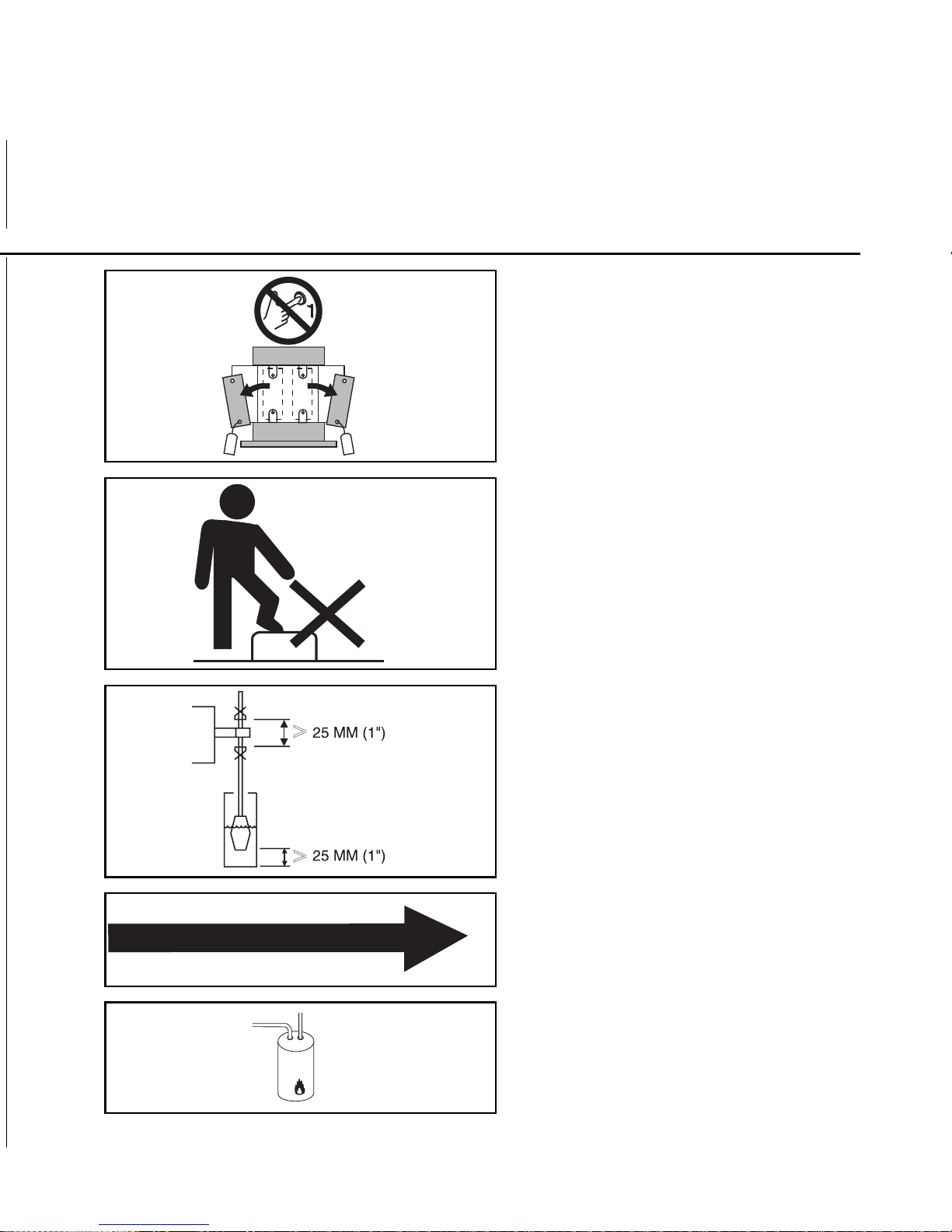

(1") above the bottom of the float tube.

This motor or pump should rotate in the

direction of the arrow.

This is the hot water inlet.

Do not start this machine until the part with

this tag is installed on the machine.

Do not remove this component from the

machine.

Install the appropriate part here before

operating the machine.

Do not strap or chain over box

7\_ccQbi _V DQW 9\\ecdbQdY_^c±

Cec`U^TUT GQcXUb5hdbQSd_bc =C9E@ED715)( (1F " #

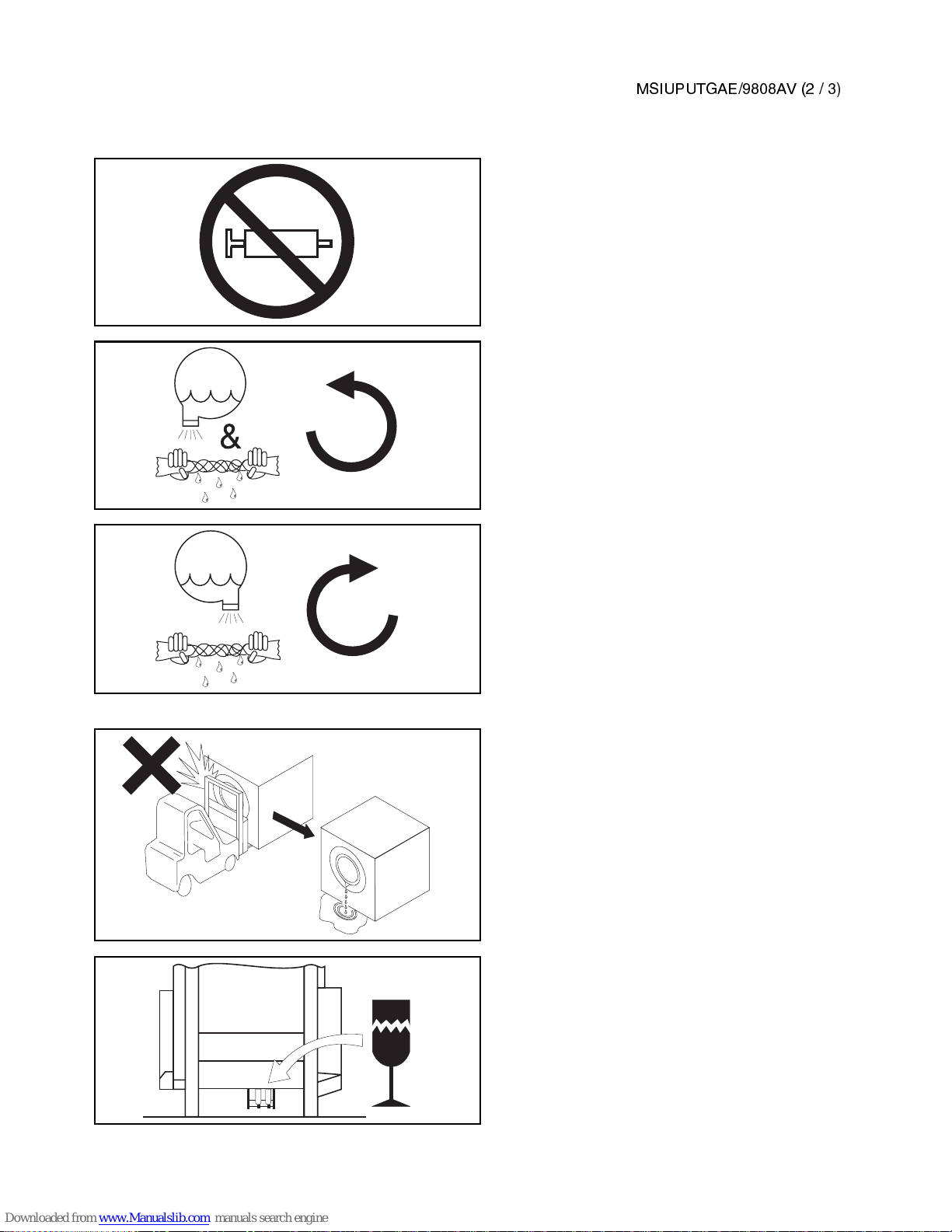

Do not pump grease here.

During drain and extract, the cylinder must

rotate counterclockwise when viewed from

here.

During drain and extract, the cylinder must

rotate clockwise when viewed from here.

Do not strike shell front of washer-extractors

during fork lifting. Striking shell front will

cause door to leak.

Brake assembly under machine is fragile.

Forklift blades should only be placed under

main structural beams

&

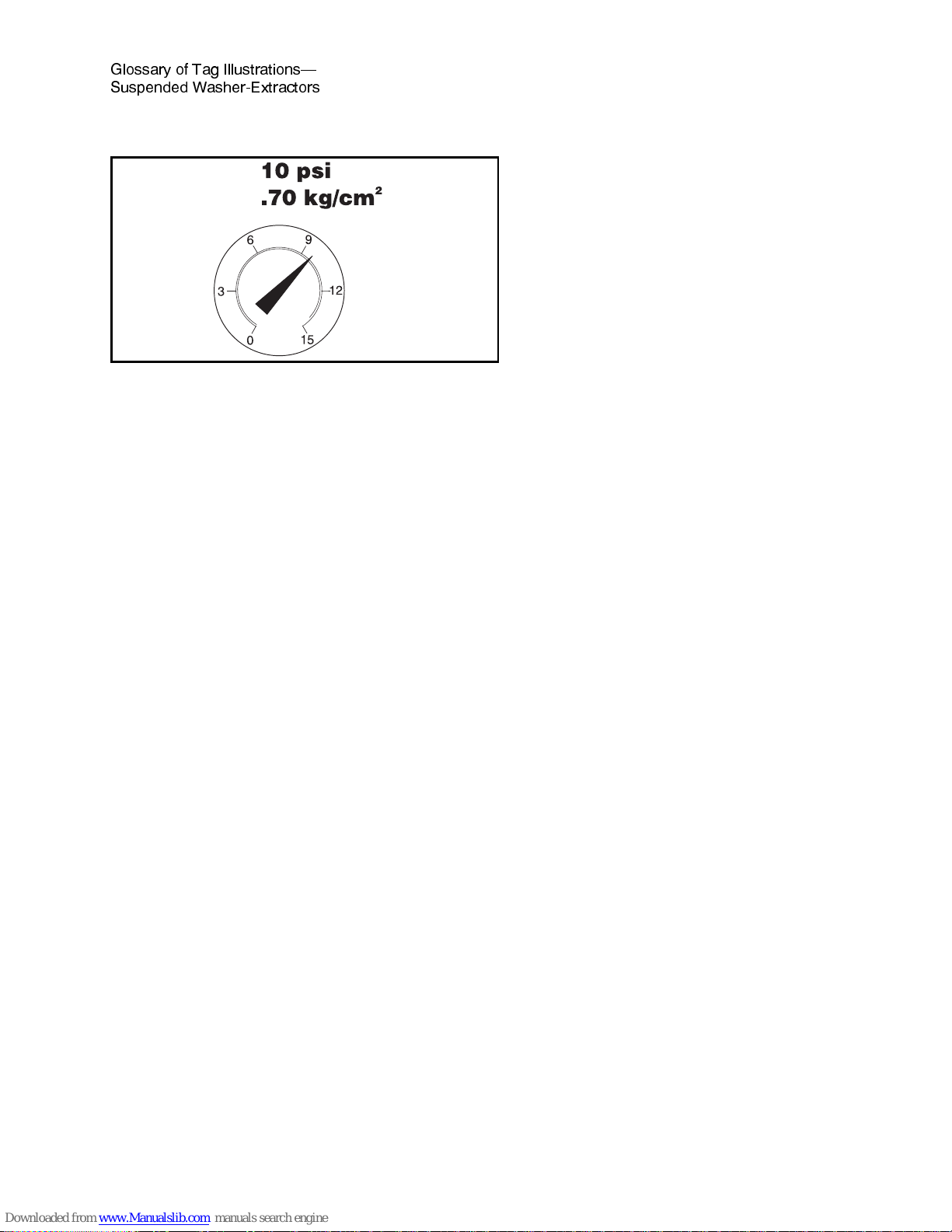

Set main bearing air pad gauge at 10 psi

(.70 kg/cm2), 64" and 72" ExN and JxN

models only.

Set disc brake air gauge at 10 psi

(.70 kg/cm2), 64" and 72" ExN and JxN

models only.

7\_ccQbi _V DQW 9\\ecdbQdY_^c±

Cec`U^TUT GQcXUb5hdbQSd_bc =C9E@ED715)( (1F # #

Section 1

Service and Maintenance

MSSM0201CE/9 84 0A V (1of 11)

ÈLUBRICATION AND PREVENTIVE MAINTENANCE

FOR HYDRO-CUSHION

®

MACHINES

ÊGeneral Requirements

Maintenance procedures require:

• A hand operated grease gun.

• The correct lubricants (see “LUBRICANTS FOR MILNOR MACHINES,” in the Table of Contents).

ÊLubricant Requirements

To achieve the optimum performance and service life from th e Milnor® machine and as a warranty require-

ment, the machine must be lubricated in strict accordance with the instructions in this section.

ENTANGLE AND CRUSH HAZARD—Belts and pulleys can entangle and crush

body parts.

☞ Lock OFF and tag out power at the wall disconnect before servicing, except

where specifically instructed otherwise in this section.

☞ Insure belt and pulley guards are in place during service procedures.

☞ Permit only qualified maintenance personnel to perform these procedures.

CRUSH/SEVER HAZARD—Tilting mechanism can crush or sever parts of your

body caught in them.

☞ Install the safety stands before performing maintenance under a tilted ma-

chine.

☞ NEVER test or operate (manually or automatically) any machine function

with any portion of a person’s body under the tilted machine—even if the

safety stands are inst al le d.

CRUSH/SEVER HAZARD—Tilting machines with tilt wheels/cradles may lunge

forward or rearward and even fall over if the tilt wheels at the non-tilted end are

raised out of their cradles—killing/injuring personnel and/or damaging property.

☞ NEVER manually tilt (lift) both ends of the machine at the same time. One end must

always be seated in it s cradle.

☞ ALWAYS visually inspect the tilt wheels to be sure they are all fully seated in their cra-

dles before each manual tilt up.

☞ Hydraulic valve manual operation must be done by trained competent maintenance per-

sonnel who thoroughly understand the system and all the consequences of manual

operations.

☞ ALWAYS understand beforehand all the consequences of manually operating hydraulic

valves.

☞ Never permit operation with malfunctioning tilt limit switches.

ÊCorrect Grease Gun Procedures

1. Do not use a pneumatic grease gun. Pump grease slowly, taking 10-15 seconds to complete each stroke.

A grease gun can build up extremely high pressure which will force seals out of position and cause them to

leak, even though both the seal and the bearing housing are equipped with spring loaded relief plugs.

2. Apply quantity of grease called for in the checklist. Over-lubrication can be as damaging as under-lubrica-

tion. Where quantities are stated in strokes, one stroke of the grease gun is assumed to provide .0624 fluid

ounces (1.77 grams) (by volume) of grease. Therefore, one fluid ounce (28.3 grams) of grease would be provided by 16 strokes of the grease gun. Determine the flow rate of your grease gun by pumping one ounce

into a calibrated container. If fewer than 16 strokes are required, all quantities in strokes in the chart should

be reduced accordingly, and if more than 16 strokes are required, the number of strokes should be increased.

Before starting lubrication, make sure your grease gun is working and that you get a full charge of

grease with every stroke.

3. Do not pump grease in until it oozes out of the spring loaded relief plugs. Plugs bleed out excess grease

and help prevent abnormal pressures from building up in the housing during operation (especially when the

machine is first commissioned and after each lubrication). Plugs will not protect against over-lubrication.

4. Do not over-lubricate motors. Over-lubrication of a motor can seriously damage it by forcing grease into

motor windings. Over-lubrication of the extract motor can force grease into the centrifugal switch causing it

to malfunction.

5. Do not allow grease to drip on the brake disk or clutch tire/drum during lubrication. This will reduce

the braking action considerably, and may permit the cylinder to creep while loading and unloading.

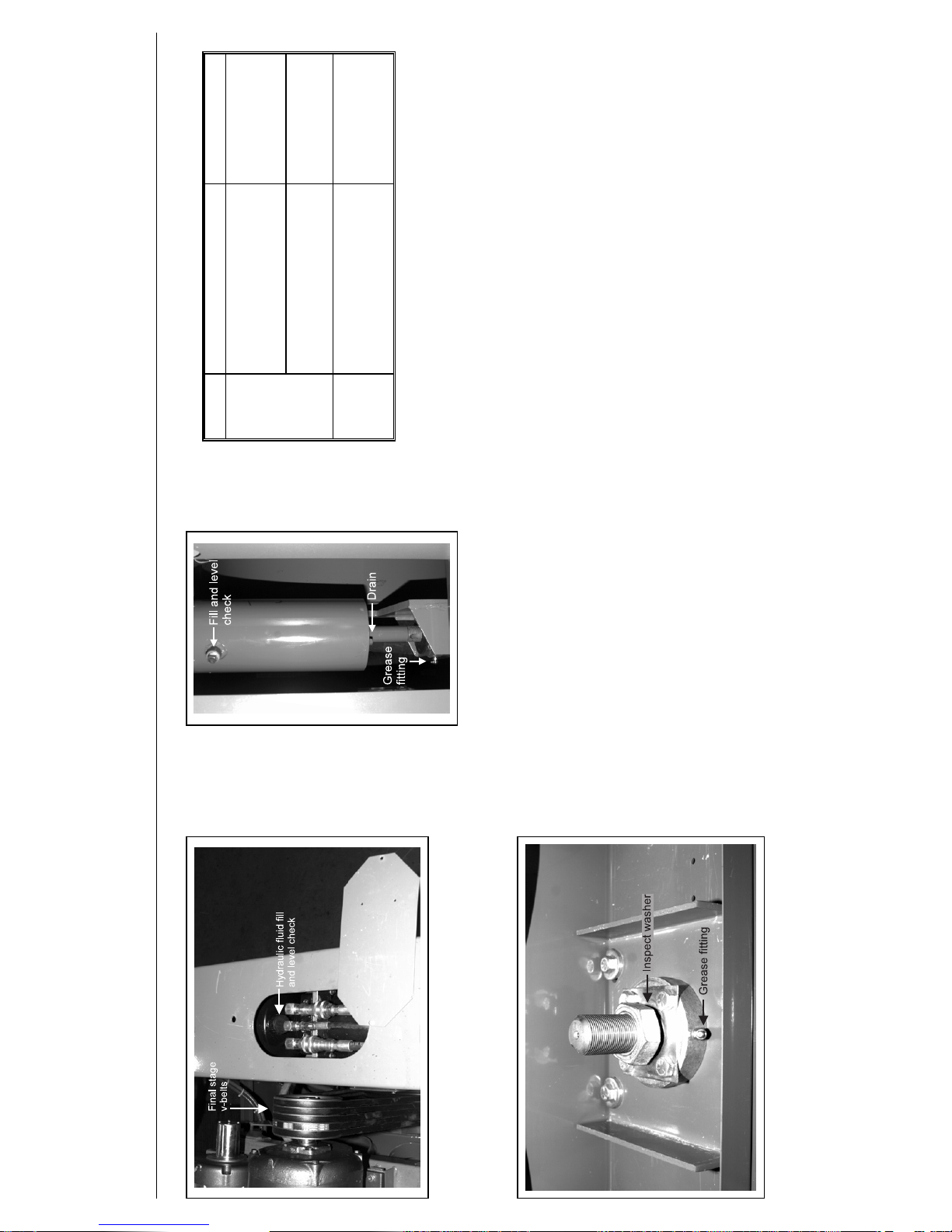

ÏDaily and Weekly Maintenance Items

Frequency Component Action

Daily Hydraulic Tilt System

(48", 52", and 72" Tilt machines)

• Reservoir

FIGURE 1 and NOTE 1

Check fluid with

machine not tilted

Hydro-Cushions

®

(all machines)

FIGURES 2 and 3

Check for leaks

Weekly Final stage and other v-belts

(throughout all machines)

FIGURES 1 and 12

NOTES 2 and 3

Check for wear and

tension

NOTE 1: Tank should be approximately three-quarters full when the machine is not

tilted. Do not over-fill.

NOTE 2: V-belt instructions for the first week of operation

• After 24 hours operation (three eight hour days), tighten final stage v-belts.

• After 80 hours operation (ten eight hour days), tighten final stage v-belts

again.

• After 160 hours of operation (twenty eight hour days), tighten final stage

v-belts, and check all other v-belts and tighten if necessary.

NOTE 3: All v-belts are not alike. “Super” or “High Capacity” v-belts frequently have

considerably higher capacities than “Standard” belts. Sometimes, one brand of

v-belt is more suitable than another brand of v-belt, although both v-belts are

“interchangeable”. It is always best to purchase replacement belts from the

original manufacturer of the equipment. Purchasing exact replacements of the

original belts is the best way to assure belt life equal to the original set.

Occasionally, Milnor

®

will change a belt specification to improve belt life.

Belts purchased from Milnor

®

are as currently specified.

ÎFIGURE 1

(MSSM0201CE)

ÎHydraulic Fluid Reservoir Fill and Level Check Point

(located at rear of 48", 52", and 72" tilt machines only)

ÎFIGURE 2

(MSSM0201CE)

ÎTypical Hydro-Cushion

®

Maintenance Points

ÎFIGURE 3

(MSSM0201CE)

ÎTypical Upper Hydro-Cushion

®

Grease Fitting

LUBRICATION AND PREVENTIVE MAINTENANCE

FOR HYDRO-CUSHION MACHINES MSSM0201CE/9840AV (3 of 11)

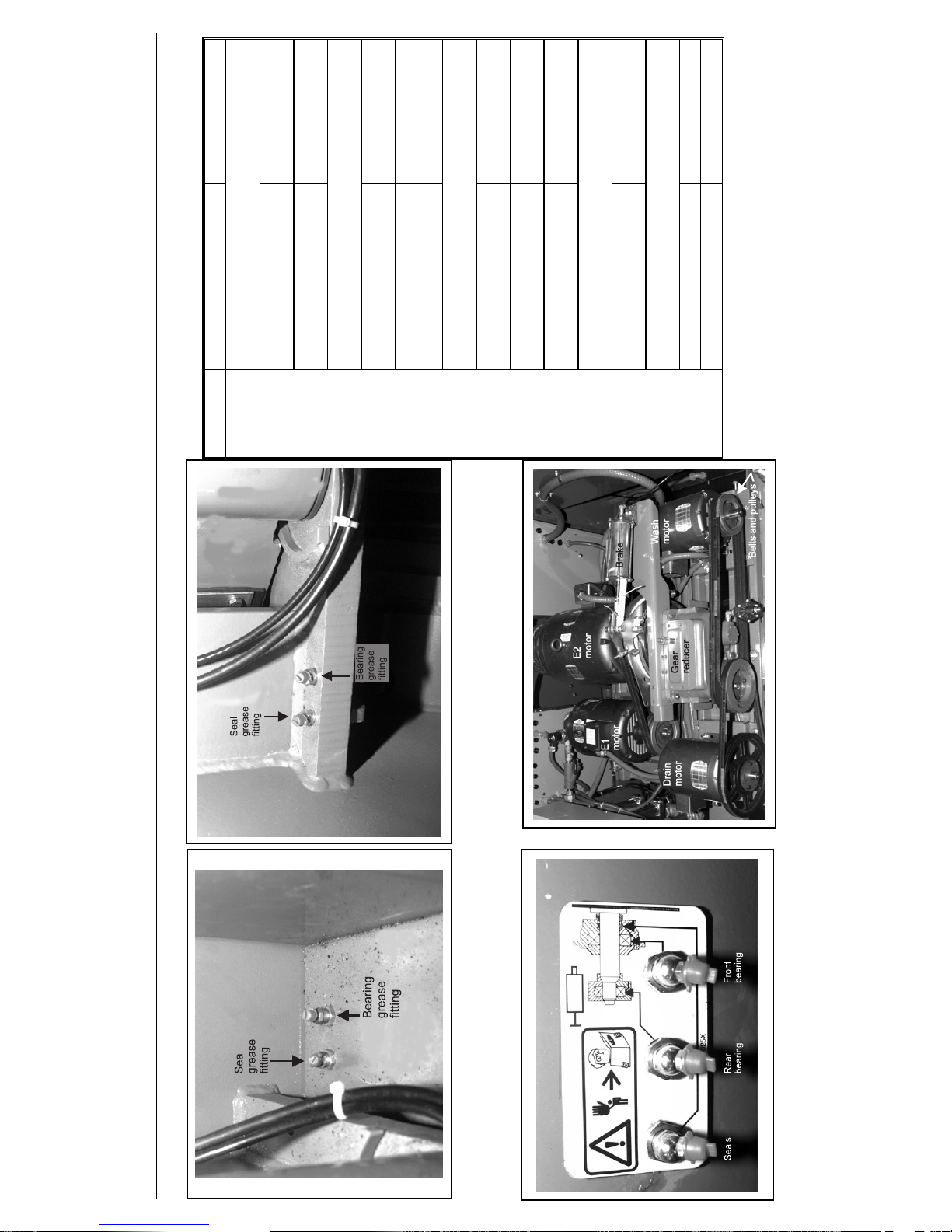

ÏMonthly Maintenance Items

Frequency Component Action

Monthly

(see NOTE 4 )

All Divided cylinder and Staph-Guard

®

main bearing and seals

FIGURES 4 through 10, NOTES 5 and 6

• Each bearing grease

fitting

0.37 ounces (10.6 grams),

six strokes at two locations

• Each seal grease

fitting

0.12 ounces (3.54 grams),

two strokes at two locations

NOTE 4: Once a month or once every 200 operating hours, whichever occurs first.

NOTE 5: Main bearings and jackshaft bearings (if so equipped) are prepacked with

lubricant at the factory. Do not add grease for thirty days. During the first

month’s operation, some grease will ooze out of the automatic grease fittings

at the bottom of the housing(s). This is normal. These grease fittings allow

excess grease to escape, thus avoiding over-heating. This escaping lubricant

need not be replaced. Every time these bearings are lubricated, the surplus

grease will come out of the spring loaded relief fittings after a few hours

running time.

NOTE 6: Bearings can run hot enough to make it extremely uncomfortable for a

person to hold his hand on the bearing housing for more than a few seconds.

This is normal.

Ï

ÎFIGURE 4

(MSSM0201CE)

Î42" Divided Cylinder Front

Bearing and Seal Grease Fittings

ÎFIGURE 5

(MSSM0201CE)

Î42" Staph-Guard

®

Front and

Rear Bearing and Seal Grease

ÎFIGURE 6

(MSSM0201CE)

Î42" Divided Cylinder Rear Bearing

and Seal Grease Fittings

ÎFIGURE 7

(MSSM0201CE)

Î60" and 72" Divided Cylinder Front

Seal and Bearing Grease Fittings

ÎFIGURE 8

(MSSM0201CE)

Î60" and 72" Divided Cylinder Rear Seal and Bearing

LUBRICATION AND PREVENTIVE MAINTENANCE

FOR HYDRO-CUSHION MACHINES MSSM0201CE/9840AV (4 of 11)

ÎFIGURE 9

(MSSM0201CE)

Î60044 and 72044 Staph-Guard

®

Front Bearing and Seal

Grease Fittings (located on front door)

ÎFIGURE 10

(MSSM0201CE)

Î60044 and 72044 Staph-Guard

®

Rear Bearing and Seal

Grease Fittings (located on rear door)

ÎFIGURE 11

(MSSM0201CE)

ÎAll Open-Pocket Machine Seal and Bearing

Grease Fitting Plate

ÎFIGURE 12

(MSSM0201CE)

ÎTypical Drive Train Components (48" machine shown)

ÏMonthly Maintenance Items

Frequency Component Action

Monthly

(see NOTE 4)

42" Open pocket main bearings and seals

FIGURE 11, NOTES 5 and 6

• Front and rear bearing grease fitting 0.12 ounces (3.54 grams),

two strokes at two locations

• Seal grease fitting 0.06 ounces (1.77 grams),

one stroke at one location

48" Open pocket main bearings and seals

FIGURE 11, NOTES 4, 5, and 6

• Front and rear bearing grease fitting 0.31 ounces (8.85 grams),

five strokes at two locations

• Seal grease fitting See “Semi-Annual

Maintenance Items” in this

section

52" and 72" Open pocket main bearings and seals

FIGURE 11, NOTES 4, 5, and 6

• Front bearing grease fitting 1.87 ounces (53.1 grams),

thirty strokes at one location

• Rear bearing grease fitting 0.62 ounces (17.7 grams),

ten strokes at one location

• Seal grease fitting 0.19 ounces (5.31 grams),

three strokes at one location

Hydro-cushions

®

FIGURES 2 and 3

• Upper and lower ball joints 0.12 ounces (3.54 grams),

two strokes at two locations

Drive train components

FIGURE 12

• Pulleys and clutches Check for wear

• All components Remove soil build-up

LUBRICATION AND PREVENTIVE MAINTENANCE

FOR HYDRO-CUSHION MACHINES MSSM0201CE/9840AV (5 of 11)

ÎFIGURE 13

(MSSM0201CE)

ÎHandwheel Screw

(42" Divided Cylinder and Staph-Guard

®

only)

ÎFIGURE 14

(MSSM0201CE)

ÎTypical Door Hinge

ÎFIGURE 15

(MSSM0201CE)

ÎHandwheel Stop

(42" Divided Cylinder and Staph-Guard

®

only)

ÎFIGURE 16

(MSSM0201CE)

Î42" Staph-Guard

®

ldler Shaft

Grease Fitting

ÎFIGURE 17

(MSSM0201CE)

Î60" and 72" Staph-Guard

®

Idler Shaft

and Disc Brake Grease Fittings

(60" shown)

ÎFIGURE 18

(MSSM0201CE)

ÎTypical Jackshaft

Grease Fittings

( 52" machine shown)

LUBRICATION AND PREVENTIVE MAINTENANCE

FOR HYDRO-CUSHION MACHINES MSSM0201CE/9840AV (6 of 11)

Ï Monthly Maintenance Items

Frequency Component Action

Monthly

(see NOTE 4)

Handwheel screw

(42" Divided Cylinder and

Staph-Guard

®

)

• Screw thread

FIGURE 13

Three drops of light machine

oil

Door hinges

• Grease fittings

FIGURE 14

0.12 ounces (3.54 grams),

two strokes at each location

Handwheel stop

(42" Divided Cylinder and

Staph-Guard

®

)

• Grease fitting

FIGURE 15

0.06 ounces (1.77 grams),

one stroke at one location

Idler shaft

(Staph-Guard

®

only)

• Grease fittings

FIGURES 16 and 17

0.31 ounces (8.85 grams),

five strokes at two locations

Disc brake

(60" and 72" Staph-Guard

®

only)

• Grease fittings

FIGURE 17

0.12 ounces (3.54 grams),

two strokes at one location

Jackshaft

(if equipped)

• Grease fittings

FIGURE 18

NOTES 5 and 6

0.12 ounces (3.54 grams)

two strokes at two locations

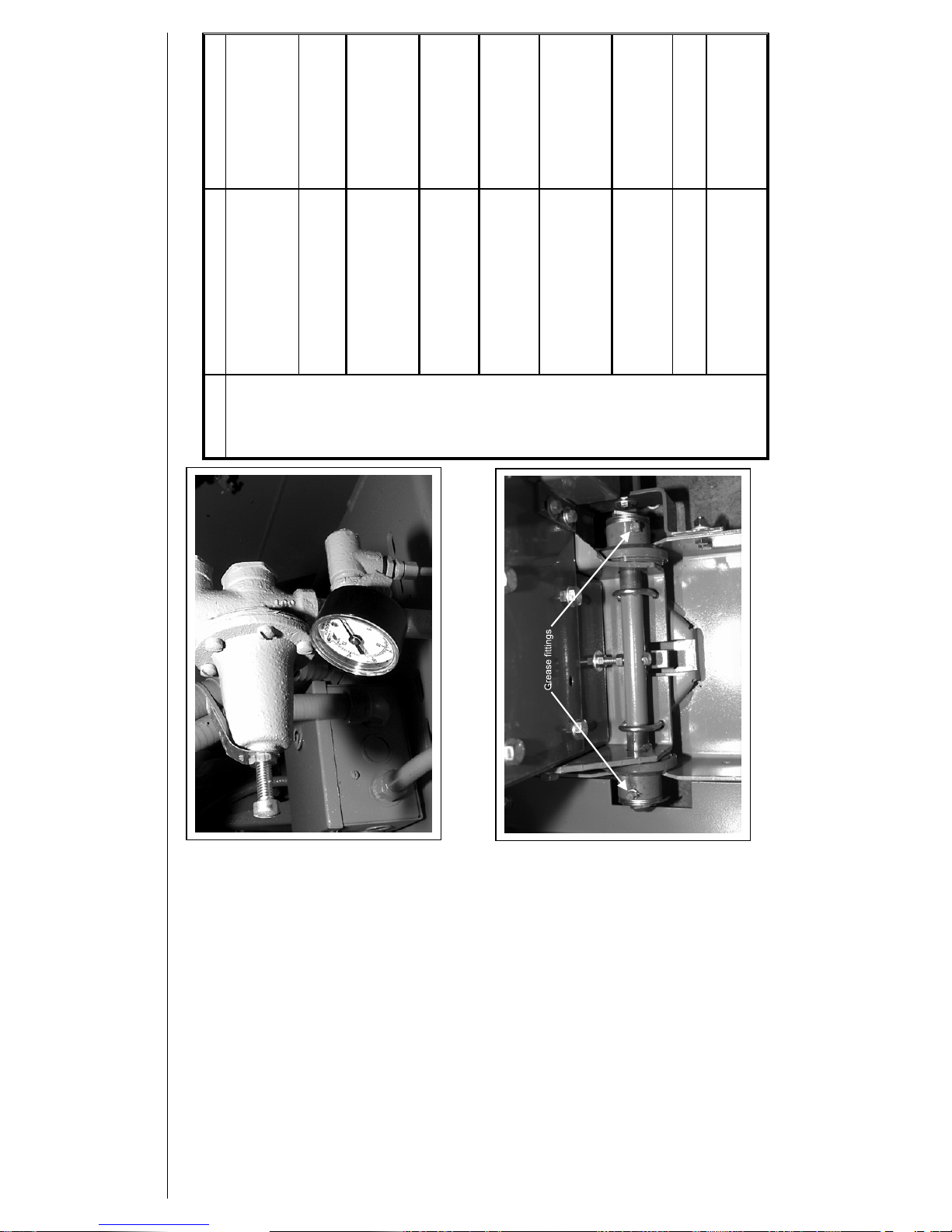

Water pressure regulator

(if equipped)

• Gauge

FIGURE 19

28 psi (0.14 kg/cm

2

)

Foundation

• Anchor bolts and grout Check condition

Tilt wheels

(42", 48", and 72" Tilt Models )

• Grease fittings

FIGURE 20

0.12 ounces (3.54 grams),

two strokes at each locations

ÎFIGURE 19

(MSSM0201CE)

ÎWater Pressure Regulator and Gauge

(42" machine shown)

ÎFIGURE 20

(MSSM0201CE)

ÎTilt Wheels

(42"and 48" tilt machines only)

LUBRICATION AND PREVENTIVE MAINTENANCE

FOR HYDRO-CUSHION MACHINES MSSM0201CE/9840AV (7 of 11)

Loading...

Loading...