Page 1

42030 V6J

♦

y

o

o

t

g

r

y

(s)

g

(s)

s

160 LB. (72KG) CAPACITY

IGID-MOUNT WASHER-EXTRACTOR

R

FLOOR REQUIREMENT 12” MINIMUM

RECOMMENDED ▼,

MECHANICAL SPECIFICATIONS

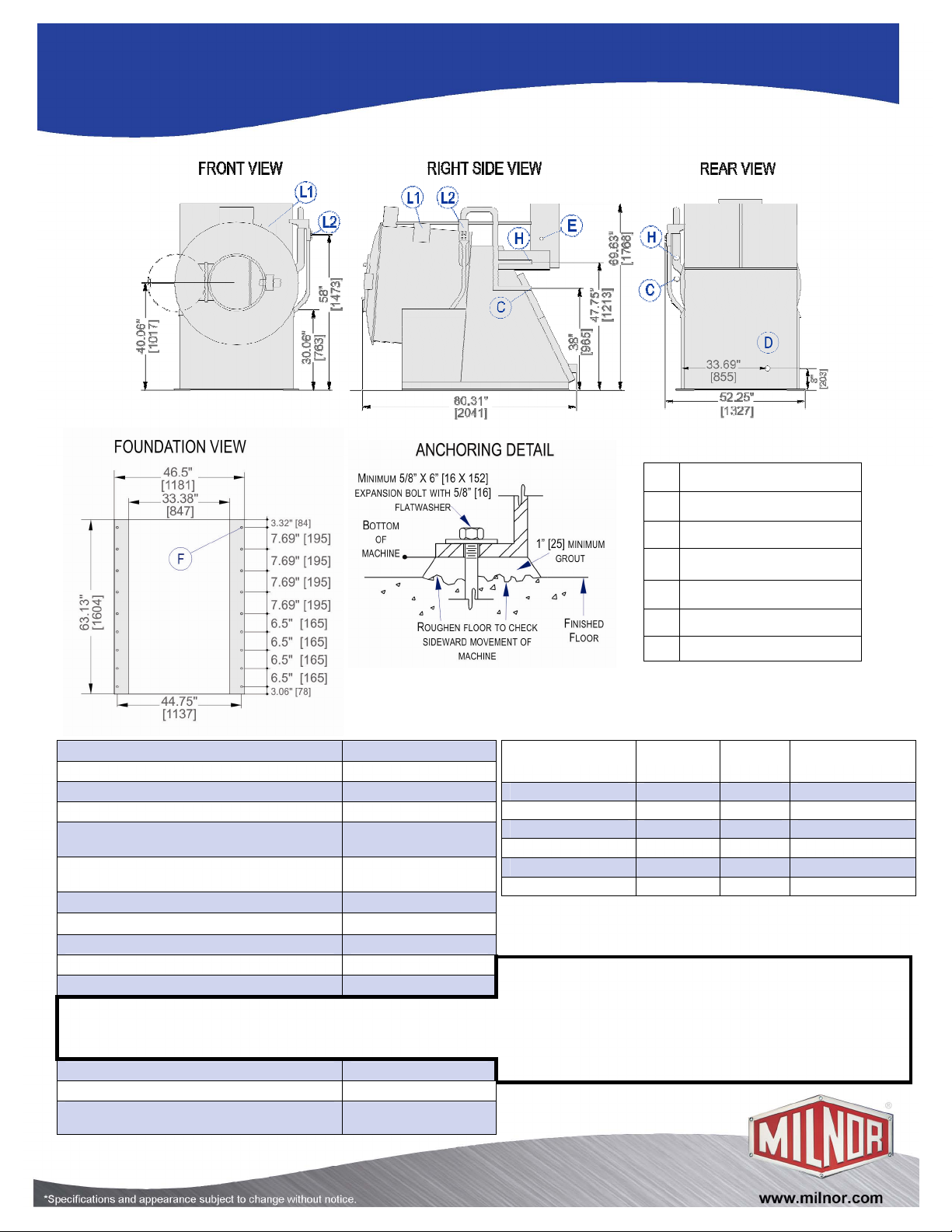

Capacity – lbs (kg) 160 (72)

Cylinder Diameter x Depth – ins (mm) 42 x 30 (1067 x 762)

Door Opening – ins (mm) 20 (508)

Cylinder Volume – cu. ft. (L) 24.0 (679)

Machine Dimensions

(W x D x H) – ins (mm)

Shipping Dimensions

(W x D x H) – ins (mm)

Motor – HP (kW) 10 (7.45)

Wash Speeds – RPM 33-40

Distribution Speed – RPM 60

Extraction Speeds – RPM 425-600 (710♦)

Extraction G-Force 215 (300♦)

Static Weight – lbs (kg) 3603 (1634)

Max. Dynamic Load RMS- lbs (kg)

Frequency (Hz) 11.82

(Required)

Water Pressure

– psi (bar) 10-75 (.68-5.1)

Water Valve CV Rating – gal/min (L/min) 12.9 (49)

Minimum Recommended Distance

Between Machines – ins (mm)

52.25x80.31x69.63

(1327x2041x1768)

85 x 66 x 77 (2159 x

1676 x 1956)

5916 (2683)

12 (305)

SPECIFICATION SHEET

LEGEND

Cold water inlet, 1.25”

C

(32 mm) NPT

Drain to rear, 3” (76 mm) pipe

D

socket joint

E Main electrical connection

Anchor bolt holes, .8125”

F

(21 mm) diameter

Hot water inlet, 1.25” (32 mm)

H

NPT

L1 Standard soap chute

L2 Liquid supply inlets

ELECTRICAL SPECIFICATIONS

Voltage Running

Amps

208/3/60 21 FRN50 50

220/3/50-60 20 FRN50 50

240/3/60 18 FRN50 50

380/3/50-60 13 FRS30 30

415/3/50 11 FRS25 25

480/3/60 9 FRS25 25

See Fuse and Wire Size manual MAEFUSE1BE for safety information.

With optional ExactXtract speed optimizer.

See dimensional drawing for complete details.

▼

It is the sole responsibilit

thersupporting structure exceeds not only all applicable building codes, but als

hat the floor and/or any other supporting structure for each washer-extractor or

roup of washer-extractors has sufficient strength and rigidity (i.e., a natural or

resonant f

reasonable factor

machine

published 360º rotatin

machine

equency many times greater than the rotational machine speed with a

including the weight of the water and goods, and including the

tructural engineer.

. Contact the factory for additional machine data for use by a

of the owner/user to assure that the floor and/or any

of safety) to support the weight of all the fully loaded

sinusoidal RMS forces that are transmitted by the

Fuse

(Amps)

Circuit Breaker

(Amps)

B22SS1006/10495 Page 1 of 2

Page 2

W

42030 V6J

160 LB. (72KG) CAPACITY

IGID-MOUNT WASHER-EXTRACTOR

R

SPECIFICATION SHEET

Standard Features:

®

• RinSave

• 7 speeds

• E-P PLUS

water saving technology

(2 wash, 1 distribution, 1 RinSave, 3 extract)

®

programmable controller

• Back-lit LCD display

• Single-motor inverter drive

• Tall, lifting ribs

• Tapered roller bearings

• High M.A.F. (Mechanical Action Factor)

• Large cylinder perforations

• Fresh-water flushing chemical manifold

• Auto tension V-belt drive

• Six (6) liquid chemical injection ports

• Control reads in English/second language

• 5-year limited warranty on frame, cylinder & shell

hy Purchase Milnor?

• RinSave

more efficient rinsing. BENEFIT: Saves water, energy, and time.

• Larger cylinder volume than most competitive similar sized washer-extractors

provides greater productivity. More linen washed per day, or fewer hours required

to process. BENEFIT: Saves labor.

• Faster process times reduce fabric wear, promoting longer linen life!

BENEFIT: Saves linen replacement costs.

• Tall perforated ribs provide excellent lift and high drop.

BENEFIT: Greater mechanical action (M.A.F.) leads to better wash quality.

• 215-G high extract (300-Gs with optional ExactXtract

provides excellent moisture removal. Lower extract speeds are available for

uniforms, delicate textiles and blended fabrics.

BENEFIT: Better extraction saves dryer fuel.

• E-P Plus Controller with back-lit LCD display allows operator to choose formulas

from real words, not codes. Standard controller features English/Spanish (other

languages optional). Controller also provides diagnostic and error messages.

Shortens training time of new employees. BENEFIT: Fewer operator errors.

• Superior product support through local, highly-skilled dealers.

BENEFIT: Faster repairs mean less downtime.

®

water saver in conjunction with large cylinder perforations provides

®

extraction optimizer)

Contact Milnor for your local, authorized dealer:

Pellerin Milnor Corporation

P.O. Box 400 ● Kenner, LA 70063

t: 504-467-9591 ● f: 504-468-3094

Optional Features:

• ExactXtract

®

extraction

optimizer control

• Steam

• 5 compartment flushing

supply injector

• Prison package

Safe chemical injection

Superior cylinder design

Solid industrial frame

B22SS1006/10495 Page 2 of 2

Loading...

Loading...