Milnor 42026 X7W Installation Manual

Published Manual Number: MQCWFO01EN

• Specified Date: 20070507

• As-of Date: 20070507

• Access Date: 20070507

• Custom: n/a

• Applicability: 42032F7W 42044WP2 42044WP3 48040F7W 60044WP2 60044WP3

• Language Code: ENG01, Purpose: publication, Format: 1colA

Operator Guide—

Non-tilting Washerextractor with Mark VI

Controller

PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063 - 0400, U.S.A.

Applicable Milnor® products by model number:

42032F7W 42044WP2 42044WP3 48040F7W 60044WP2 60044WP3

Table of Contents

Table of Contents

Sections Figures, Tables, and Supplements

Chapter 1. Controls

1.1. Controls on Mark VI Non-Tilting Washer-extractors

(Document BICWCO02)

1.1.1. Where are the Controls? Figure 1: Locations of Controls

1.1.2. Where do I Connect the Data Storage Device? Figure 2: Serial Connection for Data

1.1.3. What are the Operating Controls? Figure 3: Mark V Controls

1.1.4. What are the Loading Controls?

1.1.5. What does this Switch do? Figure 6: Mildata/Local Selector switch

Transfer

Figure 4: Mark VI Control Panel

Figure 5: Keypad

Figure 7: Manual Supply Flush button

Figure 8: Autospot selector switch

Chapter 2. Normal Machine Operation

2.1. Operating Instructions for Plant Personnel (Document

BICWCO03)

2.1.1. Start Here for Safety

2.1.2. Check Switch Settings

2.1.3. How do I Load a Non-tilting Machine?

2.1.4. How do I Select a Formula? Figure 9: Selecting a Local or Remote

2.1.4.1. Selecting a Local Formula Figure 10: Select Local Formula Screen

2.1.4.2. Selecting a Mildata Formula Figure 12: Select Remote Formula Screen

2.1.4.3. Entering Mildata Batch Codes Figure 13: Batch Data for Remote Formula

2.1.5. Start the Selected Formula Supplement 2: Chemical Injections with

2.1.6. What Does the Run Display Tell Me? Figure 14: How to Read the Run Display

2.1.6.1. Formula and Step Information Table 1: Machine Status Messages

2.1.6.2. Basket Rotation

2.1.6.3. Bath Temperature and Level

2.1.6.4. Formula Steps and Chemical Injection

2.1.7. Unload the Machine Figure 15: Typical Message when Formula

2.1.7.1. For any End Code

Formula

Supplement 1: About Load Weight and

Metered Water

Figure 11: Entering Load Weight for

Metered Water

Operation

the Operator Signal

Ends

PELLERIN MILNOR CORPORATION

Table of Contents

Sections Figures, Tables, and Supplements

2.1.7.2. For End Code 3 (Tumbling)

Chapter 3. Signals and Errors

3.1. Operator Intervention (Document BICWCT04)

3.1.1. Error with Operator Signal Figure 16: Typical Error with Operator

Signal

3.1.2. Operator Signal for a Chemical Figure 17: Chemical Injection View on

Run Display

PELLERIN MILNOR CORPORATION

Chapter 1. Controls

Chapter 1

Controls

1.1. Controls on Mark VI Non-Tilting Washer-extractors

BICWCO02 (Published) Book specs- Dates: 20070507 / 20070507 / 20070507 Lang: ENG01 Applic: 42032F7W 42044WP2

42044WP3 48040F7W 60044WP2 60044WP3

Refer to other parts of this document (Section 1.1.2 through Section 1.1.5) for the location and

basic function of individual controls. Don't use this document as instructions for operating the

machine.

1.1.1. Where are the Controls?

The essential controls for normal operation are located on the front control panel (Figure 1)

(Figure 3). Additional controls and connections are located elsewhere on the machine, as

described here.

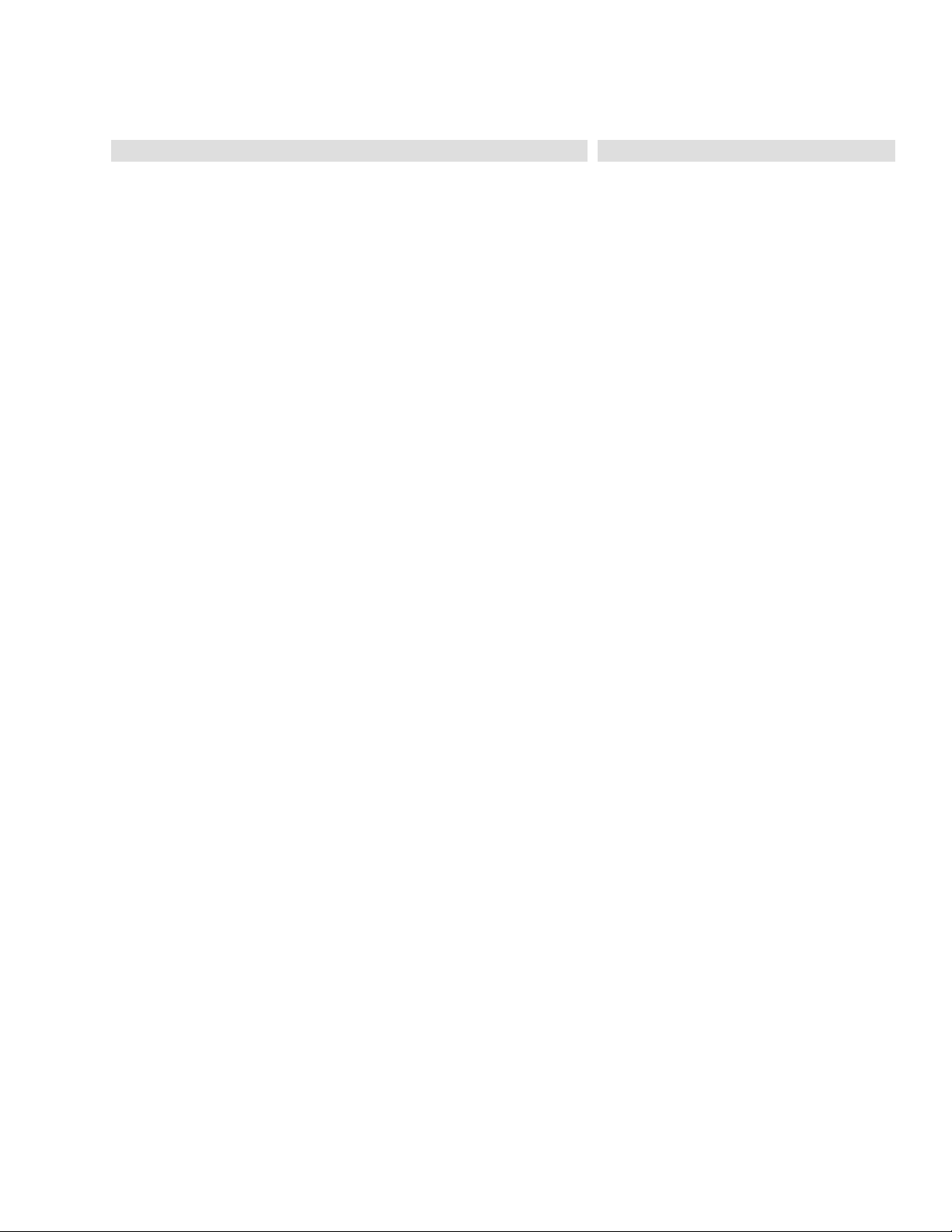

Figure 1: Locations of Controls

Front Left View Rear View Legend

.

A. Microprocessor control

box (68036F_B shown)

B. Control panel

C. Manual supply flush

button

D. Hydraulic pressure gauge

for loading door

E. Air pressure gauge for tilt

system (behind lower rear

panel)

1.1.2. Where do I Connect the Data Storage Device?

The microprocessor box in the upper rear corner of the machine left side panel (see Figure 1)

contains a DIN-type connection for serial communications. Use this connection, labelled as

shown in Figure 2, with a serial data transfer device to save or restore machine programming and

configuration memory.

PELLERIN MILNOR CORPORATION

Chapter 1. Controls

Figure 2: Serial Connection for Data Transfer

1.1.3. What are the Operating Controls?

The primary operating controls are required to start and stop the machine, select wash formulas,

and monitor machine operation.

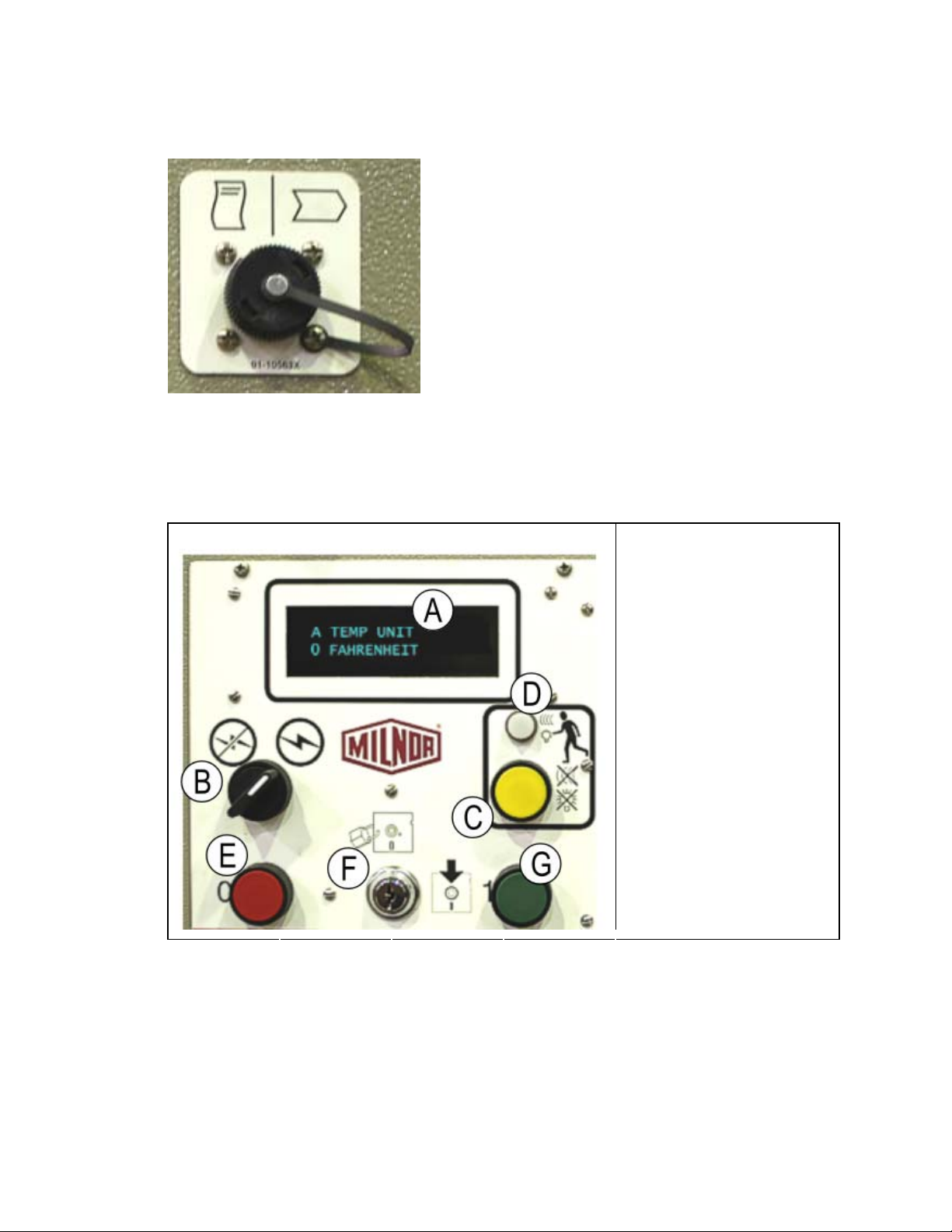

Figure 3: Mark V Controls

Switches and Controls Legend

A. Vacuum fluorescent

display

B. Master switch for power

C. Operator signal cancel

button

D. Operator signal light

E. Stop button

F. Run/Program keyswitch

G. Start button

.

PELLERIN MILNOR CORPORATION

Chapter 1. Controls

y

Figure 4: Mark VI Control Panel

Panel and Controls Legend

A. Emergency stop button

B. Master switch for power

C. Tilt front/rear selector switch (tilting

models only)

D. Tilt up/down selector switch (tilting models

only)

E. Door open/close switch

F. Operator signal cancel button

G. Operator signal light

H. Liquid crystal graphic display

I. Keypad

J. Door open button

K. Start button

L. Stop button

M. Run/Program keyswitch

N. Jog direction switch

O. Door open jog button (tilting models only)

.

Figure 5: Keypad

Emergency stop button—disables the 3-wire circuit. This switch locks in when pressed, so you

must turn it a quarter turn to allow it to return to the normal position to allow the machine to

run.

Notice 1 : Press the emergency stop button immediately in any emergency situation. This

disables the 3-wire circuit, which stops all machine operation and causes the drain to open.

• When

ou reset this button, you have the option of cancelling or resuming the interrupted

PELLERIN MILNOR CORPORATION

Loading...

Loading...