Page 1

®

®

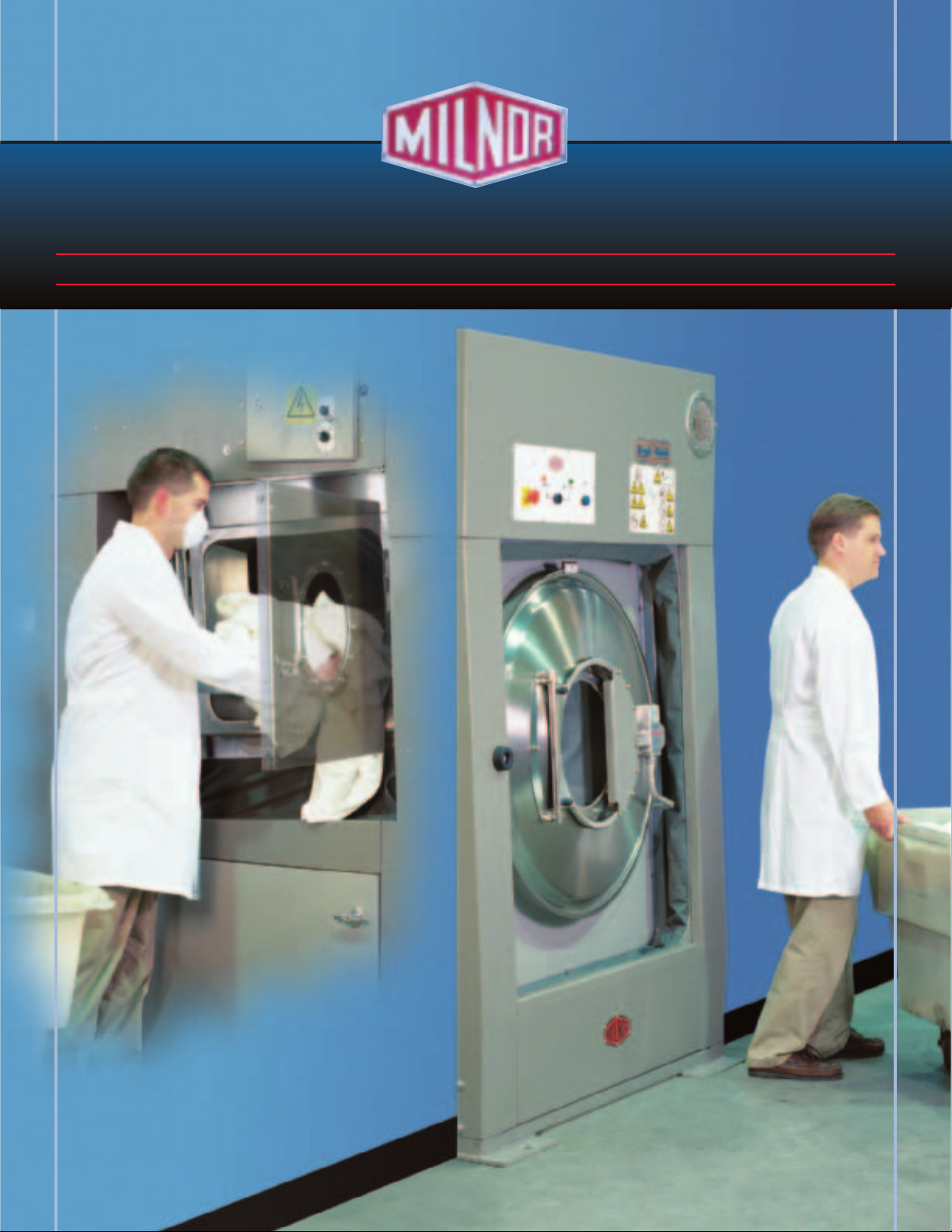

OPEN-POCKET STAPH-GUARD WASHER-EXTRACTORS

MORE PRODUCTIVE .HIGH SPEED EXTRACTION .2 SIZES

Model 36030 F8S

Page 2

A barrier laundry

should be designed

to include positive

pressure ventilation

in the clean section

and negative pressure

circulation in the

soiled section.

Automatically-controlled

safety interlocks help

ensure complete separation.

Loading and unloading

doors cannot be opened

simultaneously.Also, the

unloading door will not

open until all cycles are

complete. When the unloading door is open,

there are no openings

within the machine —

even the drain valve

closes. Also, discharge

water only drains to the

soiled side work area.

OPEN-POCKET STAPH-GUARD

they feature:

Here’s how:

Model 36030 F8S, 110 lbs. (50 kg)

Model 42032 F7R, 165 lbs. (75 kg)

Milnor’s patented Staph-Guard system helps prevent cross-contamination.

WASHER-EXTRACTORS

Milnor’s StaphAIRTROL

®

air circulation system

helps to protect health

care linen from reconta-

mination. It allows air to

be drawn into the washerextractor from the clean

side only and discharged

only into the soiled side.

All drive components of

Milnor open-pocket StaphGuard washer-extractors

are located on the soiled

side of the machines,

eliminating the spread of

operating residue to the

clean side.

A barrier completely separates

the soiled laundry handling

area from the clean laundry

section. The Staph-Guard

®

machine is installed within this

restrictive barrier.

®

Staph-Guard washer-extractors are sophisticated barrier units with

the advantages of open-pocket machines. Ideal

for healthcare work,

◆

Improved production and wash quality through

open-pocket design-- 110 lb. (50 kg) or 165 lb.

(75 kg) capacities.

◆

Patented, proven air circulation system to

guard against airborne pathogens.

◆

High-speed extraction -- up to 300 Gs -- boosts

moisture removal.

◆

Precise, easy-to-use controls that deliver

consistent quality. Wash, extraction and

distribution speeds -- along with many other

functions -- are completely programmable.

®

Page 3

Open-pocket Staph-Guard machines are

More

Productive.

Milnor cylinders are designed to be more productive. Large volume allows the room needed for

robust lift-and-drop action and for goods to open

up and absorb chemicals and water. Also, lift-anddrop action is greater than in barrier machines with

cylinder dividers. Increased cylinder perforated

area means: better wash quality (promotes

intense interchange of wash solutions with goods);

better rinsing (promotes interchange of water and

goods and lets water drain freely); and better

extraction (allows water to escape from goods

easily and quickly). High ribs provide excellent

lifting.

Suspended Unit Cushions Vibration.

The suspension system used in Staph-Guard

machines is based on advanced designs that work

in Milnor’s 700 lb. (318 kg) washer-extractors.

This dynamically-tuned suspension helps minimize

vibration. The result is smoother extraction and

less wear-and-tear on the machinery.

The open-pocket Staph-

Guard units use Milnor’s

proven Mark V controller,

which provides up to

100 formulas (98 program-

mable). Every function of

the machine is completely

programmable, giving the

operator total command

over wash functions. Time,

water levels, chemical

quantities, and cylinder

speeds can be easily

adjusted for specific goods

types or pre-programmed for routine loads. The

microprocessor provides help screens on each

individual function and step. Operators see real

words, not codes in the Mark V display. Electronic

self-diagnostics aid trouble-shooting, keeping the

machine in production. The Mark V control can

also output reports directly to a printer.

Operator lights on both the soiled and clean sides

clearly indicate which door is available to open.

Easy-to-understand, push-button controls allow

quick transfer of power from one side of the

machine to the other.

For total washroom control, the Mildata computer network system lets you link a computer with

the open-pocket Staph-Guard machine, other

Milnor equipment and other vendors’ equipment.

The result is central programming, system monitoring, and data collection (including printed reports).

Milnor open-pocket machines stay in production

longer because there are fewer doors to load and

unload the machine compared to a divided cylinder. Cylinders in end-loading and side-loading

barrier machines can sometimes leave processed

goods in difficult-to-reach areas. Processed goods

in a Milnor open-pocket cylinder are always an

easy reach from

the unloading door.

These open-pocket Staph-Guard machines

conserve valuable floor space, making washrooms more efficient. The minimal footprint

makes them ideal where space is limited. Also,

machines are available with the loading door on

either side of the machine shell. This feature allows

flexibility in washroom design and helps to create

specific areas in which work traffic is channeled.

Good ergonomics also assist in loading and

unloading. Doors are placed at convenient

heights to save time, reduce fatigue and minimize the chance of back strain. Extracted work

is unloaded from the end of the cylinder for easy

access. All points of operator interaction doors,

controls, supply injector, etc. are designed to

provide maximum ease and efficiency in use.

A sophisticated inner

door design simplifies

operation. Thumboperated levers open

the soiled-side inner

door, which retracts

within the cylinder

and slides away from the opening for ease of

loading. If the door isn’t fully closed, it will close

automatically when the cylinder begins to spin,

helping safeguard against operator error.

Sophisticated Controls are

Versatile,

Easy-to-use.

Door opens easily.

Mark V controller is versatile

and user-friendly.

Simple controls boost productivity.

Goods are loaded through a single inner door.

One door for unloading.

Plus...

The inner door on a Staph-Guard machine is

easily opened to the load position via gravity

assist. With the inner door in load position,

levers on the door are released and set into a

preparatory position. The outer

door is then

closed and the

cylinder is set to

Auto-spot. The turing cylinder automatically moves

the inner door to

an open position

ready for loading.

dvanced drive system provides effective, efficient

A

operation. An inverter drive generates all speeds

from only one single-speed motor. A single-speed

motor is simple and reliable. The energy-efficient

drive also reduces electric peak load demand.

Easy service thanks to readily-accessible, topmounted motor, controls and other components.

Self-diagnostics help shorten — or even avoid —

service calls.

Page 4

◆

Open-pocket design boosts

productivity.

◆

Choice of 2 sizes -- 110 lbs. (50 kg)

or 165 lbs. (75 kg).

◆

Ergonomically-friendly design.

◆

Proven StaphAIRTROL system helps

prevent infection.

◆

Advanced controls with completely

programmable functions.

◆

Self-diagnostics and “help”messages

keep machine in production.

◆

High extract is 300 Gs.

◆

Programmable wash and extract

speeds.

◆

One single-speed motor with inverter.

◆

Dynamically-tuned suspension

cushions vibration.

◆

Rugged construction.

◆

Superior cylinder design provides

better washing/extracting.

◆

Five-year limited warranty on frame,

cylinder and shell; two years on

main bearing assembly and microprocessor boards.

Features at a Glance

Specifications

Pellerin Milnor Corporation

P.O. Box 400, Kenner, LA 70063 USA

504/467-9591, Ext. 222

800/469-8780

Sales Fax: 504/468-3094

E-mail: mktg@milnor.com

http://www.milnor.com

Printed in U.S.A.

© Pellerin Milnor Corporation -- 1998

Class 5-7 Brochure B22SL98006/07202

A NTI- VIBRATION SUSPENSION: Shall

include four compression-type spring isolator

units, capable of withstanding compression to

solid height without exceeding fiber stress

limitations of spring metal. Providing a

reasonable safety factor exists, machines shall

be capable of installation on any floor strong

enough to safely support dead weight of fullyloaded machine, if floor is also rigid enough to

support such rotating machinery without undue

deflection while it is in operation.

M

ICROPROCESSOR: Shall have two pre-set

formulas for immediate use and capacity for up

to 98 field-programmable formulas. Display

shall prompt operator while program-ming

each step. Programming functions shall include

ability to duplicate complete formulas, and/or to

add, delete or modify individual steps without

need for reprogramming subsequent steps.

Forty-character, alphanumeric, vacuum fluorescent display shall indicate operation under way.

Shall allow for full manual operation including

manual output testing. Error displays shall signal

operator and indicate specific malfunction.

Machine shall be equipped with thermo-modulated

hot and cold water valves (optional) plus third

water valve (optional ) if specified. All hot, all

cold, both hot and cold full open, plus any

other desired water temperature between 50°F

(10°C) and 205°F (96°C) may be programmed in each bath.

A UTOMATIC SUPPLY: Fittings shall permit

connecting tubes from remote liquid supply

systems. Controls shall provide start signals for

injection of five liquid chemicals at required

time. (Optional: Shall have machine-mounted,

five-compartment flushing supply injection for

dry or liquid supplies.)

S TAINLESS STEEL: If welded, shall be Type

304 or 304 L corrosion-resisting steel. To

prevent carbide precipitation damage, stainless

shell interior shall not be welded directly to

carbon steel.

C YLINDER: Shall be open-pocket design,

with no interior divider.

S

HELL: Shell side shall have two circumfer-

ential ribs covered by a steel ring for extra strength.

M AIN BEARINGS: Shall be heavy duty

tapered roller bearings, with triple seal between

front bearing and wash water to retain lubrication and shield bearing from washing

solution. The 36030 and 42032 shall be

grease-lubricated with V-ring excluder seal.

M OTOR DRIVE: Shall have one singlespeed motor with inverter, producing programmable wash and extract speeds plus load

distribution speed. All drive components shall

be on soil side.

D RAIN VALVE: Shall be air-operated

gravity valve.

W ATER INLET VALVES: Shall be commercial type, electrically-operated (optional:

air-operated).

I SOLATION OF CLEAN AND SOIL AREAS:

Machine shall be designed to permit installation

in a barrier, completely separating clean and

soil areas. Shall have separate doors for loading (on shell-side in soil area) and unloading

(on shell-end in clean area).

I NTERLOCKING OF DOORS: Shell doors

shall be interlocked, mechanically and electrically so that (a) both shell doors may not be

opened simultaneously; (b) clean side door

may not be opened until wash/extract cycle

has been completed; (c) soil side door may

not be opened unless clean side operator has

unloaded and/or released machine, clean side

door may not be opened again until a new

wash/extract cycle has been completed; (d)

once clean side operator has released

machine, clean side door may not be opened

again until a new wash/extract cycle has been

completed; (e) whenever clean side door is

open, there shall be no openings (including

drain valve) between inside of the machine

and soil side or loading area that would

permit air to pass from soil side to clean side.

A IR CIRCULATION CONTROL DEVICE:

Shall be integrally mounted and shall operate

continuously during all phases of washing

and extracting, loading and unloading, and

when machine is at rest or out of service.

Shall allow air to enter machine from clean

side only, and exit machine only into soil side.

®

36030 F8S* 42032 F7S*

36030 F8R** 42032 F7R**

Max. capacity

lbs. (kg)+ 110 (50) 165 (75)

Cylinder Diameter

ins. (mm) 36 (914) 42 (1067)

Cylinder Depth

ins. (mm) 30 (762) 32 (813)

Gross cylinder

volume cu. ft. (L) 17.7 (500) 25.7 (727)

Motor -- HP (KW) 7.5 (5.6) 15(11.2)

Wash -- RPM++ 10-43 +++ 10-40+++

Distribution -- RPM++ 65 60

Extract -- RPM++ 765 710

High extract G

forces++ 300 300

Overall width

ins. (mm)++++ 63.25 (1607) 70.75 (1798)

Overall depth ++++

ins. (mm) 72.5 (1841) 78.87 (2003)

Overall height ++++

ins. (mm) 86.06 (2186) 86.5 (2197)

Specifications and appearance subject to change without notice.

* Left-side mounted loading door.

**Right-side mounted

loading door. + Depending on density and soil

content of goods. ++Approximate. +++Programmable range.

++++ Standard accessories.

Loading...

Loading...