Milnor 36026V5J, 36026V7J, 42026V6J, 36026V7J/V7W, 42026V6J/V6W Service Manual

...

Published Manual Number/ECN: MAP36VXXCE/2006145A

• Publishing System: TPAS

• Access date: 4/6/2006

• Document ECN's: Latest Available

Service—

36026V5J, 36026V7J/V7W

42026V6J/V6W

Washer-Extractors

PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063-0400, U.S.A.

Please Read

About the Manual Identifying Information on the Cover

The front cover displays pertinent identifying information for this manual. Most important, are

the published manual number (part number) /ECN (date code). Generally, when a replacement

manual is furnished, it will have the same published manual number, but the latest available ECN.

This provides the user with the latest information applicable to his machine. Similarly all

documents comprising the manual will be the latest available as of the date the manual was

printed, even though older ECN dates for those documents may be listed in the table of

contents.

When communicating with the Milnor factory regarding this manual, please also provide the

other identifying information shown on the cover, including the publishing system, access date,

and whether the document ECN’s are the latest available or exact.

References to Yellow Troubleshooting Pages

This manual may contain references to “yellow pages.” Although the pages containing

troubleshooting procedures are no longer printed on yellow paper, troubleshooting instructions, if

any, will be contained in the easily located “Troubleshooting” chapter or section. See the table of

contents.

Trademarks of Pellerin Milnor Corporation

The following, some of which may be used in this manual, are trademarks of Pellerin Milnor

Corporation:

®

Ampsaver

Autolint

®

Auto-Purge

Autovac E-P OneTouch® Mildata

®

CBW

Dye-Extractor® Gear Guardian

Dyextractor® Hands-Off

®

E-P Express® Hydro-Cushion

E-P Plus

®

®

®

®

®

®

Milnet

Milnor

®

Staph-Guard

System 4

Miltrac System 7

Miltron Totaltrol

®

®

®

®

Comments and Suggestions

Help us to improve this manual by sending your comments to:

Pellerin Milnor Corporation

Attn: Technical Publications

P. O. Box 400

Kenner, LA 70063-0400

Fax: (504) 469-1849

Table of Contents

for MAP36VXXCE/2006145A

36026V5J, 36026V7J/V7W 42026V6J/V6W Washer-Extractors

Page Description Document/ECN

1 Warranty BMP720097/92732A

3 How to Order Parts BMP720097R/72332A

4 Safety—Rigid Washer Extractors BIUUUS27/20051111

9 Guards & Covers 36026 V7J,V7W 42026V6J,V6W BMP010013/2002022V

12 Guards & Covers 36026V5J BMP010034/2002103V

14 About the Forces Transmitted by Milnor Washer-Extractors BIWUUI02/20001108

16 Glossary of Tag Illustrations - F-Style, Q-Style,

36" & 42" V-Style and X-Style Washer-Extractors MSIUUQTGAE/2003045V

21 Avoiding Damage from Allied Remote Chemical

Delivery Systems BIWUUI03/20030306

26 Safety Placard Use and Placement 36026V5J,

36021CPE, NSP & V5J BMP020109/2002145V

28 Safety Placard Use and Placement ISO 36026V5J,

36021CPE, NSP & V5J BMP020110/2002145V

30 Safety Placard Use and Placement 36026V7J/W

& 42026V6J/W BMP020111/2002145V

32 Safety Placard Use and Placement ISO 36026V7J/W

& 42026V6J/W BMP020112/2002145V

35 Section 1: Service and Maintenance

36 Preventive Maintenance BIRQUM01/20050302

42 Aligning 36 and 42Vxx Motor Mount Plate with

the Drive Pulley BIRQVM01/20010822

44 Fastener Torque Requirements MSSM0101CE/9906AV

63 Baldor Motor Maintenance MSSM0274AE/9731AV

67 Section 2: Drive Assemblies

68 Drive Chart 36026V5J BMP000009/2002032V

69 Drive Chart 36026V7J BMP000010/2000455V

70 Drive Chart 42026V6J BMP000011/2000455V

71 Motor Mount 30015, 30022,36026, & 42026Vxx,Txx BMP000008/2001036V

73 Section 3: Bearing Assemblies

74 Main Bearing, Shell, and Cylinder Installation BMP930004/2003483V

76 Main Bearing Assembly BMP930001/2003276V

78 Main Bearing, Shell, & Cylinder Installation 36Q6x,

V7J, 4226QXX,V6J BMP900047/2000455V

80 Main Bearing Assembly 36Q6X,V7J 42QXX,V6J BMP860021/2000455V

83 Section 4: Shell and Door Assemblies

84 Shellfront Assembly, Conduit, and Interlock BMP930002/2003276V

86 Door Assembly BMP930003/2003276V

88 Interlock Assembly BMP750046/2001036V

Table of Contents, cont.

Page Description Document/ECN

91 Section 5: Control and Sensing

92 Vibration Safety Switch Adjustments MSSMA408BE/9273BV

94 Vibration Safety Switch BMP910038/2000302V

95 Level Sensing BMP050027/2005171V

97 Section 6: Chemical and Supply Devices

98 Soap Chute Assembly BMP870042/2003276V

99 Peristaltic Supply Assembly BMP000043/2001242V

101 5 Compartment Supply BMP860026/2000333V

103 Flushing Manifold - 5 Compartment Supply BMP900019/2000455V

105 Section 7: Water Piping Assemblies

106 Schematic Symbols Key BMP920008/2000302V

107 Water Schematic BMP000045/2005234V

108 Water Inlet Assembly BMP000044/2005234V

109 Steam Inlet Assembly BMP010027/2002064V

111 Drain Valve Installation BMP010014/2002034V

113 3" Electric Drain Valve BMP920017/2002044V

3(//(5,10,/125&25325$7,21

/,0,7('67$1'$5':$55$17<

We warrant to the original purchaser that MILNOR machines including electronic

hardware/software (hereafter referred to as “equipment”), will be free from defects in material

and workmanship for a period of one year from the date of shipment from our factory with no

operating hour limitation. This warranty is contingent upon the equipment being installed,

operated and serviced as specified in the operating manual supplied with the equipment, and

operated under normal conditions by competent operators.

Providing we receive written notification of a warranted defect within 30 days of its discovery,

we will – at our option – repair or replace the defective part or parts, FOB our factory. We

retain the right to require inspection of the parts claimed defective in our factory prior to

repairing or replacing same. We will not be responsible, or in any way liable, for unauthorized

repairs or service to our equipment, and this warranty shall be void if the equipment is repaired

or altered in any way without MILNOR’s written consent.

Parts which require routine replacement due to normal wear – such as gaskets, contact points,

brake and clutch linings and similar parts – are not covered by this warranty, nor are parts

damaged by exposure to weather or to chemicals.

We reserve the right to make changes in the design and/or construction of our equipment

(including purchased components) without obligation to change any equipment previously

supplied.

ANY SALE OR FURNISHING OF ANY EQUIPMENT BY MILNOR IS MADE ONLY UPON

THE EXPRESS UNDERSTANDING THAT MILNOR MAKES NO EXPRESSED OR IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR USE OR

PURPOSE. MILNOR WILL NOT BE RESPONSIBLE FOR ANY COSTS OR DAMAGES

ACTUALLY INCURRED OR REQUIRED AS A RESULT OF: THE FAILURE OF ANY OTHER

PERSON OR ENTITY TO PERFORM ITS RESPONSIBILITIES, FIRE OR OTHER HAZARD,

ACCIDENT, IMPROPER STORAGE, MISUSE, NEGLECT, POWER OR ENVIRONMENTAL

CONTROL MALFUNCTIONS, DAMAGE FROM LIQUIDS, OR ANY OTHER CAUSE BEYOND

THE NORMAL RANGE OF USE. REGARDLESS OF HOW CAUSED, IN NO EVENT SHALL

MILNOR BE LIABLE FOR SPECIAL, INDIRECT, PUNITIVE, LIQUIDATED, OR

CONSEQUENTIAL COSTS OR DAMAGES, OR ANY COSTS OR DAMAGES WHATSOEVER

WHICH EXCEED THE PRICE PAID TO MILNOR FOR THE EQUIPMENT IT SELLS OR

FURNISHES.

WE NEITHER ASSUME, NOR AUTHORIZE ANY EMPLOYEE OR OTHER PERSON TO

ASSUME FOR US, ANY OTHER RESPONSIBILITY AND/OR LIABILITY IN CONNECTION

WITH THE SALE OR FURNISHING OF OUR EQUIPMENT TO ANY BUYER.

BMP720097

92732A

How to order repair parts

Repair parts may be ordered either from the authorized dealer who sold you this

machine, or directly from the MILNOR factory. In most cases, your dealer will

have these parts in stock.

When ordering parts, please be sure to give us the following in formation:

1. Model and serial number of the machine for which the parts are required

2. Part number

3. Name of the part

4. Quantity needed

5. Method of shipment des ired

6. In correspondence regarding motors or electrical controls, please include all

nameplate data, including wiring diagram number and the make or

manufacturer of the motor or controls.

All parts will be shipped C.O.D. transportation charges collect on ly.

Please read this manual

It is strongly recommended that you read the installation and operating manual

before attempting to install or operate your machine. We suggest that this manual

be kept in your business office so that it will not become lo st.

PELLERIN MILNOR CORPORATION

32%2;.(11(5/$ 86$

FAX: Administration 504/468-9307, Engineering 504/469-1849, Service 504/469-9777

BMP720097R

72332A

Safety—Rigid Washer Extractors

BIUUUS27 (Published) Book specs- Dates: 20051111 / 20051111 / 20060322 Lang: ENG01 Applic: RUU

Safety—Rigid Washer Extractors

1. General Safety Requirements—Vital Information for

Management Personnel

Incorrect installation, neglected preventive maintenance, abuse, and/or improper repairs, or

changes to the machine can cause unsafe operation and personal injuries, such as multiple

fractures, amputations, or death. The owner or his selected representative (owner/user) is

responsible for understanding and ensuring the proper operation and maintenance of the machine.

The owner/user must familiarize himself with the contents of all machine instruction manuals.

The owner/user should direct any questions about these instructions to a Milnor® dealer or the

Milnor® Service department.

Most regulatory authorities (including OSHA in the USA and CE in Europe) hold the owner/user

ultimately responsible for maintaining a safe working environment. Therefore, the owner/user

must do or ensure the following:

• recognize all foreseeable safety hazards within his facility and take actions to protect his

personnel, equipment, and facility;

• work equipment is suitable, properly adapted, can be used without risks to health or safety,

and is adequately maintained;

• where specific hazards are likely to be involved, access to the equipment is restricted to those

employees given the task of using it;

• only specifically designated workers carry out repairs, modifications, maintenance, or

servicing;

• information, instruction, and training is provided;

• workers and/or their representatives are consulted.

[Document BIUUUS04]

Work equipment must comply with the requirements listed below. The owner/user must verify

that installation and maintenance of equipment is performed in such a way as to support these

requirements:

• control devices must be visible, identifiable, and marked; be located outside dangerous zones;

and not give rise to a hazard due to unintentional operation;

• control systems must be safe and breakdown/damage must not result in danger;

• work equipment is to be stabilized;

• protection against rupture or disintegration of work equipment;

• guarding, to prevent access to danger zones or to stop movements of dangerous parts before

the danger zones are reached. Guards to be robust; not give rise to any additional hazards; not

be easily removed or rendered inoperative; situated at a sufficient distance from the danger

zone; not restrict view of operating cycle; allow fitting, replacing, or maintenance by

restricting access to relevant area and without removal of guard/protection device;

• suitable lighting for working and maintenance areas;

• maintenance to be possible when work equipment is shut down. If not possible, then

protection measures to be carried out outside danger zones;

• work equipment must be appropriate for preventing the risk of fire or overheating; discharges

of gas, dust, liquid, vapor, other substances; explosion of the equipment or substances in it.

PELLERIN MILNOR CORPORATION

Safety—Rigid Washer Extractors

y

y

r

r

1.1. Laundr

Facilit

—Provide a supporting floor that is strong and rigid enough to support–with

a reasonable safety factor and without undue or objectionable deflection–the weight of the fully

loaded machine and the forces transmitted by it during operation. Provide sufficient clearance fo

machine movement. Provide any safety guards, fences, restraints, devices, and verbal and/or

posted restrictions necessary to prevent personnel, machines, or other moving machinery from

accessing the machine or its path. Provide adequate ventilation to carry away heat and vapors.

Ensure service connections to installed machines meet local and national safety standards,

especially regarding the electrical disconnect (see the National Electric Code). Prominently post

safety information, including signs showing the source of electrical disconnect.

1.2. Personnel—Inform personnel about hazard avoidance and the importance of care and

common sense. Provide personnel with the safety and operating instructions that apply to them.

Verify that personnel use proper safety and operating procedures. Verify that personnel

understand and abide by the warnings on the machine and precautions in the instruction manuals.

1.3. Safety Devices—Ensure that no one eliminates or disables any safety device on the machine

or in the facility. Do not allow machine to be used with any missing guard, cover, panel or door.

Service any failing or malfunctioning device before operating the machine.

1.4. Hazard Information—Important information on hazards is provided on the machine safety

placards, in the Safety Guide, and throughout the other machine manuals. Placards must be kept

clean so that the information is not obscured. They must be replaced immediately if lost or

damaged. The Safety Guide and other machine manuals must be available at all times to

the appropriate personnel. See the machine service manual for safety placard part numbers.

Contact the Milnor Parts department for replacement placards or manuals.

1.5. Maintenance—Ensure the machine is inspected and serviced in accordance with the norms of

good practice and with the preventive maintenance schedule. Replace belts, pulleys, brake

shoes/disks, clutch plates/tires, rollers, seals, alignment guides, etc. before they are severely

worn. Immediately investigate any evidence of impending failure and make needed repairs (e.g.,

cylinder, shell, or frame cracks; drive components such as motors, gear boxes, bearings, etc.,

whining, grinding, smoking, or becoming abnormally hot; bending or cracking of cylinder, shell,

frame, etc.; leaking seals, hoses, valves, etc.) Do not permit service or maintenance by

unqualified personnel.

2. Safety Alert Messages—Internal Electrical and Mechanical

Hazards

[Document BIUUUS11]

The following are instructions about hazards inside the machine and in electrical enclosures.

WARNING 1 : Electrocution and Electrical Burn Hazards—Contact with electric powe

can kill or seriously injure you. Electric power is present inside the cabinetry unless the main

machine power disconnect is off.

• Do not unlock or open electric box doors.

• Do not remove guards, covers, or panels.

• Do not reach into the machine housing or frame.

• Keep yourself and others off of machine.

• Know the location of the main machine disconnect and use it in an emergency to remove

all electric power from the machine.

PELLERIN MILNOR CORPORATION

Safety—Rigid Washer Extractors

WARNING 2 : Entangle and Crush Hazards—Contact with moving components normally

isolated by guards, covers, and panels, can entangle and crush your limbs. These components

move automatically.

• Do not remove guards, covers, or panels.

• Do not reach into the machine housing or frame.

• Keep yourself and others off of machine.

• Know the location of all emergency stop switches, pull cords, and/or kick plates and use

them in an emergency to stop machine motion.

3. Safety Alert Messages—Cylinder and Processing Hazards

[Document BIUUUS13]

The following are instructions about hazards related to the cylinder and laundering process.

DANGER 3 : Entangle and Sever Hazards—Contact with goods being processed can

cause the goods to wrap around your body or limbs and dismember you. The goods are normally

isolated by the locked cylinder door.

• Do not attempt to open the door or reach into the cylinder until the cylinder is stopped.

• Do not touch goods inside or hanging partially outside the turning cylinder.

• Do not operate the machine with a malfunctioning door interlock.

• Know the location of all emergency stop switches, pull cords, and/or kick plates and use

them in an emergency to stop machine motion.

• Know the location of the main machine disconnect and use it in an emergency to remove

all electric power from the machine.

WARNING 4 : Crush Hazards—Contact with the turning cylinder can crush your limbs. The

cylinder will repel any object you try to stop it with, possibly causing the object to strike or stab

you. The turning cylinder is normally isolated by the locked cylinder door.

• Do not attempt to open the door or reach into the cylinder until the cylinder is stopped.

• Do not place any object in the turning cylinder.

• Do not operate the machine with a malfunctioning door interlock.

WARNING 5 : Confined Space Hazards—Confinement in the cylinder can kill or injure

you. Hazards include but are not limited to panic, burns, poisoning, suffocation, heat prostration,

biological contamination, electrocution, and crushing.

• Do not attempt unauthorized servicing, repairs, or modification.

WARNING 6 : Explosion and Fire Hazards—Flammable substances can explode or ignite

in the cylinder, drain trough, or sewer. The machine is designed for washing with water, not any

other solvent. Processing can cause solvent-containing goods to give off flammable vapors.

• Do not use flammable solvents in processing.

• Do not process goods containing flammable substances. Consult with your local fire

department/public safety office and all insurance providers.

PELLERIN MILNOR CORPORATION

Safety—Rigid Washer Extractors

4. Safety Alert Messages—Unsafe Conditions [Document BIUUUS14]

Damage and Malfunction Hazards

4.1.

4.1.1. Hazards Resulting from Inoperative Safety Devices

DANGER 7 : Entangle and Sever Hazards—Cylinder door interlock—Operating the

machine with a malfunctioning door interlock can permit opening the door when the cylinder is

turning and/or starting the cycle with the door open, exposing the turning cylinder.

• Do not operate the machine with any evidence of damage or malfunction.

WARNING 8 : Multiple Hazards—Operating the machine with an inoperative safety device

can kill or injure personnel, damage or destroy the machine, damage property, and/or void the

warranty.

• Do not tamper with or disable any safety device or operate the machine with a

malfunctioning safety device. Request authorized service.

WARNING 9 : Electrocution and Electrical Burn Hazards—Electric box doors—

Operating the machine with any electric box door unlocked can expose high voltage conductors

inside the box.

• Do not unlock or open electric box doors.

WARNING 10 : Entangle and Crush Hazards—Guards, covers, and panels—Operating

the machine with any guard, cover, or panel removed exposes moving components.

• Do not remove guards, covers, or panels.

4.1.2. Hazards Resulting from Damaged Mechanical Devices

WARNING 11 : Multiple Hazards—Operating a damaged machine can kill or injure

personnel, further damage or destroy the machine, damage property, and/or void the warranty.

• Do not operate a damaged or malfunctioning machine. Request authorized service.

WARNING 12 : Explosion Hazards—Cylinder—A damaged cylinder can rip apart during

extraction, puncturing the shell and discharging metal fragments at high speed.

• Do not operate the machine with any evidence of damage or malfunction.

WARNING 13 : Explosion Hazards—Clutch and speed switch (multiple motor

machines)—A damaged clutch or speed switch can permit the low speed motor to engage during

extract. This will over-speed the motor and pulleys and can cause them to rip apart, discharging

metal fragments at high speed.

• Stop the machine immediately if any of these conditions occur: • abnormal whining sound

during extract • skidding sound as extract ends • clutches remain engaged or re-engage

during extract

PELLERIN MILNOR CORPORATION

4.2. Careless Use Hazards

(

Safety—Rigid Washer Extractors

4.2.1. Careless Operation Hazards—Vital Information for Operator Personnel

see also

operator hazards throughout manual)

WARNING 14 : Multiple Hazards—Careless operator actions can kill or injure personnel,

damage or destroy the machine, damage property, and/or void the warranty.

• Do not tamper with or disable any safety device or operate the machine with a

malfunctioning safety device. Request authorized service.

• Do not operate a damaged or malfunctioning machine. Request authorized service.

• Do not attempt unauthorized servicing, repairs, or modification.

• Do not use the machine in any manner contrary to the factory instructions.

• Use the machine only for its customary and intended purpose.

• Understand the consequences of operating manually.

4.2.2. Careless Servicing Hazards—Vital Information for Service Personnel (see also

service hazards throughout manuals)

WARNING 15 : Electrocution and Electrical Burn Hazards—Contact with electric

power can kill or seriously injure you. Electric power is present inside the cabinetry unless the

main machine power disconnect is off.

• Do not service the machine unless qualified and authorized. You must clearly understand

the hazards and how to avoid them.

• Abide by the current OSHA lockout/tagout standard when lockout/tagout is called for in

the service instructions. Outside the USA, abide by the OSHA standard in the absence of

any other overriding standard.

WARNING 16 : Entangle and Crush Hazards—Contact with moving components

normally isolated by guards, covers, and panels, can entangle and crush your limbs. These

components move automatically.

• Do not service the machine unless qualified and authorized. You must clearly understand

the hazards and how to avoid them.

• Abide by the current OSHA lockout/tagout standard when lockout/tagout is called for in

the service instructions. Outside the USA, abide by the OSHA standard in the absence of

any other overriding standard.

WARNING 17 : Confined Space Hazards—Confinement in the cylinder can kill or injure

you. Hazards include but are not limited to panic, burns, poisoning, suffocation, heat prostration,

biological contamination, electrocution, and crushing.

• Do not enter the cylinder until it has been thoroughly purged, flushed, drained, cooled,

and immobilized.

— End of BIUUUS27 —

PELLERIN MILNOR CORPORATION

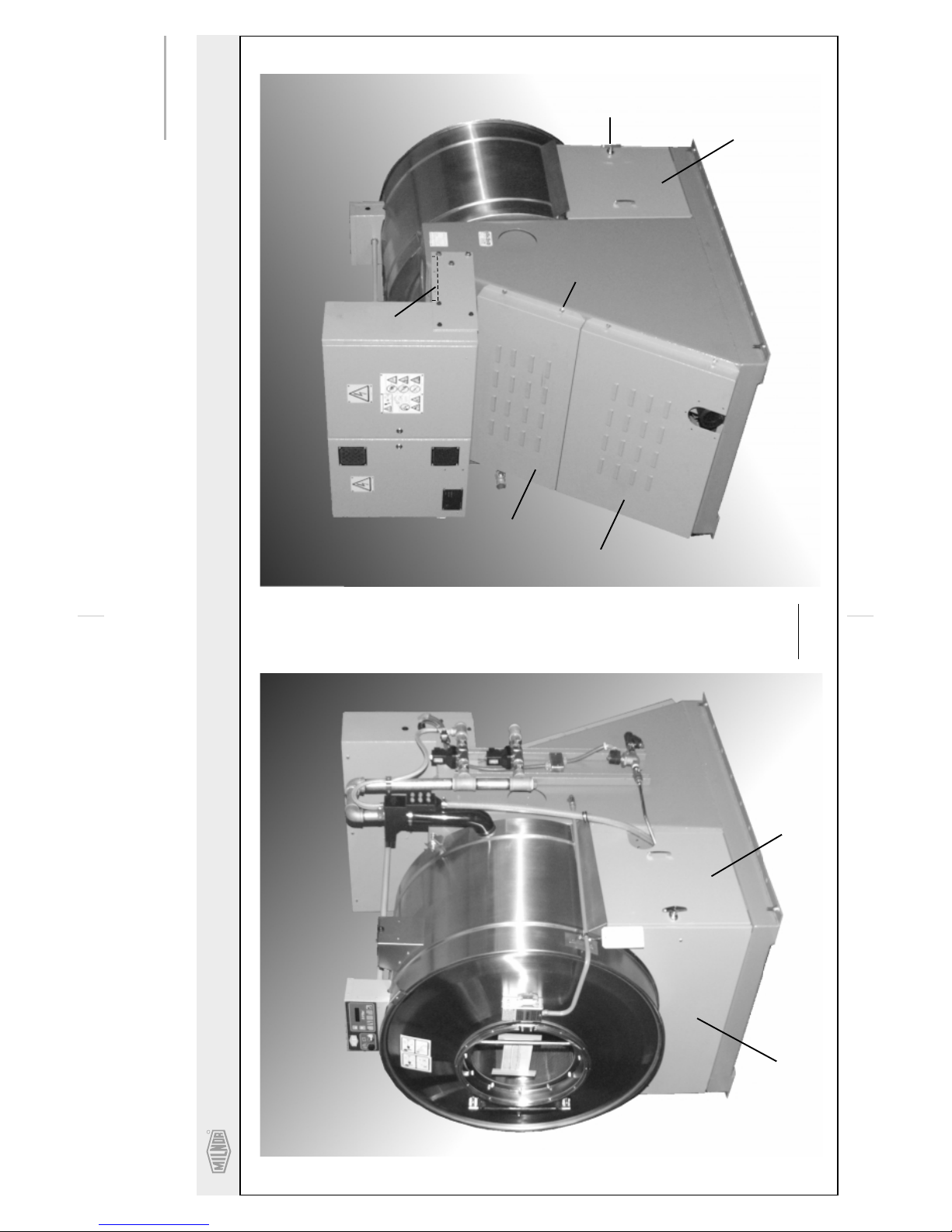

BMP010013/2002022V

(Sheet 1 of 3)

Guards and Covers

36026V7J,V7W 42026V6J,V6W

BMPxxxxxx/xxxxxV (1 of 2)

R

Pellerin Milnor CorporationPellerin Milnor Corporation

P. O. Box 400, Kenner, LA 70063-0400

Litho in U.S.A.

1

2

3

4

5

6

7

8

(8 PLACES)

42026V6J

SHOWN

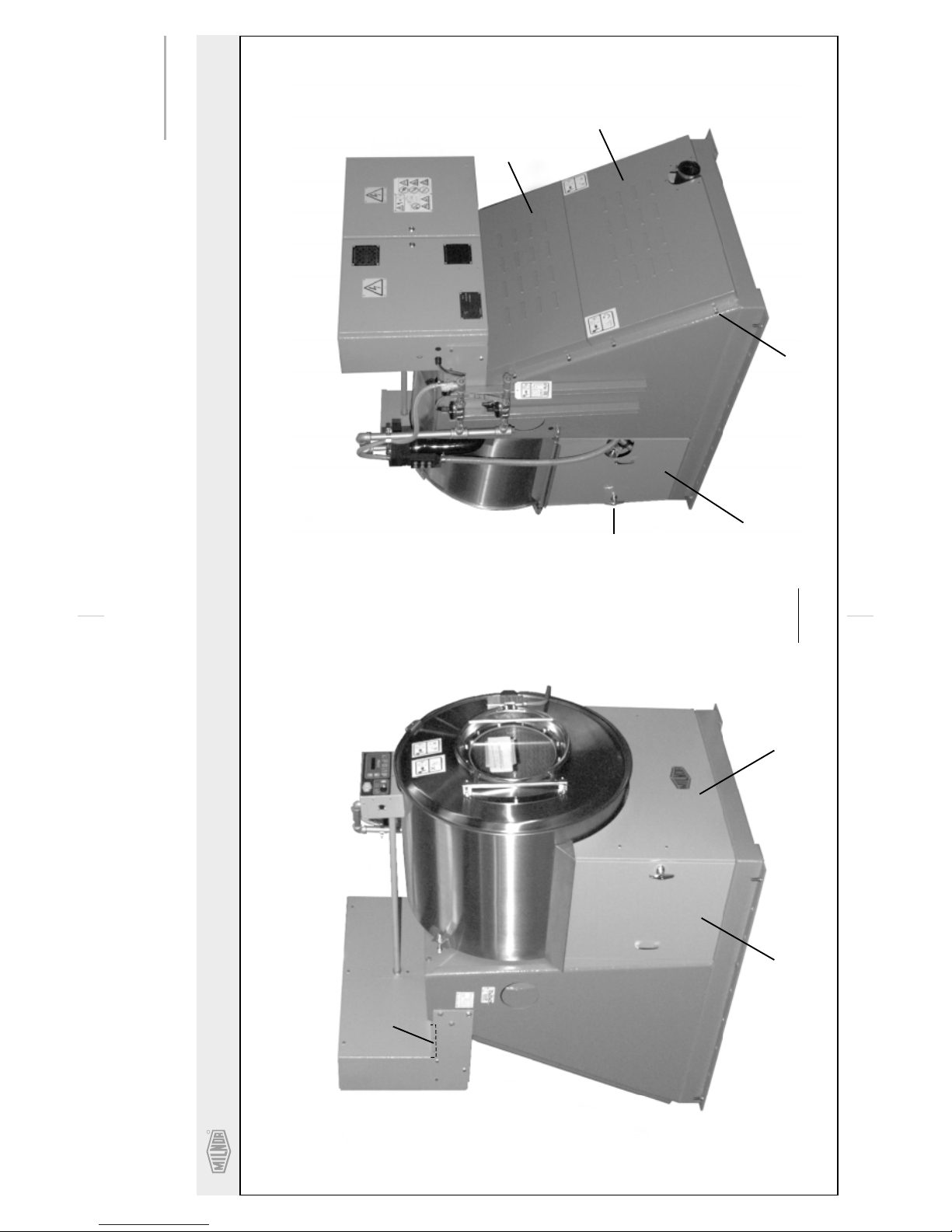

BMP010013/2002022V

(Sheet 2 of 3)

Guards and Covers

36026V7J,V7W 42026V6J, V6W

BMPxxxxxx/xxxxxV (1 of 2)

R

Pellerin Milnor CorporationPellerin Milnor Corporation

P. O. Box 400, Kenner, LA 70063-0400

Litho in U.S.A.

1

3

2

4

5

6

7

8

(8 PLACES)

36026V7J

SHOWN

R

Pellerin Milnor CorporationPellerin Milnor Corporation

P. O. Box 400, Kenner, LA 70063-0400

BMP010013/2002022V

(Sheet 3 of 3)

Litho in U.S.A.

Find the correct assembly first, then find the needed components. The item letters (A, B, C, etc.) assigned to

Parts List—Guards & Covers

assemblies are referred to in the "Used In" column to identify which components belong to an assembly. The item

numbers (1, 2, 3, etc.) assigned to components relate the parts list to the illustration.

Used In

.

---------------------------------------------------------------------ASSEMBLIES------------------------------------------------------------------

-------------------------------------------------------------------COMPONENTS------------------------------------------------------------------

all 1 02 11908E +COVER=FRONT COSMETIC 42QU

all 1 02 14821A +FRONT COSMETIC 36Q

all 2 02 11908H +COSM=RT/DOOR

all 2 02 14821B +COSMETIC RIGHT DOOR 36Q

all 3 02 11908I +COSM=LFT/DOOR

all 3 02 14821C +COSMETIC LEFT SIDE 36Q

all 4 27A012LTKS LOCK"T"HANDL,S.LTCH&MTGHDW

all 5 03 11071 REAR COVER UP 36V7/42V6

all 6 03 11070 REAR COVER LOW 36V7/42V6

all 7 03 11069 COVUPREAR CNTLBOX 36V7/42V6

all 8 15P200 TRDCUT-F HXWASHD 3/8-16X3/4NIK

Item

A GGS119001S COVER ASSY 42R6P&G

B AGS119001S ASSY SIDECOVER +HANDLES

C GGS119003V REAR COVER ASSY 4226V

D GGS14801S GUARDS+COVER ASSY 36R7P&G

E AGS14801S GUARDS&COVERS ASSY 36Q

Part Number

Description

Comments

R

Pellerin Milnor CorporationPellerin Milnor Corporation

P. O. Box 400, Kenner, LA 70063-0400

Litho in U.S.A.

BMP010034/2002103V

(Sheet 1 of 2)

Guards and Covers

36026V5J

36026V5J

1

2

3

2

3

4

(8 PLACES)

R

Pellerin Milnor CorporationPellerin Milnor Corporation

P. O. Box 400, Kenner, LA 70063-0400

BMP010034/2002103V

(Sheet 2 of 2)

Litho in U.S.A.

Find the correct assembly first, then find the needed components. The item letters (A, B, C, etc.) assigned to

Parts List—Guards and Covers

assemblies are referred to in the "Used In" column to identify which components belong to an assembly. The item

numbers (1, 2, 3, etc.) assigned to components relate the parts list to the illustration.

Used In

.

---------------------------------------------------------------------ASSEMBLIES------------------------------------------------------------------

-------------------------------------------------------------------COMPONENTS------------------------------------------------------------------

all 1 AGS14808 FRONT COVER ASSY 36V5

all 2 03 11064 BELTGD-UPPER REAR 36V5

all 3 03 11065 BELTGD-LOWER REAR 36V5

all 4 15P200 TRDCUT-F HXWASHD 3/8-16X3/4NIK

Item

A GGS14808 GUARD + COVER INSTALL 36V5 Mk2

Part Number

Description

Comments

About the Forces Transmitted by Milnor® Washer-extractors

2

8

8

8

U

About the Forces Transmitted by Milnor

Washer-extractors

During washing and extracting, all washer-extractors transmit both static and dynamic

(cyclic) forces to the floor, foundation, or any other supporting structure. During washing, the

impact of the goods as they drop imparts forces which are quite difficult to quantify. Size for size,

both rigid and flexibly-mounted machines transmit approximately the same forces during

washing. During extracting, rigid machines transmit forces up to 30 times greater than equivalent

flexibly-mounted models. The actual magnitude of these forces vary according to several factors:

• machine size,

• final extraction speed,

• amount, condition, and type of goods being processed,

• the liquor level and chemical conditions in the bath preceding extraction, and

• other miscellaneous factors.

Estimates of the maximum force normally encountered are available for each Milnor

and size upon request. Floor or foundation sizes shown on any Milnor

on-grade situations based only on previous experience without implying any warranty, obligation,

or responsibility on our part.

1.

Rigid Machines

Size for size, rigid washer-extractors naturally require a stronger, more rigid floor,

foundation, or other supporting structure than flexibly-mounted models. If the supporting soil

under the slab is itself strong and rigid enough and has not subsided to leave the floor slab

suspended without support, on grade installations can often be made directly to an existing floor

slab if it has enough strength and rigidity to safely withstand our published forces without

transmitting undue vibration. If the subsoil has subsided, or if the floor slab itself has insufficient

strength and rigidity, a deeper foundation, poured as to become monolithic with the floor slab,

may be required. Support pilings may even be required if the subsoil itself is “springy” (i.e., if its

resonant frequency is near the operating speed of the machine). Above-grade installations of rigid

machines also require a sufficiently strong and rigid floor or other supporting structure as

described below.

®

Document..................... BIWUUI0

Specified Date.................2000110

As-of Date.......................2000110

Access Date..................... 2000110

Applicability...........................WU

®

®

document are only for

model

2.

Flexibly-mounted Machines

Size for size, flexibly-mounted machines generally do not require as strong a floor,

foundation, or other supporting structure as do rigid machines. However, a floor or other

supporting structure having sufficient strength and rigidity, as described in section 3, is

nonetheless vitally important for these models as well.

3.

How Strong and Rigid?

Many building codes in the U.S.A. specify that laundry floors must have a minimum live

load capacity of 150 pounds per square foot (732 kilograms per square meter). However, even

compliance with this or any other standard does not necessarily guarantee sufficient rigidity. In

any event, it is the sole responsibility of the owner/user to assure that the floor and/or any other

supporting structure exceeds not only all applicable building codes, but also that the floor and/or

any other supporting structure for each washer-extractor or group of washer-extractors actually

has sufficient strength and rigidity, plus a reasonable factor of safety for both, to support the

weight of all the fully loaded machine(s) including the weight of the water and goods, and

including the published 360º rotating sinusoidal RMS forces that are transmitted by the

machine(s). Moreover, the floor, foundation, or other supporting structure must have sufficient

rigidity (i.e., a natural or resonant frequency many times greater than the machine speed with a

reasonable factor of safety); oth erwise, the m enti oned 360º ro ta ting sinuso ida l RMS forces can be

multiplied and magnified many times. It is especially important to consider all potential vibration

problems that might occur due to all possible combinations of forcing frequencies (rotating

speeds) of the machine(s) compared to the natural frequencies of the floor and/or any other

supporting structure(s). A qualified soil and/or structural engineer must be engaged for this

purpose.

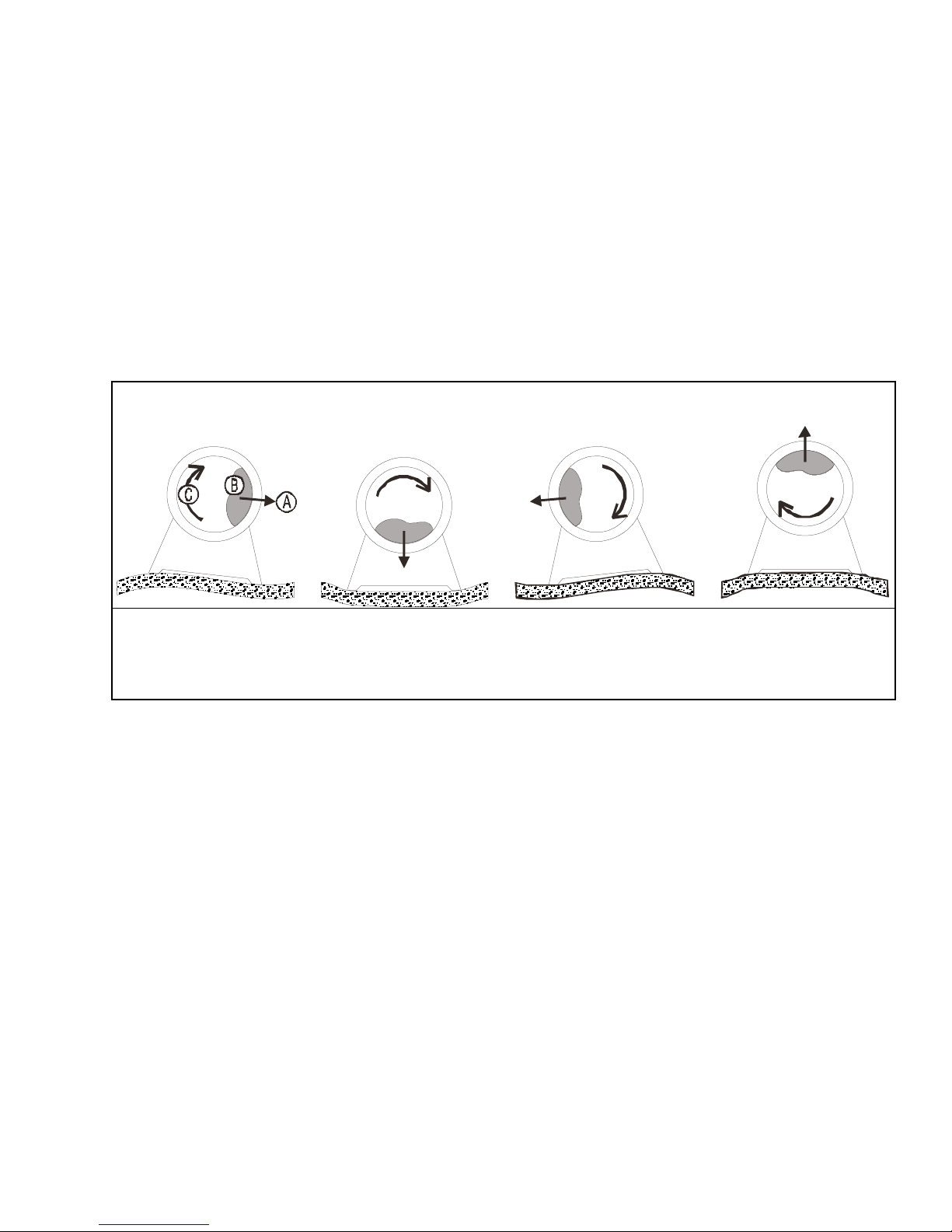

Figure 1: How Rotating Forces Act on the Foundation

Typical Machine

A.

Direction of force

B.

Load

C.

Rotation (Frequency = RPM / 60)

Figure 1 above is intended to depict both on-grade and above-grade installations and is

equally applicable to flexibly-mounted washer-extractors, as well as to rigid models installed

either directly on a floor slab or on a foundation poured integrally with the slab. Current machine

data is available from Milnor

have changed since last printed. It is the sole responsibility of every potential owner to obtain

written confirmation that any data furnished by Milnor

number(s) of the specific machines.

Legend

®

upon request. All data is subject to change without notice and may

®

applies for the model(s) and serial

— End of BIWUUI02 —

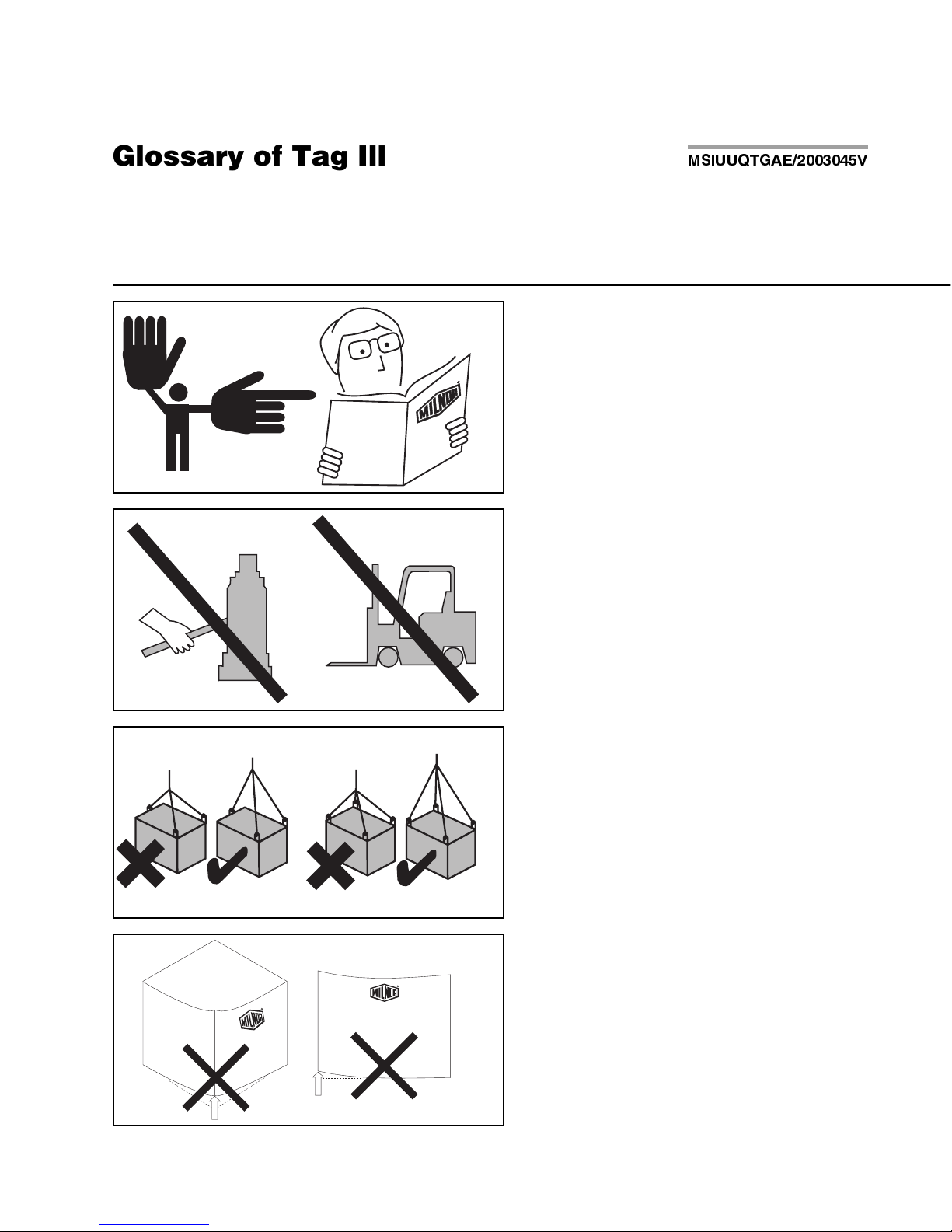

7\_ccQbi_VDQW9\\ecdbQdY_^c±

6Cdi\UACdi\U#&$"FCdi\U

Q^THCdi\UGQcXUb5hdbQSd_bc

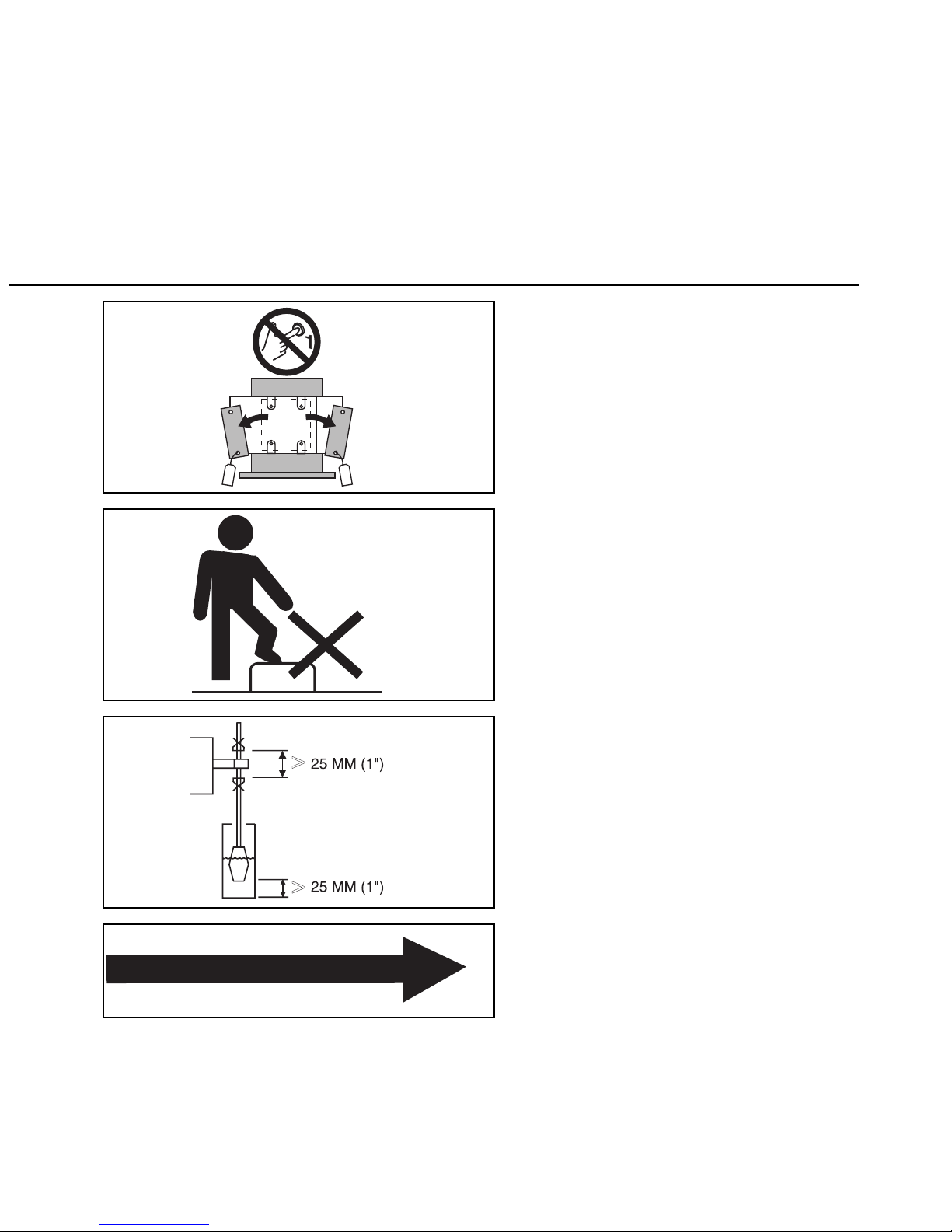

Illustration Explanation

Stop! Read the manual first for complete

instructions before continuing.

Do not jack the machine here.

Do not lift the machine here.

<B8DD@C604!"#$E

Use three point or four point lifting as

determined by the lifting eyes furnished. Rig

the load using lifting cables of sufficient size

and length to ensure cables are not

over-stressed.

Do not lift the machine from one corner or one

side edge.

Illustration Explanation

Do not start this machine until the packing

materials, lifting brackets, etc. with this tag

attached or behind this panel are removed.

These materials are painted red. Safety stands

or brackets (also painted red) may be provided

with this machine. Do not discard safety

stands or brackets

Do not step or stand on this machine part.

Maintain a 25 mm. (1") minimum clearance

between float clips. Set "low level" so that the

bottom of the float is always at least 25mm

(1") above the bottom of the float tube.

This motor or pump should rotate in the

direction of the arrow.

7\_ccQbi _V DQW9\\ecdbQdY_^c±

6Cdi\U ACdi\U #& $" FCdi\U Q^T HCdi\U GQcXUb5hdbQSd_bc

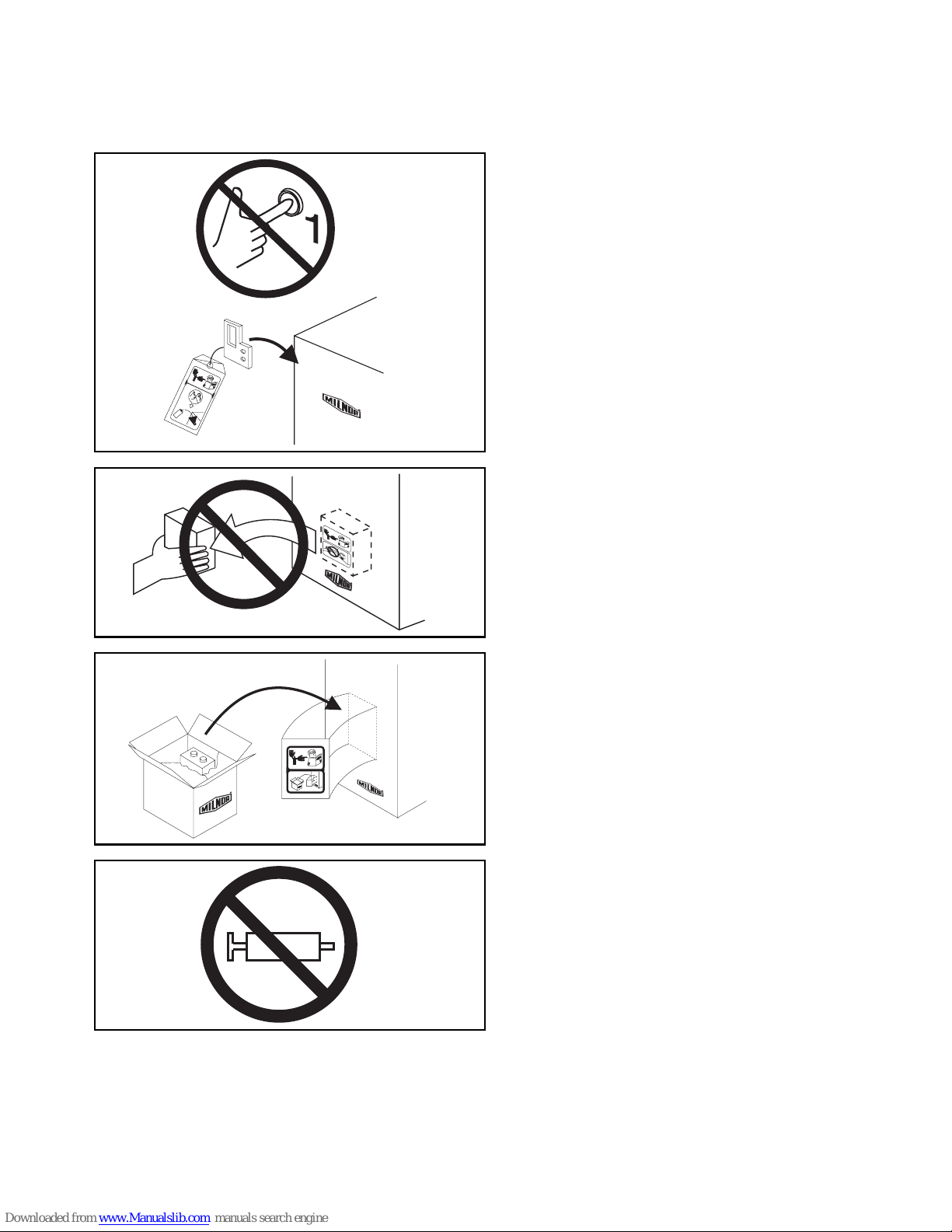

Do not start this machine until the part with

this tag is installed on the machine.

Do not remove this component from the

machine.

Install the appropriate part here before

operating the machine.

Do not pump grease here.

=C9EEAD715" # $%F " #

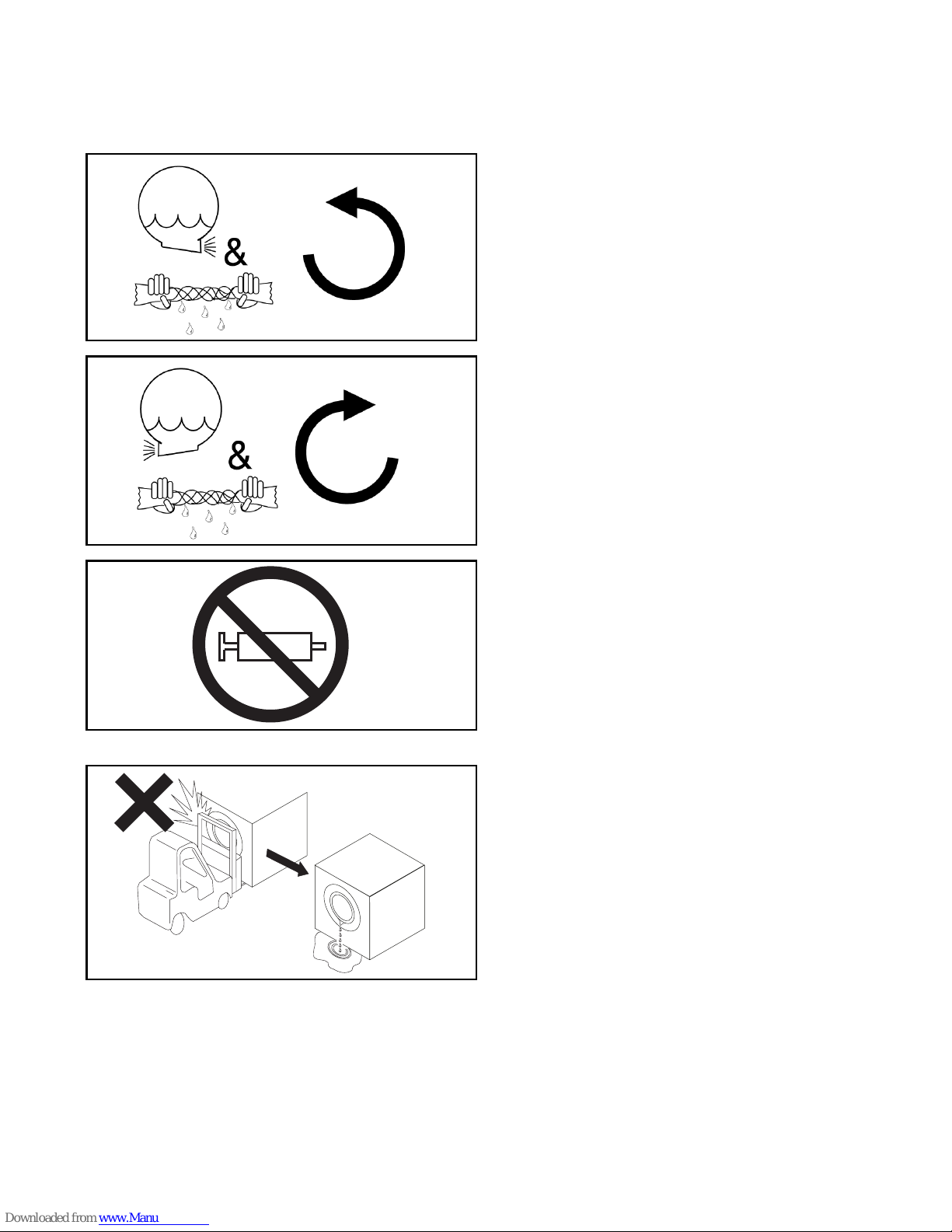

During drain and extract, the cylinder must

rotate counterclockwise when viewed from

here (rear of machine).

During drain and extract, the cylinder must

rotate clockwise when viewed from here

(front of machine).

Do not pump grease here.

.

Do not strike shell front of washer-extractors

during fork lifting. Striking shell front will

cause door to leak.

7\_ccQbi _V DQW9\\ecdbQdY_^c±

6Cdi\U ACdi\U #& $" FCdi\U Q^T HCdi\U GQcXUb5hdbQSd_bc

Make cold water connection here.

H0

2

Make hot water connection here.

H0

2

H0

2

Make third (reuse) water connection here.

Hold the connection side of the valve with a

wrench when connecting plumbing.

BIWUUI03 (Published) Book specs- Dates: 20030306 / 20030306 / 20030306 Lang: ENG01 Applic: WUU

Avoiding Damage From Allied Remote Chemical Delivery

Systems

Milnor® does not manufacture or supply remote chemical delivery systems and this document is

meant only to illustrate some of the possible problems that can be minimized during installation

of such systems by the chemical supply company. Milnor washer-extractors and CBW

washers (tunnels) are available with convenient inlets for such systems (see Figure 1). Most

common of the types of systems currently used in commercial laundering operations are pumped

chemical systems. Other types, such as constant pressure, re-circulating ring main systems have

also been, and may continue to be used with Milnor equipment.

This document warns about some of the possible hazards posed by chemical systems and lists

certain requirements needed to minimize those hazards. The procedures for interfacing with allied

chemical systems and information pertinent to chemical use in general are provided elsewhere in

the product manuals (see Note 1).

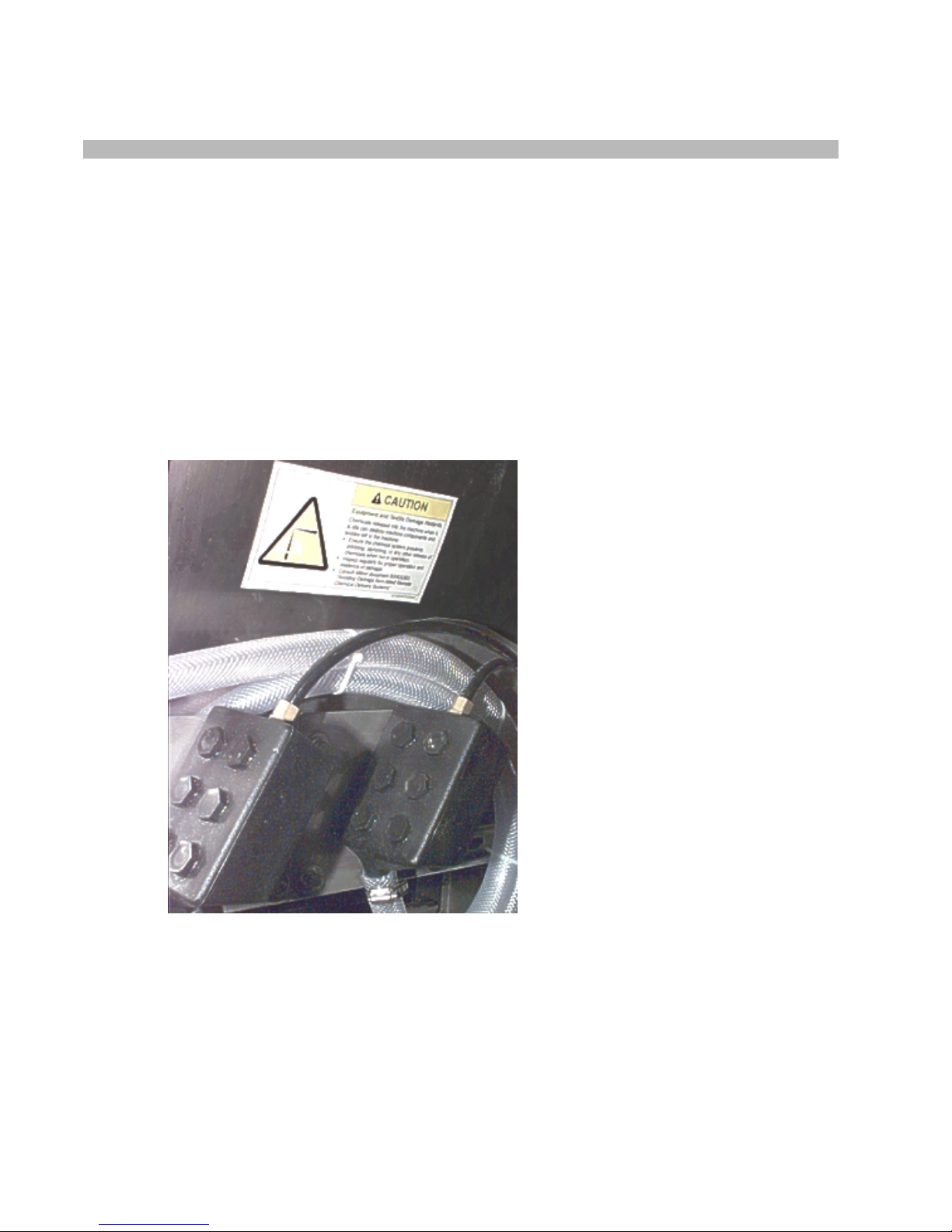

Figure 1: Pumped Chemical Inlets on CBW Batch Washer

®

batch

Note 1:

permitting acid sours to react with hypo chlorite) due to incorrect formulation can also be hazardous.

Information pertinent to chemical u se is provided elsewhere in th e product manuals.

1.

How a Chemical System Can Damage the Machine It Serves

Misuse of laundering chemicals (such as injecting excessive concentrations of chlorine bl each or

Milnor has manufactured washer-extractors and tunnel washers with the same stainless steel

specification since its founding. Every batch of steel used is certified and documented by the steel

mill. Testing of samples damaged by corrosion have, in every case, proven the steel to be well

within the AISI 304 specification.

PELLERIN MILNOR CORPORATION

Avoiding Damage From Allied Remote Chemical Delivery Systems

Chemical products commonly found in the laundry industry, when used in established dosages

and proper operating parameters, under the auspices of an experienced chemical specialist, should

produce satisfactory results, with no consequential detrimental effects. The industry has published

standards in Riggs and Sherrill, “Textile Laundering Technology”. However, the stainless steel

can be damaged and even destroyed by abnormal contact with chlorine bleach, hydrofluosilicic

acid and other commonly used chemicals, as will occur if chemicals are unintentionally leaked

into the machine, particularly when it is no longer in use and especially when machine surfaces

are dry.

Some chemical systems have been found to permit chemicals to dribble from the supply lines, or

worse, to siphon from the supply tank into the machine, during operation and long after the

system is shut down—as after working hours and during weekends. If this occurs, deterioration

(rusting) of the stainless steel and damage to any textiles therein will inevitably result. If this

condition goes undetected, machine damage is likely to be catastrophic. No machine is

immune to such damage.

CAUTION 1 : Equipment and Textile Damage Hazards

—Chemicals leaked into the

machine, particularly when it is idle can destroy machine components and textiles left in the

machine. Pellerin Milnor Corporation accepts absolutely no responsibility for damage to its

equipment or to textiles therein from abnormal contact with chemicals.

• Ensure that the chemical system prevents uninten ti ona l rele ase of chemicals.

• Inspect regularly for proper operation and evidence of damage.

2.

Requirements for Chemical Systems Used With Milnor Machines

It is the responsibility of the chemical system manufacturer and supplier to ensure that their

system is safe for personnel and equipment. Some important points are described below.

2.1.

Ensure the System Cannot Siphon.

—The supply system must be designed to

counteract any siphoning that could occur as a result of having a sealed supply line between the

bottom of the chemical tank and the internal machine connection at the drain trough. As shown in

the Figure 2 examples, if the pump (P) and/or the valving does not provide positive closure and

there is no vacuum breaker protection, siphoning is likely to occur. In each of the Figure 2

illustrations, the volume of chem ical in the tank above th e siphon level (S), and indi ca ted by

shading, will flow into the machine.

PELLERIN MILNOR CORPORATION

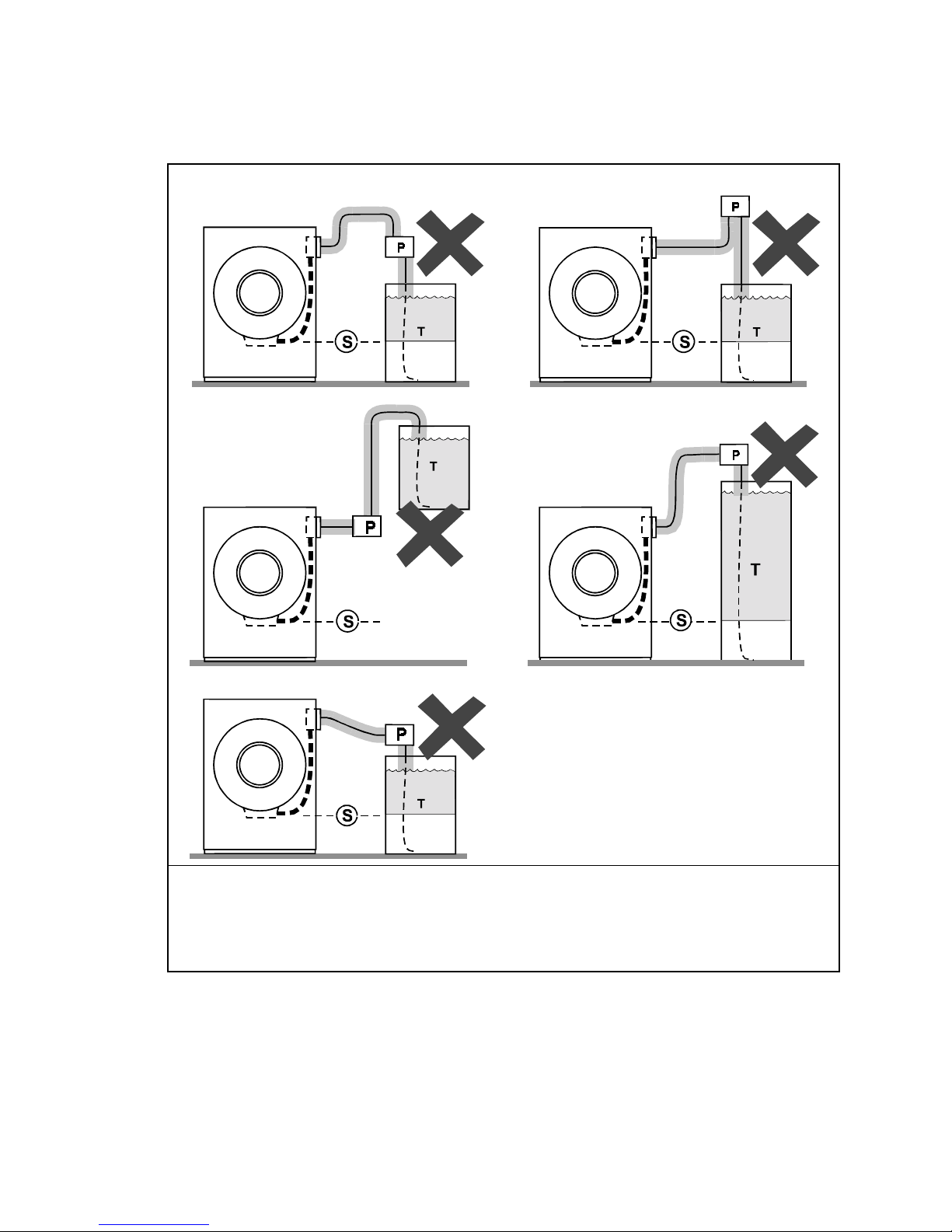

Figure 2:

Siphoning From the Chemical Tank into the Machine

Examples

Pump

P.

Siphon level. Shading indicates the chemical delivery line and tank content that can siphon into

S.

the machine.

Chemical tank

T.

2.2.

Ensure the Chemical Lines Cannot Dribble

provide a means of positively closing the chemical line at the pump location, but not at the

injection site. Hence, any concentrated chemical that remains in the injection line between the

pump and the machine is free to flow into the machine. Some examples of this are shown in

Figure 3.

Legend

—The pumped chemical system may

PELLERIN MILNOR CORPORATION

Avoiding Damage From Allied Remote Chemical Delivery Systems

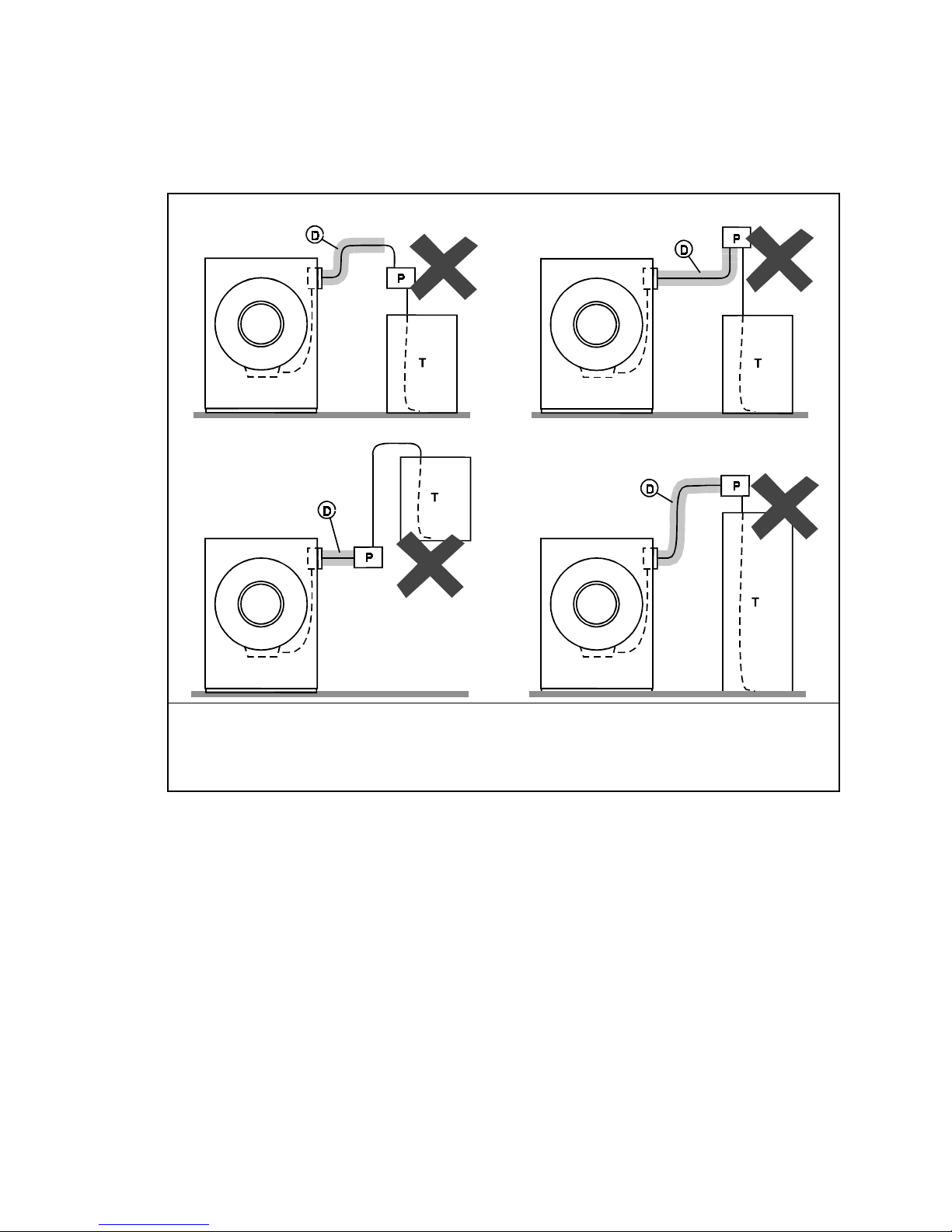

Figure 3:

Dribbling From Chemical Supply Line Into Machine

(assumes positive closure at the pump)

Examples

Legend

Portion of supply line, the contents of which can dribble into the machine

D.

Pump

P.

Chemical tank

T.

3.

Design and Installation Recommendations

It is the responsibility of the chemical system manufacturer and supplier to use whatever

measures are necessary to ensure that their system is safe for personnel and equipment. The

following are some of the possible methods the manufacturer or supplier may wish to use, as

appropriate.

3.1.

Siphoning: Positively close the line.

—If the pump does not provide positive closure

when the system is off, employ a shutoff valve in the line to serve this purpose.

3.2.

Siphoning: Break the siphon.

—Provide an air gap or vacuum breaker in the chemical

delivery line. This must be located above the “full” line of the tank.

3.3.

Dribbling: Flush the entire chemical delivery line.

—If any concentrated chemical

that remains in the injection line between the pump and the machine is free to flow into the

machine, employ a system that flushes the entire line between the pump and the injection point

with fresh water after each injection.

PELLERIN MILNOR CORPORATION

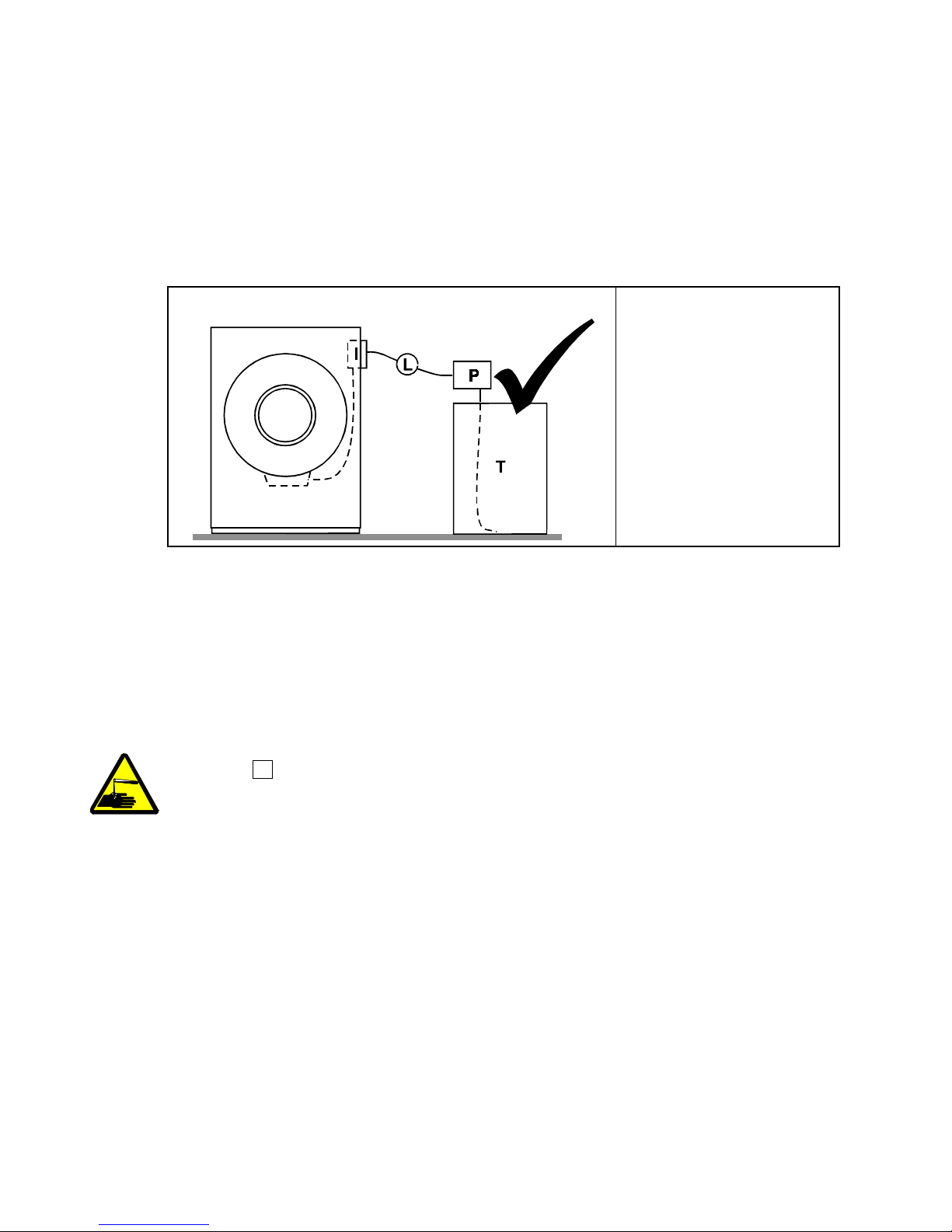

3.4.

Dribbling: Locate the entire chemical line below the machine inlet.

—

Assuming the chemical system does not retain any line pressure and that the pump provides

positive closure when the system is off, locate the entire chemical delivery line below the level of

the chemical inlet. An example of this is shown in Figure 4.

Figure 4:

Locating a Pumped Chemical System With Positive

Closure To Protect Against Machine Damage

Example of Correct Placement Legend

Chemical inlet on

I.

machine

Chemical delivery line

L.

Pump with positive

P.

closure when system is

off

Chemical tank

T.

4.

Guarding Against Leaks

All personnel who may work with the chemical system (e.g., chemical system manufacturer,

chemical system supplier, chemical supplier, operator, maintenance personnel) should be vigilant

in observing for leaks in the system. When connecting, or reconnecting chemical lines, whether at

installation, after taking samples, or when replacing components, at a minimum ensure that:

1. the proper components are used,

2. all connections are the proper fit, and

3. all components are securely connected.

CAUTION 2 : Injury and Damage Hazards

may be corrosive or toxic. Such chemicals can injure personnel and damage equipment.

• Use care when connecting chemical lines.

• Inspect regularly for leaks.

—Chemicals leaking from a chemical system

— End of BIWUUI03 —

PELLERIN MILNOR CORPORATION

R

Pellerin Milnor CorporationPellerin Milnor Corporation

P. O. Box 400, Kenner, LA 70063-0400

Litho in U.S.A.

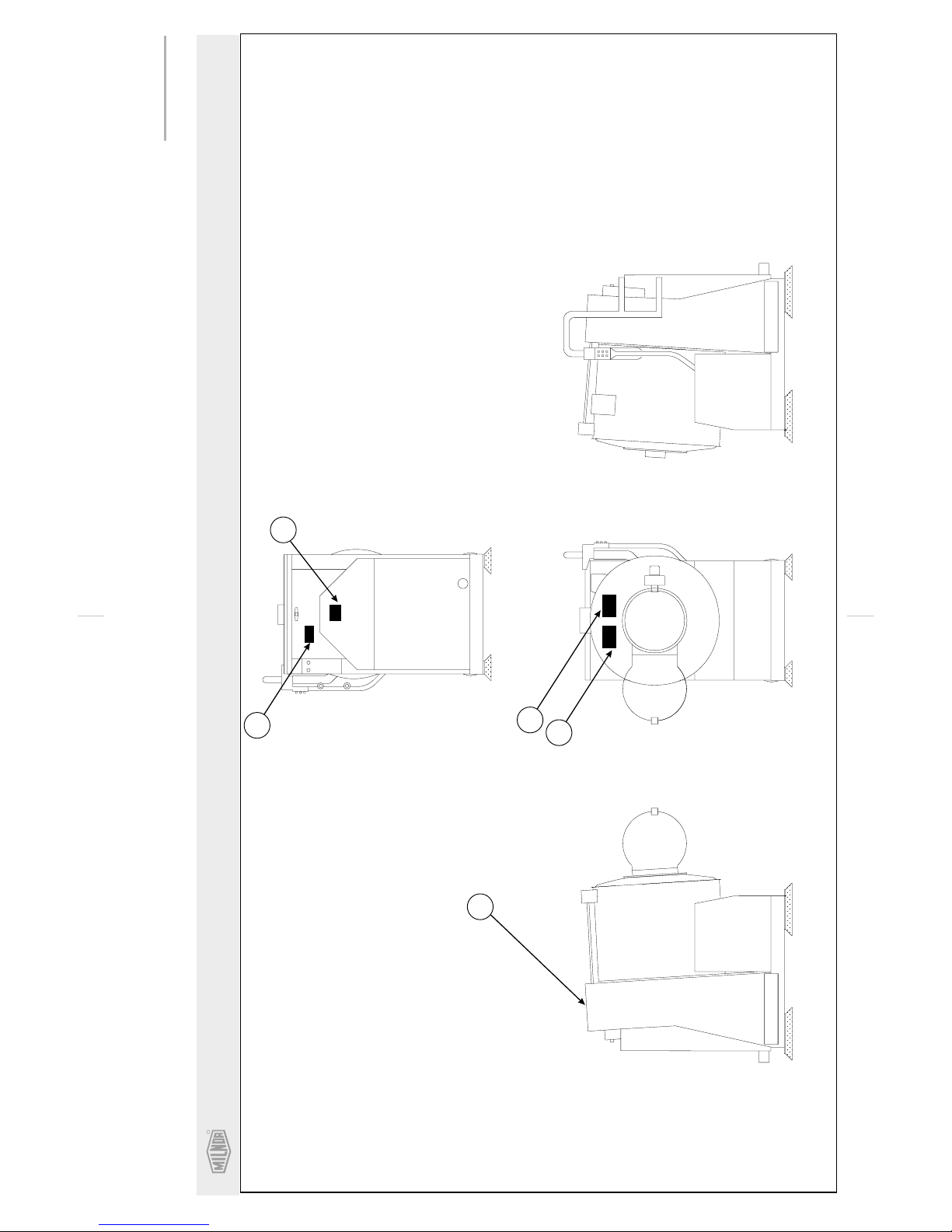

BMP020109/2002145V

(Sheet 1 of 2)

Safety Placard Use and Placement

36026V5J, 36021CPE, NSP & V5J

Notes:

1

. Approximate locations of placards are shown.

Mounting holes are provided on machine.

If aluminum placard use #8 self-tapping screws.

. Replace placard immediately, if removed or

unreadable.

2

20

On Top

40

50

60

10

FRONT VIEWLEFT VIEW

RIGHT VIEW

REAR VIEW

Loading...

Loading...