Page 1

XLS/XLTTRANSDUCERS

S/

S

UC

S

Instruction Manual PL-522 January 2001

ER

D

33455220

Rev. 2.1

XLTTRAN

L

Page 2

Safety Guideline s

Warning notices must be obser ved to ensure personal safety as well as that of others, and to

protect the product and the connected equipment. These warning notice s ar e accomp anied

by a clarification of the level of caution to be observed.

Qualified Personnel

This device/system may only be set up and oper ated in conjunction with this manu al.

Qualified personn el ar e only authorized to insta ll and op erate this equipment in accordance

with established safety practices and standards.

Warning: This product can only function properly and safely if it is correctly transported,

stored, installed, set up , operated, and maintained.

Note: Always use p r od uct in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2000. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to

purchase authorized bound manuals, or to view

electronic versions as designed and authored by

Siemens Milltronics Process Instruments Inc.

Siemens Milltronics Process Instruments Inc. will

not be responsible for t he contents of partial or

whole reproductions of eit her bound or electronic

versions.

MILLTRONICS®is a register ed trademark of Siemens Milltronics Pr ocess Instruments Inc.

Contact SMPI Technical Publications at the following address:

Technical Publicat ions

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontari o, Canada, K9J 7B1

Email: techpubs@milltronics.com

While we have verified the contents of

this manual for agreement w it h t h e

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The

contents of this manual are regularly

reviewed and corrections are included

in subsequent editions. We welcome

all suggestions for improvement.

Technical data subject to change.

For the library of SMPI instr uction manuals, visit our Web site: www.milltronics.com

© Siemens Milltronics Process Instruments Inc. 2001

Page 3

Table of Contents

Table of Contents....................................................................................3

Specifications..........................................................................................5

About the Transduce r..............................................................................7

General Guid e lines.............................................................................8

Outline and Dimensions ..........................................................................9

Mounting................................................................................................11

Recommendations............................................................................11

Solids Applications............................................................................11

Liquid App lications............................................................................12

Interconnection......................................................................................13

Recommendations............................................................................14

Applications...........................................................................................15

Solids...............................................................................................15

Liquids..............................................................................................16

Maintenance...........................................................................................18

Installation Diagrams.............................................................................19

Connection Diagram .........................................................................19

Interconnection Diagram ...................................................................20

PL-522 XLS/XLT Series Transducers Page 3

Page 4

Page 4 XLS/XLT Series Transducers PL-522

Page 5

Specifications

Beam Angle

• 5°

Environmental

Location

• indoor / outdoor

Altitude

• 2000 m maximum

Pollution Degree :

• 4

Ambient Pressure:

• 800 kPa (8 Bar, 120 PSI)

Construction

Exposure

• aluminum, 304 stainless steel and silicone

Mounting

• 1" NPT conduit connection

Cable

• 2 wire sh ielded / t wisted, 0. 5 m m2 (2 0 AWG)

Specifications

Supply Source

•

transdu c er s h a ll only be supplie d by Millt ro nic s ce rt ified controller s

Separation :

• 365 m (1200 ft) from t r ansducer

Approvals :

• CE

• see nameplate or consult Milltr onics for current approvals

1,

CSA, FM, SIRA/CENELEC

1

EMC perf ormanc e av ai lable up on r e qu es t

PL-522 XLS/XLT Series Transducers Page 5

Page 6

XLS - 60

Measurement Range

• 1.8 – 60 m (6 - 200 ft)

Frequency

• 13 kHz

Environmental

Specifications

Ambient Temp

• – 40 to 90 °C (– 40 to 195 °F )

Construction

Cable

• PVC jacket

Weight

2

• 4.3 kg (9.5 lb)

XLT - 30

Measurement Range

• 0.9 - 30 m (3 - 100 ft)

Frequency

• 22 kHz

Environmental

Ambient Temp

• – 40 to 150 °C ( – 40 to 300 °F )

Construction

Cable

• Silicone jacket

Weight

2

• 6.6 kg (14.5 lb)

XLT - 60

Measurement Range

• 1.8 - 60 m (6 - 200 ft)

Frequency

• 13 kHz

Environmental

Ambient Temp

• – 40 to 150 °C ( – 40 to 300 °F )

Construction

Cable

• Silicone jacket

Weight

Page 6 XLS/XLT Series Transducers PL-522

2

• 6.6 kg (14.5 lb)

Page 7

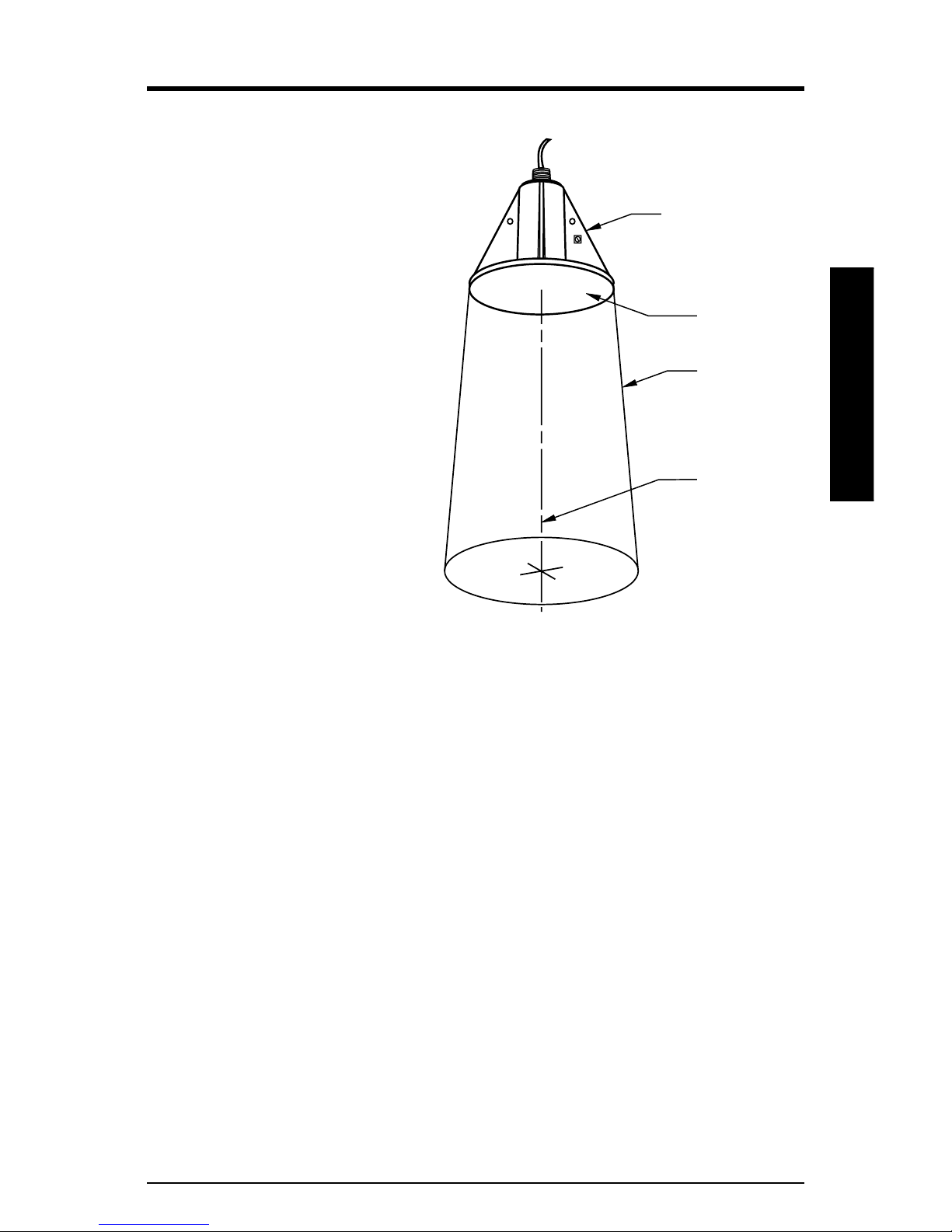

About the Transducer

The Echomax XLS / XLT series of

transducers operates in

association with Milltronics

ultrasonic level monitoring

products.

The transducer converts the

electrical energy of the transmit

pulse from the transceiver into

acoustical energy. It then

converts the acoustical energy

of the echo back into electrical

energy for the transceiver

receive period.

The effective acoustical

energy is emitted from the

transducer face and radiated

outward, decreasing in

amplitude at a rate inversely

proportional to the square of

the distance. Maximum

power is radiated axially

(perpendicular) from the

transducer face in a line referred to as the axis of transmission. Where

power is reduced by half ( – 3 dB), a conical boundary def ining the sound

beam, centered about the axis of transmission, is established. The diametric

measurement of the cone in degrees defines the beam angle. Impedance

matching techniques are used to optimize the transfer of pow er from the

transducer into air and vice versa.

transducer

transducer

face

-3db

boundary

axis of

transmission,

perpendicular

to transducer

face

About the Transducer

The XLS / XLT transducers incorporate an integral temperature sensor that

reports the air temperature at the transducer to the transceiver. The

connection is transparent, in that both the ultrasonic and temperature

components of the transducer use the same wires.

PL-522 XLS/XLT Series Transducers Page 7

Page 8

General Guidelines

The equipment may be used in all hazardous areas with all gases with

temperature classes T1, T2, T3, T4, and T5 for the XLS-30 and XLS-6 0, and

T1, T2, and T3 for the XLT-30 and XLT-60. The XLS series is only certified

for use in ambient temperatures in the range of -40°C to 90°C and the XLT

series is only certified for use in an ambient range of -40°C to 150°C. Neither

should be used outside their respective temperature ranges.

• Installation shall be carried out in accordance with the applicable code of

practice, and by suitably trained personnel.

• These devices should only be supplied from a circuit containing a suitablyrated fuse that has a breaking capacity of 4000A. This fuse is included in

Milltronics’ transceivers.

• Repair of this equipment shall be carried out in accordance with the

applicable code of practice.

About the Transducer

• The certification of the XLS and XLT range of transducers rely upon the

following materials used in its construction:

Enclosure: Aluminum

Encapsulant: Durapot 861-F3 / 864

• Manual override can be accomplished by using the disconnect switch

provided in the building installation of the associated controller.

Page 8 XLS/XLT Series Transducers PL-522

Page 9

Outline and Dimensions

safety connection

9 mm (3/8") dia.

hole (2 places)

1” NPT

earth connection

screw clamp

(1 place)

h

(nominal)

Outline & Dimensions

d

XLS / XLT - 30 XLS / XLT - 60

h 249 mm (9.8") 324 mm (12.75")

d 264 mm (10.4") 335 mm (13.2")

PL-522 XLS/XLT Series Transducers Page 9

Page 10

Outline & Dimensions

Page 10 XLS/XLT Series Transducers PL-522

Page 11

Mounting

Recommendations

• Mount the transducer so that it is above the maximu m material level by at

least the blanking value. Refer to the associated transceiver manual.

• On liquid applications, the transducer must be mounted so that the axis of

transmission is perpendicular to the liquid surface.

• On solids applications, a Milltronics Easy Aimer should be used to facilitate

aiming of the transducer.

• Secure installation by connecting a safety chain from the transducer to a

structural member.

• Consider the optional temperature sensor when mounting the transducer.

Notes:

• Wear proper ear protection in the vicinity of the operating transducer.

The XLS/XLT 60 transducers could emit hazardous sound

pressure. They sha ll be installed in such a manner that the

sound pressure will be reduced to a non-hazardous level.

Solids Applications

Easy Aimer

(typical model)

to nearest earth

Mounting

PL-522 XLS/XLT Series Transducers Page 11

safety chain

earth connection

Page 12

Liquid Applications

Flexible Conduit

flexible conduit

coupling

safety chain

transducer

Blind Flange

nipple welded to blind flange

coupling

to nearest earth

to nearest earth

Mounting

safety chain

Flange, gasket and hardware supplied by customer.

Refer to Standpipes on page 16.

Page 12 XLS/XLT Series Transducers PL-522

coupling

Page 13

Interconnection

Direct Connection

blk

wht

Milltronics transceiver

(typical)

blk/hot

wht/shld

2 Wire Extension

Coaxial Extension

blk

wht

junction

box

drain/shield

extend cable using 18 AWG

shielded / twisted pair

Note:

Grounding transducer as shown is mandatory per safety regulations,

and for isolation against elec tr ical interference.

PL-522 XLS/XLT Series Transducers Page 13

extend cable using RG – 62 A/U

coax for optimum signal to noise ratio

Interconnection

Page 14

Recommendations

Note:

Installation shall only be performed by qualified personnel and in

accordance with local gove rning regulations.

For best results follow these installation rules:

• Do not route cable openly, instead run cable separately in a grounded metal

conduit to p rotect it from ambient electrical noise.

• Seal all thread connections to prevent the ingress of moisture.

• Do not run cable near high voltage or current runs, contactors or SCR

control drives.

Interconnection

Page 14 XLS/XLT Series Transducers PL-522

Page 15

Applications

Notes:

• The transducer is to be used only in the manner outlined in this

instruction manual.

• This transducer requires no maintenance, and is recommended for use

with liquids only.

Solids

Applications

1

bin wall seams

2

filling profile

emptying profile

1. Transducer angled to avoid wall seams, and

aimed at discharge in order to read empty bin.

2. Avoid intersecting bin wall seams, structural

members an d wall irregularities. Otherwise,

refer to transceiver manual

Easy Aimer

3

3. Transducer too close to materi al inlet.

Falling material will intersect sound beam

and cause erroneous readings or loss of

echo.

4

4. On fluid-like sol ids, aim transducer

perpendic ular to material s urface

PL-522 XLS/XLT Series Transducers Page 15

transducer

5

minimal angle

of repose

discharge

5. On dual discharge bins, aim each

transduc er at the discharge point.

Page 16

Liquids

Standpipes

In many applications, access must be made via a standpipe. In such cases

the transducer is hung from a blind flange.

Applications

The standpipe length should be as short and the diameter as large as

possible. As a rule of thumb, the -3 dB cone of the sound beam should not

intersect the standpipe wall in applications opening into a vessel or larger

area. Otherwise, additional blanking will be required to compensate for the

interference zone created by the opening.

nipple welded

into blind flange

transducer

no

intersection

no additional blanking required.no additional blanking required.

sound beam

intersects

no additional blanking required.

reflection at

interference

zone created

by opening

near blanking extension of 150 mm (6") past end of

standpipe may be required.

Page 16 XLS/XLT Series Transducers PL-522

Page 17

Volume

Maintain full

fluid level for

full or offset

calibration.

Do not allow

material to

enter blanking

zone.

‘B’

‘A’

‘C’

Applications

2

3

span:

corresponds to

beam

angle

tank

manufacturer’s

empty level

Empty level for ‘B’

location. Below this

level, echo would

reflect away from

the transducer.

rise

run

1

discharge

4

tank

manufacturer’s

empty level

A. Primary location. This is the preferred location and should be used

whenever possible. The centre of the tank generally gives the most reliable

readings because there are fewer obstructions to provide false echos.

B. Alternate location. This location is used if the centre of the tank is already

in use or if the tank roof is too weak to hold the transducer safely.

C. Poor location. This is a poor installation location. The echos are shown

reflecting away from the transducer face.

PL-522 XLS/XLT Series Transducers Page 17

Page 18

Notes

1. Beam should not detect bin bottom.

If this occurs, use range extension parameters (on transceivers where

available) to omit false echoes. A 5° beam angle represents a rise:run ratio

of approximately 20:1. In most tanks the transducer should be centred as

Applications

much as possible (without interference from inlet) for optimum reading

range.

2. Sound beam must be perpendicular to liquid surface.

When mounting the standpipe and flange you must ensure that the

transducer face will be parallel with the liquid’s surface.

3.

Echo has missed an improperly levelled transducer.

As in 2, ensure that the standpipe and flange are mounted to set the

transducer face level with the measured liquid.

4.

Calibrate under normal conditions.

When performing an empty or full calibration, the tank must contain its

normal vapour and be at its normal temperature.

Maintenance

This transducer requires no maintenance, but if performance changes are

observed, shut down the system and promptly inspect the complete system

including the transducer.

Page 18 XLS/XLT Series Transducers PL-522

Page 19

Installation Diagrams

Connection Diagram

Installation Diagrams

PL-522 XLS/XLT Series Transducers Page 19

Page 20

Interconnection Diagram

Installation Diagrams

Page 20 XLS/XLT Series Transducers PL-522

Page 21

*7ml19981al01*

Loading...

Loading...