Page 1

Instruction Manual January 2003

pointek

ULS 200

Page 2

Safety Guidelines

Warning notices must be observed to ensure personal safety as well as that of others, and to

protect the product and the connected equipment. These warning notices are accompanied

by a clarification of the level of caution to be observed.

Qualified Personne l

This device/system may only be set up and operated in conjunction with this manual.

Qualified personnel are only authorized to install and operate this equipment in accordance

with established safety practices and standards.

Warning: This product can only function properly and safely if it is correctly transported,

stored, installed, set up, operated, and maintained.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2003. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to

purchase authorized bound manuals, or to view

electronic versions as designed and authored by

Siemens Milltronics Process Instruments Inc.

Siemens Milltronics Process Instruments Inc. will

not be responsible for the contents of partial or

whole reproductions of either bound or electronic

versions.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

Contact SMPI Tech nical Publications at t he following address:

Technical Publications

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs@siemens-milltronics.com

While we have verified the contents of

this manual for agreement with the

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The

contents of this manual are regularly

reviewed and corrections are included

in subsequent editions. We welcome

all suggestions for improvement.

Technical data subject to change.

For the library of SMPI instruction manuals, visit our Web site: www.siemens-milltronics.com

© Siemens Milltronics Process Instruments Inc. 2003

Page 3

Table of Contents

Pointek ULS 200 ...................................................................................................................2

Specifications ............................................................................................................. .........3

Installation ...........................................................................................................................5

Location .....................................................................................................................................................5

Mounting and Dimensions ................................................................................................6

Threaded ....................................................................................................................................................6

Sanitary ......................................................................................................................................................7

Interface ...............................................................................................................................9

Interconnection ..... .................... ..................... ..................... ....................... .................... ...10

Operation .......... ................................. ............................... ............................... ...................11

Start Up ....................................................................................................................................................11

Quick Start ..............................................................................................................................................11

Display / Operation Status ..................................................................................................................13

Applications ..... .................... ..................... ..................... ...................... ..................... .........14

Adjustments ............................... ........................................................................................20

Troubleshooting .................................................................................................................28

Maintenance . ..... .... .... ...... .... .... ..... .... .... .... ...... .... .... ..... .... .... ...... .... .... ..... .... .... .... ...... .... .....29

Certifications .....................................................................................................................30

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 1

Page 4

Pointek ULS 200

Note: Pointek ULS 200 is to be used only in the manner outlined in this instruction

manual.

Pointek ULS 200 is an ultrasonic based process level switch providing high or low switch

action on liquids or solids. The process part (sensor) is Tefzel®or Kynar Flex®, allowing it

to be used in a wide variety of industries.

Pointek ULS 200 contains an ultrasonic transducer and temperature sensing element. The

transducer emits a series of ultrasonic pulses. Each pulse is reflected as an echo from

the material and sensed by the transducer. Pointek ULS 200 processes the echo using

Milltronic's proven Sonic Intelligence®techniques. Filtering is applied to help

discriminate between the true echo from the material and the false echoes from

acoustical and electrical noises and agitator blades in motion. The time for the pulse to

travel to the material and back is temperature compensated and then converted into

distance for display and relay actuation.

The Pointek ULS 200 is an excellent primary detection device, but should not be used as

a backup device. For backup devices use a contacting technology such as the Pointek

CLS 200. The optional sanitary version affords quick removal and ease of cleaning as

demanded by the food, beverage, and pharmaceutical industries.

Pointek ULS 200 Outputs

• switch outputs programmable for high-high, high, low, and low-low level actions

• fail-safe programmable

Pointek ULS 200 Features

• 2" NPT, 2" BSP or PF2 or 4" 3A approved Tri-clamp process connection

• 2 conduit connections, 1/2 “NPT or PG 13.5

• non-corrosive enclosure and wetted parts

• 2 button programming

• level run/program LCD display

Pointek ULS 200 Applications

• liquids, slurries, and fluid materials

• foods and pharmaceuticals

• chemicals

Page 2 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 5

Specifications

ac V ersion

Power

• 100 - 230 V ac, + 15%, 50/60 Hz, 12 VA (5W) max.

Fuse

• Slow-Blow, 0.25 A, 250 V ac

Output:

• repeatability: 0.25 % of full range

• resolution: 3 mm (0.1")

•relay: 2 form C (SPDT) contacts, rated 5A at 250 V ac, non-

inductive

dc Version

Power

• 18 to 30 V dc, 3 W

Output:

• repeatability: 0.25 % of full range

• resolution: 3mm (0.1")

• relay: 2 form C (SPDT) contacts, rated 5 A at 48 V DC

OR

• transistor: 2 transistor switches, rated 100 mA maximum at 48 V DC

Environmental

• location: indoor/outdoor

• altitude: 2000m max

• ambient temperature: - 40° to 60° C (- 40° to 140° F)

* - 20° C (-5° F) if metal mounting

• relative humidity: suitable for outdoor (Type 6 / NEMA 6 / IP67 enclosure)

• installation category: II

• pollution degree: 4

Process Pressure:

• vented to atmosphere

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 3

Page 6

Switching Range

• liquids: 0.25 to 5m (0.8 to16.4 ft)

• solids: 0.25 to 3m (0.8 to 9.8 ft)

Memory

• non-volatile EEPROM

Programming

•2 keys

Temperature Compensation

• built-in to compensate over the operating range

Display

• liquid crystal

• three 9mm (0.35") digits for reading of distance between sensor face and material,

multi-segment graphic for operation status

Electronics/Enclosure

• termination: terminal block, 2.5mm2 (14 ga) solid1.5 mm2 (16 ga)

stranded, maximum

•material: plastic

OR

epoxy coated aluminum with gasket

• ingress protection: Type 6 / NEMA 6 / IP67

• conduit: aluminum, 2 connections 1/2” NPT

plastic, 2 connections PG 13.5

1

Sensor

• material: Tefzel2®or Kynar Flex3®

• mounting: threaded:

• 2" NPT, 2" BSP or PF2

• optional flange adapter, to 3" ANSI, DIN 65PN10,

and JIS 10K3B

sanitary:

• 4" 3A compliant Tri-clamp fitting

Approvals

• CE (EMC performance available upon request.), CSA

• CSA/FM Class 1, Division 1, Group A, B, C, D; Class II, Group E, F, G; Class III

• Europe: ATEX II 2G, EEx md IIC T5

(see product nameplate for approval details)

1.

Use only approved, suitable size hubs for watertight applications.

2.

Tefzel ® is a registered trademark of Dupont.

3.

Kynar Flex® is a registered trademark of Elf Atochem North America.

Page 4 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

NRTL/C

, FM, 3A

Page 7

Installation

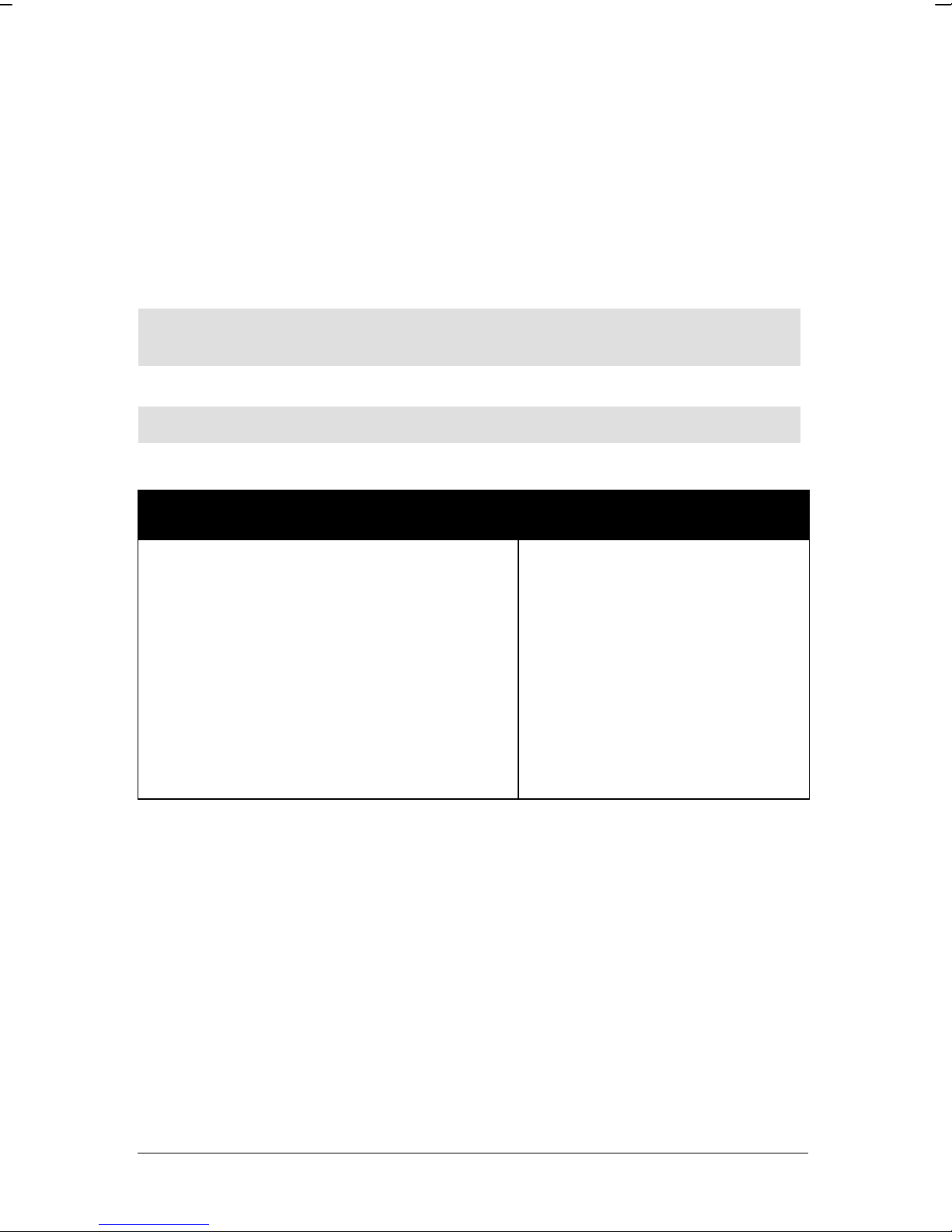

The Pointek ULS 200 should be mounted in an area within the temperature range

specified and suitable to the housing rating and materials of construction. Make sure the

cover is accessible to allow programming, wiring, and access to the display.

Keep the Pointek ULS 200 away from high voltage or current runs, contactors, and SCR

control drives.

-40°C

60°C

Warning: Explosion Hazard. Substitution of components may impair

suitability for Class 1, Division 2 applications.

Location

Locate the Pointek ULS 200 so that it has a clear sound path perpendicular to the

material surface.

The Pointek ULS 200 sound path should not intersect the fill path, rough walls, seams,

rungs, or any other obstruction.

fill

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 5

sanitary ferrule

pipe

rungs

seams

Page 8

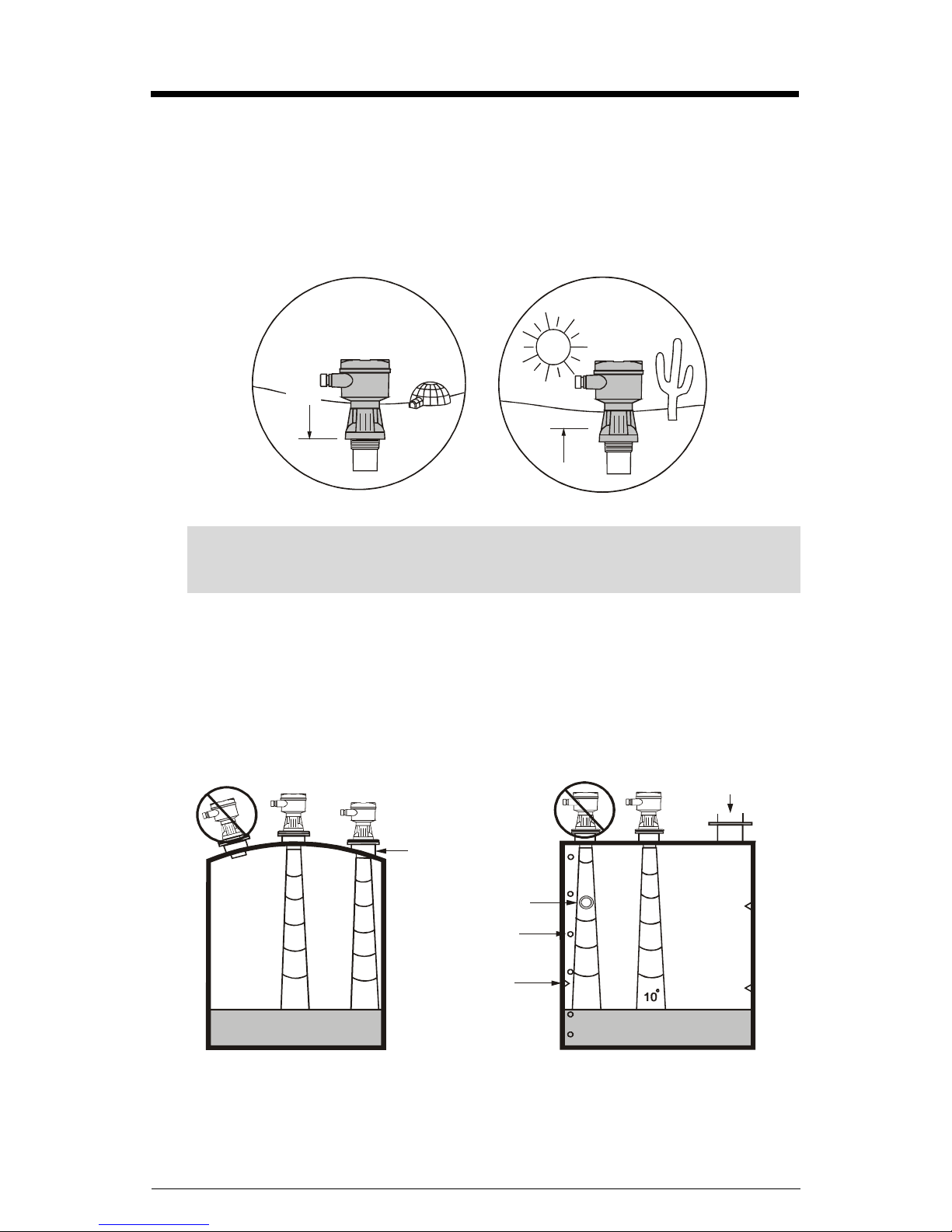

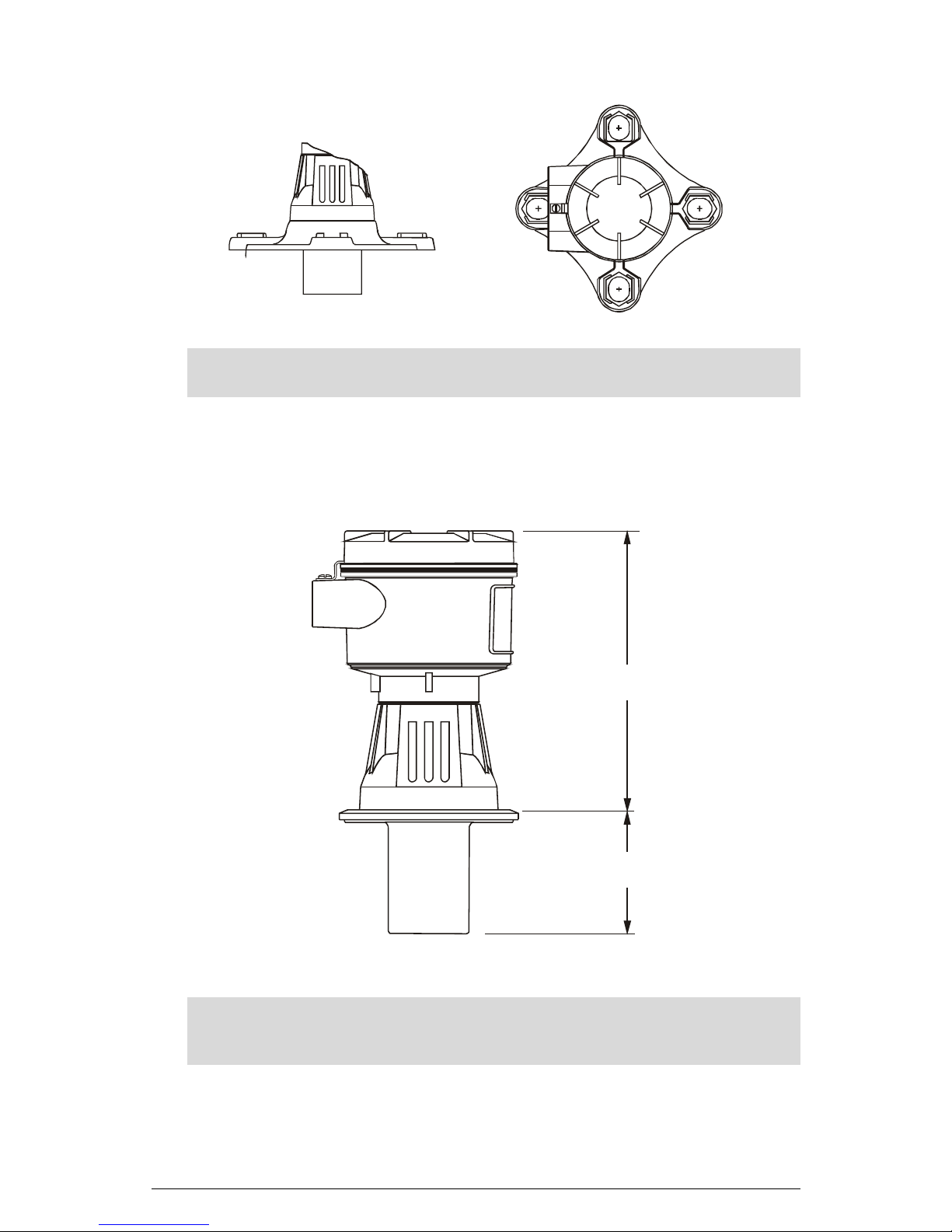

Mounting and Dimensions

Mount the ULS 200 with sensor face at least 25cm above the highest anticipated level.

Threaded

The Pointek ULS 200 is available in three thread types: 2" NPT, 2" BSP, or PF2.

Before mounting the Pointek ULS 200, ensure that the mating threads are of the same

type, otherwise the threads can be damaged.

74 mm

(2.9”)

120 mm

(4.7”)

conduit

connection

½” NPT

or

PG13.5

lid clip

#8-32x3/8”

machine screw

lid

2” NPT

2” BSP

or

PF 2

57 mm

(2.25”)

180 mm

(7.1”)

74 m m

(2.9”)

electronics /

enclosure

sensor /

transducer

Notes:

• Dimensions are nominal and may vary with material types.

• Non-metallic enclosure does not provide grounding between connections.

• Use grounding type bushings and jumpers.

Page 6 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 9

The Pointek ULS 200 can be fitted with the optional 75 mm (3") flange adapter for mating

to 3" ANSI, DIN 65PN10 and JIS 10K 3B flanges.

Note: For CSA/FM approved Hazardous Location Models, see Siemens Milltronics

drawing 0-9440026Z-DI-A.

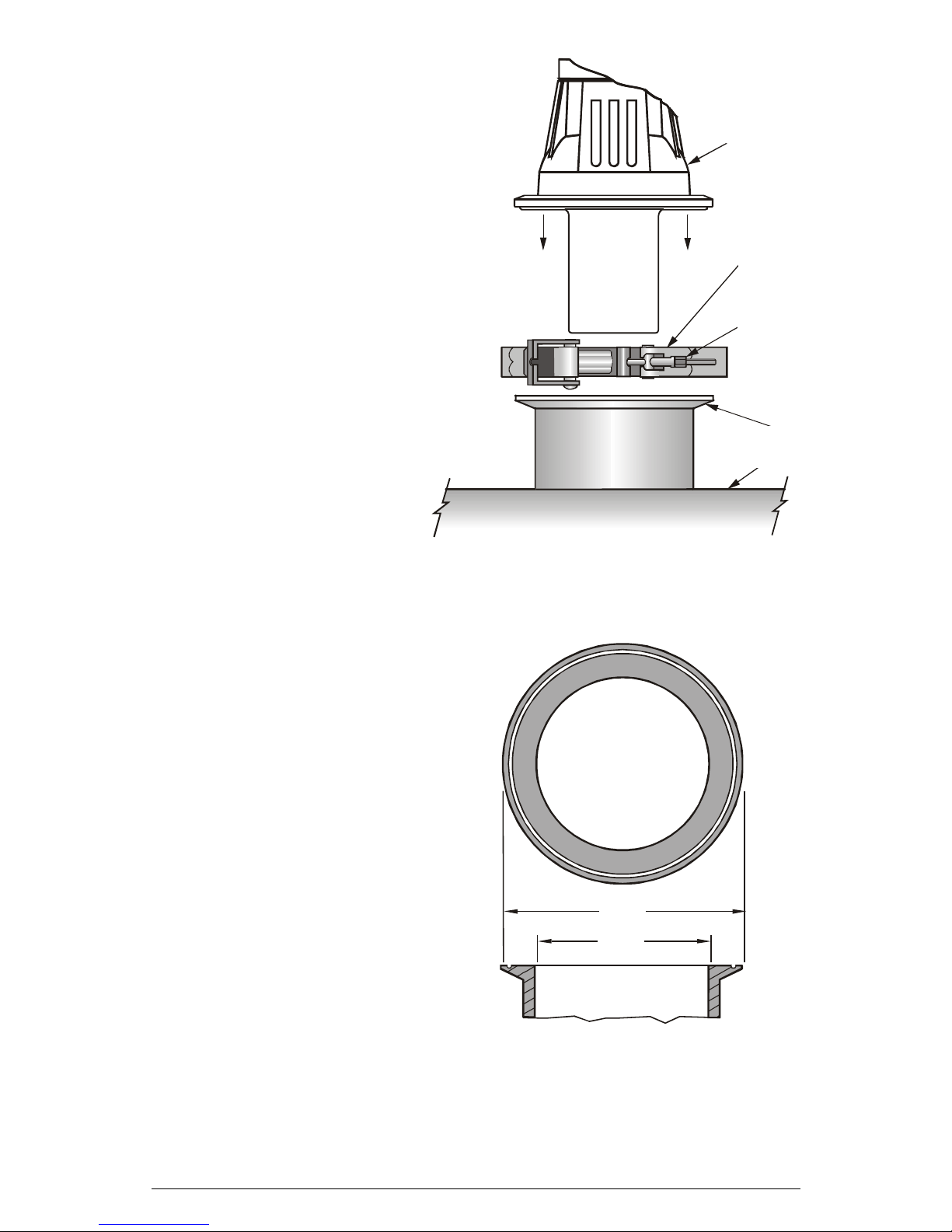

Sanitary

The Pointek ULS 200 also comes in a sanitary version for use in the food and

pharmaceutical industries.

Notes:

• Dimensions are nominal and may vary with material types.

• Refer to threaded for other dimensions.

178 mm

(7.0”)

79 mm

(3.1”)

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 7

Page 10

Mount the Pointek ULS 200

onto the top of the tank's

sanitary ferrule.

Secure mating by surrounding

the joint with the optional clamp.

Tighten the adjusting nut

with your hand. Do not

use a wrench.

Point ek

ULS 200

optional

clamp

adjusting

nut

ferrule

tank

Sanitary Ferrule, 4" FDA Approved

(U.S. Food and Drug Administration)

119 mm

(4.68”)

97 mm

(3.83”)

*dimensions are approximate

Page 8 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 11

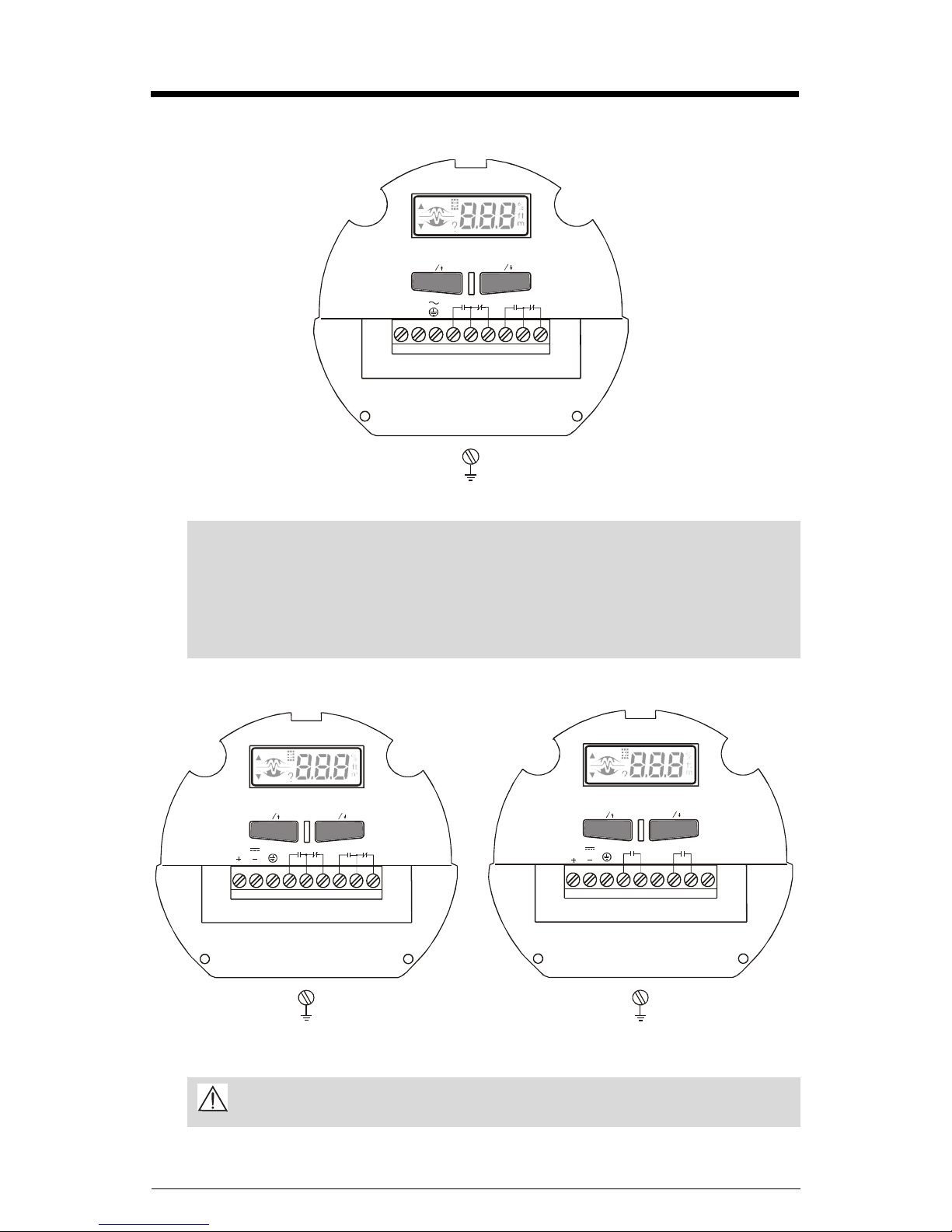

Interface

ac Version

1

2

1

2

100 - 230 V

NL

213456789

12

Notes:

• A circuit breaker or switch in the building installation, marked as the

disconnect switch, shall be in close proximity to the equipment and within

easy reach of the operator.

• Relay contact terminals are for use with equipment having no accessible live

parts and wiring having insulation suitable for at least 250 V.

dc Version - Relay Output dc Version - Transistor Output

1

1

2

1

24V

21 3 456789

12

Note: dc terminals shall be supplied from an SELV source in accordance with

IEC 1010-1 Annex H.

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 9

2

2

1

24V

213456789

2

12

Page 12

Interconnection

Notes:

• Installation shall only be performed by qualified personnel and in

accordance with local governing regulations.

• This product is susceptible to electrostatic shock. Follow proper grounding

procedures.

Separate cables and conduits may be required to conform to standard instrumentation

wiring or electrical codes.

Relay Output

12

relay 1

56789

4

relay 2

n/o

comn/c

n/ocom

n/c

All relays are shown in their de-energized (unpowered) state.

Optional Transistor Output – dc Version only

relay 1

12

18 to 30 V

24-30 V

213456789

relay 2

Power

ac Version

100 - 230 V

N

L

dc Version

18 to 30 V

1

100 to 230 V ac supply

Page 10 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

2

3

21

18 - 30 V dc supply

Page 13

Operation

Start Up

With the Pointek ULS 200 correctly installed (or aimed at a wall 0.25 to 5 m away), apply

power and observe the Pointek ULS 200 start up sequence. The unit will cycle through the

following screens:

1. Lighting of all possible LED values

2. Product revision number

3. Product model number

4. Run mode

The display and operation sequence arrives within a few seconds at the run mode, which

is the measurement of the distance from the transducer face to the material level in the

units indicated. Full instructions on setting up the unit are found at Applications on page

13 and Adjustments on page 19.

Quick Start

Use this setup method if you have a basic high/low application and you are setting up the

unit in a place where you can easily adjust the measured distance.

The Pointek ULS 200 relays are preset as: relay 1 = alarm 1, high alarm at 0.25 m

relay 2 = alarm 2, low alarm at 5.00 m

To change the setpoints by reference method, set the material or target to the distance as

displayed. Press the ` 1 /

setpoint function and value. By pressing the alarm key a second time, the Pointek ULS

200 changes the setpoint to the value currently being measured.

After viewing or changing the setpoint, the Pointek ULS 200 reverts to the run mode.

↑‘or ` 2 / ↓ ' key. The display responds by displaying the current

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 11

Page 14

relay 1

1. Position the unit so that it reads 0.75 m.

2.

1/↑

3.

1/↑

relay 2

1. Position the unit so that it reads 3.50 m.

2.

2/↓

function display:

function display:

high alarm

high alarm

current setpoint,

0.5 m

m

m

0.75 m

4. Once installed, the unit

will register a high alarm

at 0.75 m from the

sensor face.

Loss of Echo

if

retry

function display:

pump up control

m

3.

2/↓

4. Once installed, the

3.5 m

unit will register a low

alarm at 3.50 m from the

m

sensor face.

Loss of Echo

if

retry

Page 12 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 15

Display / Operation Status

reading

output 1

ft

m

output 2

operation

status

Operation Status - Run Mode

- echoes are valid and within range.

-echoes are lost due to poor conditions or out of range.

This may be typical in applications where there are deep

vessels and the material level is normally out of range.

Refer to Troubleshooting.

-extended loss of echo period. Operation has gone into fail-safe.

Refer to Troubleshooting.

↑ key

units

↓ key

program

mode

adjustment

value

m

ft

units

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 13

Page 16

Applications

Pointek ULS 200 is designed for use as a process level switch. The local display is used

only as an aid during start up. The instrumentation interface is comprised solely of the

two relay outputs. Switching applications are based on the relay functions adjustment.

The outputs can be set to function in the desired mode.

Application Function Relay 1 Relay 2

High / Low level switch *1 High Alarm Low Alarm

High level switch with two height alarms 2 High Alarm High Alarm

Low level switch with two height alarms 3 Low Alarm Low Alarm

High level switch with loss of echo alarm 4 High Alarm LOE Alarm

Low level switch with loss of echo alarm 5 Low Alarm LOE Alarm

Pump down control with low level alarm 6 Pump Down Low Alarm

Pump down control with high level alarm 7 Pump Down High Alarm

Pump up control with low level alarm 8 Pump Up Low Alarm

Pump up control with high level alarm 9 Pump Up High Alarm

Pump down control with loss of echo alarm 10 Pump Down LOE Alarm

Pump up control with loss of echo alarm 11 Pump Up LOE Alarm

Pump up control and Pump down control 12 Pump Down Pump Up

Dual pump down control 13 Pump Down Pump Down

Dual pump up control 14 Pump Up Pump Up

* Factory setting

Alarm: the relay de-energizes to set the alarm ‘ON’

Control or Pump: the relay energizes to set the device ‘ON’

Page 14 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 17

High Level Alarm Switch

This application uses Pointek ULS 200 to provide an alarm output, high and/or high-high

alarm, when the process material rises to a high level. The device range applies to its

switching capability, and not the process range of the material.

It is therefore common to apply the switch on vessels where the material is normally

below the unit's range. Under such a condition the Pointek ULS 200 loses echo, and if

prolonged, defaults to fail-safe operation. As this would be a normal occurrence, it is not

advisable to select the fail-safe high option.

If the high level switch is being applied to a vessel within the 3 / 5 m range, a loss of echo

and ensuing fail-safe condition would not be a common occurrence. The fail-safe default

would then be at the user's discretion.

Application Adjustments

alarm function 2 - high / high-high alarm

4 - high / Loss of Echo (LOE)

alarm setpoint set the high and / or high– high alarms to the desired values

fail-safe mode 1 - high, except if the process range is beyond the Pointek ULS 200

operating range (3 / 5 metres)

2 - low

3 - hold

fail-safe = 1, 2 or 3

high-high,

eg. 0.75 m

high,

eg. 1 m

blanking

e.g. 0.5 m

range limit

e.g. 5.5 m

fail-safe = 2 or 3

high-high,

eg. 0.75 m

blanking

e.g. 0.5 m

high,

eg. 1 m

range limit

e.g. 5.5 m

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 15

Page 18

High / Low Level Alarm Switch

This application uses Pointek ULS 200 to provide high and low level alarms. The device

range applies to its switching capability, and not the process range of the material. As

such the low and/or low-low level setpoints must be within the device's range (3 / 5

metres).

If the material can fall below the unit's range, the Pointek ULS 200 loses the echo, and if

prolonged, defaults to fail-safe operation. The fail-safe default should be set to suit the

application.

Application Adjustments

alarm function 1 - high / low alarm

alarm setpoint set the high and/or low alarms to the desired values

fail-safe mode 1 - high

2 - low

3 - hold

fail-safe = 1, 2 or 3

high,

eg. 1 m

low,

low,

e.g. 4.5 m

e.g. 4.5 m

range limit

e.g. 5.5 m

blanking

e.g. 0.5 m

high,

eg. 1 m

low,

e.g. 4.5 m

fail-safe = 2 or 3

blanking

e.g. 0.5 m

range limit

e.g. 5.5 m

Page 16 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 19

Low Level Alarm Switch

This application uses the Pointek ULS 200 to provide one or two low level alarms. The

device range applies to its switching capability, and not the process range of the material.

As such the low and / or low-low level setpoints must be within the device's range (3 / 5

metres).

If the material can fall below the unit's range, the Pointek ULS 200 loses the echo,

and if prolonged, defaults to fail-safe operation. The fail-safe default should be set to

suit the application.

Application Adjustments

alarm function 3 - low / low-low alarm

5 - low / LOE alarm

alarm setpoint set the low and / or low-low alarms to the desired values

fail-safe mode 1 - high

2 - low

3 - hold

low,

eg. 3.5 m

lo w, l ow,

e.g. 4.5 m

fail-safe = 1, 2 or 3

blanking

e.g. 0.5 m

range limit

e.g. 5.5 m

low,

eg. 3.5 m

low, low,

e.g. 4.5 m

fail-safe = 2 or 3

blanking

e.g. 0.5 m

range limit

e.g. 5.5 m

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 17

Page 20

Dual Pump Control

This application uses Pointek ULS 200 to provide a control output when the process

material rises to a high level. The device range applies to its switching capabilities, and

not to the process range of the material. As such, the level setpoints must be within the

device’s range (3 / 5metres).

Typically, wet wells are used to temporarily hold storm and/or waste water. When the

water surface reaches a high level setpoint, the wet well is pumped down. The process

material will be pumped down by the deadband value to another setpoint where the

control will turn off.

Application Adjustments

relay function 6 - high control / low alarm

7 - high control / high alarm

10 - high control / LOE alarm

13 - high control / high control

relay setpoints: set to desired values

deadband values: referenced from relay setpoints

(distance from Pump Start setpoint to Pump Stop setpoint)

Relay Function 13: Dual Pump Down

relay 2

e.g. 0.75 m

relay 1

e.g. 1 m

4 m

deadband 1

e.g. 3 m

deadband 2

e.g. 3.25 m

pump 2 start

pump 1 start

both pumps stop

blanking

e.g. 0.5 m

Page 18 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 21

Pump Control with Level Alarm

This application uses the Pointek ULS 200 to provide pump control and one level alarm.

The device range applies to its switching capability, and not the process range of the

material. As such the low level setpoints must be within the device's range (3 / 5 metres).

If the material reaches a control setpoint, the well is pumped down or up respectively. If

the material reaches an alarm setpoint, the alarm will sound until the material moves

beyond the deadband value.

Application Adjustments

relay function 6 - high control / low alarm

7 - high control / high alarm

8 - low control / low alarm

9 - low control / high alarm

10 - high control / LOE alarm

11 - low control / LOE alarm

alarm setpoint set the low alarm to the desired values

Relay Function 8: Pump Up Control with Low Alarm

relay 1

(pump up)

e.g. 3m

relay 2

(low alarm)

e.g. 3.5 m

deadband 1

e.g. 2 m

deadband 2

e.g. 1 m

pump off

alarm off

pump on

alarm on

blanking

e.g. 0.5 m

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 19

Page 22

Adjustments

There are several operating adjustments that can be made to the Pointek ULS 200.

To access the operating adjustments, simultaneously press both keys repeatedly until the

desired adjustment is obtained. A viewing period of the adjustment value is initiated.

During this time the value can be changed by pressing either the `up' or `down' key. After

viewing or changing, operation automatically reverts to the run mode.

Deadband 2

Blanking

Deadband 1

Delay

Relay 2

Range Limit

Speed of Response

Fail-safe

Fail-safe timer

Relay 1

Units

Page 20 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Relay Function

Page 23

To adjust a value:

1/↑

select adjustment

current value

change value

new value

m

m

m

6 s delay

return to run

m

For faster scrolling, hold the key depressed and

release when the desired value is obtained.

e.g.relay 1

e.g. 0.5 m

e.g. increase to 0.75 m

e.g. new setpoint 0.75 m

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 21

Page 24

Output Function

The alarms can be set to function in the desired mode.

Function Relay 1 Relay 2

1 * high alarm low alarm

2 high alarm high alarm

3 low alarm low alarm

4 high alarm LOE alarm

5 low alarm LOE alarm

6 pump down low alarm

7 pump down high alarm

8 pump up low alarm

9 pump up high alarm

10 pump down LOE alarm

11 pump up LOE alarm

12 pump down pump up

13 pump down pump down

14 pump up pump up

* Factory setting

Function display:

high alarm H

high-high alarm HH

low alarm L

low-low alarm LL

loss of echo alarm LOE

pump up control PU

pump down control PD

high-high

high

low

low-low

Page 22 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 25

Setpoints

The setpoints can be set where reference levels, either from the material in the vessel or

from a target, cannot be provided. This method can also be used to trim the output levels

obtained by the Reference Method (Quick Start).

The setpoints are referenced from the face of the sensor. They should not be set at or

above the blanking value, or at or below the range limit.

Point ek ULS 200

blanking

setpoint

range

limit

Factory Setting: Relay 1 = 0.5 m (1.64 ft)

Relay 2 = 4.50 m (14.76 ft)

Relay Delay

Adjust the time delay, in seconds, from when the material reaches the relay level and the

relay is actuated. If the material level withdraws from the setpoint level, the delay is reset

to 0.

The set time delay applies to both relays and all functions except `Loss OF Echo'.

Factory setting: 0 seconds.

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 23

Page 26

Relay Deadband (Reset)

Deadband (sometimes referred to as hysteresis) prevents relay chatter due to material

level fluctuations at the set point. These fluctuations are often waves or turbulence on a

fluid's surface caused by agitators in the tank.

Once a relay is tripped the detection level must move beyond the deadband value before

it is reset. The direction in which the deadband is measured depends on the application

of the relay. If the relay is for a high state then the deadband is measured below the set

point. If the relay is for a low state then the deadband is measured above the set point.

Refer to the diagram below.

Deadband 1 is used for Relay 1 and Deadband 2 is used for Relay 2.

high / high-high alarm

on setpoint

deadband

off

low / low-low alarm

off

deadband

on setpoint

The deadband value is entered in the units selected, and applies to both relays and all

alarm or control functions except `Loss Of Echo'.

Factory setting: 0.05 m (0.16 ft)

Page 24 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 27

Blanking

Blanking is used to ignore the zone in front of the transducer where false echoes are at a

level that interfere with the processing of the true echo. It is measured outward from the

sensor face. The minimum recommended blanking value is 0.25 m (0.82 ft) but can be

increased in order to extend the blanking.

Point ek ULS 200

blanking

Factory setting: 0.20 m (0.66 ft)

Range Limit

The range limit is the distance at which measurements are ignored. Generally this refers

to the bottom of the container being measured. If a measurement is detected beyond the

range limit it results in a Loss Of Echo (LOE) reading. The result of this reading is

determined by the Fail-Safe Mode, see page 25 for more information.

Pointek ULS 200

range

limit

0 to 3 / 5 m* vessels

Pointek ULS 200

range

limit

greater than 3 / 5 m* vessels

Factory setting: 5.50 m (18.0 ft)

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 25

* solids range 3 m maximum

liquids range 5 m maximum

Page 28

Speed of Response

The speed of response adjustment allows the user to collectively set a number of

operating parameters.

measurement is the limit to which the Pointek ULS 200 is able to keep up with

response: rates of change.

If the Pointek ULS 200 measurement cannot keep up with the

rate of level change, set the adjustment from `1' to `2'.

If the Pointek ULS 200 still cannot keep up with the rate of

level change, set the adjustment option to `3'. Avoid

choosing an option that is too fast for your application.

agitator discriminates between agitator blades in motion

discrimination: and the material (target) surface.

filter: discriminates between false echoes from acoustical

and electrical noise and the material (target) surface.

fail-safe timer: establishes the `Waiting' period from the time a loss

of echo or operating fault condition starts until the

fail-safe default is effected.

SP

1

2*

3

4 immediate off off 3 min

* Factory setting

measurement

response

0.3 m / min

(0.1 ft / min)

1 m / min

(3.3. ft / min)

5 m / min

(16.4 ft / min)

agitator

discrimination

on on 10 min

on on 10 min

on on 3 min

filter FLS timer

Page 26 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 29

Fail-Safe Mode

In the event that a loss of echo condition exceeds the fail-safe timer (speed of response

variable), `?' appears in the display; and if a relay is assigned to `LOE' (alarm function

option), it is engaged. This function must be used with the Output Function on page 22.

fail-safe mode function reading

high and high-high low and low-low

1 high on off hold

2 low off on hold

3* hold hold hold hold

* Factory setting

Fail-Safe Timer

The fail-safe timer allows the user to vary the waiting period from the time of a loss of

echo or operating fault condition begins, until the fail-safe default is effected. The waiting

period is adjustable from 1 to 15 minutes, in 1 minute increments.

Note: The fail-safe timer will default to settings determined by the speed of response

(see page 26). If a different value is desired, the fail-safe timer should be adjusted after

the speed of response is set.

Units

The units of the measurement reading can be selected as follows:

1 = metres, m

2 = feet, ft

The selected units are also applicable to the `Blanking' and `Relay' adjustments.

(Factory setting)

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 27

Page 30

Troubleshooting

The echo is not reliable and Pointek ULS 200 is waiting for a

valid echo before updating the measurement.

Probable causes are: Remedy

material or object in contact with

sensor face

Pointek ULS 200 is not perpendicular to

the material surface

change in level too fast adjust speed of response

material out of range

foam on liquid surface

too much dust or interference from

material filling

high level of vibration in the

mounting structure

material inside blanking zone or

below range limit

lower material level or raise Pointek

ULS 200

check Pointek ULS 200 mounting

if angle of repose is too steep, angle

Pointek ULS 200 mounting

acceptable on some high level switch

applications

mount Pointek ULS 200 via stilling well

or pipe

relocate Pointek ULS 200

relocate Pointek ULS 200 or limit

vibration

adjust blanking or range limit

Fail-safe default after prolonged Loss Of Echo.

Investigate the probable causes listed above.

Page 28 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 31

Maintenance

The Pointek ULS 200 requires no maintenance or cleaning.

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 29

Page 32

Certifications

The following instructions apply to equipment covered by certificate number SIRA

00ATEX1205:

1. The equipment may be used with flammable gases and vapours with apparatus

group IIC and temperature class T5.

2. The equipment is certified for use in an ambient temperature range of -20 to 60°C

(-4 to 140°C).

3. The equipment has not been assessed as a safety related device (as referred to by

Directive 94/9/EC Annex II, clause 1.5).

4. Installation and inspection of this equipment shall be carried out by suitably trained

personnel in accordance with the applicable code of practice (EN 60079-14 and EN

60079-17 in Europe).

5. Repair of this equipment shall be carried out by suitably trained personnel in

accordance with the applicable code of practice (e.g. EN 60079-19 within Europe).

6. Components to be incorporated into or used as replacements in the equipment shall

be fitted by suitably trained personnel in accordance with the manufacturer’s

documentation.

7. The certification of this equipment relies upon the following materials used in its

construction:

Aluminum alloy T356 T6 (main enclosure) and A356 T6 (lid)

GE Lexan 943A polycarbonate

Two-part epoxy encapsulant

Silicon based coating

Santophrene 111-55 gasket

Polysulphide encapsulant (transducer)

Dupont Tefzel 210 (transducer)

Epoxy syntactic foam (transducer)

If the equipment is likely to come in contact with aggressive substances, then it is

the responsibility of the user to take suitable precautions that prevent it from being

adversely affected, thus ensuring that the type of protection is not compromised.

Aggressive substances: e.g. acidic liquids or gases that may attack metals, or

solvents that may affect polymeric materials

Suitable precautions: e.g. regular checks as part of routine inspections or

establishing from the material’s data sheet that it is

resistant to specific chemicals.

Page 30 ULS 200 – INSTRUCTION MANUAL 7ML19981AS01

Page 33

8. Equipment Marking: The equipment marking contains at least the following

information:

PART #:

12345670 89

SERIAL No.:

POWER: 1 8 – 30 V , 3W

RELAY CON TACTS: 5A @, 48 V , N ON – INDUCT IVE

ENCL.: TYPE 6/NEMA 6/IP67

PART #:

SERIAL No.:

POWER: 100 – 230 V ,±

RELAY CONTACTS: 5A @ 250 V , NON – INDUCTIVE

ENCL.: TYPE 6/NEMA 6/IP67

2001 / 12345 6078

1234567089

2001 / 123456078

SIRA certificate 00ATEX1205X

15%, 50–60 Hz, 12VA

SIRA certificate 00ATEX1205X

1234567089

PART #:

SERIAL No. 2001 /

POWER: 18 – 30 V , 3W

ENCL.: TYPE 6/NEMA 6/IP67

TRANSISTOR O/P: 100 mA, 48 V , NON – INDUCTIVE

123456078

SIRA certificate 00ATEX1205X

9. Special Condition for Safe Use: The apparatus must only be supplied from a circuit

containing a suitable rate fuse having a breaking capacity of at least 4000 A.

7ML19981AS01 ULS 200 – INSTRUCTION MANUAL Page 31

Page 34

Page 35

Page 36

www.siemens-milltronics.com

Siemens Milltronics Process Instruments Inc.

1954Technology Drive, P.O. Box 4225

Peterborough, ON, Canada K9J 7B1

Tel: (705) 745-2431 Fax: (705) 741-0466

Email: techpubs@siemens-milltronics.com

Siemens Milltronics Process Instruments Inc. 2003

Subject to change without prior notice

Rev. 1.2

*7ml19981AS01*

Printed in Canada

Loading...

Loading...