Page 1

Instruction Manual February 2004

smartlinx interface module

MODBUS RTU

Page 2

Safety Guidelines

Warning notices must be observed to ensure personal safety as well as that of others, and to

protect the product and the connected equipment. These warning notices are accompanied

by a clarification of the level of caution to be observed.

Qualified Personne l

This device/system may only be set up and operated in conjunction with this manual.

Qualified personnel are only authorized to install and operate this equipment in accordance

with established safety practices and standards.

Warning: This product can only function properly and safely if it is correctly transported,

stored, installed, set up, operated, and maintained.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2004. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to

purchase authorized bound manuals, or to view

electronic versions as designed and authored by

Siemens Milltronics Process Instruments Inc.

Siemens Milltronics Process Instruments Inc. will

not be responsible for the contents of partial or

whole reproductions of either bound or electronic

versions.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

Contact SMPI Tech nical Publications at t he following address:

Technical Publications

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs@siemens-milltronics.com

While we have verified the contents of

this manual for agreement with the

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The

contents of this manual are regularly

reviewed and corrections are included

in subsequent editions. We welcome

all suggestions for improvement.

Technical data subject to change.

For the library of SMPI instruction manuals, visit our Web site: www.siemens-milltronics.com

© Siemens Milltronics Process Instruments Inc. 2004

Page 3

Table of Contents

About this Module .......................................................................................................................................1

Typical Modbus RTU RS-485 System .................................................................................................1

Typical Modbus RTU RS-232 System .................................................................................................2

About this Manual .......................................................................................................................................3

Specifications ...............................................................................................................................................4

Installation ......................................................................................................................................................5

Compatibility .............................................................................................................................................5

Module Outline ........................................................................................................................................5

Termination Switch .................................................................................................................................6

Port Configuration ...................................................................................................................................6

Reserved Switch ......................................................................................................................................6

Cable Connection ....................................................................................................................................7

Operation .........................................................................................................................................................9

Status LEDs ...............................................................................................................................................9

Initialization LED ......................................................................................................................................9

Communications Setup ..........................................................................................................................10

General .....................................................................................................................................................10

Specific Parameters .............................................................................................................................10

Application Layer ......................................................................................................................................12

Parameter Indexes ................................................................................................................................12

How Modbus RTU Works ....................................................................................................................13

Register Mapping ..................................................................................................................................14

Data Access Methods ..........................................................................................................................15

Register Map – Level Products .........................................................................................................17

Data Types ...............................................................................................................................................21

Modbus RTU Error Codes ...................................................................................................................24

Troubleshooting ..........................................................................................................................................25

Generally .................................................................................................................................................25

Specifically ..............................................................................................................................................25

Wiring Guidelines .....................................................................................................................................26

i

Page 4

ii

Page 5

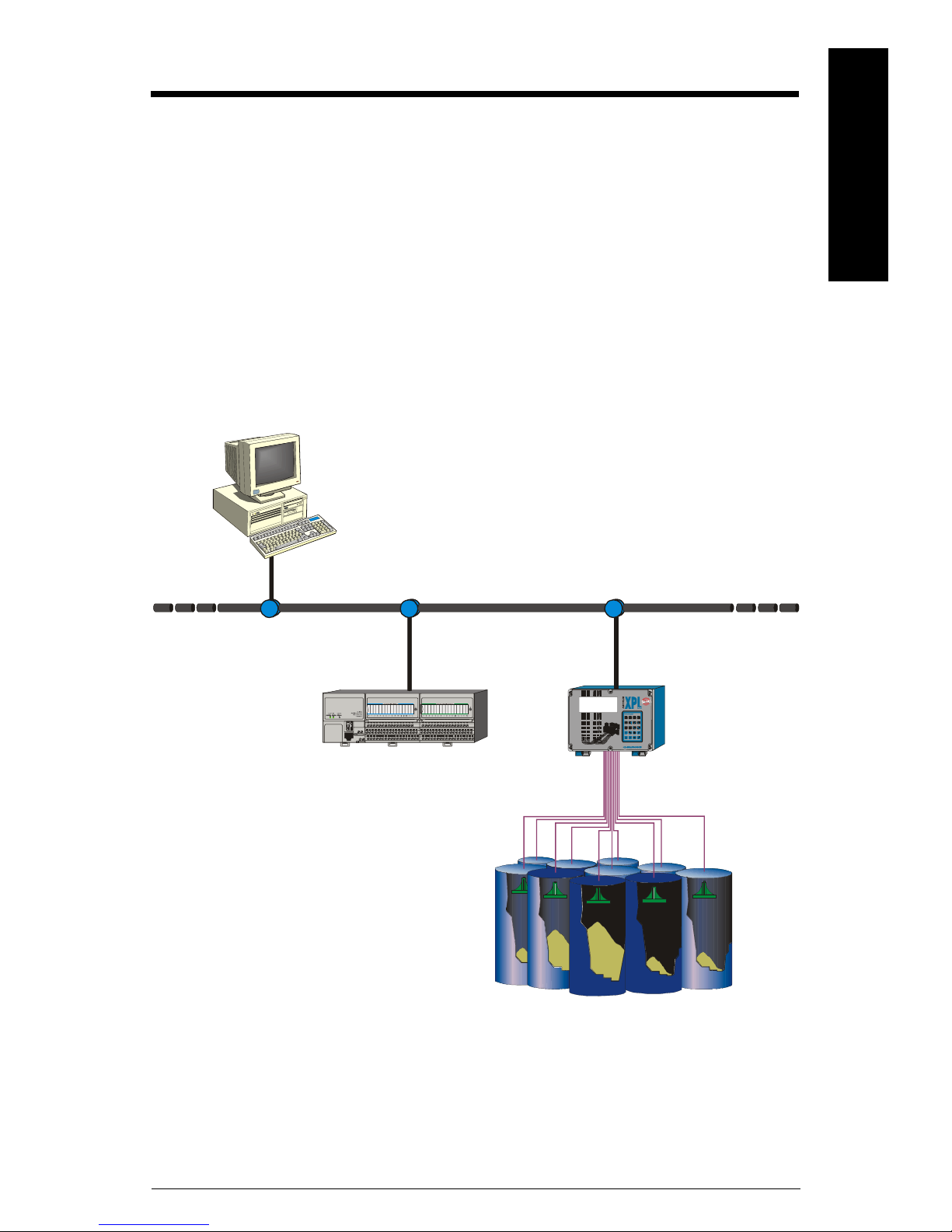

About this Module

About this Module

The Milltronics SmartLinx®Modbus® RTU Module plugs into a compatible Milltronics

instrument to allow connection to any Modbus RTU master controller.

Modbus RTU is an industry standard protocol that is supported by many different

instruments. A brief description of the protocol and the Milltronics memory map are

outlined in Modbus RTU Protocol section of this manual (see page 20).

Only those instruments which support the SmartLinx Modbus RTU module can use this

card. See Specifications on page 5 for a list of compatible instruments.

Typical Modbus RTU RS-485 System

mmmmm

®.

Modbus is a registered trademark of Schneider Electric.

1234

5

mA

9

C

6078

PP

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 1

Page 6

mmmmm

About this Module

Typical Modbus RTU RS-232 System

1234

5

6078

mA

9

PP

C

Page 2 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 7

About this Manual

This manual is intended to provide the user with the information required to successfully

install and connect a Milltronics SmartLinx Modbus RTU module and set it up for

communication within a Modbus RTU network.

This manual is targeted to a technical audience in the industrial communications field

with a sound working knowledge of Modbus RTU.

Modbus RTU is an industry standard protocol owned by Schneider Electric and is used

throughout process control industries for communication between instruments, including

those manufactured by Milltronics, and controllers, such as PLCs and PCs.

A brief description of Modbus RTU is given in this manual. For a full description of the

Modbus RTU protocol, contact Schneider Electric or visit their website at

www.modicon.com

Note: Milltronics does not own the Modbus RTU protocol. All information regarding

that protocol is subject to change without notice.

If you have any questions, comments, or suggestions about the manual contents, please

email us at techpubs@siemens-milltronics.com.

.

About this Manual

mmmmm

For the complete library of Siemens Milltronics manuals,

go to www.siemens-milltronics.com

.

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 3

Page 8

Specifications

Application:

• compatible with Modbus RTU masters that use function codes 03, 06, 16

Compatible Instruments:

• AiRanger XPL Plus/SITRANS LU 10

• AiRanger DPL Plus/SITRANS LU 02

• AiRanger SPL/SITRANS LU 01

•CraneRanger

• InterRanger DPS 300

Communication Settings

• baud rate: 1200, 2400, 4800, 9600, 19200, 38400 bps

• parity: none, odd or even

• stop bit: 1 or 2

• data bits: 8

• hardware flow control: none

Connection:

• 6-position screw terminal

Termination:

mmmmm

• RS-485 switch selectable, open or 110 Ω internal

Cable:

Specifications

• for RS-232 connection use cable consistent with the RS-232 standard

• for RS-485 connection use cable consistent with the RS-485 standard

(see Wiring Guidelines on page 26 for more suggestions)

Page 4 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 9

Installation

The SmartLinx module may have been shipped installed in your unit, or separately for

onsite installation. Refer to the manual for the Milltronics SmartLinx instrument for

details on module location and physical installation.

Compatibility

AiRanger Series

• AiRanger XPL Plus/SITRANS LU 10

• AiRanger DPL Plus/SITRANS LU 02

• AiRanger SPL/SITRANS LU 01

•CraneRanger

• InterRanger DPS 300

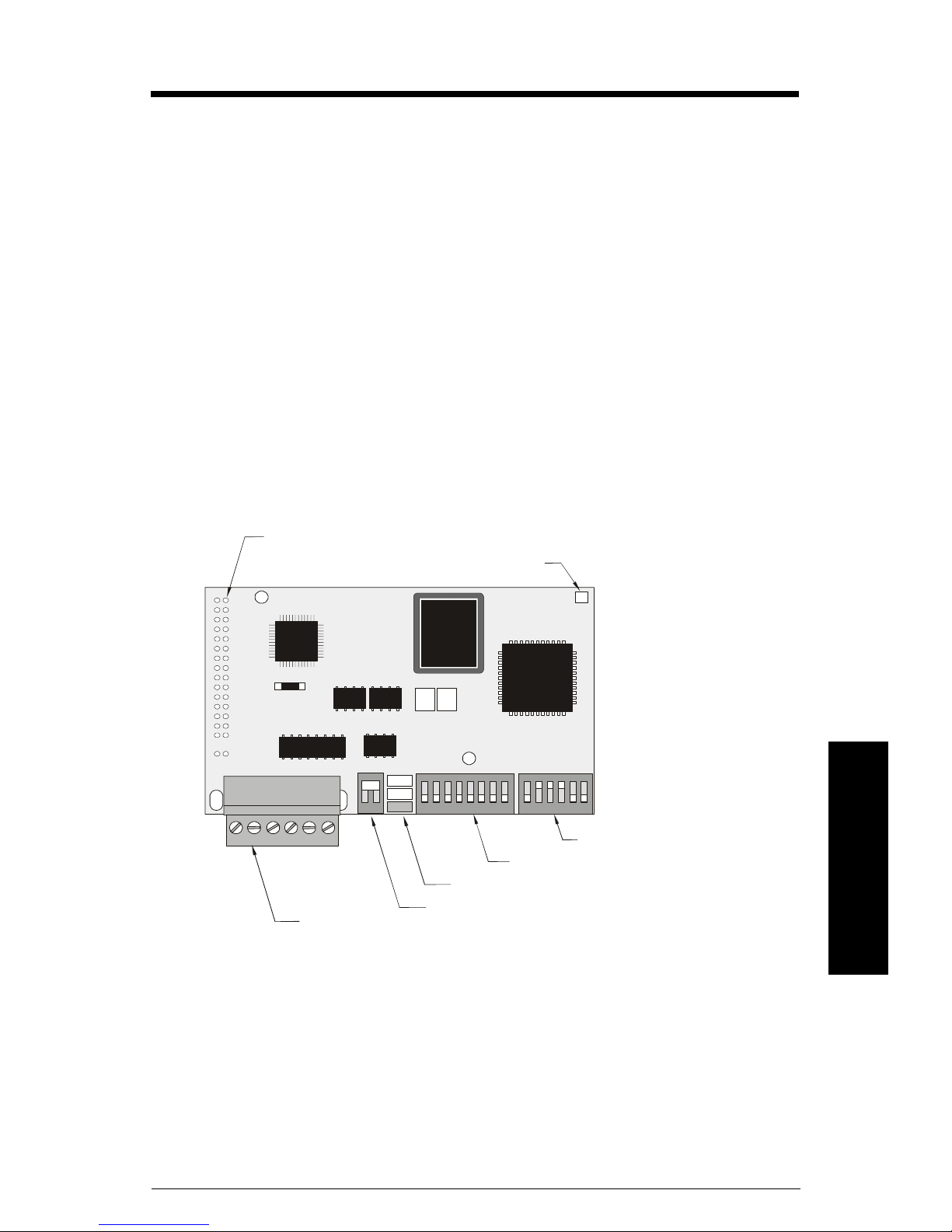

Module Outline

module connector (underside) to

Milltronics instrument

cable connector

to host

initialization LED

status LEDs

termination switch

1.6 m

reserved

port configuration

Installation

mmmmm

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 5

Page 10

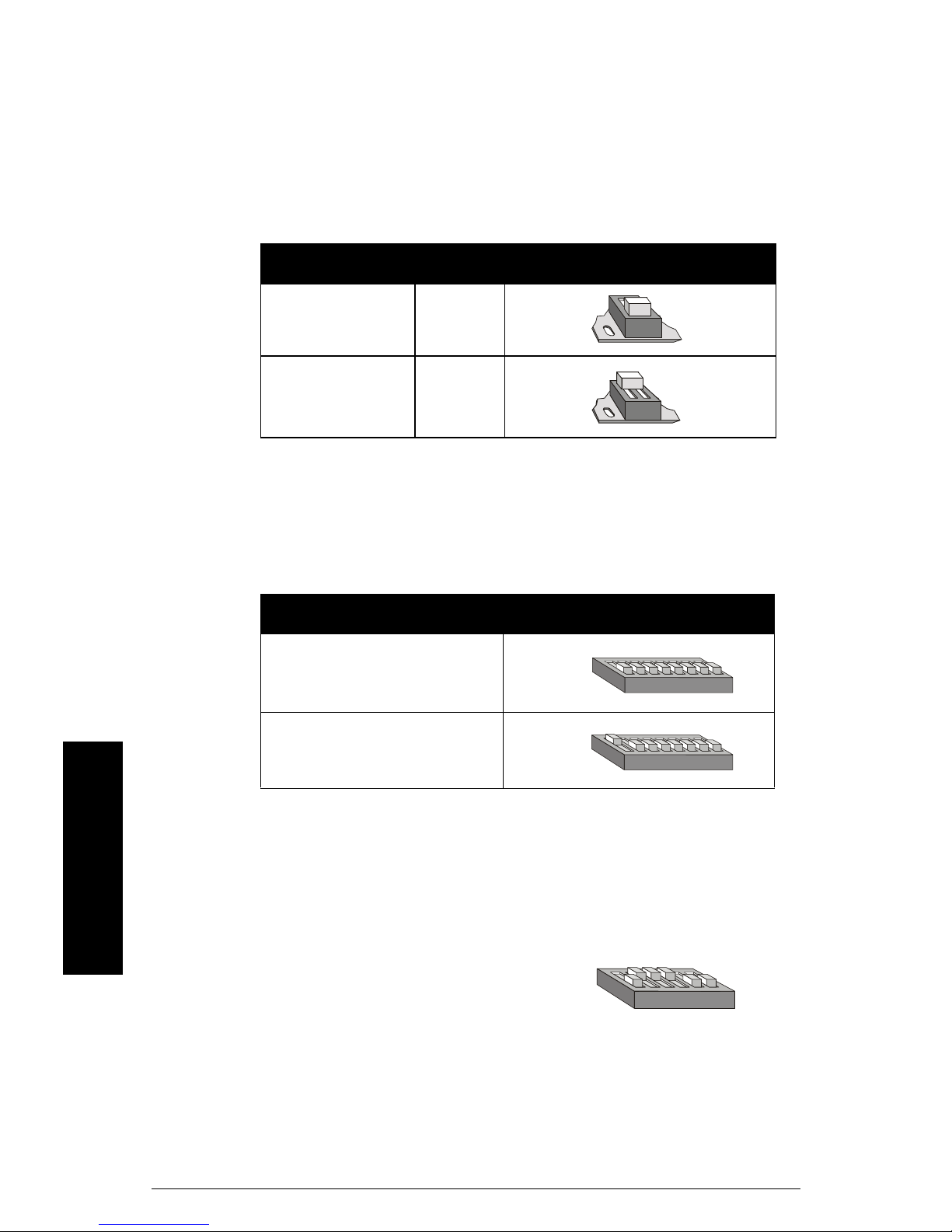

Termination Switch

Termination is generally of concern when communicating at higher baud rates, and when

the Milltronics host instrument is the unique or terminating slave.

If the 110 Ω switched termination is inappropriate, set the switch to open and connect an

appropriate resistor across terminals 4 and 5.

termination setting

open off

110 Ω on

Port Configuration

Switch one configures the port for either RS-232 or RS-485 transmission.

transmission dip switches

ON

RS-232

18

ON

RS-485

18

Reserved Switch

mmmmm

Installation

These switches are reserved and must be left in their factory setting.

ON

Page 6 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

16

Page 11

Cable Connection

Note: No hardware flow control is used.

RS-232 Connection PC Connection

SmartLinx Modbus

RTU

RS 232

RX

TX

GND

253

customer instrument

9-pin D-shell 25-pin D-shell

RS-232 Connect to Modem

SmartLinx Modbus

RTU

A

RS 485

B

RS 232

RX

SHLD

TX

654321

273

RS 485

GND

A

SHLD

B

654321

modem

Note: When using a modem, set the value of P758 to 15. See page 18.

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 7

RX

RS 232

TX

RS 485

GND

A

SHLD

B

RX

654321

253

9-pin D-shell 25-pin D-shell

RS 232

TX

RS 485

GND

A

SHLD

B

Installation

654321

273

mmmmm

Page 12

RS-485 Connection

SmartLinx Modbus

RTU

RX

RS 232

TX

RS 485

GND

A

SHLD

B

6543

Connect ground as required.

B

Refer to page 12 for termination.

Customer instrument

2

1

A

SG

Use a quality dual twisted pair shielded cable, such as Belden 9842, (120 Ohms and less

than 17 pf per foot). Sometimes A is marked "-" and B is marked "+". Do not connect A to B

(or - to +) on an RS-485 link or it will not work. (This is a common error.) SG refers to signal

ground; the cable shield must be kept separate and be connected to earth at one end

only.

Note: For multidrop applications, pin 6 can be used to continue the shield. This

terminal is not connected internally to anything.

mmmmm

Installation

Page 8 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 13

Operation

Communication on the Modbus RTU network is indicated by four SmartLinx LEDs. Three

of the LEDs are grouped together at the bottom centre of the module and the other is

located on the upper right of the module.

Status LEDs

Green LED

• blinks as the module is initialized

• remains ON to indicate module is ready

Green LED

• blinks as the module is initialized

• turns ON when the first Modbus RTU

command is received

• flickers as additional Modbus RTU

commands are received

Initialization LED

Red LED

• blinks as the module is initialized

• indicates module failure (replace

module):

• flashes 4 times per second to

indicate a DPRAM fault

• flashes 2 times per second to

indicate a ROM fault

• flashes once per second to indicate

a RAM fault

LED

• blinks orange as the module is initialized

• flashes green during normal operation

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 9

Operation

mmmmm

Page 14

Communications Setup

mmmmm

General

The following parameters must be defined in the Milltronics instrument to establish

successful communication. Instructions on how to set these parameters are found in the

Communications Setup

associated instrument manual.

Notes:

•f denotes factory setting.

• The SmartLinx module only supports 8 data bits, and no hardware flow control.

• For odd or even parity, use 1 stop bit. For no parity, use two stop bits (as per

Modbus RTU specification).

Specific Parameters

P751 Baud Rate

Sets the baud rate according to the table:

0=1200 bps

1=2400 bps

2=4800 bps

3=9600 bps

4 = 19200 bps

5 = 38400 bps

f

P752 Parity Mode

Sets the parity mode according to the table:

0=no parity

1=odd parity

2=even parity

f

P753 Slave Address

Sets the slave address. Valid address range is 1 to 247 (factory setting is 1).

Page 10 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 15

P758 Interframe Spacing

The silent time expected, in milliseconds, between two adjacent data packets.

Communications Setup

Note: When a modem is being used, set this parameter to a value of 15. See page 13

for more information on configuring a modem.

A value of zero “0” selects the traditional 3 and half characters (recommended) as the

time interval that separates one command from the next.

Any value from 1 to 32 specifies the time in milliseconds. A value of 33 specifies the

highest possible value of 32.678 ms.

Values:

0 to 33

Preset: 0

mmmmm

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 11

Page 16

Application Layer

Modbus RTU is an industry standard protocol owned by Schneider Electric and is used

throughout process control industries for communication between instruments. Modbus

RTU is a master-slave type protocol. An instrument with a SmartLinx Modbus RTU is a

slave unit.

not

SmartLinx Modbus RTU only supports the RTU mode of Modbus, and

A brief description of Modbus RTU is given in this manual. For a full description of the

Modbus RTU protocol, contact Schneider Electric or visit their website at

www.modicon.com

ASCII.

mmmmm

Parameter Indexes

Most parameters used on Milltronics SmartLinx instruments are indexed. Indexing allows

Application Layer

a parameter to relate to more than one input or output. For example, some parameters

are indexed by measurement point while others are indexed by relay or discrete input.

An index that relates to an input or output is called a Primary Index.

Example of a primary index:

P111[3] = 50 (Relay Control Function for relay 3 = 50, pump control)

P111

[1] [2] [3] [4] [5]

Sometimes a parameter requires a second index to allow for multiple values on an

indexed input or output. For example a measurement point which calculates a reading on

volume can require characterization breakpoints.

These breakpoints are given on a secondary index (the primary index relates to the

transducer input).

An index that relates to a previously indexed parameter is called a secondary index.

Page 12 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 17

Examples of secondary indexes are:

P054[1,5] = P054 (Breakpoint Levels) for breakpoint 5 on transducer 1 = 1.6 m

P054

[1] [2] [3] [4] [5]

[1]

[2]

[3]

[4]

[5]

[6]

1.6 m

The way that indexes are handled in the memory map depends on the data access

method used.

How Modbus RTU Works

As mentioned previously, Modbus RTU is a master-slave type protocol. Sometimes this is

referred to as a query-response protocol. These terms mean is that on the network, there

is one master which requests information from the slave instruments. This is done using

a “function code” which indicates the information or the action being requested. The

slave instruments are not permitted to talk unless they have been asked for information.

When responding, the slave will either give the information that the master has

requested or send back an error code which would either say why it cannot give the

information or that it did not understand the request.

Application Layer

mmmmm

Modbus RTU was designed for communication between PLCs and sensing instruments.

Therefore the protocol makes reference to inputs, outputs, coils, registers, and forcing.

For our purposes, everything has been mapped into holding registers so that Modbus

RTU function code 03 can read them and Modbus RTU function codes 06 and 16 can write

to them.

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 13

Page 18

To give you a better idea of how a Modbus RTU message works, a master on network

would send a message in a format similar to this:

Slave

Address

Function

Code

Information

Error

Check

Where:

Slave Address

Function Code

SmartLinx supports function codes 03, 06, and 16.

Information

mmmmm

Error Check

There is more to the frame than is described above; this is shown to give the user a

Application Layer

general idea of what is going on. For a full description, please refer to the Modbus RTU

specifications.

the network address (P753) of the slave you are talking to.

number that represents a Modbus RTU command. As described above,

register data, depending on the function code.

cyclical redundancy check (CRC).

Register Mapping

SmartLinx Modbus RTU only works with the compatible Milltronics SmartLinx

instruments (see page 5). These instruments range from one to 10 points of

measurement. As such, this manual covers the maximum 10 point measurement

capability. If your instrument has fewer than 10 points, ignore data in registers associated

to non-existing points of measurement. These registers are present but they contain

undefined values.

Note: Parameter P999 (Master Reset) is not accessible via the SmartLinx interface.

Page 14 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 19

Data Access Methods

Modbus master units may be PLCs, PCs or DCS controllers. By issuing appropriate

commands, a controller can access data in three different ways.

Note: The design of the SmartLinx module requires that a maximum delay of 0.1

seconds between the time that the master writes a value to the time that it can read

the response. Ensure that the master device takes this delay into account.

Direct Access

Common values are mapped directly into registers.

Multiple Parameter Access (MPA)

This is a hand-shaking method where the Modbus RTU master requests the parameter

number, secondary index, decimal place, and format, and then the SmartLinx module

writes all 10 primary indexes of that parameter into the mapped registers. The PLC can

then read these values. (Recall that in Milltronics products, the memory is arranged as

parameter number, primary index, secondary index).

Note: MPA values are only updated in Run mode.

Using Multiple Parameter Access (MPA)

Words 40032 through 40035 are used for MPA, allowing continuous monitoring in words

40022 through 40031 of selected parameters for points 1 to 10. Using these words does

not allow the changing of parameter values.

1. Write the values into words 40032 through 40035 that define the requested

information.

2. Monitor the address variables. When the values returned match those that were

written, go to step 3.

3. Read the requested values in words 40022 through 40031. These values are

continuously updated. Continue reading from these words until new values are

required. At that time, go back to step 1.

Application Layer

mmmmm

Single P arameter Access (SPA).

This is a hand-shaking method where the PLC requests the parameter number, primary

index, secondary index, decimal place, format, read/write flag, and value, and then the

SmartLinx module either reads or writes the value. With this method any value in the

Milltronics product can be read or written.

Using Single Parameter Access (SPA)

Words 40036 through 40043 are used for SPA, allowing continuous monitoring or demand

programming of a parameter for a given indexed measurement point, individually

selected for each point.

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 15

Page 20

Reading a Parameter

1. After setting word 40043 to 0 (read) write the required parameter information to

words 40038 through 40042.

2. Monitor the address variables that are reflected back. When the values returned

match those that were written, go to step 3.

3. Read the requested value from word 40036. This value is continuously updated.

Continue reading from this word until a new value is required. At that time, go back

to step 1.

Writing a Parameter

1. Write the required parameter information to words 40038 through 40042, the new

value in word 40037 and set word 40043 to 1 (write).

2. Monitor the address variables. When the values returned match those that were

written, your write is proceeding.

mmmmm

3. Read the value in word 40036 to confirm that the correct value has been written.

4. Set word 40043 back to 0 (read).

Application Layer

Note: Parameters should only be written in Program mode. Ensure word 40044 = 1.

Page 16 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 21

Register Map – Level Products

Registers Description Access Data Type

400 01 point status (read only)

400 02 to 40011 point reading (read only) integer

40012 to 40021 point alarm and status (read only) bitmapped

40022 to 40031 returned values (read only)

40032 parameter number integer

40033 secondary index integer

40034 decimal place integer

40035 format integer

40036 current value (read only)

40037 new value integer

40038 parameter number integer

40039 secondary Index integer

40040 primary Index integer

40041 decimal place integer

40042 format 0/1

40043 write flag 0/1

40044 operating mode

40045 point on priority bitmapped

direct

MPA

SPA

direct

bitmapped

integer

integer

0/1

Application Layer

mmmmm

R40001: Point Status (read only)

bit Description

00 to 09:

10:

11 to 15:

Point Status

Indicates the operation of the points 1 to 10.

bit

point

09 08 07 06 05 04 03 02 01 00

10 987654321

If a bit status is 0, the corresponding point is deemed to be

operational based on the criteria defined by R40012 to R40021, bits

01 to 04. If the bit status is 1, then the corresponding point is deemed

non-operational. To further diagnose a point’s operation, examine

the corresponding point alarm and status R40012 to R40021.

If a bit status is 1, then for the corresponding point alarm word, one

or more of the alarm bits 01 to 04 are also 1 to indicate the

operational problem.

Operating Mode

0 = instrument in Run mode

1 = instrument in Program mode

Reserved

These bits are undefined.

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 17

Page 22

R40002 to R40011: Point Reading (read only)

These words contain the value of parameter P920 (Reading) for points 1 to 10,

respectively. The reading is expressed as a percent of full scale, multiplied by 100, giving

a range of -20,000 to 20,000 which corresponds to –200.00% to 200.00%. Refer to the

Milltronics’ instrument documentation for a definition of ‘P920’.

Note that these values may contain numeric level data for inoperative or malfunctioning

points; refer to R40001 point status, and R40012 to R40021 point alarm and status for the

actual operational status of the measurement points.

R40012 to R40021: Point Alarm and Status (read only)

These words contain the corresponding alarm and status bits for point 1 to 10. So

R40012 = measurement point 1 and R40021 = measurement point 10.

mmmmm

Application Layer

Bit status:

0 = false

1 = true

bit description

00 point not in operation

01 point failsafe timer expired

02 point failed (cable shorted, open, or transceiver problem)

03 point temperature sensor failed

04* Low-Low Alarm (1=ON)

05* Low Alarm (1=ON)

06* High Alarm (1=ON)

07* High-High Alarm (1=ON)

08-12 reserved for future use

13 level emptying

14 level filling

15 scan mode priority

*Available in version 5.19 or above

R40022-R40031: Returned Values, MPA (read only)

These words contain values requested by writing to R40032 to R40035. The type of data

and format are specified with that request (see below). In this, the index number 1 to 10,

corresponds to R40022 to R40031. So R40022 = measurement point 1 and R40031 =

measurement point 10.

R40032: Parameter Number, MPA

Specifies the parameter number for the returned value in R40022 to R40031.

Page 18 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 23

R40033: Parameter Secondary Index, MPA

Specifies the parameter index for the value returned in R40022 to R40031. This word is

ignored for parameters which don’t use indexes.

Some specific Milltronics instrument parameters use indices to address the multiple

values stored within the single parameter. See Parameter Indexes on page 12 for details.

Note: The primary index is implicit in the word location where register 40022 = index

1 and register 40031 = index 10.

R40034: Decimal Place, MPA

Specifies the number of decimal places that the returned values are shifted. This affects

words R40022 to R40031.

Positive values indicate that the decimal place shifts to the left.

i.e. A 1 means that all returned values have the decimal place shifted 1 space to the

left and a returned value of 5,213 is interpreted as 521.3.

Negative values indicate that the decimal place shifts to the right.

i.e. for example if this word is -1, a returned value of 5,213 is interpreted as 52,130.

R40035: Format, MPA

This word sets the format for the returned values.

Values:

0 = normal

1 = percent of span

Application Layer

mmmmm

R40036: Current Value, SPA (read only)

This word is the current value of the parameter specified in the SPA area R40038 to

R40042.

R40037: New Value, SPA

This is the new value for the parameter specified in R40038 to R40042. To verify the write

check that R40036 returns the value that was written here.

Word R40043 must be set to “1” to enable the write.

R40038: Parameter Number, SPA

Specifies the parameter number.

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 19

Page 24

R40039: Parameter Secondary Index, SPA

Specifies the secondary index for the parameter specified by R40038. This word is

ignored for parameters which do not use multiple indexes. See Parameter Indexes on

page 12 for details.

R40040: Parameter Primary Index, SPA

Specifies the primary index number for the parameter specified by R40038. See

Parameter Indexes on page 19 for details.

R40041: Decimal Place, SPA

Specifies the number of decimal places that the returned values are shifted. This affects

mmmmm

words R40037 and R40036.

Positive values indicate that the decimal place shifts to the left.

Application Layer

i.e. A 1 means that all returned values have the decimal place shifted 1 space to the

left and a returned value of 5,213 is interpreted as 521.3.

Negative values indicate that the decimal place shifts to the right.

i.e. for example if this word is -1, a returned value of 5,213 is interpreted as 52,130.

R40042: Format, SPA

This word sets the format for the value in R40036, R40037.

Values:

0 = normal

1 = percent of span

R40043: Read / Write Flag, SPA

This word determines whether the master system is reading a value from R40036 or

writing a value to R40037. It is good practice to confirm the write by reading current value

R40036 and then reset this register to zero.

Values:

0 = read parameter value in R40036

1 = continually write new value to R40037 until reset to 0

Page 20 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 25

R40044: Operating Mode

This word sets the operating mode of the Milltronics SmartLinx instrument. The

instrument changes mode only when the status of the bit changes.

The operating mode is also set via the instrument keypad.

Bit status

0 = run mode

1 = program mode

R40045: Point-on-Priority

Bits 00 to 09 set the priority status of corresponding points 1 to 10.

bit

point

Bit status

0 = normal

1 = priority

e.g.

bit

status

…shows that measurement points 3 and 1 are on priority scan

All other bits are reserved and should contain 0.

09 08 07 06 05 04 03 02 01 00

10 987654321

09 08 07 06 05 04 03 02 01 00

0 000000101

Application Layer

mmmmm

If this word is used to control point-on-priority, then the Milltronics instrument must be

configured to permit this. Parameter P720 must be set to 1 (manual, SmartLinx) for each

point to permit priority control for that point. To enable priority control for all points, store

‘1’ to parameter P720, point ‘0’.

Data Types

The Milltronics instrument parameters take on many values in various formats, as

discussed in the Milltronics SmartLinx instrument manual. For the convenience of the

programmer, those values are converted to and from 16-bit integer numbers, since those

are easily handled by most PLCs.

Integer

Integer parameter values are by far the most common. For example, parameter P920

(Reading), returns a number representing the current reading (either level or volume,

depending on the Milltronics SmartLinx instrument configuration).

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 21

Page 26

Numeric values may be requested or set in either units or percent of span, and may be

specified with a number of decimal places.

Numeric values must be in the range -20,000 to be +20,000 to be valid. If a parameter is

requested and its value is more than +20,000, the number 32,767 is returned; if it is less

than -20,000, the number -32,768 is returned. If this happens, increase the number of

decimal places for that parameter.

If a parameter cannot be expressed in terms of percent (e.g. span), or has no meaningful

value, the special number 22,222 is returned. Try requesting the parameter in units, or

refer to the Milltronics host instrument manual to understand the format and use of the

requested parameter.

Bit Values

Bits are packed into registers in groups of 16 bits (1 word). In this manual we number the

mmmmm

bits from 0 to 15, with bit 0 being the least significant bit and bit 15 referring to the most

significant bit.

Application Layer

Split Values

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

MSB LSB

Certain parameters are actually a pair of numbers separated by a colon, in the format

xx:yy.

One example is P807, Transducer Noise, where:

xx = the average noise value in dB.

yy = the peak noise in dB.

The number which corresponds to xx:yy, either for reading or setting a parameter, is

determined by the following formula:

For storing to the Milltronics instrument:

value = (xx + 128) x 256 + (yy + 128)

For reading from the Milltronics instrument:

xx = (value / 256) – 128

yy = (value % 256) – 128

Where:

% is the modulus operator.

The modulus can be computed by following these steps:

= value / 256

value

1

= remainder of value

value

2

value3 = value2 x 256

yy = value

Page 22 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

- 128

3

1

Page 27

It may simplify programming to notice:

xx = (most significant byte of value) – 128

yy = (least significant byte of value) – 128

Text Messages

Note: Used for Level products only.

If a Milltronics instrument parameter returns a text message, that message is converted

to an integer and provided in the register. The numbers are shown in the table below:

Application Layer

Number Text Message as displayed on LCD

22222 invalid value

30000 off

30001 on

30002 ≡ ≡ ≡ ≡

300 03 (parameter does not exist)

30004 err

30005 err1

30006 open

30007 shrt

30008 pass

30009 fail

30010 hold

30011 lo

30012 hi

30013 de

30014 en

30015 (parameter has not been set)

-32768 value is less than -20,000

32767 value is greater than 20,000

mmmmm

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 23

Page 28

Relay Function Codes (P111 Only)

Note: Used for Level products only.

If a Milltronics instrument parameter returns a relay function code, that message is

converted to a number and provided in the register. The numbers are shown in the table

below:

Relay Function Code Number P111 =

Off, relay not used 0 0

Undesignated Level Alarm 1 1

Low-Low Level Alarm 2 1 – LL

Low Level Alarm 3 1 – L

High Level Alarm 4 1 – H

High-High Level Alarm 5 1 – HH

mmmmm

Application Layer

In Bounds Alarm 6 2

In Bounds Alarm 7 2 – b1

In Bounds Alarm 8 2 – b2

Out of Bounds Alarm 9 3

Out of Bounds Alarm 10 3 – b1

Out of Bounds Alarm 11 3 – b2

Rate of Level Change Alarm 12 4

Rate of Level Change Alarm 13 4 – r1

Rate of Level Change Alarm 14 4 – r2

Temperature Alarm 15 5

Loss of Echo (LOE) Alarm 20 6

Transducer Cable Fault Alarm 16 7

Non-sequenced Pump Control 25 50

unknown function 200

Note: See the manual for the host instrument for full information on P111.

Modbus RTU Error Codes

With the memory map shown in Register Map – Level Products on page17, if the user

tries to write to a read only register, no error code will be generated and the value will be

ignored. If the user tries to access an invalid parameter to write a read only parameter by

using MPA or SPA, then no error code will be generated and for the read, a value of some

sort will be returned, for a write, the value will be ignored.

If the host used an unsupported function code, undocumented results may occur. The

error should be “01” but this is not guaranteed. The host should not do this.

Page 24 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 29

Troubleshooting

Generally

In all cases, first check that the SmartLinx Modbus RTU Module has passed its on-going

built-in self test (instrument parameter P790). The result should be PASS.

If FAIL is indicated, either the module is defective, or the module connector on the

Milltronics instrument is defective.

If ‘ERR1’ is indicated, the Milltronics software doesn’t recognize the ID number of the

installed module. Please contact Milltronics or your distributor for instructions and/or

upgraded Milltronics SmartLinx compatible instrument software.

Specifically

Q1: I tried to set a Milltronics instrument parameter using a SPA write, but the

parameter remains unchanged.

A1.1: Some parameters can only be changed when the Milltronics instrument

isn’t scanning. Try putting the Milltronics instrument in program mode,

using operating mode R40044.

A1.2: Try setting the parameter from the keypad. If it can’t be set using the

keypad, check the lock parameter (P000).

Q2: I have communications, but periodically the Modbus master gets a series of

Modbus time out errors, and the red LED on the SmartLinx module comes on.

A2.1: Check the configuration of the SmartLinx module and if you are using no

parity (P752), then verify that the Modbus master is set for two stop bits.

A.2.2: Consult your Milltronics representative.

Q3: I’ve connected using RS-485 and checked all the communications parameters and

wiring, and I’m still not getting communication.

A.3.1 Check to make sure that the RS-485 A line at the Milltronics SmartLinx

instrument is connected to the A line at the master, and that the B line is

connected to the B line.

Troubleshooting

mmmmm

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 25

Page 30

Wiring Guidelines

The improper wiring and improper chose of cables is one of the most common sources of

communication problems. Listed below are some comments that should help:

• Length (maximum):

• 15 meters (50 feet) for RS-232

• 1200 meters (4000 feet) for RS-485

• make sure that communication cable is run separately from power and control

cables (i.e. do not tie wrap your RS-232 cable to the 120 V AC power cable or have

them in the same conduit)

• cable is shielded, and the cable should be connected to ground at one end of the

cable only

• 24 AWG (minimum)

• follow proper grounding guidelines for all instruments on the LAN

• use good quality, communication grade (shielded, twisted pairs) cable that is

recommended for the RS standard that you are using

mmmmm

Wiring Guidelines

Page 26 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 31

Index

A

About this Manual ............................................3

About this Module ............................................1

Typical RS-232 System

Typical RS-485 System ..........................1

Address .....................................................10, 14

AiRanger DPL Plus

AiRanger Series ................................................5

AiRanger DPL Plus ...........................4, 5

AiRanger SPL

AiRanger XPL Plus ...........................4, 5

CraneRanger .....................................4, 5

InterRanger DPS 300

AiRanger SPL ..............................................4, 5

AiRanger XPL Plus .....................................4, 5

Application Layer

Data Access ......................................... 15

How Modbus RTU Works .................. 13

Parameter Indexes

Register Mapping ................................ 14

Audience ............................................................3

................................................................. 26

AWG

.....................................4, 5

....................................4, 5

.......................................... 12

..........................2

.......................4, 5

.............................. 12

B

Baud rate ............................................................4

Baud rate (P751) ............................................ 10

Bit Values

........................................................ 22

C

Cable ............................................................4, 26

Length ..................................................... 26

........................................................ 26

Type

Cable Connection See Connection ..............7

Cable See Wiring Guidelines

Communication parameters

Communication Settings

Baud rate

Hardware flow control ..........................4

Parity

Stop bit

Communications Setup ................................ 10

Specific Parameters

Compatible Instruments

Connection ...................................................4, 7

RS-232

RS-485

CraneRanger

Current Value ................................................. 19

..................................................4

.........................................................4

......................................................4

.......................................................7

.......................................................8

............................................... 4, 5

........................4

....................... 10

................................4

........................... 10

...........................4, 5

D

Data Access ....................................................15

Direct Access ........................................15

Multiple Parameter Access

Single Parameter Access ..................15

Data bits .............................................................4

Data Types

Decimal Place

Delay .................................................................15

Direct Access ..................................................15

.......................................................21

Bit Values ...............................................22

Integer .....................................................21

P111 Values

Split Values .............................22, 23, 24

Text Messages .....................................23

...........................................24

......................................... 19, 20

...............15

E

Error Check ......................................................14

Error Codes ......................................................24

F

Factory setting .......................................... 6, 10

Format

Function Code .................................................14

.......................................................19, 20

H

Hardware flow control ....................................4

I

Indexes .............................................................12

Primary ...................................................12

Secondary ..............................................12

Information

Installation .........................................................5

Integer ..............................................................21

Interconnection See Connection

Interframe spacing

InterRanger DPS 300

......................................................14

.................7

........................................11

................................. 4, 5

L

LEDs .....................................................................9

Initialization

Status

Level Products ........................................ 23, 24

Register Map

..............................................9

........................................................9

.........................................17

M

Mapping ...........................................................14

Master Reset (P999) ......................................14

Modbus RTU

modem

Module Outline

MPA See Multiple Parameter Access

........................................1, 3, 12

........................................................ 7, 11

.................................................5

.....15

Index

mmmmm

7ML19981BF01 SmartLinx Modbus RTU – INSTRUCTION MANUAL Page 27

Page 32

Multiple Parameter Access (MPA) ........... 15

N

New Value ...................................................... 19

O

Operating Mode ......................................17, 21

Operation ............................................................9

Outline

.................................................................5

P

P720 .................................................................. 21

P751 .................................................................. 10

.................................................................. 10

P752

P753 .................................................................. 10

P758 Interframe spacing

.................................................................. 14

P999

Parameter Indexes

Parameter Number

Parameter Secondary Index

Parameters

Parity

Parity (P752) .................................................... 10

Point Alarm ..................................................... 18

Point Reading

Point status ..................................................... 17

Point-on-Priority ............................................ 21

Port Configuration

Primary Index

..................................................... 10

Interframe spacing

Reading in block .................................. 16

Writing in a block ................................. 16

...................................................................4

................................................. 18

RS-232 .......................................................6

RS-485 .......................................................6

..........................................12, 20

.............................. 11

....................................... 12

................................18, 19

...................... 19

.............................. 11

............................................6

R

Read / Write Flag ........................................... 20

Register Map ...........................................17, 24

Current Value (R40036)

Decimal Place, MPA (R40034) .......... 19

Decimal Place, SPA (R40041) ........... 20

Format, SPA (R40042)

Format,MPA (R40035)

New Value (R40037) ............................ 19

Operating Mode (R40044)

Parameter Number, MPA (R40032)

Parameter Number, SPA (R40038) .. 19

Parameter Primary Index (R40040)

Parameter Secondary Index (R40039)

20

Point Alarm (R40012 to R40021)

mmmmm

Index

Point Reading (R40002 to R40011)

Point-on-Priority (R40045) .................. 21

Read / Write Flag, SPA (R40043)

....................... 19

......................... 20

......................... 19

.................. 21

.18

.. 20

.

........ 18

.... 18

...... 20

Returned Values (R40022 to R40031)

Secondary Index (R40033)

Register Mapping

Registers ..........................................................14

.................................................................24

Relay

Relay Function Codes ...................................24

Reserved Switch ..............................................6

Returned Values

RS-232 ........................................................... 6, 7

Modem connection ................................7

PC Connection

RS-485 .................................................................6

Connection

..........................................14

.............................................18

........................................7

...............................................8

..................19

18

S

Secondary Index ............................................20

Secondary Indexes

Shielded cable

Single Parameter Access (SPA)

SITRANS LU 01

SITRANS LU 02

SITRANS LU 10 ........................................... 4, 5

Slave Address .................................................14

Slave Address (P753)

SPASee Single Parameter Access ............15

Specifications ...................................................4

.........................................................4

Cable

Communication Settings ......................4

Compatible Instruments .......................4

Connection

Termination ..............................................4

Split Values .......................................22, 23, 24

................................................................18

Status

Stop bit ................................................................4

........................................13

................................................26

................15

........................................... 4, 5

........................................... 4, 5

....................................10

...............................................4

T

Termination ................................................. 4, 6

Text Messages

Troubleshooting .............................................25

...............................................23

W

Wiring .................................................................7

Wiring Guidelines

....................................4, 26

Page 28 SmartLinx Modbus RTU – INSTRUCTION MANUAL 7ML19981BF01

Page 33

www.siemens-milltronics.com

Siemens Milltronics Process Instruments Inc.

1954Technology Drive, P.O. Box 4225

Peterborough, ON, Canada K9J 7B1

Tel: (705) 745-2431 Fax: (705) 741-0466

Email: techpubs@siemens-milltronics.com

Siemens Milltronics Process Instruments Inc. 2004

Subject to change without prior notice

Rev. 1.3

*7ml19981BF01*

Printed in Canada

Loading...

Loading...