Page 1

Instruction Manual

PL-590

XRS-5 Transducer

Page 2

t Milltronics, we endeavour

Ultrasonic level

Capacitance

Radar

Point level

A

to design equipment that is

simple to use and reliable in its

operation, with the aim of

satisfying our customers' needs.

Milltronics has been designing

and manufacturing electronics

based process measurement

equipment since 1954. Our

fields of expertise include

continuous and point level

measurement, weighing and

feeding systems and motion

sensing.Technologies include

ultrasonic, capacitance and

microwave radar.

Communications

Weigh feeders

Motion sensing

Belt scales

Flowmeters

Acoustic sensing

Milltronics sells and markets

world wide through

subsidiaries, distributors and

representatives. Through

continuous improvement, we

are striving to provide our

customers with first rate sales

information, engineering

assistance and after sales

support.

For more details on our

products and services, please

contact us and we will provide

you with a listing of the offices

or representatives nearest you.

Page 3

Table of Contents

Specifications

About the Transducer ..................................................................................7

General Guidelines .................................................................................8

Installation.....................................................................................................9

Outline and Dimensions ..........................................................................9

Mounting .....................................................................................................11

Recommendations ................................................................................ 11

Applications................................................................................................ 13

Open Channel Meter............................................................................. 13

Standpipes and Stilling Wells................................................................14

Water / Wastewater............................................................................... 15

Transducer Placement ..........................................................................16

Locations............................................................................................... 16

Interconnection

Direct Connection.................................................................................. 19

Coaxial Connection ...............................................................................20

2-Wire Extension (for EnviroRanger ERS 500 only) .............................20

Maintenance

..............................................................................................5

..........................................................................................19

...............................................................................................20

Installation Diagram ...................................................................................21

PL-590 XRS-5 Transducer Page 3

Page 4

Page 4 XRS-5 Transducer PL-590

Page 5

Specifications

Specifications

Process Application:

{

Measurement Range{0.3 to 5m (1 to 15 ft) typical

{

Vessel Pressure

Operation:

{

Beam Angle

{

Frequency

{

Temperature Sensor

{

Supply Source

Environmental

{

Location

{

Ambient temperatures{-20 to 65 °C (-4 to 149 °F)

{

Altitude

{

Pollution degree

:

Construction:

{

Housing

{

Mounting

{

liquids and slurries

(may depend on application variables)

{

vented to atmosphere

{

10°

{

43 KHz

{

internal

{

transducer shall only be supplied by Milltronics

certified controller

{

indoor / outdoor

{

2000 m maximum

{

4

2

{

Kynar Flex®1 body and Hypalon

{

1” NPT conduit connection

face

Cable:

{

2 wire shielded / twisted, 0.5 mm2 (18 AWG) PVC jacket

Ingress protection:

{

IP-68

Weight

Options

3

:

{

1.2 Kg (2.6 lb)

:

{

factory flanged to suit ANSI , DIN or JIS standard

{

split flange (field mount) to suit ANSI, DIN or JIS standard

{

submergence shield (flooding applications)

Cabling (maximum run):

{

365 m (1200 ft) using RG-62 A/U coaxial cable

{

365 m (1200 ft) using 2-wire twisted pair / braided and foil shielded 20

AWG (0.5 mm

Approvals

{

CE4, CSA, FM, CENELEC, ATEX, see device nameplate

:

2

), PVC jacket (EnviroRanger ERS 500 only)

1

Kynar Flex® is registered trade mark of ELF Atochem.

2

Hypalon® is a registered trademark of Du Pont

3

approximate weight of transducer with standard cable length

4

EMC performance available upon request

PL-590 XRS-5 Transducer Page 5

Page 6

Specifications

Page 6 XRS-5 Transducer PL-590

Page 7

About the Transducer

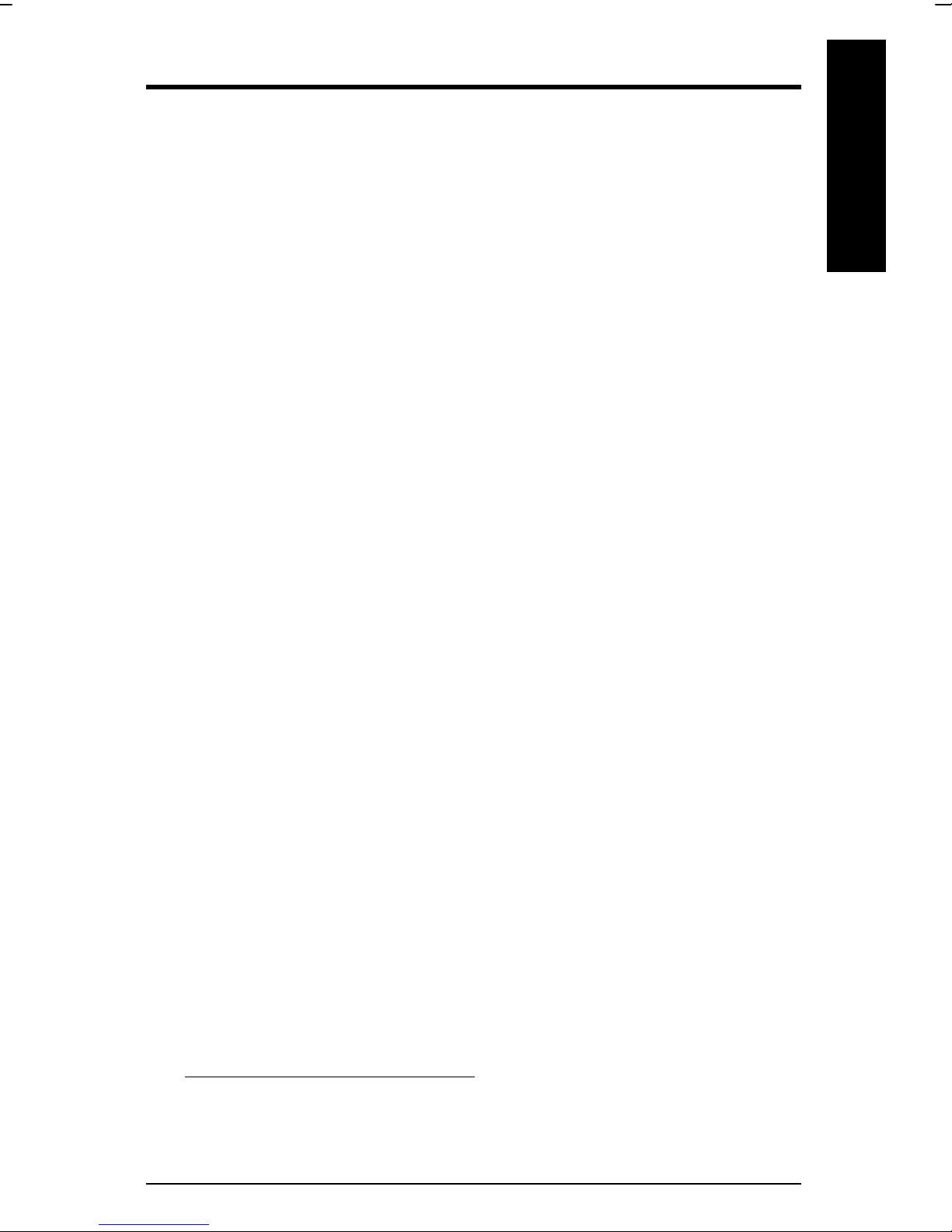

The Echomax XRS-5 transducer works with Milltronics transceivers and

provides the ultrasonic pulse and echo reception

that these devices require.

The transducer converts electrical pulses

provided by the transceiver to ultrasonic pulses

used for measurement and then converts the

ultrasonic echoes back to an electrical signal.

This signal is interpreted by the Milltronics

tranceiver using the patented Sonic

Intelligence™ algorithms. The ultrasonic pulse

reduces in power by 3dB in a 10° cone from the

transducer face. It is important to keep objects

out of this cone to reduce the chance of false

echos being recorded.

The XRS-5 transducer incorporates an

integral temperature sensor that reports the

ambient temperature to the transceiver. The

connection is transparent in that both the

ultrasonic and temperature components of

the transducer use the same leads. This

ensures that the Milltronics transceiver can

automatically compensate the speed of

sound constant for varying temperatures.

transducer

transducer

face

-3db

boundary

axis of

transmission,

perpendicular

to transducer

face

About this …

PL-590 XRS-5 Transducer Page 7

Page 8

General Guidelines

The equipment may be used in all hazardous zones with all gases with

temperature classes T1, T2, T3, T4, T5 and T6. The equipment is only

certified for use in ambient temperatures in the range of -20°C to +65°C and

should not be used outside this range.

• Installation shall be carried out in accordance with the applicable code of

practice by suitably trained personnel.

• The apparatus shall only be supplied from a circuit containing a suitably-

rated fuse having a breaking capacity of 4000A. This fuse is included in

Milltronics’ transceivers.

• Repair of this equipment shall be carried out in accordance with the

applicable code of practice.

• The certification of this equipment relies on the following materials used in its

About this …

construction:

Enclosure: Kynar Flex 2800-02 (former designation 2820) /

Chlorosulfonated polyethylene / Nitrile / Ethylene propylene

/ Chloroprene

Encapsulant: LA-9823-76

• Manual override can be accomplished by using the disconnect switch

provided in the building installation of the associated controller.

Page 8 XRS-5 Transducer PL-590

Page 9

Installation

Outline and Dimensions

Standard Flange (optional)

127mm

(5.0”)

89mm

(3.5”)

ANSI, DIN or JIS

standards

Submergence Shield Split Flange (optional)

155mm

(6.1”)

127mm

(5.0”)

Installation

133mm

(5.2”)

nominal

124mm

(4.9”)

Refer to Milltronics

instruction manual PL-530.

PL-590 XRS-5 Transducer Page 9

ANSI, DIN or JIS

standards

Page 10

Installation

Page 10 XRS-5 Transducer PL-590

Page 11

Mounting

Recommendations

• Mount the transducer so that it is above the maximum material level by more

than the blanking value to ensure that accurate results are achieved. Refer

to the associated transceiver manual for information on setting the blanking

value.

• The transducer must be mounted so that the axis of transmission is

perpendicular to the liquid’s surface.

• Do not over tighten mounting. Hand tightening of the mounting hardware is

sufficient.

• Consider the optional temperature sensor when mounting the transducer.

Suspended Conduit Bracket

flexible conduit

rigid metal

conduit

steel channel

coupling

transducer

Flexible conduit transducer should not be

subjected to wind, vibration or jarring.

Submersible Plywood

rigid metal

conduit

coupling

coupling

Mounting

coupling

Submersible transducer, used in

applications where flooding is possible.

PL-590 XRS-5 Transducer Page 11

submergence

shield

Plywood mounting provides excellent

isolation, but must be rigid enough to

avoid flexing if subjected to loading.

Page 12

Blind Flange

nipple welded

to bind flange

coupling

Mounting

Face Flange

coupling

factory flanged

transducer

bolt

gasket

customer flanged,

flat face only

nut

Page 12 XRS-5 Transducer PL-590

Page 13

Applications

Notes:

• The transducer is to be used only in the manner outlined in this

instruction manual.

• This transducer requires no maintenance, and is recommended for use

with liquids only.

Open Channel Meter

refer to Milltronics

transceiver manual for

minimum distance above

maximum head.

Refer to OCM manufacturer specification for proper point of head

measurement.

The use of an external temperature sensor provides better temperature

tracking in applications where the temperature can change quickly.

PL-590 XRS-5 Transducer Page 13

typical flume or weir

Applications

Page 14

Standpipes and Stilling Wells

In many applications, access must be made via a standpipe. In such cases,

Milltronics can provide factory flanged transducers or split flange kit that will

readily mate to the flanged standpipe. Another option is to hang the

transducer from a blind flange.

The standpipe length should be as short and the diameter as large as

possible. As a rule of thumb, the -3 dB cone of the sound beam should not

intersect the standpipe wall in applications opening into a vessel or larger

area. Otherwise, additional blanking will be required to compensate for the

interference zone created by the opening.

flanged

transducer

vent

no

intersection

vessel

no additional blanking required no additional blanking required

blind flange

mounting

transducer

can read

level inside

or below

standpipe

no

vessel

blind flange

mounting

transducer

sound beam

intersects

no additional blanking required

Applications

Page 14 XRS-5 Transducer PL-590

standpipe

end cut on a

45° angle

typically

vessel

reflection at

interference

zone created

by opening

near blanking extension of 150 mm (6”)

past end of standpipe may be required.

Page 15

Water / Wastewater

Differential Level

Pump Control

Sewage Lift

PL-590 XRS-5 Transducer Page 15

Applications

Page 16

Transducer Placement

r

r

The following graphic shows the best placement of the XRS-5 transducer.

‘B’

Maintain full fluid

level for full o

offset calibration.

Do not allow

material to ente

blanking zone.

‘A’

‘C’

Empty level for ‘B’

location. Below this

level, echo would

reflect away from

the transducer.

may require target to

obtain empty reading

Locations

rise

run

discharge

beam

angle

span:

distance between

Empty and Full

levels in the

measured process

tank

manufacturer’s

empty level

Primary location.

A.

whenever possible. The centre of the tank generally gives the most reliable

readings because there are fewer obstructions to provide false echos.

Alternate location.

B.

in use or if the tank roof is too weak to hold the transducer safely.

Poor location.

C.

This is a poor installation location. The echos are shown

reflecting away from the transducer face.

Applications

Page 16 XRS-5 Transducer PL-590

This is the preferred location and should be used

This location is used if the centre of the tank is already

Page 17

Notes

Beam should not detect bin bottom.

1.

If this occurs, use range extension parameters (on

transceivers where available) to omit false echoes.

The XRS-5 transducer operates with a beam

angle of 10° and has a rise:run ratio of

approximately 12:1. This means that for every 1m

(3.3’) of tank height, the transducer projects a

circular area over the material surface with a

radius of 83mm (32.7”). In most tanks the

transducer should be centred as much as

possible (without interference from inlet) for

optimum reading range.

Sound beam must be perpendicular to

2.

liquid surface.

When mounting the standpipe and flange you must ensure that the

transducer face will be parallel with the liquid’s surface.

Echo has missed an improperly levelled transducer.

3.

1m

83mm

As 2, ensure that the standpipe and flange are mounted to set the

transducer face level with the measured liquid.

Calibrate under normal conditions.

4.

When performing an empty or full calibration, the tank must contain its

normal vapour and be at its normal temperature.

PL-590 XRS-5 Transducer Page 17

Applications

Page 18

Applications

Page 18 XRS-5 Transducer PL-590

Page 19

Interconnection

k

Note:

Installation shall only be performed by qualified personnel and in

accordance with local governing regulations.

Dos and Don’ts

For best results follow these installation rules:

• Do not route cable openly, instead run cable separately in a grounded metal

conduit to protect it from ambient electrical noise.

• Seal all thread connections to prevent the ingress of moisture.

• Do not run cable near high voltage or current runs, contactors or SCR

control drives.

In all of the following examples the terminal blocks on the transceiver are

described in the transceiver manual.

Interconnection

Direct Connection

Connect the transducer directly to the Milltronics transceiver via the 2

conductor shielded cable.

bl

Note:

When connecting to an EnviroRanger ERS 500, the white, black, and

shield wires are all connected separately. Do not tie the white and shield

wires together

wht

drain / shield

PL-590 XRS-5 Transducer Page 19

Page 20

Coaxial Connection

Connect the transducer to the Milltronics transceiver via a junction box and

RG–62 A/U coaxial cable. This setup is effective for combined runs up to

365m (1200’).

Interconnection

Note:

When connecting to an EnviroRanger ERS 500, do NOT use coaxial

cable, see diagram below for proper procedure.

extend cable using

RG – 62 A/U coax

2-Wire Extension

wht

Maintenance

(for EnviroRanger ERS 500 only)

blk

junction box

drain / shield

extend cable using 18 AWG

shielded / twisted pair

The XRS-5 requires no special maintenance.

Page 20 XRS-5 Transducer PL-590

Page 21

Installation Diagram

Installation Diagram

PL-590 XRS-5 Transducer Page 21

Page 22

Installation Diagram

Page 22 XRS-5 Transducer PL-590

Page 23

CANADA

GERMANY

SWITZERLAND

AUSTRALIA

BELGIUM

ENGLAND

FRANCE

HONG KONG

MEXICO

THE NETHERLANDS

1954 Technology Dr., P.O. Box 4225,

Peterborough, Ontario, Canada K9J 7B1

Tel.: (705) 745-2431 Fax: (705) 741-0466

August van de Wielelei 97, 2100 Deurne, Antwerp, Belgium

Tel.: +32(0)3326 45 54 Fax: +32(0)3326 05 25

Parc de la Sainte Victoire, Bât. 5, 13590, Meyreuil, France

Tel.: +33 4 42 65 69 00 Fax: +33 4 42 58 63 95

Amores No. 1155, Col. Del Valle, 03100, Mexico D.F., Mexico

Tel.: +52 5 575-27-28 Fax: +52 5 575-26-86

Nikkelstraat 10, NL-4823 AB Breda, The Netherlands

Tel.: +31(0)76 542 7 542 Fax: +31(0)76 542 8 542

182 Normanby Rd., Box 339, South Melbourne, Australia

Tel.: +011-613-9695-2400 Fax: +011-613-9695-2450

Century House, Bridgwater Road, Worcester, England WR4 9ZQ

Tel: +44 1905 450500 Fax: +44 1905 450501

Friedrichstrasse 69, D-76703, Kraichtal, Germany

Tel: +49 (0) 7251/9642-0 Fax: +49 (0) 7251/9642-15

1 Hoi Wan Street, Suite 602, Quarry Bay, Hong Kong

Tel.: +011 852-2856-3166 Fax: +011 852-2856-2962

CP 168, Crêt de Plan 23, CH-1095 LUTRY

Tel. +41 21 791 58 28 Fax. +41 21 791 58 40

Loading...

Loading...