Page 1

Interface Module

for Allen-Bradley Remote I/O

33455330

Rev 1.0

Instruction Manual

PL-533

March 1997

Technology based. Customer driven.

Page 2

Thank you for purchasing Milltronics’ products. We endeavour to design equipment that

is simple to use and reliable in its operation, with the aim of satisfying our customers’ needs.

Milltronics has been designing and manufacturing process equipment since 1954. Our

fields of expertise include ultrasonic level measurement, in-line weighing of dry bulk solids

and motion sensing.

Milltronics is established world wide through associate offices and representatives. Our network

is continually being refined to provide our customers with first rate sales information, engineering

assistance and after sales support.

For more details on our products and service, please contact us and we will provide you with

a listing of the offices or representatives nearest you.

Canada : 1954 Technology Dr., P.O. Box 4225,

Peterborough, Ontario, Canada K9J 7B1

Tel.: 705-745-2431 Fax: 705-741-0466

U.S.A. : 709 Stadium Drive, Arlington, Texas U.S.A. 76011

Tel.: 817-277-3543 Fax: 817-277-3894

England : Oak House, Bromyard Road, Worcester , England WR2 5XZ

Tel.: 01905-748404 Fax: 01905-748430

France : Parc de la Sainte Victoire, Bât. 5, 13590 Meyreuil, France

Tel.: +33 4 42 65 69 00 Fax: +33 4 42 58 63 95

Belgium : August van de Wielelei 97, 2100 Deurne, Antwerp, Belgium

Tel.: 03/326 45 54 Fax: 03/326 05 25

Mexico : Amores No. 1155, Col. Del Valle, 03100 Mexico D.F., Mexico

Tel.: 575-31-44 / 575-83-13 / 575-27-78 Fax: 575-26-86

Internet : http://www.milltronics.com

Page 3

TABLE OF CONTENTS

About this module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Physical

Hardware Set Up

Software Set Up

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Application Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Parameter Values

Numeric values

“Split values”

Text messages

Relay function codes

Block Transfers

Block Transfer Write

Block Transfer Read

Discrete I/O

Discrete Output Words

Discrete Input Words

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Generally…

Specifically…

==================================================================

3 PL-533

Page 4

ABOUT THIS MODULE

Milltronics SmartLinx module for Allen-Bradley is a ‘plug in’ communications circuit card

designed to interface any Milltronics SmartLinx compatible device to Allen-Bradley

Remote I/O.

The module may have been shipped installed in your unit, or shipped separate for site

installation. Refer to your associated Milltronics device instruction manual for details on

its location or physical installation.

=================================================================

SPECIFICATIONS

Electrical: compatible with any Milltronics SmartLinx compatible device and Allen-

Bradley Remote I/O

Physical: compatible with any Milltronics SmartLinx compatible device

Application: compatible with Allen-Bradley Remote I/O

Connection: 3-position terminal block for wire end

Termination: switch selectable, open or 82 Ω internal

Cable: Belden 9463 ‘Blue Hose’ or equivalent

============================================================================

PL-533 4

Page 5

INSTALLATION

================================================================================

PHYSICAL

Refer to associated Milltronics SmartLinx compatible device instruction manual for

location or installation of the module.

HARDWARE SETUP

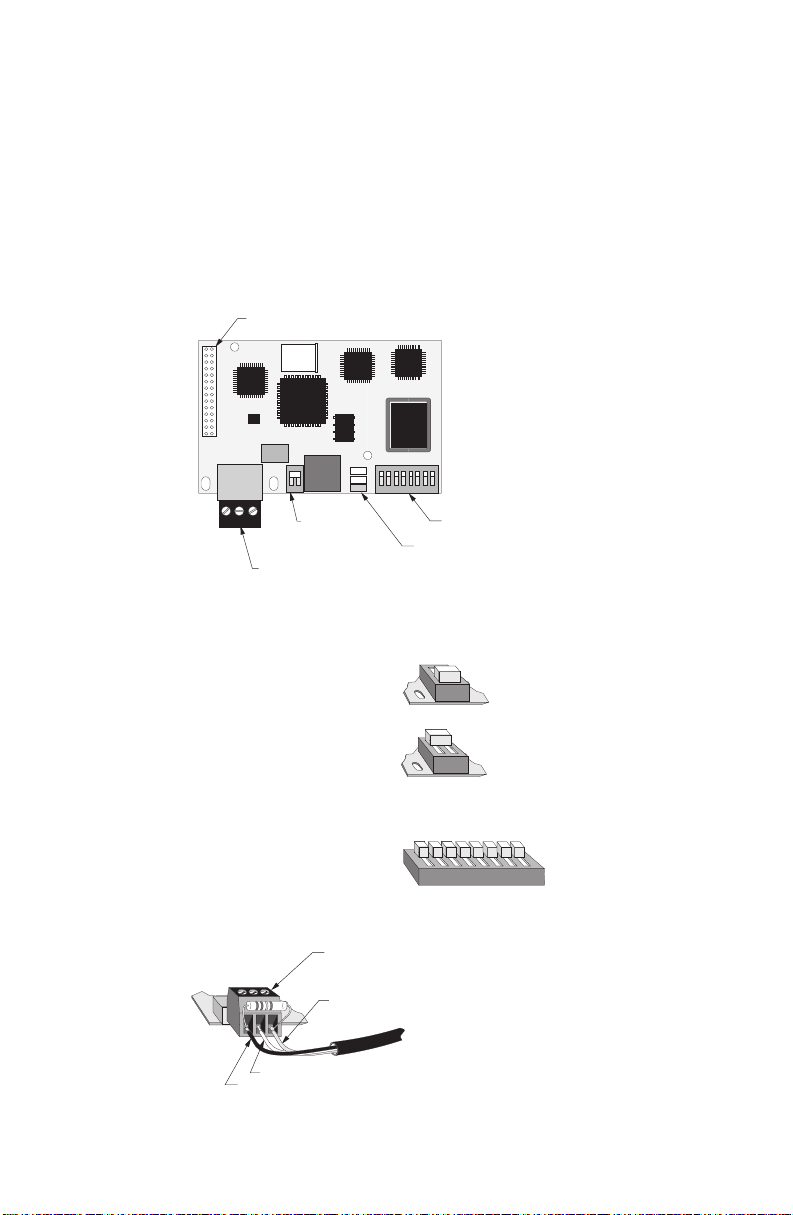

SmartLinx module for Allen-Bradley Remote I/O

module connector (underside) to Milltronics device

termination

switch

cable connector

reserved switches

status LEDs (refer to Operation)

TERMINATION SWITCH

termination setting

open off

150 Ω external* off

82 Ω on

RESERVED SWITCH

setting

all on

CABLE CONNECTION

*termination resistor (as required)

clear

shield

blue

Connect using Belden 9463 ‘Blue Hose’ cable or equivalent and terminate (blue/clear)

according to Allen-Bradley specification and conventions.

5 PL-533

Page 6

SOFTWARE SETUP

GENERAL

It is recommended to set up the Milltronics device as a 1⁄4 rack size, to conserve remote

rack space available to the PLC. As discrete I/O operation is very limited when using 1⁄4

rack size configuration, block transfer read and write commands are recommended.

Avoid discrete I/O as it does not provide any advantage over block transfers. (Transfer

speed is not an issue, as transfer rates are much greater than the rate where new

readings are generated by the Milltronics device.)

It is also recommended to exercise caution when deciding how often to trigger the BTR

and BTW instructions. Too often increases the delay of all block transfers on the

Remote I/O link. A recommended guideline is to trigger the BTR and BTW instructions

no faster than every 0.3 seconds.

SPECIFIC PARAMETERS

P751 baud rate

Sets the baud rate for Remote I/O communication between

Milltronics device and Allen-Bradley.

values: 0 = 57.6 kbaud

1 = 115.2 kbaud

2 = 230.4 kbaud

The default value is 0.

P752 rack number

Enter the rack number (octal) that the Milltronics device has been assigned

on the Remote I/O link. The valid range is 01 – 73. Check your PLC manual

for the supported range.

The default value is 2.

P753 starting group

Sets the starting group number for the Milltronics device.

starting group rack size (P754)

values: 0 1, 2, 3 or full

2 1, 2 or 3 /4

4 1 or 2 /4

6 1/4

The default value is 0.

PL-533 6

Page 7

P754 rack size

Sets the discrete I/O address space. Valid settings are 1 to 4 quarter racks,

dependent upon the starting group (P753).

rack size starting group (P753)

values: 1/4 0, 2, 4 or 6

The default value is 0.

P755 last rack

The last rack is defined as the highest numbered rack on the Remote I/O link.

Determine the position of Milltronics device and set this parameter

accordingly.

value: 0 = not last

The default value is 0.

2/4 0, 2 or 4

3/4 0 or 2

full 0

1 = last

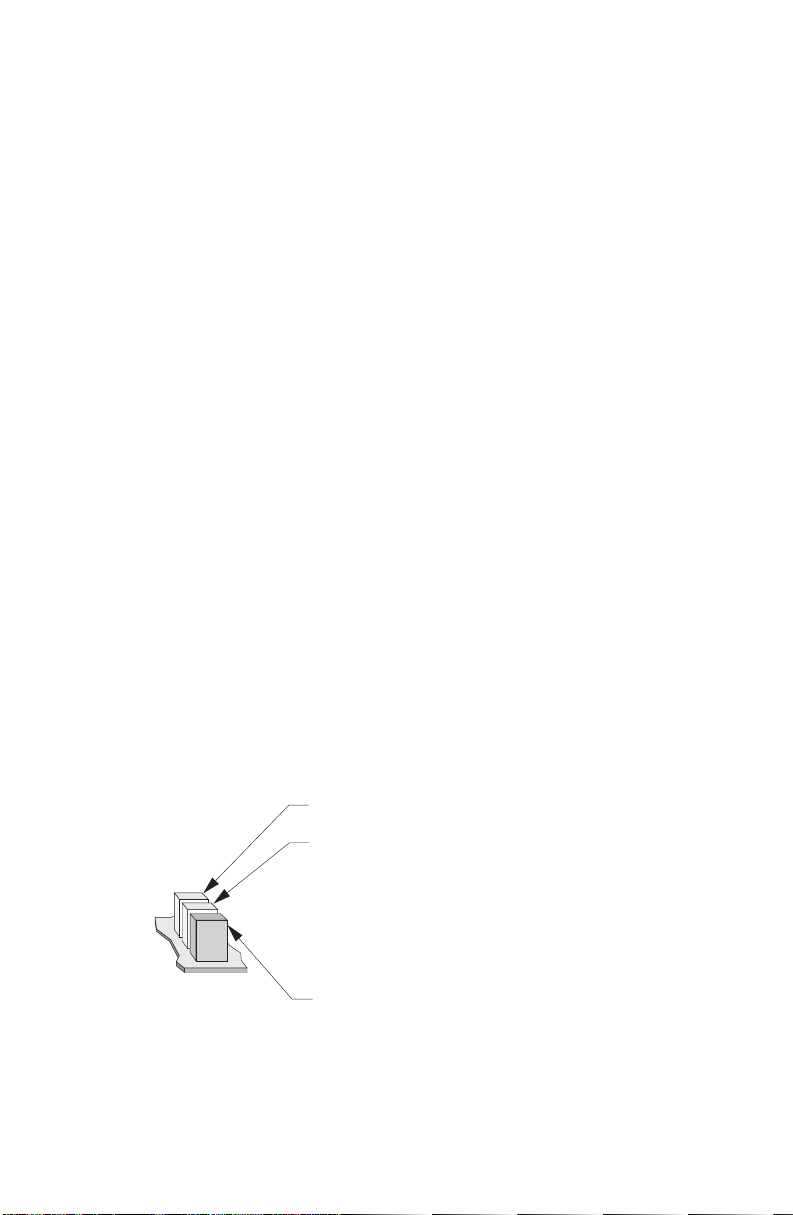

OPERATION

Communication on the Remote I/O link is indicated by the SmartLinx LEDs.

=======================================================================================

on module is powered

off no communication between bus and module

flash bus intact, Allen-Bradley PLC in program; or

Milltronics device set to different rack size

than PLC

on active communication

on not being scanned by PLC

7 PL-533

Page 8

APPLICATION LAYER

The application layer is the name given to the organization and format of the discrete

I/O and block transfer communications areas of the Milltronics device . All transactions

between the PLC and the Milltronics device are either reading parameter values from

the Milltronics device, or setting parameter values in the Milltronics device.

This manual refers to a 10 point level instrument; if your device has fewer than 10

points, you should ignore data in registers which represent non-existing points. Those

registers will still be present, but will contain undefined values.

===================================================================

PARAMETER VALUES

The Milltronics device parameters take on many values in various formats, as discussed

in the Milltronics device manual. For the convenience of the PLC programmer, those

values are converted to and from a 16-bit integer number, since those are easily

handled by most PLCs. This section describes that conversion process; later sections

detail where those values are in discrete I/O and block transfer addresses, and how to

get the parameters you need.

Numeric values

Numeric parameter values are by far the most common. For example, parameter P920

(Reading), returns a number representing the current reading (either level or volume,

depending on the Milltronics device configuration).

Numeric values may be requested or set in either units or percent of span, and may be

specified with a number of decimal places.

Numeric values must be in the range -10,000 to +10,000 to be valid. If a parameter is

requested and its value is more than +10,000, the number 32,767 is returned; if it is less

than -10,000, the number -32,768 is returned. If this happens, increase the number of

decimal places for that parameter.

If a parameter cannot be expressed in terms of percent (e.g. span), or has no

meaningful value, the special number 22,222 is returned. Try requesting the parameter

in units, or refer to the Milltronics device manual to understand the requested

parameter.

“Split” Values

Certain parameters are actually a pair of numbers separated by a colon, in the format

xx:yy.

One example is P807, Transducer Noise, where:

xx = the average noise value in dB

yy = the peak noise in dB.

PL-533 8

Page 9

The number which corresponds to xx:yy, either for reading or setting a parameter, is

determined by the following formula:

– for storing to the Milltronics device:

value = (xx + 128) x 256 + (yy + 128)

– for reading from the Milltronics device:

xx = (value / 256) - 128

yy = (value % 256) - 128

where % is the modulus operator. This can be computed by finding

the remainder of an integer divide-by-256.

It may simplify programming to notice:

xx = (most significant byte of value) - 128

yy = (least significant byte of value) - 128

Text messages

If an Milltronics device parameter returns a text message, that message is converted to

a corresponding number shown in the table below:

22222 invalid value

30000 off

30001 on

30002 ≡≡≡≡

30003 [ - - ]

30004 err

30005 err1

30006 open

30007 shrt

30008 pass

30009 fail

30010 hold

30011 lo

30012 hi

30013 de

30014 en

-32768 value is less than -10,000

32767 value is greater than 10,000

9 PL-533

Page 10

Relay function codes (parameter P111 only)

Relay function codes are represented by unique numbers.

.

OFF 0

ALARM 1

LL_ALARM 2

L_ALARM 3

H_ALARM 4

HH_ALARM 5

INSIDE_BAND 6

INSIDE_BAND_1 7

INSIDE_BAND_2 8

OUTSIDE_BAND 9

OUTSIDE_BAND_1 10

OUTSIDE_BAND_2 11

RATE_ALARM 12

RATE_ALARM_1 13

RATE_ALARM_2 14

TEMPERATURE_ALARM 15

LOE_ALARM 20

NON_SEQD 25 (for pump control)

UNKNOWN_MODE 200

PL-533 10

Page 11

BLOCK TRANSFERS

In order to read or write data via block transfers, the PLC has to be programmed

accordingly. Refer to the Allen-Bradley PLC documentation on how to write block

transfer read (BTR) and block transfer write (BTW) rungs in your PLC program.

This section describes the meaning of the data read and written in block transfers to the

Milltronics device.

The data provided by the Milltronics device in a BTR operation to the PLC is set by a

BTW operation.

Block Transfer Write

The words in the block transfer write operation allow access to the Milltronics devices in

two ways: Multiple Parameter Access (MPA) and Single Parameter Access (SPA).

word description

0 point on priority

1 parameter number, MPA

2 parameter index, MPA

3 decimal place, MPA

4 format, MPA

5 parameter number, SPA

6 point number, SPA

7 parameter index, SPA

8 value, SPA

9 decimal place, SPA

10 format, SPA

11 read/write flag, SPA

12 operating mode, SPA

Words 1 to 4 are MPA, allowing continuous monitoring in BTR words 21 – 30 of

selected parameters for points 1 – 10. Using these words does not allow changing of

the parameter value.

Words 5 to 12 are SPA, allowing continuous monitoring or demand programming of a

parameter for a given point, individually selected for each point.

11 PL-533

Page 12

BTW Word 0, Point-on-Priority

Bits 00–11 set the priority status of corresponding points 1–10.

bit 11 10 07 06 05 04 03 02 01 00

point 10 9 8 7 6 5 4 3 2 1

bit status 0 = normal

1 = priority

e.g. bit 11 10 07 06 05 04 03 02 01 00

status 0 0 0 0 0 0 0 1 0 1

points 3 and 1 are on priority scan

All other bits are reserved and should contain 0.

This word is ignored if the Milltronics device is configured as a full rack (P754 Rack Size

set to 4). In that case, use discrete output word 7 to control point-on-priority.

If this word is used to control point-on-priority, then the Milltronics device must be

configured to permit this. Parameter P720 must be set to 1 (manual, BIC-II or

SmartLinx) for each point to permit priority control for that point. To enable priority

control for all points, simply store ‘1’ to parameter P720, point ‘0.’

BTW Word 1: Parameter Number, MPA

Specifies the parameter number for the returned value in BTR words 21–30.

BTW Word 2: Parameter Index, MPA

Specifies the parameter index for the parameter returned in BTR words 21–30. This

word is ignored for parameters which don’t use indices.

Some specific Milltronics device parameters use indices to address the multiple values

stored within the single parameter.

For example, parameters P054 level breakpoints and P055 breakpoint volumes use the

index to specify which breakpoint to read. High-level-language programmers might think

of this index as an array index.

BTW Word 3: Decimal Place, MPA

Specifies the number of decimal places in each of the returned values in BTR words 21–30.

For example, a 1 would mean all returned values would have 1 decimal place, i.e. a

returned value of 5,213 should be interpreted as 521.3. This value may be negative,

indicating trailing zeros; for example if this word were -1, a returned value of 5,213

should be interpreted as 52,130.

BTW Word 4: Format, MPA

Sets the format for the returned values in BTR words 21 – 30.

0 = normal

1 = percent of span

PL-533 12

Page 13

The values written in BTW words 5–11 specify the parameter read

from or written to the Milltronics device. The parameter is written

repeatedly until a 0 is written to word 11.

This would override any keypad entry for the value specified by

BTW words 5–10 while BTW word 11 is set to 1.

BTW Word 5: Parameter, SPA

Specifies the parameter number.

BTW Word 6: Point, SPA

Specifies the point number for the parameter specified by BTW word 5.

BTW Word 7: Index, SPA

Specifies the index for the parameter specified by BTW word 5. This word is ignored for

parameters which don’t use multiple values.

Some specific Milltronics device parameters use indices to address the multiple values

stored within the single parameter.

For example, parameters P054 level breakpoints and P055 breakpoint volumes use the

index to specify which breakpoint to read. High-level-language programmers might think

of this index as an array index.

BTW Word 8: Value, SPA

This word contains the value to be written to the parameter specified by BTW words

5–7, if BTW word 11 is set to 1. If BTW word 11 is set 0, this word is ignored. The

format of this word is specified by BTW words 9–10.

BTW Word 9: Decimal, SPA

This word specifies the number of decimal places for the value in BTW word 8, and also

for the parameter value returned in BTR word 38.

e.g.: given: BTW word 8 = 5,213

BTW word 9 = 1

BTW word 10 = 0

BTW word 11 = 1

then: the value is interpreted as 521.3 units and stored in the

Milltronics device.

13 PL-533

Page 14

given: BTW word 9 = -1

BTW word 10 = 0

BTW word 11 = 0

BTR word 38 = 5,213

then: the returned value in BTR word 38 is interpreted as 52,130.

BTW Word 10: Format, SPA

This word sets the format for the value in BTW word 8.

0 = normal

1 = percent of span

BTW Word 11: Read/Write Flag, SPA

This word instructs the read/write application of word 8.

0 = read parameter as described by words 5, 6, 7, 9 and 10; word 8 ignored

1= set parameter to the value described by words 5–10

BTW Word 12: Operating Mode, SPA

This word sets the operating mode of the Milltronics device. The device changes mode

only when the status of the bit changes.

The operating mode can be equally set via the device keypad.

bit status 0 = run mode

1 = program mode

PL-533 14

Page 15

Block Transfer Read

Values returned in the words in the block transfer read are in response to the block

transfer write to the Milltronics device.

Words 0 through 20 have values with fixed meanings and formats.

Words 21 through 34 have values returned in response to BTW words 1 through 4, for

Multiple Parameter Access (MPA).

Words 35 through 41 are values returned in response to BTW words 5 through 12 for

Single Parameter Access (SPA).

words description

0 point status

1–10 point reading

11–20 point alarm and status

21–30 returned values, MPA

31 decimal place, MPA

32 format, MPA

33 parameter number, MPA

34 parameter index, MPA

35 parameter, SPA

36 transducer, SPA

37 index, SPA

38 value, SPA

39 decimal place, SPA

40 format, SPA

41 read/write flag, SPA

BTR Word 0:

bit description

(octal)

00–11: point status

indicate the operation of the points 1–10.

bit 11 10 07 06 05 04 03 02 01 00

point 10 9 8 7 6 5 4 3 2 1

If a bit status is 1, the corresponding point is deemed to be operational,

based on the criteria defined by BTR words 11–20, bits 00–03. If the bit

status is 0, then the corresponding point is deemed non-operational. To

further diagnose a point’s operation, examine the corresponding word 11

through 20.

If a bit status is 1, then for the corresponding point alarm word 11–20, one or

more of the alarm bits 00–03 must be 1 to indicate the operational problem.

15 PL-533

Page 16

12: operating mode

0 = device in ‘run’ mode

1 = device in ‘program’ mode

13–17: reserved

These bits are reserved and set to 0.

BTR Words 1–10: Point Reading

These words contain the value of parameter P920 (Reading) for points 1–10,

respectively. The reading is expressed as a percent of full scale, multiplied by 100,

giving a range of 0–10,000 which corresponds to 0.00%–100.00%. Refer to the

Milltronics device documentation for a definition of ‘P920’.

Note these values may contain numeric level data for inoperative or malfunctioning

points; refer to BTR word 0, and BTR words 11–20 for the actual operational status of

the measurement points.

BTR Words 11–20: Point Alarm and Status

These words contain the corresponding alarm and status bits for point 1–10,

respectively.

Bit status: 0 = false

1 = true

bit description

(octal)

00 point not in operation

01 point failsafe timer expired

02 point failed (cable shorted, open, or transceiver problem)

03 point temperature sensor failed

04–14 reserved for future use

15 level emptying

16 level filling

17 scan mode priority

BTR Words 21–30: Returned Values, MPA

These words contain values requested by writing to words 1–4. The type of data and

format are specified with that request, and returned in block transfer read words 31–34.

PL-533 16

Page 17

BTR Word 31: Decimal Place, MPA

This word specifies the number of decimal places in each of the returned values in BTR

words 21–30.

e.g.: given: BTR word 21 = 5,213

BTR word 31 = 1

then: the returned value is interpreted as 521.3

given: BTR word 21 = 5,213

BTR word 31 = -1

then: the returned value is interpreted as 52,130

BTR Word 32: Format, MPA

This word sets the format for the returned values.

bit status description

0 normal

1 percent of span

BTR Words 33 and 34: Parameter Number and Index, MPA

These words contain the last values written to block transfer write words 1 and 2,

respectively. These words indicate what information is contained in returned values

1–10 (BTR words 21–30). These words are provided since there can be a delay

between writing a request via a block transfer write, and the appearance of the

requested values 1–10 (BTR words 21–30).

BTR Words 35–37 and 39–41:

Parameter Number/Point/Index and Decimal Place/Format/Flag, SPA

These words contain the last values written to BTW words 5–7 and 9–11, respectively.

They confirm that the parameter value has been written. These words are not updated

until the value has been successfully transferred and stored in the Milltronics device.

BTR Word 38: Value, SPA

This word contains the current value of the parameter identified by BTR words 35–37

and 39–40, regardless of the value of BTW word 11 (write flag).

If this value is different from what was written in BTW word 8, after BTR words 35–37

and 39–40 have been updated and match BTW words 5–7 and 9–10, respectively, then

the parameter was not stored. Try placing the Milltronics device in program mode.

17 PL-533

Page 18

DISCRETE I/O

The values returned in the discrete input words are determined by what has been

written into the discrete output words. By writing the correct words, values stored in

parameters can be accessed.

Discrete I/O does not allow write access to the parameters. That is, parameters cannot

be changed via a Remote I/O. In order to effect this type of operation, communication

must be carried out using Block Transfer. However, output word 7 allows scan point

priority of the Milltronics device to be altered.

The number of discrete input and output words available is determined by the rack size

as configured on the SmartLinx module. Each 1/4 rack allows two words each for

discrete inputs and outputs.

rack size number of discrete input or words

discrete output words

1/4 rack 2 0, 1

1/2 rack 4 0, 1, 2, 3

3/4 rack 6 0, 1, 2, 3, 4, 5

full rack 8 0, 1, 2, 3, 4, 5, 6, 7

In full rack configuration, discrete output word 7 may be used to configure the returned

data in discrete input word 7. This data is written in output word 7, bits 0–9 where each

bit corresponds to a transducer 1–10. The meaning of those bits is determined by

writing to bits 10–15 of output word 7, as described in the following section.

It is convenient to note the similarity between the input and output areas.

Discrete Output Words

output word description

0 communication control

1 point and parameter number, word 1

2 point and parameter number, word 2

3 point and parameter number, word 3

4 point and parameter number, word 4

5 point and parameter number, word 5

6 point and parameter number, word 6

7 point status control

PL-533 18

Page 19

Output Word 0: Communication Control

bits description

(octal)

00–07: reserved

These bits are reserved for PLC use. They may contain any value, and

therefore should not be relied upon to contain any expected value. These bits

should be ignored, or ‘masked off.’

10–11: reserved

These bits are reserved for future Milltronics use and should be set to 0.

12–14: decimal

Contains the value which indicates where the decimal place should be, for all

of the returned values 1–6. For example, a 2 indicates the decimal should be

shifted 2 places to the left or right (as determined by bit 15).

15: decimal shift

Determines the direction of shift for the decimal (bits 12–14):

0 = shift left

1 = shift right

If bits 12–14 are all 0, this bit may be ignored.

16: numerical format

Determines the numerical format for the data returned in discrete input words

1–6: 0 = normal

1 = percent of span

If a parameter isn’t available as a percent of span, the undefined value

(22,222) is returned.

17: echo

The value of this bit is echoed back from the discrete output word 0, bit 17.

This bit is only used for test purposes.

19 PL-533

Page 20

Output Words 1–6: Point and Parameter Numbers, Words 1–6

The words determine what will be returned in discrete input words 1–6. These words

contain both the parameter and the point to be read, as determined by the following

formula:

Word 1–6 = (point x 1,000) + parameter

For example, if it was desired to read the level of transducer 6 back in discrete input

word 1, where level is returned in parameter 920, the value 6,920 decimal would be

written to discrete output word 1.

In this manner, up to 6 values may be read in a full rack, or just 1 value in a quarter

rack. The choice must be made as to how many values must be read simultaneously

(i.e. data transfer bandwidth), and how much rack space may be occupied.

Any combination is possible; for example, with a full rack 6 levels from 6 points can be

read simultaneously, 3 parameters each from 2 points, 6 parameters from 1 transducer,

or any other desired combination of the 6 words available in the full rack configuration.

Output Word 7: Point Status

bits description

(octal)

00–11: point i.d.

Each bit confirms the association of the point(s) identified, to the request for

the point status, bits 12–17.

bit 11 10 07 06 05 04 03 02 01 00

point 10 9 8 7 6 5 4 3 2 1

e.g. bits 11 10 07 06 05 04 03 02 01 00

status 0 0 0 0 0 0 0 1 0 1

points 3 and 1 are identified.

12–17: point status command

Indicates the status of the points identified by bits 00–11:

bits 17 16 15 14 13 12

0 0 0 0 0 0 = point in alarm

0 0 0 0 0 1 = point-on-priority

For example, to put points 1 and 3 on priority scan, store the binary value

0000010000000101 to discrete output word 7; the actual point-on-priority status is

returned in discrete input word 7. For another example, store the value 0 to this word,

and the point alarm status is returned in discrete input word 7.

If this word is used to control point-on-priority, then the Milltronics device must be

configured to permit this. Parameter P720 must be set to 1 (manual, BIC-II or

SmartLinx) for each point to permit priority control for that point. To enable priority

control for all points, simply store ‘1’ to parameter P720, point ‘0.’

PL-533 20

Page 21

Discrete Input Words

input description

word

0 communication status

1 returned value 1

2 returned value 2

3 returned value 3

4 returned value 4

5 returned value 5

6 returned value 6

7 point status

Input Word 0: Communication Status

bits description

(octal)

00–07: reserved

Reserved for PLC use. These may contain any value, and should not be

relied upon to contain any expected value. These bits should be ignored, or

‘masked off.’

10–11: rack size

Contains the rack size as configured: 00 = 1/4 rack

This value may be useful for PLC programs to automatically ‘know’ how

much data is available.

12–14: decimal

Contains the value indicating the decimal place for all of the returned values

1–6. For example, a value of 2 indicates the decimal should be shifted 2

places to the left or right (as determined by bit 15). A zero indicates no shift.

15: decimal shift

Determines the direction of shift for the decimal (bits 12–14):

0 = shift left

1 = shift right

If bits 12–14 are all 0, this bit may be ignored.

16: numerical format

Indicates the numerical format for the returned values:

0 = normal

1 = % of span

01=1/2

10=3/4

11= full

21 PL-533

Page 22

17: echo

The value of this bit is echoed back from the discrete output word 0, bit 17.

This bit is only used for test purposes.

Example:

Input word 0 is 2,048 and input word 1 is 5,123 decimal. Input word 0 expressed in

binary is 0000 1000 0000 0000. Bits 0–7 must be ignored. Bits 10–11 indicate the

Milltronics device is configured as 1/4 rack. Bit 16 indicates the returned value is in

engineering units. Bits 12–14 are binary 010, or 2, indicating two decimal places in the

returned value. Bit 15 is 0, indicating the decimal place of the returned value should be

shifted left. So, the value 5,123 should be read as 51.23 engineering units, as specified

in the Milltronics device.

Input Words 1–6: Returned Values, Words 1–6

These words contain parameter number and value from the Milltronics device, as

determined by the values written to the corresponding discrete output words 1–6.

Returned values are between -10,000 and 10,000 inclusive, otherwise refer to

Troubleshooting.

Input Word 7: Point Status

bits description

(octal)

00–11: point i.d.

Each bit confirms the association of the point(s) identified, to the request for

the point status, bits 12–17.

bit 11 10 07 06 05 04 03 02 01 00

point 10 9 8 7 6 5 4 3 2 1

e.g. bits 11 10 07 06 05 04 03 02 01 00

status 0 0 0 0 0 0 0 1 0 1

points 3 and 1 are identified

12–17: point status

Indicates the status of the points identified by bits 00–11:

bits 17 16 15 14 13 12

0 0 0 0 0 0 = point in alarm

0 0 0 0 0 1 = point-on-priority

Refer to discrete output word 7 for instructions on how to control whether priority or

alarm status is returned in this word.

PL-533 22

Page 23

TROUBLESHOOTING

GENERALLY…

In all cases, first check that the SmartLinx module has passed its on-going built-in self

test (device parameter P790). The result should be PASS .

If FAIL is indicated, either the module is defective, or the module connector on the

Milltronics device is defective.

If “ERR1” is indicated, the Milltronics software doesn’t recognize the ID number of the

installed module. Please contact Milltronics or your distributor for instructions and/or

upgraded Milltronics SmartLinx compatible device software.

SPECIFICALLY…

Q1: I connected the Milltronics device to my remote I/O link. All

communications have stopped, and I have rack fault bits set on all remote

racks in the scan list.

A1.1: Make sure the Milltronics device is connected and terminated correctly and in

agreement with all Allen-Bradley remote I/O wiring practices (please contact your

Allen-Bradley representative for the latest guidelines).

A1.2: Make sure the termination resistor switch on the SmartLinx module is set

correctly. Improper termination can interfere with proper remote I/O operation.

==================================================================

Q2: I connected the Milltronics device to my remote I/O link. Communication

with certain racks has stopped, and I have rack fault bits set on those

remote racks.

A2.1: Make sure the Milltronics device is connected and terminated correctly and in

agreement with all Allen-Bradley remote I/O wiring practices (please contact your

Allen-Bradley representative for the latest guidelines).

A2.2: Make sure the termination resistor switch on the SmartLinx module is set

correctly. Improper termination can interfere with proper remote I/O operation.

A2.3: Check that those remote I/O devices have different rack numbers and starting

groups from the Milltronics device.

Q3: My PLC indicates a rack fault where the Milltronics device is addressed on

the remote I/O link, but all other devices operate properly.

A3.1: Check the baud rate, rack number, starting group, rack size and last rack

settings on the Milltronics device (P751-P755, respectively), and make sure they

match the entry in the PLC’s scan list.

23 PL-533

Page 24

A3.2: Check the rack number (P752) on the Milltronics device; some Allen-Bradley

PLCs can accept only a limited number of racks. Try setting the rack number to a

lower available rack number.

A3.3: Check that no other devices connected to this remote I/O link have been set to

the same rack number and starting group as the Milltronics device.

A3.4: Make sure the Milltronics device is connected and terminated correctly and in

agreement with all Allen-Bradley remote I/O wiring practices (please contact your

Allen-Bradley representative for the latest guidelines).

A3.5: Make sure the termination resistor switch on the SmartLinx module is set

correctly. Improper termination can interfere with proper remote I/O operation.

Q4: Choosing the remote I/O Autoconfigure from my PLC programming

software doesn’t show the Milltronics device on the remote I/O link.

A4.1: Check the baud rate setting (P751) on the Milltronics device; it should match the

baud rate of the remote I/O scanner port on the PLC.

A4.2: Check the rack number (P752) on the Milltronics device; some Allen-Bradley

PLCs may accept only a limited number of racks. Try setting the rack number to

a lower available rack number.

A4.3: Try manually adding the Milltronics device to the PLC remote I/O scan list. If the

problem persists, contact Milltronics technical support.

Q5: The Milltronics device indicates it is being scanned, but the PLC indicates

a rack fault at that address.

A5.1: Check the rack size setting (P754); make sure it matches the rack size in the

PLC’s remote I/O scan list.

Q6: My PLC is scanning the Milltronics device with no rack faults, but the data

I’m reading makes no sense.

A6.1: Make sure the PLC is actually addressing the Milltronics device, and that no

other units are addressed to the same remote I/O rack number and starting

group. The PLC might be reading another device at the same rack number and

starting group.

A6.2: Check the information you’ve written to the discrete output area or block transfer

write area. Most of the information returned depends on what (configuration)

information was written to the Milltronics device.

PL-533 24

Page 25

Q7: I tried to set an Milltronics device parameter using a block transfer write,

but the parameter remains unchanged.

A7.1: Some parameters can only be changed when the Milltronics device isn’t

scanning. Try putting the Milltronics device in program mode, either using the

keypad or the run/program mode bit in the discrete output image table. Its

address is O:xxy/10,

where: xx = Milltronics device rack number and

y = starting group

Q8: No matter what rack number the Milltronics device is set for (P752), the

Milltronics device always appears at another (constant) rack number.

A8.1: The SmartLinx module’s reserved DIP switches 3–8 can override the Milltronics

device rack number setting (P752). Make sure all switches on the ‘reserved’ DIP

on the module are ‘on’.

Q9: No matter what baud rate the Milltronics device is set for (P752), the

Milltronics device always uses another (constant) baud rate.

A9.1: The SmartLinx module’s reserved DIP switches 1–2 can override the Milltronics

device baud rate setting (P752). Make sure all switches on the ‘reserved’ DIP on

the module are ‘on’.

Q10: After connecting the Milltronics device to the remote I/O and programming

block transfer commands, the transfer rate of other block transfers on the

remote I/O is slower.

A10.1: Try triggering the Milltronics device block transfer instructions less frequently, to

allow other block transfers to take place.

25 PL-533

Loading...

Loading...