Page 1

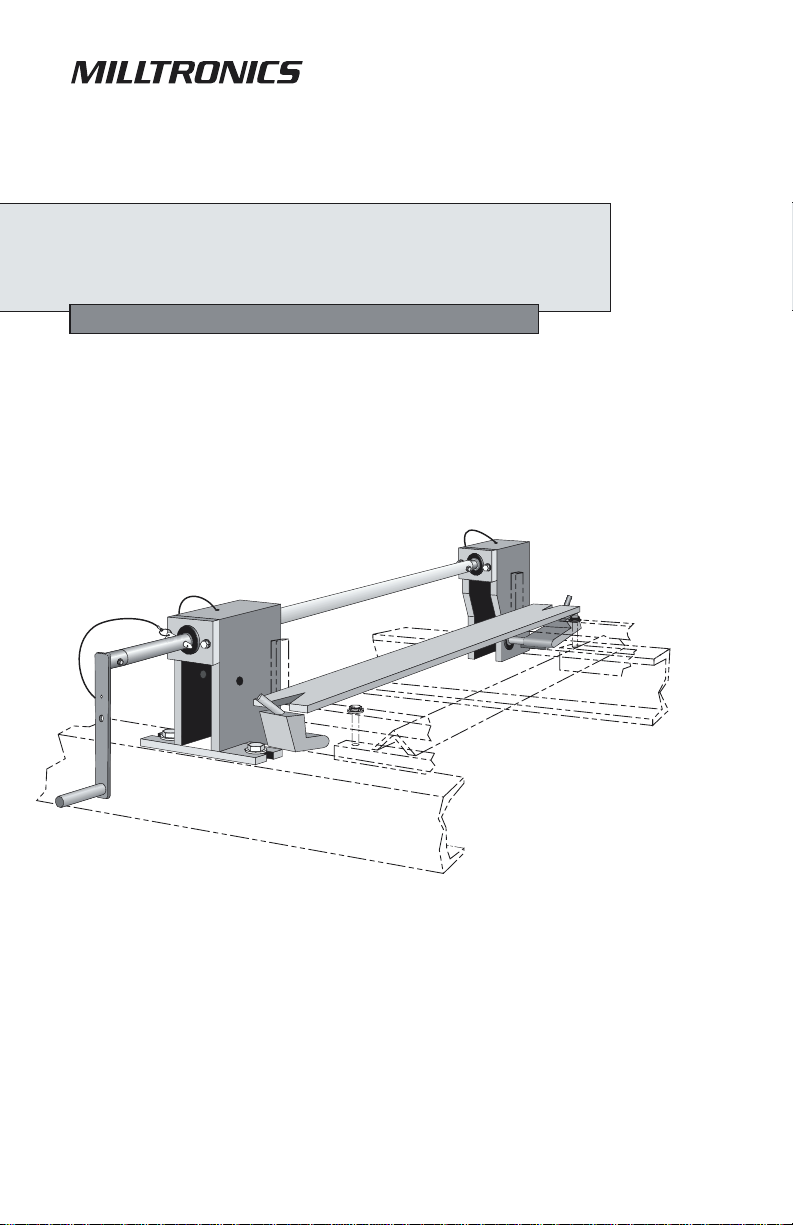

MWL

MilltronicsWeight Lifter

Instruction Manual

June 2001

Page 2

Safety Guidelines

Warning notices must be observed to ensure personal safety as well as that of others, and to

protect the product and the connected eq uip m ent . These w ar ning notices are accompanied

by a clarification of the level of caution to be observed.

Qualified Personnel

This device/system may only be set up and operated in conjunction with this manual.

Qualified personnel are on ly authorized to install and operate this equipment in accordance

with established safety practices and standards.

Warning: This product can only function properly and safely if it is correctly transported,

stored, installed, set up, oper at ed, and maintained.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2000. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to

purchase authorized bound manuals, or t o view

electronic versions as designed and authored by

Siemens Milltronics Process Instruments Inc.

Siemens Milltronics Process Instruments Inc. will

not be responsible for the content s of partial or

whole reproductions of either bound or electronic

versions.

MILLTRONICS®is a registered t rademark of Siemens Milltronics Process Instruments Inc.

Contact SMPI Technical Publications at the following address:

Technical Publications

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Ca nad a, K9J 7B1

Email: techpubs@milltronics.com

While we have verified the contents of

this manual for agreement with t he

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The

contents of this manual are regularly

reviewed and corrections are included

in subsequent editions. We welc ome

all suggestions for improvement.

Technical data subject to change.

For the library of SMPI instruction manuals, visit our Web site: www.milltronics.com

© Siemens Milltronics Process Instruments Inc. 2001

Page 3

Table of Contents

Milltronics Weight Lifter (MWL): Introduction ..............................................................2

Applications .............................................................................................................................................. 2

MWL Components ..................................................................................................................................3

Calibration Weight Arrangement ..............................................................................................4

Specifications ......................................................................................................................5

Belt Width .....................................................................................................................................5

Idler Spacing ................................................................................................................................5

Calibration Weight Capacity .....................................................................................................5

Crank Arm .....................................................................................................................................5

Calibration Weight Dimensions ..............................................................................................5

Mounting Dimensions ................................................................................................................5

Approvals ......................................................................................................................................5

Installation ........................................................................................................................... 6

Drill left and right crank body mounting holes .....................................................................6

Mount left-handed and right-handed crank body ...............................................................7

Mount torque shaft / Check clearance for conveyor belt .................................................8

Install crank handle ....................................................................................................................9

Test the unloaded MWL / Align crank bodies ...................................................................10

Install calibration weights / Check for clearance .............................................................11

Test the loaded MWL ...............................................................................................................14

Shim the MWL (if required) / Recheck base-bar weight for clearance ......................15

Operation ................ ............................... ................................. ............................... .............17

Applying calibration weights ..................................................................................................17

Storing calibration weights .....................................................................................................17

Storing crank handle ................................................................................................................17

Maintenance Procedures ................................................................................................19

Removing material accumulation ...........................................................................................19

Greasing......................................................................................................................................... 19

Appendix I: Installation Drawings .................................................................................20

MWL Installation Drawing for the MUS-STD Standard Duty Belt Scale ................................20

MWL Installation Drawing for the MUS-HD Heavy Duty Belt Scale .......................................21

Retrofitting an MUS-HD Heavy Duty Belt Scale: ...............................................................22

MWL Installation Drawing for the MSI or MMI Belt Scale ........................................................23

Retrofitting an MSI or MMI Belt Scale: ...............................................................................23

Appendix II: Customer Calculation Sheet .................................................................... 27

Calculation of Total Calibration Weight Mass ...................................................................27

Calculation of Load Reference Values .................................................................................27

Using the Factoring Function of the Belt Scale Integrator .............................................28

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 1

Page 4

Milltronics Weight Lifter (MWL):

Introduction

Note: Please follow the installation and operating procedures to ensure a quick,

trouble-free installation, and to allow for the maximum accuracy and reliability of your

Milltronics Weighing System.

The Milltronics Weight Lifter (MWL) mechanically raises and lowers the static

calibration weights used to calibrate Milltronics belt scales. It stores the weights

securely between the belt strands, above the calibration-weight support arms, and

allows the operator to lower and apply the weights safely without having to lean into the

conveyor.

The MWL is manually operated, and utilizes a high mechanical advantage to enable

weights up to 225 Kg (500 lb) to be applied with very limited effort. The crank handle can

be attached to either the left or right crank body. It uses 4 revolutions for full range of

motion, and can be removed and stored for safety on the locking ball-pin which secures

the MWL when it is not in use.

Two lifting pads support a base-bar weight above the calibration-weight supports of the

belt scale: either flat bar or horseshoe style calibration weights are available. Locating

notches in the base-bar weight engage the calibration weights securely on the lifting pads

in the stored position, and the worm gear drive locks the lifting pads in place. A manuallyapplied locking-pin secures the MWL when the calibration-weights are in the stored

position.

Applications

The MWL is designed to work with the following Milltronics belt scales:

• MUS-STD MIlltronics Standard Universal Scale

• MUS-HD Milltronics Heavy-Duty Universal Scale

• MSI Milltronics Single Idler Scale

• MMI Milltronics Multiple Idler Scale (combination of 2 MSI Scales)

Belt Scale Manuals can be downloaded from the Milltronics website at:

www.Milltronics.com

Page 2 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 5

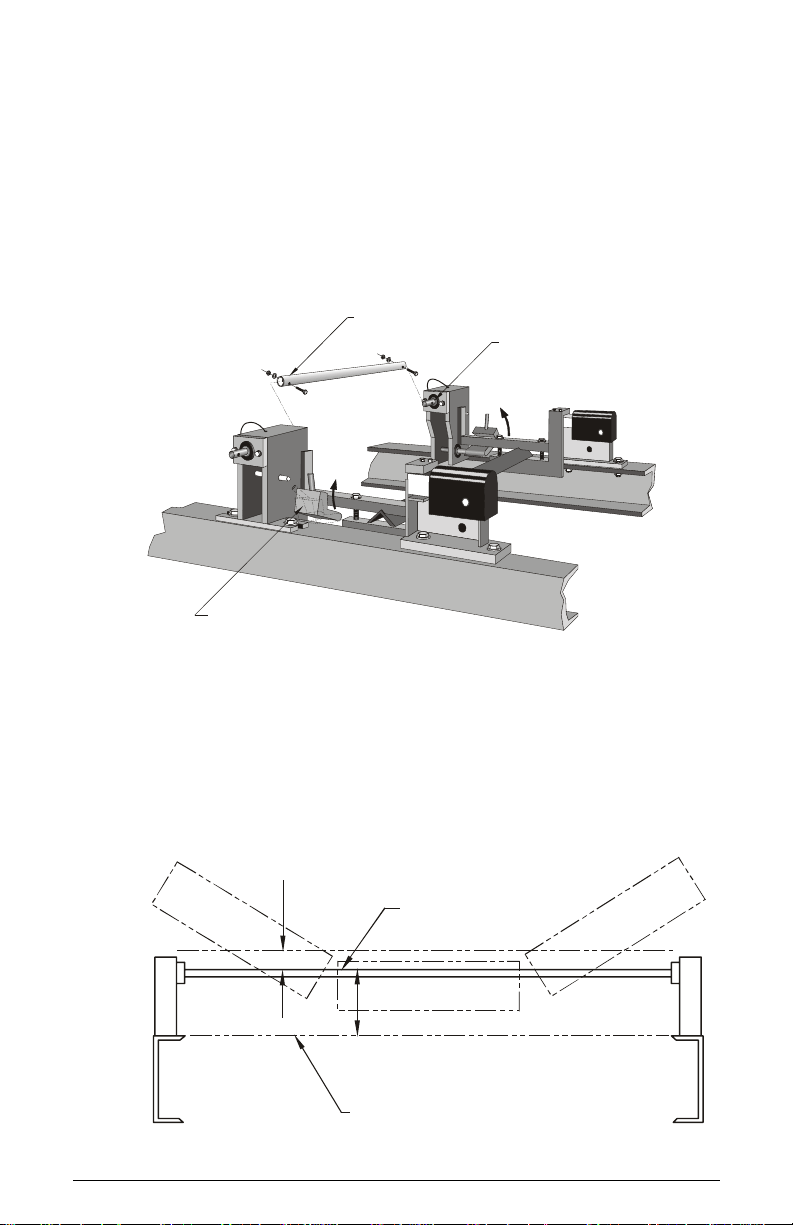

MWL Components

• a left-handed and right-handed crank body, each connected to a lifting-pad with guide-pin

• torque tube, to connect the left and right crank shafts

• crank handle, to be mounted to either the left or right input shaft

• optional shaft extension; adds 102mm (4") to handle shaft length

• base-bar weight (either flat bar or horshoe style) to support other supplied calibration

weights

• U-clamp to secure flat bar calibration weights

Shaft Extension

(optional)

Input Shaft (2)

Crank

Handle

Connecting Shaft

Torq ue Tu be

Torq ue Tu be

Right-handed

Crank Body

Lifting-pad (2)

Guide-pin (2)

Connecting Shaft (2)

Left-handed Crank Body

Base-bar Weight

Cut-away view of Gear Drive

(Left-hand, clockwise-rotating crank-body shown)

Worm Gear

Travel Sto p

Input Shaft

Guide-pin

Lifting-pad (lifts

as it rotates)

Removable

Travel Sto p

Plate Guide

Drive Plate

Output Shaft

Crank Handle

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 3

Page 6

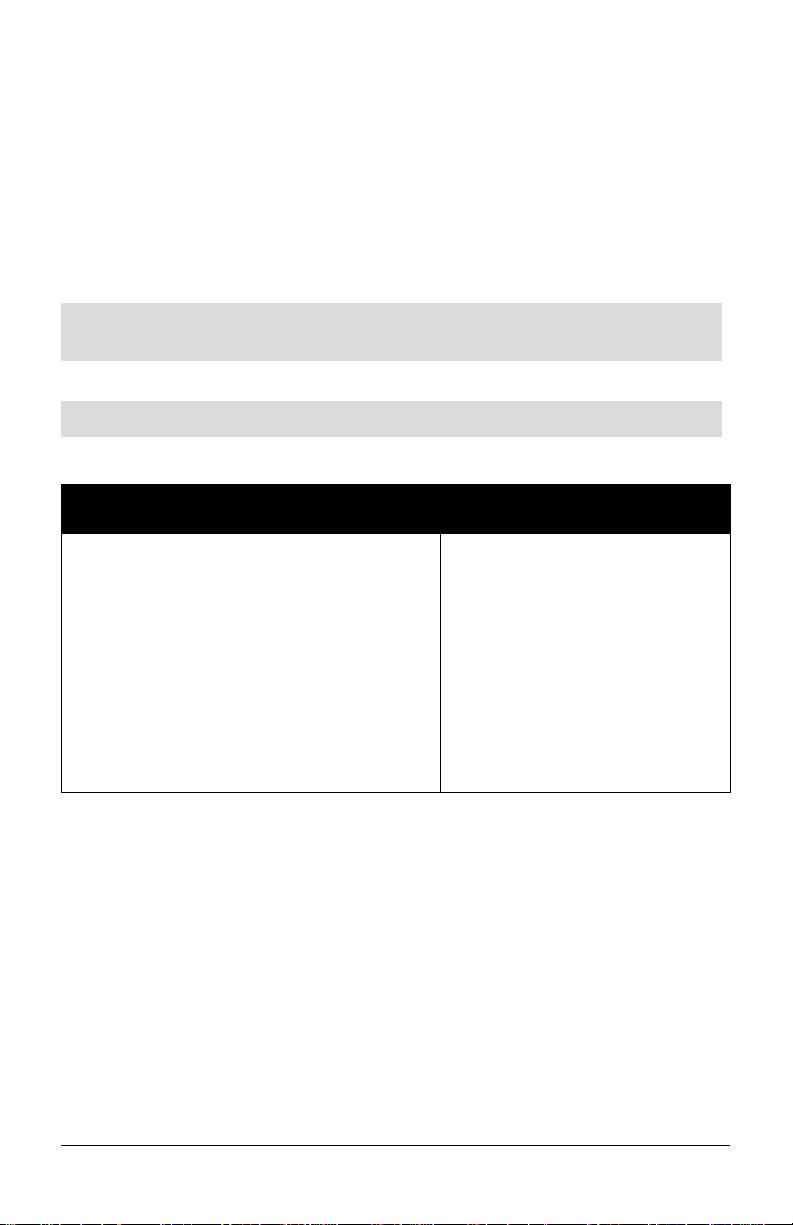

Calibration Weight Arrangement

Flat Bar Style Calibration Weights

Flat Bar Calibration Weights

Flat Bar Base-bar Weight

U-bracket

(supplied with

MWL)

Horseshoe Style Calibration Weights

Horseshoe-style Calibration Weights

Horseshoe-style

Base-bar Weight

The horseshoe weights are not symmetrical:

an offset channel locates them on the base-bar weight.

Rotate alternate weights through 180

are staggered, to stabilize the base-bar weight.

o

so that the weights

offset

Page 4 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 7

Specifications

Belt Width

• MUS-STD Standard Duty: up to 1000mm; CEMA width 42"

• MUS-HD Heavy Duty: 1200mm and up; CEMA width 48" : can also be applied to

narrower conveyors

• MSI Single Idler: 500 to 2000mm; CEMA width 18" to 84" (prepared for use

with MWL)

• MMI Dual Idler: consists of 2 MSI scales, 2 MWL units are required

Idler Spacing

• Minimum of 610mm (24")

Calibration Weight Capacity

• MUS-STD: up to 175 lb (80 kg)

• MUS-HD: up to 350 lb (160 kg)

• MSI singly, (or MMI system): up to 500 lb (225 kg)

Crank Arm

• Mechanical Advantage: 20:1

• Number of Revolutions required for raising or lowering: 4

Calibration Weight Dimensions

Idler Mounting Stance + 65mm (2.56")

Mounting Dimensions

• See detail installation drawings on page 20, page 21, and page 23, for MUS-STD

Standard Duty, MUS-HD Heavy Duty, and MSI Single Idler belt scales.

Approvals

• The MWL Milltronics Weight Lifter is in compliance with Directive 98/37/EC.

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 5

Page 8

Installation

The Milltronics belt scale must be completely installed before you install the MWL.

Please refer to the belt scale installation manual for installation details.

Note: Check that there will be sufficient clearance for the MWL. (See detail, Check

Clearance for Conveyor Belt: page 8.) Clearance can be created artificially by

shimming the idlers in the scale area.

The MWL installation has eight stages:

• Drilling the crank body mounting holes

• Mounting the crank bodies

• Mounting the torque shaft

• Installing the crank handle

• Testing the unloaded MWL

• Installing the calibration weights

• Testing the loaded MWL

• Shimming the MWL (if required)

1. Drill left and right crank body mounting holes

• Refer to the appropriate MWL installation drawing for your Milltronics belt

scale.

• Measure and mark the locations of the mounting holes for each of the crank

bodies. The left-handed unit turns clockwise to raise weights and the righthanded unit turns counter-clockwise: handing is marked on the crank bodies.

• Drill these holes as specified for 12mm (1/2") mounting hardware.

Page 6 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 9

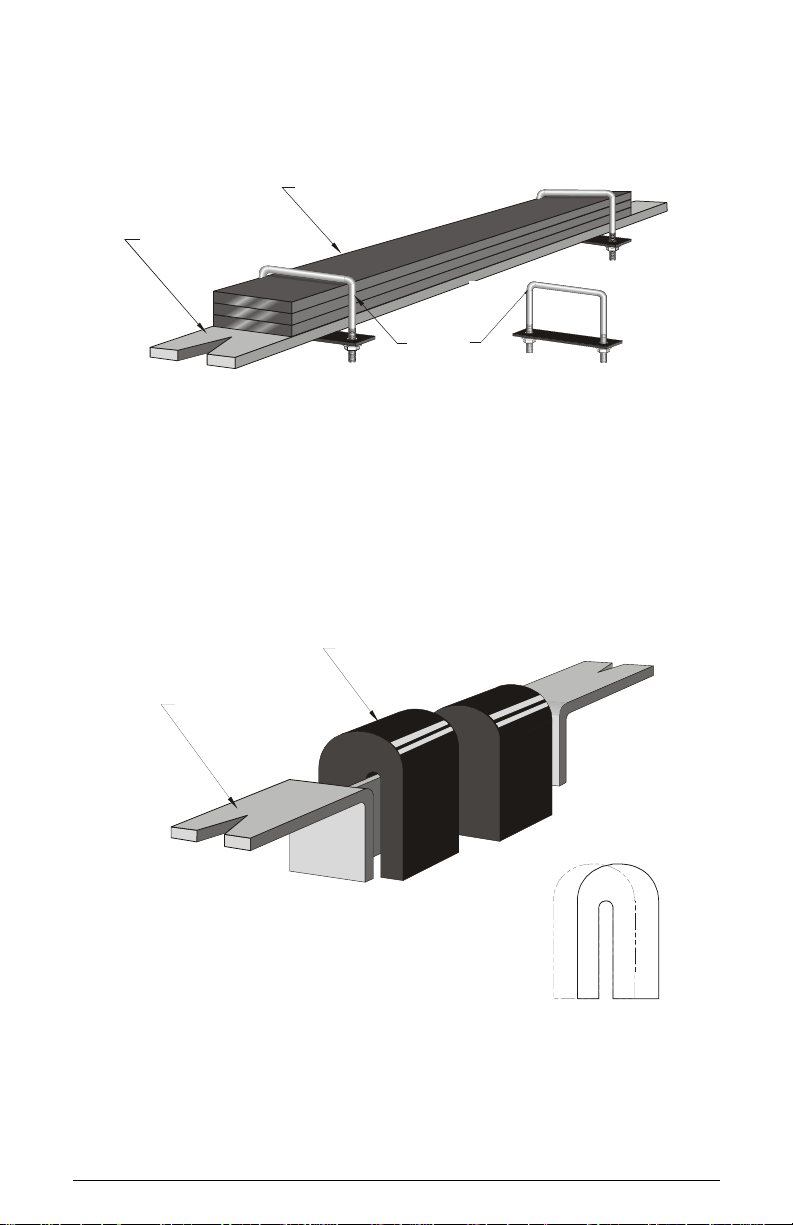

2. Mount left-handed and right-handed crank body

• Refer to the shim thickness tables on page 15 to determine whether you need to

shim the MWL. Shimming is not always required: it is more likely to be required

with the MUS scale, and less likely with the other models.

• If necessary, select and position the appropriate size shim(s).

• Loosely mount each crank body to the conveyor stringers using 12mm (1/2")

bolts, nuts, and washers.

Right-hand (counter-clockwise rotating) Crank Body Shown

Crank body

Input shaft

Locking ballpin tethered

to crank body

Shim (if required)

Bolt

Wash er

Nut

Note: The crank bodies must be left loose to allow for the torque shaft installation.

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 7

Page 10

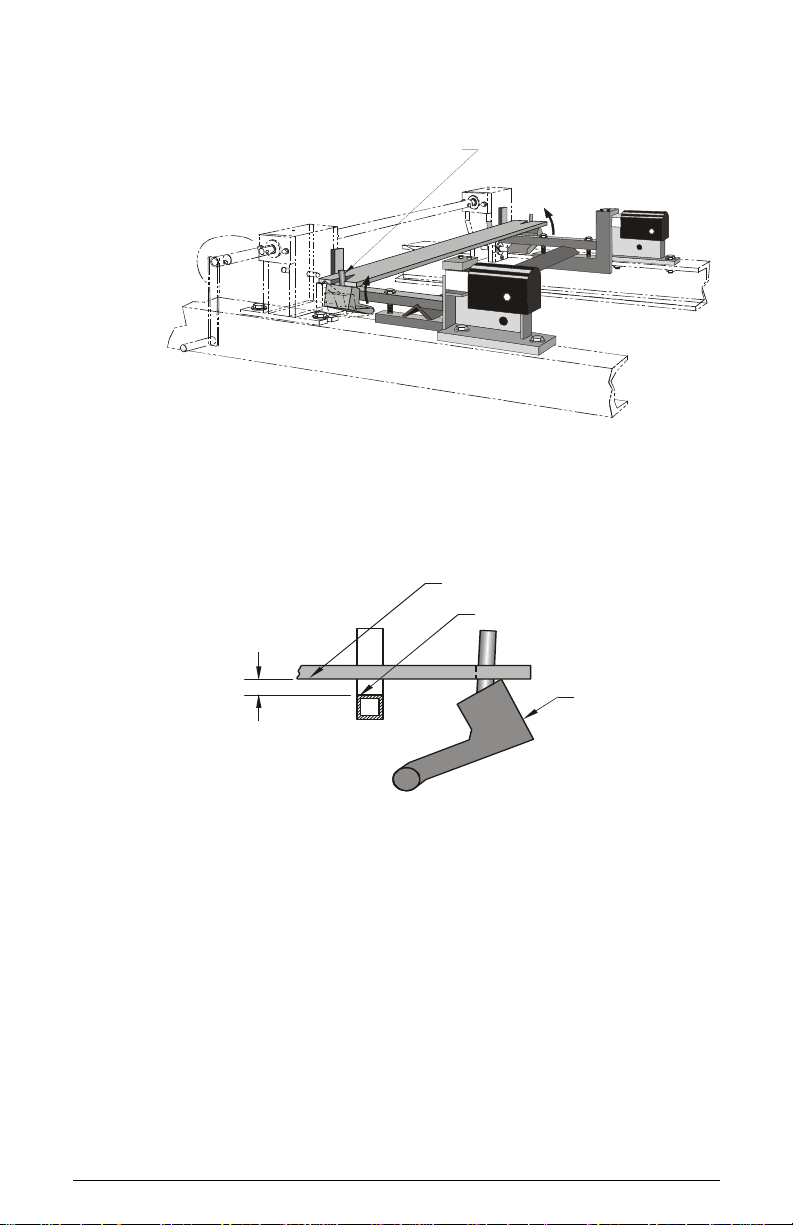

3. Mount torque shaft / Check clearance for conveyor belt

• Leave the locking ball-pins in place to hold the lifting pads of both crank bodies

in the raised position.

• Place the torque tube over the connecting shafts of the left and right crank

bodies.

• Loosely install the bolts, nuts, and washers that hold the torque tube onto the

connecting shafts.

• Hand tighten the bolts, nuts, and washers that mount the crank bodies to the

stringers.

• Hand tighten the bolts, nuts, and washers that hold the torque tube onto the

connecting shafts.

Torq ue Tub e

Connecting shaft (2)

Lifting-pad in raised position (2)

Check Clearance for Conveyor Belt

• Ensure there is 10mm (0.38") minimum clearance from the top of the torque tube

to the underside of the return belt: inadequate clearance will cause the belt to

wear.

• Allow additional clearance for belt sag.

• If necessary, shim the idlers in the scale area until the clearance is adequate.

(See the Belt Scale Instruction Manual for detailed shim procedures.)

Min.10mm (0.38") clearance to underside

of return belt + allowance for belt sag

Top of torque tube

176mm (6.94")

Top of stringers

Page 8 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 11

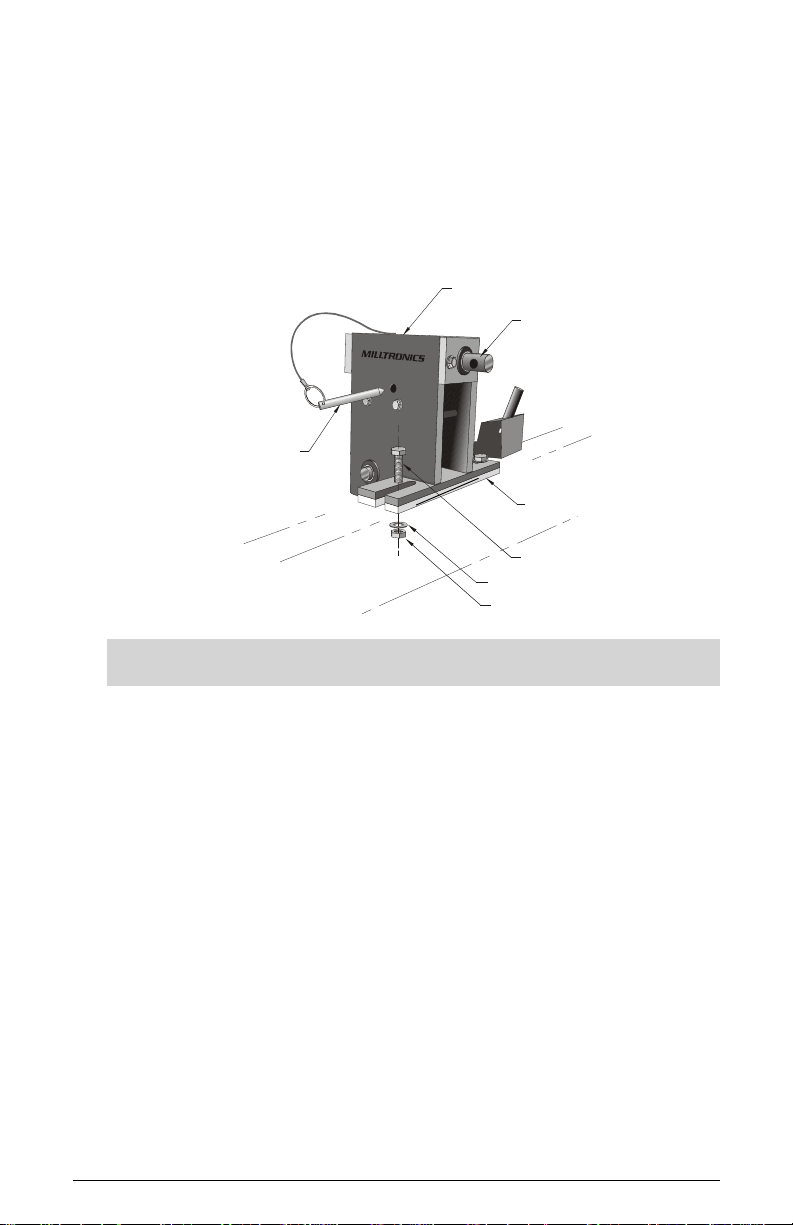

4. Install crank handle

• Determine whether it will be more convenient to have the handle attached to the

left-handed or the right-handed crank body, and if the shaft extension is

required.

• Remove the plastic cap from the input shaft on the selected side.

• If the shaft extension is required, slide the female end of the extension over the

exposed input shaft, and secure the extension with a bolt, nut, and washer.

• Slide the female end of the handle over the exposed input shaft (or shaft

extension).

• Secure the handle in place using the tethered locking ball-pin provided.

Locking ball-pin

(tethered to

Crank Body)

(tethered to Crank Handle)

Locking ball-pin

Shaft Extension

Input Shaft

Crank Handle

(female end)

Nut

Hole for storage

on locking ball-pin

Wash er

Bolt

Bolt

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 9

Page 12

5. Test the unloaded MWL / Align crank bodies

• Remove the locking ball-pins from each of the crank bodies. The ball-pin on the

access side will serve as a locking safety pin when the weights are stored.

• Turn the crank handle and watch the lifting pads move up and down.

• Check to see whether any binding occurs during the process. If there is any

binding or hesitation, the crank bodies need to be aligned to each other.

Calibration weight support (2)

Lifting-pads raised

Lifting-pads lowered

Align the crank bodies to each other, if necessary

a. Loosen the two bolts that mount each crank body.

b. Turn the crank handle until the lifting pads have completed at least one

complete cycle from a raised to a lowered position: this process should

automatically align the crank bodies.

c. Retighten the bolts that mount the two crank bodies.

d. Check again, and repeat the process until the MWL operates smoothly, with no

resistance.

Page 10 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 13

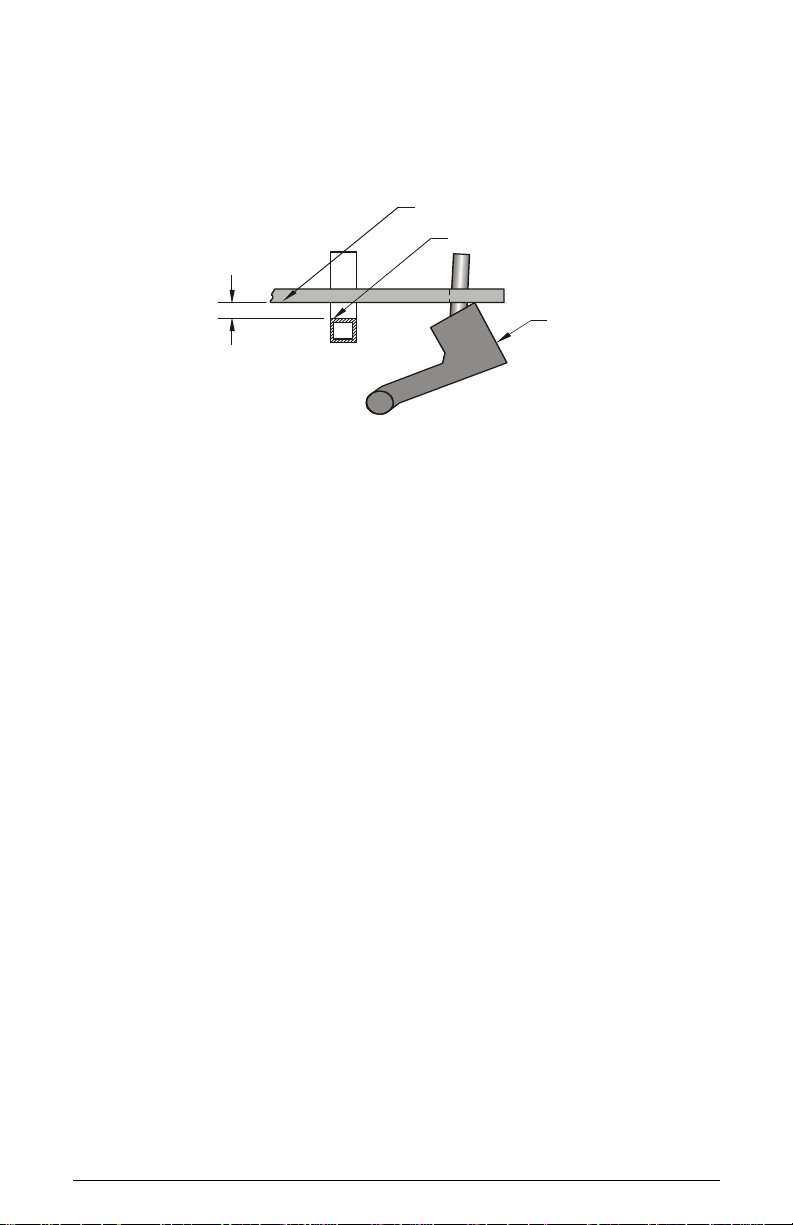

6. Install calibration weights / Check for clearance

Note: Ensure adequate base-bar weight clearance before adding calibration weights.

Base-bar weight

applied

Lifting-pads down

• Turn the crank handle until the lifting pads are fully lowered.

• Place the base-bar weight into position on the calibration-weight supports of

the Milltronics belt scale.

• Ensure there is 10mm (0.38") minimum clearance between the underside of the

base-bar weight and the top of the lowered MWL lifting pads. If necessary, shim

the belt scale and adjacent idlers to achieve this clearance.

Calibration-weight support

Underside of base-bar weight

10mm (0.38") minimum gap

Top surface of lifting-pad

Lifting-pad lowered

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 11

Page 14

• Gently turn the crank handle until the lifting pads are fully raised: you may need

to guide the notches in the base-bar weight onto the round guide-pin initially.

Round guide pin engages the notch

on the end of the base-bar weight

• Ensure there is 10mm (0.38") minimum clearance between the underside of the

base-bar weight and the top surface of the calibration-weight support when the

lifting pads are fully raised. If necessary, shim the MWL to achieve this

clearance.

Underside of base-bar weight

Top surface of calibration-

weight support

Lifting pad raised

10mm (0.38")

minimum clearance

Page 12 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 15

• Ensure there is sufficient clearance between the side of the base-bar weight

and the vertical arms of the calibration-weight support arm, or support bracket:

(see dimensions shown below). If necessary, move the two crank bodies further

from the calibration-weight supports to achieve this clearance.

Minimum clearance on MUS Scales: 10mm (0.38")

on MSI Scales: 12.5mm (0.5")

Ver tical a rm

of calibration-weight support

Base-bar weight

• Recheck the crank body alignment: (See “Align the crank bodies to each other, if

necessary” on page 10).

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 13

Page 16

7. Test the loaded MWL

Calibration weights

applied

Calibration-weight support (2)

Lifting pads raised

• Keep the lifting-pads raised, and add the other calibration weights

• Check again to ensure there is 10mm (0.38") minimum clearance between the

side of the stacked weights and the vertical arms of the calibration-weight

supports. If necessary, move the two crank bodies further from the calibrationweight supports to achieve this clearance.

Minimum clearance on MUS scales: 10mm (0.38")

on MSI Scales: 12.5mm (0.5")

Vertical arm of calibrationweight support

Calibration weights

• Recheck the crank body alignment: (See “Align the crank bodies to each other, if

necessary” on page 10)

Page 14 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 17

8. Shim the MWL (if required) / Recheck base-bar weight for clearance

When the MWL is used with the MUS belt scale, due to the wide variety of idler types

and sizes, it may be necessary to shim the MWL for proper operation.

Note: These tables are provided as a guideline only: shimming is often not required

Shim Tables

Angle Spine:

Angle Size

2" none

2-1/2" 0.31" (8mm) 1

3 " 0.31" (8mm) 2

3-1/2" 0.31" (8mm) 3

4" 0.31" (8mm) 4

• Compare your idler spine to the spine type and size in the tables above, for a

guide to the size of shims you may require.

• Select shims that will allow you to adjust the MWL crank bodies to the correct

level.

• Remove the bolt, nut, and washer on one crank body and position the shim

between the crank body and the conveyor stringer: it should not be necessary to

loosen or remove the torque tube connecting the two crank bodies.

• After the shim is in position, re-install and tighten the bolt, nut, and washer.

• Repeat the same procedure with the other crank body, then recheck the crank

body alignment. (See next page for details.)

Shim

Thickness

Number of

shims

Channel

3" none

4" 0.31" (8mm) 1

5" 0.31" (8mm) 1

6" 0.31" (8mm) 2

Size

Channel Spine:

Shim

Thickness

Number of

shims

Bolt

Shim, if required

Washer

Nut

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 15

Page 18

Recheck crank body alignment

• After shimming, raise and lower the lifting pads to check whether there is any

binding or hesitation. If there is, repeat the alignment procedure on page 10.

• Raise the lifting pads again and check the clearance between the underside of

the base-bar weight and the top surface of the calibration-weight support.

Underside of base-bar weight

Top surface of calibration-

10mm (0.38")

minimum clearance

weight support

Lifting pad raised

• Repeat the shimming procedure until the lifting pads raise the calibration

weights at least 10mm (0.38") above the calibration-weight supports.

• Tighten the torque shaft bolts and the crank-body mounting bolts, then recheck

all clearances.

The MWL installation is now complete.

Page 16 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 19

Operation

Note: To ensure accurate calibration, you must keep the area between the MWL

lifting pads and the calibration weights clear of buildup during the calibration routine.

(See Maintenance procedures on page 19.)

Applying calibration weights

Simply turn the crank handle until the calibration weights are fully lowered onto the

calibration-weight supports of the belt scale. (Please see the manuals for the Milltronics

Belt Scale and the Integrator, for the appropriate calibration procedures.)

Flat bar calibration

weights applied

Calibration-weight supports (2)

Lifting pads down

Storing calibration weights

After you have completed the scale calibration procedure, turn the crank handle until the

lifting-pads are fully raised.

Crank Handle stored on far side of

Crank Body, with locking ball-pin

Lifting-pads

raised

Storing crank handle

Remove the crank handle and store it. (See next page for details.)

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 17

Page 20

Remove the crank handle and store it, to prevent it from impeding traffic or material when

the conveyor is in operation.

• Remove the locking ball-pin tethered to the crank handle, and remove the handle.

• Use the locking ball-pin tethered to the crank body nearest to the handle to secure

the MWL from unintended use and to store the crank handle.

• Insert the locking ball-pin through the hole in the crank handle, and into the

insertion point in the center of the crank body. Two clips on the side of the crank

body help to hold the handle in position.

• Cover the input shafts with a guard, if they present a hazard to personnel when the

MWL is not in use.

Page 18 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 21

Maintenance Procedures

Removing material accumulation

To ensure that the belt scale will provide optimal accuracy, periodically inspect the area

around the calibration weights and remove any material build-up.

The calibration weights must remain consistent to calibrate the scale correctly. If material

accumulates on top of them, the added weight will cause the calibration procedure to

produce poor results. The top surface of the calibration-weight supports must also be kept

clean for the scale to produce accurate results.

Material should not accumulate inside the crank body housings under normal operating

conditions, but it is a good idea to inspect them periodically.

Note: Before starting a calibration procedure, be sure to check that there is no

material accumulation in the three areas described below:

1. Top surface of

calibration weights

(Bushed

end-plate)

3. Inside crank body

1. Remove any material build-up from the top of the calibration weights.

2. Remove any material build-up from the top surface of the calibration-weight

supports between the calibration weights and the conveyor scale.

3. Check inside the MWL crank body and inspect the worm gear drive: if material has

accumulated here, remove it with an air stream or other suitable device.

2. Top surface of calibrationweight support

Note: The worm gear and notched plate are normally not accessible to the human

hand: do not force any foreign matter into the area during operation.

Greasing

On both crank bodies, the teeth of the drive plate are greased at the factory. They should

not require further greasing for a number of operations, depending on operating

conditions. Inspect the drive plate periodically, but apply grease only when it is required.

You may need to remove the bushed end-plates temporarily, to gain access to the teeth

and worm gear.

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 19

Page 22

Appendix I: Installation Drawings

MWL Installation Drawing for the MUS-STD

Standard Duty Belt Scale

516mm

(20.30")

14mm (0.56") dia. holes (typ.)

133mm

(5.22")

214mm

(8.43")

Belt Width + 229 mm (9")

or to suit

10mm (0.38") minimum clearance

from vertical arm to weights

Base-bar weight centered

on guide-pin

Belt

Belt Width + 229 mm (9")

Belt

or to suit

Page 20 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 23

MWL Installation Drawing for the MUS-HD

Heavy Duty Belt Scale

608mm

133mm

(5.22")

246mm

(9.67")

(23.92")

14mm (0.56") dia.

holes (typ.)

Belt width + 229mm (9")

or to suit

10mm (0.38") minimum clearance

from vertical arm to weights

C

Base-bar weight

centered on guide-pin

Belt

Belt

Belt width + 229mm (9")

or to suit

Retrofitting an MUS-HD Heavy Duty Belt Scale:

See next page for details.

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 21

Page 24

Retrofitting an MUS-HD Heavy Duty Belt Scale:

Two new idler clamping brackets are supplied with the MWL. These brackets provide

better clearance for the base-bar weight and the flat bar calibration weights.

• Replace the existing idler clamping brackets with the new idler clamping brackets,

one at a time, re-using the existing bolts, nuts, and washers.

• Tighten the nuts securely while ensuring that the clamping brackets remain parallel

to the run of the conveyor stringers.

Please see the MUS instruction manual for further details.

Page 22 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 25

MWL Installation Drawing for the MSI or MMI

Belt Scale

14mm (0.56") dia.

holes (typ.)

Belt width + 229mm (9")

or to suit

133mm

(5.22")

265mm

(10.42")

Base-bar weight

centered on guide-pin

Belt width + 229mm (9")

or to suit

Belt

Belt

12.5mm (0.5") minimum clearance

from vertical arm to weights

Retrofitting an MSI or MMI Belt Scale:

Two new calibration-weight brackets are supplied with the MWL to replace the existing

calibration-weight bar. New bolts are supplied, but you will also need a C-clamp, metric

Allen keys, and metric wrenches.

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 23

Page 26

Note: Take care to protect the load cells from impact or prying forces during

installation of the new calibration-weight brackets.

1. Rotate the shipping stops on the MSI into a vertical position, and tighten screws A

to secure the stops in place. This will help to protect the load cells from damage

while the calibration-weight brackets are being installed.

Screws

A

Shipping stop in

free position

Screws

B

Shipping stop in

free position

2. Remove the idler.

Idler removed

Shipping stops in

vertical position

Calibration-weight bar removed

Calibration-weight brackets

Bolts - (step 6)

3. Remove the two socket-head cap-screws that secure the calibration-weight bar,

then remove the calibration-weight bar from the dynamic beam of the belt scale.

Page 24 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 27

4. Clamp the bottom of the idler support angle-brackets to the dynamic beam, using

two C-clamps.

Angle-bracket

Dynamic beam

C-clamp

Calibration weight

bracket

5. Remove the four socket flat-head bolts that secure the idler support angle-brackets.

6. Mount the new calibration-weight brackets using the same holes as the idler

support angle brackets. Use the new bolts and nuts supplied with the MWL, and

hand-tighten the nuts.

7. Align the new calibration-weight brackets with each other vertically and

horizontally.

8. Tighten the nuts and bolts firmly to secure all four brackets. Torque value = 54.6 Nm

(40 ft-lbs.)

9. Remove the C-clamps.

10. Re-install the idler and check idler alignment as described in the Belt Scale

Instruction Manual.

11. Free the weighing mechanism: loosen screws A and rotate the 2 shipping stops

inward and down, over screws B (See step 1, page 24). Tighten screws A to secure

them in place.

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 25

Page 28

Page 26 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 29

Appendix II: Customer Calculation Sheet

Calculation of Total Calibration Weight Mass

Record the value of the base bar and weights to be attached. The weights should be

recorded in kilograms or pounds, depending on the units system. In the case of 100mm (4")

flat bar weights, the U-bolts which secure the bars each weigh 0.43 gm. (0.95 lb).

Weight of Base Bar __________________ kg. or lb.

Mass of Calibration Weights ___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Grand Total ___________________ kg. or lb.

Calculation of Load Reference Values

Calibration Reference Value in kilograms/metre = Grand Total in kg

Idler Spacing in m

Or

Calibration Reference Value in lb/foot = Grand Total in pounds

Idler Spacing in feet

7ML19981CR01 Milltronics Weight Lifter MWL – Instruction Manual Page 27

Page 30

Using the Factoring Function of the Belt Scale Integrator

If the belt scale system has been pre-calibrated, as in the case of an MWL retrofit, the belt

scale system should be zeroed. The Factor function of the Integrator should be used to

accurately determine the value of the calibration weights in terms of the existing span

calibration. (See the Integrator manual for more detail.)

Page 28 Milltronics Weight Lifter MWL – Instruction Manual 7ML19981CR01

Page 31

*7ML19981CR01*

Loading...

Loading...