Page 1

MMI-2

2 IDLER BELT SCALE

Instruction Manual PL-327 January 2001

33453270

Rev. 2.3

Page 2

Safety Guidelines

Warning notices must be observed to ensur e personal safety as well as that of others, and to protect the product and the connected equipment.

These warning notices are accompanied by a clarification of the level of caution to be observed.

Qualified Personnel

This device/system may only be set up and operated in conjunction with this manual. Qualified personnel are only authorized to install and

operate this equipment in accordance with established safety practices and standards.

Warning

Note

This product can only function prope r ly and saf ely if it is correctly transported, stored, installed, set up , operated, and maintained.

:

Always use product in accordance with specifications.

:

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2000. All Rights Reserved

This document is available in bou nd version and in

electronic version. We encourage user s to purchase

authorized bound manuals, or t o view electronic versions as

designed and authored by Siemens Milltronics Process

Instruments Inc. Siemens Milltronics Process Instruments

Inc. will not be responsible for the contents of partial or

whole reproductions of either bound or electronic versions.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

While we have verified the contents of this

manual for agreement with the instrumentation

described, variations remain possible. Thus we

cannot guarantee full agreement. The content s of

this manual are regularly reviewed and

corrections are included in subsequent editions.

We welcome all suggestions for improvement.

Technical data subject to change.

Contact SMPI Technical Publications at the following address:

Technical Publications

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs@milltronics.c om

For the library of SMPI instruction manuals, visit our Web site:

© Siemens Milltronics Process Instruments Inc. 2001

www.milltronics.com

Page 3

TABLE OF CONTENTS

Title Page

ABOUT THIS MANUAL 1

ABOUT THE MMI-2 1

SPECIFICATIONS 2

OPERATION 3

INSTALLATION

CALIBRATION

Preamble 4

Welding 4

Load Cell Handling 4

Installation Procedure 5

General 8

Test Load 8

Zero 8

Span 8

Material Test 9

Re-Rating 9

MAINTENANCE AND SPARE PARTS 9

IDLER MOUNTING

Troughed Idler with Channel Spine 10

Troughed Idler with Pipe Spine 11

Flat Idler 12

MSI WIRING 13

OUTLINE DIMENSIONS-CEMA 14

OUTLINE DIMENSIONS-METRIC 15

PL-327 i

Page 4

ABOUT THIS MANUAL

This instruction manual, PL-327, covers the installation, operation and maintenance of the MMI-2 belt scale.

It is imperative that this manual be read and understood before installation and start up of any component of

the weighing system to which the MMI-2 is being applied. Adhering to the installation and operating

procedures will insure a quick, trouble free installation and allow for the maximum accuracy and reliability of

your weighing system to be achieved.

As the MMI-2 belt scale is used in conjunction with an integrator and optional speed sensor, the instruction

manuals covering these components must be read as well.

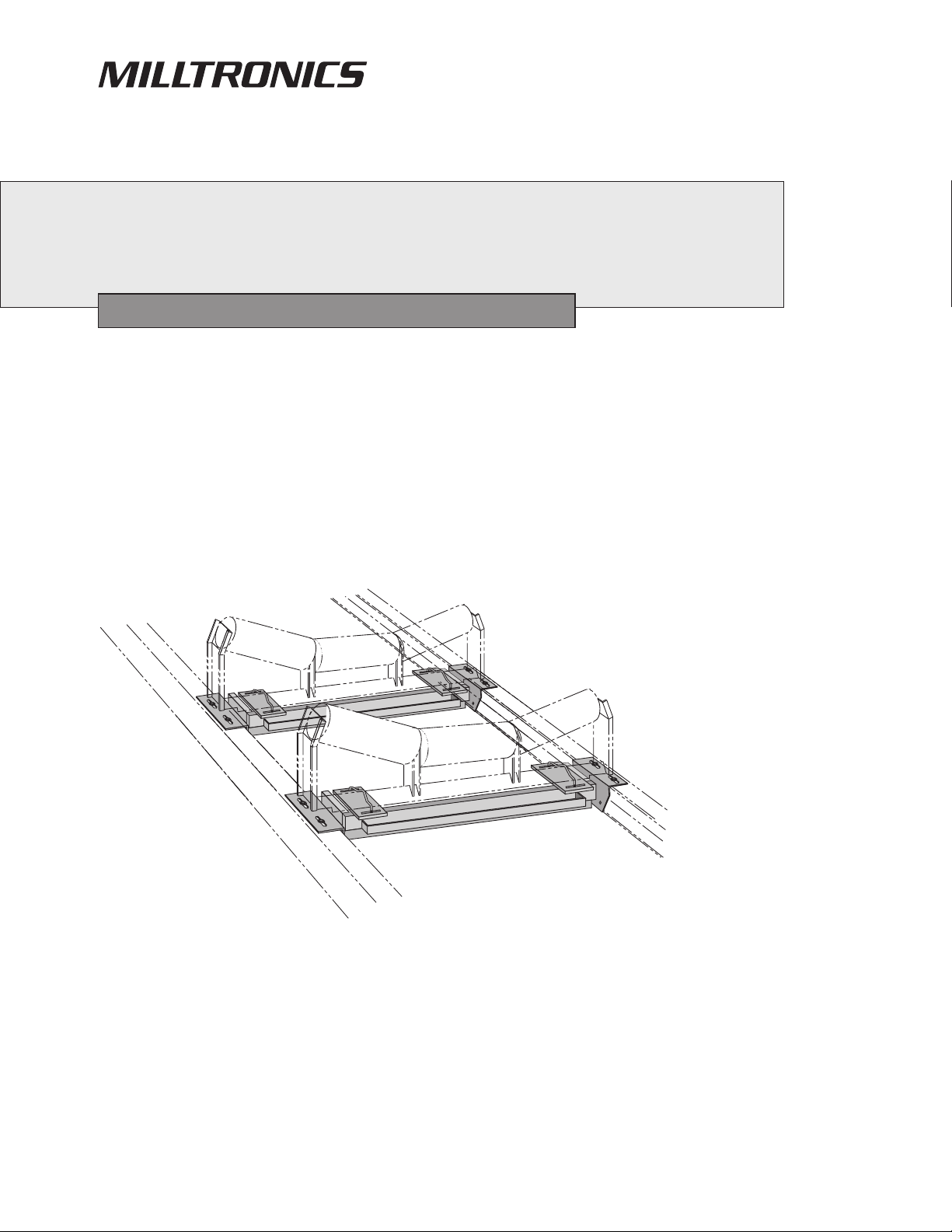

ABOUT THE MMI-2

The Milltronics Multiple Idler (MMI-2) is a belt scale application using two Milltronics Single Idler (MSI) belt

scales in succession. The scales are designed to be inserted into belt conveyors for continuous weighing of

dry bulk solids.

Each MSI is comprised of the following: - one weighbridge c/w two load cells with cables run in a

common flexible conduit

- test weight(s)

The addition of an idler (supplied and installed by customer) to each weighbridge completes th e weighing

assembly. The MMI load cells provide an electronic signal, proportional to load, which is fed to the Milltronics

CompuScale series integrator. Thus, weighing is accomplished without disturbing the process and without

affecting the process material.

The MMI-2 is used where conveyor belt speeds or belt loading charactistics result in conditions that

necessitate extending the weighing time beyond the capibilities of a single idler scale. It is also well suited for

applications that require higher sustained accuracies, such as production control inventory accountability or

where certification for trade purposes is required.

It is important to understand that the MMI-2 is an accurate and repeatable force sensor. Its performance is

ultimately dependent upon the conveyor system and the quality of the installation and alignment.

PL-327 1

Page 5

SPECIFICATIONS

Accuracy: » ± 0.25% of totalization over 5 to 1 operating range

in factory approved installations

Belt Width: » 18" to 96" in CEMA sizes

» 500 to 2000 mm in metric sizes

» refer to Outline and Dimensions

Belt Speed: » up to 4 m/s (800 fpm)

Capacity: » up to 5000 TPH at maximum belt speed

Conveyor Incline: » ± 20° from horizontial, fixed incline

» up to ± 30° with reduced accuracy

Conveyor Idler: » flat to 35°

» up to 45° with reduced accuracy

Idler Diameter: » 50 to 180 mm (2 to 7")

Idler Spacing: » 0.5 to 1.5 m (1.5 to 5.0 ft)

Load Cell: » excitation: » 10 V DC nominal

» 15 V DC maximum

» output: » 2 mV / V excitation at rated load cell capacity

» non-linearity: » 0.02% of rated output

» hysteresis: » 0.02% of rated output

» non-repeatability: » 0.01% of rated output

» capacity: » maximum ranges: 50, 100, 250, 500, 750,1000 lb

» overload: » maximum 1000% of rated capacity

» temperature: » – 40 to 85 °C (– 40 to 185 °F) operating range

» – 15 to 65 ° C ( 5 to 150 °F) internally compensated

Approvals: › CSA certified for general purpose

Hazardous Locations: › with the use of approved intrinsically safe barrier strips

Weight: › see chart, Outline and Dimensions

PL-327 2

Page 6

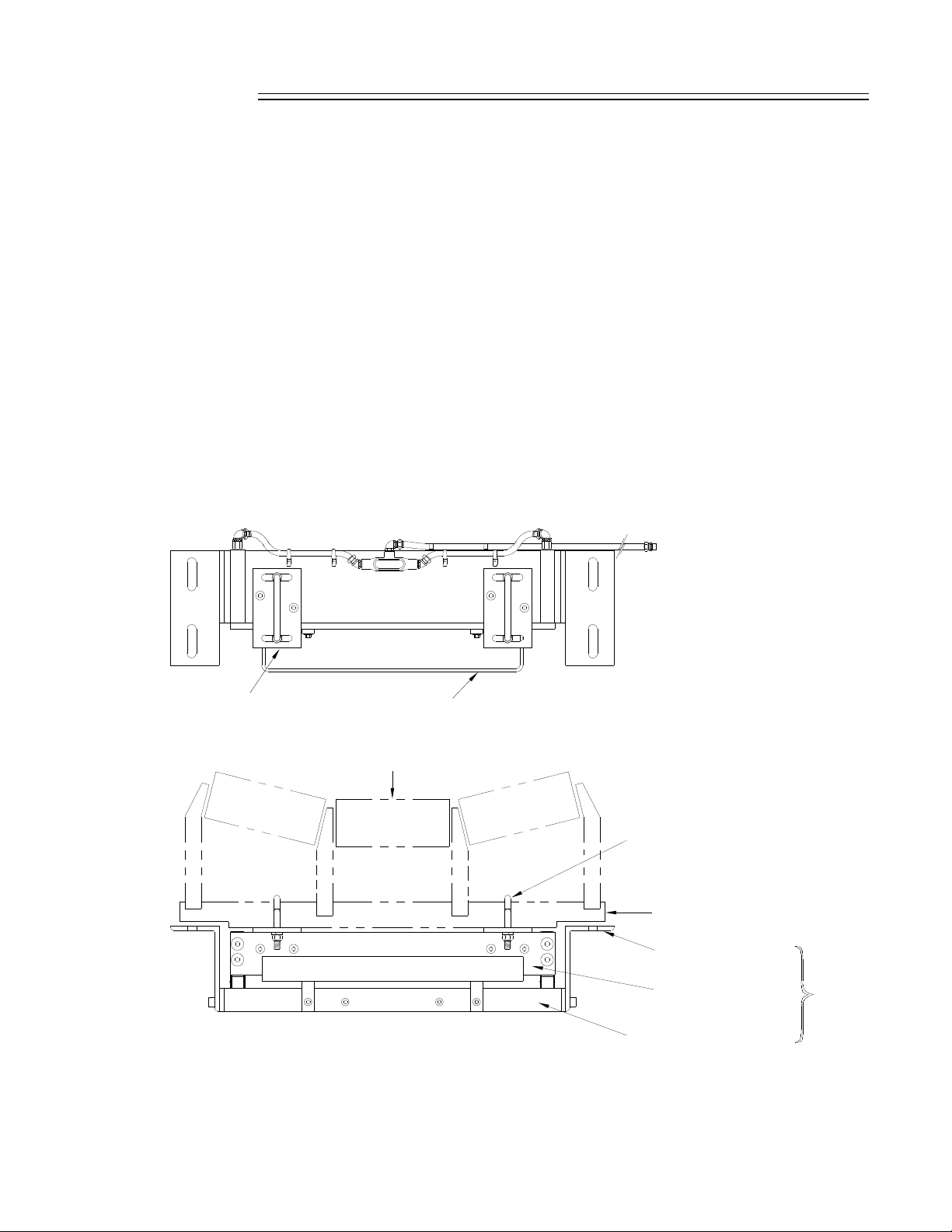

OPERATION

Each MSI weighbridge is designed to react to the vertical component of the force being applied to it. Each MSI

consists essentially of a static assembly and a weighing assembly.

The static assembly is used to mount each MSI between the conveyor stringers and supports the weighing

assembly via its load cells.

The weighing assembly supports the scale idler and transfers the weight of the material to the load cells.

These are the active components in the weighing assembly.

As the material travels along the conveyor, a force is exerted through the suspended idler onto the weighing

assembly. The weighing assembly is forced down proportionally. The movement in each load cell is sensed

by its strain gauges. These modulate the excitiation signal from the electronic integrator to produce a signal

proportional to weight, which is returned to the integrator. The movement in the load cell is limited by the

positive stop incorporated in the design of the load cell.

idler bracket

test weight bar

Force

idler clip

idler frame

scale mounting bracket

dynamic beam

static beam

weigh

bridge

PL-327 3

Page 7

INSTALLATION

PREAMBLE

The MMI-2 is shipped from the factory, attached to a frame for protection. Each MSI weighbridge must be

removed from its shipping frame and inspected for physical damage.

Insure that the conveyor design meets the installation requirements for the Milltronics MMI-2 scale. The

conveyor stringers must be rigid, straight, parallel to and square with the belt line in the area of the scale

installation. The idlers to be used on the scale and at least the next two approach and retreat idlers must be

of the same style and manufacture and in good condition.

Prepare the site in accordance with the Milltronics drawing(s) provided or by reference to Milltronics

instruction manual PL-328, Applications Guidelines.

WELDING

Extreme caution should be used when arc welding in the area of the belt scale. Insure that no welding current

can flow through the belt scale. Welding currents through the scale are sufficient to functionally destroy the

load cells.

LOAD CELL HANDLING

The load cell can tolerate very little negative displacement, otherwise the load cell will be functionally destroyed.

When handling the individual MSI’s install both shipping stops to their vertical position to protect the load cells.

Do not lift the MSI’s by the weighing assembly or subject it to shock from blows of a hammer when trying to

position it.

DO NOT STAND OR WALK ON THE SCALE.

OVERLOADING, SHOCK AND TWISTING OF THE SCALE CAN ALL

FUNCTIONALLY DESTROY THE LOAD CELLS.

PL-327 4

Page 8

INSTALLATION PROCEDURE

1. Remove the conveyor idlers currently at the desired points of installation.

2. Remove the foot plates and modify the idler frame at both ends of the idlers as shown .

customer’s idler

12.7 mm

(0.5")

100 mm

(4")

before

after

3. Insert the MSI’s in the place of the removed idlers. The MSI is designed to use the existing holes in the

stringer and should not require further drilling. Install the mounting bolts and nuts, but do not tighten .

Remove the idler clips. Refer to Outline and Dimensions.

location of

removed idlers

material flow

test weight(s)

test weight(s)

MSI belt scales

Insure that there is sufficient clearance between the return belt and the MSI and test weight (when used

during the calibration procedure).

PL-327 5

Page 9

4. Position the individual MSI’s such that they are centered and square to the stringer. Mount the modified

idlers such that they are centered onto the scale using the idler clips. Tighten all mounting hardware.

Refer to Idler Mounting for alternate idler mounting arrangements.

Orient the scale so that the large arrow on the scale mounting brackets is pointing in the direction

of material flow.

idler clips

conveyor stringer

(typical)

5. Release the shipping stops on each MSI in order to free the weighing mechanism. Loosen screws ‘A’ and

rotate both shipping stops inward until the underside slots slide around the shoulder bolts ‘B’. Tighten

screws ‘A’ to secure in place.

‘A’ screws

shipping stop

‘B’ shoulder bolts

PL-327 6

shipping stop

Page 10

6. The idlers in the weighing area must be properly aligned and leveled by shimming the scale idler (S#), the

two approach (A#) and the two retreat idlers (R#) until they are within ± 0.8 mm (1/32") of each other.

Be sure to check that the idlers are centered and squared to the conveyor during the shimming process.

Center of

idlers to

be in line

90°

CC

idlers must be square to stringers

R 1

R 2

alignment of idlers

A 2 to R 2 to be within

±

0.8 mm (1/32")

A 2

material flow

S 1

S 2A 1

7. Precise idler alignment is very important if maximum accuracy of the weighing system is to be achieved.

Misaligned idlers will result in unequal forces being applied on each idler in the weighing area, causing

calibration and measurement errors. Use a good quality wire or string to check for alignment. The wire

or string must be able to withstand sufficient tension as to eliminate any sag. By shimming, make the

necessary adjustments to bring all the rolls of the A2 through to the R2 idlers in line within 0.8 mm(1/32").

A 2

approach idlers

A 1

S 1

S 2

MSI with modified scale idler

wire or string

(for alignment)

PL-327 7

R 1

retreat idlers

R 2

Page 11

Although the accepted tolerance for idler alignement is ±0.8 mm (1/32"), the scale mounted idlers should

never be lower than the adjacent idlers. Establishing good idler alignment is the most important part of the

installation procedure. Scale accuracy is directly affected by alignment. Proper attention must be given here.

CALIBRATION

GENERAL

After the MMI-2 has been properly installed, calibration of the weighing system must be done in conjunction

with the integrator. Refer to the integrator instruction manual for programming and calibration. The

calibration is initially done using the supplied test load. Material tests are recommended to achieve maximum

accuracy.

TEST LOAD

The test load value for each MSI is the same and is given on the accompanying data sheet. The value is to

be entered into the dedicated programming parameter of the integrator, in kilograms per meter or pounds per

feet. An equal number and mass of weights must be applied to each suspension during the span calibration

function.

If the actual idler spacing differs from that recorded on the design data sheet, the test load must be

recalculated as follows. Failure to do so will cause the design test load value to be in error.

test load = total weight of all test weights per MSI kg lb

idler spacing m ft

ZERO

Perform the zero calibration as described in the Calibration section of the integrator manual.

SPAN

The test load used in the calibration procedure is the two sets of test weights ( 1 to 12 ) supplied, one for each

MSI suspension.

Place each set of the test weights onto the calibration weight bar of the respective MSI as shown.

Perform the span calibration as described in the Calibration section of the integrator instruction manual.

After the span calibration has been completed, remove the test load and store it.

( )

OR

( )

MSI

PL-327 8

test weight(s)

Page 12

MATERIAL TEST

The MSI is guaranteed to be accurate to ±0.25% when installed on a conveyor in accordance with this manual

and meeting the qualifications outlined in Manual PL-328 "MMI Applications Guidlines". This guarantee is

based on calibrations performed using the test weights furnished with the scale and as previously referenced.

When the existing conditions are such that the installation of the scale cannot meet the above mentioned

requirements for an approved installation it is recommended that material tests be performed. This will enable

the user to compare the present scale results to the results of the material tests. The scale is then adjusted or

factored so that subsequent scale calibrations with test weights will agree with actual run of material.

At least 3 samples of a minimum of 10 minutes duration at normal capacity should be taken to insure

repeatability. Refer to "Material Test" and subsequent "Factoring" sections of the integrator manual.

RE-RATING

Any significant change in rate, speed and /or idler spacing from original design specifications should be

referred to your local Milltronics office to insure that proper design parameters are maintained.

MAINTENANCE AND SPARE PARTS

Each weighbridge should be kept clean. Accumulations of material between the weighing assembly and

static assembly as well as around each load cell can be detrimental to the weighing accuracy.

Periodically check the mechanical integrity of the scale and alignment of the stringers and idlers within the

weighing area.

The integrity of the load cells can be seen when zero and span calibrations are performed. If the zero and

span deviations display a continuous unidirectional drift or the system becomes uncalibratable for no apparent

mechanical reason, the load cells may be suspect.

Replacement of load cell(s) will require a re-balancing of the load cells. Refer to the load cell balancing

procedure for four load cells in the integrator manual.

The only spare part recommended for the MSI is the load cell. Refer to the load cell nameplate for the proper

size and model number.

Precautions :

» when arc welding near the scale do not allow current to pass through the belt scale.

» reset the shipping stops to reduce physical shock to the load cells during maintenance.

» recalibrate after maintenance and prior to use.

PL-327 9

Page 13

IDLER MOUNTING

The MSI is usually installed in conveyors employing conventional rigid structure idlers. Within this type of

idler, construction will vary depending on the manufacture and the application. The idler depicted in the

Installation Procedure uses an angle iron spine. The following depicts alternate idler construction and tips on

how they should be modified and installed.

TROUGHED IDLER WITH CHANNEL SPINE

gusset reinforcement

if required, see

Installation Procedure

customer’s idler

12.7 mm

(0.5")

foot pads welded

to idler spine

before after

100 mm

(4")

idler modification

idler clip

idler installation

PL-327 10

customer bolts

(4 places)

Page 14

TROUGHED IDLER WITH PIPE SPINE

customer’s idler

12.7 mm

(0.5")

foot pads welded

to idler spine

before after

100 mm

(4")

idler modification

idler clip

idler installation

PL-327 11

customer bolts

(4 places)

Page 15

FLAT IDLER

customer’s idler

before after

in most applications standard

conveyor manufacturers’

brackets cannot be used,

replacement brackets

(as shown) are needed

12.7mm

(0.5")

idler modification

customer bolts

(4 places)

idler installation

PL-327 12

idler clip

Page 16

MMI-2 WIRING

load cell ‘A’ (‘C’)

see detail ‘A’

load cell ‘A’

MSI #2

belt travel

MSI #1

load cell ‘B’ (‘D’)

load cell ‘B’

DETAIL ‘A’

conduit and connector

load cell

‘A’

+

E

X

E

–

E

X

E

MSI #1

–

+

S

S

I

I

G

G

A

A

to integrator

belt travel

load cell

‘B’

load cell

‘A’

MSI #2

load cell

‘B’

customer

junction

box

–

+

–

S

S

S

I

G

B

H

I

I

G

E

L

B

D

–

+

E

E

X

X

E

E

+

S

S

I

I

G

G

A

A

+

–

S

I

G

B

S

S

H

I

I

G

E

L

B

D

to integrator

PL-327 13

Page 17

OUTLINE DIMENSIONS - CEMA

‘C’

178 mm

(7")

‘D’

‘A’

‘B’

conveyor mounting scale minimum drop-in ‘C’ ‘D’ weight

belt width width ‘A’ width ‘B’

18 " 27 " 24.5 " 9.5 " 5.5 " 82 lb

20 " 29 " 26.5 " 9.5 " 5.5 " 85 lb

24 " 33 " 30.5 " 9.5 " 5.5 " 90 lb

30 " 39 " 36.5 " 9.5 " 5.5 " 99 lb

36 " 45 " 42.5 " 9.5 " 5.5 " 107 lb

42 " 51 " 48.5 " 9.5 " 5.5 " 116 lb

48 " 57 " 54.5 " 12 " 8" 162 lb

54 " 63 " 60.5 " 12 " 8" 174 lb

60 " 69 " 66.5 " 12 " 8" 185 lb

72 " 81 " 78.75 " 12 " 8" 235 lb

84 " 93 " 90.75 " 12 " 8" 261 lb

96 " 105 " 102.75 " 12 " 8" 288 lb

PL-327 14

Page 18

LINE DIMENSIONS - METRIC

‘C’

178 mm

(7")

‘D’

‘A’

‘B’

conveyor mounting scale minimum drop-in ‘C’ ‘D’ weight

belt width width ‘A’ width ‘B’

500

650

800

800

1000

1000

1200

1200

1400

1600

1800

2000

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

740

mm

890

mm

1040

mm

1090

mm

1240

mm

1290

mm

1450

mm

1540

mm

1650 / 1740

1900 / 1940

2100 / 2140

2300 / 2340

mm

mm

mm

mm

677

mm

827

mm

977

mm

1027

mm

1177

mm

1227

mm

1387

mm

1477

mm

1587 / 1677

1837 / 1877

2037 / 2077

2237 / 2277

mm

mm

mm

mm

241

241

241

241

241

305

305

305

305

305

305

305

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

140

140

140

140

140

203

203

203

203

203

203

203

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

37 kg

40 kg

44 kg

48 kg

52 kg

73 kg

78 kg

83 kg

88 kg

93 kg

98 kg

103 kg

PL-327 15

Page 19

Siemens Milltronics Process Instruments Inc.

1954Technology Drive, P.O. Box 4225

Peterborough, ON.Canada K9J 7B1

Tel: (705) 745-2431 Fax: (705) 741-0466

www.milltronics.com

c

Siemens Milltronics Process Instruments Inc. 2001

Subject to change without prior notice

*7ML19981dr01*

Printed in Canada

Loading...

Loading...