Page 1

MiniRangerPlus

mA

33454470

Rev 2.0

Instruction Manual

PL-447

October 1997

Technology based. Customer driven.

Page 2

T

hank you for purchasing Milltronics products. We endeavour to design

equipment that is simple to use and reliable in its operation, with the aim of satisfying

our customers needs.

Mill tronics has been designing and manufacturing process equipment since 1954.

Our fields of expertise include ultrasonic level measurement, in-line weighing of dry

bulk solids and motion sensing.

Milltronics is established world wide through associate offices and representatives.

Our network is continua lly b eing re fined to provide our customers with first rate

sales information, engineering assistance and after sales support.

For more details on our products and service, please contact us and we will provide

you with a listing of the offices or representatives nearest you.

P.O. Box 4225

730 The Kingsway

Peterborough, ON

Canada K9J 7B1

Tel. (705) 745-2431

Fax (705) 745-0414

709 Stadium Drive

Arlington, Texas

U.S.A. 76011

Tel. (817) 277-3543

Fax (817) 277-3894

Oak House

Everoak Estate

Bromyard Road

Worcester, WR2-5HP

England

Tel. (01905)748404

Fax (01905) 748430

Château de la Saurine

Pont de Bayeux

B.P. 6

13590 Meyreuil

Aix en Provence

France

Tel. 42.65.69.00

Fax 42.58.63.95

Page 3

Table of Contents

General Information

About This Manual 5

About MiniRanger Plus 6

Specifications

MiniRanger Plus 7

Transducer 7

Installation

Dimensions 9

Interconnection Transducer 10

Synchronization 10

Current Output 11

Relay Output 11

Power 12

ComVerter 12

Start Up

General 15

Display & Keypad Run Mode 16

Setting Up 18

Display Messages 21

PL-447 3

Program Mode 17

Page 4

Functional

Transceiver 23

Transducer 23

Temperature 23

Sound Velocity 24

Blanking 24

Loss of Echo 25

Relays General 25

Functions Alarm 25

Pump 26

Setpoints 26

Status 27

Programming 27

Run 28

Analog Output 29

Run/Program 30

Applications 33

Simple Level Application 34

Pump Control Application 36

High Level Switch 38

Applications with Standpipe 40

Parameter Description

Parameters 43

Troubleshooting 53

Appendices

Alphabetical Parameter Listing 57

Programming Chart 58

PL-447 4

■

Page 5

GENERAL INFORMATION

ABOUT THIS MANUAL

It is essential that this manual be referred to for proper installation and operation

of your MiniRanger Plus. As MiniRanger Plus requires an STH or Echomax ultrasonic

transducer to make a working system, refer to the associated transducer manual

as well.

GENERAL INFO.

Installation

Start Up

instructs you how to operate the keypad, program and

Functional

Applications

Parameters

Troubleshooting

Appendices

gives you step by step direction for the installation and

interconnection of your MiniRanger Plus.

read the display.

describes the functionality of the MiniRanger Plus, detailing the

interoperation of the salient features, and highlights transceiver,

relay and mA operation.

looks at the MiniRanger Plus from a practical point of view, using

examples of the applications it is likely to encounter.

lists the parameters available to you, with a description of their

function and use. You are urged to read this section; to familiarize

yourself with the parameters available to you, and get your

MiniRanger Plus working to its fullest.

tabulates symptoms, causes and actions to common installation and

application problems that you might encounter. Hopefully you will

never have to read this section, but know it’s there to help you.

what manual would be complete without one! Ours is an

alphabetical cross reference of the parameters and their numbers,

and a record sheet for jotting down parameter values. Handy indeed!

PL-447 5

Page 6

ABOUT MINIRANGER PLUS

GENERAL INFO.

MiniRanger Plus is a versatile material level monitoring instrument. Material level

measurement is achieved using advanced sonic echo ranging techniques. The unit is

complete with an integral multifunction liquid crystal display, a four button keypad and

an integral junction box.

Remotely coupled to an appropriate transducer, MiniRanger Plus is well suited for

short to medium range measurements of liquids or solids, in open or closed vessels.

MiniRanger Plus is at home in a wide variety of industries: food, pharmaceutical,

chemical, water, waste water - to name a few.

The MiniRanger Plus emits a series of ultrasonic pulses from the associated

transducer. Each pulse is reflected as an echo from the material and sensed by the

transducer. The echo is processed by the MiniRanger using Milltronics’ proven ‘Sonic

Intelligence’ techniques. Filtering is applied to help discriminate between the true echo

from the material, and false echoes from acoustical and electrical noise and agitator

blades in motion. The time for the pulse to travel to the material and back is

temperature compensated and then converted into distance for display, mA output

and relay actuation.

MiniRanger Plus is equipped with a two-way infrared link for compatibility with

Milltronics Dolphin communication system.

MiniRanger Plus features:

✓ multi-field LCD for: parameter, reading and bar graph display, and relay

and fail-safe status.

✓ two alarm / pump control relays

✓ quick connect wiring terminals

✓ high level switch operation

✓ lead / lag pump operation

✓ Dolphin compatibility

✓ isolated mA output

✓ sonic intelligence

✓ integral keypad

PL-447 6

■

Page 7

SPECIFICATIONS

MINIRANGER PLUS

Power: » 100 / 115 / 200 / 230 V ±15%, switch selectable

» 50 / 60 Hz, 15 VA

Range: » solids applications: 5 m (transducer dependent)

» liquid applications: 10 m (transducer dependent)

Accuracy: » 0.25% of range or 6 mm (0.24"), whichever is greater

Resolution: » 2 mm

Memory: » program stored in non-volatile FLASH memory, for

software upgrades via optional Dolphin interface

» parameters stored in non-volatile EEPROM

Display: » 38 x 100 mm (1.5 x 4") multi-field liquid crystal display

Ambient Temperature: » – 20 to 50 °C (– 5 to 122 °F)

Outputs: » transducer drive: » 43.5 kHz, 400 V peak pulses of 1 msec

max duration at max repetition rate

of 300 msec

» mA: » optically isolated 0 / 4 - 20 mA

» max loading: 750 Ω

» resolution: 0.1% of 20 mA

» relays: » 2 alarm / pump control relays

» 1 form ‘C’ SPDT contact per relay,

rated 5 A at 230 V ac non-inductive

» communication: » Dolphin Compatible via optional

Milltronics ComVerter

Enclosure: » Type 4X / NEMA 4X / IP 65

» polypropylene alloy

SPECIFICATIONS

Weight: » 1 kg ( 2.2 lb )

Approvals: » CE

(EMC performance available on request.)

TRANSDUCER

Compatible models: » ST - 25 Ultrason ®, STH and Echomax models XPS-10,

PL-447 7

XPS-15, XCT-8 and XCT-12.

Refer to the associated transducer manual.

97\08\12

Page 8

SPECIFICATIONS

⊗

PL-447 8

■

Page 9

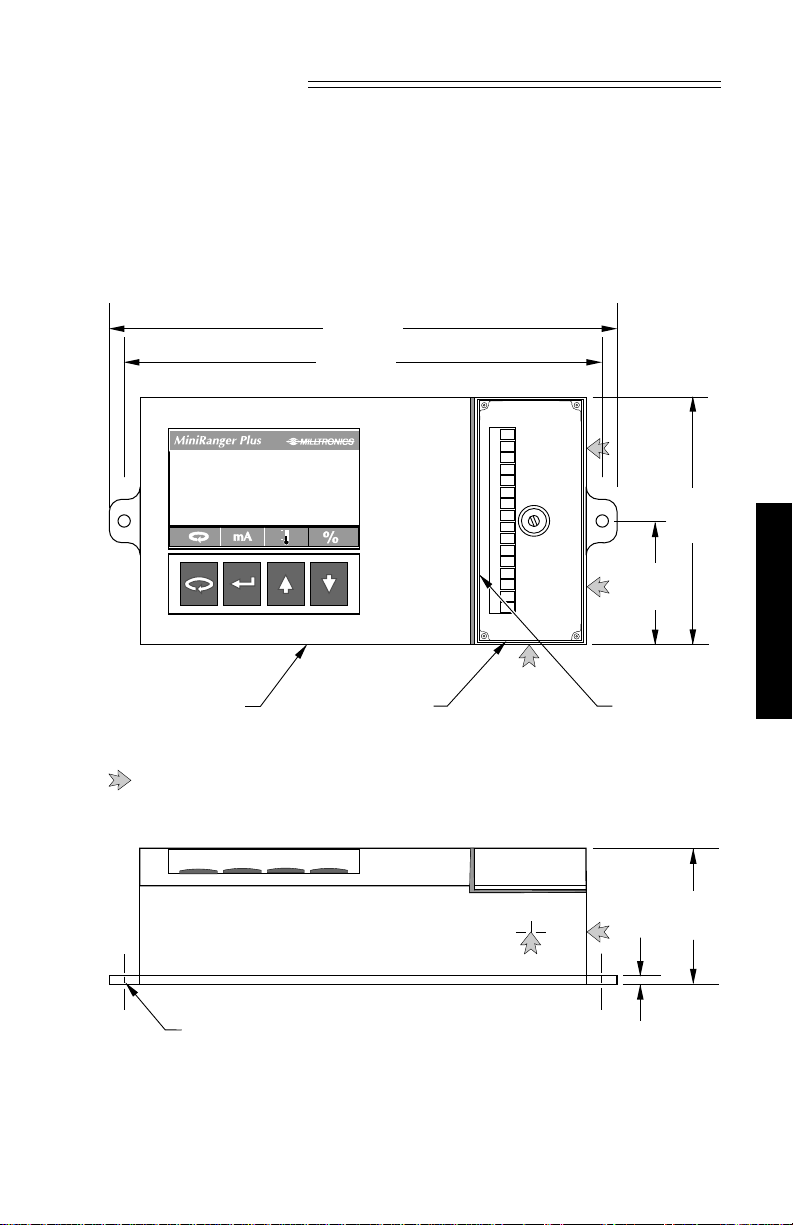

INSTALLATION

138 mm

(5.4")

5 mm

(0.2")

terminal

block

layout

This product is susceptible to electrostatic shock.

DIMENSIONS

Follow proper grounding procedures.

270 mm

(10.6")

254 mm

(10")

INSTALLATION

69 mm

(2.7")

integral junction box

sealed enclosure

(cover removed)

with terminal block and

voltage selection switch

Conduit entry location. Recommend drilling the enclosure with a hole saw

and the use of suitable cable glands to maintain ingress rating.

mounting hole

6.4 mm (1/4") Ø

PL-447 9

74 mm

(2.9")

97\08\12

Page 10

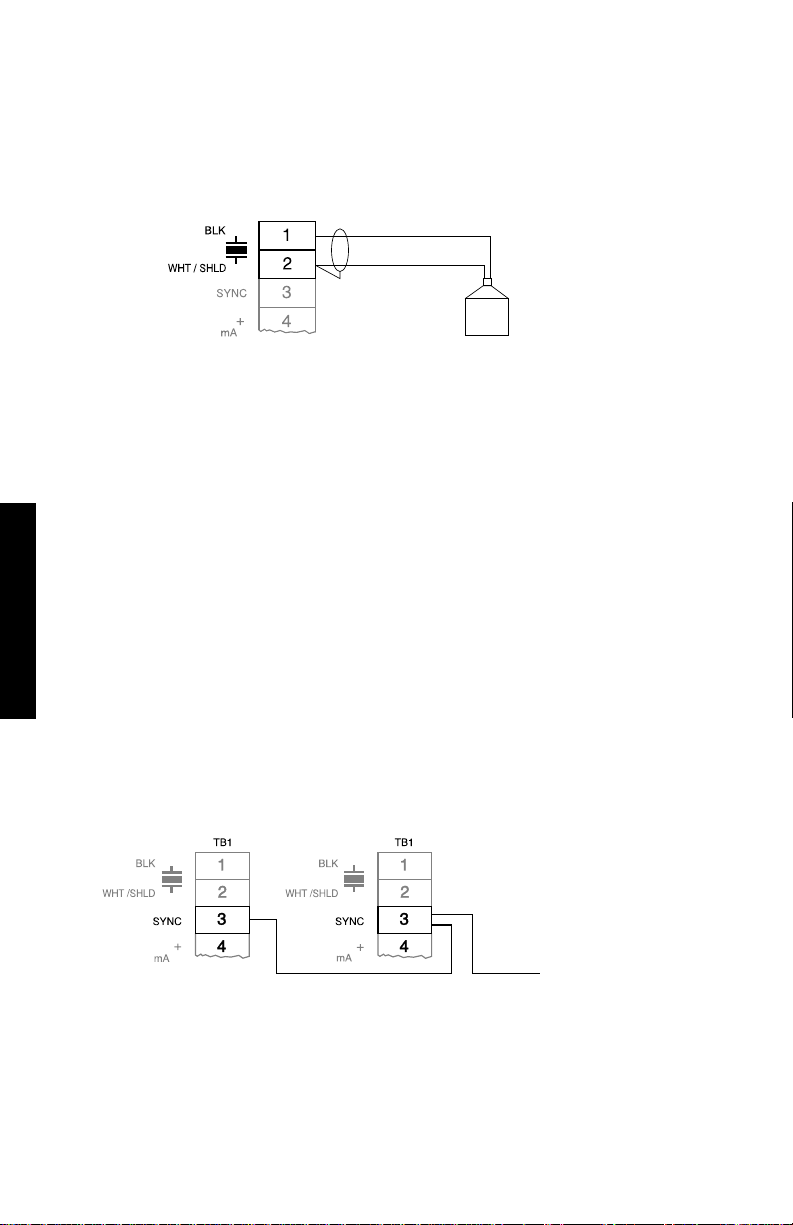

INTERCONNECTION

TRANSDUCER

transducer

Refer to transducer instruction manual

for location and mounting details.

INSTALLATION

SYNCHRONIZATION

In applications where more than one MiniRanger Plus, to a maximum of 8, are going

to be used or where their transducers are sharing a common conduit, synchronization

is required. When synchronized, no device transmits within 180 ms of the prior one(s).

To synchronize, interconnect the SYNC terminals of all devices and ensure that there

is a common electrical ground interconnecting all units.

To synchronize MiniRanger Plus with other Milltronics products, consult Milltronics or

your distributor.

to next

MiniRanger Plus

#1

PL-447 10

MiniRanger Plus

#2

device

Page 11

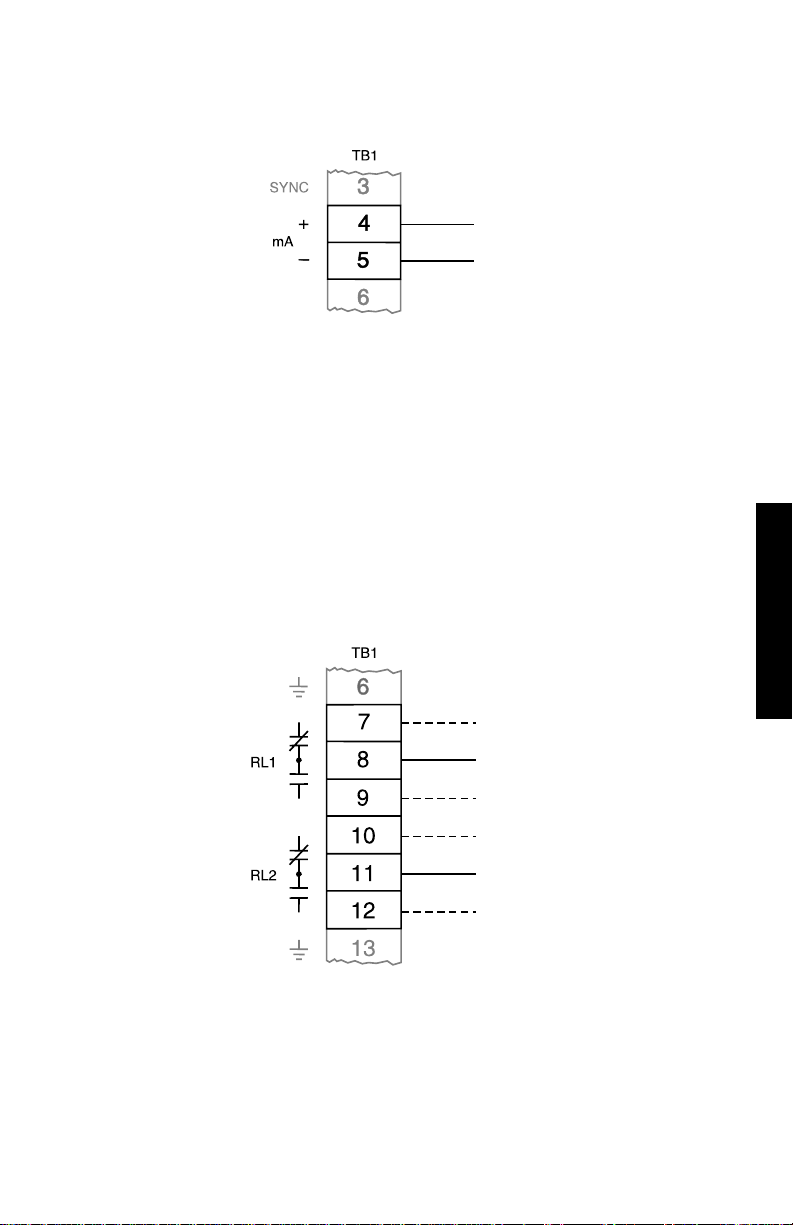

CURRENT OUTPUT

to customer

instrumentation

isolated mA output,

750 Ω max load

RELAY OUTPUT

INSTALLATION

All relays are certified for use in equipment where the short circuit

capacity of the circuits in which they are connected is limited by

fuses having ratings not exceeding the rating of the relays.

PL-447 11

n.c.

com

n.o.

n.c.

com

n.o.

relays shown in

de-energized state,

contacts rated 5 A at

230 V non-inductive

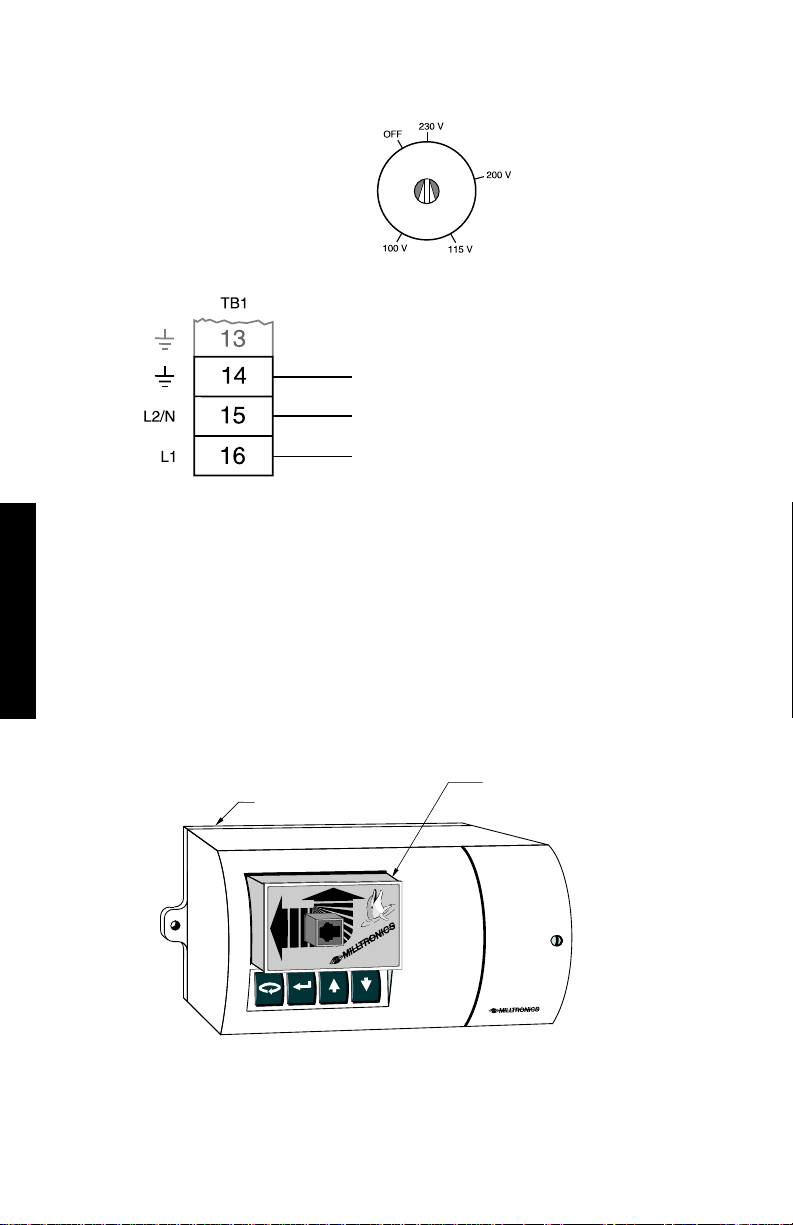

Page 12

POWER

INSTALLATION

VOLTAGE

SELECT

customer

voltage

supply

COMVERTER

Optional Dolphin Interface

MiniRanger Plus

Refer to Dolphin instruction manual for interconnection details.

PL-447 12

ComVerter

Page 13

⊗

INSTALLATION

PL-447 13

Page 14

INSTALLATION

⊗

PL-447 14

Page 15

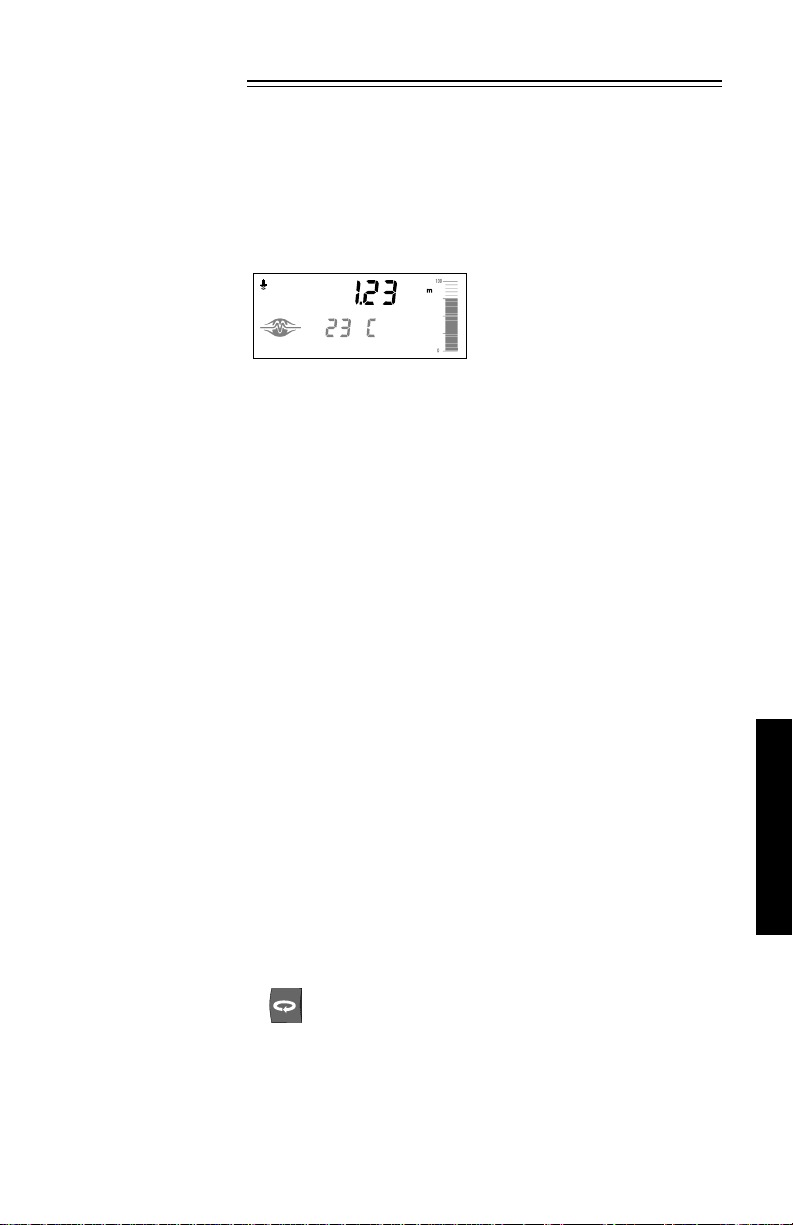

START UP

GENERAL

The MiniRanger Plus has two modes of operation:

is powered, after installation procedures have been completed, it is programmed to

start up in the run mode, to detect the distance from the transducer face to the target

in meters.

The unit can be placed into the program mode at any time; to alter a number of

program parameters in order to better suit the application or user’s preferences.

Programming can be carried out via the local keypad or the optional Dolphin

infrared interface.

The first step when programming is to reset all parameters to their factory setting by

using the master reset P-999. This must be done via the local keypad.

For a Quick Start, P001 to P007 are the key parameters requiring entry.

They set: - mode of measurement

- process material

- transducer type

- measurement response

- units

- empty distance

run

and

typical display

program

. When the unit

START UP

- span

There are a number of other program parameters, especially relay and mA output,

that can be changed subsequently or during another programming session. Refer to

Parameter List for a description of the parameters available.

When programming has been completed, the MiniRanger Plus can be put into normal

operation by pressing .

PL-447 15

Page 16

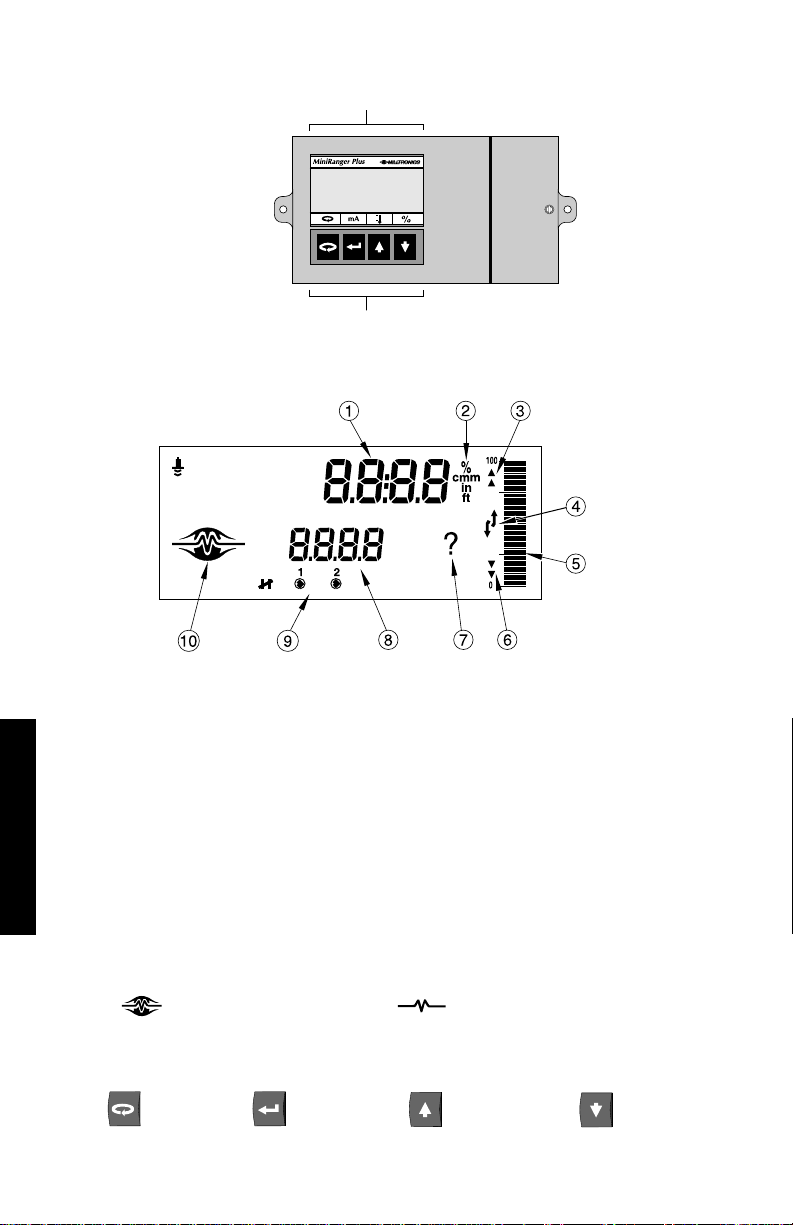

DISPLAY and KEYPAD

Run Mode

LCD

LCD

Keypad

➀ reading

➁ units

➂ high alarm indicators : = high, = high - high

START UP

➃ process material level rising or falling

▲

▲

▲

➄ bar graph representation of material level, 0 to 100% of span

➅ low alarm indicators : = low, = low - low

▼

▼

▼

➆ reading questionable, appears during fail-safe operation

➇ auxiliary reading

➈ relay status

➉ = normal operation = fail-safe operation

Keypad

access

program

mode

PL-447 16

display mA

(auxiliary)

display

temperature

(auxiliary)

toggle

% and

units

Page 17

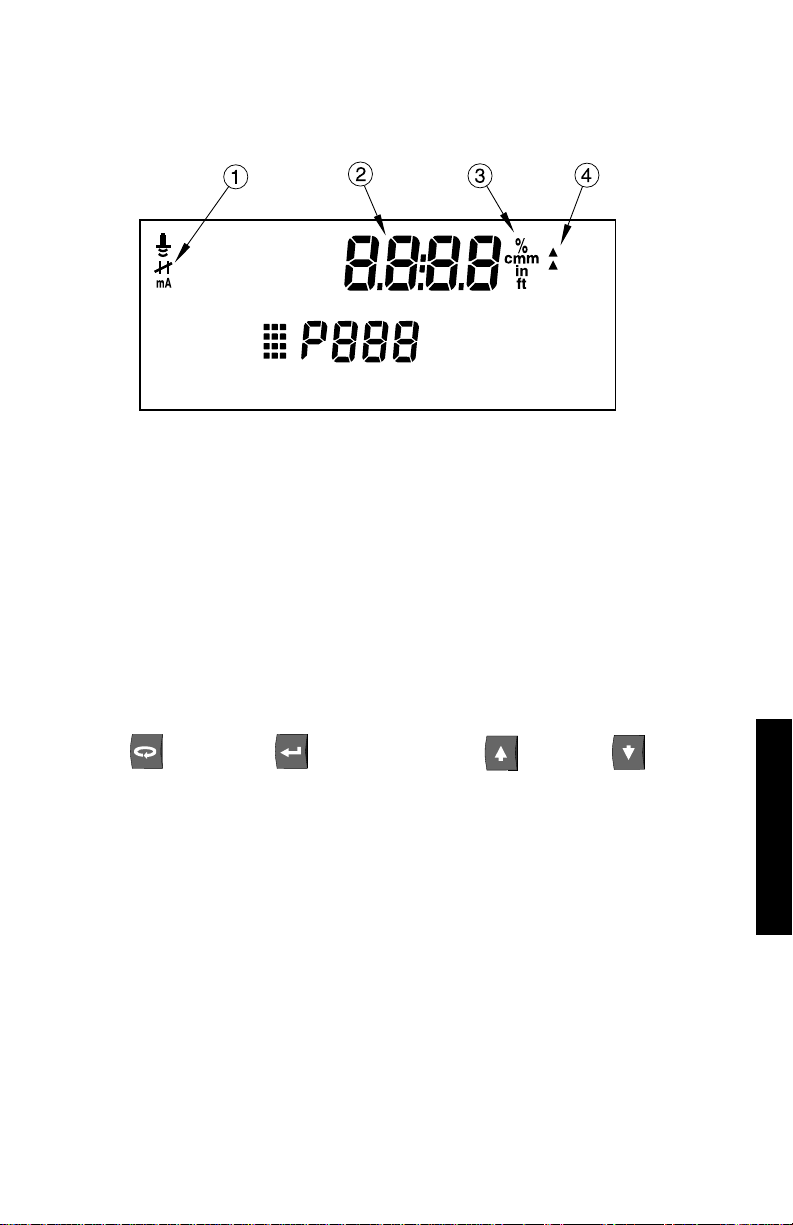

Program Mode

LCD

➀ parameter type ( transducer, relay, or mA output )

➁ reading

➂ units

➃ ‘change value’ accessed

Keypad

access

run

mode

PL-447 17

alternates program

mode between

‘select parameter’

and ‘change value’

functions

scroll

up

scroll

down

START UP

Page 18

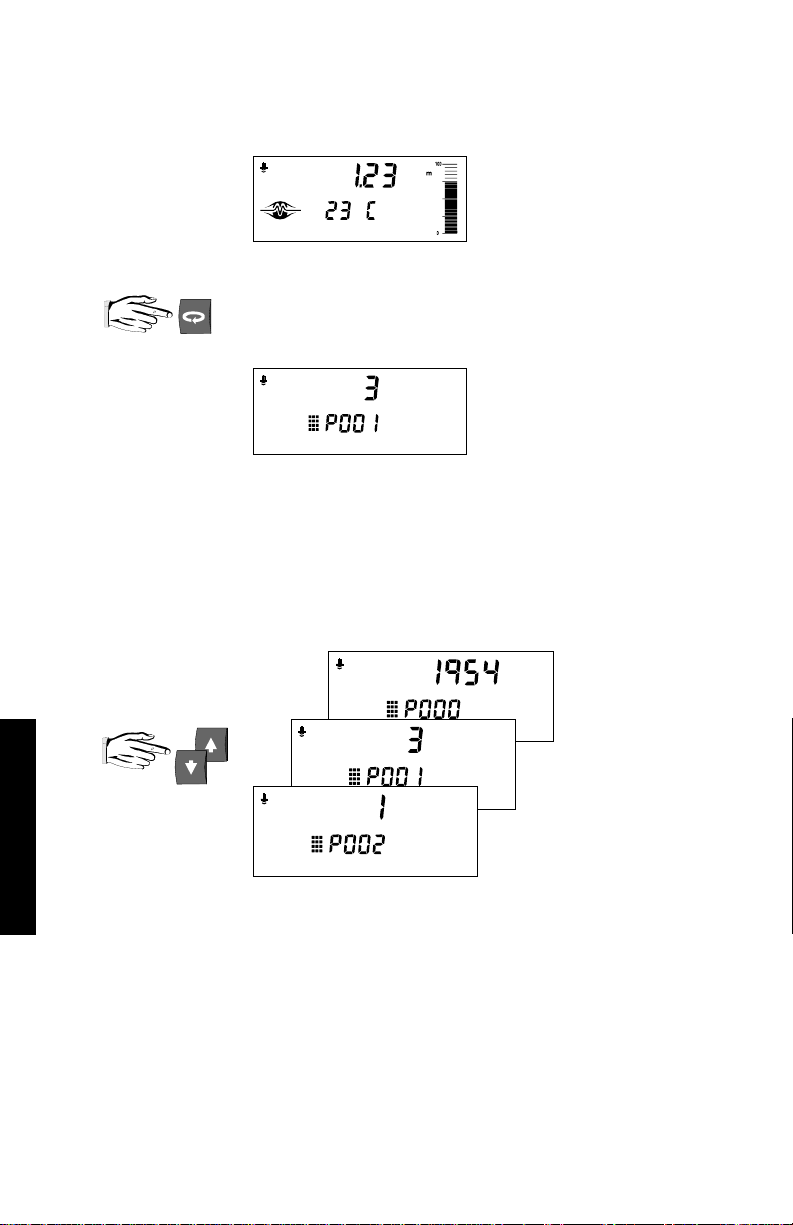

SETTING UP

To Access Program:

To Select a Parameter :

run display

program starts at

P001

START UP

PL-447 18

Page 19

To Change a Parameter Value :

increase or

decrease to the

desired value.

if no response,

security not

disabled!

select parameter,

e.g. P001 = 3

initiate change function

Security Must Be Disabled!

Must Be Pressed to

Save Change!

PL-447 19

START UP

save and return to ‘select

parameter’ function,

e.g. P001 = 4

Page 20

Express :

from the program mode

e.g. P001

exit and return to

run mode

Parameter

to jump back to P001

Value

To Return to Run Mode

or

to jump to the factory setting

e.g. P999

jump back to P001

START UP

PL-447 20

Page 21

DISPLAY MESSAGES

‘Short’ in transducer circuit

or wiring reversed. Refer to

Troubleshooting.

‘OPEN’ in transducer circuit.

Refer to Troubleshooting.

PL-447 21

START UP

Page 22

⊗

START UP

PL-447 22

■

Page 23

FUNCTIONAL

TRANSCEIVER

The MiniRanger Plus transceiver operates under 1 of 5 sets of preset conditions

(P003), summarized as follows:

parameter

value

1 0.1 m/min slow on on 100 2

2 1 m/min . on on 10 2

3 10 m/min . on on 1 2

4 100 m/min . off on 0.1 1**

5 1000 m/min fast off off 0 1**

*each measurement consists of one short pulse plus the set number of long pulses.

**set number of long pulses, only if required.

When a measurement is initiated, the set number of short and long pulses is

transmitted. Short pulse measurements are restricted to the first 2 m range

extending from the transducer face. When a short pulse is combined with a long

pulse set, the short pulse range is restricted to 1 m and the long pulse covers the

full measurement range.

When the echo of the transmitted pulse train is received, the relevant echo extraction

technique (P820), is applied to determine the true material echo.

The measurement response limits the maximum rate at which the display, analog

output and relay contacts respond to changes in measurement. It is of concern

especially where liquid surfaces are in agitation or material falls into the sound path

during filling.

measurement

response

echo

verification

filter fail-safe

timer

long

pulses*

TRANSDUCER

The transducer, which is connected to the transceiver and mounted remotely at the

measurement site, converts the electrical energy of the transmit pulse into acoustical

energy and converts the acoustical energy of the echo back into electrical energy for

the transceiver receive period.

Some transducer models incorporate an integral temperature sensor. The echo and

temperature signals share the same cable wiring, then segregated at the transceiver.

PL-447 23

FUNCTIONAL

Page 24

TEMPERATURE

range extension (P-801)

as % P-006

In order to compensate for uniform changes of the sound medium, temperature

sensing is achieved using a transducer with an integral sensor.

If the transducer does not have an integral sensor, temperature compensation is fixed

at a programmed value, P661. The difference between the fixed value and the actual

temperature surrounding the transducer will cause an error in measurement.

SOUND VELOCITY

The MiniRanger Plus can be calibrated to compensate for sound velocity error in fixed

temperature, homogenous atmospheres.

The basis is to physically measure the level (measuring tape or sight glass) and enter

the value via P651. The MiniRanger Plus then calculates the sound velocity by

comparing the entered physical measurement to its own ultrasonic measurement.

BLANKING

Near blanking (P800) is used to ignore the zone in front of the transducer where

ringdown

* or other false echoes (e.g. standing wave, ladder rung) appear as an echo

during the receive cycle. This is usually indicated by an incorrect high level reading

and can be overcome by increasing the near blanking from its factory set value.

* ringdown is the natural decay of transducer vibration after the transmit pulse ceases.

Far end blanking is a feature that ignores the zone below the zero or empty level

where false echoes can appear at levels that interfere with the processing of the

true echo.

ringdown or

false echo

end of

transmit

FUNCTIONAL

empty distance to transducer

PL-447 24

true echo

typical receiver signal

P-800

near blanking

P-006

range

typical processed signal

(level)

level

false echo

0

far end

blanking

Page 25

In applications where the zero level is above the bottom of the vessel and it is desired

high

alarm

on, P112

off, P113

to monitor the zone below the normal zero, range extension (P801) can be used to

extend the range into the far end blanking. Range extension is entered as a percent of

P006. As range extension reduces the protection afforded by the far end blanking, it

should be used judiciously. Avoid excessive range extension as this can reduce the

measurement’s reliability and accuracy. Range extension is factory set for 20% of

P006. If it is found that false echoes are appearing ahead of the blanking zone, P006

should be reduced accordingly.

Blanking is automatically corrected for sound velocity change where temperature and

velocity compensation are used; keeping the blanking at the distance at which it is set.

LOSS OF ECHO

A loss of echo occurs when the MiniRanger Plus deems that the calculated

measurement is unreliable, i.e. the echo confidence (P805) is less than the threshold

(P804). This can be due to such circumstances as high level of electrical noise, poor

grounding or poor transducer aiming. Refer to Troubleshooting. If the condition

persists for a time beyond the limit as set by the fail-safe timer (P070), the confidence

icon changes from full to partial and the reading and mA output are forced to the

fail-save default (P071) at the response rate (P003).

Upon receiving a reliable echo, the loss of echo condition is aborted (icon returns

to full) and the reading, mA and relay output return to the present level at the

response rate.

Relay operation responds, as programmed, to the default level as though an actual

material reading.

RELAYS

GENERAL

Two onboard relays are provided in the MiniRanger Plus. Each relay can be assigned

one out of three functions.

FUNCTIONS

Alarm:

high alarm : occurs when the level rises to

low alarm : occurs when the level falls to

cancelled when the level

PL-447 25

the on setpoint. The alarm is

cancelled when the level

reaches the off setpoint.

the on setpoint. The alarm is

reaches the off setpoint.

low

alarm

off, P113

on, P112

FUNCTIONAL

Page 26

Pump:

off, P113

pump down : occurs when the level rises to

the on setpoint. The pump is

stopped when the level

reaches the off setpoint.

on, P112

pump up : occurs when the level falls to

the on setpoint. The pump is

stopped when the level

reaches the off setpoint.

off, P113

pump

sequencing: pumps 1 and 2 operate in lead

lag fashion alternating roles on

successive pump cycles (first pump

on, to all pumps off) . Specifically,

pump 1 responds to relay 1 and pump 2 responds to

relay 2 during the first pump cycle. During the second cycle,

pump 2 responds to relay 1 and pump 1 responds to relay 2.

Relays programmed for pump control will not energize

within 10 seconds of a MiniRanger Plus power up,

or within 10 seconds of each other.

SETPOINTS

Relay setpoints are in the units as programmed (P005).

pump

down

pump

up

on, P112

Operation, P001 = 1, 2 or 3

The setpoints are measured from the bottom up, referenced

to zero or empty (P006).

Operation, P001 = 4

FUNCTIONAL

The setpoints are measured outward from the transducer face.

PL-447 26

Page 27

STATUS

relay 2 function

e.g. 0 = off

relay 2 on setpoint

relay 1 off setpoint

relay 1 function

e.g. 0 = off

Programming

Upon entering the program mode, the alarm relays hold their prior status, pump relays

are held off.

Relay programming: - select relay & function (P111)

- enter setpoints (P112 & P113)

•

•

•

PL-447 27

relay 1 on setpoint

FUNCTIONAL

relay 2 off setpoint

Page 28

Run

relay

status, relay 1

status, relay 2

relay operational, e.g. relay 2

alarm / pump on, e.g. relay 1

Fail-safe

When the fail-safe timer (P070) expires, the relays respond as follows * :

Fail-Safe Status

Mode (P071) high alarm low alarm pump down pump up

high on off on off

low off on off on

hold hold hold hold hold

* not applicable to high level switch operation, P001 = 4. In such cases, the timer

is bypassed and the mode is always ’low’.

FUNCTIONAL

PL-447 28

Page 29

ANALOG OUTPUT

The MiniRanger Plus can be programmed to provide an analog output (P200) of 0 to

20 or 4 to 20 mA, and for proportional or inverse span.

Programming

Upon entering the Program mode, the analog output level holds its prior value.

Run

The analog output responds in the following manner :

Level

Space

Distance

or

H. L. S.

*reference value only. mA level limited by near blanking.

0 and 100% are percentage of full scale reading (m, cm, mm, ft, in)

PL-447 29

FUNCTIONAL

Page 30

Fail-safe

When the fail-safe timer (P070) expires, the mA output responds as follows * :

Fail-safe Mode

(071)

high 20 0/4

low 0/4 20

hold hold hold

* not applicable to high level switch operation, P001 = 4. In such a case, the

measurement immediately defaults to a low value.

Status

0/4 – 20 20 – 0/4

RUN / PROGRAM

When the MiniRanger Plus changes from run to program, the transceiver stops

operating and the last measurement is stored; the associated reading, alarm status

and mA output are held (pump control relays are turned off). As a courtesy, the unit

reverts to the parameter last addressed during the previous program session. During

program, the unit does not respond to the process unless the calibration parameters

(P650 and P651) are accessed.

the reading becomes responsive.

Upon return to run, the transceiver resumes operation. The reading and associated

outputs default to the last measurement taken, either during the previous run session

or as a result of having accessed a calibration parameter. The reading and associated

outputs migrate to the current process level at a rate controlled by the measurement

response (P003).

If the calibration parameters are accessed, only

FUNCTIONAL

PL-447 30

Page 31

⊗

PL-447 31

FUNCTIONAL

Page 32

⊗

FUNCTIONAL

PL-447 32

■

Page 33

APPLICATIONS

This section highlights the most common applications to which the MiniRanger Plus is

likely to be applied. Other applications not described here, such as position monitoring

of a piston on a wood pulverizer, are basically improvisational and imaginative ways of

applying the MiniRanger Plus. The trick is knowing the parameters available to you,

and their limitations. Refer to Parameter Description.

When programming, refer to the application which is most similar to yours. A practical

example has been given to further expand on the programming features. As the

example may not completely cover your application, again, it is important that you

familiarize yourself with the list of available parameters.

APPLICATIONS

The minimum distance from the transducer face to the target is limited

by the minimum range of the transducer connected.

PL-447 33

Page 34

SIMPLE LEVEL APPLICATION

P112-1

4.0 m

relay 1

One of the most common applications of a Milltronics process material level monitor is

APPLICATIONS

simple level measurement, whereby the material level or space between the

transducer and reflecting surface is measured and displayed. This may or may not

include alarms and mA output.

Example

The application is to obtain a level measurement and corresponding 4-20 mA output

proportional to material level in a gravel bin. The transducer face is 5 m from the bin

bottom. The empty level is 0 m (bottom) and the full level (span) is 4.5 m from the

bottom. A high alarm is required at 4 m from the bottom and a low alarm is required at

1 m from the bottom. The maximum rate of filling or emptying is about 1 m/min. In the

event of a loss of echo, the MiniRanger Plus is to go into fail-safe low after 2 min.

Empty

(P006)

on

off

Span

(P007)

reset:

P999 master reset

program:

P001 enter ’1’ mode of measurement = level

P002 enter ’2’ material = solids

PL-447 34

P112-2

1.0 m

P113-1

3.9 m

relay 2

off

on

P113-2

1.1 m

Page 35

P003 enter ‘2’ measurement response = 1 m/min.

P004 enter ‘102’ the transducer model purchased with this system is an XPS-10

P005 enter ‘1’ units = metres

P006 enter ‘5’ empty distance = 5 m

P007 enter ‘4.5’ span = 4.5 m

P070 enter ‘2’ fail-safe timer = 2 min

P071 enter ‘2’ fail-safe = low

P111-1 enter ‘1’ level alarm, relay 1

P111-2 enter ‘1’ level alarm, relay 2

P112-1 enter ‘4’ relay 1, on setpoint = 4 m

P112-2 enter ‘1’ relay 2, on setpoint = 1 m

P113-1 enter ‘3.9’ relay 1, off setpoint = 3.9 m (nominal value, 0.1 m deadband)

P113-2 enter ‘1.1’ relay 2, off setpoint = 1.1 m (nominal value, 0.1 m deadband)

P200 enter ‘2’ mA output = 4 - 20

APPLICATIONS

run:

press run to start normal operation

PL-447 35

Page 36

PUMP CONTROL APPLICATION

P113-1 & 2, 0.25 m

relay 1 & 2

pumps off

The basic difference between a simple level application and a pump control

APPLICATIONS

application is that the relays assigned to pump function (P111) are normally

de-energized (off) and energized when required to run the pump. In the program

mode, pump relays are held de-energized.

Pumps can be programmed to work independently or in lead/lag fashion. Refer to

Functional \ Relays \ Functions.

In applications where flooding is possible, a submersible transducer should be used.

The submersible transducer’s air cavity insures that a high level reading is maintained

rather than establishing a loss of echo condition, when the liquid level reaches the

transducer. When using a submersible transducer, set P802 = 1.

Example

The application is to control the level in a wet well. It is required that the level be

displayed in centimetres. The transducer is mounted at 3.6 m from the bottom and is

equipped with a submergence coupling as there is possibility of flooding in the well.

Two pumps are to be controlled by the MiniRanger Plus in lead / lag fashion. The first

pump to start at 1 m and the second pump to start at 2 m. Both pumps are to stop at

0.25 m. The maximum estimated filling rate is 1 m/min. In the event of a loss of echo,

a fail-safe low after 6 sec is required to protect the pumps from running dry.

P006

3.6 m

P007

3.0 m

reset:

P999 master reset

program:

P001 enter ‘1’ mode of measurement = level

P002 enter ‘1’ material = liquids

PL-447 36

relay 1,

pump on

P112-1, 2 m

relay 2,

pump on

P112-2, 1 m

Page 37

P003 enter ‘2’ measurement response = 1 m / min

note: the associated preset fail-safe timer is 10

minutes. Override this value by setting P070.

P004 enter ‘102’ the transducer model purchased with this system is an XPS-10

P005 enter ‘1’ units = metres

P006 enter ‘3.6’ empty distance = 3.6 m

P007 enter ‘3’ span = 3 m

P070 enter ‘.1’ fail-safe timer = 6 sec (0.1 min)

P111-1 enter ‘3’ relay 1 function = 3, pump sequencing

P111-2 enter ‘3’ relay 2 function = 3, pump sequencing

P112-1 enter ‘2’ relay 1, on setpoint = 2 m

P112-2 enter ‘1’ relay 2, on setpoint = 1 m

P113-1 enter ‘.25’ relay 1, off setpoint = 0.25 m (nominal value, 0.1 m deadband)

P113-2 enter ‘.25’ relay 2, off setpoint = 0.25 m (nominal value, 0.1 m deadband)

P802 enter ‘1’ submergence = on

APPLICATIONS

run:

press run to start normal operation

PL-447 37

Page 38

HIGH LEVEL SWITCH

The MiniRanger Plus can be programmed as a high level switch. Significant

APPLICATIONS

differences between this and other modes of operation are :

- the fail-safe function (P070 and P071) is effectively disabled

- on loss of echo, the measurement immediately defaults

to a low value (P006)

- relay setpoints are measured from the face of the transducer

- the reading is distance from the face of the transducer to the material

A high level switch application is primarily used to detect a high level condition. As

such, aim the transducer so that it is perpendicular to the material angle of repose at

the alarm level when filling.

Example

A high level switch is required in a corn silo when the material comes within 1 m of the

transducer face. The maximum filling rate is 0.2 m / min.

P112, 1m

reset:

P999 master reset

program:

P001 enter ‘4’ mode of measurement = high level switch

P002 enter ‘2’ material = solids

PL-447 38

P113, 2 m

Page 39

P003 enter ‘2’ measurement response = 1 m/min

note: this is the next fastest response rate that would

satisfy the given maximum filling rate

P004 enter ‘104’ the transducer model purchased with this system is an XPS-15

P005 enter ‘1’ units = metres

P006 enter ‘4’ empty distance = 4 m (nominal value)

P007 enter ‘4’ span = 4 m (nominal value)

P111-1 enter ‘1’ level alarm, relay 1

P112-1 enter ‘1’ relay 1, on setpoint = 1 m

P113-1 enter ‘2’ relay 1, off setpoint = 2 m (nominal value, 0.1 m deadband)

APPLICATIONS

run:

press run to start normal operation

PL-447 39

Page 40

APPLICATIONS WITH STANDPIPE

transducer

In many liquid applications, access to the vessel must be made via a standpipe.

APPLICATIONS

In such cases, Milltronics can provide optional flanged transducers, or split flanges

that mate to a flanged standpipe. Another option is to hang the transducer from a

blind flange.

The standpipe length should be as short and the diameter as large as possible. As a

rule of thumb, the –3 dB cone of the sound beam should not intersect the standpipe

wall in applications opening into a vessel. Otherwise, additional near blanking (P800)

is required to compensate for the interference zone created by the opening.

transducer radiating face

no

intersection

vessel

no additional

blanking required

vessel

sound beam

intersects

pipewall

reflection at interference

zone created by opening

no vessel

no additional

blanking

required

PL-447 40

near blanking extension of 150

mm (6") past end of standpipe

may be required

Page 41

⊗

APPLICATIONS

PL-447 41

Page 42

■

APPLICATIONS

⊗

PL-447 42

Page 43

PARAMETER DESCRIPTION

P000 lock

Locks out the programming ’change value’ function such that t he val ues

of P001 through P999 cannot be changed. This however does not

prevent the ‘select’ function from use for viewing val ues . Programmi ng is

locked out if the value of P000 is other than 1954.

entry : 1954 = unlocked

1954 = locked

P001 operation

Determines the mode of measurement.

entry : 1 = level; material level referenced to empty distance (P006)

2 = space; space to material level referenced from zero span

3 = distance; distance to target referenced f rom t he

transducer face

4 = high level switch (h.I.s.)

PARAMETER DESC.

Level (P001 = 1)

Space (P001 = 2)

P002 materi al

Optimizes measurement reliability for target ty pe.

entry : 1 = liquids, fluids or flat surfac es

2 = irregular surfaces and solids

PL-447 43

Distance (P001 = 3)

or

H.L.S. (P001 = 4)

Page 44

P003 measurement res ponse

Collectively sets a number of operating parameters that det ermine the

maximum rate of change in target range that the reading, alarm and mA

output functions can keep up to.

If MiniRanger Plus cannot keep up with the rate of level change, select a

faster rate. If the reading bounces around an average value, select a slower

rate. In general, reliability is traded for speed. Noisy appl icat i ons or t hose

with agitators tend to be more reliable at a slower res pons e rate, as they

make use of filtering, echo verificat ion and longer fail-safe delay.

PARAMETER DESC.

Select P003 for a measurement response just faster than

echo verification: discriminates between agitator blades in mot ion or

filter: discriminates between false echoes from constant

fail-safe timer: establishes the period from the time a loss of ec ho st art s

long pulses: sets the number of long pulses to be fired during the course

the greater of the maximum filling or emptying rate.

spurious noise, and the target surface (true ec ho).

acoustical or electrical noise, and the target surface.

until the fail-safe default (P071) is effect ed. The P003

preset timer value can be overridden by P070.

of a measurement. Reliability (2) is traded for speed (1).

entry:

measurement

response

1 = 0.1 m/min (slow) on on 100 2

2 = 1 m/min

3 = 10 m/min

4 = 102 m/min / 1.7 m/sec

5 = 1020 m/min / 17 m/sec (fast) off off 0 1

* fail-safe function is disabled for high level swi t ch operat ion, P001 = 4.

P004 transducer

Identifies transducer model connected.

entry : 1 = ST-25 102 = XPS-10

100 = ST-H 103 = XCT-12

101 = XCT-8 104 = XPS-15

PL-447 44

verification filter

.

.

.

echo

on on 10 2

on on 1 2

off on 0.1 1

f-s timer*

(P070)

long

pulses

Page 45

P005 units

Determines the units for programming and measurement.

P006 empty

Distance from transducer

face to empty level or

maximum target range.

P007 span

Distance from empty (P006) to

full / 100% level or minimum

target range.

entry : 1 = metres

2 = centimetres

3 = millimetres

4 = feet

5 = inches

PARAMETER DESC.

P070 fail -s af e t i mer

The amount of time delay, in minutes, bef ore going into fail-safe mode.

Disabled for h.I.s. operation (P001 = 4)

P071 fail-safe material level

Selects the default measurement in the event that the fail-safe timer expires.

entry : 1 = high; maximum span value

2 = low; minimum span value

3 = hold; hold current value

Disabled for h.I.s. operation (P001 = 4)

PL-447 45

Page 46

P111 relay f unction

Assigns an alarm function to the selected rel ay . Ref er to Functional \ Relays.

PARAMETER DESC.

P112 relay A set point

The on setpoint in linear units (P005). Refer to Functional \ Rel ay s.

P113 relay B set point

The off setpoint in linear units (P005). Refer to Functional \ Relays.

P200 mA range

Enables the mA output function by sel ec t ing the range and relationship to span.

Refer to Functional \ mA output.

entry : 0 = off

1 = level alarm

2 = pump control

3 = pump sequencing

entry : 1 = 0 to 20 mA

2 = 4 to 20 mA

3 = 20 to 0 mA

4 = 20 to 4 mA

P300 temperature, transducer max

The maximum temperature encountered by the integral

(transducer) temperature sensor.

P341 run time

View the accumulated number of days the MiniRanger Plus

has been operating.

PL-447 46

Page 47

P650 offset calibration

Typically used to calibrate the ultras onic measurement, and its associated

outputs, to a known value.

- fill the tank as muc h as permissible, without going into

the near blanking.

- monitor P650 until a stable readi ng is obt ai ned.

- (to access change function).

- scroll the value to the actual level, space or distance respective

to the mode of measurement (P001).

- (to validate entry). The MiniRanger Plus calculates

the measurement offset to be applied to the readi ng.

P651 sound velocit y calibration

Provides sound velocity compensation on an empty tank. This is typically

required on an application where the atmosphere in the tank is a

homogenous gas or vapour

- empty the tank as muc h as permissible. Leave filled with normal

vapour and normal operating temperature.

PARAMETER DESC.

other than air.

- monitor P651 until a st abl e readi ng is obt ained.

- (to acces s change f unction).

- scroll value to the actual level, space or distance respective

to the mode of measurement (P001).

- (to validate entry). The MiniRanger Plus calculates

the new sound velocity for measurement correction.

P740 peripherial communication Not supported by the associated product.

P661 temp fixed

For use with ST-25 Ultrason

®

transducers. As these transducers do not have

an integal temperature sensor a nominal value representing the ambient

temperature of the transducer must be entered. If t he t emperat ure bet ween

the transducer and the target varies, enter the av erage t emperat ure.

PL-447 47

Page 48

P800 near blanking

Sets the amount of blanking as measured from the t ransducer face and

extending into the measurement range. Refer to Func t i onal \ B lank ing.

enter value referenced from the face of the transducer in uni t s of P005.

P801 range extension

PARAMETER DESC.

P802 submergence transducer

P804 confidenc e threshold

Sets the amount of range extension as measured from t he empty distance

(P006) and extending into the far end blanking. Ref er t o Func t i onal \Blanking.

enter as a % of P006, the distance below empty not bl anked.

When using a submergence transducer, set entry to ‘1’ t o enabl e

submergence feature. Refer to Applications \ Pump Control Application.

entry : 0 = normal

The minimum echo confidence in dB that either t he short or long ec ho must

meet in order to prevent a loss of echo condition and t he ex pi ration of the

fail-safe timer (P070).

short minimum echo confidenc e f or short pulse echoes; those

long minimum echo confidence for long pulse echoes.

entry : ## : ## = short : long

1 = submersible

within the short pulse echo range.

P805 echo conf idence

A measure of echo reliability.

display : ## : ## = short : long

where : ## = 0 to 99 ; confidence value

run mode :

PL-447 48

Page 49

P806 echo strengt h

The absolute strength of the selected echo, in dB above 1 uV rms.

run mode :

P807 noise

The peak and average ambient noise, in dB above 1 uV rms.

Ambient noise includes acoustical and electrical noise being picked up by the

transducer / receiver circuit while in the program mode (t ransmit disabled).

display : ## : ## = average : peak

run mode:

P820 algori t hm

Selects the algorithm to be applied to the echo profile in order t o

extract the true echo.

entry : 1 = best of first and largest

P830 TVT type

PARAMETER DESC.

2 = first echo

3 = largest echo

Selects the TVT profile applied to the echo profile.

entry : 1 = standard

2 = flat (typically; may yield higher confidences on

some solids applications)

P900 software rev ision

Displays the EPROM software revision level.

PL-447 49

96\07\22

Page 50

P901 memory

infrared

communication link

mirror

Tests the memory. Test is initiated by scrolling to the parameter

or repeated by .

P907 programmer interfac e

PARAMETER DESC.

Tests the infrared communication link. Test is init iat ed by scrolling to the

parameter or repeated by .

display : PASS = normal

FAIL = consult Milltronics

display : PASS = normal

FAIL = consult Milltronics

MiniRanger Plus

P910 rela y

Tests the alarm relays.

entry : 0 = de-energizes selected relay

1 = energizes selected relay

P911 mA out put value

Displays the value from the previous measurement. A t est val ue can be

entered and the displayed value is transmitted to the out put . Upon ret urni ng

to the run mode, the parameter assumes the actual mA output level.

PL-447 50

Page 51

P923 distance measurement

The reading corresponding to the distance between the mat eri al level

and the transducer face.

run mode

P999 master reset

Resets parameters to their factory setting.

PARAMETER DESC.

PL-447 51

Page 52

PARAMETER DESC.

⊗

PL-447 52

■

Page 53

TROUBLESHOOTING

The following is a list of operating symptoms, their probable causes and the actions

needed to resolve them.

SYMPTOM CAUSE ACTION

Loss of echo

display reads ‘Short’,

no pulsing is felt on the

transducer face

display reads ‘OPEN’, no

pulsing is felt on the

transducer face

display reads

pulsing is felt on

transducer face

short circuit or

reverse wiring

defective transducer

open circuit

defective transducer or

circuit board

level or target is out of

range

application too dusty or

steamy, under these

conditions range can be

adversely affected

check transducer wiring*

check maximum

temperature P300 against

transducer rating*

try substitute

check transducer wiring*

check maximum

temperature P300 against

transducer rating*

try substitute

check transducer

specifications*

check calibration

parameters

re-aim transducer*

use foam faced transducer

for dusty applications*.

try using a longer range

transducer

increase fail-safe timer,

P070

TROUBLESHOOTING

material build-up on

transducer face

* refer to associated transducer manual

PL-447 53

clean

move transducer to better

location*

mount in standpipe*

Page 54

SYMPTOM CAUSE ACTION

. . . continued transducer location or

Reading does not change,

but the level does

TROUBLESHOOTING

Measurement is

consistently off by a

constant amount

Reading error

progressively worsens

with distance

Screen blank loss of power check voltage selector

re-locate or re-aim

aiming :

- poor installation

- moved by material or

vibration

- flanging not level

transducer malfunction :

- temperature too high

- physical damage

- excessive foam on

liquid face

MiniRanger Plus

processing wrong echo,

i.e. vessel wall, structural

member, stationary

agitator, material hang-up

or rat-hole

transducer ringdown,

reading high level

measurement offset refer to P650

atmosphere other than air

or stratified

transducer for maximum

echo confidence, P805

check P300, P805, P807

inspect

use foam deflector or

stilling well or relocate

re-aim transducer*

check standpipe for

internal burrs or welds

mounting need only be

hand tight*

increase blanking, P800

raise short measurement

confidence threshold, P804

refer to P651

switch

* refer to associated transducer manual

PL-447 54

check power wiring

Page 55

SYMPTOM CAUSE ACTION

Reading erratic echo confidence weak,

liquid surface agitated,

material filling

electrical noise

agitator blades

Reading ‘EEEE’ reading too large re-calibrate

Reading response slow P003 setting increase response if

Reads correctly but

occasionally reads high

when vessel is not full

detecting close range echo

or ringdown

refer to P805,P807

decrease measurement

response P003

enable filter, echo

verification

relocate transducer*

check P-807 under

quiescent conditions, noise

should be under 15 dB

transducer cable must be

in grounded metal conduit

and cable grounded only

at TB-1*

enable echo verification,

P003

possible

increase blanking

increase short

measurement threshold,

P804

TROUBLESHOOTING

High level reading lower

than material level

material is within near

blanking zone

echo multiple being

processed

* refer to associated transducer manual

PL-447 55

transducer mounting*

decrease blanking P800

(limit to transducer min

range*) or raise transducer

Page 56

TROUBLESHOOTING

⊗

PL-447 56

■

Page 57

APPENDICES

Alphabetical Parameter List

algorithm P820 submergence transducer P802

confidence threshold P804 temperature fixed P661

distance measurement P923 temperature, transducer max P300

echo confidence P805 transducer P004

echo strength P806 TVT type P830

empty P006 units P005

fail-safe material level P071

fail-safe timer P070

lock P000

mA output value P911

mA range P200

master reset P999

material P002

measurement response P003

memory P901

near blanking P800

noise P807

offset calibration P650

operation P001

peripheral comm. P740 *

programmer interface P907

range extension P801

relay P910

relay A setpoint P112

relay B setpoint P113

relay function P111

run time P341

software revision P900

sound velocity calibration P651

span P007

APPENDICES

* communication not supported by the associated product.

PL-447 57

Page 58

PARAMETER

# NAME VALUE

P001 Operation

P002 Material

P003 Measurement Response

P004 Transducer

P005 Units

P006 Empty

P007 Span

P070 Fail-safe Timer

P071 Fail-safe Material Level

P111-1 Relay Function

P111-2 Relay Function

P112-1 Relay A Setpoint

P112-2 Relay A Setpoint

P113-1 Relay B Setpoint

P113-2 Relay B Setpoint

P200 mA Range

P300 Temp. Tranducer Max

P341 Run Time

APPENDICES

P650 Offset Calibration

P651 Sound Velocity Calibration

P661 Temperature, Fixed

P740 Peripheral communication*

P800 Near Blanking

P801 Range Extension

P802 Submergence Transducer

P804 Confidence Threshold

P820 Algorithm

P830 TVT Type

P923 Distance Measurement

* communication not supported by the associated product

PROGRAMMING CHART

■

PL-447 58

96/03/22

Loading...

Loading...