Page 1

MD-36 SPEED SENSOR

Instruction Manual PL-392 January 2001

Instruction Manual PL-342 August 2001

33453420

Rev. 3.4

Page 2

Safety Guidelines

Warning notices must be observed to ensure personal safety as well as that of others, and to protect the pr oduct and the connected equipment.

These warning notices are accompanied by a clarification of the level of caut ion to be observed.

Qualified Personnel

This device/system may only be set up and operated in conjunction with this manual. Qualified personnel are only authorized to install and

operate this equipment in accordance with established safety practices and standards.

Warning

Note

This product can only function proper ly and safely if it is correctly transported, stored, installed, set up , operated, and maintained.

:

Always use product in accordance with specifications.

:

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2000. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic versions as

designed and authored by Siemens Milltronics Process

Instruments Inc. Siemens Milltronics Process Instruments

Inc. will not be responsible for the contents of partial or

whole reproductions of either bound or electronic versions.

MILLTRONICS®is a registered t r ad emark of Siemens Milltronics Process Instruments Inc.

While we have verified the contents of this

manual for agreement with the instrumentation

described, variations remain possible. Thus we

cannot guarantee full agreement. The content s of

this manual are regularly reviewed and

corrections are included in subsequent editions.

We welcome all suggestions for impr ovement .

Technical data subject to change.

Contact SMPI Technical Publications at the following address:

Technical Publications

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Ca nad a, K9J 7B1

Email: techpubs@milltronics.c om

For the library of SMPI instruction ma nuals, visit our Web site:

© Siemens Milltronics Process Instruments Inc. 2001

www.milltronics.com

Page 3

SPECIFICATIONS

Power: - +15 V dc, 25 mA from integrator

Temperature: - -40 to 55° C (-40 to 130°F)

Input: - shaft rotation 0 to 1,000 rpm, bidirectional

Output: - open collector sinking output, max. 25 mA at 15 V dc

- 36 pulses / revolution

- 0 to 1,000 rpm = 0 to 600 Hz

Input:output: - 1:1 (speed ratio)

Enclosure: - MD-36 : aluminum

rating: Type 4/NEMA 4/IP 65

- MD-36A : aluminum

- MD-36SS : 304 stainless steel

Approval: - MD-36 - CSA & FM : class II, GR. E, F&G, class III

Cable (optional): - Belden 8770, 3 wire shielded, 18 AWG or equivalent

- max run 305 m (1000 ft)

REFERENCE

Associated equipment: Milltronics integrator

Compuscale

Compuscale II

Compuscale IIA

Compu-M

Compuscale III

Accumass BW 100

Accumass BW 500

GENERAL

The MD-series speed sensor is used to monitor the speed of a belt conveyor. The sensor, coupled to the

motor or pulley shaft, converts the rotation of its input shaft into an encoded speed signal. The speed

signal is transmitted to the integrating electronics for use in computing the rate of material flow.

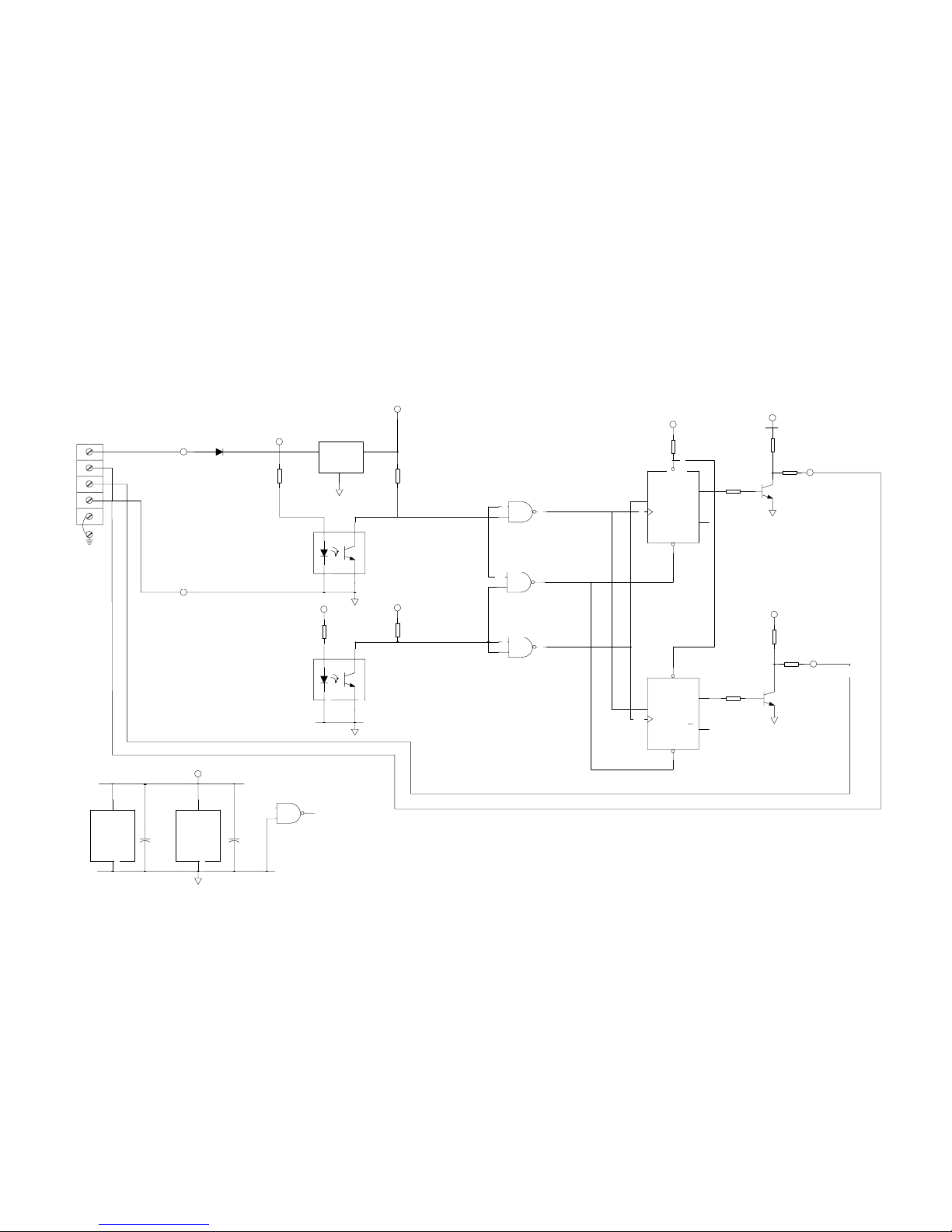

CIRCUIT OPERATION

The speed sensor is made up of a main shaft rotating in a bearing assembly fixed to the enclosure. The

shaft turns a toothed disk, which is divided into 36 teeth each separated by a gap equal to the tooth width.

The encoder card is mounted such that the two optocouplers straddle the disk’s teeth.

( Refer to FIG. 5 )

Power from the integrating de vice i s used to energize the two optocoupler LED’s and to feed the 5V dc

regulator. The 5V dc bus powers the logic circuitry and the output driver transistors.

As the shaft is rotating, the 36 toothed wheel modulates the light crossing within each optocoupler (O C1

and OC2). The resulting outputs are two 50% duty cycle square waves that are phase shifted by 90

degrees electrical or 1/4 cycle (one cycle of 360 degrees electrical corresponds to the width of one tooth

and one gap). This configuration provides directional discrimination.

PL-342 1

95/01/03

Page 4

The optocouplers’ square wave outputs are converted into CW and CCW square wave output signals by

the intermediate logic. When the shaft rotates in a CW direction, the logic produces pulses at the CW

output (1RC 2) and the CCW output is disabled. When the shaft rotates in a CCW direction, the logic

produces pulses at the CCW output (1RC 4) and the CW output is disabled.

The logic diagrams detail the operation of the electronics for both the clockwise and counterclockwise

output generation.

The speed sensor is immune to external vibration that would cause the toothed wheel to oscillate 1/4

cycle (1/2 tooth width or 5° of shaft rota tion) or less.

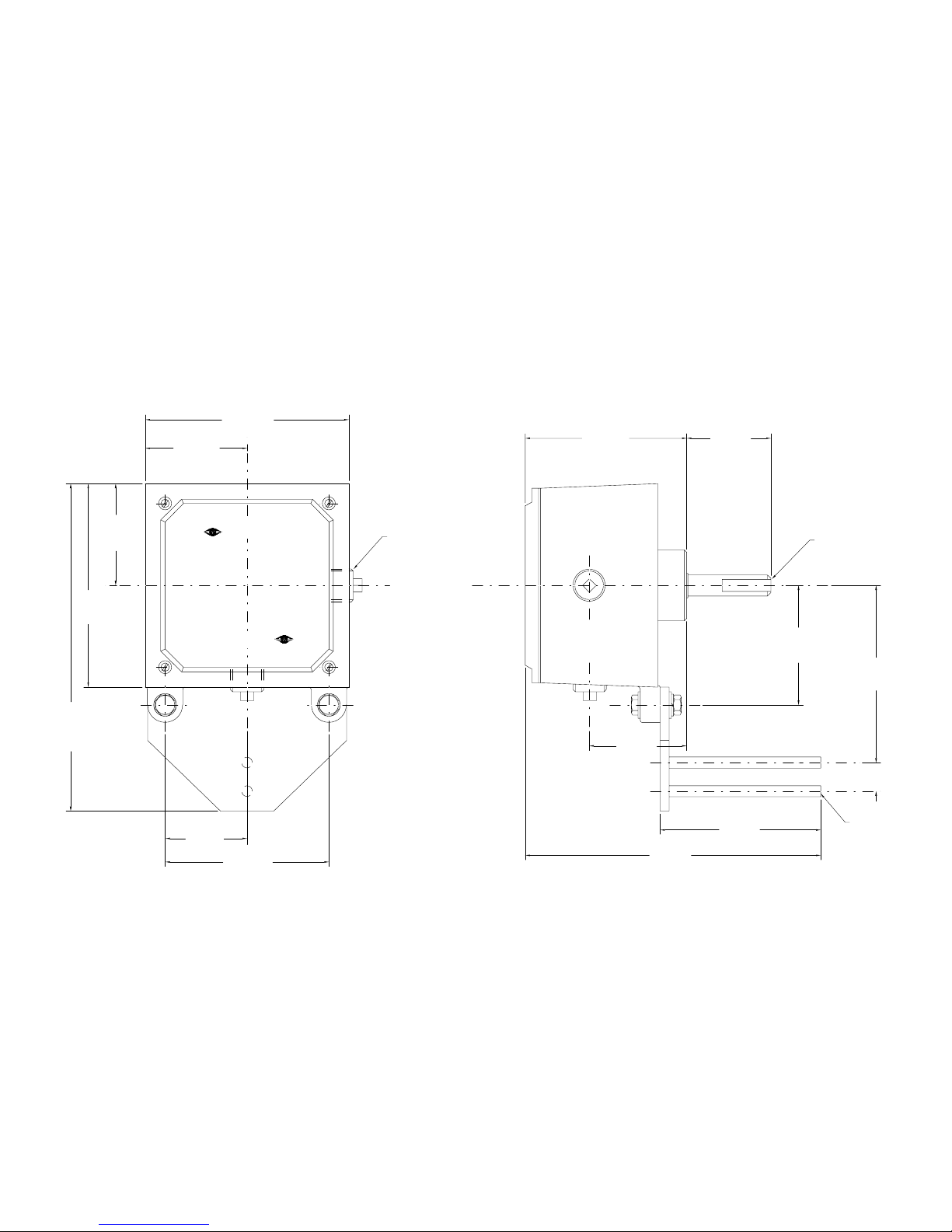

MOUNTING

The MD-36 speed sensor c an be coupled to a tail pulley, bend pulley or motor shaft. In the general

(floating) mounting arrangement, the input shaft and bearing assembly bear the weight of the speed

sensor. The unit’s arresting bracket stops the speed senso r from rotating with the shaft.

When mounting the speed sensor, ensure that the shaft alignment is true to avoid stresses on the

shaft bearing.

Mounting Reference Drawings:

MD-36 Pulley Mounting Figure 2

MD-36 Motor Shaft Mounting Figure 3

For preferred mounting locations, refer to the as sociated belt scale or weigh feeder instruction manual.

INTERCONNECTION

ALL WIRING MUST BE DONE IN CONJUNCTION WITH APPROVED

CONDUIT, BOXES AND FITTINGS AND TO PROCEDURES

IN ACCORDANCE WITH ALL GOVERNING REGULATIONS.

Interconnection between the speed sensor and the integrator should be made with 3 wire shielded, 18

AWG cable (Belden 8770 or equivalent).

Ground the shield at the integrator ONLY!

FLEXIBLE CONDUIT IS RECOMMENDED SO EXCESS STRESS

IS NOT APPLIED TO THE SHAFT BEARINGS.

PL-342 2

95/01/03

Page 5

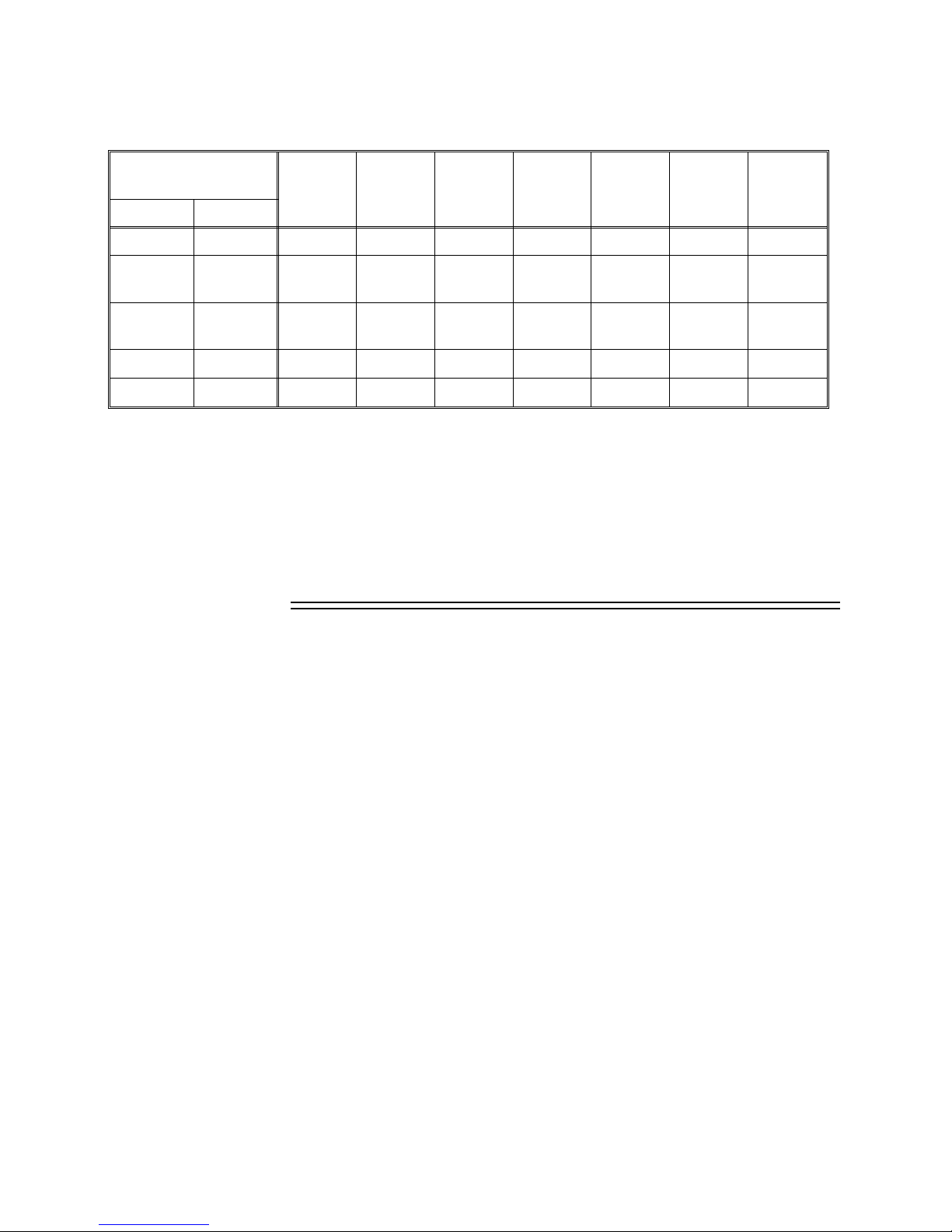

SPEED SENSOR INTERCONNECTION

MD-36 C

Description Terminal

ompuscale Compu II Compu IIA C om pu - M Compu III

to 1 TB to 1 TB to 1 TB to TB1 to TB1 to TB1 to TB1

ccumass

A

BW 100

Accumass

BW 500

+ 15 V dc 1 1 15 12 11 30 8 19

speed

2 (2) (16) (13) (12) (31) (7) (16)

out-CW

speed

3 (2) (16) (13) (12) (31) (7) (16)

out-CCW

Common 4 4 17 14 13 32 6 17

Ground G N/C N/C N/C N/C N/C N/C N/C

Terminal positions in brackets denote that only one signal may be connected at one time. To determine

direction of rotation refer to Figure 3

‘ N/C ’ denotes ‘ no connection ’

MAINTENANCE

The speed sensor electronics normally requires no maintenance, however a program of periodic checks

would be beneficial. The enclosure and circuit board should be cleaned if necessary, but only when the

power is disconnected using a vacuum cleaner and a clean dry paint brush. Check all electrical contacts

for corrosion and arcing.

The speed sensor bearing should be periodically checked for corrosion, wear and seizing. The bearing‘s

life is dependent upon the mounting, the severity of the application and surrounding environment.

PL-342 3

95/07/05

Page 6

Page 7

TRONICSMILL

TRONICS

MILL

( ref. )

61 mm

( 2.4")

213 mm

( 8.4" )

112 mm

( 4.4" )

16 mm ( 0.63" )

Ø shaft

114 mm

( 4.5" )

117 mm

( 4.6" )

124 mm

( 4.9" )

6mm ( 0.25" )

Ø shaft

(2 places)

61mm

( 2.4" )

142 mm

( 5.6" )

71 mm

( 2.8" )

218 mm

( 8.6" )

142 mm

( 5.6" )

71mm

( 2.8" )

21 mm

( 0.8" )

84 mm

( 3.3" )

56 mm

( 2.2" )

1/2 NPT plug

(2 places )

FIG. 1

MD - 36/36A OUTLINE

92/12/08

Page 8

( ref. )

76 mm

( 3" )

216 mm

( 8.5" )

102 mm

( 4" )

16 mm ( 0.63" )

Ø shaft

114 mm

( 4.5" )

127 mm

( 5" )

86 mm

( 3.4" )

6 mm ( 0.25" )

Ø shaft

(2 plac es)

61 mm

( 2.4" )

152 mm

( 6" )

76 mm

( 3" )

239 mm

( 9.4" )

152 mm

( 6" )

19 mm

( 0.75" )

21 mm

( 0.8" )

38 mm

( 1.5" )

51 mm

( 2" )

FIG. 1A

76 mm

( 3" )

cable connector

for 3 to 9 mm (.12 5"

to .25") o.d. cable

127 mm

( 5" )

MD - 36 SS OUTLINE

Page 9

Floating

MD - 36 SERIES PULLEY MOUNTING

see DETAIL ’A’

pulley

shaft

spring

’B’

MD - 36

series

127 mm

(5")approx.

secure with

hook or bo l t

anti rotation sp ring

5/16-18 UNC

set screw

( by customer )

DETAIL ‘A’

64 mm

(2.5")

25 mm

(1")

16 mm (.63 0" )

16.07 mm( .633 " )

.254mm(.010")

A

angle iron

(by cust o m er )

DIA.

A

’B’

arresting bracket (by Milltronics)

shorten if required, refer to cross

sectio n ‘ B - B’

arresting bracket

CROSS SECTION ‘B-B’

NOTE :

1. Machining on tail/bend pulley shaft per Detail ’A’ (by customer) to accommodate Milltronics speed sensor when

tail or bend pulley is not supplie d by Milltronics.

angle

iron

2. Arresting bracket is an anti-rotation device only and must not secure or support the speed sensor. Bearing life would

be greatly reduced if speed sensor is not free to "float". Use anti-rotation spring to prevent mechanical oscillation of

speed sensor.

3. Grease mating surfaces to prevent seizing.

FIG. 2

95/07/05

Page 10

C

W

C

C

W

refer to

outline

drawing

0.8 mm (0.313" )

2 places

FIG. 3

16 mm ( 0.63" )

Ø shaft

motor shaft

customer mounting bracket

( remove arresting bracket supplied )

13 mm

( 0.5" )

optimum

dimension

guard

(to suit)

MD - 36

series

rubber hose

hose clam p (typ)

motor

0.8 mm (0.03" )

max shaft offset

shaft rotation

MD - 36 SERIES MOTOR SHAFT MOUNTING

Fixed

Page 11

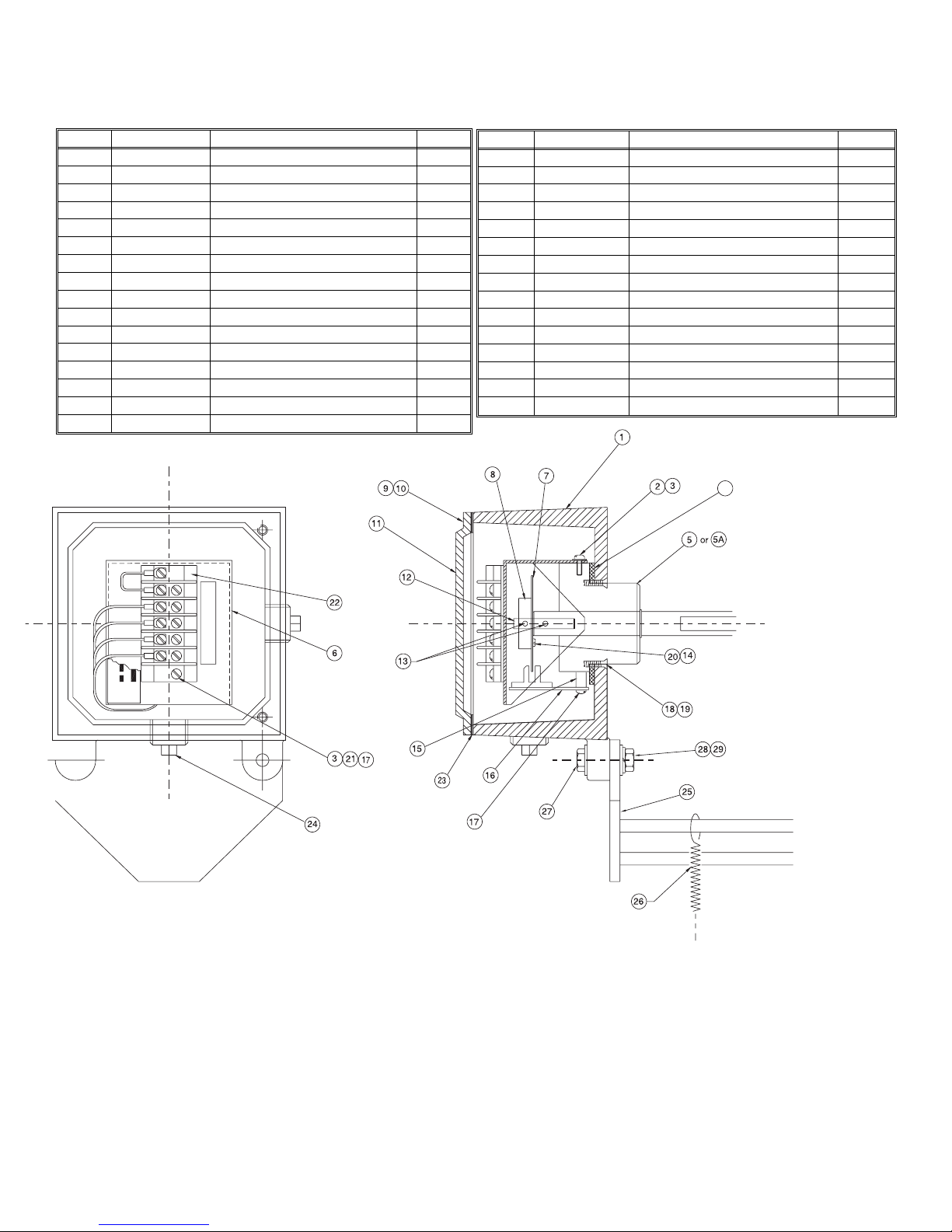

MD - 36/36A PARTS IDEN TIFICAT ION

ITEM PART No. DESCRIPTION QTY.

1 54000923 Enclosure 1

2 32900200 Screw, 6-32 x 5/16 3

3 32950135 External Lockwasher #6 5

4 22600 00 5 Gasket, Bearing Assembly 1

5 23250 09 9 MD-3 6 Bea r ing As sembly 1

5A 23250147 MD-36A Bearing Assembly

6 21550 01 6 MD-3 6 Shr o ud 1

7 20300 07 5 Disc 36 Tooth 1

8 20300 055 Disc Hub 1

9 32900480 Slot Round Head Screw 1/4" 4

10 32950100 Lockwasher Split 1/4" 4

11 45000061 Enclosure Cover 1

12 25500060 Extension Shaft 1

13 32900560 Set Screw Socket, 8-32 x 3/16 2

14 32950130 External Lockwasher #4 3

15 20550025 Bushing 2

G

4

3

2

1

ITEM PART No. DESCRIPTION QTY.

16 51016921 Speed Pickup Card Ver.3 1

17 32900212 Binding Screw, Slot, 6 - 32 x 5/8 4

18 32900878 Cap Screw, Socket, 10 - 32 4

19 32950095 Lockwasher, Split #10 4

20 32900085 Binding Screw, Slot, 4 - 40 3

21 32850030 Hex Nut, 6 - 32 2

22 26000130 Terminal Block CSA 1

23 22600008 Gasket, Cover 1

24 24700015 Threaded Plug, 1/2 NPT 2

25 20500008 Enclosure Arresting Bracket 1

26 25700025 Spring Spnr. B-604 1

27 32800065 Bolt, Hex 5/ 16 - 18 x 1 1/4 2

28 32850055 Nut, Hex 5/16 - 18 2

29 32950040 Washer, Flat 5/16 2

30 32950105 Lockwasher Split 5/16 2

P/N

MD-

Bearing Assembly Replacement

- turn supply power from integrator off

- remove speed sensor from mounting

- remove cover #11 and the 4 bearing assembly mounting screws #18 located externally around shaft

- pull out bearing assembly #5 c/w card, disc hub, disc and mounting brackets

- remove screws #17, bushing #15 and card #16

- remove speed sensor shroud screws #2

- loosen hex screw in shaft and remove extension shaft, disc hub and disc

- bearing assembly is now free

FIG. 4

Page 12

MD - 36 SS PARTS IDENTIFICATION

ITEM PART No. DESCRIPTION QTY.

1 54000050 Enclosure 1

2 32900200 Screw, 6 - 32 x 5/16 3

3 32950 13 5 E x ter nal Lockwas he r , #6 5

4 22600005 Gasket, Bearing Assembly 1

5 A32 50101 Beari ng A ss em bly 1

6 21550 01 6 MD-36 Shr o ud 1

7 20300 07 5 Disc 36 T o oth 1

8 20300 055 Disc Hub 1

9 25500060 Extension Shaft 1

10 329005 60 Set Screw Socket, 8- 32 x 3/16 2

11 32950130 External Lockwasher #4 3

12 20550025 Bushing 3

13 51016921 Speed Pickup Card Ver.3 1

G

4

3

2

1

ITEM PART No. DESCRIPTION QTY.

14 32900212 Binding Screw, Slot, 6 - 32 x 5/8 4

15 32900471 SS Screw, Socket, 10 - 32 x 1/2 4

16 32950096 Lockwasher, Split, #10 SS 4

17 32900085 Binding Screw, Slot, 4 - 40 x 3/8 3

18 328500 30 Hex Nut, 6 - 3 2 2

19 26000130 Terminal Block 1

20 A1400087 Cable Connector 1

21 A0500009 Enclosure Arresting Bracket 1

22 32850120 Locknut T&B 1/2 in # 141 1

23 25700025 Spring Spnr. B-604 1

24 32800056 Bolt, Hex 5/16 - 18 x 3/4 SS 2

25 32950041 Washer, Flat 5/16 SS 2

26 32950106 Lockwasher, Split 5/16 SS 2

27 32850056 Nut, Hex 5/16 - 18 NC SS 2

MD-

P/N

Bearing Assembly Replacement

- turn supply power from integrator off

- remove speed sensor from mounting

- open cover and remove the 4 bearing assembly mounting screws #15 located externally around shaft

- pull out bearing assembly #5 c/w card, disc assembly and MD - 36 shroud

- remove screws #14, bushing #12 and card #13

- remove MD - 36 shroud screws #2 and MD - 36 shroud c/w terminal block #19 and card #13 attached

- loosen hex screw in shaft and remove extension shaft, disc hub and disc

- bearing assembly is now free

FIG. 4A

Page 13

ref.10C 1295 R2

GRN

WHT

BLU

CCW

SPEED OUT 2

CW

SPEED OUT 1

STRIP

TERMINAL

CHASSIS

G

4

3

2

1

D COM

+15 V

4

1RC

2

1RC

P5V

R7

10K

R6

499

Q2

2N4401

R8

10K

R5

499

R9

10K

P5V

R11

10K

R10

10K

C2

.1MFD

C1

.1MFD

BLK

RED

3

1

D1

1N4005

51016921

ML

P5V

Q1

2N4401

P5V

P15V

P5V

P15V

R4

10K

R2

1K

R3

10K

R1

1K

P5V

D2

CLK 2

CLR 2

Q2

Q2

PR 2

IC3

74LS74

12

11

13

8

9

10

IC2

74HCT132

12

13

11

COM

V+

IC3

74LS74 14

7

D1

CLK 1

PR 1

CLR 1

Q1

Q1

IC3

74LS74

2

3

1

6

5

4

COM

V+

IC2

74HCT132 14

7

IC2

74HCT132

4

5

6

IC2

74HCT132

9

10

8

IC2

74HCT132

1

2

3

OC2

H21A1

1

2 4

3

OC1

H21A1

1

2 4

3

IN OUT

COM

IC1

MC78L05

Note: Chassis terminal strip, customer connection to integrator.

Refer to associated integrator manual for interconnection wiring.

FIG. 5

MD - 36 SE RIE S S CHE MAT IC

Page 14

OC1 pin 3

OC2 pin 3

IC2 pin 3

IC2 pin 6

Logic D iagrams

CW & CCW oper ation

clockwise counterclockwise

IC3 pin 8

IC3 pin 5

IC3 pin 9

1RC 2

Speed Out

CW

1RC 4

Speed Out

CCW

FIG. 5A

Page 15

Siemens Milltronics Process Instruments Inc.

1954Technology Drive, P.O. Box 4225

Peterborough, ON.Canada K9J 7B1

Tel: (705) 745-2431 Fax: (705) 741-0466

www.milltronics.com

c

Siemens Milltronics Process Instruments Inc. 2001

Subject to change without prior notice

*7ML19981DB01*

Printed in Canada

Loading...

Loading...