Page 1

MD-2000A SPEED SENSOR

Instruction Manual June 2002

Page 2

Safety Guidelines

Warning notices must be observed to ensure personal safety as well as that of others, and to protect the product and the connected equipment.

These warning notices are accompanied by a clarification of the level of caution to be observed.

Qualified Personnel

This device/system may only be set up and operated in conjunction with this manual. Qualified personnel are only authorized to install and

operate this equipment in accordance with established safety practices and standards.

Warning: This product can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and maintained.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2002. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic versions as

designed and authored by Siemens Milltronics Process

Instruments Inc. Siemens Milltronics Process Instruments

Inc. will not be responsible for the contents of partial or

whole reproductions of either bound or electronic versions.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

While we have verified the contents of this

manual for agreement with the instrumentation

described, variations remain possible. Thus we

cannot guarantee full agreement. The contents of

this manual are regularly reviewed and

corrections are included in subsequent editions.

We welcome all suggestions for improvement.

Technical data subject to change.

Contact SMPI Technical Publications at the following address:

Technical Publications

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs@milltronics.com

For the library of SMPI instruction manuals, visit our Web site:

© Siemens Milltronics Process Instruments Inc. 2002

www.siemens-milltronics.com

Page 3

SPECIFICATIONS

Power: » +15 V dc, 150 mA from integrator

Temperature: » -20 to 55° C (-4 to 130° F)

Input: » bi-directional shaft rotation

» 0.3 to 75 rpm operating input

Output: » open collector sinking output, max. 25 mA at 5 V dc

» 2048 pulses / revolution

» 10 to 2,560 Hz operating output

Enclosure: » general purpose

» material : - standard : aluminum

- optional : 304 stainless steel

Cable: » Belden 8770, 3 wire shielded, 18 AWG or equivalent

» max run 305 m (1000 ft)

REFERENCE

Associated Milltronics integrator:

CompuScale III

BW100

BW500

GENERAL

The MD-2000A speed sensor is used to monitor the speed of a weighfeeder or low speed belt conveyor ( see

input specification ). The sensor, coupled to a pulley shaft, converts the rotation of its input shaft into an

encoded speed signal. The speed signal is transmitted to the integrating electronics for use in computing the

rate of material flow.

CIRCUIT OPERATION

The speed sensor is made up of a main shaft rotating in a bearing assembly fixed to the enclosure. The shaft

turns an encoder which produces two square wave quadrature (90° electrically out of phase) outputs which

are fed to the speed sensor board to determine direction of rotation as well as the speed of rotation.

Power is provided by the integrating device. The 15 V dc supply is regulated to 5 V dc for use by the encoder

circuit and output drive transistors of the speed sensor board.

As the shaft rotates, the two quadrature square waves from the 2048 pulse per revolution encoder are

converted into clockwise (CW) and counter clockwise (CCW) square wave output signals by the intermediate

counter logic. When the shaft rotates in the CW direction, the logic produces pulses at the CW output and the

CCW output is disabled. When the shaft rotates in the CCW direction, the logic produces pulses at the CCW

output and the CW output is disabled.

The logic diagrams detail the operation of the electronics for both clockwise and counter clockwise output

generation. The speed sensor is immune to external vibration that would cause the encoder to oscillate 1/8 of

a revolution or less.

PL-361 1

Page 4

MOUNTING

The MD-2000A speed sensor is usually coupled to the tail pulley shaft of a weighfeeder. On low speed

conveyers, the speed sensor may be coupled to the tail, bend or snub pulley. The mounting arrangement

requires the input shaft and bearing assembly to bear the weight of the speed sensor. The unit’s arresting

bracket stops the speed sensor from rotating with the shaft.

When mounting the speed sensor, ensure that the shaft alignment is true to avoid stresses on the shaft

bearing. Refer to ( MD - 2000A Series Pulley Mounting ).

INTERCONNECTION

ALL WIRING MUST BE DONE IN CONJUNCTION WITH APPROVED

CONDUIT, BOXES AND FITTINGS AND TO PROCEDURES IN

ACCORDANCE WITH ALL GOVERNING REGULATIONS.

Interconnection between the speed sensor and the integrator should be made with 3 wire shielded, 18 AWG

cable (Belden 8770 or equivalent).

Ground the shield at the integrator ONLY!

FLEXIBLE CONDUIT IS RECOMMENDED SO EXCESS STRESS IS NOT

APPLIED TO THE SHAFT BEARINGS.

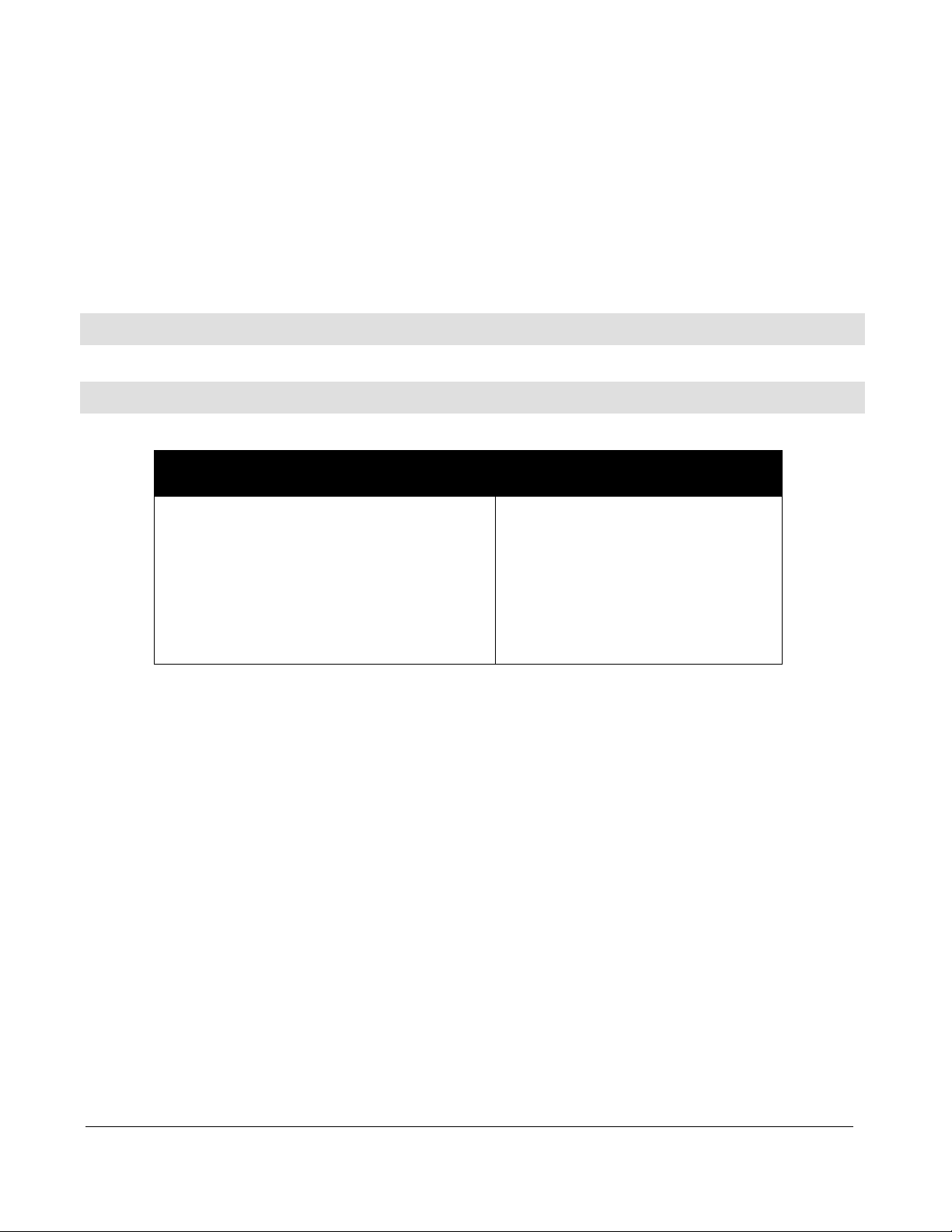

SPEED SENSOR INTERCONNECTION

MD-2000A BW100 BW500 COMPUSCALE III

DESCRIPTION TERMINAL TO 1TB

+15 V DC(Red) 1 8 19 30

speed out-CW

(White)

speed out-CCW

(Blue)

Common

(Black)

Ground 5 N\C N\C N\C

Terminal positions in brackets denote that only one signal may be connected at one time. To determine

direction of rotation refer to ( MD - 2000A Series Pulley Mounting ).

‘ N/C ’ denotes ‘ no connection ’

2 (7) (16) (31)

3 (7) (16) (31)

4 6 17 32

PL-361 2

Page 5

MAINTENANCE

The speed sensor electronics normally requires no maintenance, however a program of periodic checks

would be beneficial. The enclosure and circuit board should be cleaned if necessary, but only when the

power is disconnected using a vacuum cleaner and a clean dry paint brush. Check all electrical contacts for

corrosion and arcing.

The speed sensor bearing should be periodically checked for corrosion, wear and seizing. The bearings life is

dependent upon the mounting, the severity of the application and surrounding environment.

SPARE PARTS

Bearing Assembly: - MD 2000A

- MD 2000A SS

Speed Sensor Card - without encoder

- with encoder

PL-361 3

Page 6

PL-361

71 mm

( 2.8" )

142 mm

( 5.6" )

MD - 2000A OUTLINE

117 mm

( 4.6" )

61 mm

( 2.4" )

4

218 mm

( 8.6" )

92/12/08

142 mm

( 5.6" )

71 mm

( 2.8" )

56 mm

( 2.2" )

MILL

TRONICS

TRONICS

112 mm

( 4.4" )

MILL

1/2 NPT plug

(2 places)

( ref. )

61 mm

( 2.4")

213 mm

( 8.4" )

114 mm

( 4.5" )

16 mm ( 0.63" )

Ø shaft

84 mm

( 3.3" )

124 mm

( 4.9" )

21 mm

( 0.8" )

6 mm ( 0.25" )

Ø shaft

(2 places)

Page 7

19 mm

( 0.75" )

76 mm

( 3" )

152 mm

( 6" )

MD - 2000A SS OUTLINE

127 mm

( 5" )

61 mm

( 2.4" )

152 mm

( 6" )

239 mm

( 9.4" )

cable connector

for 3 to 9 mm (.125"

to .25") o.d. cable

76 mm

( 3" )

38 mm

( 1.5" )

102 mm

( 4" )

51 mm

( 2" )

( ref. )

76 mm

( 3" )

216 mm

( 8.5" )

114 mm

( 4.5" )

86 mm

( 3.4" )

16 mm ( 0.63" )

Ø shaft

127 mm

( 5" )

21 mm

( 0.8" )

6 mm ( 0.25" )

Ø shaft

(2 places)

Page 8

MD - 2000A SERIES CIRCUIT BOARD LAYOUT

customer connection

to integrator, refer to

associated integrator

manual.

R8

C3 C4

10D775

S3

R1

IC4

RP1

RP3

R9

RP2

J1

J2

R10

C5

IC3

IC2

HS1

C1

IC1

C2

MD2000A

MADE IN CANADA

R6

R7

Q1

Q2

1

1TB

2

D1

R1

3

R2

R3

4

R4

5

R5

PETERBOROUGH,

ONTARIO.

ARLINGTON,TEXAS

WORCESTER,ENGLAND

SN

P15V

CW

(WHT)

CCW

D

COM

GND

(RED)

(BLU)

(BLK)

(GRN)

PN 24751320

ML 51026001

C6

J3

P5V

OV

CN1

A

B

PL-361 6

Page 9

MD - 2000A SERIES PULLEY MOUNTING

see DETAIL ’A’

and note 3

pulley

shaft

spring

5/16-18 UNC

set screw, note 3

( by customer )

64 mm

(2.5")

DETAIL ’A’

25 mm

(1")

16 mm (.630")

16.07 mm( .633" )

A

angle iron

(by customer)

DIA.

A.254mm(.010")

’B’

’B’

MD-2000A

or

MD-2000A SS

arresting bracket (by Milltronics)

shorten if required, refer to cross

section ‘B-B’

127 mm

(5") approx.

arresting bracket

CROSS SECTION ’B-B’

View for

direction

of rotation

secure with

hook or bolt

angle iron

anti-rotation spring

NOTE :

1. Machining on tail pulley shaft per Deta il ’A ’ (by customer) to accomodate Milltronics sp ee d se ns or .

2. Arresting bracket is an anti-rotatio n device only and mu st not secure or support the speed sensor. Bearing life would

be greatly reduced if speed sensor is not free to "float". Use anti-rotation spring to prevent mechanical oscillation of

speed sensor.

3. Grease mating surfaces to prevent seizing.

PL-361 7

Page 10

MD - 2000A PARTS IDENTIFICATION

ITEM DESCRIPTION QTY.

1Enclosure 1

2 Enclosure Arresting Bracket 1

3 Encoder 1

4 Speed Sensor Card 1

5 Encoder Arresting Bracket 1

6 Bearing Assembly 1

7 Standoff 3

8 Threaded Plug, 1/2 NPT 2

9 Hex Bolt, 5/16 - 18 x 1 1/4 2

10 Bind. Screw, 6 - 32 x 5/16 8

11 External Lockwasher #6 8

12 Gasket, Bearing Assembly 1

13 Gasket, Cover 1

1110

P15 (RED)

1

CW (WHT)

2

CCW

3

(BLU)

COM

(BLK)

4

GND (GRN)

5

ITEM DESCRIPTION QTY.

14 Spring Spnr. B-604 1

15 Bracket 1

16 Cable Clamp 1

17 Round Head Screw 1/4 - 20 x 3/4 4

18 Enclosure Cover 1

19 Lockwasher, 1/4" 4

20 Flat Screw, Socket, 10 - 32 x 3/4 4

21 Lockwasher, Cntrsnk tooth #10 4

22 Hex Nut, 6 - 32 3

23 Hex Nut, 5/16 - 18 2

24 Split Lockwasher, 5/16 2

25 Flat Washer, 5/16 2

26 Round Screw, Slot, 6 - 32 x 3/8 2

1

15

13

11

10

17 18 19

12

20

21

6

8

3

26

16

23

9

24

25

4

11

22

7

2

5

1011

8

COVER NOT SHOWN FOR CLARITY

Bearing Assembly Replacement

- turn supply power from integrator off

- remove cover #18

- disconnect wires to terminal block 1TB

- remove speed sensor from mounting

- remove speed sensor card screws #10 & #26 and card #4. Leave encoder cable connected to card.

- remove the four bearing assembly mounting screws #20 located externally around shaft

- pull out bearing assembly #6 c/w card, encoder and mounting brackets

- loosen hex screw in shaft and remove encoder arresting bracket fastening screws #10

- remove encoder #3 and c/w arresting bracket #5

- remove bracket fastening screws #10 and bracket #15 from bearing assembly

- bearing assembly is now free

14

PL-361 8

Page 11

MD - 2000A SS PARTS IDENTIFICATION

ITEM DESCRIPTION QTY.

1Enclosure 1

2 Enclosure Arresting Bracket 1

3 Encoder 1

4 Speed Sensor Card 1

5 Encoder Arresting Bracket 1

6 Bearing Assembly 1

7 Standoff 4

8 Cable Connector 1

9 Hex Bolt, 5/16 - 18 x 3/4 SS 2

10 Screw, 6 - 32 x 5/16 9

11 External Lockwasher #6 9

10 11

P15 (RED)

1

CW (WHT)

2

CCW

3

(BLU)

COM

4

(BLK)

GND (GRN)

5

ITEM DESCRIPTION QTY.

12 Gasket, Bearing Assembly 1

13 Spring Spnr. B-604 1

14 Bracket 1

15 Cable Clamp 1

16 SS Socket Screw 10 - 32 x 1/2 4

17 Lockwasher, Split #10, SS 4

18 Hex Nut, 6 - 32 4

19 Hex Nut, 5/16 - 18, SS 2

20 Split Lockwasher, 5/16, SS 2

21 Flat Washer, 5/16, SS 2

22 Round Screw, Slot, 6-32 1

1

14

10 11

12

6

4

3

15

22

1110

18117

8

COVER NOT SHOWN FOR CLARITY

9 19 20

2

21

5

10 11

Bearing Assembly Replacement

- turn supply power from integrator off

- open cover

- disconnect wires to terminal block 1TB

- remove speed sensor from mounting

- remove speed sensor card screws #10 & #15 and card #4. Leave encoder cable connected to card.

- remove the four bearing assembly mounting screws #16 located externally around shaft

- pull out bearing assembly #6 c/w card, encoder and mounting brackets

- loosen hex screw in shaft and remove encoder arresting bracket fastening screws #10

- remove encoder #3 and c/w arresting bracket #5

- remove bracket fastening screws #10 and bracket #14 from bearing assembly

- bearing assembly is now free

16 17

13

PL-361 9

Page 12

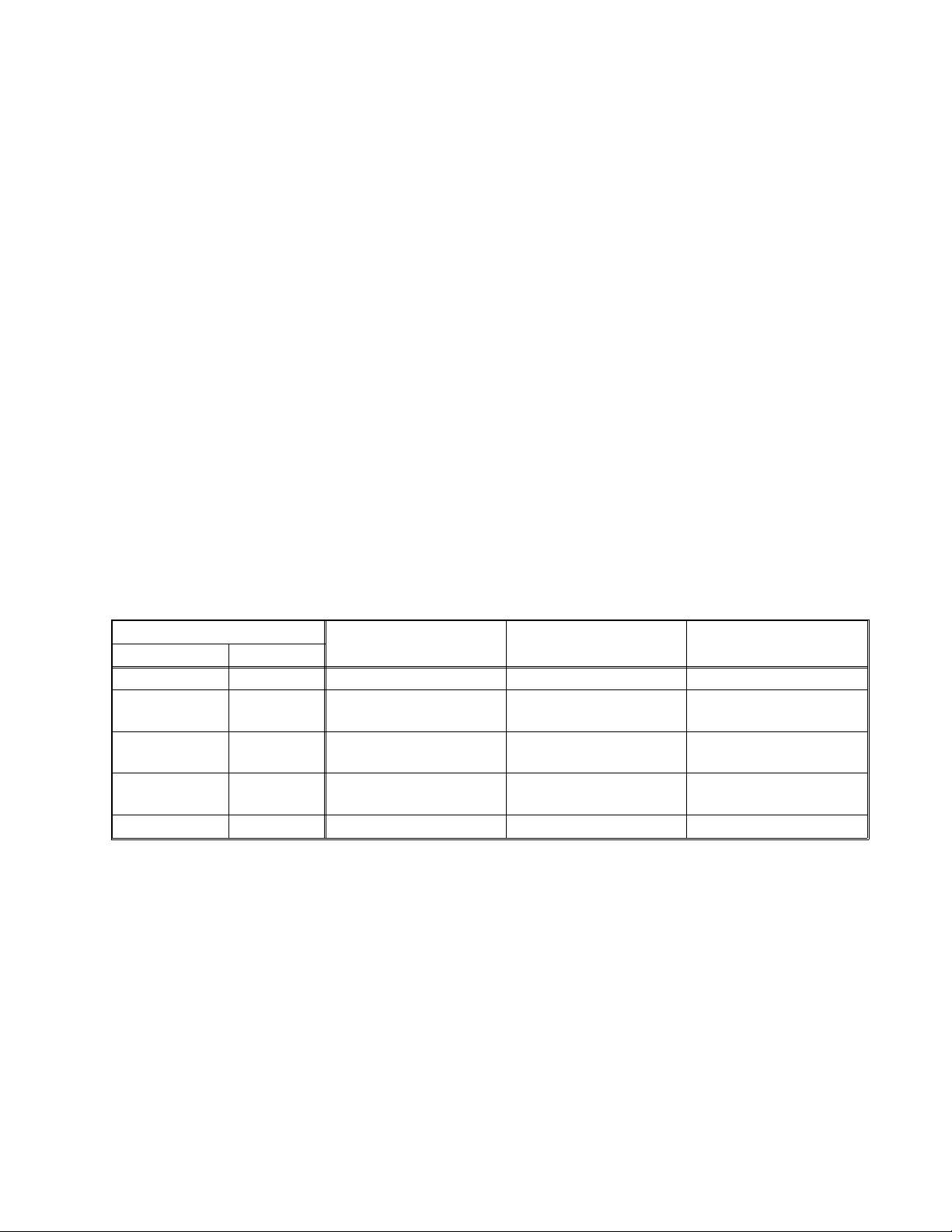

MD - 2000A SERIES SCHEMATIC

1TB

P15V

1

RED

CW

2

WHT

to associated

integrator

CCW

3

BLU

D COM

BLK

GND

GRN

4

5

ENCODER

P15V

UNUSED

74HCT32

1

2

74HCT32

9

10

IC2

IC2

R1

499

R4

499

3

8

1CN

P5V

RED

OV

BLUE

A

GREEN

B

BLACK

P5V

P5V

R2

10K

Q2

2N4401

R3

10K

Q1

2N4401

74HCT32 14

P5V

C1

1MFD

74HCT32

4

5

74HCT32

12

13

IC2

IC2

IC2

R6

10K

R7

10K

V+

COM

OUT

7

6

11

P5V

INOUT

COM

COM

68HC11A1 48

C5

.1MFD

D1

P5V

1N5060

J1

J2

C6

.1MFD

P15V

R9

10K

RP3

750-10K

R8

10M

CR1

8MHZ

C3

27PF

R10

10K

J3

C4

27PF

P5V

RP3

750-10K

IC4

68HC11A1

41

IRQ

40

XIRQ

PC0

25

MODA

PC1

24

MODB

PC2

PC3

8

PA0

PC4

7

PA1

PC5

6

PA2

PC6

5

PA3

PC7

4

PA4

3

PA5

2

PB0

PA6

1

PB1

PA7

PB2

42

PD0

PB3

43

PD1

PB4

44

PD2

PB5

45

PB6

PD3

46

PB7

PD4

47

PD5

VRL

17

VRH

PE0

18

PE1

19

PE2

20

PE3

29

EXTAL

R/W

30 39

XTAL

RST

AS

E

26

31

32

33

34

35

36

37

38

16

15

14

13

12

11

10

9

21

22

27

28

MC34064

RP1

750-10K

RP1

750-10K

P5V

IC3

R5

10K

RP2

750-10K

RP3

750-10K

P5V

P5V

IN

C2

1MFD

RP1

750-10K

RP1

750-10K

RP1

750-10K

IC4

V+

COM

23

NOTE: Terminal block 1TB provides customer connection to integrator.

Refer to associated integrator manual for interconnecton wiring.

PL-361 10

ref. 10D775 rev.0

Page 13

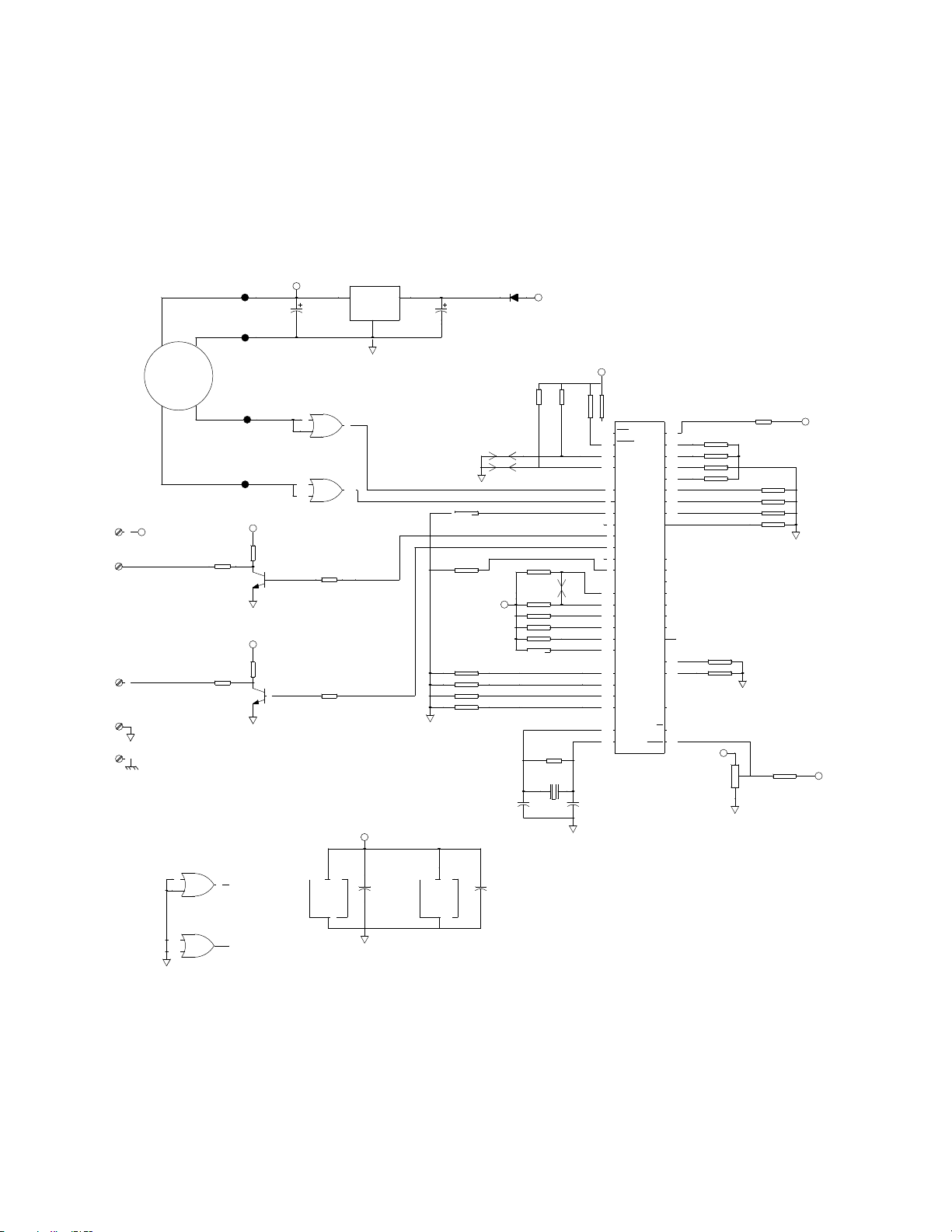

MD - 2000A LOGIC DIAGRAMS

CW & CCW operation

clockwise counterclockwise

IC2 pin 6

IC2 pin 11

IC4 pin 4

IC4 pin 3

1TB 2

Speed Out

CW

1TB 3

Speed Out

CCW

PL-361 11

Page 14

Page 15

Page 16

c

Siemens Milltronics Process Instruments Inc. 2002

Subject to change without prior notice

Siemens Milltronics Process Instruments Inc.

1954Technology Drive, P.O. Box 4225

Peterborough, ON.Canada K9J 7B1

Tel: (705) 745-2431 Fax: (705) 741-0466

www.milltronics.com

Rev. 1.0

*7ml19981ec01*

Printed in Canada

Loading...

Loading...