Page 1

33455500

Rev 1.0

Page 2

hank you for purchasing Milltronics products. We endeavour to design

T

equipment that is simple to use and reliable in its operation, with the aim

of satisfying our customers' needs.

Milltronics has been designing and manufacturing process equipment since

1954. Our fields of expertise include ultrasonic and capacitance level

measurement, in-line weighing of dry bulk solids and motion sensing.

Milltronics is established world wide through associate offices and

representatives. Our network is continually being refined to provide our

customers with first rate sales information, engineering assistance and after

sales support.

For more details on our products and service, please contact us and we will

provide you with a listing of the offices or representatives nearest you.

Page 3

_

TABLE OF CONTENTS

GENERAL INFORMATION

About This Manual .................................................................................................5

About IQ Radar 160...............................................................................................6

SPECIFICATIONS

IQ Radar 160 ...........................................................................................................7

INSTALLATION

Location ....................................................................................................................9

Dimensions............................................................................................................ 1 0

Mounting................................................................................................................ 1 1

Flanged .........................................................................................................11

Extension Requirements........................................................................... 12

Rod Assembly .............................................................................................13

Interconnection ..................................................................................................14

Terminal Block Layout ...............................................................................14

Wiring............................................................................................................. 1 5

START UP

Overview ................................................................................................................17

Display and Keypad ............................................................................................ 1 9

Local Operation.................................................................................................... 20

Run Display ..................................................................................................20

Run Keypad ................................................................................................. 21

Program Display ..........................................................................................22

Program Keypad......................................................................................... 23

Local Programming .................................................................................... 24

OPERATION

Overview ................................................................................................................ 2 7

Transceiver ............................................................................................................ 28

Blanking ................................................................................................................. 29

Loss of Echo .........................................................................................................3 0

Analog Output...................................................................................................... 31

Programming............................................................................................... 31

Ru n................................................................................................................. 31

Fail-safe......................................................................................................... 32

Run / Program ......................................................................................................3 2

Application Example........................................................................................... 33

PARAMETER DESCRIPTION ...........................................................................................35

TROUBLESHOOTING ........................................................................................................41

MAINTENANCE ...................................................................................................................43

APPENDICES

Alphabetical Parameter List .............................................................................. 4 5

Programming Chart ........................................................................................... 46

PL-550 3

Page 4

PL-550 4

Page 5

_

GENERAL INFORMATION

ABOUT THIS MANUAL

It is essential that this manual be referred to for proper installation and operation

of your IQ Radar 160.

GENERALLINFO. _

Installation

Start-up

Operation

Applications

Parameters

Troubleshooting

Appendices

gives you step-by-step direction for the installation and

interconnection of your IQ Radar 160.

instructs you in how to operate the keypad, program the unit

and read the display.

describes the operation of the IQ Radar 160, detailing the

interoperation of the salient features.

looks at the IQ Radar 160 from a practical point of view, using

a typical application example.

lists the parameters available to you, with a description of their

function and use. You are urged to read this section to

familiarize yourself with the parameters available to you and

get your IQ Radar 160 working to its fullest.

tabulates symptoms, causes and actions to common

installation and application problems that you might encounter.

Hopefully you will never have to read this section, but know it’s

there to help you.

what manual would be complete without one! Ours is an

alphabetical cross-reference of the parameters and their

numbers, and a record sheet for jotting down parameter

values. Handy indeed!

PL-550 5

Page 6

ABOUT IQ RADAR 160

The IQ Radar 160 is to be used only in the manner outlined in this manual.

IQ Radar 160 is a versatile process material level monitoring instrument. Material

level measurement is achieved using advanced pulse radar techniques. The unit

consists of an electronic component coupled to the antenna.

GENERAL INFO.

IQ Radar 160 Features:

✓ ANSI, DIN flange or sanitary tri-clamp mounting

✓ corrosion-resistant construction, aluminum enclosure with stainless steel and

Teflon® wetted parts

✓ local display

✓ infrared keypad and Dolphin-compatible

IQ Radar 160 Applications:

✓ liquids, slurries

✓ process temperatures up to 200°C

✓ vacuum and pressurized vessels

IQ Radar 160 Approvals and Certificates

✓ safety and radio

® Teflon is a registered trademark of Du Pont.

PL-550 6

Page 7

_

SPECIFICATIONS

IQ RADAR 160

Power: 100/115/200/230 ±15% V ac*, 50/60 Hz, 15 VA

*factory set – see device nameplate

Interface:

analog output: optically-isolated 0/4-20 mA into 750 Ω max,

0.02 mA resolution

Dolphin/RS-485 link: refer to Dolphin product specification

programmer link: infrared receiver (refer to P ro g rammer

specification below)

display (local): backlight , alphanumeric and multi -graphic liquid

crystal for readout and entry

SPECIFICATIONS _

Performance:

frequency: 5.8 GHz

accuracy: > ±0.3% of range (1 to 10 m)

range: 10 m

repeatability: 30 µW average

fail-safe: mA programmable high, low or hold

Mechanical:

enclosure (electronic):

resonator: plated aluminum

flange: 316 stainless steel, 150 psi ANSI, DIN PN16,

antenna:

construction: aluminum , epoxy coated

conduit: 2 x 1/2" NPT or PG 16 entry

ingress protection: Type 6 / NEMA 6 / IP-67

3" sanitary tri-clamp

type: dielectric rod

construction: Teflon

®

weight: 6.5 kg (14.3 lb) with 2"/150 psi ANSI flange,

PL-550 7

weight will vary with flange size and rating

Page 8

Environmental:

location: indoor/outdoor

altitude: 2000 m max

ambient temperature: -20 to 60° C (-4 to 140° F)

relative humidity: suitable for outdoor

installation category: II

pollution degree: 4

Process:

material dielectric: εr > 4

temperature: -40 to 200°C (-40 to 392°F)

pressure (vessel): -100 kPa to 1000 kPa

SPECIFICATIONS _

Programmer (remote keypad):

enclosure: general purpose

ambient temperature: -20 to 50° C (-5 to 122° F)

interface: proprietary infrared pulse signal

power: 9V battery (ANSI/NEDA 1604, PP3 or equivalent

weight: 150 g (0.3 lb)

(Type 6/NEMA 6/IP 67 enclosure)

(-1 to 10 bar or -10 to 150 psi)

67 mm w x 100 mm h x 25 mm d

(2.6" w x 4" h x 1" d)

Approvals (refer to device nameplate ) :

safety: CSA

radio: BAPT, Transport Canada

NRTL/C

, CE

PL-550 8

Page 9

_

INSTALLATION

LOCATION

Installation shall only be performed by qualified personnel

and in accordance with local governing regulations.

This product is susceptible to electrostatic shock.

Follow proper grounding procedures.

Do not mount in direct sunlight without the use of a sun shield.

INSTALLATION _

PL-550 9

Page 10

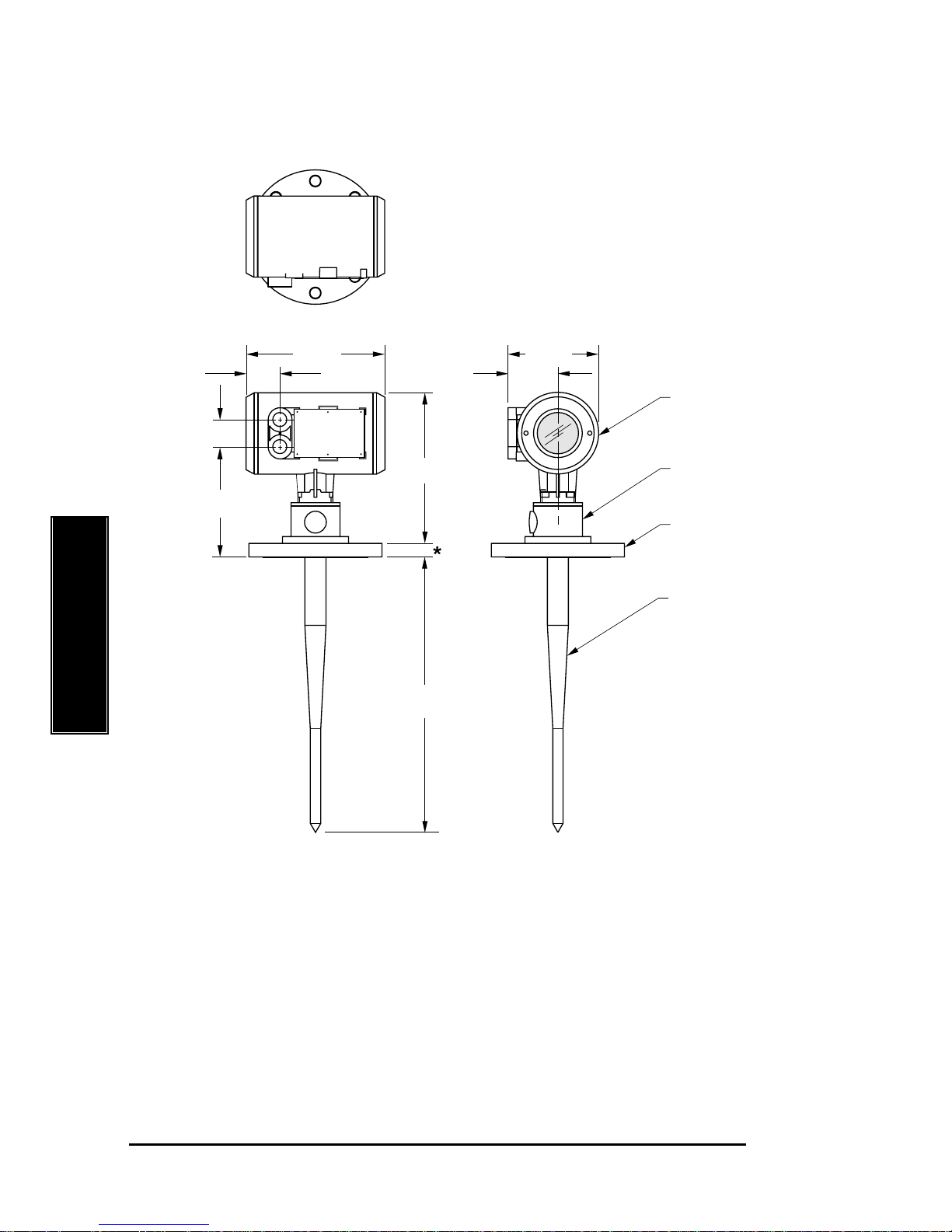

DIMENSIONS

(

)

(3.0")

(2.0")

(8.3")

(

)

(

)

(

)

211 mm

50mm

136 mm

5.4"

75 mm

enclosure/

electronics

41 mm

1.6"

245 mm

9.6"

183 mm

7.2"

antenna

(resonator)

flange or

tri-clamp

antenna

(rod)

INSTALLATION _

412 mm ◊

(16.3")

* Flange thickness varies with size and rating. 25mm (1") nominal.

Check appropriate standard.

◊ Standard length, 50 and 100 mm (2” and 4") extensions available.

PL-550 10

Page 11

MOUNTING

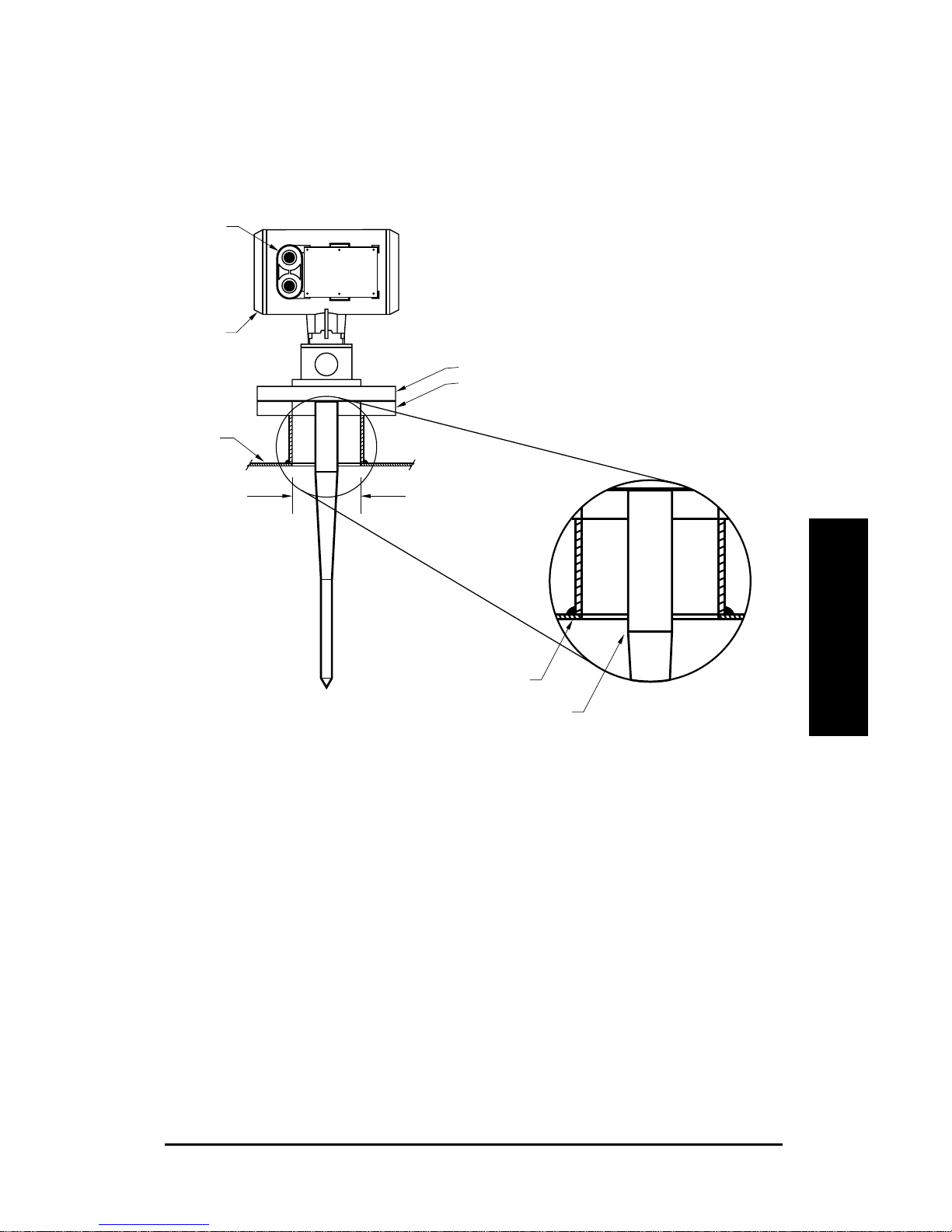

FLANGED

1/2" NPT

or PG 16

conduit entry

wiring

access

cover

tank

minimum

diameter

2" / DIN 50

_

supplied ANSI, DIN flange or sanitary tri-clamp

customer flanged standpipe to suit

standpipe/vessel juncture

rod transition

For 2" or 3" / DIN 50 or DIN 80, the straight/taper transition of the rod should

extend past the standpipe/vessel opening. Add extensions as required.

For larger diameter standpipes, refer to Extension Requirements.

INSTALLATION _

PL-550 11

Page 12

PL-550 12

INSTALLATION _

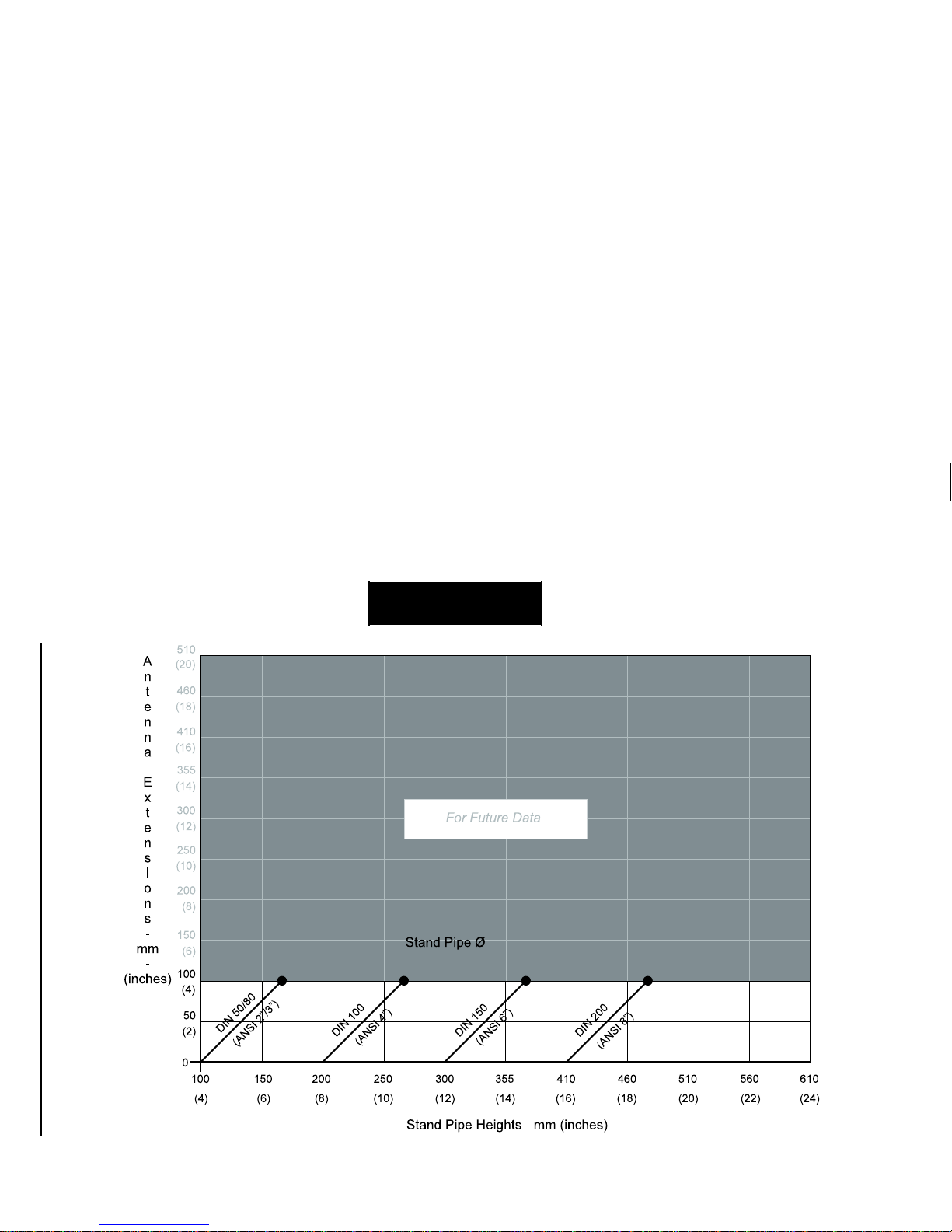

MOUNTING (continued)

EXTENSION REQUIREMENTS

Page 13

_

MOUNTING (continued)

ROD ASSEMBLY

standard

rod

INSTALLATION _

50 mm

100 mm

extensions

PL-550 13

Page 14

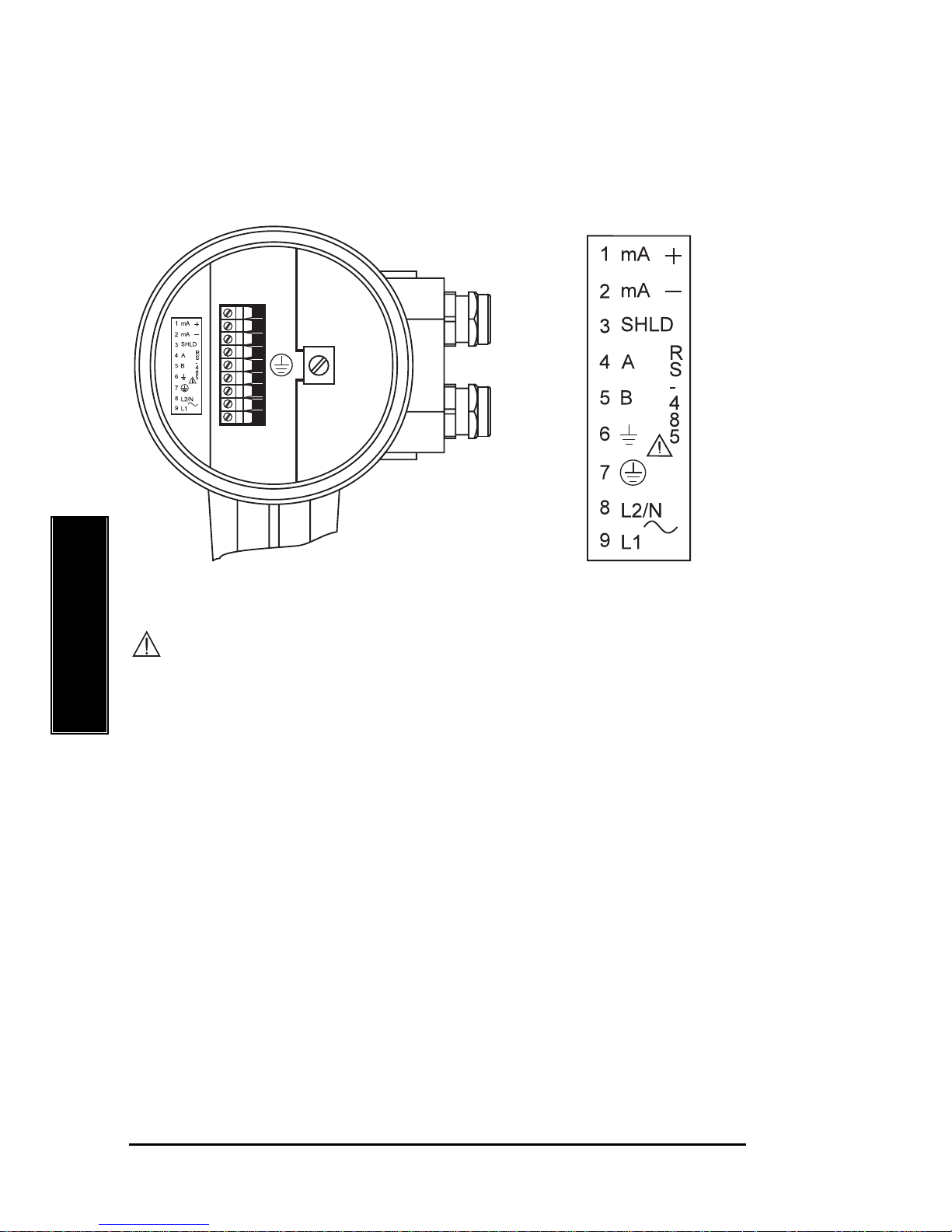

INTERCONNECTION

TERMINAL BLOCK LAYOUT

All field wiring must have insulation suitable for at least 250 V.

INSTALLATION _

– mA wiring, 14 – 20 AWG, copper wire, shielded

– RS-485, 14 – 20 AWG, copper wire, shielded

– Line, 12 – 14 AWG, copper wire

– Recommended torque on clamping screws, 0.5 – 0.6 Nm

PL-550 14

Page 15

WIRING

_

4-20 mA ,

to instrumentation

RS-485,

to host device

V supply,

see nameplate

Ground shields at one end only.

The equipment must be protected by a 15 A fuse or

circuit breaker in the building installation.

A circuit breaker or switch in the building installation, marked as the

disconnect switch, shall be in close proximity to the equipment and

within easy reach of the operator.

INSTALLATION _

PL-550 15

Page 16

INSTALLATION _

PL-550 16

Page 17

_

START UP

OVERVIEW

The IQ Radar 160 has two modes of operation:

is powered, after installation procedures have been completed, it is programmed

to start up in the

target in meters.

The unit can be placed into the

program parameters in order to better suit the application or user’s preferences.

Programming can be carried out locally via the hand programmer or remotely via

the optional Dolphin/RS-485 interface.

run

mode, to detect the distance from the antenna flange to the

typical display

program

mode at any time; to alter a number of

run

and

program

. When the unit

PL-550 17

START UP _

RS-485

hand programmer

Page 18

The first step in programming is to ensure that all parameters are at their factory

setting. The quickest way is to perform a master reset, P999.

For a Quick Start, P001 to P007 are the key parameters requiring entry.

They set: - mode of measurement

- process material

- antenna configuration

- measurement response

- units

- empty distance

- span

There are a number of other program parameters that can be changed

subsequently or during another programming session. Refer to Parameter

Description for a list of the parameters available.

When programming has been completed, the IQ Radar 160 can be put into

by pressing or exiting Dolphin.

run

START UP

PL-550 18

Page 19

_

DISPLAY AND KEYPAD

PL-550 19

START UP _

Page 20

LOCAL OPERATION

RUN DISPLAY

➀ reading

➁ units

➂ reading questionable, appears during fail-safe operation

➃ auxiliary reading

➄ = normal operation = fail-safe operation

START UP

➅ bar graph representation of material level, 0 to 100% of span

PL-550 20

Page 21

_

LOCAL OPERATION (continued)

RUN KEYPAD

In the

run

mode, the following programmer keys perform the identified functions.

Auxiliary

Reading Keys

Function

Keys

Key Auxiliary readings

5

mA

7

8

PX X X

“mA Output Value”

“Rate of Change” (in Units/minute)

“Fail-safe Time Left” (in percent)

“Material Level”

“Distance”

initiate and complete program mode access

%

toggle between Units and %

START UP _

PL-550 21

Page 22

LOCAL OPERATION (continued)

PROGRAM DISPLAY

➀ parameter type (measurement or mA output)

➁ parameter value

➂ units

➃ parameter number

START UP

PL-550 22

Page 23

_

LOCAL OPERATION (continued)

PROGRAM KEYPAD

Function

Keys

Numeric

Keys

Key

0

P

PX X X

C

to

9

values

decimal point

negative value

START UP _

clear value

enter the displayed value

parameter scroll-up

parameter scroll-down

end program session and enable

PL-550 23

run

mode

Page 24

LOCAL OPERATION (continued)

Legend

Press the associated Programmer Display shown on

key on programmer: key: IQ Radar 160:

LOCAL PROGRAMMING

To Access Program

run

mode

Initial program

starts at P000

To Access a Parameter

scroll

direct

START UP

Scroll up

or down

e.g. P000 accessed

0

0

5

mA

index parameter field

PL-550 24

e.g. P005 accessed

Page 25

_

LOCAL OPERATION (continued)

Local Programming (continued)

To Change a Parameter Value:

Security must be disabled!

change

Select parameter

e.g. P001 = 3

clear

C

e.g. P001 = 1

START UP _

e.g. field entry = 2

e.g. P001 = 1

PL-550 25

Page 26

LOCAL OPERATION (continued)

Local Programming (continued)

reset

e.g. P001 = 1

To Access Run:

START UP

C

Reset to factory value

P001 = 3

from

program

exit and return to

run

PL-550 26

Page 27

_

OPERATION

OVERVIEW

IQ Radar 160 is a process material level measuring device using advanced pulse

radar technology. The device emits a series of radar pulses and analyses the

reflection to calculate the material level.

The device consists of an enclosed electronic component, mounted to a flanged

antenna component. The electronic component generates a 5.8 GHz radar signal

which is directed to the antenna, a Teflon® dielectric rod coupled to the core of the

device’s mounting flange.

The radar signal is emitted axially from the antenna and propagates along this

axis in a defined conical beam decreasing in strength at a rate inversely

proportional to the square of the distance.

Radar reflection is based on the dielectric constant and planar property of the

materials encountered and thus radar is very suitable for still (non-agitated) liquids

and slurries. Radar is immune to temperature and atmospheric conditions and

variations in the vessel. In an ideal application, echoes from stratified vapours are

either non-existent, or minimal compared to major echoes from the process

material. Where atmospheric conditions are such that dielectric constants and

stratifications are of significance, their echoes can compete with the desired

reflection from the process material, making the application troublesome.

The series of echoes from the pulses transmitted are sensed by the antenna

during the receive period of the electronics. The echoes are stored as a profile of

the activity in the vessel. The profile is analysed and the distance of the material

surface to the radar antenna is determined. This distance is used as a basis for

display of material level and mA output.

_

OPERATION _

PL-550 27

Page 28

TRANSCEIVER

The IQ Radar 160 transceiver operates under 1 of 5 sets of preset conditions

(P003), summarized as follows:

parameter

value

measurement

response

echo

verification

filter fail-safe

timer

1 0.1 m/min slow on on 10 0

2 1 m/min • on on 10

3 10 m/min • on on 1

4 100 m/min • off on 0. 1

5 1000 m/min fast off off 0

When the echoes are received, the relevant echo extraction technique (P820) is

applied to determine the true material echo.

The measurement response limits the maximum rate at which the display and

analog output respond to changes in measurement. It is of concern especially

where liquid surfaces are in agitation or falls into the radar path during filling.

OPERATION

PL-550 28

Page 29

_

BLANKING

Near blanking (P800) is used to ignore the zone in front of the antenna where

false echoes (e.g. ladder rung) appear as an echo during the receive cycle. This is

usually indicated by an incorrect high level reading and can be overcome by

increasing the near blanking from its factory set value.

Far end blanking is a feature that ignores the zone below the zero or empty level

where false echoes can appear at levels that interfere with the processing of the

true echo.

end of

transmit

false echo false echo

true echo (level)

Typical receiver signal

0

P800

near blanking

empty distance to antenna

P006

level

far end blanking

range extension

(P801) as % P006

range

Typical receiver signal

In applications where the zero level is above the bottom of the vessel and it is

desired to monitor the zone below the normal zero, range extension (P801) can

be used to extend the range into the far end blanking. Range extension is

entered as a percentage of P006. As range extension reduces the protection

afforded by the far end blanking, it should be used judiciously. Avoid excessive

range extension as this can reduce the measurement’s reliability and accuracy.

Range extension is factory set for 20% of P006. If it is found that false echoes are

appearing ahead of the blanking zone, P006 should be reduced accordingly.

PL-550 29

_

OPERATION _

Page 30

LOSS OF ECHO

A loss of echo occurs when the IQ Radar 160 deems that the calculated

measurement is unreliable, i.e. the confidence (P805) is less than the threshold

(P804). This can be due to such circumstances as high level of electrical noise or

poor grounding. Refer to Troubleshooting. If the condition persists for a time

beyond the limit as set by the fail-safe timer (P070), the confidence icon changes

from full to partial and the reading and mA output are immediately forced to the

fail-safe default (P071).

Upon receiving a reliable echo, the loss of echo condition is aborted (icon returns

to full) and the reading and mA output return to the present level immediately.

OPERATION

PL-550 30

Page 31

_

ANALOG OUTPUT

The IQ Radar 160 can be programmed to provide an analog output (P200) of 0 to

20 or 4 to 20 mA, and for proportional or inverse span.

Programming

Upon entering the Program mode, the analog output level holds its prior value.

Run

The analog output responds in the following manner:

Level

(P001=1)

Space

(P001=2)

0/4 – 20 mA

(P200 = 1 or 2)

20 – 0/4 mA

(P200 = 3 or 4)

Distance

(P001=3)

*reference value only. mA level limited by near blanking.

0 and 100% are percentage of full scale reading (m, cm, mm, ft, in)

PL-550 31

_

OPERATION _

Page 32

Fail-safe

When the fail-safe timer (P070) expires, the mA output responds as follows:

Fail-safe Mode (071) Status

0/4 - 20 20 - 0/4

high 22 0/2

low 0/2 22

hold hold hold

RUN / PROGRAM

When the IQ Radar 160 changes from

run

to

program

, the transceiver stops

operating and the unit no longer responds to the process. The last measurement

is stored and the associated reading and mA output are held.

As a courtesy, the unit reverts to the parameter last addressed during the previous

program session.

Upon return to

run

, the transceiver resumes operation. The reading and mA

output default to the last measurement taken. The reading and associated

outputs migrate to the current process level at a rate controlled by the

measurement response (P003).

OPERATION

PL-550 32

Page 33

_

APPLICATION EXAMPLE

The minimum distance from the antenna face to the target

is limited by the near blanking, P800.

The application is to obtain a level measurement and corresponding 4-20 mA

output proportional to material levels in a chemical tank. The antenna flange is

5 m from the tank bottom. The empty level is 0 m (bottom) and the full level

(span) is 4.5 m from the bottom. The maximum rate of filling or emptying is about

1 m/min. In the event of a loss of echo, the IQ Radar 160 is to go into fail-safe low

after 2 minutes.

Empty

(P006)

Span

(P007)

reset:

P999 master reset

program:

P001 enter ‘1’ mode of measurement = level

P002 enter ‘1’ material = liquid

P003 enter ‘2’ measurement response = 1m/min.

P004 enter ‘240’ antenna = dielectric rod, standard length

P005 enter ‘1’ units = metres

P006 enter ‘5’ empty distance = 5 m

P007 enter ‘4.5’ span = 4.5 m

P070 enter ‘2’ fail-safe timer = 2 min.

P071 enter ‘2’ fail-safe = low

run:

press run to start normal operation

_

OPERATION _

PL-550 33

Page 34

OPERATION

PL-550 34

Page 35

_

PARAMETER DESCRIPTION

P000 lock

Locks out the ability to change parameter values P001 through P999.

The program mode is still active, but restricted to viewing only. The lock

is enabled if P000 value is other than 1954.

entry: 1954 = unlocked

1954 = locked

P001 operation

Determines the mode of measurement.

entry: 1 = level; material level referenced to empty

distance (P006)

2 = space; space to material level referenced

from zero span

PARAMETER DESCRIPTION _

3 = distance; distance to target referenced

from the flange face

Level Space Distance

(P001 = 1) (P001 = 2) (P001 = 3)

PL-550 35

Page 36

P002 material

Optimizes measurement reliability for target type.

entry: 1 = liquids, fluids or flat surfaces

P003 measurement response

Collectively sets a number of operating parameters that determine the

maximum rate of change in target range that the reading and mA

output can keep up to.

PARAMETER DESCRIPTION

If IQ Radar 160 cannot keep up with the rate of level change, select a

faster rate. If the reading bounces around an average value, select a

slower rate. In general, reliability is traded for speed. Noisy applications

or those with agitators tend to be more manageable at slower response

rates, as these make use of filtering, echo verification and longer failsafe delay.

Select P003 for a measurement response just faster than the

greater of the maximum filling or emptying rate.

echo verification: discriminates between agitator blades in motion or

spurious noise, and the target surface (true echo).

filter: discriminates between false echoes from constant

aco ustical or electrical noise and the target surface.

fail-safe timer: establishes the period from the time a loss of echo

starts until the fail-safe default (P071) is effected.

The P003 preset timer value can be overridden by

P070.

entry:

measurement response echo

verification

filter f-s timer

(P070)

1 = 0.1 m/min slow on on 100

2 = 1 m/min • on on 10

3 = 10 m/min • on on 1

4 = 102 m/min • off on 0 .1

5 = 1020 m/min fast off off 0

PL-550 36

Page 37

_

P004 antenna

Identifies antenna configuration.

entry: 240 = dielectric rod

P005 units

Determines the units for programming and measurement.

entry: 1 = metres

P006 empty

Distance from flange face to empty

level or maximum target range.

P007 span

Distance from empty (P006) to

full/100% level or minimum target

range.

PARAMETER DESCRIPTION _

241 = rod + 50 mm extension

242 = rod + 100 mm extension

243 = rod + 150 mm extension (50 + 100mm)

2 = centimetres

3 = millimetres

4 = feet

5 = inches

P070 fail-safe timer

The amount of time delay, in minutes, before going into fail-saf e mode.

P071 fail-safe material level

Selects the default measurement in the event that the fail-safe timer

expires.

entry: 1 = high; maximum span value

2 = low; minimum span value

3 = hold; hold current value

P200 mA range

Enables the mA output function by selecting the range and

relationship to span.

Refer to Functional / mA output.

entry: 1 = 0 to 20 mA

2 = 4 to 20 mA

3 = 20 to 0 mA

4 = 20 to 4 mA

PL-550 37

Page 38

P341 run time

View the accumulated number of days the IQ Radar 160 has been

operating.

P652 offset correction

An offset value can be applied to the reading as a correction

to the measurement.

values: -999 to 9999

PARAMETER DESCRIPTION

P800 near blanking

Sets the amount of blanking as measured from the flange face and

extending into the measurement range. Refer to Operation /

Blanking.

enter value in units of P005.

P801 range extension

Sets the amount of range extension as measured from the empty

distance (P006) and extending into the far end blanking. Refer to

Operation / Blanking.

enter as a % of P006, the distance below empty not blanked.

P804 confidence threshold

The minimum echo confidence in dB that the echo must meet in order

to prevent a loss of echo condition and the expiration of the fail-safe

timer (P070).

enter value in the range of 0 to 99.

P805 echo confidence

A measure of echo reliability.

P806 echo strength

The absolute strength of the selected echo, in dB above 1 µV rms.

PL-550 38

Page 39

_

P820 algorithm

Selects the algorithm to be applied to the echo profile in order to extract

the true echo.

entry: 1 = best of first and largest

2 = first echo

3 = largest echo

P830 TVT type

Selects the TVT profile applied to the echo profile.

entry: 1 = standard

2 = flat

P900 software revision

Displays the EPROM software revision level.

P901 memory

Tests the memory. Test is initiated by scrolling to the parameter or

repeated by

PARAMETER DESCRIPTION _

display: PASS = normal

FAIL = consult Milltronics

P911 mA output value

Displays the value from the previous measurement. A test value can be

entered and the displayed value is transmitted to the output. Upon

returning to the run mode, the parameter assumes the actual mA output

level.

P920 reading measurement

Displays the reading measurement that the unit is programmed for in

run mode (P001, operation).

P921 material measurement

Displays the reading measurement as though the unit were

programmed to read level (P001 = 1).

P922 space measurement

Displays the reading measurement as though the unit were

programmed to read space (P001 = 2).

PL-550 39

Page 40

P923 distance measurement

Displays the reading measurement as though the unit were

programmed to read distance (P001 = 3)

P999 master reset

Resets parameters to their factory setting

PARAMETER DESCRIPTION

C

initiate reset

reset complete

PL-550 40

Page 41

_

TROUBLESHOOTING

The following is a list of operating symptoms, their probable causes and the

actions needed to resolve them.

SYMPTOM CAUSE ACTION

display reads level or target is out of

range

application too steamy,

under these conditions

range can be adversely

affected.

material build-up on

antenna

location or aiming:

-poor installation

-moved by material

or vibration

-flanging not level

-standpipe not vertical

antenna malfunction:

-temperature too high

-physical damage

-excessive foam or skin

check specifications

check parameters

re-locate IQ Radar 160

increase fail-safe timer,

P070

clean

re-locate IQ Radar 160

relocate or re-aim

IQ Radar 160 for

maximum echo

confidence, P805

inspect

use foam deflector or

stilling well or relocate

TROUBLESHOOTING _

Reading does not

change, but the level

does

*refer to associated manual

PL-550 41

IQ Radar 160 processing

wrong echo, i.e. vessel

wall, or structural member

re-locate IQ Radar 160

check standpipe for

internal burrs or welds

increase blanking, P800

raise short measurement

confidence threshold,

P804

… continued

Page 42

SYMPTOM CAUSE ACTION

Measurement is

consistently off by a

constant amount

Screen blank power error check nameplate rating

Reading erratic echo confidence weak,

TROUBLESHOOTING

Reading ‘EEEE’ reading too large re-program

measurement offset correct using P652

against voltage supply

check power wiring or

source

refer to P805

liquid surface agitated,

material filling

decrease measurement

response P003

enable filter, echo

verification

re-locate IQ Radar 160

ie. empty distance P006

or span P007

Reading response slow P003 setting increase response if

possible

Reads correctly but

occasionally reads high

detecting close range

echo

increase blanking

when vessel is not full

High level reading lower

than material level

material is within near

blanking zone

decrease blanking P800

PL-550 42

Page 43

_

MAINTENANCE

The IQ Radar 160 requires no maintenance or cleaning; however, a program of

periodic checks is advised.

MAINTENANCE _

PL-550 43

Page 44

MAINTENANCE

PL-550 44

Page 45

_

APPENDICES

ALPHABETICAL PARAMETER LIST

algorithm..................................................................................................P820

antenna ..................................................................................................P004

confidence threshold ............................................................................ P804

echo confidence .................................................................................... P805

echo strength.......................................................................................... P806

empty........................................................................................................ P006

fail-safe material level ...........................................................................P071

lock............................................................................................................P000

long shot number* ................................................................................. P841

mA output value .................................................................................... P911

mA range ................................................................................................. P200

master reset ............................................................................................P999

material .................................................................................................... P002

measurement response....................................................................... P003

memory.................................................................................................... P901

near blanking .......................................................................................... P800

offset correction...................................................................................... P652

operation.................................................................................................. P001

range extension..................................................................................... P801

run time ....................................................................................................P341

software revision ....................................................................................P900

span ..........................................................................................................P007

TVT type ..................................................................................................P830

units ..........................................................................................................P005

* accessible in Dolphin only.

APPENDICES _

PL-550 45

Page 46

PROGRAMMING CHART

PARAMETER

# NAME VALUE

P001 Operation

P002 Material

P003 Measurement Response

P004 Antenna

P005 Units

P006 Empty

P007 Span

P070 Fail-Safe Timer

P071 Fail-Safe Material Level

P200 mA Range

P652 Offset Correction

P800 Near Blanking

P801 Range Extension

P804 Confidence Threshold

P820 Algorithm

P830 TVT Type

P841 Long-Shot Number

APPENDICES

PL-550 46

Loading...

Loading...