Page 1

HydroRangerPlus

33455070

Rev 2.1

Instruction Manual

PL-507

October 1997

T echnology based. Customer driven.

Page 2

hank you for purchasing Milltronics products. We endeavour to design

T

equipment that is simple to use and reliable in its operation, with the aim

of satisfying our customers' needs.

Milltronics has been designing and manufacturing process equipment since

1954. Our fields of expertise include ultrasonic and capacitance level

measurement, in-line weighing of dry bulk solids and motion sensing.

Milltronics is established world wide through associate offices and

representatives. Our network is continually being refined to provide our

customers with first rate sales information, engineering assistance and after

sales support.

For more details on our products and service, please contact us and we will

provide you with a listing of the offices or representatives nearest you.

Page 3

TABLE OF CONTENTS

TITLE PAGE #

INTRODUCTION

About this Manual 5

About the HydroRanger Plus 6

Important HydroRanger Plus Features 8

INSTALLATION

Environmental 9

Outline 9

Mounting 11

Programmer 17

ComVerter 17

Interconnection 18

PROGRAMMING

Program Mode Entry 27

Display 28

Keypad 29

Parameter Value Alteration 31

Special Parameters 31

Parameter Reset Features 31

Programming Security 32

OPERATION

Run Mode Entry 33

Display 34

Keypad 35

System Performance Evaluation 36

Performance Test Results 37

Maintaining Operation 38

APPLICATIONS

General Application 39

Wet Well Control (Pump Down) 42

Reservoir Control (Pump Up) 44

Rake Control (Differential Level) 46

Penstock Control 48

General Alarms 50

OCM (Open Channel Monitor) 52

Volume Calculation 54

Pumped Volume Total 56

Failsafe Operation 58

Application Assistance 60

3

Page 4

TITLE PAGE #

PARAMETERS

Security 61

Quick Start 62

Volume 65

Reading 67

Failsafe 69

Relays 71

mA Output 89

mA Input 94

Data Logging 95

OCM 105

Totalizer 119

Range Calibration 122

Temperature Compensation 124

Rate 126

Measurement Verification 128

Scanning 130

Display 131

Echo Processing 133

Advanced Echo Processing 136

Test 144

Measurement 146

Master Reset 148

TECHNICAL REFERENCE

Transmit Pulse 149

Echo Processing 149

Scope Displays 149

Distance Calculation 150

Sound Velocity 150

Scanning 151

Volume Calculation 152

Flow Calculation 153

Measurement Response 154

Relay Set Up 155

Maintenance 156

TROUBLESHOOTING

Troubleshooting Chart 157

Measurement Difficulties 158

SPECIFICATIONS

HydroRanger Plus 161

Programmer 163

Options 163

PROGRAMMING CHART 165

4

Page 5

INTRODUCTION

ABOUT THIS MANUAL

INTRODUCTION

This instruction manual provides information specific to the Milltronics

(HYDRO+) level monitor*. Other products (including transducers) associated with

Plus

a HYDRO+ based level monitoring system, are supplied with individual instructions.

All general start up information is included in the white pages. Refer to the grey pages

for additional information or technical assistance, if required.

After reading this INTRODUCTION and completing the physical INSTALLATION, first

time system installers may wish to use the

Guide, PL-439

INTRODUCTION

INSTALLATION

PROGRAMMING

OPERATION

APPLICATIONS

PARAMETERS

TECHNICAL REFERENCE

TROUBLESHOOTING GUIDE

SPECIFICATIONS

PROGRAMMING CHART

INTRODUCTION

HYDRORANGER PLUS Quick Start

for step by step start up instructions.

briefly describes key features.

step by step mounting and wiring procedure.

program mode LCD and keypad functions.

run mode LCD and keypad functions.

10 brief examples of common HYDRO+ uses.

specific programmable feature definitions.

detailed information for complex features.

quick problem solving techniques.

lists physical and operational characteristics.

space to record all programming for future

reference. (Also used as a Parameter index).

HydroRanger

INSTALLATION

"Programming is not complete until the Programming Charts are completed".

*

This manual applies to the wall, rack, and panel mount HYDRO+ versions.

For simplicity, the rack mount version is illustrated only

where necessary to identify version differences.

Throughout this manual (unless stated otherwise) "level" refers to the

PL-507 5

relative position of a monitored liquid surface.

REMEMBER!

Page 6

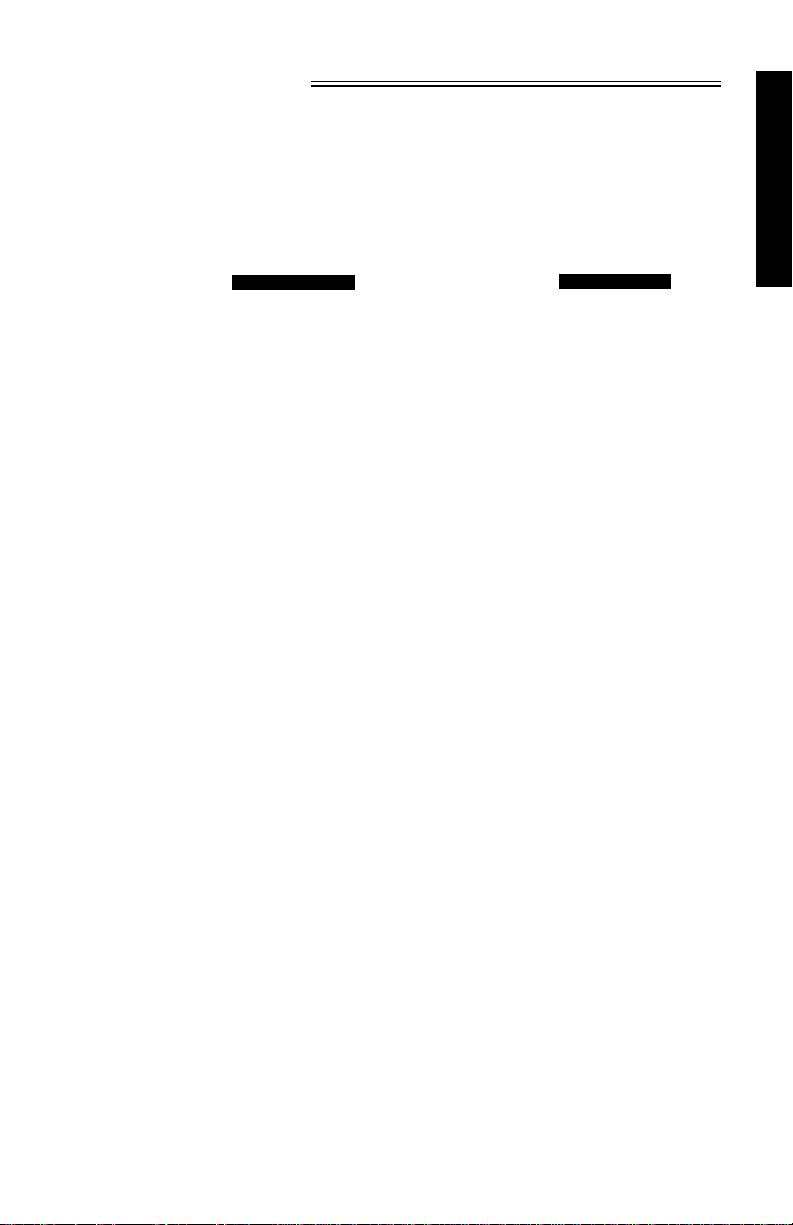

ABOUT THE HYDRORANGER PLUS

Reservoir

Screen Rake

The HydroRanger Plus is to be used only in the

manner outlined in the instruction manual.

The HYDRO+ includes the features of the successful Milltronics "HydroRanger 1"

PLUS a variety of new features, incorporating advances in electronic component,

manufacturing, and software technology.

This multi-purpose microprocessor based level monitor contains numerous features

ideally suited for liquid monitoring and pump control applications.

Open Channel

HYDRO +

%

3

5

214

Wet Well

A HYDRO+ level monitor, utilizing a single ultrasonic transducer (ordered separately),

accurately monitors level without contacting the surface monitored.

The HYDRO+ provides the transmit pulse to the transducer. The transducer emits

ultrasonic pulses in a narrow beam, perpendicular from the transducer face. The

HYDRO+ measures the time between pulse emission and reflection (echo) reception,

to calculate the transducer face to monitored surface distance.

The transducer internal temperature sensor is used to automatically compensate

for sound velocity variations due to air temperature changes within the

measurement range.

PL-507 6

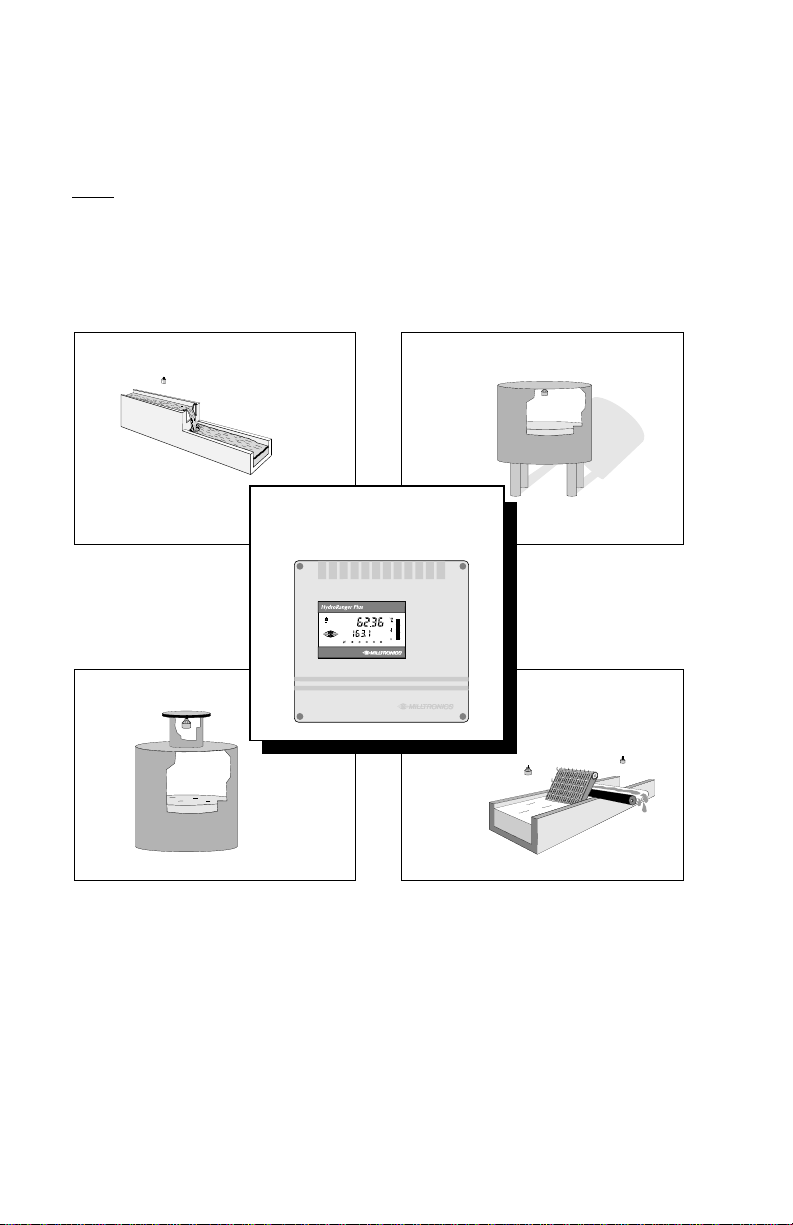

Page 7

The HYDRO+ monitors levels 0.3 to 15 m (1 to 50 ft) from the transducer face, with

Alarm

outstanding accuracy, usually within 0.25% of range. (Ensure the transducer selected

suits the material and measurement range monitored).

TM

This versatility is accomplished by Milltronics patented Sonic Intelligence

, providing

high measurement reliability, regardless of operating conditions.

LCD

The HYDRO+ provides the following

(Liquid Crystal Display) Readings:

» Level, space, distance, volume, or remaining capacity in open or closed vessels.

» Differential level across a channel filter or screen (2 transducers required).

» Average level in a large vessel with an uneven material surface (2 transducers).

» Head, flow, or totalized flow in free flowing open channels.

» Pumped volume from wet wells or into reservoirs.

The HYDRO+ relays and/or mA output may be used as preset (or programmed as

desired) to activate alarms, pump controls, chart recorders, or virtually any process

control equipment.

Chart

Recorder

HYDRO +

INTRODUCTION

Pump

%

3

5

214

PLC

The HYDRO+ infrared interface permits one programmer to be used for any number

of HYDRO+ level monitors. Upon programming completion, the programmer may be

locked away for programming security. All Operator programming is stored in

non-volatile memory, unaffected by power interruption.

While the HYDRO+ is typically used to monitor liquid level, any process which

requires a distance measurement or object presence/lack of presence (within the

system maximum measurement range) is a candidate for HYDRO+ application.

Refer to APPLICATIONS for detailed descriptions of a small sample of process

measurement requirements to which the HYDRO+ may be applied.

PL-507 7

Page 8

IMPORTANT HYDRORANGER PLUS FEATURES

FIXED FEATURES

ENCLOSURE: Chemical resistant, light weight, dust/liquid tight.

LCD: Large digits and symbols for Readings and continuous

HAND PROGRAMMER: 20 tactile feedback keys, (ordered separately).

DOLPHIN COMPATIBLE: HYDRO+ / RS 232C interface, (ordered separately).

COMMUNICATIONS: Non-invasive infra-red digital data transfer.

SPEED: 16/32 bit microprocessor at 16.7 MHz clock speed.

RELIABILITY: Sonic Intelligence

PROGRAMMABLE FEATURES

Typically, a very small percentage of the HYDRO+ operator programmable features

require alteration from default settings. However, for demanding measurement

requirements any number of features may be adjusted as required.

Following is a list of the features that make the HYDRO+ easy to program, yet

versatile enough to handle complex level measurement requirements.

GENERAL FEATURES

DIRECT ACCESS: Any operator programmable feature may be accessed directly.

SCROLL ACCESS: Scroll forward or backward to key programmable features.

OPERATION: 7 modes of operation to suit specific requirements.

MATERIAL: Preset for optimum performance on all liquid surfaces.

RESPONSE: Slow, medium, or fast response to level changes.

UNITS: Readings in m, cm, mm, ft, in, %, (or any other units desired).

operating condition indication.

TM

Surface Mount Technology (SMT)

Immune to power interruptions. All programming is retained

indefinitely. Operating data is retained for 30 seconds min;

updated promptly upon resumption.

ADDITIONAL FEATURES (use as desired)

VOLUME: 8 pre-programmed tank shape options

2 universal tank shape programming methods

FLOW: Open channel flowrate and total, 5 pre-programmed flumes.

PUMPED TOTAL: Total volume pumped including/excluding inflow/discharge.

DATA LOGS: Time and Date of important operational events.

FAIL-SAFE: Automatic process control equipment activation.

RELAYS: 6 alarm functions, 7 pump functions, 5 control functions,

storm condition and energy saving pump function modifiers.

mA OUTPUT: 7 functions, range selectable and scalable, overrange limits.

mA INPUT: HYDRO+ features based on any level monitor mA output.

PL-507 8

Page 9

INSTALLATION

Installation shall only be performed by qualified personnel,

and in accordance with local governing regulations.

ENVIRONMENTAL

Choose a mounting location suited to the HYDRO+ enclosure.

The ideal HYDRO+ mounting location is where the:

1. Ambient temperature is always within -20 to 50°C (-5 to 122°F).

2. HYDRO+ display window is at eye level.

3. Cable length requirements are minimal.

4. Mounting surface is free from vibration.

Avoid mounting locations where the HYDRO+ is:

» exposed to direct sunlight, (otherwise, provide a sun shield).

» close to high voltage/current runs, contactors, SCR control drives, or

frequency inverters.

This product is susceptible to electrostatic shock.

Follow proper grounding procedures.

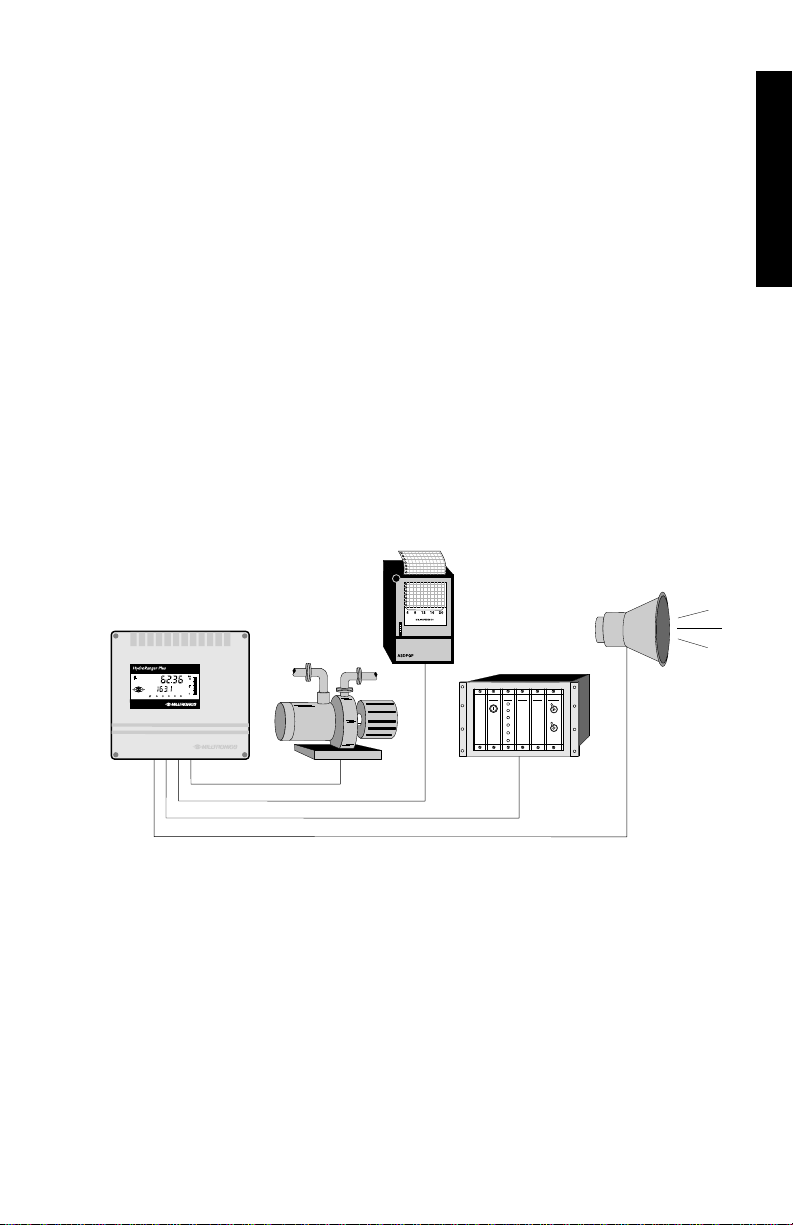

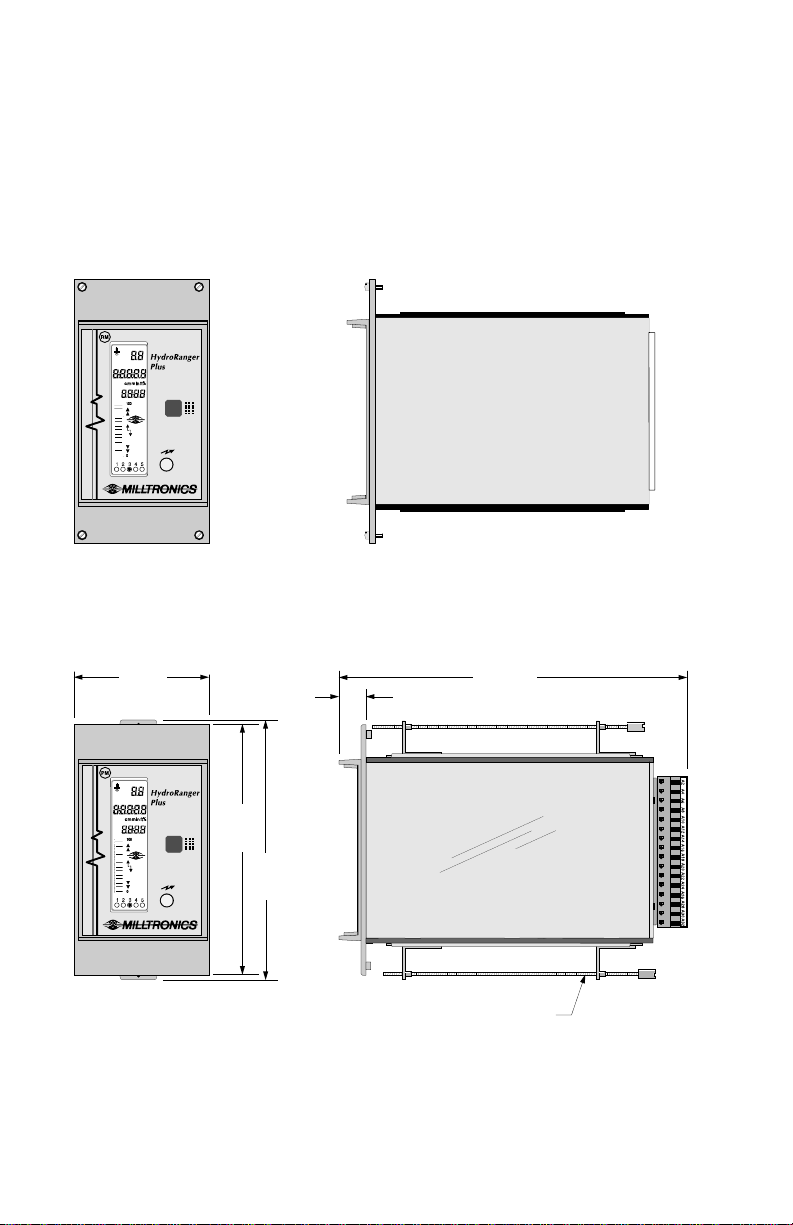

OUTLINE

WALL MOUNT

195 mm

(7.7")

13 mm (0.5")

20 mm (0.8")

168 mm

(6.6")

77 mm

(3.0")

INSTALLATION

102 mm

(4")

180 mm

(7.1")

Suitable location for conduit entrances. Use water

tight conduit hubs to maintain the enclosure rating.

Non metallic enclosure does not provide grounding between conduit

connections. Use grounding type bushings and jumpers.

PL-507 9

mounting holes,

4.5 mm (0.18") Ø,

4 places

Page 10

RACK MOUNT

The HYDRO+ rack mount version is a standard DIN 3U/14 HP, 4 rail plug-in unit, for a

standard 84 HP deep sub-rack.

PANEL MOUNT

72 mm

(2.9")

144 mm

(5.7")

150 mm

(5.9")

slip on mounting bracket top & bottom

screws to be tightened to no more than

PL-507 10

16 mm

(0.6")

1 inch / lb. torque.

201 mm

(7.9")

Page 11

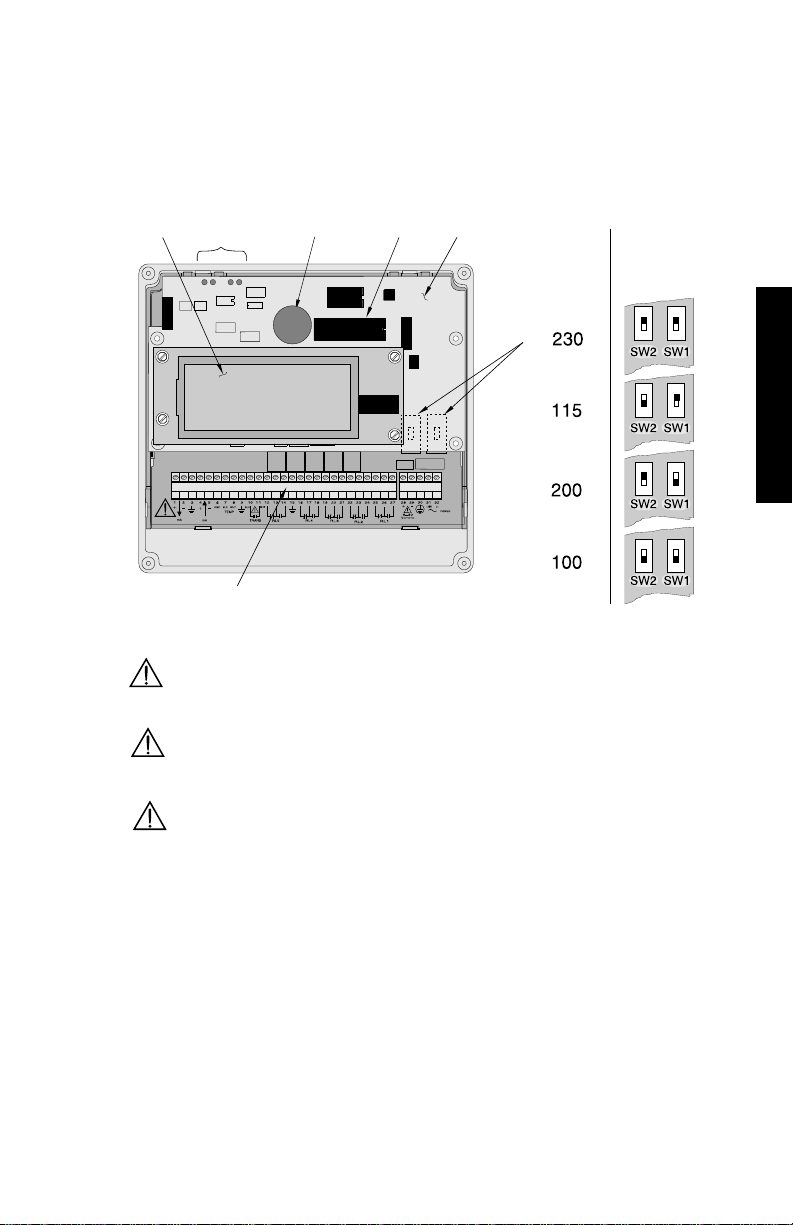

MOUNTING

WALL MOUNT

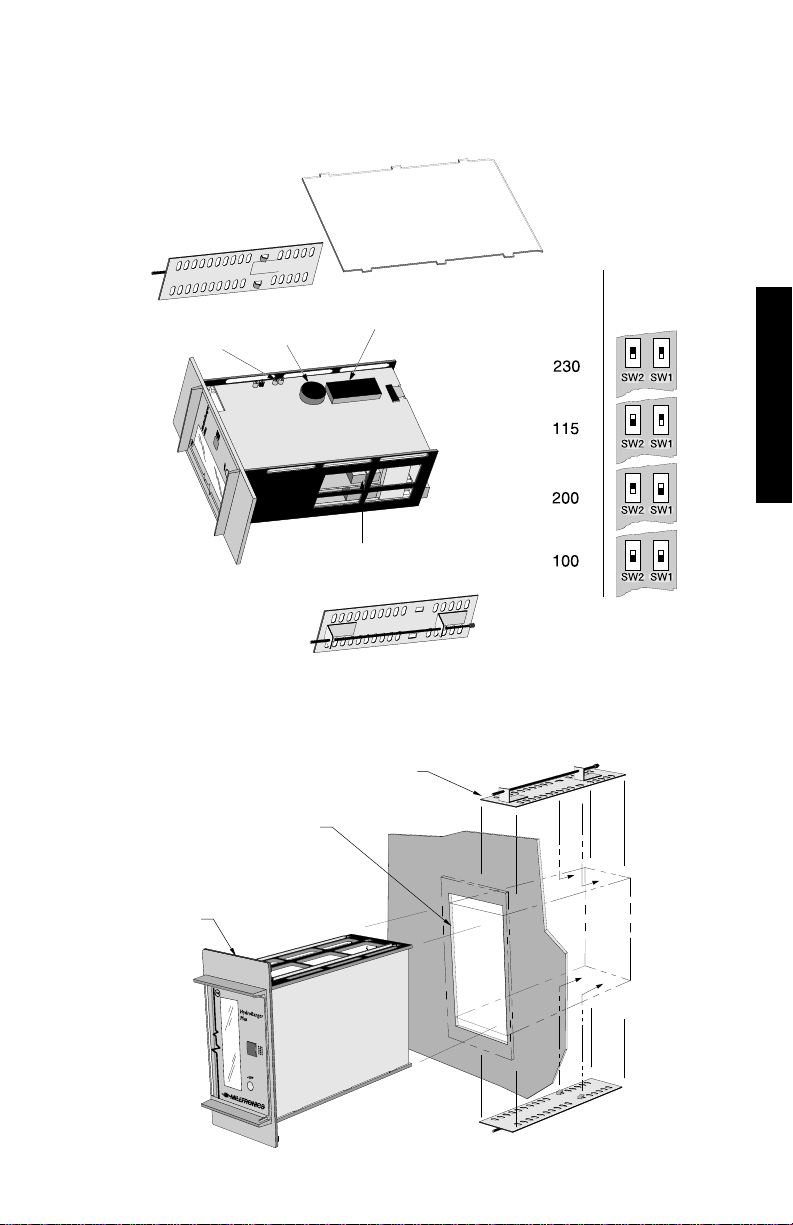

Voltage Selection

display

terminal block

scope

connection

clock module

EPROM

board A

Supply

Voltage

(ac)

All field wiring must have insulation suitable for at least 250 V .

Hazardous voltage present on transducer terminals during operation.

Voltage

Selection

Switches

INSTALLATION

dc terminals shall be supplied from an SELV source

in accordance with IEC 1010-1 Annex H.

Relay contact terminals are for use with equipment having no accessible

live parts and wiring having insulation suitable for at least 250 V.

The maximum allowable working voltage between

adjacent relay contacts shall be 250 V.

PL-507 11

Page 12

Installation

The HYDRO+ wall mount version enclosure design permits quick electronic package

removal for enclosure drilling and mounting.

1. Remove the HYDRO+ enclosure lid (4 captivated screws).

2. With the enclosure upright, press down enclosure TABS A and B.

3. Push in on TABS C and D to release the electronics package.

4. Drill sufficient holes for cable / conduit entry in the enclosure bottom.

5. Fasten the enclosure to the mounting surface, (4 predrilled screw holes).

6. Attach the conduit / cable hubs to the enclosure. (Do not apply undue force.)

7. Snap the electronics package back into the enclosure.

PL-507 12

Page 13

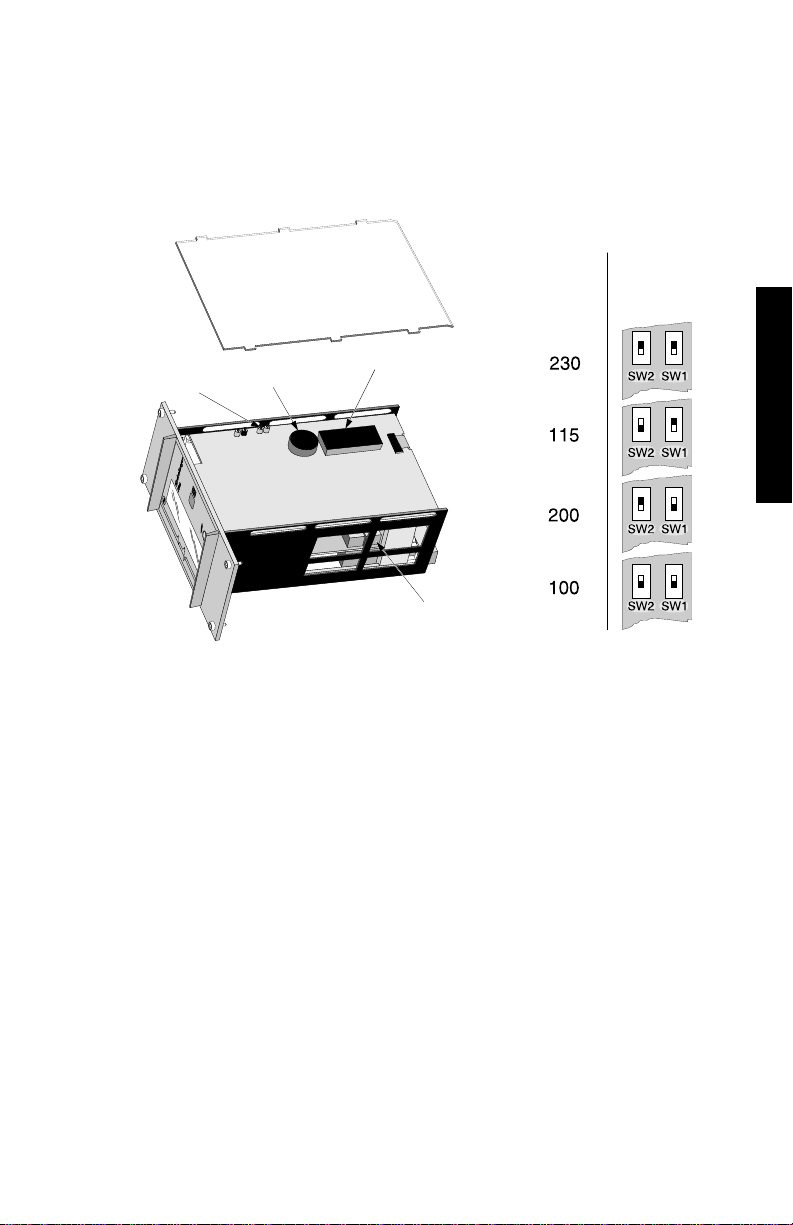

RACK MOUNT

Voltage

Selection

Switches

Voltage Selection

1. Set the voltage switches.

Supply

Voltage

(ac)

scope

connections

clock module

EPROM

voltage

selection

switches

INSTALLATION

PL-507 13

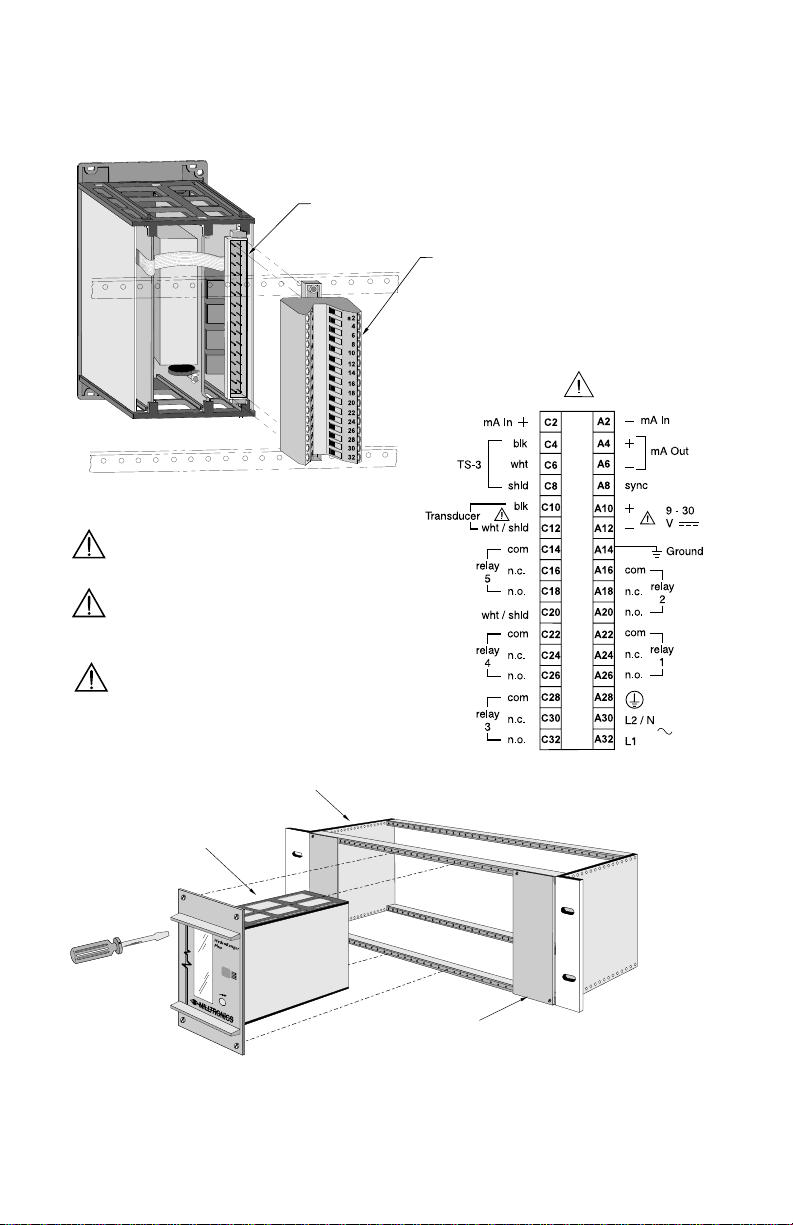

Page 14

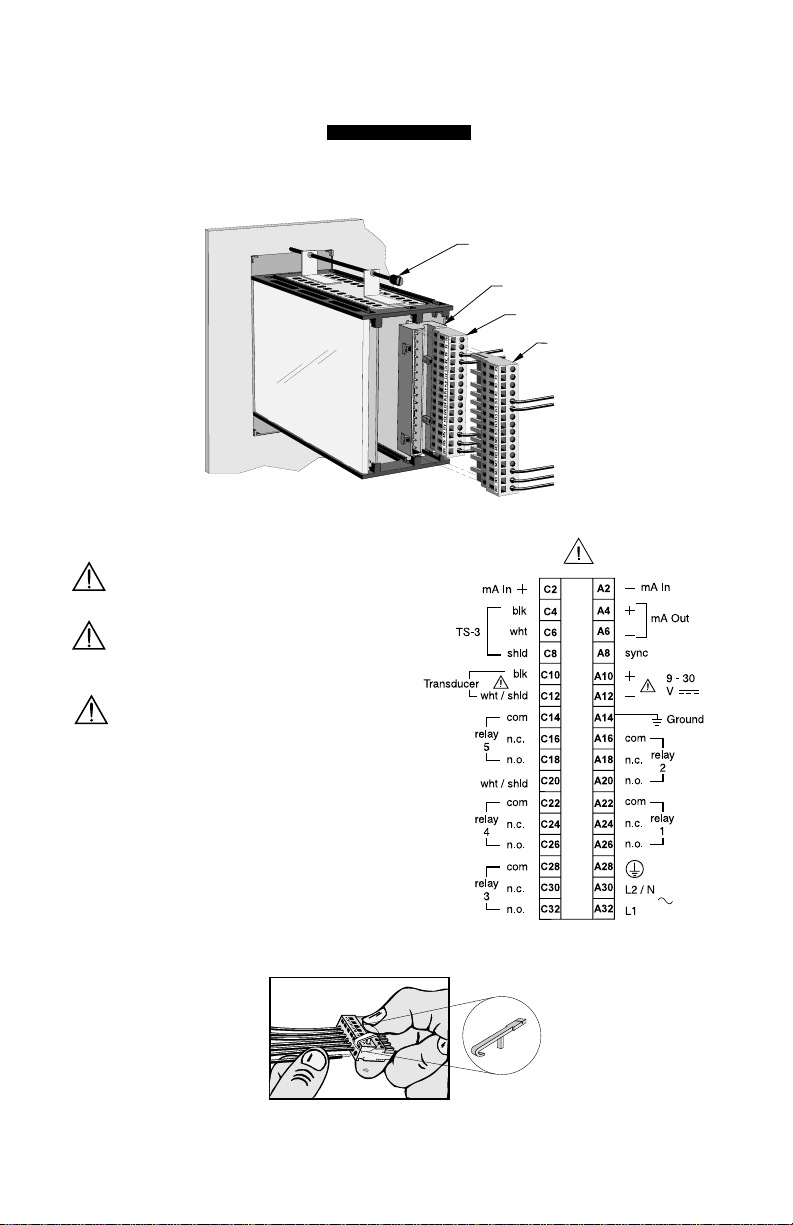

Installation

1. Slide the Hydro+ into the sub-rack, aligning the connector with the

rail mounted terminal block.

connector,

2 row form D male 32 way, per DIN41612

terminal block,

2 row form D female 32 way,

per DIN41612

All field wiring must have insulation

suitable for at least 250 V .

Hazardous voltage present on transducer

terminals during operation.

dc terminals shall be supplied

from an SELV sourcein

accordance with IEC 1010-1

Annex H.

84 HP (19") sub-rack

HYDRO+

DIN 3U/14 HP

plug-in unit

blanking panels must

cover any unused slots

2. Push the Hydro+ into the sub-rack until the HYDRO+ front

cover is snug to the front rails.

3. Tighten the 4 captivated screws to secure the HYDRO+ in place.

PL-507 14

Page 15

PANEL MOUNT

Voltage

Selection

Switches

Supply

Voltage

(ac)

Voltage Selection

1. Set the voltage switches.

scope

connections

clock module

EPROM

voltage

selection

switches

Installation

1. Slide the HYDRO+ through the panel cut-out.

2. Assemble mounting brackets to the HYDRO+ chassis by hooking them into

the top and bottom

mounting bracket

(top & bottom)

cut-out dimension

68 + 0.7 mm x 138 + 1.0 mm

(2.68 + 0.03" x 5.43 + 0.04")

INSTALLATION

DIN 43700

72 x 144

PL-507 15

Page 16

3. Tighten mounting bracket clamping screw (top & bottom)

terminal block ‘A’

4. Plug terminal blocks ‘A’ and ‘C’ into corresponding connector sockets,

prewired by customer (refer to \ Rack and Panel Mount).

INTERCONNECTION

clamping screw

connector

terminal block ‘C’

All field wiring must have insulation

suitable for at least 250 V .

Hazardous voltage present on transducer

terminals during operation.

dc terminals shall be supplied

from an SELV source in

accordance with IEC 1010-1

Annex H.

Use the tool provided

to open terminals for

insertion of wires.

PL-507 16

Page 17

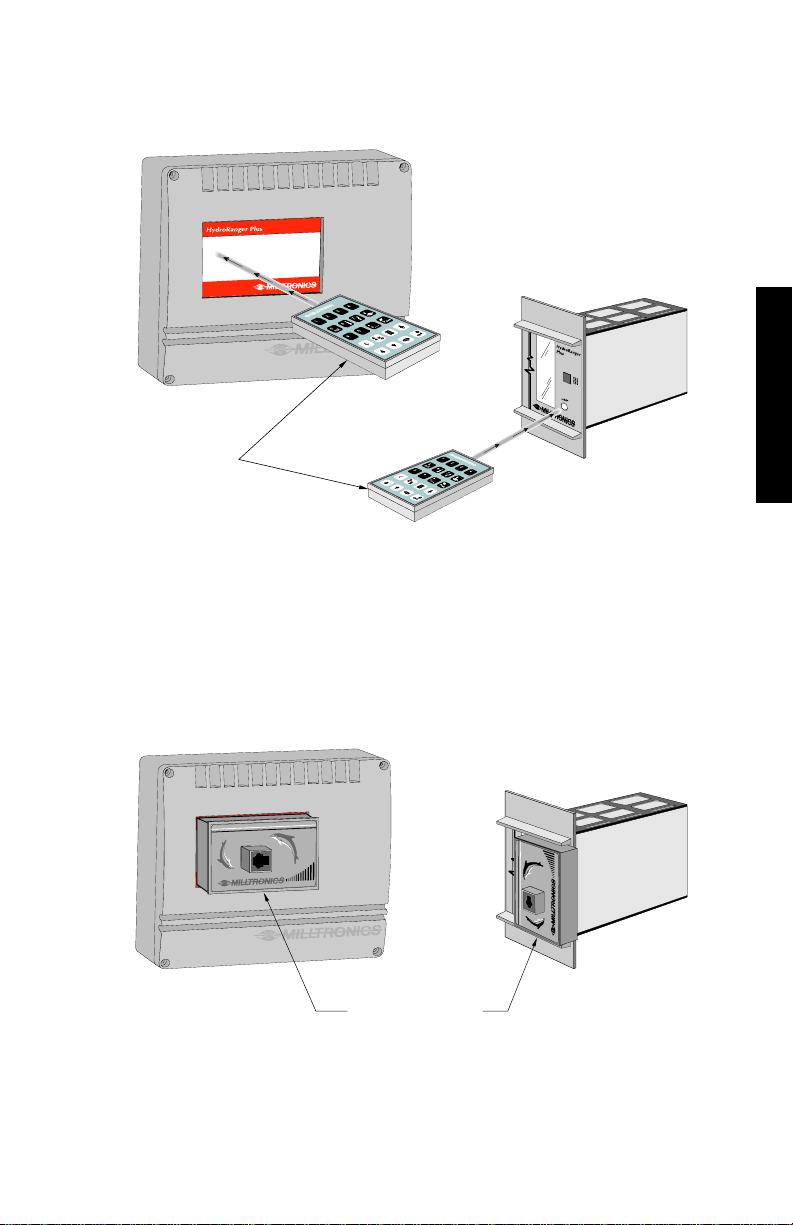

PROGRAMMER

Rack or Panel Mount

Rack or Panel Mount

Wall Mount

Programmer

The hand held programmer is aimed at the receiver as depicted, while the

keys are pressed.

INSTALLATION

COMVERTER (optional)

The ComVerter is pressed into the docking area as depicted and held in place

by its pressure tabs.

Refer to Dolphin instruction manual, for interconnection details.

PL-507 17

Wall Mount

ComVerter

Page 18

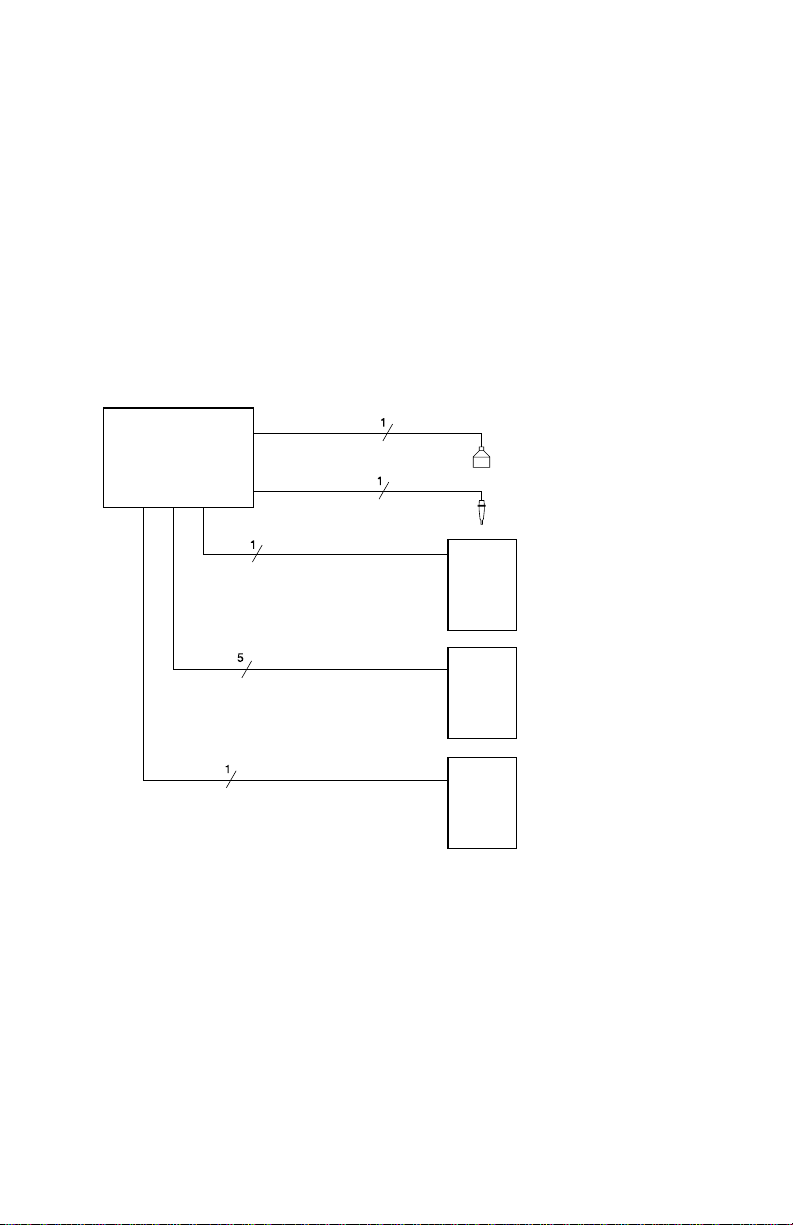

INTERCONNECTION

Milltronics transducer,

see Specifications

Milltronics TS-3

temperature sensor

(optional)

Verify all HYDRO+ system components have been installed in accordance with the

associated product instruction manuals.

Connect all cable shields to the HYDRO+ shield connections. To avoid differential

ground potentials, do not connect cable shields to ground (earth) elsewhere. Insulate

(tape) cable shields at all shield junctions to prevent ground loops

SYSTEM DIAGRAM

HydroRanger

Plus

mA output

customer

device

relay output

customer alarm, pump

or control device

mA input

PL-507 18

customer

device

Page 19

TRANSDUCER

#1 #2

to transducers

Run the transducer cable in grounded metal conduit, separate from other wiring,

(except TS-3 temperature sensor wiring, if applicable).

Typically, one transducer is used. However, if differential or average level monitoring

is required, 2 transducers are used.

Wall Mount

Single Transducer

to transducer

Rack or Panel Mount

Single Transducer

to

transducer

blk

wht

See transducer

instructions for

wiring details.

to

transducer

#1

to

transducer

#2

Dual Transducer

INSTALLATION

Dual Transducer

jumper

blk

blk

wht

Hazardous voltage present on transducer terminals during operation.

PL-507 19

Page 20

TEMPERATURE SENSOR

All Milltronics Echomax and ST-H transducers have an internal temperature sensor.

For optimum accuracy, use a separate TS-3 temperature sensor if:

» the transducer is exposed to direct sunlight (or other radiant heat source),

» the transducer connected is not an Echomax or ST-H, or

» the transducer face and monitored surface temperature differs.

» faster response to temperature changes are required.

TECHNICAL REFERENCE

(See TECHNICAL REFERENCE Sound Velocity).

Wall Mount Rack or Panel Mount

blk

wht

to optional TS-3

to optional TS-3

See TS-3 instructions for wiring detail.

Use a TS-3 temperature sensor only. Don’t jumper unused TS-3 terminals.

PL-507 20

Page 21

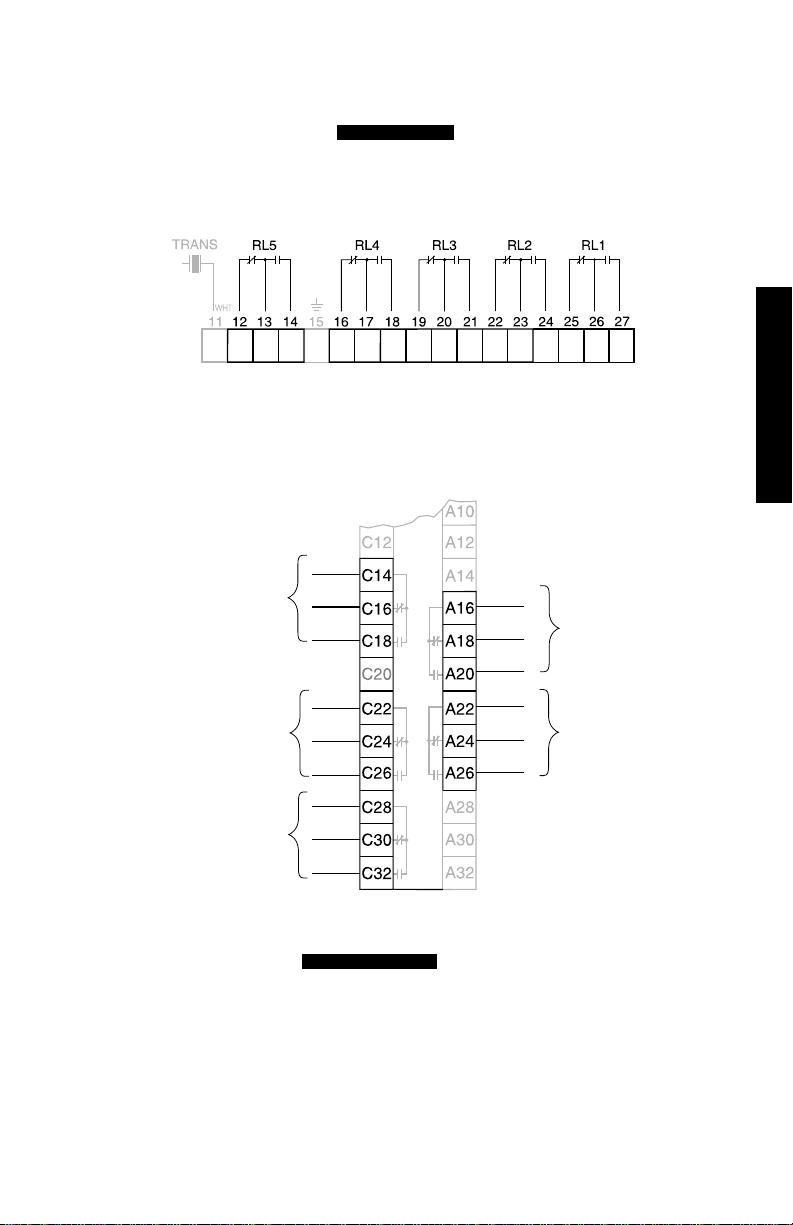

RELAYS

n. o.

Connect, alarm, pump, and/or control devices, to the HYDRO+ relays, after RUN

mode operation is verified. (See for connection details).

APPLICATIONS

Wall Mount

Rack or Panel Mount

com

relay 5

n. c.

n. o.

com

n. c.

relay 2

INSTALLATION

com

n. c.

n. o.

relay 1

relay 4

com

n. c.

n. o.

com

relay 3

n. c.

n. o.

See for relay ratings.

SPECIFICATIONS

Relays are shown in the alarm on / pump off / power off / de-energized position.

PL-507 21

Page 22

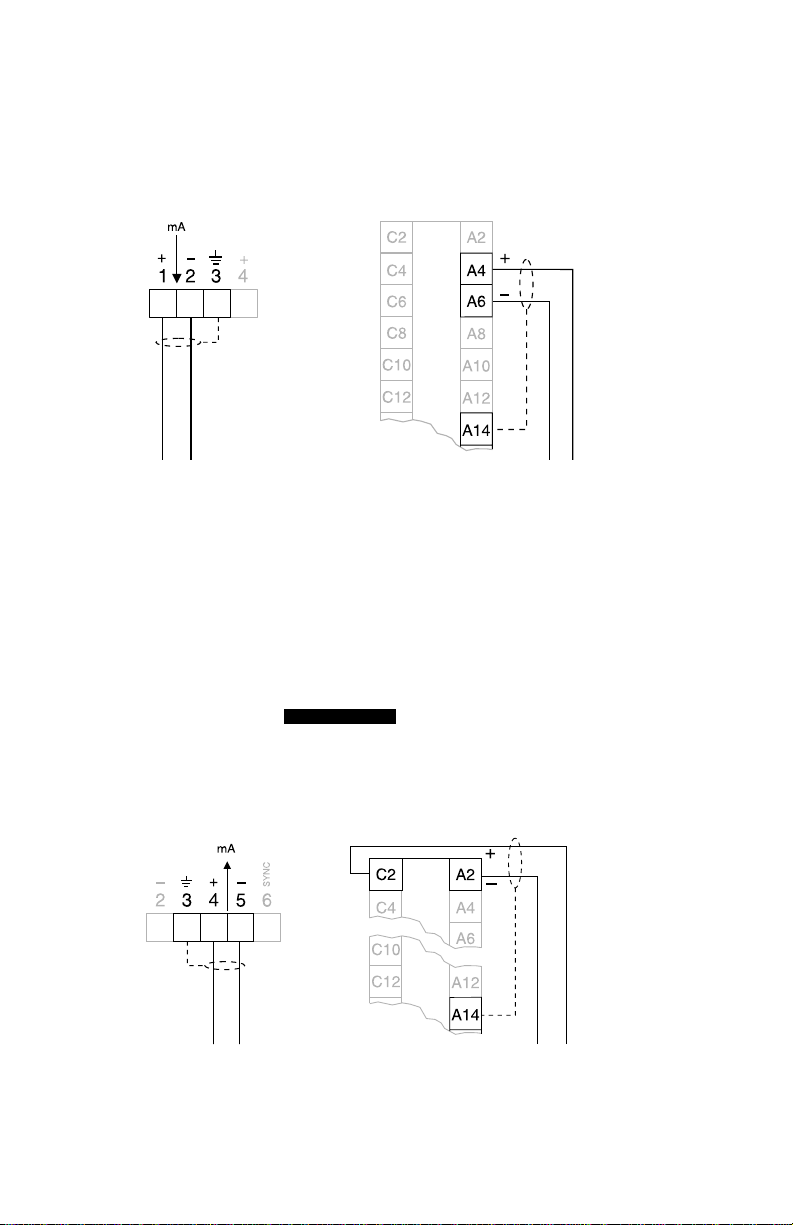

mA OUTPUT

The HYDRO+ mA output may be used to operate a variety of control/monitoring

devices (1000 Ω max. load), providing 300 Vac continuous isolation.

Wall Mount

mA out

Rack or Panel Mount

mA out

mA output to customer instrumentation, ground shield at one end only.

mA INPUT

If HYDRO+ features are required based upon measurements obtained from another

level monitor, connect the level monitor mA output, to the HYDRO+ mA input

terminals. Most HYDRO+ display, relay and mA output features may be used based

upon the measurements provided by the auxiliary level monitor.

If this feature is used, refer to Transducer (P004) and mA Input

PARAMETERS

Parameters (P250, P251, and P252).

Wall Mount

Rack or Panel Mount

mA input

mA input proportional to level, ground shield at one end only.

PL-507 22

mA input

Page 23

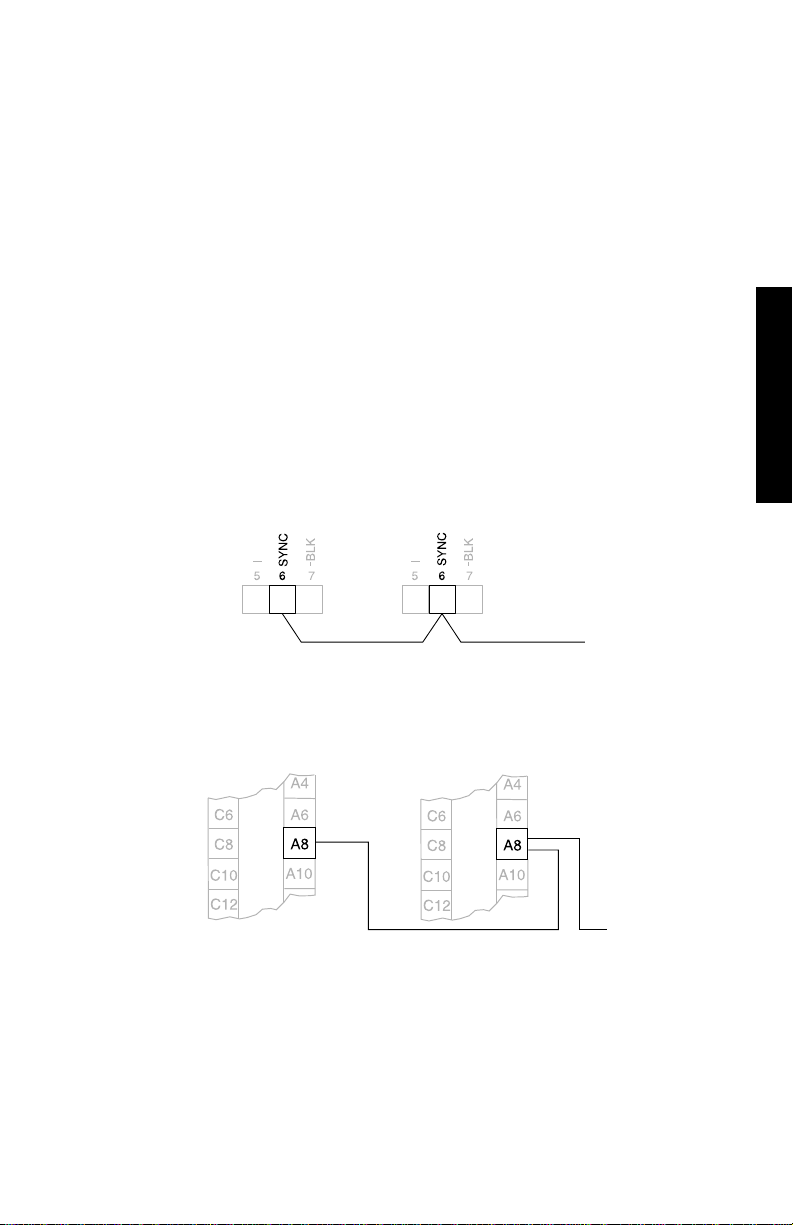

LEVEL SYSTEM SYNCHRONIZATION

to next

device

When multiple ultrasonic level monitors are installed within a single plant/facility,

ensure the transducer cable(s) of each system are run in separate grounded metal

conduits. Otherwise, synchronize the level monitors.

When level monitors are synchronized, no unit can transmit while another is awaiting

echo reception.

To synchronize the HYDRO+ with a DPL+, XPL+, and/or another HYDRO+...

1. Mount the level monitors together in one cabinet.

2. Use a common power (mains) supply and ground (earth) for all units.

3. Interconnect the SYNC terminals of all level monitors.

Wall Mount

INSTALLATION

Rack or Panel Mount

HYDRO +

# 1

HYDRO +

# 1

HYDRO +

# 2

to next

device

HYDRO +

# 2

To synchronize the HYDRO+ with other Milltronics

ultrasonic level monitors contact Milltronics

or your local distributor.

PL-507 23

Page 24

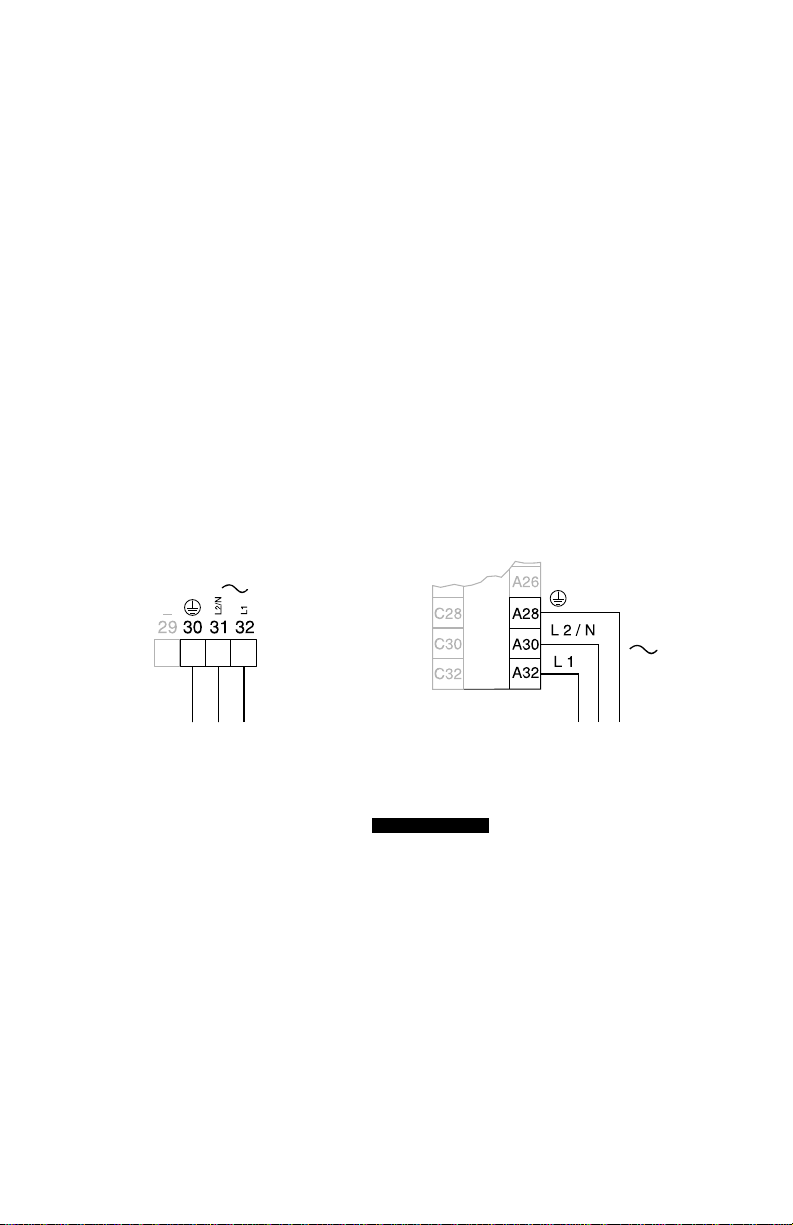

POWER

The HYDRO+ uses 100, 115, 200, or 230 Vac or 9 to 30 Vdc power. If ac and dc

power are supplied, the HYDRO+ draws power from the ac supply. In the event of an

ac power interruption, the dc supply is used until ac power is restored.

IMPORTANT!

Before applying ac power (mains), ensure the correct voltage is selected!

Never operate the HYDRO+ with the enclosure lid open,

or with the ground (earth) wire disconnected!

Before applying power to the HYDRO+ for the first time,

ensure any connected alarm/control equipment is disabled

until satisfactory system operation and performance is verified!

AC SUPPLY WIRING

Wall Mount

to ac supply

Set voltage selection switches per Mounting instructions.

Rack or Panel Mount

to ac supply

INSTALLATION

PL-507 24

Page 25

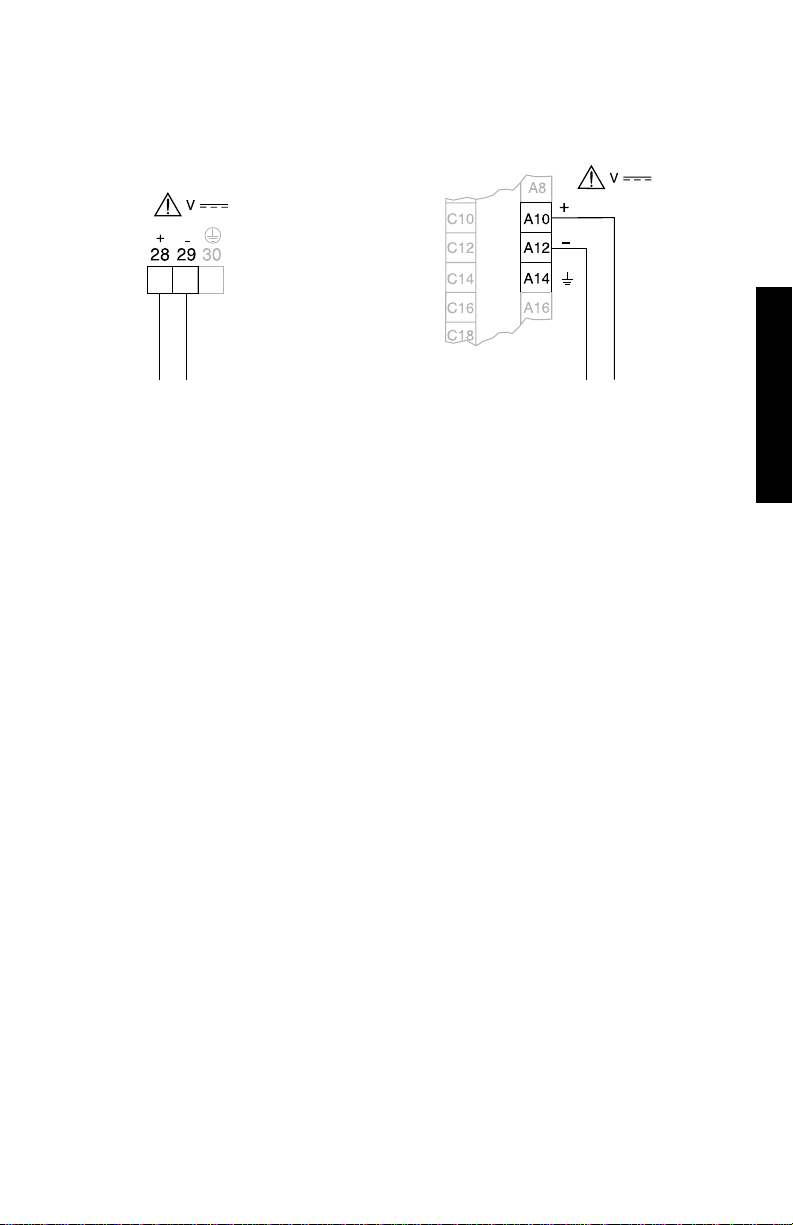

DC SUPPLY WIRING

Rack or Panel Mount

to dc supply

Wall Mount

to dc supply

Negative dc input (A12) is tied to earth (A14).

INSTALLATION

Customer voltage supply 9 to 30 V dc.

The equipment must be protected by a 15 A fuse or circuit

breaker in the building installation.

A circuit breaker or switch in the building installation, marked

as the disconnect switch, shall be in close proximity to the

equipment and within easy reach of the operator.

PL-507 25

Page 26

PL-507 26

Page 27

PROGRAMMING

Those not previously familiar with the HYDRO+, may wish to use the step by step

initial start up procedure illustrated in the HYDRORANGER PLUS QUICK START

GUIDE provided. Then, reference to the remainder of this instruction manual is only

necessary if operation modification is required.

All programmable features are identified by a Parameter Number, which has a preset

Parameter Value. Programming is accomplished by altering the Parameter Value of

specific Parameter Numbers to obtain the RUN mode operation desired.

When applicable, the Point Number to be affected, must be identified before the

Parameter Value is altered.

See APPLICATIONS for common HYDRO+ programming requirements. If more

APPLICATIONS

detailed parameter information is required, see PARAMETERS .

To enable the programmer

interface of the HYDRO+

rack or panel mount version,

press the key on the

front panel.

Program enable is confirmed

by the icon appearing in

the display. To disable

programming, press again.

Program disable is confirmed by

absence of the icon in the

display. Disable all nearby units

to avoid inadvertent programming.

PARAMETERS

PROGRAMMING

PROGRAM MODE ENTRY

Upon power application, RUN mode operation begins. To enter the program mode,

hold the programmer within 0.3 m (1 ft) of the

display window and,

When the program mode is entered, all operating data is retained in memory.

Alarm relay status and mA output values are "held" at "last known" values and

control relays are de-energized (unless affected by a parameter alteration

or is pressed), until the RUN mode is re-entered. The RUN mode is

automatically re-entered if the HYDRO+ is left unattended in the program

mode for an extended period (approximately 5 minutes).

PL-507 27

Page 28

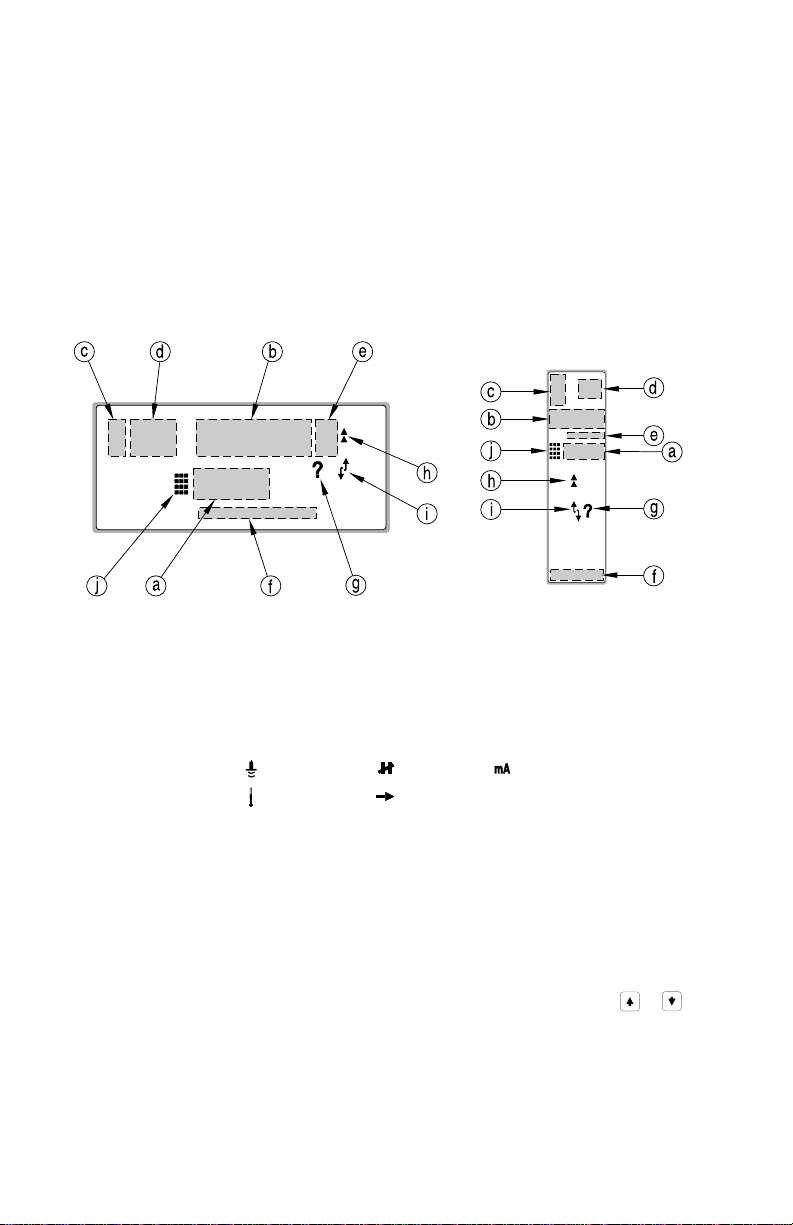

DISPLAY

In the program mode, the Parameter Number, Parameter Value (and Point Number if

applicable) may be viewed (as well as numerous other programming indicators).

Note that some indicators are specific to certain programming conditions and

therefore,

e.g. The Transducer Point Number is only displayed when Differential or Average

all indicators are not displayed at any given time.

level monitoring is selected, (requiring programming for 2 transducers).

wall mount rack or panel mount

a) Parameter Number (programmable feature accessed).

b) Parameter Value (setting for the Parameter Number displayed).

c) Point Type: transducer relay analog output

temperature index

d) Point Number (of the Point Type accessed).

e) Units (the Parameter Value is displayed in: m, cm, mm, ft, in, or %).

f) Relay Number (programmed for RUN mode operation).

g) Invalid Entry (the Parameter Value is questionable, are you sure?).

h) Auxiliary Function (of the Parameter Number is accessed).

i) Scroll Access Tag (the Parameter Number may be scroll accessed, or ).

j) Program Mode On (is accessed, operation has ceased).

Wall Mount: Program Mode accessed.

Rack or Panel Mount: Programmer interface enabled / Program Mode accessed.

PL-507 28

Page 29

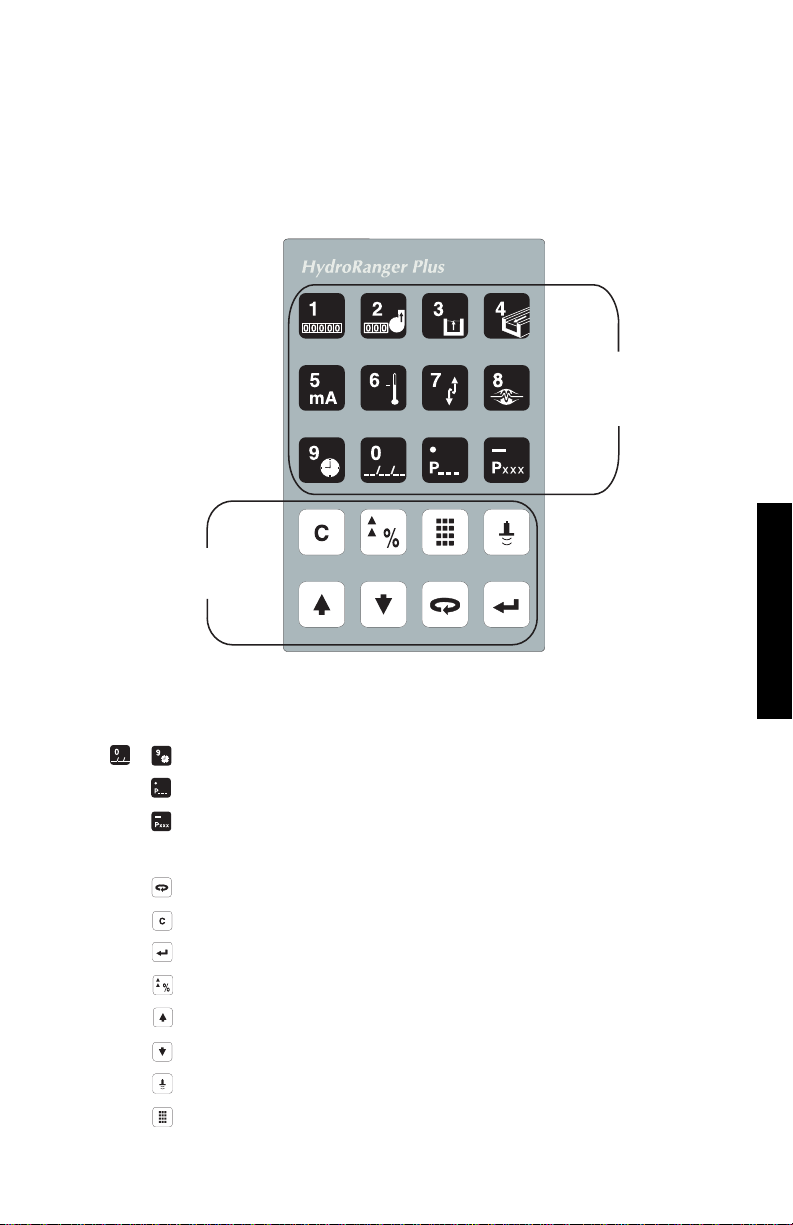

KEYPAD

These instructions ar e for hand programmer (keypad) use. Use the instructions

provided with the DOLPHIN interface package, if applicable.

Aim the HYDRO+ programmer infra-red transmitter at the HYDRO+ display within 0.3

m (12") of the display window. In the program mode, use the HYDRO+ programmer

keys to perform the following identified functions.

Numeric

Value

Keys

Function

Keys

KEY NUMERIC ENTRIES

input a numeric value into the display field accessed.

to

input a decimal point (moves TVT Pointers left).

input a negative value (moves TVT Pointers right).

FUNCTION

shift access to another display field.

delete the current field value (initiate a parameter reset).

store the field values in memory (complete a parameter reset).

switch to % or Units (access Auxiliary Parameter Function).

increase the current field value.

decrease the current field value.

fire the transducer to take an ultrasonic measurement.

enter the RUN mode.

PROGRAMMING

PL-507 29

98/03/19

Page 30

PARAMETER VALUE ALTERATION

In the program mode...

1. to underline the Parameter Number display field and...

a) key in the desired Parameter Number, (

b) as required (

(As preset, only Quick Start and altered parameters may be scroll accessed).

2. If the Point Number field is not displayed, proceed to step 3. Otherwise...

a) key in the desired Point Number, (

b) as required, (

To alter all Point Numbers at once, select Point Number 00.

3. With the Parameter Number (and Point Number if applicable) displayed...

key in the desired Parameter Value and,

or

to underline the Point Number display field and...

or

scroll access

scroll access

direct access

).

direct access

).

) or...

) or...

Record Parameter Value alterations on the appropriate

If Parameter Value alteration is not permitted, access the Lock parameter (P000)

and enter the security code, (see Programming Security).

PL-507 30

PROGRAMMING CHA

PROGRAMMING CHARTS

Page 31

SPECIAL PARAMETERS

Some Parameter Values are for display purposes only and cannot be operator

altered. These are referred to as

PARAMETERS

In the PARAMETERS section of this instruction manual, View Only parameters are

view only

parameters.

identified by a "(V)" beside the Parameter Number.

Many Parameter Values must be common for all Point Numbers. These are referred

global

to as

parameters.

When a global parameter is accessed, the Point Number display automatically

disappears. When a non-global parameter is accessed, the Point Number previously

selected is displayed.

In the parameters sections of this manual, Global parameters are identified by a "(G)"

beside the Parameter Number.

PARAMETER RESET FEATURES

To return an operator adjusted Parameter Value to the preset value, with the

appropriate Parameter Number (and Point Number if applicable) displayed...

To reset all parameters to preset values, see Master Reset (P999).

Perform a Master Reset (P999) to preset all parameters to "original"

values before initial system installation, following an EPROM

replacement, or whenever complete reprogramming is required.

PARAMETERS

PROGRAMMING

PL-507 31

Page 32

PROGRAMMING SECURITY

All operator programming is retained in non-volatile memory, immune to power

interruptions. When programming is complete, the programmer may be locked away

to prevent inadvertent programming alteration. As well, the Lock (P000) parameter

may be used.

PL-507 32

Page 33

OPERATION

With parameter alteration complete, the HYDRO+ may be put into operation.

Once put into operation (the RUN mode is entered), the HYDRO+ continues to

operate unattended, indefinitely. However, numerous RUN mode features are

available for aquiring specific operating information without removing the HYDRO+

from service.

RUN MODE ENTRY

The HYDRO+ automatically starts up in the RUN mode when power is applied.

After a programming alteration, do not use the HYDRO+ to

operate alarms or controls until system programming and

To enter the RUN mode from the Program mode...

"----" is displayed briefly while the Reading is calculated and verified.

When complete, the Reading and other data is displayed; the mA output

value and relay status are immediately updated accordingly.

(During "differential" or "average" Operation (P001 = 4 or 5), the display scrolls

sequentially through Point Numbers 1, 2, and 3. Point Number 3 represents the

difference between or average of Point Numbers 1 and 2).

performance is verified.

If the HYDRO+ is left unattended in the Program mode

for more than 5 minutes, the RUN mode

is automatically entered.

PL-507 33

OPERATION

Page 34

DISPLAY

In the RUN mode, the following values and indicators may be observed.

Note that many indicators are specific to certain operating conditions and

therefore,

all indicators are not displayed at any given time.

wall mount rack or panel mount

1. the current display pertains to a Transducer measurement.

2. Transducer Number 1, 2, or Result 3 (DPD or DPA operation only).

3. Reading resulting from Operation selected, (error message).

4. the Reading is in m, cm, mm, ft, in or %.

▲

5. = HI alarm, = HI HI alarm.

▲

▲

6. Bar graph representation of level from 0 to 100% (absolute).

7. monitored surface is rising (nearer transducer).

8. monitored surface is falling (farther from transducer).

▼

9. = LO alarm, = LO LO alarm.

10. = Relay # programmed.

¡

l

¡

11. = pump, control, or alarm on.

▼

▼

12. Auxiliary Reading (see Keypad for selection).

13. = Normal operation.

14. = Failsafe operation.

15. programmer interface enable (rack or panel mount only)

PL-507 34

Page 35

KEYPAD

Auxiliary Reading Keys

In the RUN mode, the following programmer keys perform the identified functions.

Function Keys

KEY READING

"8 Digit Totalizer" ("OCM" or "PT" Operation, P001 = 6 or 7)

AUXILIARY READINGS

"Pump Running Time" (key in Pump Number, hold for Starts)

"Head" (OCM Operation, P001 = 6)

"Flow based on Head" (OCM Operation, P001 = 6)

"mA Output Value"

"Temperature" (air in °C)

"Rate of Change" (in Units/minute)

"Failsafe Time Left" (in percent)

"Time" (HH:MM, 24 hour format)

"Date" (MM:DD, of the current year)

"Parameter Value" (key in Parameter Number)

"Material Level" (may be altered via P731)

"Distance" (surface to transducer face)

OPERATION

PL-507 35

FUNCTION

initiate program mode access (see )

toggle between Units and % (complete program mode access)

stop/start the Point Number auto display scroll

select the next Point Number (stop the display scroll)

select the previous Point Number (stop the display scroll)

Page 36

SYSTEM PERFORMANCE EVALUATION

1. to enter the RUN mode.

If a pump or control is ON, the corresponding relay is energized. If an alarm is ON, the

relay is de-energized.

2. to display the Reading in

%

(percent of Span, P007).

OPERATION LEVEL SPACE or DISTANCE

Empty to Full = 0 to 100% 100 to 0%

3. to observe the current mA output value (Auxiliary Reading).

OPERATION LEVEL SPACE or DISTANCE

Empty to Full = 4-20 mA 20-4 mA

4. and then or to observe accumulated

pump running hours

5. and hold the or key (for 5 seconds) to

observe the number of accumulated pump starts

2

for pumps 1 to 5 respectively.

2

for

pump 1 to 5 respectively.

6. to observe the

Failsafe Time Left

(in %) to failsafe activation.

When the Reading is updated, this value (Auxiliary Reading) resets to

100 and begins to decrease until the next valid measurement is made.

If the Failsafe Time Left reaches 0, "LOE" flashes in the Reading display.

1

less than 0.3m (1 ft) cannot be reliably measured; a 0% Reading or 4 mA

cannot be achieved during "distance" Operation.

2

if the associated relay is programmed for a pump control function.

1

1

PL-507 36

Page 37

PERFORMANCE TEST RESULTS

Monitor system performance carefully, under all anticipated operating conditions.

A. When the HYDRO+ performs exactly as required, programming is complete.

B. If alternate Reading units, failsafe action, relay, or mA output operation is

desired, proceed to APPLICATIONS and/or PARAMETERS as required.

C. Should system performance not meet installation requirements, (or the "LOE"

display persists after start up), proceed to TROUBLESHOOTING .

If all operating conditions cannot be observed during the System Performance

Evaluation, refer to PARAMETERS Reading Measurement (P920). Perform a

PARAMETERS

Reading Measurement simulation to verify programming.

Conduct a System Performance Evaluation following any installation modification or

programming (parameter) alteration.

APPLICATIONS

PARAMETERS

TROUBLESHOOTING

PL-507 37

OPERATION

Page 38

MAINTAINING OPERATION

With programming complete, record all parameter alterations.

a) If the keypad programmer is used, enter the program mode and scroll

access altered parameters (skipping parameters left at preset values).

Record parameter alterations on the PROGRAMMING CHARTS.

b) If the DOLPHIN interface package is used, refer to the associated

instructions to record all operator programming.

For normal operation, return to the RUN mode. The HYDRO+ will perform reliably,

requiring little or no maintenance.

Connect (or enable) process control/alarm equipment to the

HYDRO+ only after satisfactory performance is verified for

all possible operating conditions.

PROGRAMMING CHARTS

PL-507 38

Page 39

APPLICATIONS

The following examples illustrate how easily the HYDRO+ may be programmed to

meet specific application requirements.

While your installation may not match these examples exactly, by reviewing the

closest example (or combination of examples), the relationship between HYDRO+

features and your process measurement requirements may be more easily identified.

In every case, refer to General Application. This example defines the minimum

programming required for any application. Then refer to the applicable "add on"

examples for programming information specific to your application.

If additional parameter detail is required, (than provided in these examples), see

PARAMETERS

PARAMETERS for complete parameter definitions.

Ensure all alarms and controls are disabled until all application programming is

complete and satisfactory RUN mode performance is verified.

1. General Application (common programming to all applications).

2. Wet Well Control add on (combine with example 1).

3. Reservoir Control add on (combine with example 1).

4. Screen Rake Control add on (combine with example 1).

5. Penstock Control add on (combine with example 1).

6. General Alarm add on (combine with example 1).

7. Volume Calculation add on (combine with example 2 or 3).

8. Pumped Volume Calculation add on (combine with example 2 or 3 and 7).

9. OCM Flow Calculation add on (combine with example 1).

10. Failsafe Operation add on (combine with example 1 to 5).

PL-507 39

APPLICATIONS

Page 40

GENERAL APPLICATION

PARAMETER PRESET OPERATION

P001 Operation 3 = distance display Reading referenced to transducer face

P002 Material 1 = liquid anticipates echoes from a flat reflective surface

P003 Response 2 = 1 m/min typical liquid surface rate of change

P004 Transducer 100 = ST-H compensates for temperature variation

P005 Units 1 = metres displays all linear dimensions in metres

P006 Empty 8.000 0% level bar graph reference point.

P007 Span 8.000 100% level bar graph reference point.

P008 Date YY.MM.DD automatic leap year adjustment

P009 Time HH.MM.SS 24 hour format

If power is applied before any programming is performed, the HYDRO+ starts running,

using the parameter preset values. As long as the transducer connected has an

internal temperature sensor and a maximum range of 15 m (50 ft) or less, the preset

Transducer (P004) value is suitable for operator orientation with HYDRO+ operation.

If "Error" and the transducer terminal numbers are displayed, the transducer does not

have an internal temperature sensor. See Transducer (P004) options.

The HYDRO+ operates like an ultrasonic tape measure, displaying distance from the

transducer face to the surface monitored.

PL-507 40

Page 41

PARAMETER VALUE OPTIONS

(use to key in ":".

Operation 1 = "level", Full = 100% Reading = 20 mA (most common)

(P001) = 2 = "space", Empty = 100% Reading = 20 mA (less common)

3 = "distance", (references measurements to transducer face)

4 = "DPD", (displays differential level, 2 transducers required)

5 = "DPA", (displays average level, 2 transducers required)

6 = "OCM", (calculates flowrate for head and total flow volume)

7 = "PT", (calculates total pumped volume)

Material 1 = "liquid", flat perpendicular reflective surface (most common)

(P002) = 2 = "solid", angled rough reflective surface (for heaping solids)

Measurement 1 = "0.1 m/min", very slow moving surface (less common)

Response 2 = "1.0 m/min", typical liquid surface (usual setting)

(P003) = 3 = "10 m/min", very fast moving surface (less common)

Transducer 0 = "out-of-service"

(P004) 1 = "ST-25"

2 = "ST-50"

100 = "ST-H"

101 = "XCT-8" Enter the appropriate transducer type

102 = "XPS-10"

103 = "XCT-12"

104 = "XPS-15"

250 = "mA input"

Units 1 = "metres"

(P005) = 2 = "centimetres"

Empty

(P006) = "0.000" to "9999" Enter value in P005 Units

Span

(P007) = "0.000" to "9999" Preset by P006, change if desired.

Date

(P008) = "00:01:01" to "99:12:31"

Time

(P009) = "00:00:00" to "23:59:59"

With General Application programming complete, a System Performance Evaluation

OPERATION

(see OPERATION ) is recommended before proceeding to the following Application

programming examples.

PL-507 41

3 = "millimetres" Enter the linear dimension units desired

4 = "feet"

5 = "inches"

APPLICATIONS

Page 42

WET WELL CONTROL (Pump Down)

Typically, wet wells are used to temporarily hold storm and/or waste water. When the

surface reaches a high level setpoint, the wet well is pumped down. The discharge

goes on to another wet well or directly to the treatment facility.

The HYDRO+ provides wet well control with only minimal application programming.

For the following example, we’ll assume Empty (P006) was set from the transducer

face to the wet well floor. (To monitor wet well overflow, see the note at the end of the

OCM Application example).

(If the transducer cannot be located to avoid acoustic beam interference from the

pumps, set Empty (P006) from the transducer face to the top of the pump(s).

FULL

HI Alarm On

HI Alarm Off

Start Pump 1

Start Pump 2

Pump Down,

2 Alternate

Assist Pumps

Stop Pumps

Lo Alarm Off

Lo Alarm On

EMPTY

RELAY INTERCONNECTION

The relay contact illustrations adjacent to the HYDRO+ relay terminals are shown in

the power off, de-energized, alarm on, pump off condition.

Connect the HYDRO+ relays as follows:

RL1 to Pump 1 control (energized = pump on, de-energized = pump off)

RL2 to Pump 2 control (energized = pump on, de-energized = pump off)

RL3 to Hi Alarm indicator (energized = alarm off, de-energized = alarm on)

RL4 to Lo Alarm indicator (energized = alarm off, de-energized = alarm on)

RL5 not used

PL-507 42

Page 43

PROGRAMMING

Set Relay Set Up to "Wet Well 1" (P100=1) to preset relays as follows.

PARMETER RL#1 RL#2 RL#3 RL#4 RL#5

P111 Relay Function 52 52 1 1 0

P112 Relay A Setpoint 70% 80% 90% 10% ---P113 Relay B Setpoint 20% 20% 85% 15% ---For one pump, set the RL#1 or RL#2 Relay Function to "off" (P111 = 0).

For 3 or more pumps (5 max.), choose the relay(s) to be used and program P111,

P112 and P113 similar to RL# 1 and RL# 2 (but stagger the P112 setpoints).

OPERATION

By level (as indicated on bar graph) for 2 pumps...

1. Pump controls are operated as "alternate duty assist" (P111 = 52):

NORMAL OPERATION

a) Pump 1 (lead pump) starts at 70%.

b) Pump 1 stops at 20%, shift setpoints (lead) to next pump.

PEAK DEMAND OPERATION

a) Pump 1 (lead pump) starts at 70%.

b) Pump 2 (next pump) starts at 80%.

c) Pump 1 and 2 stop at 20%, shift lead to next pump.

2. Alarms indicate control/pump malfunction (or excessive/insufficient capacity).

a) HI alarm "on" at 90%, off at 85%.

b) LO alarm "on" at 10%, off at 15%.

c) Both alarms "on" = HYDRO+ power interruption.

3. Use the 4-20 mA output if desired...

a) proportional to level if Operation = "level" (P001 = 1).

b) inversely proportional to level if Operation = "space" (P001 = 2).

4. To view pump information in the RUN mode...

a) and then the pump # (to view the pump running hours total).

b) and hold the pump # (to view the number of pump starts total)

PL-507 43

APPLICATIONS

Page 44

RESERVOIR CONTROL (Pump Up)

Empty

Typically, reservoirs are used to temporarily hold processed water. When the water

surface reaches a low level setpoint, the reservoir is pumped up.

The HYDRO+ provides reservoir control with only minimal application programming.

For the following example, we’ll assume Empty (P006) was set from the transducer

face to the reservoir bottom.

FULL

HI Alarm On

HI Alarm Off

Stop Pumps

Start Pump 1

Start Pump 2

Lo Alarm Off

Lo Alarm On

RELAY INTERCONNECTION

The relay contact illustrations adjacent to the HYDRO+ relay terminals are shown in

the power off, de-energized, alarm on, pump off condition.

Connect the HYDRO+ relays as follows:

RL1 to Pump 1 control (energized = pump on, de-energized = pump off)

RL2 to Pump 2 control (energized = pump on, de-energized = pump off)

RL3 to Hi Alarm indicator (energized = alarm off, de-energized = alarm on)

RL4 to Lo Alarm indicator (energized = alarm off, de-energized = alarm on)

RL5 not used

PL-507 44

Page 45

PROGRAMMING

Set Relay Set Up to "Reservoir 1" (P100=3) to preset relays as follows.

PARAMETER RL#1 RL#2 RL#3 RL#4 RL#5

P111 Relay Function 52 52 1 1 0

P112 Relay A Setpoint 30% 20% 90% 10% ---P113 Relay B Setpoint 80% 80% 85% 15% ---For one pump, set the RL#1 or RL#2 Relay Function to "off" (P111 = 0).

For 3 or more pumps (5 max.), choose the relay(s) to be used and program P111,

P112 and P113 similar to RL# 1 and RL# 2 (but stagger the P112 setpoints).

OPERATION

By level (as indicated on bar graph) for 2 pumps...

1. Pump controls are operated as "alternate duty assist" (P111 = 52):

NORMAL OPERATION

a) Pump 1 (lead pump) starts at 30%.

b) Pump 1 stops at 80%, shift setpoints (lead) to next pump.

PEAK DEMAND OPERATION

a) Pump 1 (lead pump) starts at 30%.

b) Pump 2 (next pump) starts at 20%.

c) Pump 1 and 2 stop at 80%, shift lead to next pump.

2. Alarms indicate control/pump malfunction (or excessive/insufficient capacity).

a) HI alarm "on" at 90%, off at 85%.

b) LO alarm "on" at 10%, off at 15%.

c) Both alarms "on" = HYDRO+ power interruption

3. Use the 4-20 mA output if desired...

a) proportional to level if Operation = "level" (P001 = 1).

b) inversely proportional to level if Operation = "space" (P001 = 2).

4. To view pump information in the RUN mode...

and then the pump # (to view the pump running hours total)

and hold the pump # (to view the number of pump starts total)

PL-507 45

APPLICATIONS

Page 46

RAKE CONTROL (Differential Level)

Typically a water purification process has a screen on the inlet side to filter solids from

entering the process. Should the screen become blocked, and inflow sufficiently

reduced, process efficiency can often be compromised.

The HYDRO+ provides screen rake control with only minimal application

programming. For the following example, we’ll assume Operation was set for

"differential" (P001 = 4) and Empty (P006) was set from the transducer face to the

channel bottom for both transducer 1 and transducer 2.

RAKE CONTROL

RELAY INTERCONNECTION

The relay contact illustrations adjacent to the HYDRO+ relay terminals are shown in

the power off, de-energized, alarm on, control off condition.

Connect the HYDRO+ relays as follows:

RL1 to Rake control (energized = rake on, de-energized = rake off)

RL2 to Hi Alarm (Point 1) (energized = alarm off, de-energized = alarm on)

RL3 to Lo Alarm (Point 2) (energized = alarm off, de-energized = alarm on)

RL4 to Hi Alarm (Point 3) (energized = alarm off, de-energized = alarm on)

RL5 to transducers See INSTALLATION Interconnection\Transducer

PL-507 46

INSTALLATION

Page 47

PROGRAMMING

Set Relay Set Up to "Rake Control" (P100=5) to preset relays as follows.

PARAMETER RL#1 RL#2 RL#3 RL#4 RL#5

P110 Relay Allocation 31231

P111 Relay Function 50 1 1 1 49

P112 Relay A Setpoint 80% 90% 10% 90% ---P113 Relay B Setpoint 20% 85% 15% 85% ----

OPERATION

By level (as indicated by the Point Number bar graphs)...

1. The rake control:

a) is turned "on" when Point # 3 = 80%.

b) is turned "off" when Point # 3 = 20%.

2. Alarms indicate critical operating conditions.

a) Hi Alarm (Point 1) = high channel inflow (on 90%, off 85%).

b) Lo Alarm (Point 2) = low channel outflow (on 10%, off 15%).

c) Hi Alarm (Point 3) = rake malfunction (on 90%, off 85%).

d) All Alarms = HYDRO+ power interruption.

3. The 4-20 mA output is proportional to level on Point 1. If desired, set the mA

Allocation for Point 2 (P202 = 2) or for differential Point 3 (P202 = 3).

PL-507 47

APPLICATIONS

Page 48

PENSTOCK CONTROL

A

penstock

open channel flowrate. In some cases, penstock control is used to limit storm flow

conditions through the channel by diverting excess (storm condition) flow to a

temporary holding vessel.

To monitor open channel flow downstream from a penstock, see the note at the end

of the OCM application example.

The HYDRO+ provides time step penstock control based on open channel level with

only minimal application programming. For the following example, we’ll assume

Operation was set for "level" (P001 = 1) and Empty (P006) was set from the

transducer face to the channel bottom.

(motorized liquid flow control gate) is often used to control and maintain

penstock

storm

spillway

transducer

RELAY INTERCONNECTION

The relay contact illustrations adjacent to the HYDRO+ relay terminals are shown in

the power off, de-energized, alarm on, control off condition.

Connect the HYDRO+ relays as follows:

RL1 to "OPEN" control (energized = open penstock per P112,P114 and P115)

RL2 to "CLOSE" control (energized = close penstock per P112, P114 and P115)

RL3 to Hi Alarm (energized = alarm off, de-energized = alarm on)

RL4 to Lo Alarm (energized = alarm off, de-energized = alarm on)

RL5 not used

PL-507 48

Page 49

PROGRAMMING

GENERAL

P001 Operation = 1 (level)

P006 Empty = 1.7 m (e.g. Transducer to channel bottom)

P007 Span = 1.3 m (e.g. Channel bottom to highest head)

RELAYS

Set Relay Set Up to "off" (P100=0, preset) prior to relay programming.

PARAMETER RL#1 RL#2 RL#3 RL#4 RL#5

P111 Relay Function 63 63 1 1 0

*

P112 Relay A Setpoint

P113 Relay B Setpoint

P114 Relay C Setpoint

45% 55% 65% 35% ----

*

---- ---- 60% 40% ----

*

0.1 ---- ---- ---- ----

P115 Relay D Setpoint * 1 ---- ---- ---- ----

*

Relay Setpoints above are for illustration purposes only. Program Relay Setpoints

as required to satisfy individual application requirements.

OPERATION

By level (as indicated by the bar graph)...

1. The Penstock is:

a) driven more open for 0.1 minute at 45% level or less (RL1).

b) driven more closed for 0.1 minute at 55% level or more (RL2).

c) control operation is limited (P115) to every 1 minute (for stabilization).

d) both controls are held "off" if the level is between 45.01% and 54.99%.

2. Alarms indicate critical operating conditions.

a) Hi Alarm = close control malfunction (on 65%, off 60%)

b) Lo Alarm = open control malfunction (on 35%, off 40%)

c) Both Alarms = HYDRO+ power interruption

3. Use the 4-20 mA output if desired...

a) proportional to level if Operation = "level" (P001 = 1).

b) inversely proportional to level if Operation = "space" (P001 = 2).

PL-507 49

APPLICATIONS

Page 50

GENERAL ALARMS

HI Alarm On

Lo Alarm Off

HI Alarm Off

If relay operated controls are not required, the following general alarms may be added

to the general application programming.

Alarms (similar to controls) are always based on level regardless of the Operation

(P001) selected.

FULL

HI HI Alarm On

HI HI Alarm Off

RELAY INTERCONNECTION

The relay contact illustrations adjacent to the HYDRO+ relay terminals are shown in

the power off, de-energized, alarm on, control off condition.

Connect the HYDRO+ relays as follows:

RL1 to Hi Alarm (energized = alarm off, de-energized = alarm on)

RL2 to Lo Alarm (energized = alarm off, de-energized = alarm on)

RL3 to Hi Hi Alarm (energized = alarm off, de-energized = alarm on)

RL4 to Lo Lo Alarm (energized = alarm off, de-energized = alarm on)

RL5 not used

PL-507 50

Lo Alarm On

Lo Lo Alarm Off

Lo Lo Alarm On

EMPTY

Page 51

PROGRAMMING

RELAYS

Set Relay Set Up to "General Alarms" (P100 = 6) to preset relays as follows.

PARAMETER RL#1 RL#2 RL#3 RL#4 RL#5

P111 Relay Function 11110

P112 Relay A Setpoint 80% 20% 90% 10% ---P113 Relay B Setpoint 75% 25% 85% 15% ----

OPERATION

1. Alarms indicate critical operating conditions.

a) Hi Alarm = high level (on 80%, off 75%).

b) Lo Alarm = low level (on 20%, off 25%).

c) Hi Hi Alarm = higher level (on 90%, off 85%).

d) Lo Lo Alarm = lower level (on 10%, off 15%).

2. Use the 4-20 mA output if desired...

a) proportional to level if Operation = "level" (P001 = 1).

b) inversely proportional to level if Operation = "space" (P001 = 2).

PL-507 51

APPLICATIONS

Page 52

OCM (Open Channel Monitor) Flow and Total Calculation

Typically, a water treatment process has a free flowing open channel on the inlet side.

The channel is often restricted by a

head/flow relationship.

(See note at end of example for monitoring overflow from a wet well or flow

downstream from a Penstock).

The HYDRO+ provides OCM flow and totalized flow calculation with only minimal

application programming. Ensure Operation is set for "OCM" (P001 = 6) and Empty

(P006) is set from the transducer face to the channel bottom at the distance from the

PMD (if used) prescribed by the supplier.

RELAY INTERCONNECTION

The relay contact illustrations adjacent to the HYDRO+ relay terminals are shown in

the power off, de-energized, alarm on, control off condition.

Connect the HYDRO+ relays as follows:

RL1 As indicated by the alarm/control application example used.

RL2 As indicated by the alarm/control application example used.

RL3 As indicated by the alarm/control application example used.

RL4 As indicated by the alarm/control application example used.

RL5 to the remote totalizer (if used)

PMD

(Primary Measuring Device) having a known

PL-507 52

Page 53

PROGRAMMING

OCM

P600 PMD = 1 (preset, change to applicable PMD)

P601 Flow Exponent = 2.50 (preset, change per PMD used, P600 = 1 only)

P602 Flume Dimension D = 1 (preset, change per PMD used, P600 = 2 or 3)

P603 Max Head = Span (preset, change to actual head at Max Flow)

P604 Max Flow = 1000 (preset, change to flow at Max Head)

P605 Zero Head = 0.000 (preset, change to zero head distance above Empty)

P606 Time Units = 1 (preset, time portion of Max Flow)

P607 Flow Decimal = 3 (e.g. display value to 3 decimal places)

P610 Head Breakpoints = ---- (change to known flow heads; 32 max, P600 = 4 or 5)

P611 Breakpoint Flowrates = ---- (change to flow at P610 heads; P600 = 4 or 5)

P620 Low Flow Cutoff = 5% (preset, below this head, flow is not totalized

LCD TOTALIZER

0

P630 LCD Total Factor = 0 (preset, display in 1 x 10

Max Flow volume units)

P633 LCD Total Decimal = 3 (e.g. display value to 3 decimal places)

REMOTE TOTALIZER (optional)

P111 Relay Function = 40 (totalizer) for RL5

0

P640 Relay Total Factor = 0 (preset, pulse every 1 x 10

(P604) volume units)

P645 Relay On Time = 0.2 seconds (preset, adjust if necessary to suit totalizer)

OPERATION

1. Alarms and/or controls operate as programmed by other Application examples.

2. The totalizer relay energizes for (P645) seconds for every (P640) units.

3. The 4-20 mA output is proportional to flow.

4. to display 8 digit total flow volume.

5. to display head.

6. to display flowrate.

To monitor the overflow (through a weir) from a wet well, program the HYDRO+ as

indicated above, except program Empty (P006) and relays as illustrated in the Wet

Well Control application example.

To monitor flow downstream from a Penstock, program the HYDRO+ as

indicated above, except program relays as illustrated in the Penstock Control

application example.

PL-507 53

APPLICATIONS

Page 54

VOLUME CALCULATION

Universal

Linear

10 =

Sometimes, an indication of the liquid volume contained within a vessel, or remaining

vessel capacity is required.

The HYDRO+ provides volume calculation with only minimal application programming.

Ensure Empty (P006) is set from the transducer face to the vessel bottom and Span

(P007) is set from the vessel bottom to the vessel top.

1 =

2 =

3 =

flat level bottom

cone / pyramid bottom

or

A

parabola bottom

A

4 =

5 =

6 =

7 =

half sphere bottom

A

flat sloped bottom

or

A

flat ends

parabola ends

sphere

8 =

9 =

Universal

Curved

LA

RELAY INTERCONNECTION

Connect the HYDRO+ relays as indicated by the alarm/control example used.

Ensure the surface monitored is controlled from coming within 0.33 m (1.1 ft) of the

transducer face, (see INSTALLATION Transducer).

INSTALLATION

Volume calculation does not alter relay programming.

PL-507 54

Page 55

PROGRAMMING

VOLUME

P050 Tank Shape = 0 (preset, change to applicable shape)

P051 Max Volume = 100 (preset, display in %, other = volume of Span, P007).

P052 Tank Dimension A (required for Tank Shapes: P050 = 2,3,4,5, or 7).

P053 Tank Dimension L (required for Tank Shape P050 = 7)

P054 Level Breakpoint (32 max., required for Tank Shapes: P050 = 9 or 10).

P055 Breakpoint Volumes = volume associated with Level Breakpoints (P054).

OPERATION

1. Alarms and/or controls operate as programmed by other Application examples.

2. Use the 4-20 mA output if desired . . .

a) proportional to liquid volume if Operation = "level" (P001 = 1).

b) proportional to remaining capacity if Operation = "space" (P001 = 2).

PL-507 55

APPLICATIONS

Page 56

PUMPED VOLUME TOTAL

Remote Totalizer

Sometimes, an indication of the total liquid volume pumped from a wet well or into a

reservoir is required.

The HYDRO+ provides total volume pumped calculation with only minimal application

programming. Ensure Operation is set for "Pumped Total" (P001 = 7) and the Wet

Well or Reservoir Control and Volume Calculation application programming is

complete before proceeding.

(not supplied)

RELAY INTERCONNECTION

The relay contact illustrations adjacent to the HYDRO+ relay terminals are shown in

the power off, de-energized, alarm on, control off condition.

Connect the HYDRO+ relays as follows:

RL1 As indicated by the alarm/control application example used.

RL2 As indicated by the alarm/control application example used.

RL3 As indicated by the alarm/control application example used.

RL4 As indicated by the alarm/control application example used.

RL5 To the remote totalizer (if used)

PL-507 56

Page 57

PROGRAMMING

LCD TOTALIZER

P622 In/Out Correction = 1 (preset, auto total inflow/discharge adjust)

P630 LCD Total Factor = 0 (preset, display total in Max Volume units)

P633 LCD Total Decimal = 3 (e.g. display 3 decimal places)

REMOTE TOTALIZER (optional)

P111 Relay Function = 40 (totalizer) for RL5

0

P640 Relay Total Factor = 0 (preset, pulse every 1 x 10

Max Volume units)

P645 Relay On Time = 0.2 seconds (preset, adjust if necessary to suit totalizer)

OPERATION

1. Alarms and/or controls operate as programmed by other

Control Application programming examples.

2. The totalizer relay energizes for (P645) seconds for every (P640) volume units.

3. The 4-20 mA output is proportional to volume (per Volume Calculation).

4. to display 8 digit total volume pumped value.

5. To view pump information in the RUN mode...

and then the pump # (to view the pump running hours total)

and hold the pump # (to view the number of pump starts total)

PL-507 57

APPLICATIONS

Page 58

FAILSAFE OPERATION GENERAL

As preset, upon a loss of echo, the HYDRO+ Reading, alarm relays, and mA output

are held at last "known" values and pump/control relays are de-energized, until a valid

measurement is regained.

If desired, program the HYDRO+ to provide alternative display, relay and/or mA

output operation under loss of echo conditions to provide failsafe operation.

PROGRAMMING

1. Enter the

P071: HI = 100% bar graph level

2. Enter the Measurement Response for advance to the Failsafe Material Level.

P003 Response: 1 = 100 minute delay, advance at 0.1 metres/minute

3. To test failsafe operation (with the monitored surface still), disconnect the

transducer cable and ensure alarms/controls activate.

For more failsafe programming and operation information,

see PARAMETERS P003,P070,P071,P072,P129,P219,P700,P701.

Failsafe Material Level

LO = 0% bar graph level and or to access.

HOLd = last level (preset)

specific level = -50% to 150% of Span (P007) in Units or %.

2 = 10 minute delay, advance at 1 metre/minute

3 = 1 minute delay, advance at 10 metres/minute

PARAMETERS

(where alarms warn "unsafe" operation).

If any of these parameters are altered, retest Failsafe Operation.

PL-507 58

Page 59

WET WELL FAILSAFE

HI Alarm

HI Level

Fault

Detector

LO Level

Fault

Detector

OPERATION

For this example we’ll assume:

P001 Operation is set to "level" (P001 = 1).

P003 Measurement Response is set to "medium" (P003 = 2, preset).

P006 Empty is set for 6.000 metres.

P007 Span is set for 5.000 metres.

P071 Failsafe Material Level is set for "HI".

P100 Relay Set Up is set for Wet Well 1 (P100 = 1).

a) high alarm is to indicate failsafe operation.

b) lead pump starts (as preset) at 70% (3.5 m).

c) high alarm trips on (as preset) at 90% (4.5 m) and off at 85% (4.25 m).

d) normal wet well filling rate is 0.3 m/minute.

e) back up system takes over if level reaches 5.5 m.

f) at 9:15 am, the HYDRO+ transducer cable was accidentally cut.

APPLICATIONS

e.g. 09:15:00 am Echo lost at 2.2 m, pump(s) turn off, countdown begins

09:25:00 am Failsafe activated, reported level advances at 1 m/min (P003).

09:26:00 am backup control takes over, actual level = 5.5 m (and falling).

09:27:18 am HI alarm trips on, reported level = 4.5 m.

09:27:48 am HI alarm still on, reported level = 5 m.

PL-507 59

Page 60

APPLICATION ASSISTANCE

The preceding examples describe only a few ways in which the HYDRO+ can be

applied to process measurement requirements.

The HYDRO+ can be used to monitor and/or activate alarm/control relays for almost

any process (within the temperature, measurement range, and chemical immunity

capabilities of the system) where a distance measurement or determination of

presence vs. lack of presence of an object is desired.

By thoroughly reviewing the PARAMETERS sections, you may identify some

interesting ways of using the HYDRO+ to monitor specific processes.

Milltronics has many years experience applying ultrasonic level measurement to a

variety of processes in the mining, aggregate, lumber, grain, chemical, pulp and

paper, water, and waste water industries.

If you encounter a difficulty applying the HYDRO+ to a process measurement

requirement, or successfully apply the HYDRO+ to a "unique process" we may have

never considered, contact Milltronics or your local distributor.

PARAMETERS

PL-507 60

Page 61

PARAMETERS

SECURITY PARAMETER (P000)

P000 (G) LOCK

Use this feature to secure all programming from inadvertent alteration.

Direct access (cannot be scroll accessed) this parameter after all

programming is complete and enter any value (other than 1954) to

activate the programming Lock.

When Lock is activated, the HYDRO+ may be switched from the RUN

mode to the program mode and the value of any parameter may be viewed

but not altered. To unLock the HYDRO+, direct access this parameter and

enter the value "1954".

Normally, during a measurement simulation (see Measurement Parameters,

P920 - P927), control relays remain de-energized. If desired, set Lock for

"simulation controls" to have control relays functional during a simulation.

This parameter cannot be reset by

values: 1954 = off (Parameter Value alteration permitted)

-1 = simulation controls

other = activated (programming secured)

PARAMETERS

PL-507 61

Page 62

QUICK START PARAMETERS (P001 TO P009)

P001 (G) OPERATION

Enter the type of RUN mode operation desired.

If "out-of-service" is entered, the transducer is not fired, alarm relay(s)

energize, pump relay(s) de-energize, and mA output(s) assume the surface

is at the Empty (P-006) value.

*

If "DPD" or "DPA" is entered, 2 transducers are required, see

INSTALLATION Transducer.

INSTALLATION

DPD = Point 3 = Point 1 - Point 2.

DPA = Point 3 = (Point 1 + Point 2) 2.

values: 0 = out-of-service

1 = level (display how full a vessel is)

2 = space (display how empty a vessel is)

3 = distance (preset, surface to transducer face distance)

4 = DPD (display the absolute difference between 2 levels)

5 = DPA (display the average of 2 levels)

6 = OCM (display flow in an open channel)

7 = PT (display total pumped volume)

P002 (G) MATERIAL

Enter the type of material monitored.

values: 1 = liquid or flat solid surface (preset)

2 = solid (heaping or angled away from transducer)

P003 MEASUREMENT RESPONSE

Enter the typical monitored surface rate of change in position.

This feature presets a variety of independently programmable parameters,

substantially simplifying start up requirements.

If Failsafe, Rate, Measurement Verification, or Scanning parameters have

been previously independently programmed, refer to

TECHNICAL REFERENCE Measurement Response before altering.

TECHNICAL REFERENCE

values: 1 = slow (0.1 m/min)

2 = medium (1 m/min) (preset)

3 = fast (10 m/min)

PL-507 62

Page 63

P004 (G) TRANSDUCER

Enter the type of transducer(s) connected to the HYDRO+.

values: 0 = not entered 100 = STH 103 = XCT-12

1 = ST-25 101 = XCT-8 104 = XPS-15

2 = ST-50 102 = XPS-10 (preset) 250 = auxiliary

P005 (G) UNITS

Enter the units of measure desired for programming and/or display.

values: 1 = metres (m) (preset) 4 = feet (ft)

2 = centimetres (cm) 5 = inches (in)

3 = millimetres (mm)

P006 EMPTY

Enter the maximum transducer face to surface distance, in Units (P005).

For mA input applications ( P004 = 250 ), set Empty value equal

to Span ( P007 ).

values: 0.000 to 9999 (preset to 8.000 m, or equivalent)

PARAMETERS

(see mA Input)

PL-507 63

Page 64

P007 SPAN

Enter the maximum surface distance from Empty (P006).

Span is automatically preset to 1.1 x the blanking value (P800) less than

the Empty value, unless it is altered manually.

For "distance" Operation (P001=3), Span is preset to Empty (P006).

Enter a lower value if desired. If the automatic setting is not high enough,

(see Transducer). Always prevent the monitored surface

from entering the blanking zone.

values: 0.000 to 9999

INSTALLATION

P008 (G) DATE

Enter the current date in YY.MM.DD format.

values: 00.00.00 to 99.12.31

P009 (G) TIME

Enter the current time in HH.MM.SS (24 hour) format.

values: 00.00.00 to 23.59.59

With the Quick Start Parameters altered as

required, proceed to to

OPERATION

identify / verify system performance

Year 2000 Compliance

The year is stored and displayed as a 2 digit number

from 00 to 99. Year values less than 69 are 21st

century (2000 – 2069). Year values greater than

70 are 20th century (1970 – 1999).

PL-507 64

Page 65

VOLUME PARAMETERS (P050 to P055)

sphere

Universal

Linear

If Readings proportional to volume are desired, adjust the following parameters.

P050 TANK SHAPE

Enter the Tank Shape option that matches the vessel monitored.

If additional vessel dimension entry is required, the

associated parameters

(as indicated below) may be scroll accessed.

When Operation is "level" (P001 = 1), liquid (material) volume is calculated.

Alternatively, when Operation is "space" (P001 = 2), remaining vessel

capacity is calculated.

In the RUN mode, Readings are displayed in percent of (and mA outputs

are proportional to) maximum volume. To convert Readings to volumetric

units, see Max Volume (P051).

values: 0 = volume calculation not required (preset)

1 =

flat level bottom

4 =

half sphere bottom

A

8 =

PARAMETERS

flat sloped bottom

cone / pyramid bottom

or

5 =

2 =

A

parabola bottom

6 =

3 =

A

7 =

PL-507 65

or

A

flat ends

parabola ends

L

A

9 =

10 =

Universal

Curved

Page 66

P051 MAX VOLUME

e.g. level breakpoint,

breakpoint 1,

value blank

For Readings in volumetric units (rather than percent), enter the vessel

between Empty (P006) and Span (P007).

volume

3

e.g. 1) If volume = 3650 m

, enter 3650.

2) If volume = 267500 gallons, enter 267.5 (1000’s of gallons).

values: 0.000 to 9999

P052 TANK DIMENSION A

Enter the height of the tank bottom if P050 = 2,3,4, or 5, or the length of

one end section of the tank if P050 = 7, in Units (P005).

values: 0.000 to 9999

P053 TANK DIMENSION L

Enter the tank length (excluding both end sections) if P050 = 7.

values: 0.000 to 9999

P054 LEVEL BREAKPOINTS (Universal Volume Calculation)

*

Enter the level breakpoints

(where volume is known) if P050 = 9 or 10.

values: 0.000 to 9999

P055 BREAKPOINT VOLUMES (Universal Volume Calculation)

*

Enter the volume

corresponding to each Level Breakpoint entered.

values: 0.000 to 9999

*

To enter a Level Breakpoint or Breakpoint Volume...

Enter the desired value.

Scroll ( or ) or direct access

the desired Breakpoint.

Refer to Volume Calculation

PL-507 66

for breakpoint value selection assistance.

TECHNICAL REFERENCE

e.g. 7.5 m

e.g. breakpoint 2

Page 67

READING PARAMETERS (P060 to P062)

Alter the following parameters to:

a) change the number of decimal places displayed.

b) convert the Reading to alternate units.

c) reference measurements to other than Empty (P006) or Span (P007).

P060 DECIMAL POSITION

Enter the maximum number of Reading decimal places to be displayed.

In the RUN mode, the number of decimal places displayed is automatically

adjusted (if necessary) to prevent the number of Reading digits from

exceeding display capabilities.

This value is automatically altered when Units (P005) and/or Max Volume

(P051) is altered.

values: 0 = no digits after the decimal point

1 = 1 digit after the decimal point

2 = 2 digits after the decimal point

3 = 3 digits after the decimal point

P061 CONVERT READING

Enter the value to multiply the Reading by, (before display).

This feature is preset to 1.000 (no conversion).

e.g. If the Reading is displayed in feet, to display in yards, enter 3.

PARAMETERS

Avoid entering a value that, when multiplied by the maximum

current Reading, could exceed 5 digits before the

values: -999 to 9999

PL-507 67

Decimal Position.

Page 68

P062 OFFSET READING

Enter the value to be added to the Reading, (before display).

This feature is preset to 0.000, (no offset).

e.g. To reference the current level to sea level, enter the distance in Units

(P005), between Empty (P006) and sea level. (Enter a negative value

if Empty is below sea level.)

This feature affects the Reading only.

(Relays and mA outputs are not affected).

values: -999 to 9999

Empty

(P006)

sea

level

display offset

vessel

(P062)

PL-507 68

Page 69

FAILSAFE PARAMETERS (P070 to P072)

As preset, if Failsafe Operation is activated, the display, alarm relays, and the mA

output are held at their last "known" values, and control relays de-energize, until a

valid measurement is regained.

To automatically operate alarms / controls under these conditions, alter the following

parameters as required.

FAILSAFE OPERATION

If Failsafe Operation is not required, proceed to RELAY PARAMETERS.

If a difficulty occurs, the display, relay status, and mA outputs are held at their last

"known" values and the Failsafe Timer is activated.

When a valid measurement is made before the Failsafe Timer (P070) expires, the

HYDRO+ advances to the "new" material level, per the Max Empty / Fill Rate (P700 /

P701, preset by Measurement Response, P003), and the timer resets.

If the timer expires, the HYDRO+ advances to the Failsafe Material Level (P071), per

Failsafe Advance (P072), operating relays per Relay Failsafe (P129) and the mA

output per mA Failsafe (P219).

When a valid measurement is made after the timer expires, the HYDRO+ advances to

the "new" material level, per Failsafe Advance, and the timer resets.

If Failsafe Operation is activated frequently, see TROUBLESHOOTING .

TROUBLESHOOTING

P070 FAILSAFE TIMER

Enter the time to elapse (in minutes), upon a measurement or

technical difficulty, before failsafe operation is activated.

If the timer expires due to a measurement difficulty, "LOE" flashes

in the Reading display.

Technical difficulty messages ("Short", "OPEn", and/or "Error") flash in

the Reading display before the timer expires. The offending terminal

connections are displayed in the Auxiliary Reading display.

PARAMETERS

Use a short duration Failsafe Timer value when fast

moving surfaces are monitored, however avoid entering

a value so short as to cause nuisance activation.

This value is automatically altered when Measurement Response (P003)

is altered. See TECHNICAL REFERENCE Measurement Response.

TECHNICAL REFERENCE

values: 0.000 to 9999

PL-507 69

Page 70

P071 FAILSAFE MATERIAL LEVEL

Select the material level to be reported when the Failsafe Timer expires.

"HOLd"

If

If

Failsafe Level Advance (P072).

If

per Failsafe Level Advance (P072).

Select the Failsafe Material Level based upon the relay and/or mA output

operation required during failsafe operation.

(preset) is selected, the "last known" material level is held.

"HI"

is selected, the HYDRO+ advances to the Span (P007) level, per

"LO"

is selected, the HYDRO+ advances to the Empty (P006) level,

e.g. 1) To de-energize a HI alarm relay, select "HI" (if P129 = "OFF").

e.g. 2) To force a low mA output, select "LO" (if P219 = "OFF").

Ensure relays and mA outputs used for Failsafe Operation

To select HI, LO, or HOLd...