Page 1

EnviroRanger ERS 500

33455560

Rev 2.0

Programming Reference

PL-556

Nov. 1999

Page 2

t Milltronics, we endeavour

Ultrasonic level

Capacitance

Radar

Po in t level

A

to design equipment that is

simple to use and reliable in its

operation, with the aim of

satisfying our customers' needs.

Milltronics has been designing

and manufacturing electronics

based process measurement

equipment since 1954. Our

fields of expertise include

continuous and point level

measurement, weighing and

feeding systems and motion

sensing.Technologies include

ultrasonic, capacitance and

microwave radar.

Communications

Weigh feeders

Motion sensing

Belt scales

Flowmeters

Acoustic sensing

Milltronics sells and markets

world wide through

subsidiaries, distributors and

representatives. Through

continuous improvement, we

are striving to provide our

customers with first rate sales

information, engineering

assistance and after sales

support.

For more details on our

products and services, please

contact us and we will provide

you with a listing of the offices

or representatives nearest you.

Page 3

Table of Contents

Introduction .......................................................................................... 7

About this Manual............................................................. 7

Using this Manual ............................................................. 8

About the EnviroRanger ...................................................................... 9

Display............................................................................10

Hand Programmer .......................................................... 11

Readings in Run Mode ...................................................12

Programming the EnviroRanger.......................................................15

Starting Program Mode...................................................16

Parameter Indexing.........................................................16

Changing Parameters (Dolphin Plus).............................. 17

Changing Parameters (Hand Programmer) .................... 18

Using Units or Percent (%).............................................. 18

Special Parameters.........................................................19

Parameter Reset............................................................. 19

Security........................................................................... 20

Displays ..........................................................................20

Planning Considerations...................................................................21

Review the Application.................................................... 21

Design the Control Scheme............................................ 21

Install the EnviroRanger.................................................. 21

Program the EnviroRanger.............................................21

Test the Installation.........................................................22

Document the Installation................................................22

Application Examples........................................................................23

Simple Level and Alarms ................................................ 23

Pump Control..................................................................26

Open Channel Monitoring (OCM) ...................................32

Gate Control.................................................................... 44

Rake (Screen) Control....................................................46

Testing the Configuration.................................................................. 49

Simulation....................................................................... 49

I/O Checkout...................................................................51

Application Test ..............................................................52

Programming Documentation .........................................52

Parameter Reference.......................................................................... 55

How to Read the Reference............................................55

Quick Start (P001 to P009) .............................................57

Volume (P050 to P055)................................................... 62

PL-556 EnviroRanger Programming Reference Page 3

Page 4

Display and Reading (P060 to P062)..............................66

Failsafe (P070 to P072) ..................................................69

Relays (P100 to P119).................................................... 72

Pump Setpoint Modifiers (P121 and P122)..................... 88

Independent Relay Failsafe (P129)................................. 90

Advanced Pump Control Modifiers (P130 to P136)......... 91

Pump Energy Cost Reduction (P140 to P145)................95

Overflow / Underflow (P160 to P169)..............................99

Flush Systems (P170 to P173) ..................................... 103

Pump Efficiency (P180 to P186) ................................... 105

mA Input (P250 to P254)............................................... 108

mA Input Trim (P260 to P262) ...................................... 110

Discrete Input Functions (P270 to P275)......................111

Data Logging (P300 to P321)........................................ 115

Record Temperatures (P300 to P303)..........................115

Record Readings (P304 and P305) .............................. 117

Pump Records (P310 to P312) ..................................... 118

Overflow (CSO) Records (P313 to P316).....................119

Flow Records (P320 and P321)....................................120

LCD Totalizer (P322 and P323)....................................121

Profile Records (P330 to P337) .................................... 122

Auto Record “on” and “off” Setpoints (P334 to P337) ... 125

Installation Records (P340 to P342) ............................. 127

Pump Interlock Allocation (P500 to P509).....................128

Pump Fault Status (P510 to P515) ...............................134

Pump Control Source (P520 to P524)........................... 138

OCM (P600 to P621) ....................................................140

Pumped Volume Totalizer (P622 to P623).................... 148

Totalizer (P630 to P645)............................................... 150

Range Calibration (P650 to P654) ................................ 154

Temperature Compensation (P660 to P664) ................157

Rate (P700 to P708) .....................................................159

Measurement Verification (P710 to P713) ....................162

Transducer Scanning (P726 to P728)...........................164

Display (P730 to P739)................................................. 166

SmartLinx Reserved (750 to 769) ................................. 169

Communications (P770 to P782)..................................170

SmartLinx Hardware Testing.........................................175

Echo Processing (P800 to P807).................................. 176

Advanced Echo Processing (P810 to P825)................. 180

Profile Pointer (P817 to P825) ......................................182

Advanced TVT Adjustment (P830 to P835) .................. 185

Advanced Shot Adjustment (P840 to P852).................. 188

Test (P900 to P913)...................................................... 190

Measurement (P920 to P927).......................................193

Master Reset (P999).....................................................196

Page 4 EnviroRanger Programming Reference PL-556

Page 5

Appendix A – Technical Reference.................................................197

Transmit Pulse.............................................................. 197

Echo Processing........................................................... 197

Distance Calculation ..................................................... 198

Sound Velocity.............................................................. 199

Scanning....................................................................... 199

Volume Calculation....................................................... 200

Flow Calculation............................................................ 201

Maximum Process Speed.............................................203

Appendix B – Troubleshooting.......................................................205

Common Problems Chart..............................................205

Noise Problems............................................................. 206

Measurement Difficulties...............................................209

Fixed Reading............................................................... 211

Wrong Reading............................................................. 213

Transducer Ringing.......................................................214

Appendix C – Pump Control............................................................ 215

Pump Control Options................................................... 215

Discrete Inputs.............................................................. 216

Pump Control Algorithms .............................................. 216

Other Pump Controls....................................................221

Appendix D – Discrete inputs.......................................................... 223

Wire the Discrete Input .................................................223

Program the Discrete Input Logic..................................223

Program the Interlock Logic..........................................224

Test the Interlock ..........................................................226

Index.................................................................................................. 227

PL-556 EnviroRanger Programming Reference Page 5

Page 6

Page 6 EnviroRanger Programming Reference PL-556

Page 7

Introduction

The EnviroRanger is intended for advanced water and wastewater

applications. This device can handle virtually all of your pump control and

level monitoring needs – often replacing expensive PLCs and integrating into

a SCADA system for a fraction of the cost of competitive systems.

The EnviroRanger is programmable.

It can be configured for nearly any water or wastewater application and

control up to five pumps, gates, or alarms – and can communicate its status

by way of direct serial connection, modem, or industrial communication

network.

The EnviroRanger is flexible.

It can take discrete input from pumps or other devices and modify its

operation based on that input. It can also time events to maximize efficiency

or minimize cost.

About this Manual

Introduction

This is the Programming Reference manual for the Milltronics EnviroRanger

integrated level monitoring and control system.

The manuals in the EnviroRanger library are:

Manual Uses

Programming Reference

(PL-556)

Installation Guide

(PL-557)

Communications Reference

(PL-558)

• Parameter values

• Parameter uses

• Programming methods

• Outline diagrams

• Wiring diagrams

• Installation requirements

• MODBUS register mapping

• Modem configuration

PL-556 EnviroRanger Programming Reference Page 7

Page 8

Introduction

Using this Manual

Information Section Page

Learn the concepts behind how

the EnviroRanger operates.

Learn how to change parameter

values.

To configure the EnviroRanger

for a particular application.

To test the unit’s programming

before putting it into full

operation..

Find detailed information about

any parameter.

Find detailed information on

how the EnviroRanger uses

ultrasonic technology to detect

levels and convert them to

usable values.

If your EnviroRanger installation

is experiencing problems.

To look up a concept or

keyword.

About the EnviroRanger 9

Programming 15

Application Examples 23

Testing the Configuration 49

Parameter Reference 55

Appendix A – Technical

Reference

Appendix B –

Troubleshooting

Index 227

197

205

Page 8 EnviroRanger Programming Reference PL-556

Page 9

About the EnviroRanger

The EnviroRanger has two modes of operation:

Program Mode

Program mode allows the programmer to change parameter values and alter

the way the unit operates.

Note:

• If the unit has been programmed and is in normal operation then

putting it in program mode will de-energize all control relay outputs.

Therefore it is advisable to bypass the EnviroRanger while

programming the unit to avoid overflows.

• After a programming alteration, do not use the EnviroRanger to

operate alarms or controls until system programming and performance

is verified.

To enter Program mode from Run mode:

About the EnviroRanger

1. Press the program button on the front of the device (Rack or Panel only)

2. Look for the program icon on the display (

3. Press

If the EnviroRanger is idle in Program mode for more than 5 minutes, then

Run mode is automatically entered.

For information on the individual programming parameters see the chapters

Application Examples on page 23 or Parameter Reference on page 55.

and then .

) (Rack or Panel only)

Run Mode

Run mode detects material level and provides control functions. The

EnviroRanger automatically starts up in the Run mode when power is

applied.

To enter Run mode from Program mode, press

“----“ is displayed briefly while the measurement reading is calculated and

verified. Reading level and other data is displayed and any relays are

operated based on the unit’s programming.

.

While the unit is in Run mode you can view system status. This information

is shown on the LCD on the front of the unit or can be accessed remotely

using communications software.

PL-556 EnviroRanger Programming Reference Page 9

Page 10

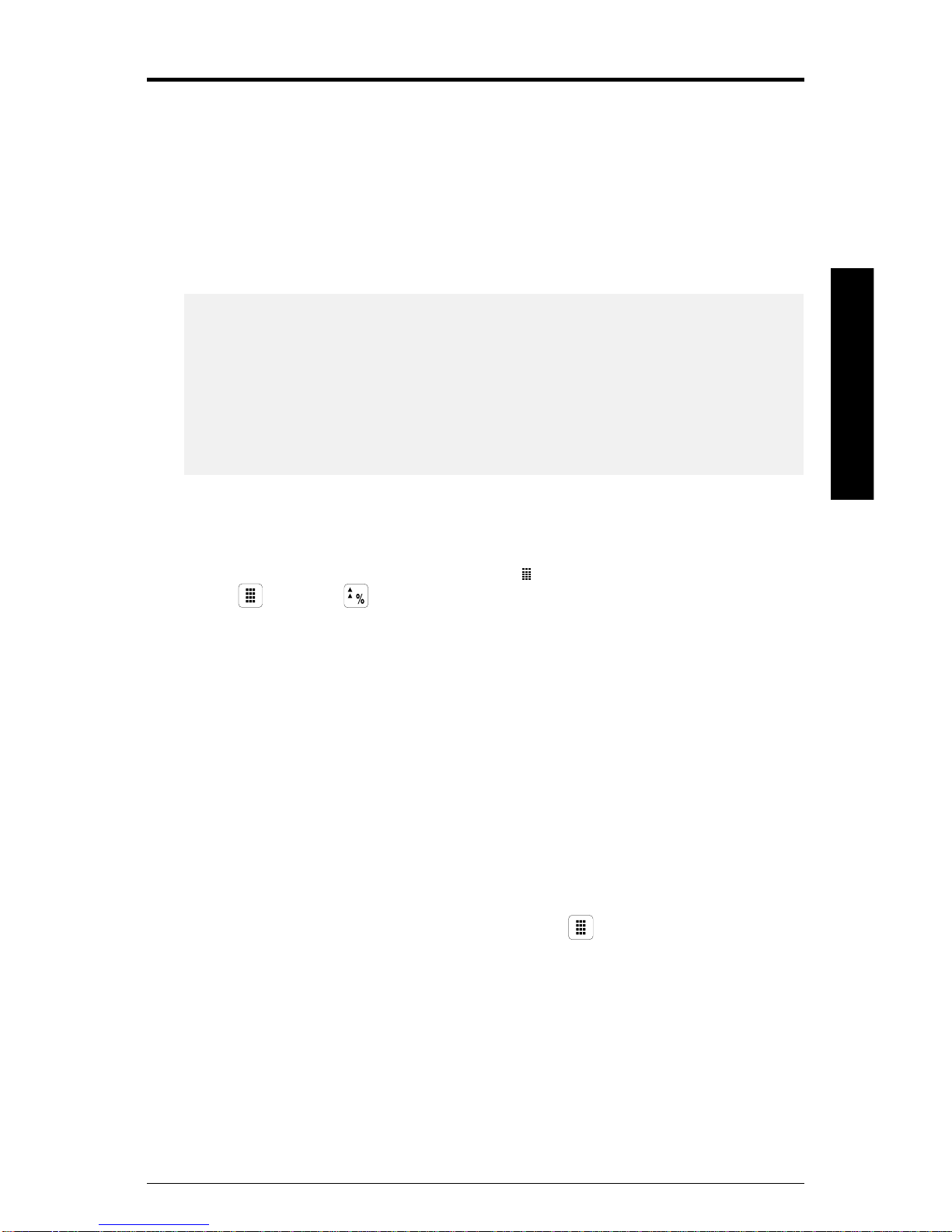

Display

About the EnviroRanger

Wall Mount Rack or Panel Mount

Program Mode Run Mode

1 index type index type

2 index index

3 parameter value primary reading

4 units units

5 auxiliary function hi and hi hi alarm

6 n/a level display

7 scroll access tag filling display

8 scroll access tag emptying display

9 n/a loandloloalarm

relay # programmed

10

flashing = unavailable

11 relay # activated relay # activated

12 parameter number auxiliary reading

13 n/a

14 n/a failsafe operation:

15 program mode programming enabled

relay # programmed

flashing = unavailable

normal operation:

Page 10 EnviroRanger Programming Reference PL-556

Page 11

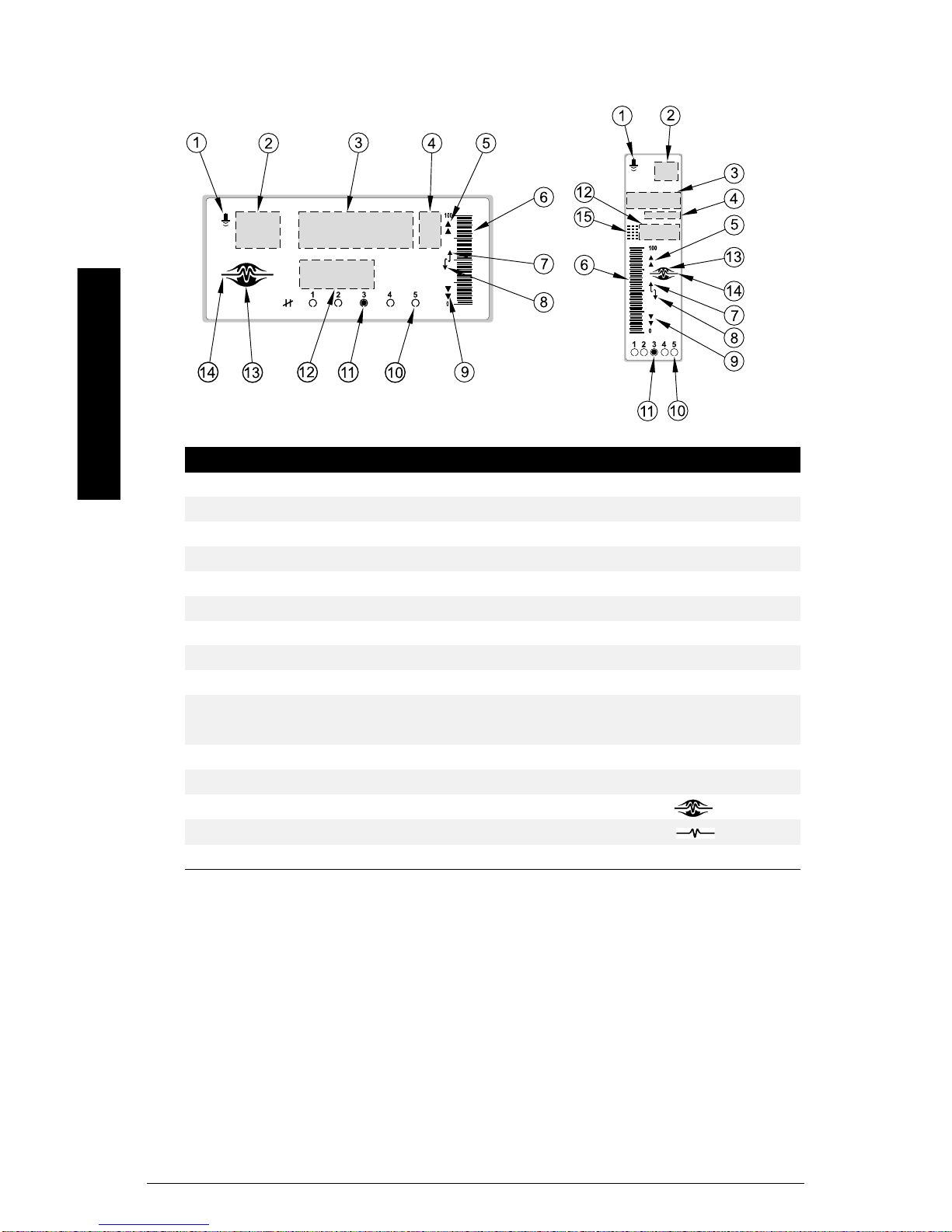

Hand Programmer

y

Note:

The hand programmer is ordered separately from Milltronics.

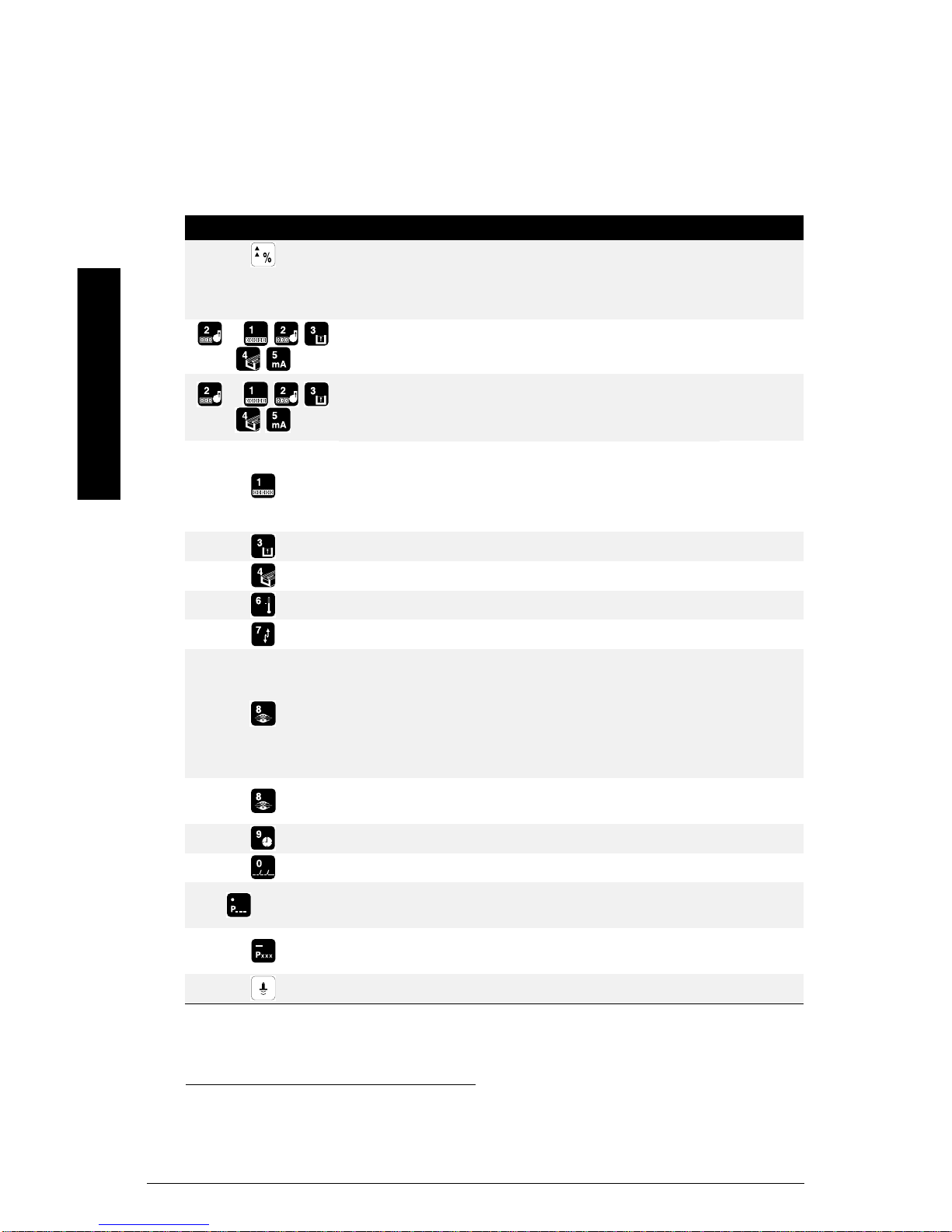

Function

Key Programming Mode Run Mode

1 8-digit Totalizer (toggle)

2 Pump Running Time

3 Head

4 Flow based on Head

5

6 Temperature

7 Rate of Change

Numeric

and

Auxiliar

About the EnviroRanger

8 Failsafe Time Left

9Time

0 Date

Decimal Point (TVT left) Parameter Value

Negative Value (TVT right) Material Level (P731)

Fire Transducer Distance

Run Mode Program Mode (Key 1)

Units or % Units or % (Program Mode (Key 2))

Next Display Field Pause Display Toggle

Increase Value Next Index

Decrease Value Previous Index

Enter Value

,

Clear to Preset

PL-556 EnviroRanger Programming Reference Page 11

Page 12

Readings in Run Mode

When the EnviroRanger is in run mode the values displayed can be changed

by using keys on the hand programmer.

All readings are shown in the Auxiliary field except for the totalizer and P920.

PressthisKey Function P#

Toggle Readings between percent and units P920

Level Space or Distance

0 to 100% 100 to 0%

+

Accumulated pump running hours2for

numbered pump

1

P310

About the EnviroRanger

+

Hold number key for five seconds to display

the number of accumulated pump starts2for

P311

numbered pump

8-digit totalizer, uses index and reading

areas, press again to toggle, P737 sets

default

P322,

P323,

P920

Used for OCM and Pumped Volume.

Head measurement

Instantaneous flow based on head (OCM)

Temperature

Rate of level change

P926

P925

P664

P707

Failsafe Time Left (in %). When the Reading

is updated, this value (Auxiliary Reading)

resets to 100 and begins to decrease until

the next valid measurement is made. If the

Failsafe Time Left reaches 0, “LOE” flashes

in the Reading display.

Hold for four seconds to show echo

P805

confidence

Time (hh:mm)

P009

+ ###

1

Distances less than 0.3m (12”) from the transducer face cannot be reliably measured

so a 0% rea ding cannot be achieved during “distance” operation.

2

If the associated relay is programmed for pump control.

Page 12 EnviroRanger Programming Reference PL-556

Date (dd:mm or mm:dd as P736)

Display the value of the entered parameter

which is global or indexed by transducer

Auxiliary reading, displays parameter

specified in P731

Distance

P008

typed

number

P731

P923

Page 13

Scrolling Display

During “differential” or “average” Operation (P001 = 4 or 5), the display

scrolls sequentially through Point Numbers 1, 2, and 3. Point Number 3

represents the difference between or average of Point Numbers 1 and 2.

See Display (P730 to P739) on page 166 for more information.

About the EnviroRanger

PL-556 EnviroRanger Programming Reference Page 13

Page 14

About the EnviroRanger

Page 14 EnviroRanger Programming Reference PL-556

Page 15

Programming the EnviroRanger

To meet the needs of any given application the EnviroRanger must be

correctly programmed. The EnviroRanger is programmed by changing

parameter values. The available parameters are described in detail in the

Parameter Reference on page 55 and sample applications are given in

Application Examples on page 23.

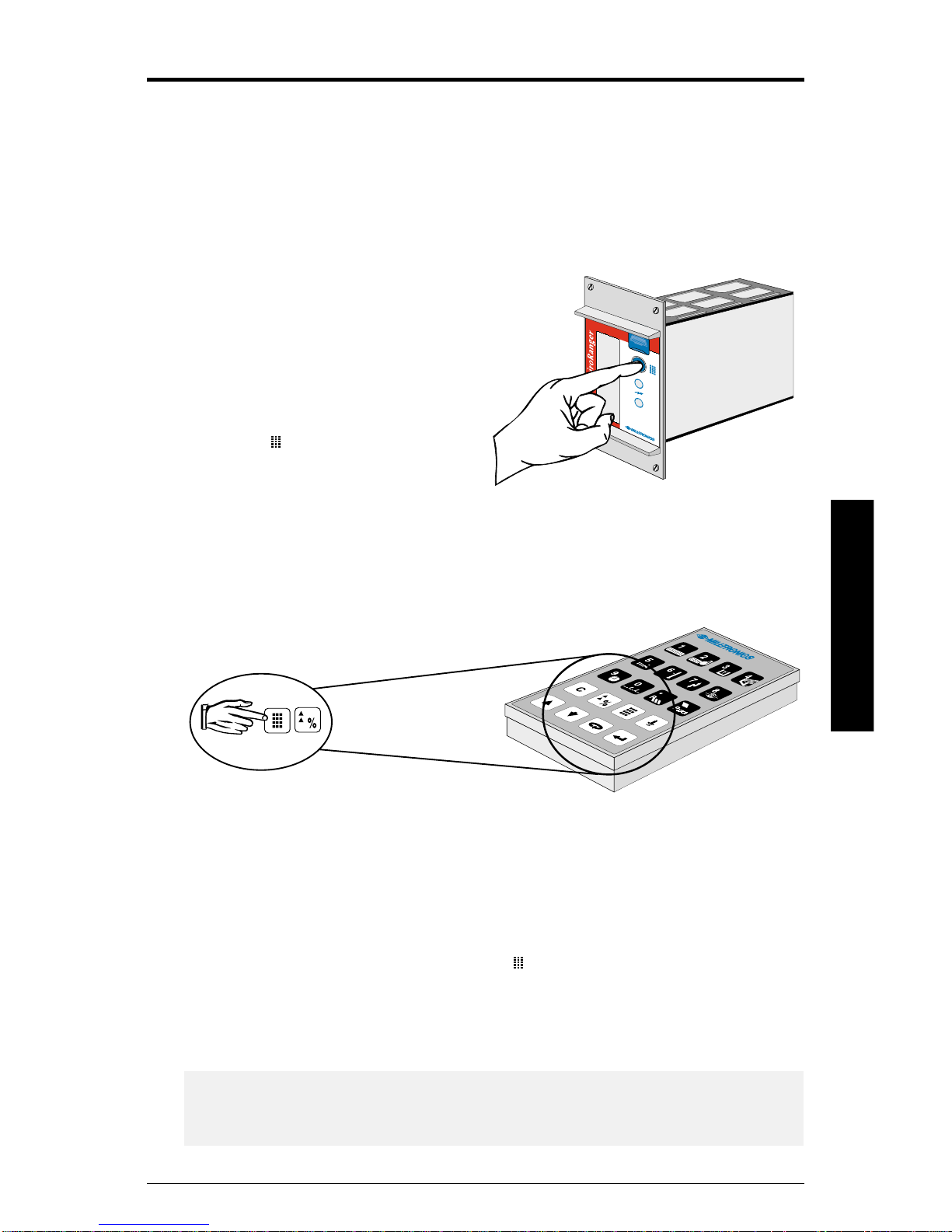

Rack or Panel Mount

To enter program mode on a rack

or panel mount unit:

Press the program button on the

front of the unit (shown at right)

This icon (

canbeplacedinprogrammode.

) appears when the unit

Wall Mount

The wall mount version has no program button, it is always ready for

program mode.

Aim the hand programmer and press the program keys on the hand

programmer (shown above).

Programming

The program button allows multiple units to be installed close together and

still be programmed one at a time.

Program mode is confirmed by the icon (

disable programming, press again. Run mode is confirmed by absence of

the icon in the display. Disable all nearby units to avoid inadvertent

programming when using the infrared handheld programmer.

Note:

Unless otherwise noted, each valid key press should produce a change in

the LCD, look for this when programming the unit.

PL-556 EnviroRanger Programming Reference Page 15

) appearing in the display. To

Page 16

Starting Program Mode

Entering program mode has the following effects:

• all operating data is retained in memory

• alarm relay status is held at last known values

• control relays are de-energized (unless affected by parameter alteration or

is pressed)

• discrete inputs are detected but not acted on

The Run mode is automatically re-entered if the EnviroRanger is left

unattended in the program mode for an extended period (approximately 5

minutes).

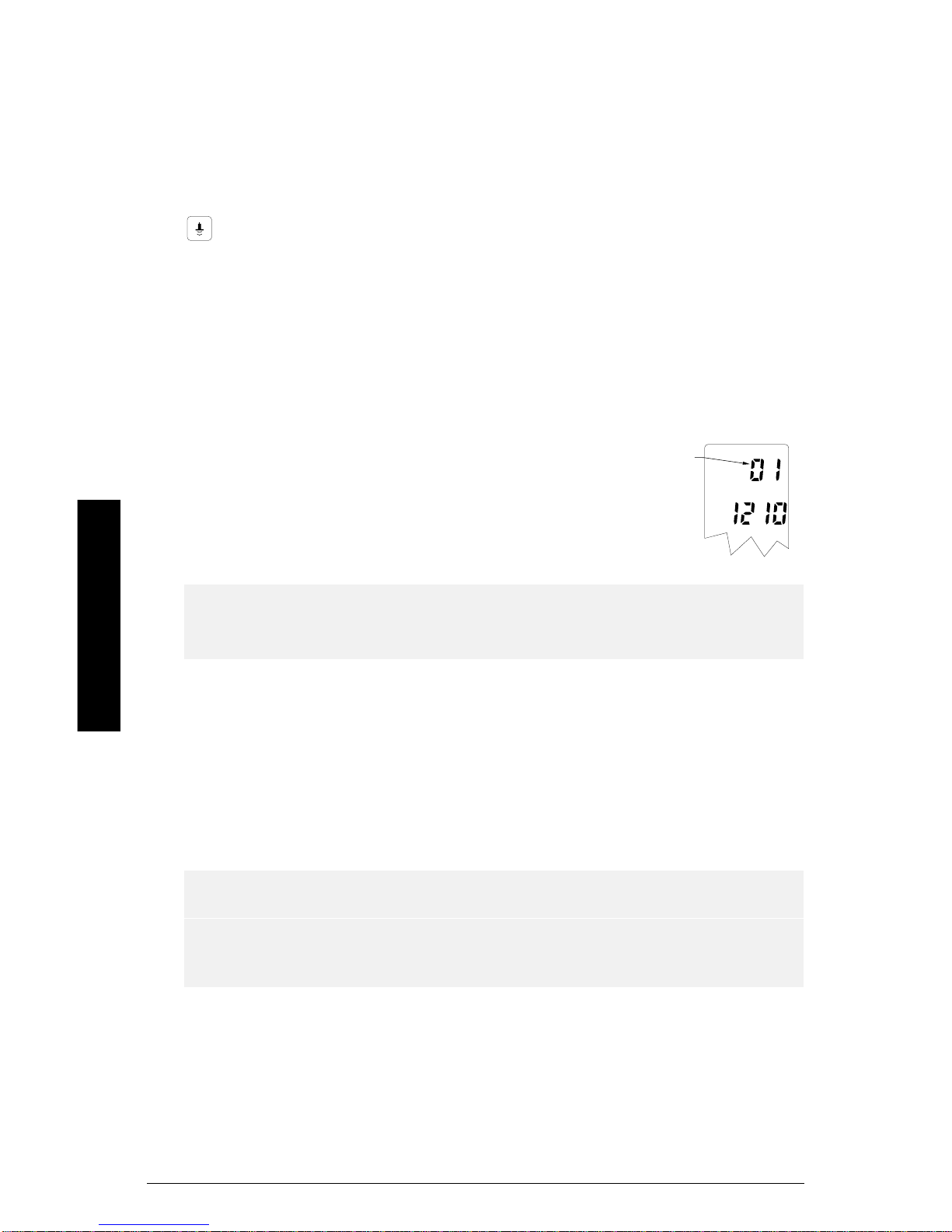

Parameter Indexing

Parameters are indexed if they can apply to more

than one input or output. The index value defines to

which input or output the particular parameter value

relates. Indexed parameters contain a value for

each index, even if that index is not used.

Note:

To set all indexed values for a given parameter to the same value use

index “0”.

Programming

For example, to change the Relay Control Function (P111) for relay three

you must ensure that “03” is displayed in the index field before you change

the parameter value.

In this manual parameter index values are shown in brackets after the

parameter number. For example P111[3] refers to parameter 111 index

value 3.

Note:

Transducer parameters are indexed only if Operation (P001) is set to

“Difference” (value=4) or “Average” (value=5). An indexed transducer is

commonly referred to as a Point (short for measurement point). The term

Point Number refers to indexed transducers.

index

field

rack or panel display shown

Page 16 EnviroRanger Programming Reference PL-556

Page 17

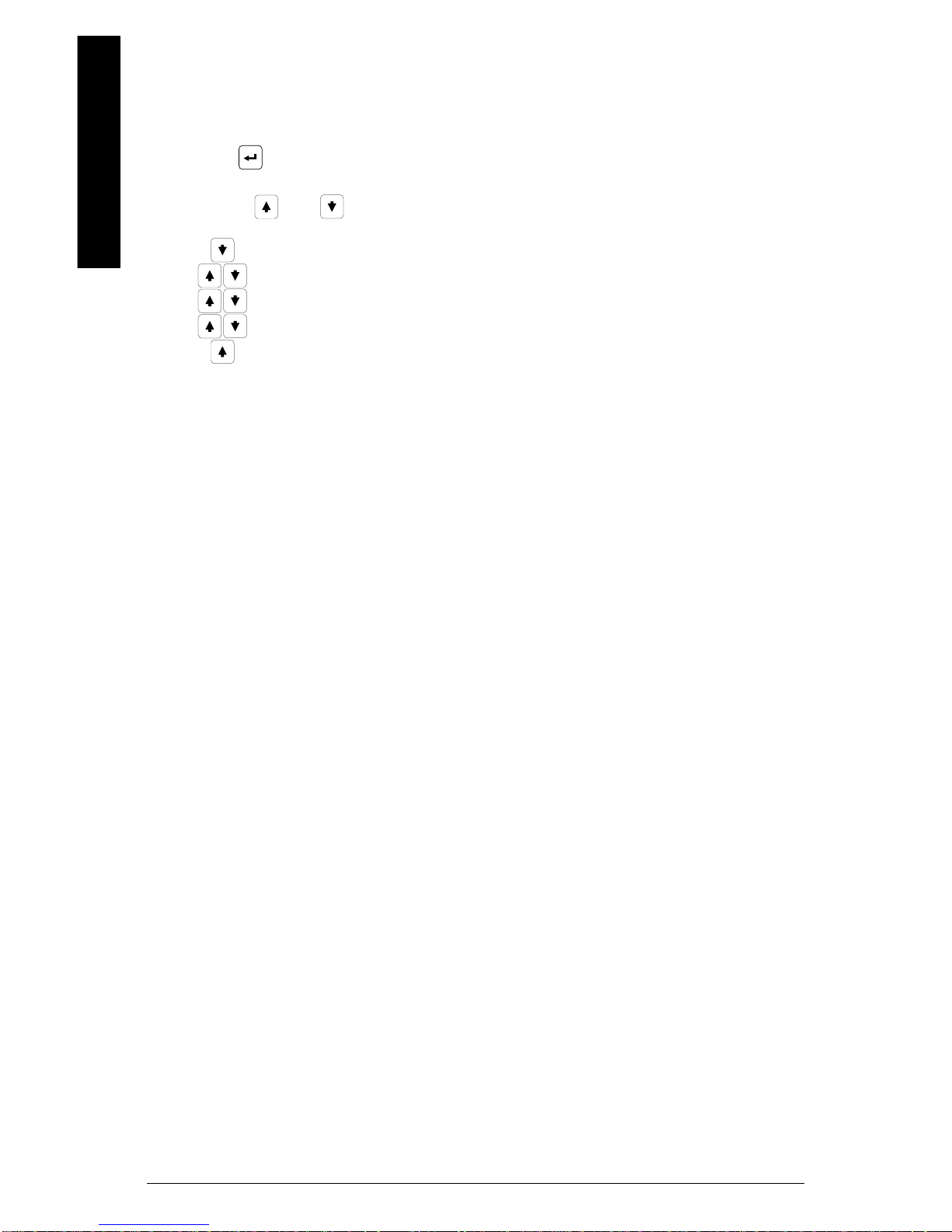

To access the index of a particular parameter:

w

r

r

• Press

once

• Enter the parameter number

• Press

twice

• Press the number of the required index, or

• Press

or to scroll through the available values

Note:

When dealing with indexed parameters it is critical to ensure that you set

the values accurately. Take extra time to ensure that the correct index

value is being changed for each parameter value.

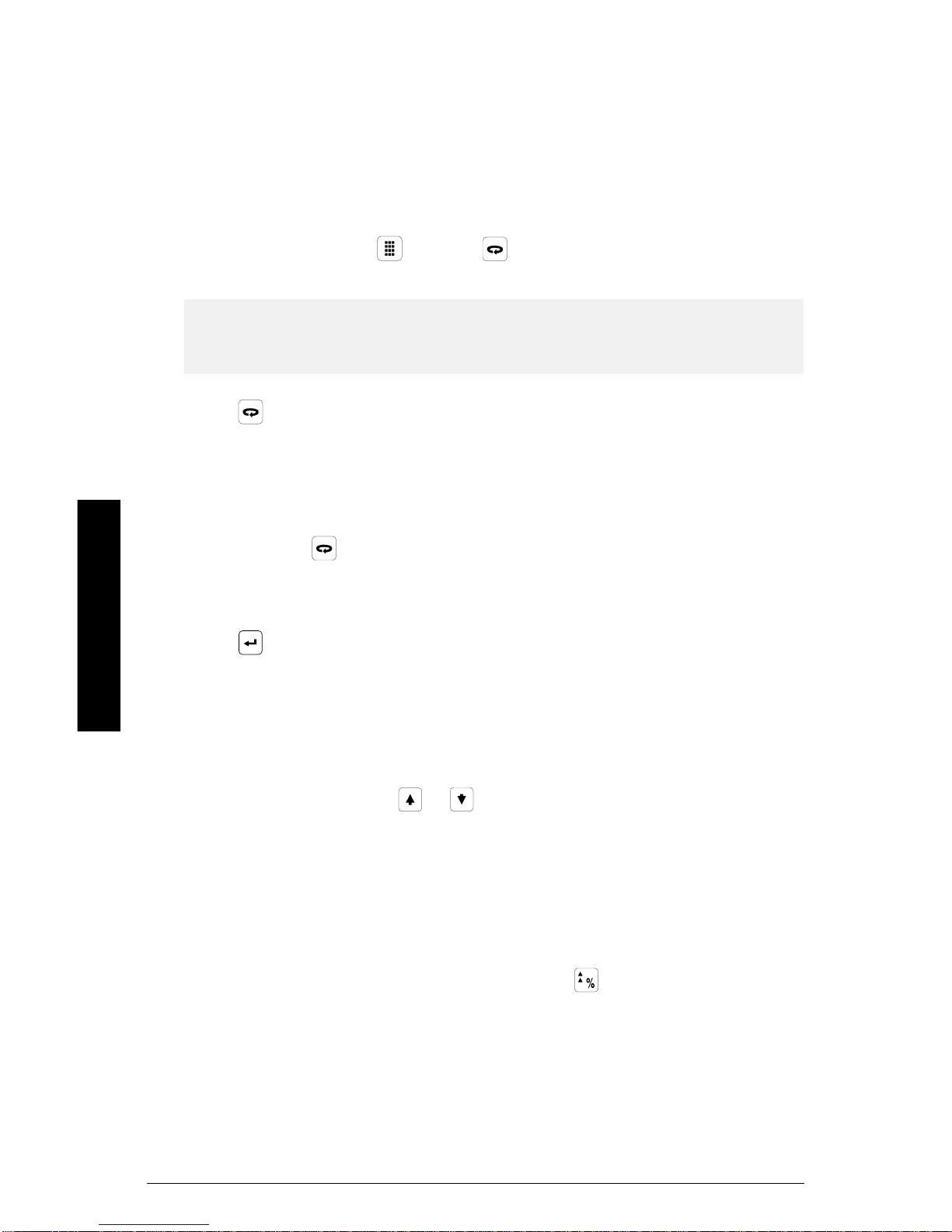

Changing Parameters (Dolphin Plus)

Tabs sho

groups of

parameters

Parameters have

roll-overs which

show numbe

Programming

The attached

device can be

programmed,

debugged, and

monitored from

Dolphin Plus

The status bar

informs you of

program actions

and data transfer

status

Parameters can

be tracked while

the EnviroRange

is running

PL-556 EnviroRanger Programming Reference Page 17

Page 18

Dolphin Plus is the primary method of changing EnviroRanger parameters.

Most examples in this manual use the icons from the hand programmer but

nearly all functions are also available through Dolphin Plus.

The Dolphin Plus software is available separately from Milltronics.

Changing Parameters (Hand Programmer)

1. From Run mode, press and then to put the unit into Program mode.

Note:

If Parameter Value alteration is not permitted, access the Lock parameter

(P000) and enter the security code, (see Programming Security).

2. Press to select the Parameter Number field (see page 10)

3. Type the Parameter Number (e.g. 110)

When you type the third digit the value for that parameter is shown

For lower numbered parameters, such as 007, you can type the number “7”

and then press

4. Type the new value

5. Press

Programming

The EnviroRanger interprets the value and either accepts it, or replaces it

with a valid value. See the Parameter Reference for descriptions of values.

The “?” icon indicates that the EnviroRanger has accepted the value but that

it conflicts with other values entered. Double-check your programming.

By default the scroll keys (

and any that have been changed. Use P733 (G) Scroll Access on page 167

to allow all parameters to be scroll-accessed.

Using Units or Percent (%)

Many parameters can be viewed in either measurement units (P005) or

percent. View the parameter and then press the

units and percent. The LCD shows the current measurement type, either

units (m, mm, ft, etc.) or percent (%).

to show that parameter.

to enter the new value

or ) only show the Quick Start parameters

key to toggle between

Page 18 EnviroRanger Programming Reference PL-556

Page 19

Special Parameters

View Only

Some Parameter Values are for display purposes only and cannot be

altered. These are referred to as view only parameters.

In the Parameter Reference section of this instruction manual, view only

parameters are identified by a “(V)” beside the Parameter Number.

Global

Some parameter values must be common for all inputs and outputs on the

EnviroRanger. These are referred to as global parameters.

When a global parameter is accessed, the index display automatically

disappears. When a non-global parameter is accessed, the index previously

selected for that parameter is displayed.

In the Parameter Reference section of this manual, Global parameters are

identified by a “(G)” beside the Parameter Number.

Indexed

Some parameter values relate to indexed items. Examples of this are

parameters which are different for each:

• Relay, shown with an “(IR)”

• Transducer, shown with an “(IT)”

• Discrete Input, shown with an “(IDI)”

For full descriptions of parameters and how they are indexed, see How to

Read the Reference on page 55.

Parameter Reset

To set any parameter back to the factory default:

• Display the appropriate parameter number

• Display the appropriate index value (if required)

• Press

• Press

Programming

To reset all parameters to preset values, see Master Reset (P999).

Perform a Master Reset (P999) to reset all parameters to “original” values

before initial system installation, following a software upgrade, or whenever

complete reprogramming is required. Use Dolphin Plus to store and retrieve

parameter groups.

PL-556 EnviroRanger Programming Reference Page 19

Page 20

Security

All operator programming is retained in non-volatile memory, immune to power

interruptions. When programming is complete, the programmer may be locked

away to prevent inadvertent programming alteration. As well, the Lock (P000)

parameter may be used.

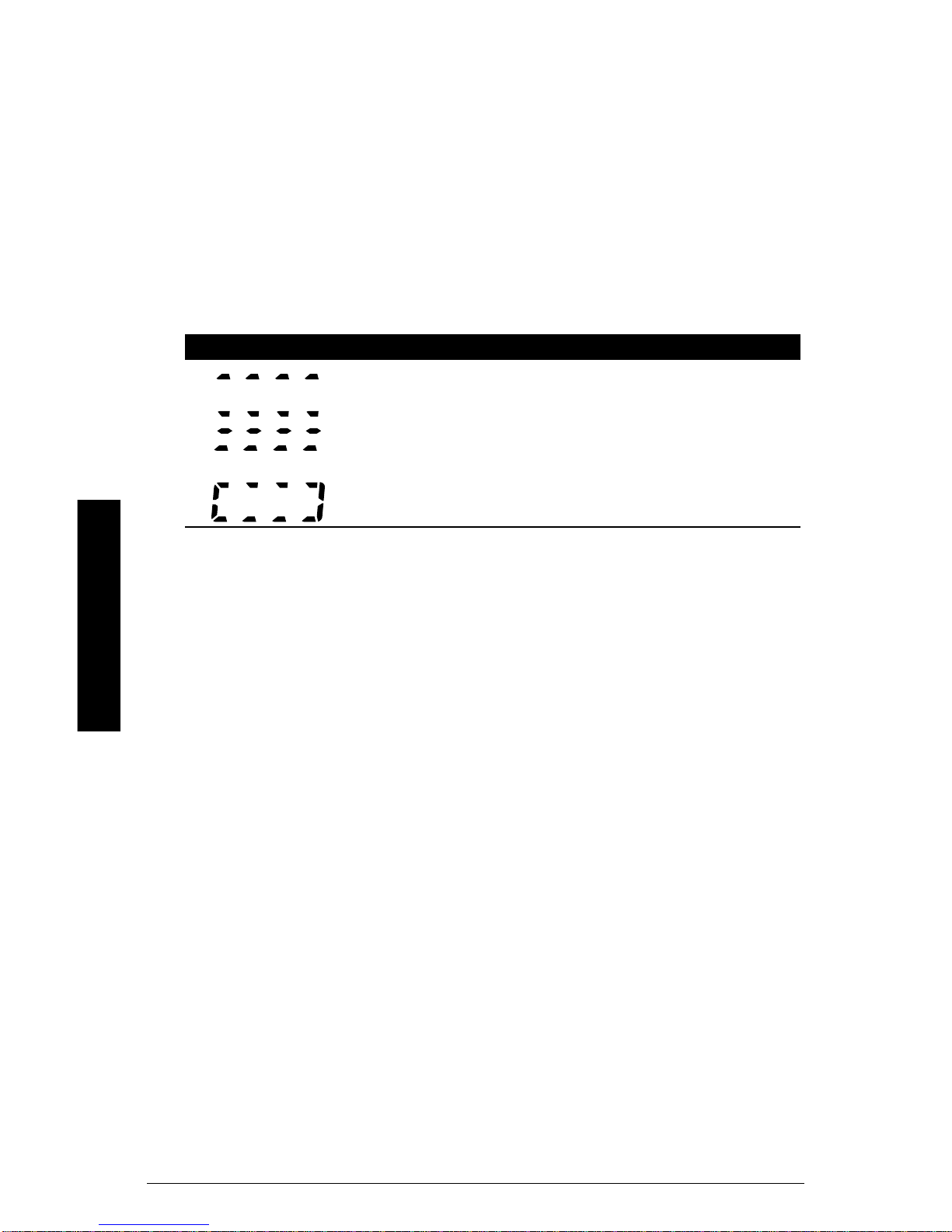

Displays

The following displays are shown when the EnviroRanger cannot display a

number.

Display Meaning

parameter has not been set

all values not same when viewing index 0

parameter entered does not exist for this device

Programming

Page 20 EnviroRanger Programming Reference PL-556

Page 21

Planning Considerations

Review the Application

When reviewing the application into which the EnviroRanger will be installed,

note the:

• Pump control system inputs and outputs

• Dimensions of the wet well or reservoir (especially if pumped volume will be

used)

• Maximum measurement distance required (will determine transducer

requirement)

• Communication type required (modem, industrial communication network)

Design the Control Scheme

Choose the most appropriate pump control strategy from those available.

See Appendix C – Pump Control on page 215 for a description of the

EnviroRanger pump control strategies and options.

Map the Control Scheme to EnviroRanger

Once the control scheme is designed, map its requirements to the

EnviroRanger’s parameters. Be aware of the EnviroRanger’s abilities:

• Number of relay outputs (5)

• Number of discrete inputs (8)

• Number of mA inputs (1)

Install the EnviroRanger

Mount and wire the EnviroRanger as detailed in the EnviroRanger

Installation Guide (PL-557).

Program the EnviroRanger

Use the Application Examples (page 23) and Parameter Reference (page

55) to determine the best method of programming the EnviroRanger to

satisfy the control scheme.

Planning

Use either Dolphin Plus or a hand programmer to set the parameter values

to those required.

PL-556 EnviroRanger Programming Reference Page 21

Page 22

Test the Installation

Test the inputs and outputs as shown in Testing the Configuration on page

49.

Document the Installation

Use Dolphin Plus to record your parameter values for later reference.

Planning

Page 22 EnviroRanger Programming Reference PL-556

Page 23

Application Examples

Note:

When the unit is first turned on it will give distance (P001=3) in meters

from the transducer face to the material surface. If the wet well or reservoir

is empty then this reading is the empty distance (P006) from the

transducer face to the reservoir bottom. P006 is preset to 5.0m (16.4’), so

reservoirs deeper than that will read LOE until P006 is updated.

Output Limitations

The standard EnviroRanger comes with 5 relay outputs. Each relay is

programmed using P111 (IR) Relay Control Function (see page 74) from a

large number of options. Use these application examples as a guideline for

the relay programming.

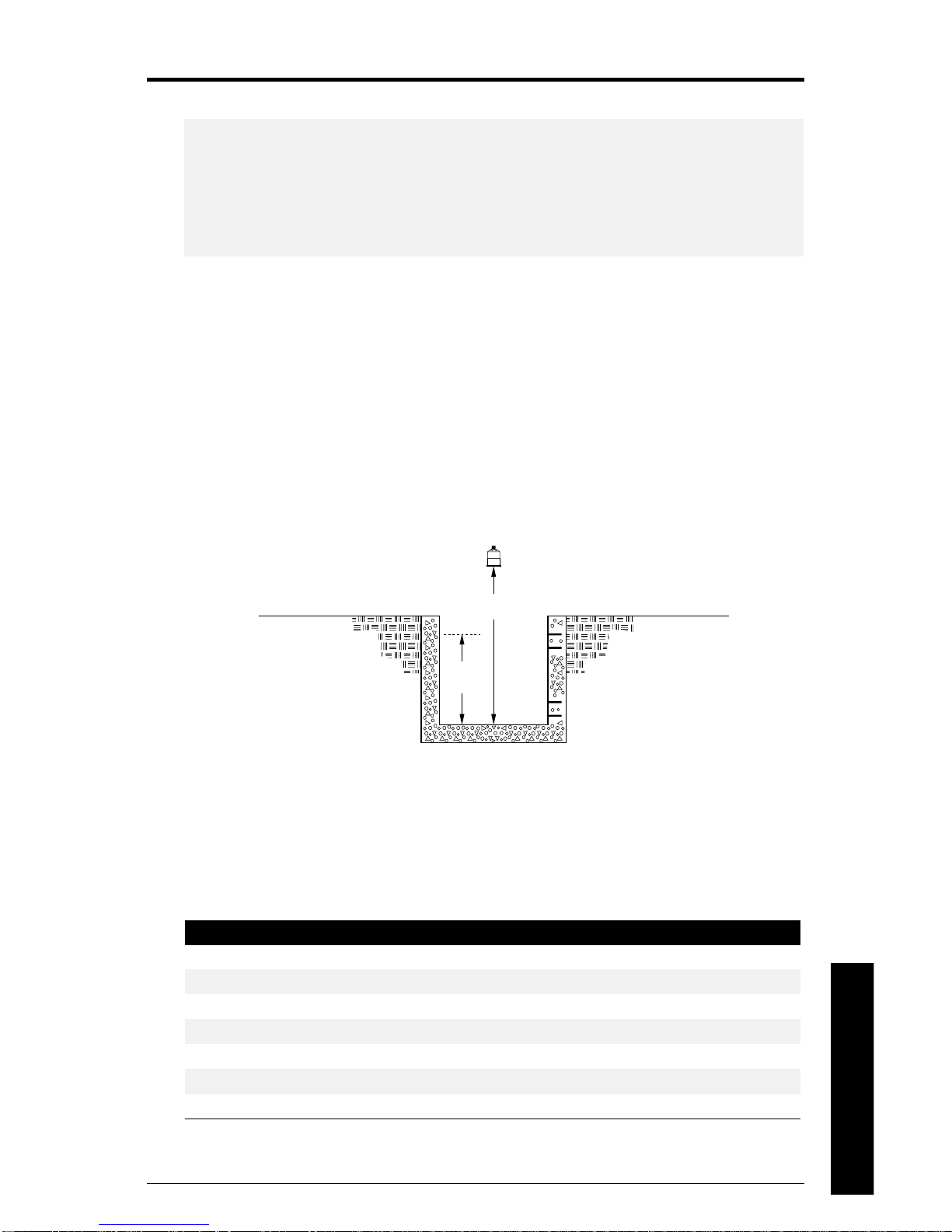

Simple Level and Alarms

See Parameter Reference on page 55 for complete details on specific

parameter values.

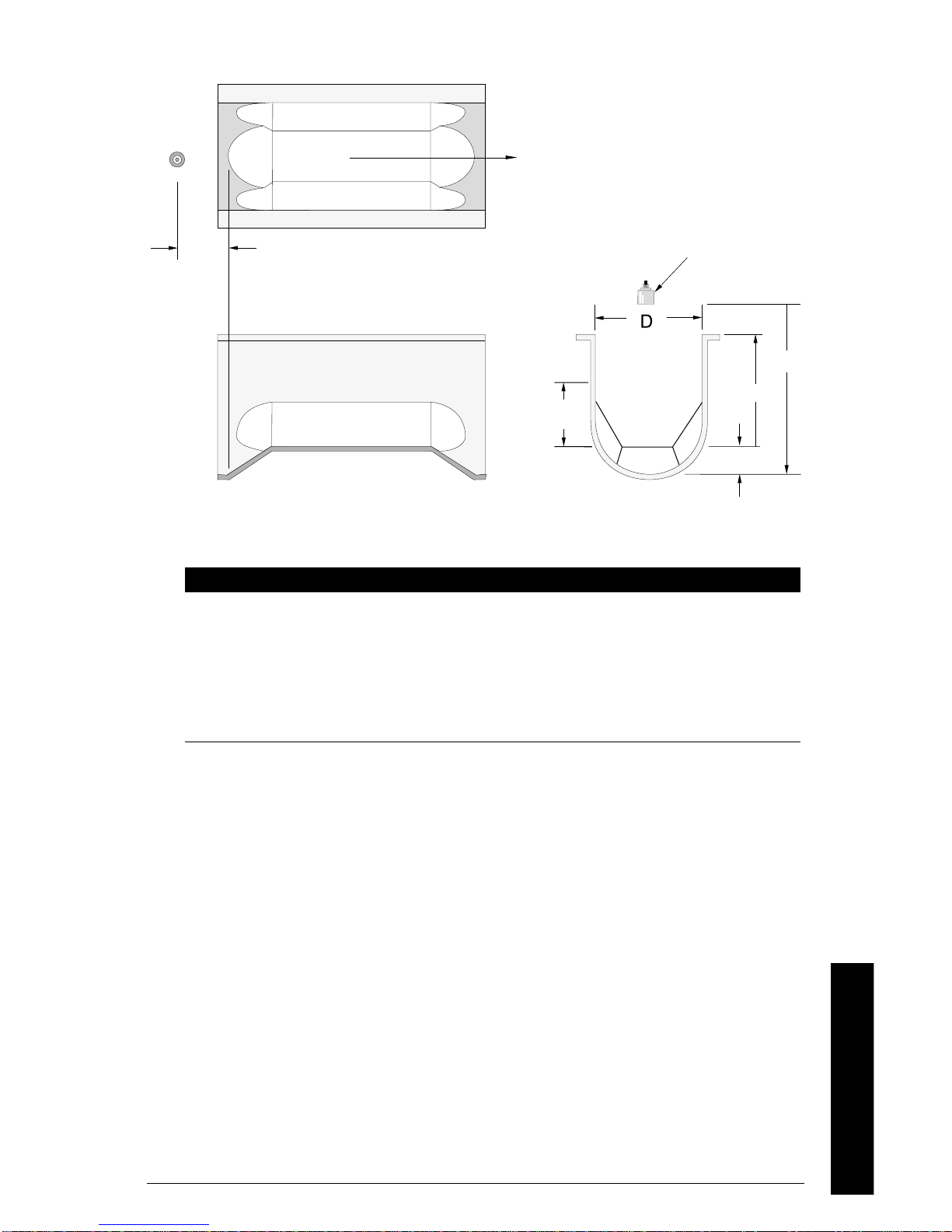

P006

hi hi

hi

P007

lo

lo lo

Set the Common Parameters

Prerequisite: You must know the details of your application and substitute

the values for the sample values provided. If you are bench testing the unit

then set your test values to be the same as the sample values.

Parameter Index Value Description

P001 G 1 Operation = level

P002 G 1 Material = liquid

P003 G 2 Maximum Process Speed = medium

P004 G 102 Transducer = XPS-10

P005 G 1 Units = meters

P006 G 1.8 Empty = 1.8m

P007 G 1.4 Span = 1.4m

Applications Examples

PL-556 EnviroRanger Programming Reference Page 23

Page 24

Setting a High High Alarm

Parameter

P111 1 1

P112 1 1.2m

P113 1 1.15m

Relay

Index

Value Description

These settings trip the alarm when the

level rises above 1.2m and reset the

alarm when the level falls below 1.15m.

Setting a Low Alarm

Parameter

P111 3 1

P111 Aux. L

P112 3 0.3

P113 3 0.4

To select a Level Alarm Designation (L,LL,H,HH or blank) do the following:

1. Press

2. Press

3. Press

to display the Auxiliary Function symbol,

or as required to scroll to the alarm designation,

to enter the value.

Relay

Index

Value Description

These settings trip the alarm when the

level falls below 0.3m and reset the

alarm when the level rises above 0.4m.

The low alarm (▼) icon is displayed on

the LCD when the alarm is tripped.

Setting a Loss of Echo (LOE) Alarm

Parameter

P111 5 6

P070 G 0.5

Relay

Index

Value Description

These settings trip the alarm when 0.5

minutes (30 seconds) pass without a

valid echo being detected.

Setting an Out of Bounds Alarm

Parameter

P111 5 3

P112 5 1.3

P113 5 0.3

P116 5 0.05

Relay

Index

Value Description

These settings do the following:

trips alarm resets alarm

above 1.35m below 1.25m

below 0.25m above 0.35m

Application Examples

Page 24 EnviroRanger Programming Reference PL-556

Page 25

Setting a Filling Rate Alarm

Parameter

P111 5 4

P112 5 1m

P113 5 0.9m

Relay

Index

Value Description

These settings trip the alarm when the

reservoir is filling faster than 1m per

minute and reset it at 0.9m per minute.

Setting an Emptying Rate Alarm

Parameter

P111 5 4

P112 5 -10%

P113 5 -5%

Relay

Index

Value Description

These settings trip the alarm when the

reservoir is emptying faster than 10% of

span per minute and reset the alarm

when emptying falls to 5%..

PL-556 EnviroRanger Programming Reference Page 25

Applications Examples

Page 26

Pump Control

See Parameters section for complete details on specific parameter values.

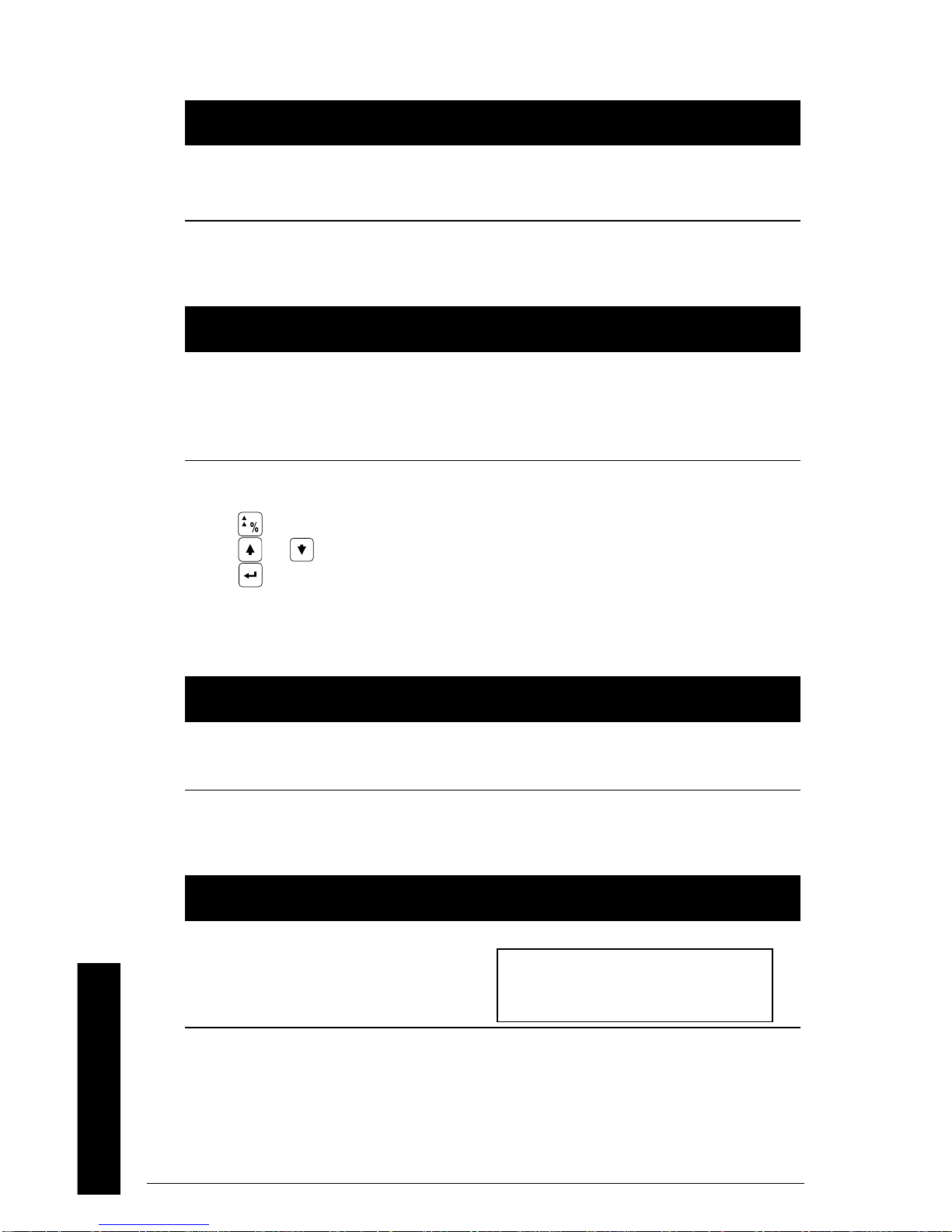

Setting a Pump Down (Wet Well) Group

Sets a group of three pumps to pump down a wet well.

EnviroRanger with

advanced pump

control algorithms

P006

outflow

inflow

P007

Set the Common Parameters

Prerequisite: You must know the details of your application and substitute

the values for the sample values provided. If you are bench testing the unit

then set your test values to be the same as the sample values.

Parameter Index Value Description

P001 G 1 Operation = level

P002 G 1 Material = liquid

P003 G 2 Maximum Process Speed = medium

P004 G 102 Transducer = XPS-10

P005 G 1 Units = meters

P006 G 1.8 Empty = 1.8m

P007 G 1.4 Span = 1.4m

Set the Pump Relays to “Alternate duty assist”

Parameter

P111 1 52

P111 2 52

P111 3 52

Application Examples

Page 26 EnviroRanger Programming Reference PL-556

Relay

Index

Value Description

Sets the pump relays (index 1, 2, and 3)

to “alternate duty assist”.

Page 27

Set the “On” Setpoints

Parameter

P112 1 1.0m

P112 2 1.1m

P112 3 1.2m

Relay

Index

Value Description

Sets the three setpoints for the pump

relays. The first cycle will use these

setpoints. Subsequent cycles rotate the

setpoints among the pumps.

Set the “Off” Setpoints

Parameter

P113 0 0.5m

Relay

Index

Value Description

By using index 0 all five relays are set

at the same time, including any alarm

relays. Use index 0 with caution.

Optional: Starting Pumps by Rate of Level Change

Parameter

P112 1 1.35

P112 2 1.35

P112 3 1.35

P113 1 0.5m

Relay

Index

Value Description

Starting pumps by rate allows all

setpoints to be set higher to save money

by pumping from the highest safe level of

the wet well.

P113 2 0.5m

P113 3 0.5m

P121 1 1

P121 2 1

P121 3 1

P132 G 20.0

Notice that all indexed relays for both

P112andP113aresettothesame

levels.

The pumps will start on 20 second

intervals until the rate set in P703 is met.

Optional: Rotating Pumps by Service Ratio

Prerequisite: the pump relays must be set to a “service ratio” value (P111 =

54 or 55).

Parameter

P122 1 1

P122 2 2

P122 3 1

Relay

Index

Value Description

These values will start pump 2 50% of

the time and pumps 1 and 3 25% of the

time each.

Applications Examples

PL-556 EnviroRanger Programming Reference Page 27

Page 28

Optional: Totalizing Pumped Volume

Prerequisite: the volume of the wet well or reservoir must be known.

Parameter Index Value Description

P001 G 7 Operation = pumped volume

P002 G 1

P003 G 2

P004 G 102

P005 G 1

P006 G 1.8

P007 G 1.4

P050 G 1 Tank volume is “flat-bottom”

P051 G 17.6 Max volume is 17.6 m3or 17,600 liters

P111 1 52

P111 2 52

P111 3 52

P112 1 1.0

P112 2 1.2

P112 3 1.4

P113 0 0.2 Sets the “off” setpoints for all relays.

These parameters are “as above.”

Sets relays 1, 2, and 3 as a pump group

using Alternate Duty Assist control.

Sets the “on” setpoints for the pump

group.

Run Mode

• Press

• Press

• Press

to enter Run mode.

to display the pumped volume on the totalizer.

to display the current level in the auxiliary reading area.

Other Optional Functions

Function Page Description

Independent Failsafe 90 Overrides default per relay

Pump Run-on 91 Pumps past “off” setpoint

Pump Start Delay 92 Staggers pump starts

Power Resumption Delay 92 Delays first pump start

Pump Exercising 93 Pumps based on time

Wall Cling Reduction 93 Randomizes setpoints

Pump Group 94 Separates pump groups

Pump Energy Saving 95 Pumps during low cost periods

Overflow Handling 99 Reaction to overflow events

Flush Systems 103 Controls a flush device

Pump Efficiency Testing 105 Removes poor performing pumps

Application Examples

Page 28 EnviroRanger Programming Reference PL-556

Page 29

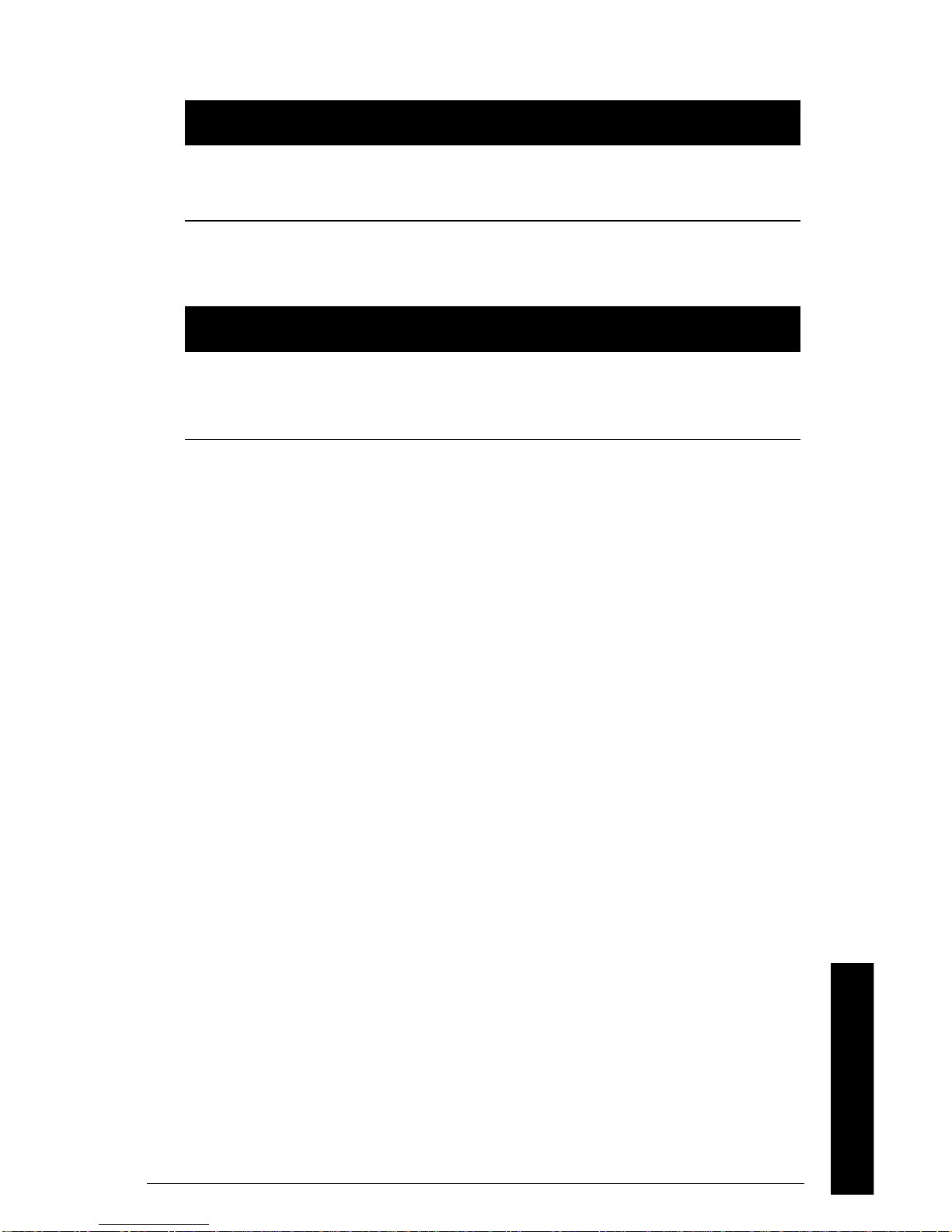

Setting a Pump Up (Reservoir) Group

Sets a group of three pumps to pump up a reservoir.

EnviroRanger with

advanced pump

control algorithms

P006

inflow

P007

outflow

Set the Common Parameters

Prerequisite: You must know the details of your application and substitute

the values for the sample values provided. If you are bench testing the unit

then set your test values to be the same as the sample values.

Parameter Index Value Description

P001 G 1 Operation = level

P002 G 1 Material = liquid

P003 G 2 Maximum Process Speed = medium

P004 G 102 Transducer = XPS-10

P005 G 1 Units = meters

P006 G 1.8 Empty = 1.8m

P007 G 1.4 Span = 1.4m

Set the Pump Relays to “Alternate Duty assist”

Parameter

P111 1 52

P111 2 52

P111 3 52

PL-556 EnviroRanger Programming Reference Page 29

Relay

Index

Value Description

Sets the pump relays (index 1, 2, and

3) to “alternate duty assist”.

Applications Examples

Page 30

Set the Relay “On” Setpoints

Parameter

P112 1 0.4m

P112 2 0.3m

P112 3 0.2m

Relay

Index

Value Description

Set the Relay “Off” Setpoints

Parameter

P113 0 1.3m

Note:

Optional parameters found on page 28.

Relay

Index

Value Description

Sets the three setpoints for the pump

relays. The first cycle will use these

setpoints. Subsequent cycles rotate

the setpoints among the pumps.

By using index 0 all relays are set to

the same value.

Application Examples

Page 30 EnviroRanger Programming Reference PL-556

Page 31

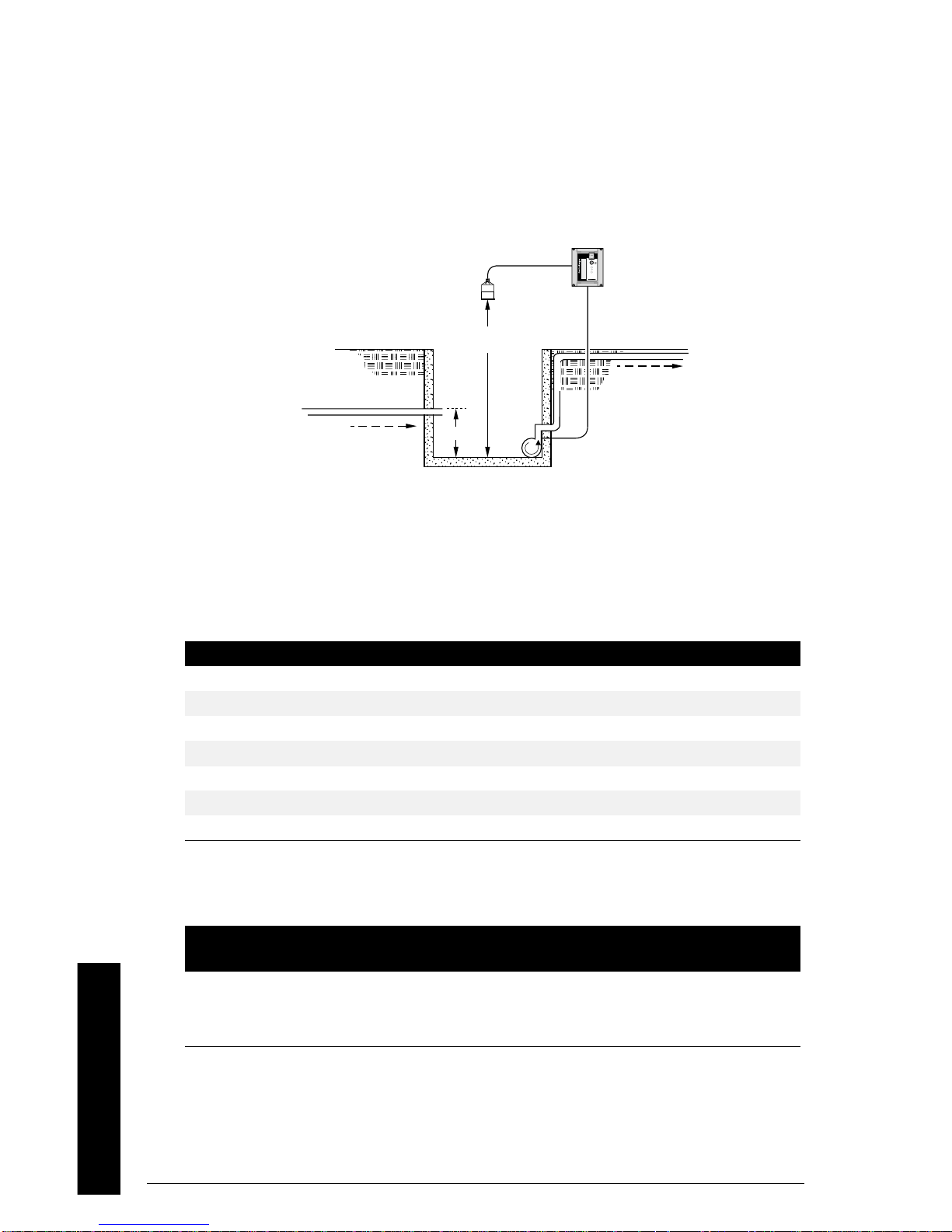

Connecting a Pump Control Interlock

P006

EnviroRanger with

advanced pump control

algorithms using pump

interlocks

outflow

discrete input

relay output

Parameter

inflow

Relay

Index

P007

Value Description

P111 1 52

P111 2 52

Sets the pump relays (index 1, 2, and

3) to “alternate duty assist”.

P111 3 52

P505 1 3

P505 2 4

P505 3 5

Sets discrete inputs 3, 4, and 5 as the

inputs for the pumps attached to relays

1, 2, and 3 respectively.

These values will ensure that any pump reporting a failure is removed from

the pumping rotation. For more information on pump interlocks and discrete

inputs see:

• Discrete Input Functions (P270 to P275) on page 110

• Pump Interlock Allocation (P500 to P509) on page 128

• Appendix C – Pump Control on page 215

PL-556 EnviroRanger Programming Reference Page 31

Applications Examples

Page 32

Open Channel Monitoring (OCM)

See Parameters section for complete details on specific parameter values.

There are three ways of defining an OCM installation depending on your

Primary Measuring Device (PMD). See the listed examples for required

parameters.

• Dimensional

is provided for some common weir and flume typ es. For these PMDs the

dimensions (P602) are entered directly.

• Exponential

is provided for most other weir and flume types. For these PMDs the

exponent provided by the manufacturer is entered. Flow is calculated using

the exponent (P601) and the maximum values (P603 and P604).

• Universal

is provided to accommodate any installation not covered by the first two

types. For all other PMDs the head-to-flow curve can be plotted and

approximated based on known breakpoints, usually supplied by the PMD

manufacturer.

Dimensional (P600=2,3,6,7)

• BS-3680 / ISO 1438/1 Thin plate V notch weir on page 35

• BS-3680 / ISO 4359 Rectangular Flume on page 36

• Palmer Bowlus Flume on page 37

• H Flume on page 38

Exponential (P600=1)

• Standard Weirs on page 39

• Parshall Flume on page 40

• Leopold Lagco on page 41

• Cut Throat Flume on page 42

Universal (P600=4,5)

• Typical Flow Characterization on page 42

• Example Flumes on page 43

• Example Weirs on page 43

Application Examples

Page 32 EnviroRanger Programming Reference PL-556

Page 33

Set the Common Parameters

These “Quick Start” parameters are required for all installations.

Dimension examples

on next page.

Parameter Index Value Description

P001 G 6 Operation = OCM

P002 G 1 Material = liquid

P003 G 2 Maximum Process Speed = medium

P004 G 102 Transducer = XPS-10

P005 G 1 Units = meters

P006 G 1.8 Empty = 1.8m

P007 G 1.0 Span = 1.4m

P801 G 0.8 Range Extension to avoid “LOE”

PL-556 EnviroRanger Programming Reference Page 33

Applications Examples

Page 34

Setting Zero Head

Many PMDs trap a pool of liquid when there is no flow. There are two

methods of accounting for this trapped liquid:

1. Use P605 Zero Head to raise the start of Span (P007) above the Empty

distance (P006). See P605 (G) Zero Head on page 143.

P006

P007

P605

P603

2. Use P801 Range Extension to ignore readings below the artificially-short

Empty distance (P006). See P801 (G) Range Extension on page 176.

P006

P603

P007

P801

The examples on the following pages show both methods.

Application Examples

Page 34 EnviroRanger Programming Reference PL-556

Page 35

Setting Totalized Volume

To display the totalized volume on the LCD use the following parameters:

Parameter Index Value Description

P737 G 2

Show the eight digit totalizer in the

primary display

Direct Support

BS-3680 / ISO 1438/1 Thin plate V notch weir

transducer

4to5xh

max

(h

= P007)

max

notch angle

P602

P006

P603

P007

P801

Parameter Index Value

P600 G 7 – ISO 1438/1 V Notch Weir

P602 1 Notch angle

(view only)

P603 G Maximum Head (preset to P007)

P801 G Range Extension

P608 G Flowrate Units

PL-556 EnviroRanger Programming Reference Page 35

Applications Examples

2 Discharge coefficient (Ce)

Page 36

BS-3680 / ISO 4359 Rectangular Flume

h

3to4xh

P006

max(hmax

= P007)

L

flow

transducer

h

P605 (p)

Parameter Index Value

P600 G 6 – ISO 4359 Rectangular Flume

P602 1 Approach width (B)

2 Throat width (b)

3 Hump Height (p)

4 Throat length (L)

(view only) 5 Velocity coefficient (Cv)

(view only) 6 Discharge coefficient (Cd)

(view only) 7 Cross sectional area

P605 G Zero Head

P608 G Flowrate Units

flow (P608)

Application Examples

Page 36 EnviroRanger Programming Reference PL-556

Page 37

Palmer Bowlus Flume

Flow

D/2, point of

measurement

Side view

Plan view

P603

Front view

Parameter Index Value

P600 G 2 – Palmer Bowlus Flume

P602 1 Flume width (D)

P603 G Maximum Head (preset = P007)

P604 G Maximum Flow

P605 G Zero Head

P606 G Time Units

transducer

P006

P007

P605

• Sizedbypipediameter,D

• Flume relief is trapezoidal

• Designed to install directly into pipelines and manholes

• Head is referenced to bottom of the throat, not bottom of the pipe

• For rated flows under free flow conditions, the head is measured at a

distance of D/2 upstream from the beginning of the converging section

PL-556 EnviroRanger Programming Reference Page 37

Applications Examples

Page 38

HFlume

r

Parameter Index Value

transduce

point of measurement

plan view

P006

P007

front view side view

P600 G 3–HFlume

P602 1 Flume height (D)

P603 G Maximum Head (preset = P007)

P604 G Maximum Flow

P606 G Time Units

• Sized by maximum depth of flume, D

• Approach is preferably rectangular, matching width and depth for distance 3

to 5 times the depth of the flume

• May be installed in channels under partial submergence (ratio of

downstream level to head). Typical errors are:

• 1% @ 30% submergence

• 3% @ 50% submergence

• For rated flows under free flow conditions, the head is measured at a point

downstream from the flume entrance

Flume Size

(D in feet)

Point of Measurement

cm inches

0.5 5 1¾

0.75 7 2¾

1.0 9 3¾

1.5 14 5½

2.0 18 7¼

2.5 23 9

3.0 28 10¾

4.5 41 16¼

• H flumes come with a flat or sloping floor. The same flow table can be used

as error is less than 1%.

Application Examples

Page 38 EnviroRanger Programming Reference PL-556

Page 39

PMDs with Exponential Flow to Head Function

For Primary Measuring Devices (PMDs) that measure flow by an exponential

equation use these parameters. Ensure that you use the correct exponent

for your PMD, the values below are samples only.

Standard Weirs

weir profile

Applicable Weir Profiles

transducer

V-notch or

triangular

suppressed

rectangular

cipolleti or

trapezoidal

sutro or

proportional

Parameter Index Value

P600 G 1 – Exponential Function

P601 G

Weir Type Value

†

V-notch 2.50

Suppressed rectangular 1.50

Cipolletti or trapezoidal 1.50

Sutro or proportional 1.00

P603 G Maximum Head

P604 G Maximum F low

P606 G Time Units

P801 G Range Extension

† These values are samples only. Consult your weir manufacturer’s

documentation for the correct flow exponent.

Applications Examples

PL-556 EnviroRanger Programming Reference Page 39

Page 40

Non-Applicable Weir Profiles

2

contracted

compound Poebing

approximate

rectangular

Flows through these weirs can be measured using the universal flow

calculation P600 = 4 or 5. See Universal Calculation Support on page 42.

Parshall Flume

C

C = converging dimension

/3C

Plan View

transducer

exponential

• sized by throat width

• set on solid foundation

• For rated flows under free flow conditions the head is measured at

Application Examples

P006

Front View Side View

2

/3the

length of the converging section from the beginning of the throat section.

Parameter Index Value

P600 G 1 – Parshall Flume

P601 G 1.22 – 1.607 (consult your flume documentation)

P603 G Maximum Head

P604 G Maximum Flow (Q)

P606 G Time Units

Page 40 EnviroRanger Programming Reference PL-556

Page 41

Leopold Lagco Flume

converging diverging

throat

plan view

transducer

point of measurement

P007

P603

0

side view

Head

front view

P605

Parameter Index Value

P600 G 1 – Leopold Lagco Flume

P601 G 1.55

P603 G Maximum Head (preset P007)

P604 G Maximum Flow

P605 G Zero Head

P606 G Time Units

• Designed to be installed directly into pipelines and manholes

• Leopold Lagco may be classed as a rectangular Palmer-Bowlus flume

• Sized by pipe (sewer) diameter

• For rated flows under free flow conditions the head is measured at a point

upstream referenced to the beginning of the converging section. Refer to the

following table:

P006

diameter in inches)

4-12 2.5 1

15 3.2 1¼

18 4.4 1¾

21 5.1 2

24 6.4 2½

30 7.6 3

42 8.9 3½

48 10.2 4

54 11.4 4½

60 12.7 5

66 14.0 5½

72 15.2 6

PL-556 EnviroRanger Programming Reference Page 41

Point of MeasurementFlume Size (pipe

cm inches

Applications Examples

Page 42

CutThroatFlume

Plan View

• Similar to Parshall flume except that the floor is flat bottomed and throat has

no virtual length.

• Refer to manufacturer’s specifications for flow equation and point of head

measurement.

Parameter Index Value

P600 G 1 – Cut Throat Flume

P601 G 1.55

P603 G Maximum Head (preset P007)

P604 G Maximum Flow

P606 G Time Units

Universal Calculation Support

When the primary measuring device (PMD) doesn’t fit one of the standard

types it can be programmed using a universal characterization. When

Universal is selected as the PMD type (P600) then both P610 and P611

must be entered to define the flow.

Two curve types are supported:

• P600 = 4 – linear (piecewise linear)

• P600 = 5 – curved (cubic spline)

Both are shown in the following chart:

Typical Flow Characterization

Maximums (P603, P604)

linear

Flow (P611)

Application Examples

Page 42 EnviroRanger Programming Reference PL-556

curved

Head (P610)

Page 43

Characterization is achieved by entering the head (P610) and corresponding

flow (P611), either from empirical measurement or from the manufacturer's

specification. The more breakpoints that are defined, the more accurate will

be the flow measurement. Breakpoints should be concentrated in areas

exhibiting the higher degrees of non linear flow. A maximum of 32

breakpoints can be defined. The curve’s end point is always specified by the

parameters Maximum Head (P603) and Maximum Flow (P604) for a

maximum total of 33 breakpoints.

Use as many breakpoints as required by the complexity of your PMD.

See Flow Calculation on page 201 for more information.

Example Flumes

These example flumes would both require a universal calculation.

Trapezoidal

Dual Range (nested) Parshall

Example Weirs

These weirs could require universal calculation.

contracted

rectangular

For further information regarding universal flow calculations, see Flow

Calculation on page 201.

compound Poebing

Applications Examples

approximate

exponential

PL-556 EnviroRanger Programming Reference Page 43

Page 44

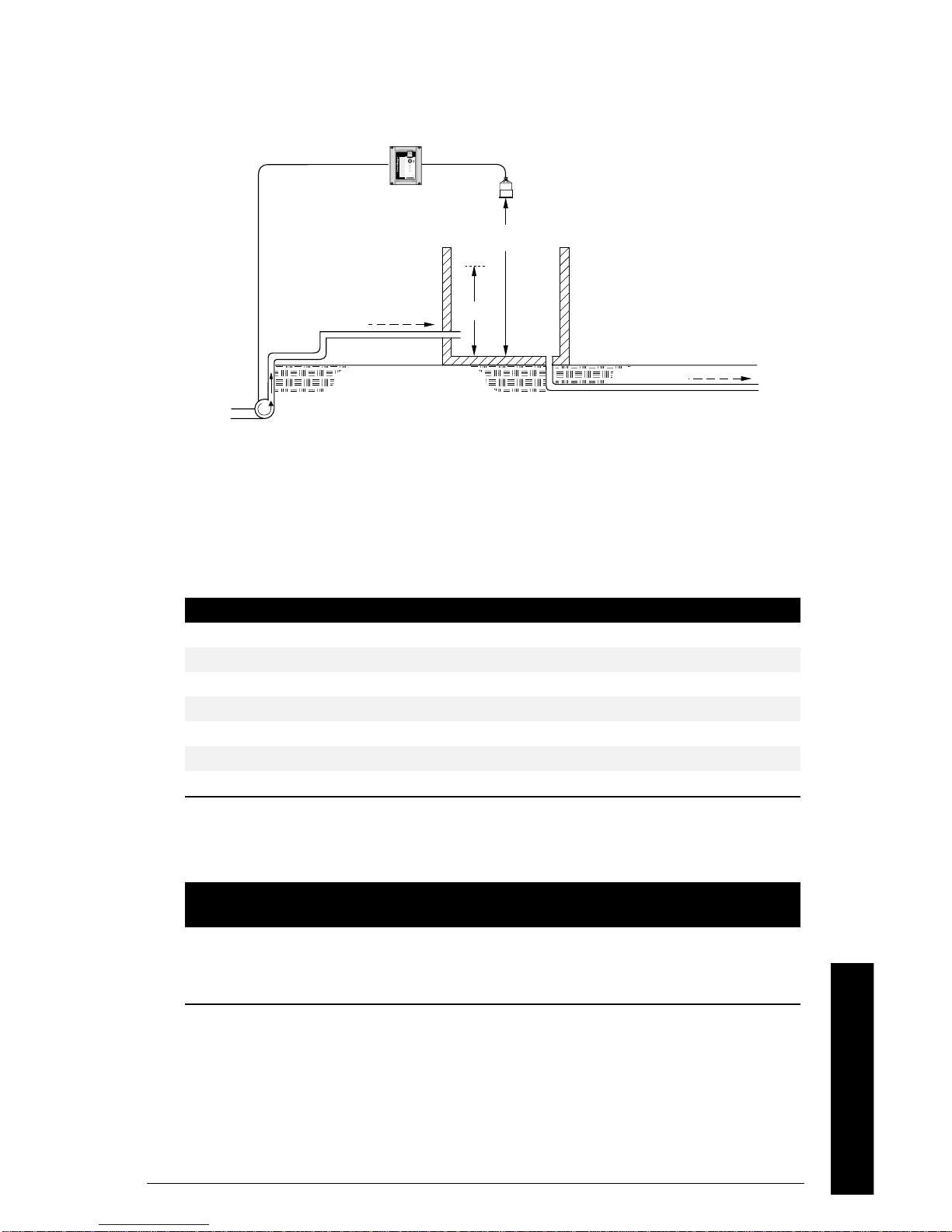

Gate Control

See Parameters section for complete details on specific parameter values.

This technique can also be applied to some types of valves.

Setting a Gate (Penstock) Control

transducer

overflow

gate

flow direction

Set the Common Parameters

Prerequisite: You must know the details of your application and substitute

the values for the sample values provided. If you are bench testing the unit

then set your test values to be the same as the sample values.

12

relays

Parameter Index Value Description

P001 G 1 Operation = Level

P002 G 1 Material = liquid

P003 G 2 Maximum Process Speed = medium

P004 G 102 Transducer = XPS-10

P005 G 1 Units = meters

P006 G 1.8 Empty = 1.8m

P007 G 1.4 Span = 1.4m

Application Examples

Page 44 EnviroRanger Programming Reference PL-556

Page 45

Set Relay 1 (Open Gate)

Relay 1 is wired to the “open” connections on the gate control. When relay 1

is energized the gate moves up.

Parameter Index Value Description

P111 1 63

P112 1 45%

P113 1 ---P114 1 0.1

P115 1 0.02

Sets relay 1 to energize (open gate)

when the level is below 45% of the span

(0.63m). The gate will open for 0.1

minute (6 seconds) and this cycle will

happen once per 0.02 hours (1 minute,

12 seconds) until the level is above 45%

Set Relay 2 (Close Gate)

Relay 2 is wired to the “close” connections on the gate control. When relay 2

is energized the gate moves down.

Parameter Index Value Description

P111 2 63

P112 2 55%

P113 2 ----

Sets relay 2 to energize (close gate)

when the level is above 55% of the span

(0.77m). The timing (P114, P115) of

relay 2 is set from the relay 1 setpoints.

Note:

Care must be taken to adjust P114 and P115 for proper proportional

integral (PI) control without overshoot or cycling. P114 is equivalent to

proportional band (P). P115 is equivalent to reset (I).

The transducer can also be placed upstream from the gate to control

upstream head.

Applications Examples

PL-556 EnviroRanger Programming Reference Page 45

Page 46

Rake (Screen) Control

r

Screens or rakes are mounted on the inflow channel of the wastewater

treatment plant to prevent debris from clogging the equipment. When

material builds up on the screen a level differential is created with the water

level higher in front of the screen than behind it. When this differential

reaches the programmed setpoint the EnviroRanger activates a relay to run

mechanical rakes to clean the screen and ensure a steady flow into the

treatment process.

Setting a Rake Control

transducer 1

transducer[1]

P006[1]

debris conveye

rake

transducer 2

transducer[2]

P007[1]

h[1]

rake

Level difference (point 3) = h[1] – h[2]

Setting the Common Parameters

Prerequisite: You must know the details of your application and substitute

the values for the sample values provided. If you are bench testing the unit

Application Examples

then set your test values to be the same as the sample values.

Page 46 EnviroRanger Programming Reference PL-556

water level

P006[2]

P007[2]

flow

h[2]

Page 47

Parameter Index Value Description

P001 G 4 Operation = Differential

P002 G 1 Material = liquid

P003 1,2 2 Maximum Process Speed = medium

P004 1,2 102 Transducer = XPS-10

P005 G 1 Units = meters

P006 1 1.8 Empty = 1.8m

2 2.2 Empty = 2.2m

P007 1 1.4 Span = 1.4m

2 1.4 Span = 1.4m

Set Relay 1 (Operate Rake)

Parameter Index Value Description

P110 1 3

P111 1 50

P112 1 0.4

P113 1 0.1

Starts the rake when the difference

between the two levels rises above

0.4m and stop the rake when the

difference falls below 0.1m.

Set Relays 2 to 4 (Level Alarms)

Parameter Index Value Description

P110 2 1

P111 2 1

P112 2 1.3

P113 2 1.2

P110 3 2

P111 3 1

P112 3 0.2

P113 3 0.4

P110 4 3

P111 4 1

P112 4 1.0

P113 4 0.9

Sets relay 2 as a high level alarm for

transducer 1 with an “on” setpoint of

1.3m and an “off” setpoint of 1.2m.

Sets relay 3 as a low level alarm for

transducer 2 with an “on” setpoint of

0.2m and an “off” setpoint of 0.4m.

Sets relay 4 as a “rake failure” alarm

as it uses the differential level point (3)

with an “on” setpoint of 1.0m and an

“off” setpoint of 0.9m.

PL-556 EnviroRanger Programming Reference Page 47

Applications Examples

Page 48

Application Examples

Page 48 EnviroRanger Programming Reference PL-556

Page 49

Testing the Configuration

Once you’ve programmed the EnviroRanger you must test the device to

ensure that it performs to your specifications. This test can be run in

simulation mode or by varying the level in the wet well. The latter is preferred

as it more accurately represents running conditions. However, if it is not

possible to do a physical test, the simulation mode will ensure that all control

programming is correct.

Simulation

When in simulation mode the LCD shows the EnviroRanger’s reaction to

level changes but any pump or control relays are held off. Alarm relays are

allowed to operate based on the simulation.

To allow pump or control relays to operate based on the simulated level, set

P000 to –1.

Simulating a Single Measurement

Access the appropriate parameter (Press and then Enter the parameter

number).

Testing

Press

associated Reading is displayed in the Parameter Value field, and any

"alarm" relays are set accordingly.

To verify Reading calculations (P920 to P926)...

1. Key in a material level in Units (P005) or % of Span (P007).

2. Press

3. Verify the calculated Reading.

To start a simulation from the level entered, press

; repeat 5 times to overcome Echo Lock (P711), if applicable. The

, the calculated Reading is displayed.

or .

PL-556 EnviroRanger Programming Reference Page 49

Page 50

Simulating a Level Cycle

To start a (P920, P921, P922, or P923) simulation (from level = 0)...

Testing

Checking Volume Characterization

1. Go to P920

2. Enter a level with a known volume

3. Press Enter

4. Check the returned volume against the manufacturer’s chart

5. Change parameters P054 and P055, as required

6. Repeat steps 2 to 5 until the volume curve is verified

Press

Use the

When the level rises to 100% or falls to 0% it reverses direction at the same

rate.

To check that the universal volume calculations (P050 = 9, 10) are accurate

do the following:

to simulate level rise and fall at 1% of Span / second.

and keys to adjust the simulated rate of rise or fall.

Rise at 4% of Span per second (maximum)

Rise at 1 % of Span per second (preset at start of simulation)

Stopped

Fall at 1% of Span per second

Fall at 4% of Span per second (maximum)

Checking OCM Flow Characterization

To check that the universal flow calculations (P600 = 4, 5) are accurate do

the following:

1. Go to P925

2. Enter a level with a known flow

3. Press Enter

4. Check the returned volume against the manufacturer’s chart

5. Change parameters P610 and P611, as required

6. Repeat steps 2 to 5 until the flow curve is verified

Page 50 EnviroRanger Programming Reference PL-556

Page 51

I/O Checkout

Once the EnviroRanger is installed a test is usually performed to verify the

wiring.

Relays

Use P119 (IR) Relay Logic Test (page 87) to force a state change and verify

that the results are as expected (pump starts, alarm sounds, etc.).

Discrete Inputs

Use P270 to force the input value and verify that the results are as expected

(pump removed from rotation, overflow event, etc.).

1. Go to P270[n] where n = the discrete input to be tested

2. Set to 0 to force the input off

3. Go to P275[n] to verify that the value is forced

4. Check the state of outputs to ensure that they respond as expected

5. Go to P270[n]

6. Set to 1 to force the input on

7. Go to P275[n] to verify that the value is forced

8. Check the state of outputs to ensure that they respond as expected

Testing

For further information see:

• Discrete Input Functions (P270 to P275) on page 111

• Overflow / Underflow (P160 to P169) on page 99

• Pump Interlock Allocation (P500 to P509) on page 128

• Pump Fault Status (P510 to P515) on page 134

• Pump Control Source (P520 to P524) on page 138

• Discrete Inputs (for pump control algorithms) on page 216

mA Input

Use P254 to test the mA input value against a true level. Use a trusted

external mA source to generate the signal required for testing and verify the

incoming signal with P260. As the mA level is changed ensure that the

system responds as expected.

Reset for Run Mode

Once testing is complete and the unit is ready for operation it is good practice to

clear any pump interlocks. Do this by setting P510[0] to 0.

PL-556 EnviroRanger Programming Reference Page 51

Page 52

Application Test

If the application is being tested by varying the material level (preferred) then

ensure that none of the control devices are connected (or at least there is no

power available to them).

Testing

1. When the EnviroRanger performs exactly as required, programming is

2. If alternate Reading units, failsafe action, or relay operation is desired,

3. If the system performance experiences problems, see Appendix B –

If the application is being tested in simulation mode (and P000 is not -1) then

control relays are not energized and they can remain connected.

While the level is being cycled, check the results of the discrete inputs by

either closing the circuit externally (preferred) or using P270 (IDI) Discrete

Input Function on page 111 to force the input on or off. Try all possible

combinations to thoroughly test the setup. For each combination run a

complete cycle to verify that the pumps operate as expected.

Monitor system performance carefully, under all anticipated operating

conditions.

complete.

update the parameters for the new functionality.

Troubleshooting on page 205.

If all operating conditions cannot be observed during the System

Performance Evaluation, refer to Measurement (P920 to P927) on page 193

for simulation instructions. Perform a Reading Measurement simulation to

verify programming.

Usually, when a simulation is run, alarm relays will energize based on

programming but control relays will not.

Conduct a System Performance Evaluation following any installation

modification or programming (parameter) alteration.

Programming Documentation

With programming complete, record all parameter alterations.

1. If the keypad programmer is used, enter the program mode and scroll to

altered parameters (skipping parameters left at preset values). Record all

parameter alterations.

2. If Dolphin Plus software is used, save a file to disk. If you require hardcopy

use the Dolphin Plus Reports feature to print either the full list or only those

parameters changed from factory default.

Page 52 EnviroRanger Programming Reference PL-556

Page 53

For normal operation, return to the Run mode. The EnviroRanger will

perform reliably, requiring little or no maintenance.

Connect (or enable) process control/alarm equipment to the EnviroRanger

only after satisfactory performance is verified for all possible operating

conditions.

Testing

PL-556 EnviroRanger Programming Reference Page 53

Page 54

Testing

Page 54 EnviroRanger Programming Reference PL-556

Page 55

Parameter Reference

How to Read the Reference

Each item in the programming reference has five sections:

Title

The number, type and name of the parameter.

Possible types are:

Type Name Description

G Global This parameter applies to the entire unit

V View only This parameter can not be set, only viewed

IT Transducer Indexed by transducer (if P001=4 or 5)

IL Level Point

IR Relay Indexed by relay (5)

IDI Discrete Input Indexed by discrete input (8)

IP Comm. Port Indexed by communications port (2)

ID Dimension Indexed by PMD dimension (up to 6)

IE Echo Profile Indexed by stored echo profile (10)

IB Breakpoint Indexed by breakpoint (10 or 32)

IC CSO Log Indexed by CSO log entry (20)

Description

The first, italic, paragraph describes the purpose of the parameter, when you

would change it, and for which applications.

Details

The following paragraphs detail the parameter and include any side-effects

of using it.

3

Indexed by level point (if P001=4 or 5))

Parameter Reference

Values or Choices

The table shows the possible values in units or numbered choices for the

parameter with short descriptions. The preset is marked with an asterisk

(*) or listed as a value.

Related

A listing of any related parameters.

3

The three level points are: transducer 1, transducer 2, and the calculated point

which can be difference (P001=4) or average (P001=5).

PL-556 EnviroRanger Programming Reference Page 55

Page 56

P000 (G) Lock

Use this parameter to secure the EnviroRanger from changes.

WARNING

Use this lock as backup security only. It uses a fixed value which can

be discovered by unauthorized personnel.

Access this parameter directly (type the number 000) and enter any value

(other than 1954) to secure the programming lock. To unlock the

EnviroRanger, access this parameter and enter the value “1954”.

When lock is activated, the EnviroRanger may be switched from the RUN

mode to the program mode and the value of any parameter may be viewed

but not altered.

Normally, during a measurement simulation (see Measurement Parameters,

Parameter Reference

P920 - P926), pump or control relays remain de-energized. If desired, set

Lock for “simulation controls” to have pump or control relays function based

on the simulated level.

Simulation mode reverts to 1954 after the unit is idle for 10 minutes.

Simulate using P920 usually does not energize control relays. If this

parameter is set to –1 then all relays will energize when the P920 simulation

is run.

Values

1954 * off (programming permitted)

-1 simulation controls (relays energize based on simulated level)

other lock activated (programming secured)

Related

• P132 (G) Pump Start Delay on page 92

• Simulation on page 49

Page 56 EnviroRanger Programming Reference PL-556

Page 57

Quick Start (P001 to P009)

P001 (G) Operation

Sets the type of measurement required for the application.

If 0 – “out-of-service” is entered alarm relay(s) energize (set “off”), and pump

relay(s) de-energize (set “off”).

If “DPD” or “DPA” is entered, either 2 transducers of the same type are

required, or one transducer and one mA input. If two transducers are used

all transducer parameters become indexed, and a third level point is

calculated:

• DPD (difference) = Point 1 - Point 2

• DPA (average) = (Point 1 + Point 2) / 2

For these operations any of three level points (transducer 1, transducer 2, or

the calculated point) can be used to trigger relays (see P110 (IR) Level

Source on page 74).

Values

0 Out-of-service

1 Level – how full the vessel is (a.k.a. volume – P050)

2 Space – how empty the vessel is (a.k.a. ullage – P050)

3 * Distance – distance from transducer to material

4 DPD – dual point difference

5 DPA – dual point average

6 OCM – flow rate in an open channel

7 Pump Totalizer – total pumped volume

Parameter Reference

P002 (G) Material

The type of material being measured, normally liquid.

For most EnviroRanger applications this entry will be liquid or slurry (value 1)

but the application could also involve solids.

Values

1 * Liquid or horizontal solid surface

2 Solid or angled surface

PL-556 EnviroRanger Programming Reference Page 57

Page 58

P003 (IT) Maximum Process Speed

Determines how quickly the EnviroRanger reacts to level changes.

Use the setting which is just fast enough to keep up with your process.

Slower settings provide higher accuracy while faster settings allow for more

level fluctuations.

Values

1 Slow (0.1 m/min)

2 * Medium (1 m/min)

3 Fast (10 m/min)

Related

• Failsafe (P070 to P072) on page 69

• P121 (G) Pump by Rate on page 88

• Measurement Verification (P710 to P713) on page 162

• Transducer Scanning (P726 to P728) on page 164

Parameter Reference

• Rate (P700 to P708) on page 159

P004 (G) Transducer

Specifies the Milltronics transducer connected.

Enter the type of transducer(s) connected to the EnviroRanger. If multiple

transducers are used they must be of the same type.

Values

0 No transducer attached

1ST-25

2ST-50

100 STH

101 XCT-8

102 * XPS-10

103 XCT-12

104 XPS-15

112 XRS-5

250 Auxiliary (see mA Input)

Related

• mA Input (P250 to P254) on page 108

Page 58 EnviroRanger Programming Reference PL-556

Page 59

P005 (G) Units

Specifies the units used for dimensional values.

Changing this value automatically changes the units displayed for all

parameters. Existing values are converted and do not have to be re-entered.

Values

1 * Meters

2 Centimeters

3 Millimeters

4 Feet

5 Inches

Related

• P060 (IT) Decimal Position on page 66

P006 (IT) Empty

Parameter Reference

The distance in “units” from the face of the transducer to the process empty

point.

Setting this value also sets Span (P007)

unless Span was already set to another

value.

Values

0.000 to 9999

Preset: 5.000m (or equivalent depending on

units)

Related

• P007 (IT) Span on page 60

• P800 (G) Near Blanking on page 176

PL-556 EnviroRanger Programming Reference Page 59

Page 60

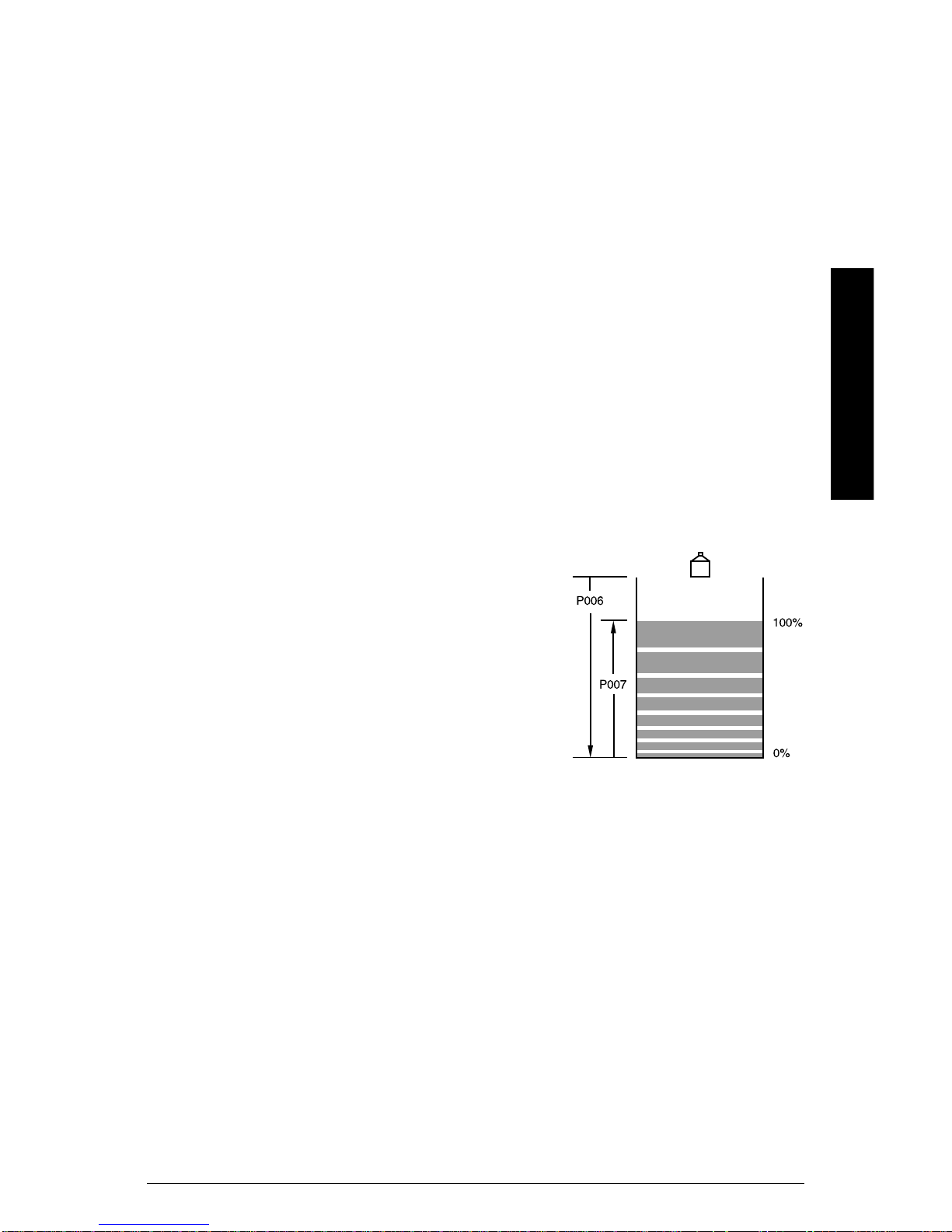

P007 (IT) Span

Span is the range of levels that the equipment is set to measure.

Span is preset for a value close to the

maximum available. Enter a value that

reflects the maximum range of your

application.

Always prevent the monitored surface from

approaching within 0.33 m (1 ft) of the

transducer face as this is the minimum

blanking for most Milltronics transducers

(some require more blanking – see your

transducer manual).

Many other parameters are set as a percentage of span (even if they are

entered in units). The values of these other parameters may change if the

Parameter Reference

span is altered after installation and they are measured based on level

(upwards from Empty towards the transducer face).

All volumes are based on span so it should be set for the maximum volume

point if volume calculations are needed.

Values

0.0 to 9999

Preset: based on Empty (P006)

Related

• P800 (G) Near Blanking on page 176

• P006 (IT) Empty on page 59

• P005 (G) Units on page 59

• Volume (P050 to P055) on page 62

• P112 (IR) Relay “on” Setpoint on page 84

• P113 (IR) Relay “off” Setpoint on page 84

P008 (G) Date

Date is the current date in the format: YY.MM.DD.

The date is entered by using the numeric keypad and the

decimal “.” key. For example, to enter December 10, 1998 you

would type in the value “98.12.10”.

Page 60 EnviroRanger Programming Reference PL-556

rack or panel

display shown

Page 61

Year 2000 Compliance

00-69 Assumed to be the years 2000 to 2069

70-99 Assumed to be the years 1970 to 1999

Values

70:01:01 to 69:12:31

P009 (G) Time

Time is the current time in 24-hour format: HH.MM.SS.

The time is entered using the numeric keypad and the decimal

“.” key. For example, to enter 9:34:45 p.m. you would type in

the value “21.34.45”.

Parameter Reference

Values

00:00:00 to 23:59:59

rack or panel

display shown

PL-556 EnviroRanger Programming Reference Page 61

Page 62

Volume (P050 to P055)

To enable the EnviroRanger to show readings based on vessel or wet well

volume (rather than level) use these parameters.

If one of the “universal” tank shapes is used then follow this procedure:

• Plot a volume to height chart

• Enter the curve values from this chart into P054 and P055

• Ensure extra points are added around sharp transitions in the chart/reservoir

Parameter Reference

If you require volume display only (based on linear multiplication of span)

then use P061 (IT) Convert Reading on page 66. This method does not

calculate volume and must not be used in place of these parameters if any

volume dependent features (such as pump efficiency) are used.

P050 (G) Tank Shape

Enter the Tank Shape value that matches the monitored vessel or wet well.

When Operation is "level" (P001 = 1), liquid (material) volume is calculated.

Alternatively, when Operation is "space" (P001 = 2), remaining vessel

capacity is calculated.

In the RUN mode, Readings are displayed in percent maximum volume. To

convert Readings to volumetric units, see Max Volume (P051).

Page 62 EnviroRanger Programming Reference PL-556

Page 63

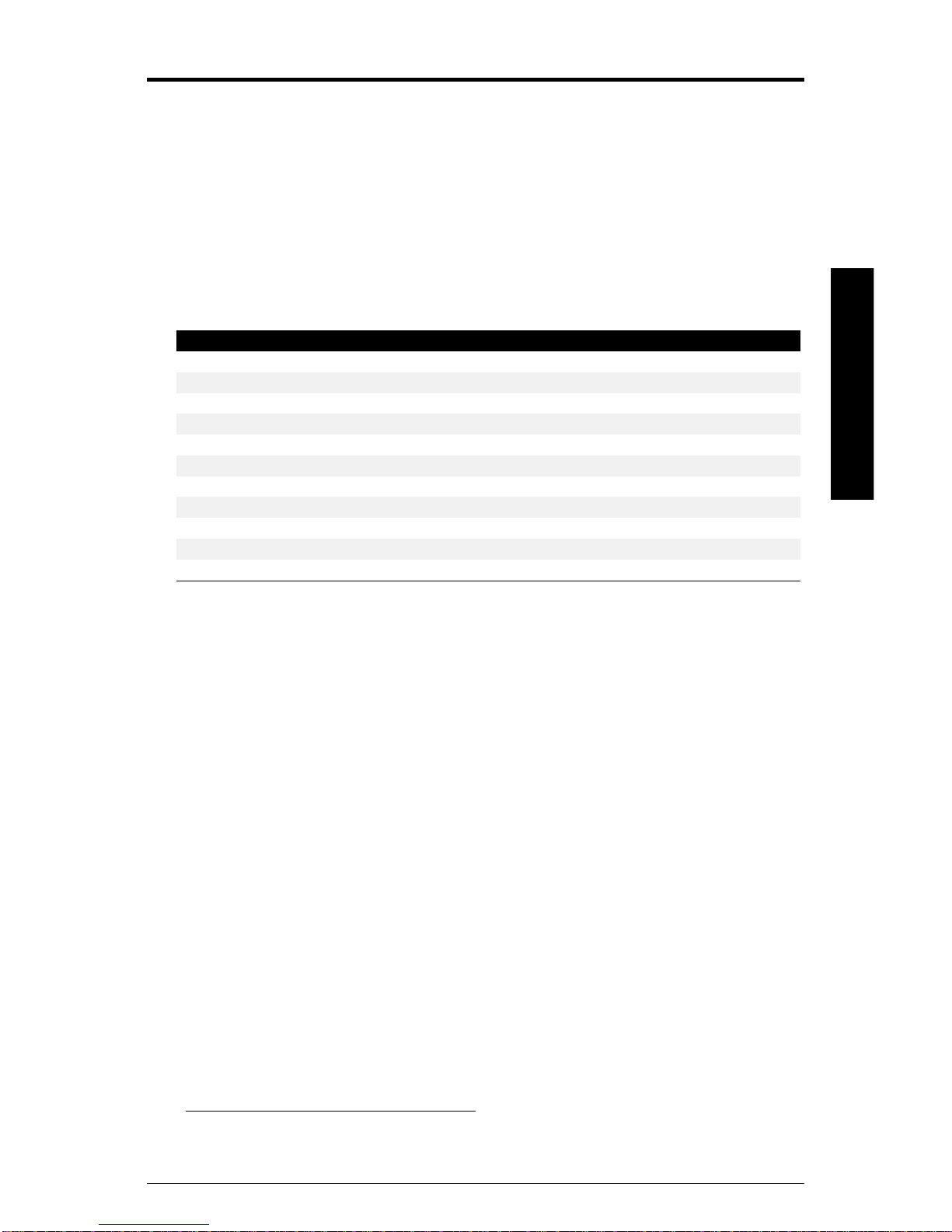

Values

0 = volume calculation not required (preset)

1 = flat level bottom 4 = half sphere bottom 8 = sphere

A

A

A

2 = cone / pyramid bottom 5 = flat sloped bottom 9 = universal linear

A

3 = parabola bottom

6 = flat ends

10 = universal curved

AL

7 = parabola ends

Related

• P051 (G) Max Volume on page 63

• Pump Efficiency (P180 to P186) on page 105

• P001 (G) Operation on page 57

• Pumped Volume Totalizer (P622 to P623) on page 148

• P920 (IL) Reading Measurement on page 193

Parameter Reference

P051 (G) Max Volume

For Readings in volumetric units (rather than percent), enter the vessel

volume between Empty (P006) and Span (P007).

The units of measurement for this reading are arbitrary. The volume is

calculated from the empty position to the maximum span position and is

scaled according to the Tank Shape (P050) value. This enables the use of

any volume units required.

Note:

Ensure that the chosen units allow the total volume to be displayed in the

four digits on the LCD.

Example

1. If max. volume = 3650 m

2. If max. volume = 267500 gallons, enter 267.5 (1000's of gallons).

PL-556 EnviroRanger Programming Reference Page 63

3

, enter 3650.

Page 64

Values

0.0 to 9999

Preset: 100.0

Related

• P006 (IT) Empty on page 59

• P007 (IT) Span on page 60

• P060 (IT) Decimal Position on page 66

P052 (G) Tank Dimension ‘A’

This is dimension ‘A’ as used in P050 (G) Tank Shape on page 62.

Enter the height of the tank bottom if P050 = 2,3,4, or 5, or the length of one

end section of the tank if P050 = 7, in Units (P005).

Values

0.000 to 9999

Parameter Reference

Preset: 0.000

P053 (G) Tank Dimension ‘L’

This is dimension ‘L’ as used in P050 (G) Tank Shape on page 62.

Enter the tank length (excluding both end sections) if P050 = 7.

Values

0.000 to 9999

Preset: 0.000

P054 (IB) Breakpoint Levels (Universal Volume

Calculation)

When the tank shape is too complex for any of the preconfigured shapes

you can specify the volume based on segments.

Enter up to 10 level breakpoints (where volume is known) if P050 = 9 or 10.

These values should be provided by the tank manufacturer.

To enter a Level Breakpoint...

1. Go to Parameter P054

2. For each index enter a breakpoint in measurement units

3. Ensure that each breakpoint corresponds to the same index for P055

Values

0.000 to 9999

Page 64 EnviroRanger Programming Reference PL-556

Page 65

P055 (IB) Volume Breakpoints (Universal Volume

Calculation)

Each segment defined by the level breakpoints (P055) requires a volume to

allow the EnviroRanger to make the level-to-volume calculations.

These values should be provided by the tank manufacturer.

Some typical volume calculations are:

Sphere

Cone

Cylinder

Enter the volume corresponding to each Level Breakpoint entered.

To enter a Volume Breakpoint...

1. Go to Parameter P055

2. For each index enter a volume