Page 1

COMPUFLO III

FLOWMETER

INTEGRATOR

Instruction Manual

PL-368

March 1993

33453680

PRR 1.1

Page 2

Page 3

TABLE OF CONTENTS

TITLE PAGE #

Gener al Inf ormation

About the CompuF lo III 1 – 1

About th is Manual

General 1 – 2

Conventions 1 – 2

Specifications

CompuFlo III 2 – 1

Options 2 – 2

Installation

CompuFlo III 3 – 1

Interconnection 3 – 1

Hazardous Locations 3 – 1

Start Up

Hardware Set Up 4 – 1

Pre Start Up Checks 4 – 3

Initial Start Up 4 – 3

Programming

Calibration

General 5 – 1

Keypad 5 – 1

Parameter Entry 5 – 2

Direct Parame ter Access 5 – 2

Automat ic Parameter Access 5 – 2

Altering Parameter Values 5 – 3

Last Parameter Recall 5 – 3

Parameter Reset 5 – 3

Programming Sequence 5 – 3

Quick Start Procedure 5 – 3

General 6 – 1

Initial Calibration References 6 – 1

Zero 6 – 2

Span 6 – 2

Calibration Accuracy 6 – 2

Calibration Alternatives 6 – 3

Auto Zero 6 – 3

Lockout Mode 6 – 3

On-Line Span Calibration 6 – 3

Alternate Test References 6 – 4

ECAL Calibration 6 – 4

PL-368 i

Page 4

Parameters

General 7 – 1

Parameters 7 – 1

Programming Chart 8 – 1

Operation

Initial Operation 9 – 1

Normal Operation

Start Up 9 – 2

Zero Calibration Check 9 – 2

Span Calibration Check 9 – 2

Reset Total 9 – 2

Run 9 – 2

Communication

General 10 – 1

Remote Com munication 10 – 2

Host Communication 10 – 2

Serial Printer Communication 10 – 2

Protocol 10 – 3

Data Field Descriptions 10 – 3

Message Requests 10 – 4

Message Responses 10 – 4

Appendices

Figures

Alphabetical Par ameter Listing 11 – 1

Maintenance and Spare Parts 11 – 2

Error Messages 11 – 3

Trouble Shooting 11 – 4

Quick Start 11 – 5

Start U p 11 – 5

Calibration 11 – 6

Operation 11 – 7

Performance Enhancement 11 – 7

FIG. 1 Outline and Mounting 12 – 1

FIG. 2 Layout 12 – 2

FIG .3 CompuFlo III / Flowmeter Interconnection 12 – 3

FIG. 4 Po wer, Auto Zero, & Rate Output Wiring 12 – 4

FIG. 5 Relay Wiring 12 – 5

FIG. 6 Communication Wiring 12 – 6

PL-368 ii

Page 5

GENERAL INFORMATION

ABOUT THE COMPUFLO

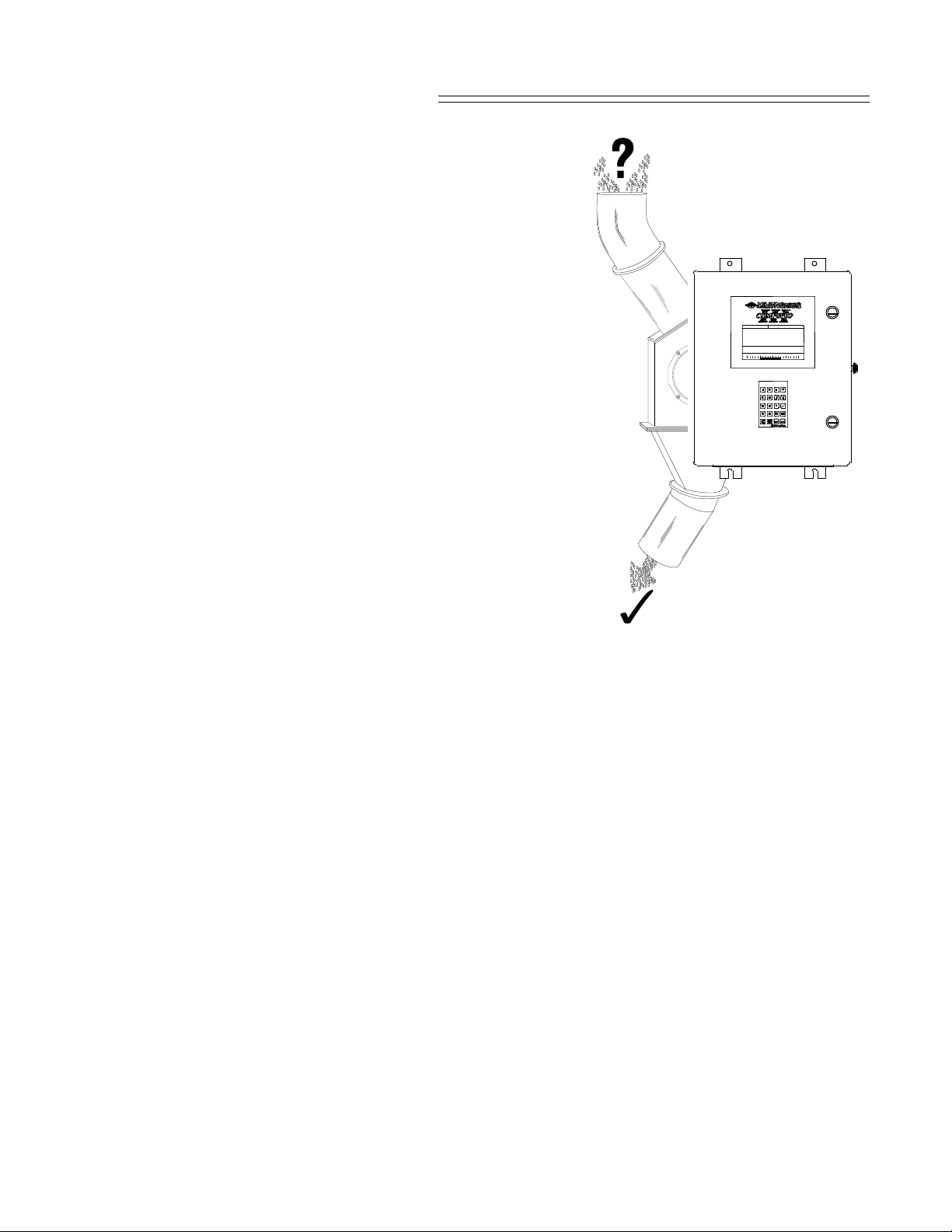

The Milltro nics CompuFlo III is a

microprocessor based integrator designed

specifically for b u lk dry solids in-line

weighing applications.

The CompuFlo III integrates a signal

proportional to material flowrate (such as

from a Milltronics flowmeter) over time to

provide material totalization.

The Com puFlo III provides:

» Rate and Total displays

» an analog mA output proportional to rate

» a relay contact f or remote total izer or PLC operation

» 2 alarm/ control relays based on rate and/or On-line Calibration

» 2 communication ports for computer , PLC, or serial printer c onnection

The CompuFlo I II has three modes of operation;

program, calib rate and run.

MULTI SPAN NO: 1R2:RATE HI R1:SPEED LO

1263957

TOTAL

T

150%100%50%0%-50%

The operator programs the CompuFlo III via the

keypad to provide displays and outputs in the

desired units of measure. The Comp uFlo III

displays the name, range of acceptable values,

(and additional information/instruction) of the

parameter (programming feature) accessed.

In the calibrate mode, the system Zero (no flow) and Span (100% flowrate) calibration is established. A test

reference (test weight) is used to simulate the force of material impacting the flowmeter sensing plate during

the Span calibration. A mater ial test is normally performed to verify the calibration accuracy. If necessary, the

material test results may be used to correct any deviation in calibration accuracy.

Calibration accuracy may be checked at any time. The results of th is check are automatically compared to the

system calibration and the deviation is displayed. The operator may choose to continue operation with the

previous calibration or the results of the calibration check.

All programming and calibration information is stored in non-volatile memor y. If desired, the security

parameter may be set to ensur e the CompuFlo III programming and calibration is not inadvertent ly altered in

the run mode.

The run mode is the normal operating mode, providing dynamic measurement displays, analog mA output,

and a variety of other features.

PL-368 1 – 1

Page 6

ABOUT THIS MANUAL

GENERAL

This instruction manual conta ins informat ion essential to successful CompuFlo III operation.

SPECIFICATIONS, includes CompuFlo III environmental, phys ical, and operational characteristics.

INSTALLATION, indicates the typical mounting and interconnection procedure.

START UP, prepares the Compu Flo III for programming.

PROGRAM MING, details activities required to ta ilor t he CompuFlo III to the par ticular application.

CALIBRATION, includes the CompuFlo III input signal to output feature corr elation procedure.

PARAMETERS, describes the function, factory setting, and range of possible settings,

of each parameter.

PROGRAM MING CH A RT, provides a space to record programmed parameter values for futur e reference.

OPERATION, describes initial and normal CompuFlo III operation.

COMMUNICATION, provides CompuFlo III serial communication information.

APPENDICES, contains Quick Start , Alphabetical Parameter L ist, Maintenance and Spare Parts,

Error Messages and Trouble Shooting information.

FIGURES, includes a complete set of installation and interconnection drawings.

CONVENTIONS

Throughout this instruction manual the following symbols and presentation practices have been utilized:

[1234567ABCDEFG] alpha numeric characters enclosed within these brackets repr esents information

displayed by the CompuFlo III display.

[T/h] units of measure were arbitrarily chosen from the imperial set. The actual units

displayed or other wise applicable will be dependent upon o perator programming.

indicates the following CompuFlo III keypad button is to be pressed.

"RUN" or alpha numeric characters enclosed within quotation marks or this symbol

ENTER

represent a key on the CompuFlo III keypad.

Italics

are used to identify the defined word(s) or phrase within a definition statement.

Informat ion of a hig her order of importance, is indented from

both left and right margins and in bold print.

PL-368 1 – 2

■

Page 7

SPECIFICATIONS

COMPUFLO III

Power: » 100/115/200/230 V AC ±10%, jumper

selectable, 50/60 Hz, 65 VA

Fuse: » FU 1 » 3/ 4 Amp MDL SLO-BLO or equivalent

» FU 2 » 1/ 4 Amp MDL SLO-BLO or equivalent

Operating » -20 to 50°C (-5 to 122°F)

Temperature:

Accuracy: » 0.1% of span, typical

Resolution: » 0.02% of span, typical

Inputs: » Load cell: » -20 to +45 mV DC per load cell

» 2 load cells max.

» LVDT: » 0 to 0.75 Vrms, 3 kHz

» Multispan: » 4 contact inputs for up to 8 spans

» Keypad: » 20 key sealed membrane with tactile feedback

» On-Line: » 4-20 mA proportional to weight

(Calibration)

» Auto Zero » contact input for enable

» Printer: » contact input for print request

Outputs: » Load cell: » 10 V DC, 250 mA max.

(excitation)

» LVDT: » 2.0 Vrms, 3 kHz, 50 mArms max.

(excitat ion)

» Analog: » 4-20 mA,(0-25 mA scaleable), isolated, proportional to rate

» 0.1% resolution

» 750 Ω max. load

» Remote » SPST sealed relay

Totalizer:

» 1 form "A" contact rated 2A at 250 V AC, 100 VA max.

» 25 msec. minimum contact closure duration

» 15 closur es per second max

PL-368 2 – 1

Page 8

» Alarm: » 2 multipurpose relays for Rate or On-line Calibration

assignment

» 1 Form "C" SPDT contact per relay, rated 5A at 230 V AC

» Communication: » 1 relay, 4PDT used for communication loop dropout,

rated 1A at 230 V AC

» Display: » illuminated 256 x 128 dot matr ix

Communication: » 2 serial ports

» RS232C and ± 20 mA current loop

Enclosure: » NEMA 4 style, steel construction with polycarbonate window

» 330 mm W x 406 mm H x 102 mm D

(13" W x 16" H x 4" D)

Shipping Weight: » 11.0 Kg (24.3 lbs), no opti o n s

OPTIONS

Cable: » Single load cell, 150m (500 ft) max. 20 AWG, 4 wire shielded,

Belden 8404 or equivalent

» Single load cell, 300m (1 000 ft) max. 20 AWG, 6 wire shielded,

Belden 8426 or equivalent

» Dual load cell, 150 m (500 ft) max. 20 AWG, 6 wire shielded,

Belden 8426 or equivalent

» Dual load cell, 300 m (1000 ft) max. 20 AWG, 8 wire shielded,

Belden 8418 or equivalent

» LVDT, 150 m (500 ft) max. 20 AWG, 4 wire shielded,

Belden 8404 or equivalent

Barrier Strips: » For hazardous location flowmeters

Enclosure Heater: » Recommended for operating temperatur es below -10 ° C

(14°F) or excessive humidity

Relay: » Food Grade remote totalizer relay

CVCC: » For bipolar current loop/RS-232C conversion

BIC-II: » For 6 port bipolar current loop/RS-232C or RS-422 conversion.

PL-368 2 – 2

■

Page 9

INSTALLATION

CompuFlo III

The CompuFlo III should be mounted in an area that is within the specified temper ature range, and that is

suitable for NEMA 4 style enclosures. The front cover should be accessible for keypad operation, display

viewing, and have sufficient room to swing open.

It is advisable to keep the CompuFlo III away from high voltage or current runs, contact ors, S CR control

drives and RF interference.

For proper totalizer relay operation, the CompuFlo III must be mounted within 30° from vertical.

Do not mount the CompuFlo III in direct sunl ight without the use of a sun shield.

INTERCONNECTION

Remov e the enclosure bottom plate prior t o drilling or punching cable/conduit entrance(s ), to ensure metal

filings do not come in contact with the CompuFlo III electronics.

Load cell or LVDT, rate output, On-Line Calibration input, communication, and low voltage contact wiring may

be run in a common conduit separated from power and high voltage contact wiring. Refer to Figures.

The power ground (TB1-50) is internally connected to SHLD connections (TB1-13,26, TB2-5), and to the

mother board bottom mounting lugs. COM connections (TB1-15,29,32,36,37, a nd TB2-8) are connected to

power ground via jumper J2 (below TB1, between the mounting lugs). If the COM connections must be

isolated from power ground, remove J2.

Refer to FIGURES

All wiring must be perf ormed in accordance with all governing regulations.

HAZARDOUS LOCATIONS

The CompuFlo III cannot be mounted in an area classed as hazardous. Where the associated flowmeter is

mounted in a hazardous area, barrier strips must be used to isola te the CompuFlo III from the hazardous area

for intrinsic safety. Encapsulated LVDT transducing elements are also available. Contact Milltronics or your

local representative for hazardous application information.

PL-368 3 – 1

■

Page 10

Page 11

START UP

HARDWARE SET UP

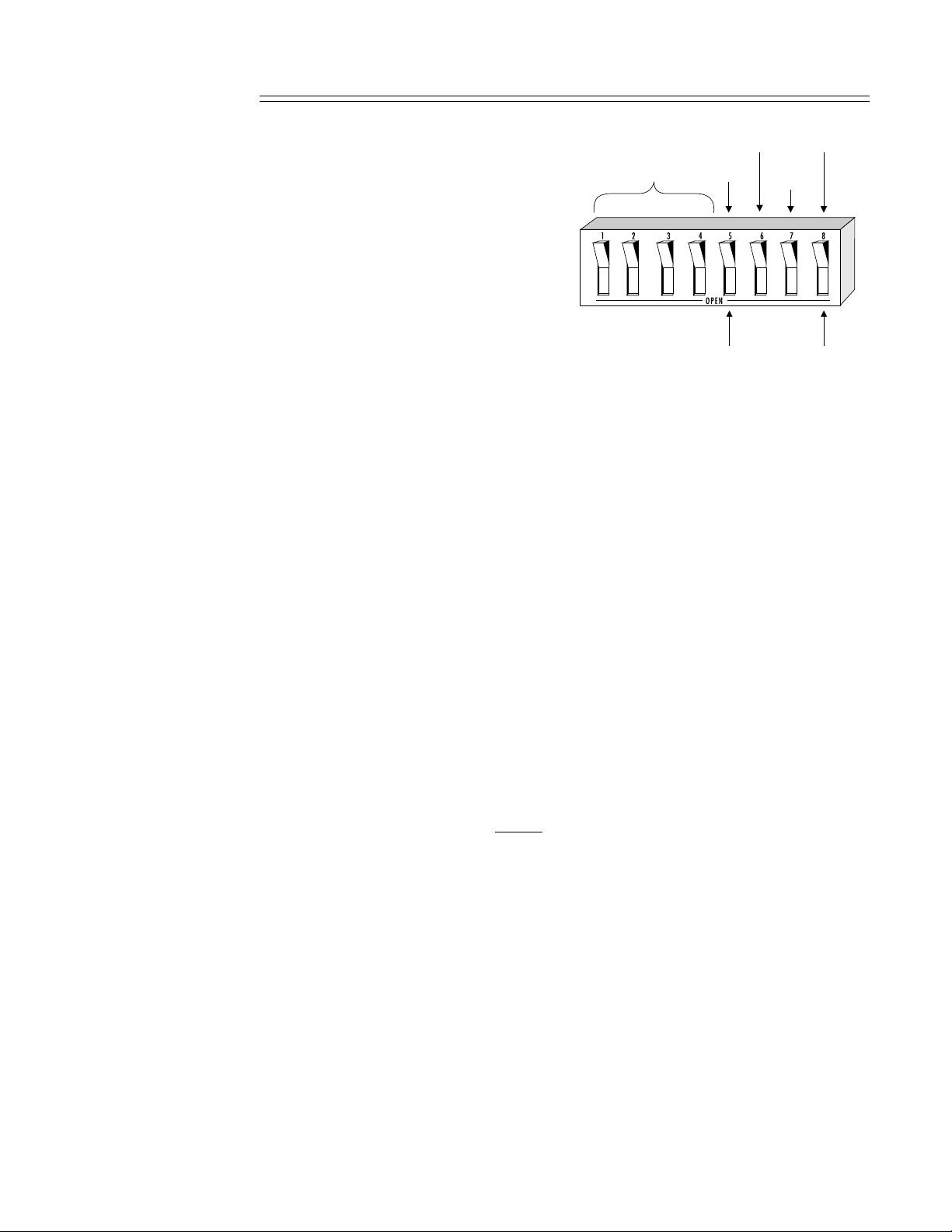

UNIT I.D.

The CompuFlo III identification code factory setting is 00,

as set by SW1 contacts 1 - 4.

When more than one CompuFlo III is connected to a

host computer or PLC, the identification code of each

CompuFlo III must be set to a differ ent value.

UNIT SW 1

I. D. 1 2 3 4

00 O O O O

01 C O O O

02 O C O O

03 C C O O

04 O O C O

05 C O C O

06 O C C O

07 C C C O

SW1

UNIT I. D. #

1248

METRIC

0000

IMPERIAL

UNIT SW 1

I. D. 1 2 3 4

08 O O O C

09 C O O C

10 O C O C

11 C C O C

12 O O C C

13 C O C C

14 O C C C

15 C C C C

LOCKOUT

MAIN

TOTAL

RESET

TEST

NORMAL

O = switch contact open C = switch contact closed

UNITS OF MEASURE

Two sets of Units are available; Imperial and Metric. Leave SW1 contact 5 (SW1-5) in the open position

for Imperial, or closed for Metric units. R efer to PARAMETERS / P0 - RATE UNITS for the Rate Unit

options available.

SW1-5 must be set to the desired position b ef ore i nitial pro grammi ng is performed.

To alter the Units of Measure of a programmed CompuFlo III, set SW1-5 as desired,

then perform a Reset. Refer to Parameters / P99 Reset.

LOCKOUT

Leave SW1 contact 6 (SW1-6) in the open position for normal applications. Close SW1-6 for Lockout Mode

operation, after all programming and calibration is complete. Refer to Calibration / Calibration Alternatives.

TOTALIZER RESET

Leave SW1 contact 7 (SW1-7) in the open position for normal operation. When this contact is closed, the

Main Total Display cannot be reset.

TEST MODE

Leave SW1 contact 8 (SW1-8) in the open position for normal operation. The closed position is reserved for

Milltronics service personnel.

PL-368 4 – 1

Page 12

ALTERNATE

TB2 BAUD

000

4

X

4

2

PRINTER

REMOTE

TERMINAL

SERIAL

TEST /

ADJUST

SW2

3

0

1

X

ENGLISH

SPARE

PORT 2 BAUD RATE

The CompuFlo III TB2 com munication port baud rate is independent of the PORT 1 baud rate, and is set by

SW2 contacts 1 and 2. Set the baud as required by the device connected. The factory setting is 300 baud.

Baud SW2

Rat e 1 2

300 O O

O = switch contact open

1200 C O

2400 O C

C = switch contact closed

9600 C C

NORMAL

LANGUAGE

Leave SW2 contact 3 (SW2-3) in the open position for English, or closed for alternate language, CompuFlo III

displays.

REMOTE DISPLAY

Leave SW2 contact 6 (SW2-6) open for normal operation. If a remote mounted terminal is used, SW2-6 of the

remote terminal (only) must be closed.

PORT 2 COMMUNICATION MODE

Leave SW2 contact 7 (SW2-7) open for normal operation, or closed if a serial printer is connected to PORT 2.

TEST/ADJUST MODE

Leave SW2 contact 8 (SW2-8) in the ope n position for normal operation. In th e closed position, a test menu is

displayed.

When the keypad test is selected, a pictorial representat ion of the keypad is displayed. As each keypad

button is depressed, the display indicates successful operation.

When the display contrast adjustment is selected, pressing "4" increases, and pressing "8" decreases the

display contrast.

PL-368 4 – 2

Page 13

PRE START UP CHECKS

After the Compu Flo III has been properly installed and interconnected, the following checks should be

performed prior to connecting power:

»all cable connections are correct and secure.

»the proper voltage has been selected (J1 on the mother board).

»SW1 and SW2 have been set as required.

»the POWER switch is in the OFF position.

Connect power to TB1 -51,52 and ground to TB1-50 of the CompuFlo III. Ensure all connections are secure.

Do not operate the CompuFlo III with the

ground (earth) wire disconnected.

INITIAL START UP

Se t the Co mpuFl o III POWER switch to the ON position. The CompuFlo III will enter the following

initialization routine:

COMPUSCALE/FLO III (REV DATE) (EPROM 2 REV)

TEST : (MESSAGES)

PL-368 4 – 3

Page 14

When the display initializa tion routine is complete, the display revert s to the last operati ng mode accessed. If

the CompuFlo III is not programmed, the paramet er entry display is accessed.

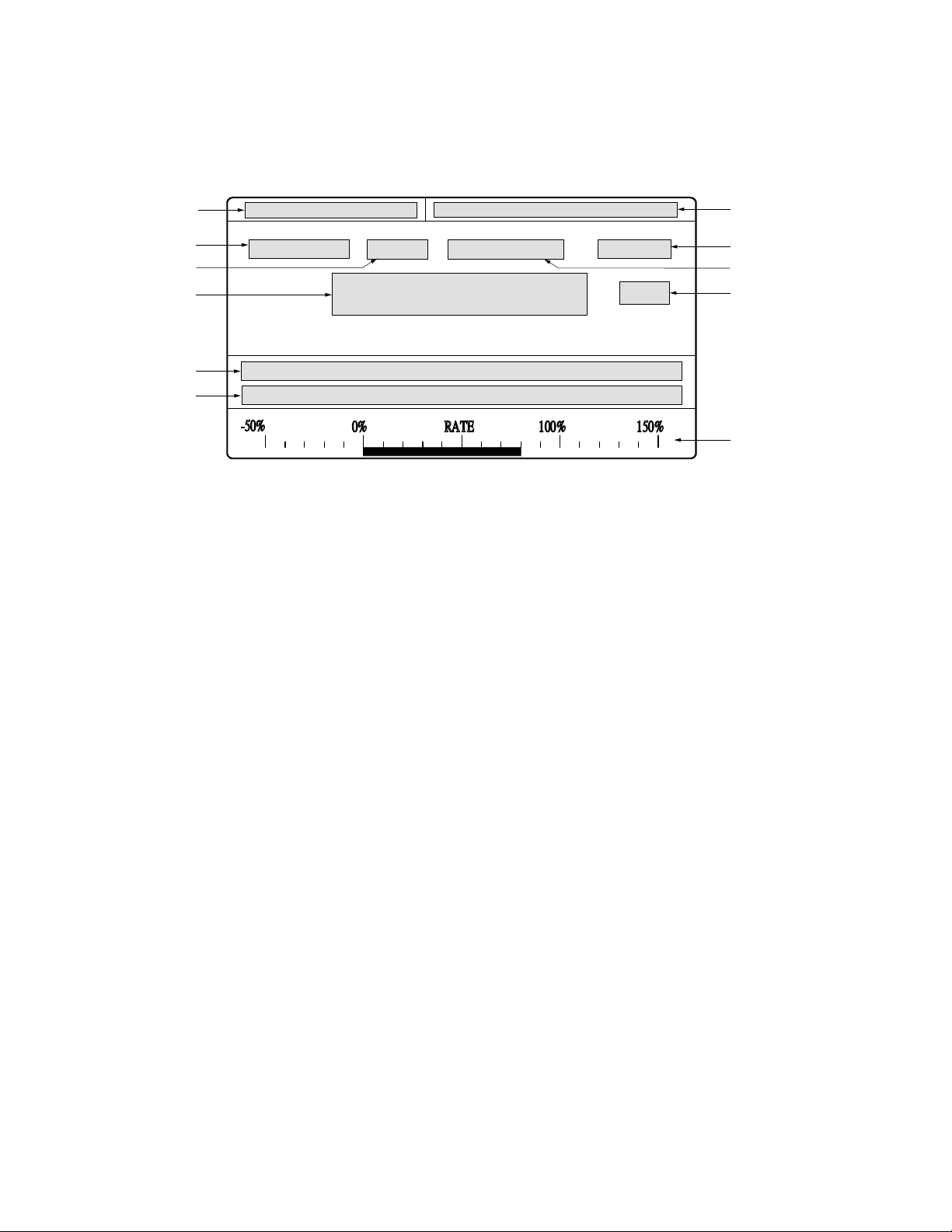

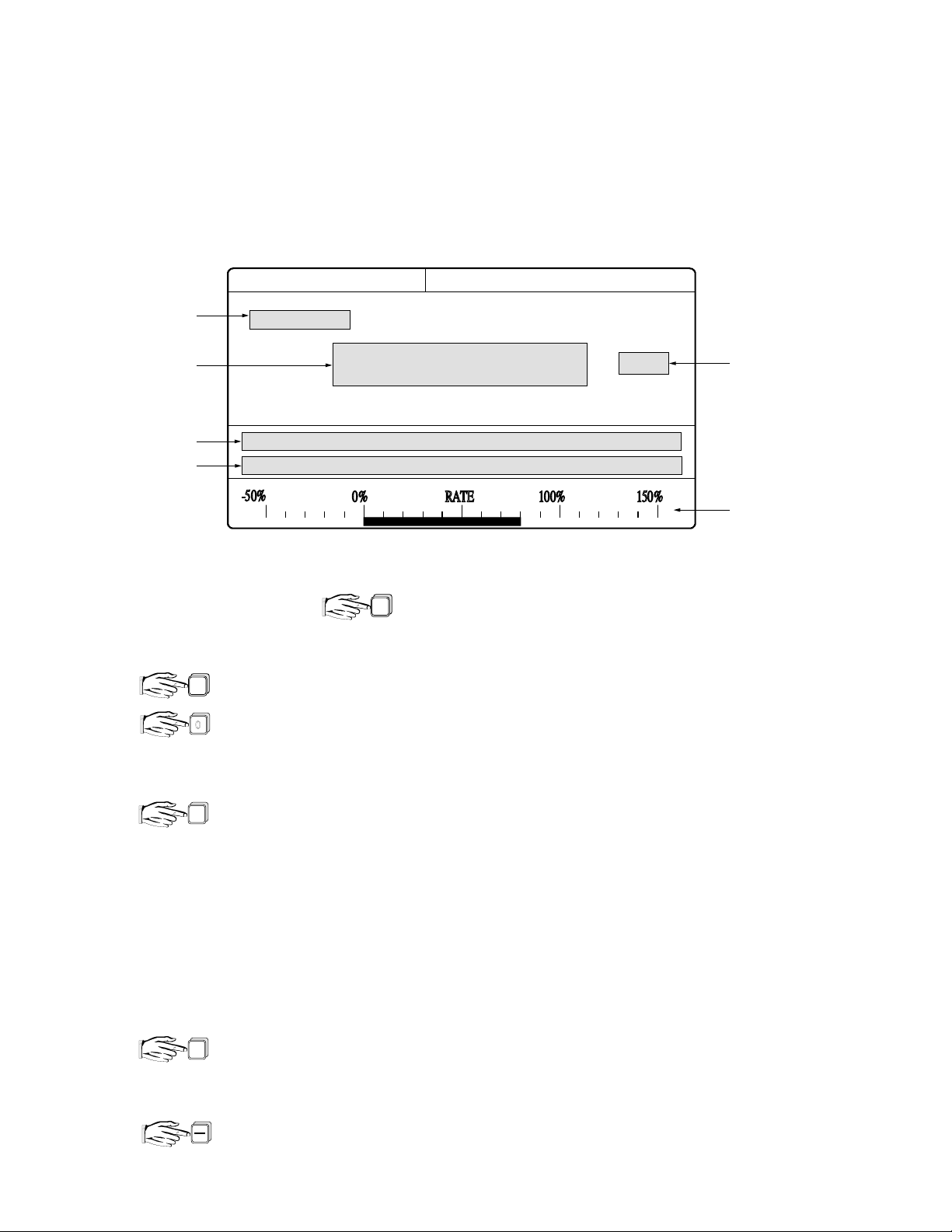

The CompuFlo III display is divided into the following fields:

MULTISPAN

FEATURE

ECAL

VALUE

RELAY

CALIB

CYCLE

UNITS

AUX 1

AUX 2

-50%

150%100%RAT E0%

RATE BAR

GRAPH

FIELD DESCRIPTION

MULTISPAN current span calibration selected. If Multispan 0 is selected, the field is blank.

RELAY current relay status (run mode). If re lays are not used, or in non-alarm, the field is blank.

FEATURE para meter number (parameter entry), calibration type (calibrate mod e), Rate or Total (run mod e)

ECAL indicates ECAL (simulated rate signal) is on. If ECAL is off, the field is blank.

CYCLE full cycles remaining before calibration completion (calibrate mode).

CALIB calibrate mode indicator. When displayed, tota lizers are on HOLD (unless otherwise specified).

VALUE the current va lue associated with the featur e selected.

UNITS the units of measure associated with the value displayed

AUX 1 parameter name (parameter entry), auxiliary message (cali b rate mode), not used (run mode).

AUX 2 parameter value range (paramet er entry) , addit ional information or error message (any mode).

BAR GRA PH represents current rate, displayed as percent of span (run mode).

PL-368 4 – 4

■

Page 15

PROGRAMMING

GENERAL

Information specific to a particular application is entered into the Com puFlo III memory, via the keypad, prior

to the calibration procedure.

KEYPAD

Button Operation Function

–

0

9

parameter entry numeric entries

4

8

RUN

PAR

ZERO

SPAN

ALT

DISP

RESET

TOTAL

parameter entry increase: analog mA output (P17 and P18 only), ECAL value (P22 only)

parameter entry decrease: analog mA output (P17 and P18 only), ECAL value (P22 only)

parameter entry decimal point

parameter entry negative entry or display prev ious parameter

any mode enter the run mode, return to previously selected display

any mode access parameter for entry or viewing

any mode access zero calibration, view current zero count

any mode access span calibration, view current span count

any mode enter the run mode, select rate or total display

any mode reset displayed totalizer value to zero (refer to Start Up\Hardware

Set Up\Total izer Reset)

CLEAR

parameter entry clear entry

calibrate mode abort calibration

ENTER

parameter entry display parameter value, or store altered parameter value,

or display next parameter

calibrate mode activate zero or span calibration, or accept calibration results

any mode with total displayed, switch to alternate total (ma in or sub)

PL-368 5 – 1

Page 16

PARAMETER ENTRY

Application information must be entered into the appropriate CompuFlo III memory locations . These locations

are identified by a Paramet er Number (P#). The information entered is referred to as a Parameter Value

(Value ). To enter informat ion, the operator accesses the desired parameter number, v iews the parameter

value displayed, and then accepts or alters the current parameter value.

Common Parameter Entry Display Fields

FEATURE

VALUE

UNITS

AUX 1

AUX 2

-50%

150%100%RATE0%

RATE BAR

GRAPH

DIRECT PARAMETER ACCESS

To directly access any parameter, followed by the parameter number.

PAR

Only valid parameter numbers will be accepted. Refer to PARAMETERS for the list of valid parameter

numbers.

eg. [PARAMETER ] is displayed in the F EAT URE field, if PARAMETER 0 is desired

[PARAMETER 0 ] is displayed in the F EAT UR E field,

PAR

0

[RATE UNITS ] is displayed in the AUX 1 field.

To view the current paramet er value and auxiliary messages for the displayed parameter,

ENTER

[PARAMETER 0 ] is displayed in the FEAT UR E field

[ 1 ] is displayed in the VAL UE field (unless previously altered)

[RATE UNITS ] is displayed in the AUX 1 field

[1:T/h;2: LT/h;3: lb/ h;4: lb/m in ] is displayed in the AUX 2 field (with SW1-5 open)

AUTOMATIC PARAMETER ACCESS

Upon accessing any parameter value, pressing "ENTER" will autom atically access the next parameter in the

programming sequence. Pressing "-" will automat ically access the previous parameter.

eg. with the VA LUE field of PARA METER 0 displayed...

ENTER

[PARAMETER 1 ] is displayed in the FEAT UR E field

[ 0.0000 ] is displayed in the VAL UE field (unless previously altered)

[RATE ] is displayed in the AUX 1 field

[ENTER VALUE ] is displayed in the AUX 2 field

all fields associated with PARAMETER 0 are displayed

PL-368 5 – 2

Page 17

ALTERING PARAMETER VALUES

Once the desired parameter number is accessed, the parameter value may be accept ed or altered as

required.

eg. if the VALUE f ield of PARAMETER 0 is 1 (T/h), however 2 (LT/h) is desired

2

ENTER

[ 2 ] is displayed in the VALUE fi eld

the new value (2) is now stored in memory

LAST PARAMETER RECALL

From the Calibrate or Run mode, the last parameter accessed in the Program mode, may be recalled.

the last parameter accessed is displayed.

ENTER

PAR

PARAMETER RESET

To reset all parameters to factory settings, refer to PARAMETE RS/P99 M aster Reset.

PROGRAMMING SEQUENCE

Typically, the CompuFlo III is programmed as follows:

a) Referring to PARAMETERS, copy the selected parameter v alues to the spaces provided on

the PROGRAMMING CHART fold out.

b) Perform a MASTER RESET (P99).

c) Access each parameter ( in sequence from P 0) and enter the parameter values

from the PROG RAMM ING CHA RT.

d) Perform a Zero and Span calibration (refer to CALIBRATION)

e) Perform Span Adjust (P8) or Factoring (P9) procedures, as req uired.

Remember to copy any parameter value alterations onto

the PROGRAMMING CHART for future refer ence.

QUICK START PROCEDURE

The Quick Start Procedure describes the minimum star t up, programming, and calibration requirements of the

CompuFlo III, to obta in successful RUN mode operation for most applications.

If desired, refer to APPENDICES /Quick Start. Parameters which are not included in the procedure may be

program med after the RU N mode is entered.

■

PL-368 5 – 3

Page 18

Page 19

CALIBRATION

GENERAL

As mater ial flow characteristics often vary, frequent calibration may be required to maintain calibration

accuracy. Normally, a Zero calibration is performed first, follo wed by a Span calibration.

When the CompuFlo III is first commissioned, several Zero and Span calibrations are normally performed to

verify the calibration results are repeatable.

A Zero or Span calibration (in progress) may be aborted by .

MULTISPAN

FEATURE

ECAL

VALUE

AUX 1

AUX 2

-50%

CLEAR

CALIB

CYCLE

UNITS

150%100%RATE0%

RATE BAR

GRAPH

INITIAL CALIBRATION REFERENCES

The first calibration performed, establishes the Initial Zero and In itial Span calibration references. Subsequent

Zero and Span calibration results are compared to these references. The maximum acceptable deviation

between an Initial Calibration Reference and a subsequent calibration result is 12.0% of span. Otherwise,

[ZERO OUT OF RANGE] or [SPAN OUT OF RANGE] is displayed in the AUX 2 field.

While a calibration in progress is establishing an initial calibration reference, the dynamic count value is

displayed in the VALUE field. Otherwise, the dynamic rate value is displayed.

The initial calibration refer ences may be reset. Refer to Parameters/P77 Initial Zero Reset and P88 Initial

Span Reset. Both initial calibration refer ences (along with other programming) are erased by a Master Reset

(P99).

PL-368 6 – 1

Page 20

ZERO

The average no flow input from the flowmeter is calculated and stored in memory as a Zero count. With no

material flow or Test Weight applied to the flowmeter...

[ZERO] is displayed in the FEATURE field. The current Zero counts are displayed in the

ZERO

VALUE field. [ENTER: CALIBRATE MODE] is displayed in the AUX 2 field.

to initiate the calibration. [CALIB] is displayed in the CALIB field and [ZERO IN PROGRESS]

ENTER

is displayed in the AUX 2 field. The time required to complete the calibration (and calibration

accuracy) is dependent upon the Calibration Duration (Refer to Parameter s/P30 Calibration

Duration). The number of full calibration cycles remaining until completion, is displayed in

the CYCLE field.

When complete, the deviation from the last Zero calibration is displayed in the VALUE field,

as a percent of span.

to accept the new calibration. Otherwise, investigate the reason for the deviation and

ENTER

perform the Zero calibration again.

SPAN

The simulated material flow provided by the Test Weight (or number of Test Weights) is calculated and stor ed

in memory as a Span count. (Ref er to Alternate Test Ref erences, if a Test Weight is not us ed.)

With no material flow or Test Weight applied to the flowmeter.. .

[SPAN] is displayed in the FEATURE field. The current S pan counts are displayed in the

SPAN

VALUE field.

With [CALIB] displayed in the CALIB field, apply the Test Weight to the flowmeter

(as described in the flowmeter manual).

If [ CALIB] is not displayed, respond to the CompuFlo III display prompts until this

indicator is obtained, before applying the Test Weight.

to initiate the calibration. The time required to complete the calibration (and calibration

ENTER

accuracy) is dependent upon the Calibration Duration (Refer to Parameter s/P30 Calibration

Duration). The number of full calibration cycles remaining until completion,

is displayed in the CYCLE field.

When complete, the deviation from the last Span calibration, is displayed in the VAL UE field,

as a percent of span.

to accept the new calibration. Otherwise, investigate the reason for the deviation

ENTER

and perform the Span calibration again.

CALIBRATION ACCURACY

With the Initial Zero and Initial Span calibration complete, RUN mode operation is possible, however greater

calibration accuracy may be requ ired. The Test Reference value (P7) is an approximation, based on typical

material flowrate characteristics.

To adjust the Span calibrat ion to suit the actual material flow characteristics encountered, perf orm a m aterial

test. (Refer to Par ameters/P8 Span Adjust). The Test Reference value is automatically adjusted so the Test

Weight will accurately simulate material flow during future Span calibrations.

The CompuFlo III is now ready to be put into servi ce, (refer to Operation).

PL-368 6 – 2

Page 21

CALIBRATION ALTERNATIVES

AUTO ZERO

This feature automatically performs a Zero calibration, whenever material flow ceases in the RUN mode.

If the Auto Zero feature is desired, provide a dry contact input to the CompuFlo III terminals TB1-34 and

TB1-37. The contact may be activated by a material feed controlling device such as a motor control, material

control gate, or valve. The contact must be closed when the material feed is stopped.

When the contact is closed, and material flow has stopped (within 4% of span from the current zero refer ence)

[AUTO ZERO IN PROGRESS] is displayed in the AUX 2 field. The time required for completion is dependent

upon Calibration Duration (P30). The number of fu ll calibration cycles remaining until completion is displayed

in the CYCLE field.

When complete, the Auto Zero is compared to the last operator Zero.

If the Auto Zero is within 2% of span from the last operator zero, the CompuFlo III briefly displays

[CALIBRATION COMP LETE] in the AUX 2 field and the deviation from the current zero refer ence in the

VALUE field. The Auto Zero is automatically accepted and RUN mode operation continues.

Otherwise, the Auto Zero results are rejected, and operation continues with the previous zero reference.

LOCKOU T MODE

In this mode, parameters may be accessed for viewing. However, if a parameter value alteration is attempted,

the alteration is not permitted and [CERTIFICATION LOC KOUT] is displayed in the AUX 2 field.

To activate the lockout mode, close SW1 contact 6 (SW1-6) after the CompuFlo III is programmed

and calibrated.

The maximum acceptable deviation between the last Zero performed by the operator (before closing this

contact) and any subsequent Zero, is limited to 2% of span. Span calibrations are not permitted in this mode.

ON-LINE SPAN CALIBRATION

The On-Line Calibration feature may be used to routinely check (and adjust if necessary) the Span calibration

in the RUN mode, without interrupting the material flow.

Install a weigh bin (bin or silo equipped to provide a 4-20 mA output proport ional to weight) preceding the

flowmeter material infeed. Connect the weigh bin out put to the CompuFlo III TB1-18,19 terminals. Install a

material feed control device, preceding the weigh bin.

feeder

Max. (e.g. 90%)

High (e.g. 80%)

Calibrate the CompuFlo III for the weigh bin 4-20 mA input (P27).

Access On-Line Parameter Selection (P28) to enter the weigh bin:

reference weight , max limit, high limit, and low limit setp oints.

Assign a relay to the On-Line Calibration function, P51=2 (Relay 1)

or P52 =2 (Relay 2). Connect the assigned relay contacts to the

weigh bin material feed control device, such that when the On-Line

reference weight

relay is energized, the weigh bin material feed is stopped.

Low (e.g. 30 %)

When the On-Line Calibration is activated (P29) , normal operat ion

continues until the weigh bin fills to the max limit (e.g. 90%). While

filling, the percent full is displayed in the VALUE field. When the

max limit is reached, the relay assigned the On-Line function,

material flow

energizes to stop the weigh bin material feed.

PL-368 6 – 3

Page 22

As material is discharged from the weigh bin, the On-Line tota lizer is automatically activated when the high

limit (e.g 80%) is reached. When the low limit (e.g. 30%) is reached, the tota lizer is de-activated and the

assigned re lay de-energizes, thereby enabling the material feed to the weigh bin.

The CompuFlo III On-Line material total is compared to the weight of material discharged from the weigh bin

between the h igh and low limits (reference weight). The deviation between these values is displayed as a

percent of span in the VALUE field. The On-Line calibration r esults may be accepted, or rejected.

ALTERNATE TEST REFERENCES

For most applications, a Test Weight is applied to the flowmeter, to simulate material flow for the Span

calibration. Alternatively, the Co mpuFl o III internal refer ence (ECAL), may be used to simulate a flowmeter

input for Span calibrations. ECAL is normally used when applying a Test Weight would be impractical or

inconvenie n t (especially when t he flowmeter is installed in a hazardous area).

When a Test Weight is used exclusively, Test Reference selection (P20) is not required.

When the ECAL reference is selected (P20=1), ECAL is automatically applied when a Span calibration or

Factoring (P9) is activated, and removed when the process is complete or aborted. If a Test Weight and

ECAL are used periodically , the appropriate Test Reference must be selected (P20) before a Span calibration

(or Factoring) is performed.

When the ECAL reference is on, [E CAL] is displayed in the ECAL field.

ECAL CALIBRATION (INITIAL REFERENCE)

With essential parameters (P0, P1,P2,P3,P7, and P21) programmed as required, select the ECAL T est

Reference (P20=1). Access P7 again, [PARAMETER 7E] is displayed. (The "E" indicates the P7 value

displayed is associated with the ECAL Test Reference.)

Perform a Zero and Span calibration. (A Test Weight is not required as ECAL is automatically applied for

Span calibrations when P20=1). To obtain an accurate ECAL/flowmeter signal corre lation, perf orm a ma terial

test. Refer to Parameters/ P8 Span Adjust.

Upon the comp letion of the material test, the new ECAL Test Reference (P7E) value is automatically adjusted

so ECAL will accurately simulate material flow during future Span calibrations.

For best re sults, if the new P7E value is not between 50% to 100% of the Design Rate (P1) value, perform an

ECAL Adjust. Refer t o Parameters/ P22 ECAL Adjust.

ECAL CALIBRATION (ALTERNATE REFERENCE)

After the CompuFlo III Span calibration is completed with a Test Weight, ECAL may be used for subsequent

Span calibration checks. Using ECAL as a secondary reference is especially useful, when frequent Span

calibration checks are required but using a Test Weight would be impractical.

Select the ECAL Test Reference (P20=1). Adjust ECAL to the value desired (P22=2). Factor the adjusted

ECAL reference to the current span (P22=2 or P9).

After a primary reference (typi cally Test Weight) Span calibra tion deviation is

accepted, Factor the secondary reference (typical ly ECAL) to the new span.

Remember to select the appropriate Test Reference (P20) before

performing a Span calibration or Factoring procedure.

PL-368 6 – 4

■

Page 23

PARAMETERS

GENERAL

(F) indicates the paramet er value factor y setting (where applicable)

(V) indicates the parameter value ma y be viewed only.

(E) indicates the parameter value is essential for basic operation.

PARAMETERS

P0 RATE UNITS ( E)

Defines the desired Rate display engineering units of measure.

With SW1, contact 5 (SW1-5) in the open position (Imperia l units):

enter: 1 = short tons per hour (F)(T/h) 1 T/h = 2000 lb/h

2 = long tons per hour(LT/h) 1 LT/h = 2240 lb/h

3 = pounds per hour(lb/h)

4 = pounds per minute(lb/h)

With (SW1-5) in the closed position ( Metric units):

enter: 1 = metric tonnes per hour (F)(t/h) 1 t/h = 1000 kg/h

2 = kilograms per hour(kg/h)

3 = kilograms per minute(kg/m)

The SW1-5 position and the value of P0 should be set before any other programming.

To alter the Rate Units of a programmed CompuFlo III, set SW1-5 as desired, perform a

Reset (refer to Parameters / P99 Reset) and set P0 to the desired value.

P1 RATE (E)

Defines the rate of m ater ial flow (in P0 units) which will produce the full scale Rate output. (F=0.0000)

enter: Design Rate, Range = 0.0001 to 99999

P2 LOCAL TOTAL (E)

Defines the amount of m aterial to be tota lized, prior to initiating an internal totalizer (and Main / Sub Tota l

display) update, (F = 1). The weight portion of the Rat e Unit (P0) is assumed.

enter: .0001 .001 .01 .1 1 10 100 1000

.0002 .002 .02 .2 2 20 200 2000

.0005 .005 .05 .5 5 50 500 5000

If [TOT AL REGIS TRA TION TOO LOW] is displayed, enter a higher value.

PL-368 7 – 1

94/04/14

Page 24

P3 REMOTE TOTAL (E)

Defines the amount of material tota lized, prior to ini tiating a remote totali zer relay contact closure, (F = 1). The

weight portion of the Rate Unit (P0) is assumed.

The frequency of remote totalizer contact closures is dependent upon t he material flowrate and the Remote

Total value. When a remote totalizer is connected to TB1-48,49, refer to the totalizer manufacturers

instructions to determine the maximum pulse frequency. Lower values increase and higher values decrease

the relay contact closure frequency.

enter: .0001 .001 .01 .1 1 10 100 1000

.0002 .002 .02 .2 2 20 200 2000

.0005 .005 .05 .5 5 50 500 5000

If [TOTAL REGISTRATION TOO LOW] is displayed, enter a higher value.

P7 TEST REFERENCE (Test Rate) (E)

Defines the simulated material flowrat e represented by the Test Reference selecte d (P20) for the Mu lti Span

(P26) selected.

This value is entered in design Rate (P0) units. If a value of 0 is entered, the system design Rate (P1)

value is assumed.

enter: Test Rate (refer to the associated flowmeter instruction manual for

calculation instructions. F = 0 until P1 is set.)

P8 SPAN ADJUST

Adjusts the test reference calibration results to improve material flowrate measurement accuracy.

% CHANGE - Calculate the deviation between the CompuFlo III Tota l and the actual material weight.

A positive value reduces (negative increases) the Rate displayed.

% Span Error = CompuFlo III Total - Actual Material Weight x 100

Actual Material Weight

MATERIAL TEST - Alternatively, the automatic method may be used. Perform a material test as follows:

a) With no material flow and the test reference (Test We ight, or ECAL) removed,

b) Sele ct the ma terial test option, select the HOLD TOTAL or ADD TO TOTAL option

press "ENTER" to activate the Material Test.

c) Feed a sample of material through the flowmet er press "ENTER" to stop the Material Test.

d) Enter the actual material sample weight. The Span deviation % is displayed.

e) Press "ENTER" to complete, (or "CLEAR" to abort ), the procedure.

Span Adjust calibrations are improved with larger material samples. Run at the normal flowrate; which should

exceed 50% of the design Rate (P1).

A Span Adjust, utilizing either method, alters the span count of the Multispan number (P26) selected, and

Test Reference (P7) value of the Test Reference selecte d (P-20). Copy the altered P7 value to the

Programm ing Chart

enter: 0 = Span Adjust not required (F)

1 = % change, (enter desired adjustment as a percent of span)

2 = material test, (ent er the actu al material weight )

PL-368 7 – 2

Page 25

P9 FACTORING

Adjusts the Test Reference value (P7) of the Test Reference selected (P20).

After the CompuFlo III is calibrated utilizing a known Test Reference (e.g. Test Weight representing 20 T/h),

the material flowrate represented by an unknown Test Reference (e.g. alternate Test Weight), may be

established.

This featur e may also be used if Span calibrations per formed with one Test Reference, tend to consistently

provide greater accuracy than Span calibrations with another Test Reference.

Factoring is not necessarily required after a Span Adjust (P8), as the T est Reference (P7) value of the Test

Reference (P20) for the Multispan Number (P26) selected , is automatically factored by the CompuFlo III.

After performing a Span calibration utilizing the known Test Reference (P20):

a) With the material flow stopped, apply the unknown Test Refer ence.

b) Select the Test Reference to be adjusted (P20).

c) press "1","ENTER" and wait for the Calibration Duration (P30) . When complete,

d) copy the adjusted Test Reference (P7) value displ ayed, to the PR OGRAMMING CHART.

If [ZERO CALIBRATION REQUIRED] is displayed, perform a Zero calibration

prior to re - attempting the factoring procedure. If a Zero calibration has

been performed very recently, press "CLEAR","ENTER", and proceed.

enter: 0 = Factoring not required (F)

1 = Factoring required (with material flow stopped, and s e lecte d test reference a ppli ed)

P10 L OW TOTAL CUTOFF

Defines the minimum material flowrate to be processed for Local Total values and Remote Total contact

closures. Range = 0.0 to 100.0.

This feature eliminates the totalizer activity which could occur due to flowmeter vibration or small amounts of

air passing through the flowmeter, when material flow is stopped.

With calibration complete, material flow stopped, and the Rate displayed, observe the highest display value.

Enter the value as a percent of design Rate (P1).

A value of 0 will permit the Total display to count up or down. Remote Total contact closures cease while the

total counts down. The contact closures will resum e when the Total display regains the amount by which it

counted down.

enter: desired value (F = 3.0)

PL-368 7 – 3

Page 26

P11 RATE DISPLAY DAMPING

Defines the level of damping to be applied to the Rate display. Range = 1 to 999

This may be used to stabilize a fluctuating rate display without affecting accuracy. Higher values provide more

stabilization. Press "RUN" to instantly update the Rat e display to the curr ent rate.

enter: desired value (F = 1)

P14 RATE OUTPUT DAMPING

Defines the level of damping to be applied to the Rate O utput. Range = 1 to 999

This may be used to stabilize a fluctuating Rate Output without affecting accuracy. Higher values provide

more stabilization. Rate Output Damping is disabled if the Rate Output Average (P15) feature is utilized.

Press "RUN" to instantly update the Rat e Output to the current rate.

enter: desired value (F = 1)

P15 RATE OUTPUT AVERAGE

Defines the period in seconds between Rate O utput updates. The value held, corresponds to the averaged

Rate of the previous period. Range = 0 to 999.

A value of 0 may be entered if Rate output averaging is not desired.

enter: desired value (F = 0)

P16 RATE BAR GRAPH ASSIGNMENT

Defines the output value the Rate Bar Graph Display represents, as a percent of span.

enter: 0 = Rate Output (P14) (F)

1 = undamped Rate

2 = Rate Display (P11)

P17 RATE OUTPUT MIN

Adjusts the Rate Output reference value for minimum material flowrat e. Range = 0 to 4095.

a) With Change Mode activate d and mA meter in series with the load connected to TB1-20,21,

b) Press "CLEAR" before keying in the estimated reference value, and pressing "ENTER".

c) Repeat step b) as required to produce the desired minimum Rate Output.

Briefly press "4" (increase by 10’s), or "8" (decrease by 1’s) to fine adjust the reference value, if necessary.

ent er: 0 = no adjust ment required

1 = Activat e Change Mode (F = 631, for 4.00 mA)

PL-368 7 – 4

Page 27

P18 RATE OUTPUT MAX

Adjusts the Rate Output refer ence value for maximum material flowrate. Range = 0 to 4095.

a) With Change Mode activated and mA meter in series with the load connected to TB1-20,21,

b) Press "CLEAR" before keying in the estimated reference value, and pressing "ENTER".

c) Repeat step b) as required to produce the desired maximum Rate Output.

Briefly press "4" (increase by 10’s), or "8" (decrease by 1’s) to fine adjust the reference va lue, if necessary.

ent er: 0 = no adjust ment required

1 = Activate Change Mode (F = 3160, for 20.00 mA)

P20 TEST REFERENCE SELECTION

Defines the type of test reference selected to represent a material flowrate.

The test reference selected is indicated when the following parameters are accessed:

OPTION DESCRIPTIO N TEST REFERENCE (P7) SPAN ADJUST (P8) FACTORING P9

0 Test Weight [PARAMET ER 7] [PARAMETER 8] [PARAMETER 9]

1 ECAL [PARAMETER 7E] [PARAMETER 8E] [PARAMETER 9E]

When P20 = 1, ECAL is automatically applied whenever a Span calibration or Factoring procedure is

activated, and removed when the procedure is complete. Refer to Calibration \ Alternate Test References for

ECAL span calibration instructions.

ent er: 0 = rate (F)( test w eight)

1 = ECAL (electronic reference)

P21 SENSOR TYPE

Defines the type and number of flowmeter transducing elements utilized.

enter: 0 = LVDT (linear variable differential transformer), (F)

1 = 1 load cell

2 = 2 load cells

PL-368 7 – 5

Page 28

P22 ECAL ADJUST

Applies and permit s the adjustment of the internal electronic test reference.

Refer to Calibration / Alternate Test References for ECAL Span calibration instructions.

ECAL Adjust cannot be accessed unless the ECAL Test Reference (P20) is selected.

ECAL is adjusted in t he R UN mode with no material flow or Test Weight appli ed to the

flowmeter. When the Adjust option is selected, t he simulated flowmet er input is

applied to the CompuFlo III . Record all totalizer values before and after ad just ing EC AL.

To adjust ECAL :

a) Enter the RUN mode before accessing P22 and selecting the adjust option.

b) Press "CLEAR" before keying in the estimated reference value, (range = 0 to 4095)

and pressing "ENTER". If Span calibration already exists, entering 0 automat ically adjusts

ECAL to 100% of the current span.

c) Repeat step b) as required while observing the Rate Bar Graph.

d) Briefly press "4" (increase by 10’s) or "8" (decrease by 1’s) to fine adjust the reference

value, if necessary.

e) When the Rate Ba r Graph indicates the desired simulated Rate, press "ENTER"

f) Press "ENTER" again to Factor ECAL to the current span and comple te the adjustment.

enter : 0 = ECAL off, (if P20 = 1, ECAL will automatically be applied when a Span calibration or

Factoring process is activat ed, and removed when the proc ess is complete.

1 = ECAL on, (ECAL will be held on except while a Zero calibration is in progress.)

2 = ECAL adjust (adjust as desired, F=2000 when P21=0, 200 when P21=1 or 2).

P25 LINEARIZER

Provides compensation for repeatable non-linear material flow characteristics.

If the material flowrate through the flowmeter is relatively constant during normal operation (except for a few

moments during start up and shut down) linearization should not be requi red.

In rare cases, electron ic linearization may be required if the process monitored demands high accuracy over a

wide range of flowrates.

If the flowmeter linearity seems to vary (beyond acceptable limits) at various material flowrates:

1) Perform a new Zero and Span calibration (as close as possible

to 100% of P1 Rate) and a Span Adjust (P8).

2) Apply various Test Weights to the flowmeter to verify mechanical linearity, Non-linear operation with

Test Weights indicates a mechanical flowmeter problem. Investgate and correct.

3) Referring to the associated flowmeter manual(s), ensure all fl owmeter application recommendations

were followed. (If possible, modify the feeder or chute work as recommended).

PL-368 7 – 6

Page 29

If operation still seems to be non-linear, perform the following tests at 25%, 50%, and 75% of the P1 Rate.

a) With material flow stopped, reset the Sub Total.

b) Run a batch of material (larger is bett er) thr o ugh the flowmeter, maintaining a constant flowrate.

c) Record the batch Sub Total

d) Weigh the material batch (if the actual batch weight is not already known).

If for every flowrate tested, the actual batch wei ght is equal (or within the accuracy requirements) to the

displayed Sub Total, the act ual flowrate to measured flowrate relationship is linear.

Otherwise, enter the % comp en sation required for each flowrate (automatically selected).

% Compensation = Actu al Batch Weight - Sub Tota l x 100

Sub Tota l

Turn th e linearizer on, and repeat steps a) to d). Adjust the Point 1, 2, and 3 flow rates and % compensation

values as required until the desired results are obtained.

The linearizer values are applied to any Multispan (P26) selected.

enter: 0 = off

1 = on

2 = adjust, enter: point 1 flowrate (F=25% of (P1) Rate)

point 1 adjustment (F=0%)

point 2 flowrate (F=50% of (P1) Rate)

point 2 adjustment (F=0%)

point 3 flowrate (F=75% of (P1) Rate)

point 3 adjustment (F=0%)

P26 MULTISPAN

Defines the Span calibration result to be used for subsequent measurements. Range = 0 to 8.

This feature may be used to store the Span calibratio n associated with a number of different materia l types,

flow characteristics, particle sizes, etc.

To perform a Span calibration for a specific operating condition:

a) Select the Multispan number to be associated with the current operating condition.

b) Enter the Test Reference value (P7) for the Test Reference to be used (P20).

c) Perform a Zero and Span calibration.

d) Perform a Span Adjust (P8) or Factoring (P9), as required.

To recall the c alibration result (when the associated operating condition is re-encountered), select the

appropriate Multispan number. The Mu ltispan number may be selected by providing one or more temporary or

permanent closed contact(s) between the TB1 COM (e.g. TB1-37) and the following TB1 terminals:

PL-368 7 – 7

Page 30

MULTISPAN TB1 TERMINALS CONNECTED TO COM

NUMBER 41 40 39 38

1OOOC

2OOCO

3OOCC

4OCOO

5OCOC

6OCCO

7OCCC

8COOO

O = contact open C= contact closed

For convenience, the Multispan number selection may be provided by a BCD switch connected to the

appropriate TB1-38,39,40,41, and COM contacts.

Alternatively, the Multispan number may be selected via the keypad. If "0" is entered, the MULTISPAN field of

the display is blank and Multispan 1 is utilized.

enter: desired value, (TB1-38,39,40, and 41 contacts must be open), (F = 0).

P27 ON-LINE: INPUT CALIBRATION

Calibrates the CompuFlo III for the Zero and Span mA input from the b in weighing system. These values

represent the empty and full weight of the On-line calibration weigh bin. Range = 0.000 to 25.00

enter: 0 = On-line calibration not required (F)

1 = Zero calibration (with weigh bin empty, press "ENTER" when the display value is stable.)

2 = Span calibration (with weigh bin full, press "ENTER" when the display value is stable.)

P28 ON-LINE: PARAMETER SELECTION

Defines the actual material weights associated with the On-line calibr ation.

The reference weight is the actual weight of material contained in the wei gh bin between the high and low

limits. Enter the reference weight value in the weight portion of the Rate Units (P0) selected. Enter the max,

high, and low limits as a percent of full weigh bin :

Refer to Calibration / On-Line Span Calibration for comp lete calibration instruct ions.

enter : reference weight, range = 0.000 to 99999 (F = 0)

max limit, (material weight required to stop mater ial feed). Range = 0.000 to 100.0, (F = 0)

high limit, (material weight required to activate totalizer). Range = 0.000 to 100.0 (F = 0)

low limit, (material weight required to de-activate total izer). Range = 0.000 to 100.0 (F = 0)

PL-368 7 – 8

93/12/01

Page 31

P29 ON-LINE CALIBRATION

Activ a tes the On-line calibration.

Upon completion, the On-line calibration may be accepted, or rejected. Refer to Calibration / On-Line Span

Calibration for complete instruct ions.

enter: 0 = On-Line calibration not required (F)

1 = Act ivate On-L ine calibration

P30 CALIBRATION DURATION

Defines the number of 10 second time periods the CompuFlo III will utilize to perform a Zero or Span

calibration, Factoring (P9) , or Verification Totalizer (P31) operation.

Range = 0.01 to 99

A low value reduces calibration time, while a high value increases calibration accuracy.

ent er: desired value, (F = 1)

P31 VERIFICATION TOTALIZER

Activates a secondary internal totalizer which totals the amount of material conveyed during the Calibration

Duration (P30). This feature may be used to verify calibration accuracy from the RUN mode without stopping

material flow.

The amount of material totalized by the verification totalizer may be included or excluded from the

totalizer counts.

enter: 0 = verification totalizer off (F)

1 = do not totalize material during the verif icat ion.

2 = totalize material during the verification.

P32 VERIFICATION TOTALIZER RESOLUTION

Defines the amount of m aterial weight to be measured, prior to initiating a verification tot alizer update. The

weight portion of the Rate Unit (P0) is assu med.

enter: 0 = same as the Local Total (P2) value.(F)

1 = 1/10 of the Local Total (P2) value.

PL-368 7 – 9

Page 32

P40 BAUD RATE

Defines the baud rate for PORT 1 data message communication.

The baud r ate must be set to the value required by t he externa l dev ice(s) connected to the PORT1 (T B1)

current loop or RS-232C communication connections.

enter: 300

1200

2400

9600 (F)

P41 DATA TRANSMIT INTERVAL

Defines the time lapse in minutes between unsolicited data message transmissions.

Range = 0 to 99999

The Data Transm it Interval may be adjusted as re quired to control the level of message traffic between the

CompuFlo III and the external device(s) connected to the PORT 1 and/or PORT 2 bipola r current loop or

RS-232C communication connections.

If a value gr eater than 50,000 is enter ed, the data message (P42) is transmitted only when the TB1-35,37

contacts are closed.

enter: desired value, (F = 30)

P42 DATA MESSAGE

Defines the ASCII message to be transmitted after every Data Transmit Interval (P41) or when TB1- 35,37

contacts are closed.

The current tim e and date ar e transmitt e d with each messa ge. The SYSTEM message includes the value of

parameters P0, 1,2,3, 7, and 21.

enter: 0 = no message (F)

1 = RATE

2 = MAIN TOTAL

5 = RATE and MAIN TOTAL

9 = SYSTEM

P43 SERIAL PRINTER

Sets the communication mode to suit a serial printer.

enter: 0 = off (F)

1 = on (SW2-7 must be closed for PORT 2/printer communication)

PL-368 7 – 10

Page 33

P51 RELAY 1

Defines the operation of Relay 1 as a Rate Alarm or On-Line calibration prefeed control.

If the Rate Alarm function is selected, the High Limit, Low Limit, and Deadband values are entered as a

percent of span.

The High Limit is the high alarm set p o int value which will cause the re lay to de-en ergize. If a high limit is not

required, set the high limit to 0.

The Low Limit is the low alarm set point value which will cause the re lay to de-energize. If a low limit is not

required, set the low limit to 0.

The Deadband is the amount which the dynam ic Rate must exceed the low limit and/or fall below the high

limit before the re lay energizes. The deadband value must be less than the difference between the high and

low limit setpoints.

If the On-line calibration function is selected, the Max Li mit and Low Limit values are set by On-line:

Parameter Selection (P28). When the Max Limit setpoint value is reached the relay energizes and remains

energized until the Low Limit setpoint value is reached.

ent er: 0 = Relay 1 off (F) (always de-energized)

1 = RATE

2 = ON-LINE

If the Rate function was select ed, the High Limit may now be set.

enter: desired High Limit value, (Range = 0.000 to 100.0, F = 98), advances to Low Limit

desired Low Limit value, (Range = 0.000 to 100.0, F = 35), advances to Deadband

desired Deadband value, (Range = 0.000 to 100.0, F = 5)

P52 RELAY 2

Defines the operation of Relay 2 as a Rate Alarm or On-Line calibration prefeed control.

If the Rate Alarm function is selected, the High Limit, Low Limit, and Deadband values must be enter ed as a

percent of span.

The High Limit is the high alarm set p o int value which will cause the re lay to de-en ergize. If a high limit is not

required, set the high limit to 0.

The Low Limit is the low alarm set point value which will cause the re lay to de-energize. If a low limit is not

required, set the low limit to 0.

The Deadband is the amount which the dy namic va lue must exceed the low limit and/or fall below the high

limit before the re lay energizes. The deadband value must be less than the difference between the high and

low limit setpoints.

If the On-line calibration function is selected, the Max Li mit and Low Limit values are set by On-line:

Parameter Selection (P28). When the Max Limit setpoint value is reached the relay energizes and remains

energized until the Low Limit setpoint value is reached.

ent er: 0 = Relay 1 off (F) (always de-energized)

1 = RATE

2 = ON-LINE

PL-368 7 – 11

Page 34

If the Rate function was selected, the High Limit may now be set.

enter: desired High Limit value, (Range = 0. 000 t o 100.0, F = 98), advances to Low Limit

desired Low Limit value, (Range = 0.000 to 100.0, F = 35), advances to Deadband

desired Deadband value, (Range = 0.000 t o 100.0, F = 5)

P55 100% TEST REFERENCE (V)

Displays the design Rate (P1) value.

P60 SOFTWARE REVISION (V)

Displays the revision number of the software progr am stored in EPROM 1.

P61 MEMORY TEST (V)

Perform s a test on th e EPROM 1 memory. U pon completion, [CHECKSUM CORRECT] is displayed to

indicate a successful test.

P63 TOTALIZER CONTACT DURATION

Defines the duration of the remote totalizer relay contact closure in seconds. Range = 0.025 to 8.323

This value is automatically set, based on the Rate (P1) and Remote Total (P3) values entered. If necessary,

adjust this value to provide the duration required by the device connected to TB1-51,52. An entered value is

automatically adjusted to the next higher value permitt ed.

If t he value entered is too high, [TOT AL REGISTRATI ON TOO LOW] will be displayed. Incre ase the Remote

Total (P3) value.

When 0 is entered, the system selected value is entered.

enter: desired value (F = 1, until P1 and P3 values are entered)

P64 ZERO RECORD (V)

Displays the number of operator initiated Zero calibrations perf ormed since the last Master Reset (P99) or

Initial Zero Reset. (F = 0).

P65 SPAN RECORD (V)

Displays the number of operator initiated Span calibrations performed since the last Master Reset (P99) or

Initial Span Reset (P88). (F = 0).

PL-368 7 – 12

Page 35

P66 SECURITY LEVEL

Defines the level of operator access permitted.

This feature may be utilized to ensure the programming and/or calibration is not inadvertentl y altered. Access

to all RUN mode displays and the P66 value is permitted at all Security levels. When a security level is

selected, Security is not invoked until the RUN mode is enter ed. From th e RUN mode, accessing P66

disables Security until the RUN mode is entered again.

enter: 0 = fu ll access permitted (F)

1 = parameter values secured

2 = parameter and Main Total display values secured.

3 = parameter values, Zero and Span calibrations secured.

4 = parameter and Main Total display values, Zero and Span calibrations secured.

P70 CLOCK/CALENDAR

Defines the current Time and Date, to be ma inta ined by the internal clock.

enter: desired value, (Hours, range = 0 to 23, advances to minut es),

desired value, (Minutes, range = 0 to 59, advances to day),

desired value, (Day, range = 1 to 31, advances to month),

desired value, (Month, range = 1 to 12, advances to year),

desired value, (Year, range = 00 to 99, r eturns to hours)

P71 TIME (V)

Displays time in t wenty-f our hour format, (HH:MM).

P72 DATE (V)

Displays date in YY/MM/DD format.

P77 INITIAL ZERO RESET

Performs a Zero Calibration to estab lish the new Initial Zero count value.

This feature is normally used in response to the [ZERO OUT OF RANGE ] message, when the cause of the

deviation is not otherwise correctable. This condition could occur as the result of an intended change in the

Design Parameter values or a mechanical change to the flowmeter assembly.

enter: 0 = not required (F)

1 = Initial Zero Reset

P80 V/F CONVE RTER OUTP UT (V)

Displays a reference count propo rtional to the input level from the flowmeter. Range = 0 to 131,000.

This feature is normally used to verify the integrity of the flowmeter load sensors and cable(s).

PL-368 7 – 13

Page 36

P81 LOAD CELL A (V)

Displays the input from the load cell connected to TB1-1,2 in mV. Range = 0.00 to 50.00

Access to this parameter may on ly be gained when SENSOR TYPE (P21) is set to 2. This feature is normally

used to verify the integrit y of th e load cell after initial installation or subsequent replacement.

P82 LOAD CELL B (V)

Displays the input from the load cell connected to TB1-3,4 in mV. Range = 0.00 to 50.00

Access to this parameter is gained when SENSOR TYPE (P21) is set to any value greater than 0. This

feature is normally used to verify t he integrity of the load cell after initial installation or subsequent

replacement.

P85 V/F CONVERTER INPUT (V)

Displays the sum of the amplified load sensor (P21) input voltage(s). Range = -1.00 to 4.00.

P86 ON-LINE CALIBRATION (Input Current) (V)

Displays the CompuFlo III TB1-18,19 mA input from the bin weighing system. Range = 0.00 to 25.00.

P88 INITIAL SPAN RESET

Performs a Span calibration to establish a new Initial Span count value.

This feature is norm ally used in response to the [SPAN OUT OF RANGE] message, when the cause of the

deviation is not otherwise correct able. This condition could occur as the result of an intended change in the

Design Parameter values or a mechanical change to the flowmeter assembly.

enter: 0 = not required (F)

1 = Initial Span Reset

P90 BALANCING PROCEDURE

Initiates the Load Cell Balancing procedure.

This procedure is only required if the connected flowmeter util izes two load cell sensing elements and is

equipped with two Test Weight suspension points. This parameter may on ly be accessed when Sensor Type

is set for 2 load cells (P21 = 2).

Prior to initial calibration or fo llowing a load cell replacement, the load cell balancing procedure should be

performed. When the flowmeter load cell signals are balanced, variable material flow patterns have less effect

on flowmeter measurements.

When the load cell balancing procedure is initiated, P91 through P95 must be accessed in sequence. Direct

access to these parameters is not permitted.

PL-368 7 – 14

Page 37

When the loadcell balancing procedure is completed, perform a Zero and Span calibraton before entering the

Run mode.

enter: 0 = load cell balancing not required (F)

1 = balancing procedure required, (press "1", "ENTER" to advance to P91)

P91 POS B LC (A+B) (V)

Displays the summed load cell input counts.

Apply the Test Weight to a flowmeter Test Weight suspension point. (Refer to the flowmeter instruction

manual for Test Weight application instructions).

enter: the displayed value (when stable) to advance to P92.

P92 POS B LC (B) (V)

Displays the load cell input counts of one load cell.

Ensure the Test Weight (as applied for P91) is not moved or otherwise disturbed.

enter: the displayed value to advance to P93.

P93 POS A LC (B) (V)

Displays the load cell input counts of one load cell.

Move the Test Weigh t to the other flowmeter Test Weight suspension point.

enter: the displayed value (when stable) to advance to P94.

P94 POS A LC (A+B) (V)

Displays the summed load cell input counts.

Ensure the Test Weight (as applied for P93) is not moved or otherwise disturbed.

enter: the displayed value to advance to P95.

P95 LOAD CELL BALANCE (V)

Displays the count value, which when entered, will ba lance the load cell signals.

enter: the displayed value to complete the load cell balance.

PL-368 7 – 15

Page 38

P99 RESET

Initiates a memory reset.

This feature clears memory locations and restores paramet er values to their original factory sett ings. The

implementation of a Reset necessitates CompuFlo III reprogramming and recalibration.

Neither Reset Level affects the Clock/Calendar settings. A Partial Reset maintains the previous, P17, P18,

P20, P21, P22, P27, P40, P41, P42, P43 and load cell balanc ing settings.

enter: 0 = reset not required (F)

1 = Partial Reset

9 = Master Reset

P100 PARAMETER LIST (V)

Displays paramet er names in groups of 10. Pr essing "ENTER" advances the display to the next group. This

parameter is not automatically scrolled and therefore must be accessed directly.

PL-368 7 – 16

■

Page 39

PROGRAMMING CHART

PAR NAME VALUE VALID RANGE (F or _ = factory setting)

P0 RATE UNITS [ ] IMP: 1(T/h), 2(LT/h), 3(lb/ h),4(lb/min) Metric: 1(t/h),2(kg/h),3(kg/min)

P1 RATE [ ] 0.0001 to 99999 (F = 0.000)

P2 LOCAL TOTAL [ ] 1,2,or 5 x .0001 .001,.01,.1,1,10,100,or 1000

P3 REMOTE TOTAL [ ] 1,2,or 5 x .0001 .001,.01,.1,1,10,100,or 1000

P7 TEST REFERENCE [ ] 0.0001 to 99999 (F = 0)

P8 SPAN ADJUST [ ] 0 (off), 1 (%change), 2 (material test)

P9 FACTORING [ ] 0 (off ), 1(fa ctor test refer ence)

P10 LOW TOTAL CUTOFF [ ] 0.0 to 100.0 (F=3.00)

P11 RATE DISPLAY DAMPING [ ] 1 to 999

P14 RATE OUTPUT DAMPING [ ] 1 to 999

P15 RATE OUTPUT AVERAGE [ ] 0 to 99999

P16 RATE BAR GRAPH ASSIG NMENT [ ] 0 (Rate Output, P14), 1 (undamped Rate), 2 (Rate Display, P11)

P17 RATE OUTPUT MIN [ ] 0 to 4095 (F = 631)

P18 RATE OUTPUT MAX [ ] 0 to 4095 (F = 3160)

P20 TEST REFERENCE SELECT [ ] 0 (test weight), 1 (ECAL)

P21 SENSOR TYPE [ ] 0 (LVDT), 1 ( 1 load cell), 2 (2 load cells)

P22 ECAL ADJUST [ ] 0 (off), 1 (on), 2 (adjust ), [ ] count

P25 LINEARIZER [ ] 0 (off), 1 (on), 2 (adjust)

[ ](pt 1),[ ](pt 2),[ ](pt 3) RATE

[ ](pt 1),[ ](pt 2),[ ](pt 3) % COMP

P26 MULTISPAN [ ] 0 to 8 (F = 0)

P27 ON-LINE:INPUT CALIB. [ ] 0 (off), 1 (zero), 2 (span)

P28 ON-LINE:PARAMETER SELECT [ ] (ref weight)[ ],(max) [ ],(hi)[ ], (lo)[ ]

P29 ON-LINE CALIBR ATI O N [ ] 0 (off), 1 (activate)

P30 CALIBRATION DURATION [ ] 0.1 to 99 (F = 1)

P31 VERIFICATION TOTAL [ ] 0 (off), 1 (HOLD TOTAL), 2 (add to Total)

P32 VERIFICATION TOTAL RES [ ] 0 (same as P2) , 1 (P2 x 1/ 10)

P40 B AUD RATE [ ] 300, 1200, 2400, 9600

P41 DATA TRANSMIT INTERVAL [ ] 0 to 99999 (F = 30)

P42 DATA MESSAGE [ ]

P43 SERIAL PRINTE R [ ] 0 (off), 1 (on)

P51 RELAY 1 [ ] 0 (off), 1 (Rate), 2 (On-line)

P52 RELAY 2 [ ] 0 (off), 1 (Rate), 2 (On-line)

P55 100% TEST REFERENCE [ ] 0.0001 to 99999 (F = Rate (P1), display only)

P60 SOFTWARE REVISION [ ] 1.00 to 99.99 (display only)

P61 MEMORY TEST [ ] Pass or F ail, (display only)

P63 TOTALIZER CONTACT DUR [ ] 0.025 to 8.323 seconds (F = 1 until P1 and P3 are set)

P64 ZERO RECORD [ ] (display only)

P65 SPAN RECORD [ ] ( d isplay only)

P66 SECURITY LEVEL SELECT [ ] 0(off),1(P#’s),2(P#’s,Total),3(P#’s,Zero,Span),4(P#’s,Total,Zero,Span)

P70 CLOCK/CALENDAR [ ] hrs(0-23),min(0-59),day(1-31),month(1-12),year(00-99)

P71 TIME [ ] HH:MM display, (24 hour format)

P72 DATE [ ] YY/ MM/DD format

P77 INITIAL ZERO RESET [ ] 0 (off), 1 (reset)

P80 V/F CONVERTER OUTPU T [ ] 0 to 131,000 counts, (display only)

P81 LOAD CELL A INPUT [ ] 0.00 to 50.00 mV, (display only)

P82 LOAD CELL B INPUT [ ] 0.00 to 50.00 mV, (display only)

P85 V/F CONVERTER INPUT [ ] -1.00 to 4.00 V, (display only)

P86 ONLINE: MA INPUT [ ] 0 to 25.0 mA, (display only)

P88 INITIAL SPAN RESE T [ ] 0 (off), 1 (reset)

P99 RESET [ ] 0 (off), 1 (Partial ), 9 (Master)

P100 PARAMETER LIST [ ] 0 to 99 in groups of 10, (display only)

0 (off), 1 (Rate),2 (Total),5 (Rate and Total),9 (System)

[ ](hi),[ ](lo),[ ] (deadband) in %

[ ](hi),[ ](lo),[ ] (deadband) in %

PL-368 8 – 1

Page 40

Page 41

OPERATION

INITIAL OPER ATION

Prior to the initial operation of the CompuFlo III the following checks should be made:

» the test ref erence should be removed from the flowmeter.

» the totalizer(s) should be reset to zero.

The CompuFlo III is now ready for service.

Ensure the CompuFlo III is in the RUN mode.

To enter the RUN mode,

RUN

The CompuFlo III assumes the last RUN mode display accessed.

ALT

If necessary, to display Ra te.

Open the material prefeed, ensuring the design Rate is not exceeded.

ALT

to display the current material tota l. Observe the total value incrementing.

DISP

DISP

A program of calibration checks should be performed frequently at first . The frequency of these checks may

be reduced as time and experience dictate.

All personnel should be inst ruct ed on the safe and proper operation of the CompuFlo III and be instructed

when and if a calibration check should be performed, what level of zero and span deviation is acceptable, and

when to reset the totalizer(s).

If desired, a photocopy of the following page may be provided, to personnel responsible for CompuFlo III

daily operation.

PL-368 9 – 1

Page 42

NORMAL OPERATION

START UP

Ensure power is supplied to the CompuFlo III.

When power is first applied, the CompuFlo III will automatically perfor m a series of tests for about 10 seconds

and then resume operation in the last mode entered.

The following procedures may be perf ormed on a routine basis, as required. Access to the Zero and Span

calibration, and Reset Total functions may be restrict ed.

ZERO CALIBRATION CHECK

Ensure the flowmeter test reference (Test Weight or ECAL) is removed. With no material flow,

ZERO

ENTER

to initiate a zero calibration. When complete (time dependent on programming) the

deviation from the last operator initiated zero calibration is displayed.

ENTER

if the zero deviation is acceptable.

If the zero deviation is not acceptable, or if [ZERO OUT OF RANGE] is displayed, investigate the reason for

the deviation, correct the condition, and try the zero calibration again.

SPAN CALIBRATION CHECK

If the following features were implemented during system programming, perform the following checks:

FEATURE CHECK

Test Reference Select (P20) Ensur e the desired Test Reference is selected.

Mu ltispan Number (P26) Ensure the appropriate Multispan number is selected.

Apply the flowmeter test reference (Test Weight or ECAL). With no material flow,

SPAN

ENTER

to initiate a span calibration. When complete (time dependent on programming) the

deviation from the last operator initiated span calibration is displayed.

ENTER

if the span deviation is acceptable.

If the span deviation is not acceptable, or if [SPAN OUT OF RANGE] is displayed, investigate the rea son f or

the deviation, correct the condition, and try the span calibration again.

Remove the flowmeter test reference.

RESET TOTAL

If necessary, reset the CompuFlo III tota lizer.

RESET

TOTAL

ENTER

CLEAR

to initiate a total izer reset.

to select the Main o r Sub Total.

to reset the selected Total display value to 0.

Refer to the manufacturers instructions to reset the remote to ta lizer , if any.

RU N

RUN

(and then if necessary) to display Rate.

ALT

DISP

Ac tiva te the material prefeed control device (if any) to begin running material through the flowmeter.

ALT

DISP

since the last Total Reset.

to access the Total displa y, observe the amount of material run through the flowmeter

PL-368 9 – 2

■

Page 43

COMMUNICATION

GENERAL

The CompuFlo III may be operated in one of the following serial communication modes:

» Remote (Milltronics Terminal)

» Host (IBM PC compatible computer or PLC)

» Serial Printer

The Bipolar Current Loop may be utilized for cable runs up to 1500 metres (5000 ft). If communication with an

RS-232 device is required, the Milltronics BIC-II or CVCC may be used to convert the Bipolar Current Loop to

RS-232. The BIC-II is also capable of Bipolar Current Loop to RS-422 conversion.

The CompuFlo III RS-232 port may be connected directly to an RS-232 device, where the communication

cable run is less than 15 m (50 ft).

To set the Port 1 communication baud rate to suit the device connected, refer to PARAMETERS/P40. To set

the Port 2 baud rate, refer to START UP/Hardware Set Up.

CompuFlo III

CVCC

or BIC II

( if required )

serial

printer

remote

terminal

OR

customer’s computer*

(*remote terminal emulation

software available)

( or BIC II )

customer’s

computer

PL-368 10 – 1

CVCC

Page 44

REMOTE COMMUNICATION

This mode provides complete access to all CompuFlo III functions via a Milltronics remote terminal. To

receive communication from the CompuFlo III PORT 1 or PORT 2 connection, SW2-6 of the remote terminal

must be closed.

Alternatively, a remote terminal emulation software package is available for IBM PC compatible computers

supporting colour graphics (VGA).

If the computer (supporting a parallel printer) is connected to PORT 1, (when P43=1) a printout containing the

Data Message (P42) selected is initiated each time:

» the Data Transmit Interval (P41) lapses

» a dry contact is provided across CompuFlo III TB1-35 and COM (e.g. TB1-36).

HOST COMMUNICATION

Host communication permits up to 16 CompuFlo III’s (serially connected via PORT 1), to communicate with a

computer or Programmable Logic Controller. Refer to Start Up\Hardware Set Up\Unit I.D. Code).

In this mode, data acquisition and analysis is accomplished by a customer supplied software package. Refer

to Protocol.

SERIAL PRINTER COMMUNICATION

Two modes of serial printer operation are available.

The Port 1 mode (similar to previous Milltronics integrator versions) printout is initiated each time :

» a dry contact is provided across pins 7 and 17 of the printer DP25 connector.

» the Printer Test button is pressed.

The printout contains the : time, date, total, and total engineering units.

The Port 2 mode is compatible with any serial printer.

Close the CompuFlo III SW2 contact 7 (SW2-7) and set the Data Transmit Interval (P41), Data Message

(P42) and Serial Printer (P43) parameters as desired. Refer to Parameters.

The printout, containing the Data Message selected, is initiated each time :

» a dry contact is provided across the CompuFlo III TB1-35 and COM (e.g. TB1-36)

» the Data Transmit Interval elapses.

PL-368 10 – 2

Page 45

PROTOCOL

Protocol refers to the format, sequence and value of the data fields utilized in Host Mode communication

messages. Each data field of a CompuFlo III message contains one or more bytes of ASCII binary code.

Each byte contains:

» 8 data bits

» no parity bit

» 1 stop bit

DATA FIELD DESCRIPTIONS

The following data fields are utilized in CompuFlo III host mode messages.

somIdentifies the start of a message (STX), ASCII character = 02.

DEVICE

Identifies the CompuFlo III to which the message applies. The device number equals the Unit

I.D. code, as set by SW1 contacts 1 - 4. ASCII characters = 00 to 15.

+20 mA

0

-20 mA

s12345678s

tsnrtttttt

at ddhhhhho

rp

t

MTIdentifies the message type transmitted, ASCII characters:

50 = material flow rate

53 = totalized material

READING

Contains the measurement value in the units of measure selected during CompuFlo III

programming. The number of bytes in this data field will vary dependent upon the reading

value. Up to 8 ASCII characters including the decimal point may be transmitted.

UNITS

Three ASCII characters identify the totalizer engineering units (MT = 53 only). The first

character is always a space. The remaining characters may be:

t = Metric Tons

LT = Long Tons

T = Short Tons

kg = Kilograms

lb = Pounds

EOM

Identifies the end of a message (CR), ASCII character = 0D.

PL-368 10 – 3

Page 46

MESSAGE REQUESTS

Message requests must be transmitted from the host to the CompuFlo III in the following format.

som DEVICE MT eom

Example:

Data ASCII Example

Field Character Description

som 02 start of message

DEVICE 01 for CompuFlo III # 1

MT 50 material flow rate request

eom 0D end of message

MESSAGE RESPONSES

The CompuFlo III response to a flow rate (MT=50) message request will be in the following format.

som DEVICE MT READING eom

Example:

Data ASCII Example

Field Character Description

som 02 start of message

DEVICE 00 from CompuFlo III# 0

MT 50 material flow rate response