Page 1

Pointek CLS 200

Capacitance Liquids/Solids

33455400

Rev 1.1

Instruction ManualInstruction Manual

PL-540

February 1998

Technology based. Customer driven.

Page 2

hank you for purchasing Milltronics products. We endeavour to design

T

equipment that is simple to use and reliable in its operation, with the aim

of satisfying our customers' needs.

Milltronics has been designing and manufacturing process equipment since

1954. Our fields of expertise include ultrasonic and capacitance level

measurement, in-line weighing of dry bulk solids and motion sensing.

Milltronics is established world wide through associate offices and

representatives. Our network is continually being refined to provide our

customers with first rate sales information, engineering assistance and after

sales support.

For more details on our products and service, please contact us and we will

provide you with a listing of the offices or representatives nearest you.

Page 3

ABOUT POINTEK CLS 200

Pointek CLS 200 is to be used only in the manner

outlined in this instruction manual.

The Pointek CLS 200 capacitance level switch provides output on high or low process material

levels. When the measured material approaches or contacts the switch’s probe, an increase in

capacitance is sensed and a high level alarm can be triggered. If a low level alarm is required

then the lack of material contact is sensed and this condition triggers the low level alarm.

Pointek CLS 200 Outputs

✓ One form ‘C’ (SPDT) relay

✓ One open isolated, non-polarized, solid-state switch

Pointek CLS 200 Features

NPT, BSP and 3A compliant Tri-clamp connections

✓

(other connections on request)

✓ Corrosion resistant construction, Kynar® and 316 stainless steel wetted parts

✓ 35m (115 ft) maximum insertion length

✓ Fully adjustable process alarm: level, time delay, and fail-safe mode

✓ Rigid extensions of standard and sanitary versions

✓ Cable version with customizable length

Pointek CLS 200 Applications

✓ Liquids, slurries, powders, granules, and solids

✓ Foods and pharmaceuticals

✓ Chemical and petrochemical

✓ High pressure and temperature

PL-540 3

Page 4

SPECIFICATIONS

Power: » 12 - 250 V ac/dc 50/60 Hz, 2 VA / 2 W max

Environmental: » location: » indoor / outdoor

» altitude: » 2000 m max

» ambient temperature: » -40 to 85 °C (-40 to 185 °F)

» relative humidity: » suitable for outdoor (Type 4X / NEMA 4X /

IP65)

» installation category: » II

» pollution degree: » 4

Process: » dielectric constant (

» temperature: » -40 to 125° C (-40 to 257° F)

» pressure: » standard and rigid extension versions

Alarm Output: » relay: » 1 form ‘C’ (SPDT) contact, rated 8 A at 250 V

» solid state switch: » rated 250 V ac / 300 V dc, 100 mA max

» time delay: » ‘on/off alarm’ selectable, 1 to 60 s adjustable

» hysterisis: » 2 mm (0.08")

» repeatability: » 2 mm (0.08")

» fail-safe operation

Electronics/Enclosure:» termination: » removable terminal block, 2.5 mm

» construction: » epoxy coated aluminum with gasket

» ingress protection: » Type 4X / NEMA 4X / IP65

» electrical: » 2 x

ε

r

)

:» 1.5 min

0 to 25 bar / 365 p.s.i. / 2500 kPa

gauge (nominal)

» cable version

0 to 10 bar / 150 p.s.i. / 1000 kPa gauge

(nominal)

ac / 5 A at 30 V dc, non-inductive

2

» optional thermal isolator, 316 stainless steel

1

/2" NPT conduit entry

max

PL-540 4

Page 5

Probe:

length, max. mounting * extension tensile, max. sensor

3

Standard 5.5 m (18 ft)

/4" NPT, 1" BSP,

1

/2" BSP,

1

316 stainless steel

Sanitary 5.5 m (18 ft) 1", 1 1/2" and 2", 3A

compliant Tri-clamp

Cable 35 m (115 ft)3/4" NPT, 1" BSP,

1

/2" BSP,

1

316 stainless steel

316 stainless

steel

316 stainless

steel

® **

Kynar

n / a Kynar

n / a Kynar

180 kg

Kynar®

(400 lb)

®

®

Approvals: » CE, CSA

®

Kynar

* other process connections available on request.

** for a chemical resistance list for Kynar, contact your local distributor.

FM, CENELEC, 3A, refer to device nameplate

NRTL/C

is a registered trade mark of ELF Atochem

PL-540 5

Page 6

INSTALLATION

LOCATION

Installation shall only be performed by qualified personnel

and in accordance with local governing regulations.

This product is susceptible to electrostatic shock.

Follow proper grounding procedures.

The Pointek CLS 200 standard probe length is normally mounted into the vessel top (high

detection alarm) or through the tank wall at the detection level (high or low detection alarm).

The extended versions are designed for top mounting. The probe suspends vertically so that it

reaches into the process at the desired detection level (high or low detection alarm).

vertical

PL-540 6

angle horizontal

Page 7

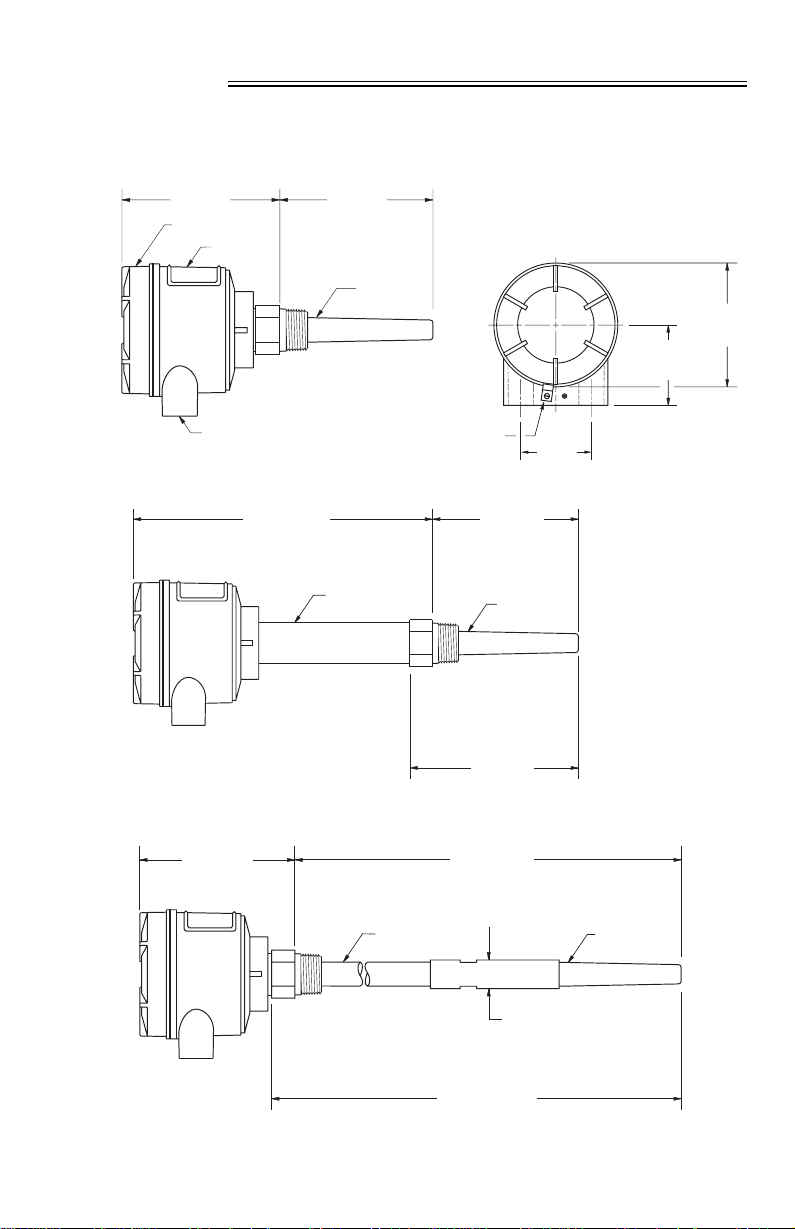

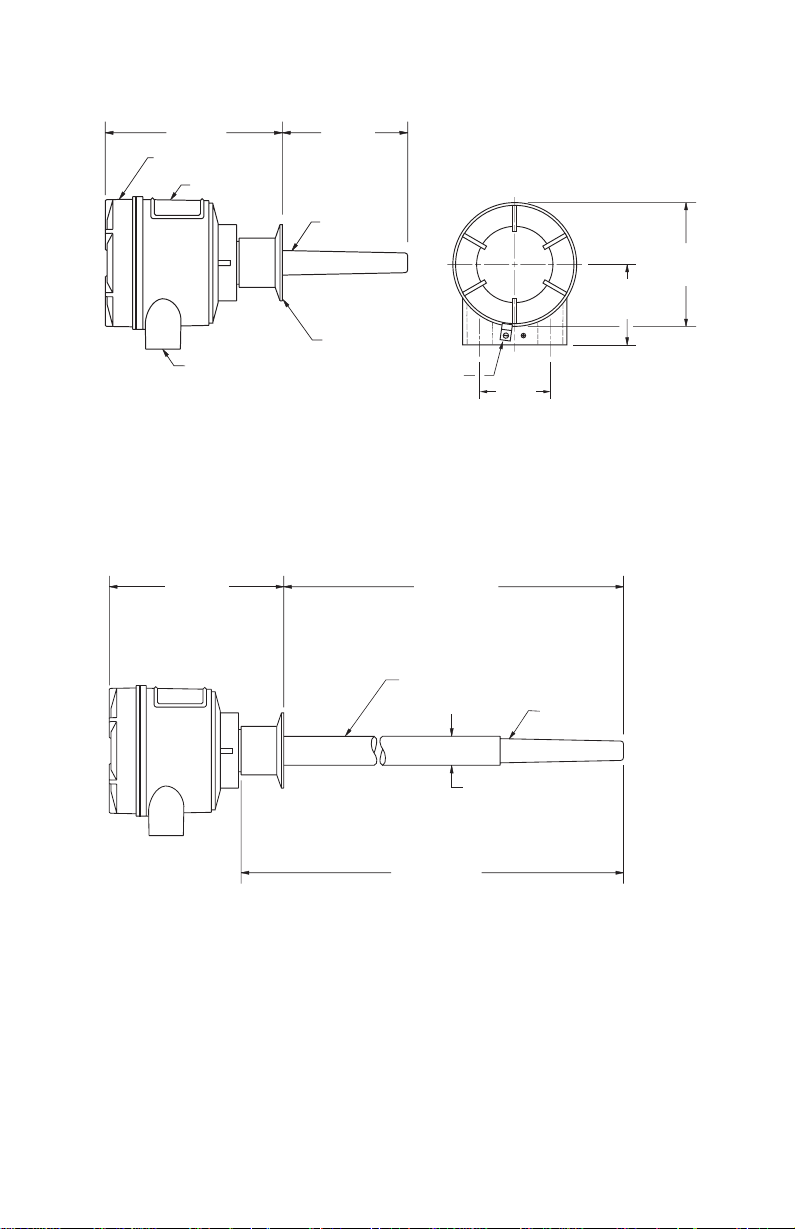

DIMENSION

CLS 200 VERSIONS

Standard

145 mm

(5.7")

lid

electronics /

enclosure

◆

120 mm

(4.7")

probe /

sensor *

120 mm

(4.7")

76 mm

(3")

1

/2" NPT

Standard with Thermal Isolator

245 mm

(9.7")

Standard with Extension

◆

145 mm

(5.7")

◆

thermal

isolator

extension

lid

clip

120 mm

probe*

5.5 m

(18 ft)

max

59 mm

(2.3")

(4.8")

sensor

sensor

* wetted parts are Kynar® and 316 stainless steel.

◆

nominal values

PL-540 7

20 mm (0.8") Ø

probe*

Page 8

Sanitary

165 mm

(6.5")

lid

electronics /

enclosure

1

/2" NPT

Sanitary with Extension

165 mm

(6.5")

◆

100 mm

◆

(3.9")

probe /

sensor *

120 mm

(4.7")

76 mm

(3")

sanitary

Tri-clamp

lid

clip

◆

5.5 m

59 mm

(2.3")

(10 ft)

max.

* wetted parts are Kynar® and 316 stainless steel.

◆ nominal values

PL-540 8

extension

sensor

23 mm (0.9") Ø

probe*

98\03\30

Page 9

Cable

76 mm

(3")

lid

clip

59 mm

1

/2" NPT

(2.3")

flexible

extension *

120 mm

(4.7")

145 mm

(5.7")

nominal value

35 m

(115 ft)

max

lid

electronics /

enclosure

◆

cable

◆ to set the sensor at the

desired alarm point, by

shortening the cable,

refer to Appendix \

Shortening the Cable

for the proper procedure.

probe *

* wetted parts are Kynar

and 316 stainless steel.

®

PL-540 9

sensor

weight

20 mm

(0.8") Ø

sensor

Page 10

MOUNTING

DO’S AND DONT’S

STANDPIPES

MULTIPLE UNITS

< 50 mm (2")

> 100 mm

(4") Ø

100 mm

(4") min

100 mm

(4") min

Sensors must be 100 mm apart.

PL-540 10

100 mm

(4") min

Mount diagonally if there is

not enough vertical space.

Page 11

DO’S and DONT’S (cont’d)

WALL RESTRICTION

50 mm

(2")

min

50 mm

(2")

min

PL-540 11

Page 12

DO’S and DONT’S (cont’d)

PROCESS CONCERNS

keep out of path of falling material

protect probe from falling material

consider material angle of repose

50 mm

(2")

min

tensile load must not exceed probe

or vessel rating

avoid areas where material build up occurs

PL-540 12

Page 13

INTERCONNECTION

Loosen the lid clip and remove the lid.

identification label (underside of lid)

Switch and potentiometer settings are for illustration

purposes only. Refer to Operation \ Setup.

All field wiring must have insulation suitable for at least 250 V.

Relay contact terminals are for use with equipment having no accessible

live parts and wiring having insulation suitable for at least 250 V.

Maximum working voltage between adjacent relay contacts shall be 250 V.

PL-540 13

Page 14

RELAY OUTPUT CONNECTION

SOLID STATE SWITCH

relay shown in de-energized

state, K2 contacts rated for

8 A at 250 V ac /

5 A at 30 V dc

solid state switch to customer’s

control or instrumentation device

Switch shown in de-ene rgized state, K3 contact rated

for 250 V ac / 300 V dc, 100 mA max, non-polarized.

PL-540 14

98\03\30

Page 15

ANCILLARY 2-WIRE OUTPUT CONNECTION

optically isolated switch

customer supplied

refer to Power Connection

V dc

POWER CONNECTION

Nominal 24 V dc 48 V dc

V

dc

R

22 – 26 V 46 – 50 V

Ω

120

output

(Phoenix DEK-OE-5DC/48DC/100

or equivalent)

Ω

234

12 - 250 V

ac / dc

PL-540 15

Page 16

OPERATION

SET UP

Set up can be done in the field with the Pointek CLS mounted

into process, or in the shop prior to mounting.

Dip Switch 1

Set on to open the alarm relay immediately when the sensor detects a change in contact.

Use this setting when time is critical.

Set off to keep the alarm relay closed by the amount set on potentiometer #1 (P1).

Use this setting when you want to slow the response to account for turbulence or

false readings.

Dip Switch 2

Set on to open the alarm relay immediately when the sensor detects a change in

contact. Use this setting when you need the alarm to stop as soon as the contact

state changes.

Set off to keep the alarm relay closed by the amount of time set on potentiometer #1

(P1). Use this setting when you want to avoid false or early alarm relay cut outs due

to turbulence or false readings.

Dip Switch 3

Set on for fail-safe high alarm.

Set off for fail-safe low alarm.

Dip Switch 4

Set on to test the delay of the alarm relays as set by the potentiometer #1 (P1).

Set off for normal operation.

Dip Switch 5

Set on for normal sensitivity

on the sensor. Use this setting

in situations where you are

measuring dry solids or

non-conductive liquids.

Set off for low sensitivity

on the sensor. Use this

setting when you are

measuring conductive

liquids or wet conductive

solids which are likely

to build up.

switches shown in off position

PL-540 16

delay, ‘alarm on’

delay ‘alarm off ’

fail-safe

delay test

sensitivity

Page 17

delay on delay off fail-safe delay test sensitivity

S1 - 1 S1 - 2 S1 - 3 S1 - 4 S1 - 5

on disabled disabled high test normal

off enabled enabled low normal low

START UP

After the CLS is properly mounted and the switch bank set up, apply power to the unit. The

green LED (L3) lights to indicate the unit is powered and operational.

INDICATORS

The Pointek CLS uses three LEDs for visual indication of the following:

L1 (yellow), sensor status: when P2 is properly set, this LED is on when the sensor is

L2 (red), output status: this LED is an indication of the relay and solid switch

L3 (green), power: this LED is on when the Pointek CLS is properly powered.

Proceed with the set up of the alarm output.

in contact with the process material (material capacitance

is greater than the setpoint, P2). L1 is off when the sensor

is out of contact with the process material (material

capacitance is less than the setpoint).

contact status. Refer to Operation \ Output Status.

PL-540 17

Page 18

ALARM OUTPUT

ALARM OUTPUT STATUS

high

alarm

low

alarm

SETPOINT ADJUSTMENT

In order to assist you in properly adjusting the alarm setpoint for reliable and accurate

detection of the process material, we have categorized the materials and applications into

three cases. Follow the setup procedure associated to the case which covers your application.

Case 1:

Case 2:

Case 3

PL-540 18

this is the general case encountered in most applications, characterized

by the following:

- dry solids

- low viscosity liquids

demand applications, characterized by the following:

- hygroscopic / wet solids

- high viscosity and high conductivity liquids

: interface detection: - e.g. liquid A / liquid B, foam / liquid

Page 19

trip

point

delay

output

status

(red)

switches

sensor

status

(yellow)

power

(green)

Case 1

Preamble: - insure that L3 (green) is ‘

- turn both potentiometers, P1 and P2, fully

- set S1 switches 1 to 4 ‘

on

’

ccw

(counterclockwise)

off

’ and S1 switch 5 to ‘on’ (normal sensitivity)

1. With sensor uncovered and a minimum 100 mm free space all around, turn P2 cw

on

until L1 (yellow) goes ‘

’.

2. Turn P2 ccw until L1 goes ‘

off

’.

Case 2

Preamble: - insure that L3 (green) is ‘on ’

- turn potentiometer P1 fully

- set S1 switches 1 to 4 ‘

ccw

(counterclockwise), and P2 fully cw (clockwise)

off

’ and S1 switch 5 to ‘

off

’ (low sensitivity)

1. Adjust the material level of the process so that the sensor is immersed, L1 (yellow)

on

should be ‘

’. If L1 does not light, reset S1 switch 5 to ‘on ’ (back to normal

sensitivity; the appropriate position of S1 switch 5 depends on the dielectric

properties of the material).

2. Adjust the material level of the process so that the sensor is uncovered , but retains

significant (as much as possible) build up of material on the sensor.

3. Adjust P2 ccw until L1 ‘

adjust P2 cw then ccw a couple of times to insure that L1 is

off

’.To get the true feel of the correct position, it is wise to

off

just

‘

Case 3

Preamble: - insure that L3 (green) is ‘on ’

- turn potentiometer P1 fully

- set S1 switches 1 to 5 ‘

ccw

(counterclockwise), and P2 fully cw (clockwise)

off

’

1. Immerse the sensor in the material that has the lowest dielectric constant.

on

L1 (yellow) should be ‘

2. Adjust P2

ccw

until L1 goes ‘

’. If not, S1 switch 5 should be set to ‘on’ (normal sensitivity).

off

’.

’.

3. Immerse the sensor in the material that has the highest dielectric constant,

L1 should come ‘

on

’.

PL-540 19

Page 20

DELAY

The alarm actuation can be delayed for either or both ‘on alarm’ and ‘off alarm’ conditions.

The selection is made by setting S1-1 and S1-2, refer to Set Up \ Switch Bank. The amount of

delay is adjustable from 1 to 60 seconds by setting potentiometer, P1.

After completing the set up, replace the Pointek CLS lid and lid clip.

The unit is now in service, providing level detection of your process.

PL-540 20

Page 21

TROUBLESHOOTING

Symptom Observation Action

No alarm response L3 off check power supply

Alarm doesn’t switch when

sensor is uncovered.

Alarm doesn’t switch when

sensor is covered.

L1 doesn’t respond to

uncovering the sensor.

L1 responds to uncovering

the sensor

L1 doesn’t respond to

covering the sensor.

L1 responds to covering

the sensor

L1 flashes when

approaching the

alarm setpoint.

check sensitivity S1-5,

sensor (and zener barrier,

if used)

check that relay changes

state when S1-3 is toggled

check sensitivity S1-5,

sensor (and zener barrier,

if used)

check that relay changes

state when S1-3 is toggled

MAINTENANCE

The Pointek CLS requires no maintenance or cleaning.

PL-540 21

Page 22

APPENDIX

SHORTENING THE CABLE

Allowed in general purpose version only,

see device nameplate.

Preamble

Measure the actual length of the cable and subtract the desired length to determine the

length to be cut off in step 5.

e.g. actual length 10 m

desired length

- 9 m

excess = 1m

actual

length

desired

length

excess

length

1. Unscrew the cable gland, compression nut, to relieve the compression ferrule

and release the cable.

cable gland,

compression nut

sleeve

probe,

lower assembly

2. Unscrew the probe sleeve from the lower assembly using two wrenches (17 mm)

across the flats, exposing the leads (3) and tension block.

PL-540 22

Page 23

tension block

connection

3. Remove the insulation covering the solder connections.

4. Unsolder the connections.

Do not cut the connection to the probe leads, as this

can render them too short to work with later.

5. Remove the sheathing around the tension block. Remove the block for reuse in

step 7, and cut off the excess length of cable.

6. Remove approximately 6 cm (2.4") of cable jacket, shield and filler strands.

7. Replace the tension block and shorten the lead to approximately 4 cm (1.6").

8. Prepare the leads for soldering.

If heat shrink is to be used to insulate splices and sheath the tension

block (steps 9 and 11), remember to slip them on before soldering the leads.

9. Make the solder connections and insulate.

5 cm

(2")

tension block

10. Remove the excess core.

11. Sheath the tension block.

PL-540 23

core

98\03\30

Page 24

12. Re-dress the probe sleeve thread with Teflon tape or sealant.

13. Reassemble the sleeve and cable gland. Insure that the cable is not

turned excessively, as this could break the leads.

14. Check unit for proper operation.

PL-540 24

■

Loading...

Loading...