Page 1

OPERATION

When the Quick Start procedure is complete...

1.

"----" is displayed briefly...

The AIRANGER DPL PLUS rapidly takes measurements,

verifies repeatability, and calculates Readings.

For one vessel, the Reading is displayed continuously.

For two vessels, Readings are scroll displayed.

Difference or Average Readings (if selected) are also scroll

displayed, as Point Number 3.

The Bar Graph indicates material level (0 to 100%),

regardless of the Operation selected.

If "▲" is displayed the vessel level has exceeded 80% and

not yet fallen below 75% (Hi Alarm).

If "▼" is displayed the vessel level has fallen below 20% and

not yet exceeded 25% (Lo Alarm).

When in alarm, the corresponding relay is de-energized.

Transducer # Alarm Relay #

2.

Readings are displayed in % (based upon Operation).

Empty

➞

3.

View mA output values in the Auxiliary Reading display.

Empty

➞

4.

View the Failsafe Time Left in % (before "LOE" is displayed).

If the value reaches 0, the "old" Reading, Bar Graph, relays,

and mA outputs are "held" and "LOE" flashes.

When a valid measurement is made, the value resets to 100.

The AIRANGER DPL PLUS advances to the "new" level;

operating displays and outputs accordingly.

to enter the RUN mode

1Hi1

1Lo2

2Hi3

2Lo4

%

level space or distance

Span = 0 ➞ 100% Empty ➞ Span = 100 ➞ 0%

level space or distance

Span = 4 ➞ 20mA Empty ➞ Span = 20 ➞ 4mA

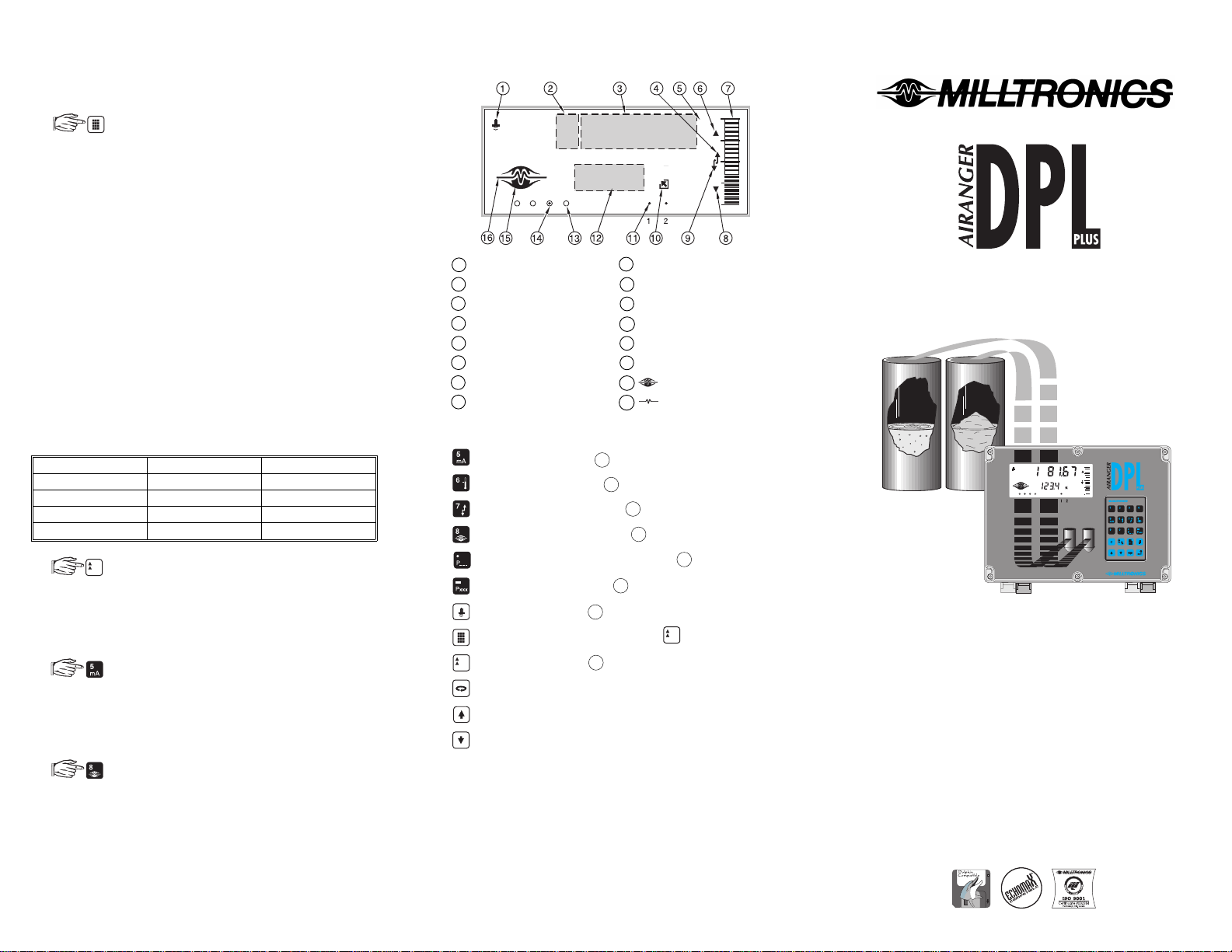

5 6 1

RUN MODE DISPLAY FUNCTIONS

100

%

1

1

Transducer

2

Point Number

3

Reading

4

Filling

5

Percent

6

Hi Alarm

7

Bar Graph

8

Lo Alarm

234

9

Emptying

10

Data Out

11

Point Scanned

12

Auxiliary Reading

13

Relay #4 energized

14

Relay #3 de-energized

15

Normal Operation

16

Failsafe Operation

0

RUN MODE KEYPAD FUNCTIONS

Display mA output in 12 .

Display temperature in 12 .

Display Empty / Fill Rate in 12 .

Display Failsafe Time Left in 12 .

Key in Parameter # to display value in 12 .

Display Material Level in 12 .

Display Distance in 12 .

Initiate program mode access ( see ).

Display Units / % in 3 (complete program mode access).

%

Stop / Start scroll display.

Display next Point Number (scroll display stopped).

Display previous Point Number (scroll display stopped).

%

PERFORMANCE EVALUATION

Monitor system performance, under all operating conditions.

If alternate display, relay, or mA output operation is required,

or "LOE" is displayed, see instruction manual PL-421.

Connect (or enable) alarm/control equipment only after

satisfactory performance is verified.

DUAL POINT LEVEL MONITOR

QUICK START GUIDE

100

%

1

234

ACCURATE, RELIABLE

LIQUID and SOLID LEVEL MEASUREMENT

with

CUSTOM GRAPHIC LCD,

VOLUME CONVERSION,

ANALOG mA OUTPUTS,

ALARM RELAYS,

& BIC-II SUPPORT

PL-431

September 1995

33454310

PRR 2.3

0

%

Page 2

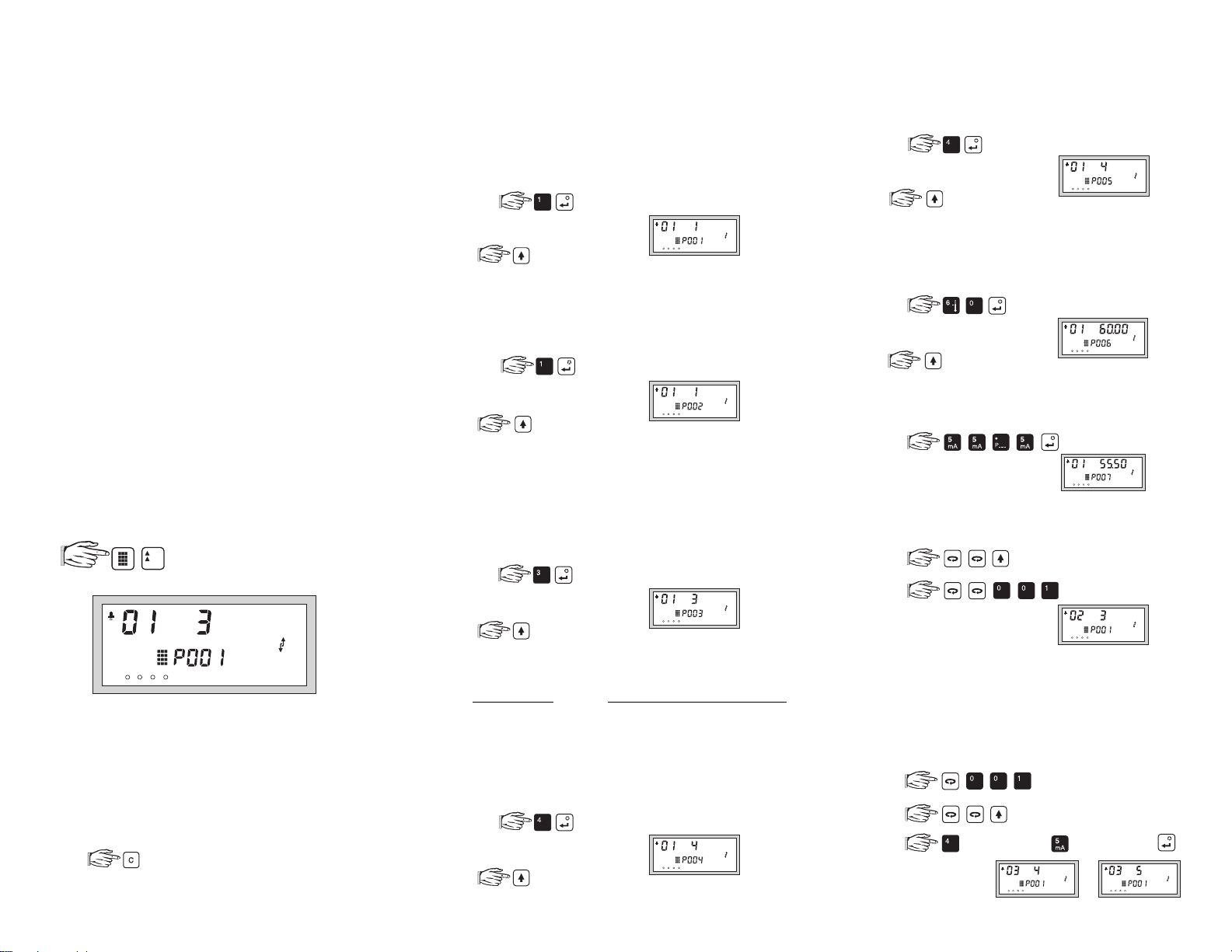

GENERAL

Quick Start details the minimum recommended start up

procedure for most AIRANGER DPL PLUS installations.

Refer to the individual product instruction manuals for

complete installation and interconnection instructions for the:

AIRANGER DPL PLUS

Ultrasonic Transducers

TS-3 Temperature Sensors (if used)

BIC-II Buffered Interface Converter (if used)

To measure distances greater than 60 m (200ft), refer to the

AIRANGER DPL PLUS manual (PL-421).

Ensure all process control equipment is disabled until

satisfactory AIRANGER DPL PLUS performance is verified.

INITIAL START UP

1.

Place the programmer in the AIRANGER DPL PLUS

enclosure lid recess. The magnetic programmer base

holds it in place.

2.

Apply power to the AIRANGER DPL PLUS,

is displayed.

OFF

3.

During the following procedure:

a) If the selection desired is already displayed...

no entry is required. (Advance to the next step.)

b) If an entry error is made...

%

1

234

and try again.

to enter the program mode

and display . . .

VESSEL # 1

STEP 1

(P001)

Which type of

off

0 =

level

1 =

space

2 =

distance

3 =

e.g. for level

STEP 2

(P002)

1 =

2 =

Which

liquid

solid

e.g. for liquid

STEP 3

(P003)

1 =

2 =

3 =

Which

slow

medium

fast

(Slower response improves measurement stability!)

e.g. for fast

STEP 4

(P004)

Which

ULTRASONIC

not entered

0 =

ST-25

1 =

ST-50

2 =

ST-100

3 =

LR-21

4 =

LR-13

5 =

e.g. for LR-21

Operation

is desired?

(point out of service)

(how full the vessel is)

(how empty the vessel is)

(from the transducer face)

1

234

to advance

Material

is being monitored?

(flat level surface)

(uneven sloped surface)

1

234

to advance

Measurement Response

(0.1 m/min)

(1 m/min)

(10 m/min)

1

234

to advance

Transducer

is connected (check nameplate)?

ULTRASONIC/TEMPERATURE

ST-H

100 =

XCT-8

101 =

XPS-10

102 =

XCT-12

103 =

XPS-15

104 =

XPS-30

105 =

1

234

to advance

is desired?

106 =

107 =

108 =

109 =

110 =

111 =

112 =

XPS-40

XLT-30

XLT-60

XLS-30

XLS-60

XKS-6

XRS-5

STEP 5

(P005)

1 =

2 =

3 =

Which measurement

metres (m)

centimetres (cm)

millimetres (mm)

Units

4 =

5 =

feet (ft)

inches (in)

are desired?

e.g. for feet

1

234

to advance

STEP 6

(P006)

Where is

(Presets Span to the maximum recommended value).

Empty

(transducer face to vessel bottom)?

0.000 to 9999

e.g. for 60 Units

1

234

to advance

STEP 7

(P007)

What is the

0.000 to 9999

Span

(Empty to highest material level)?

e.g.

1

234

To monitor 1 vessel, proceed to OPERATION.

VESSEL # 2

a.

b.

(switch to next vessel)

(return to STEP 1)

1

234

c. Repeat STEP 1 to 7

(Use the same STEP 5 value as for Vessel # 1).

To monitor 2 vessels, proceed to OPERATION.

DIFFERENCE or AVERAGE DISPLAYS

To display the difference or average of 2 vessels...

a.

b.

c. (difference) or (average) and .

or

1

234

Proceed to OPERATION.

1

234

432

Loading...

Loading...